Enhancing 5G Antenna Manufacturing Efficiency and Reliability through Blockchain and Smart Contract Integration: A Comprehensive AHP Analysis

Abstract

1. Introduction

1.1. Blockchain and 5G: Revolutionizing Industry and Telecom

1.2. Objective of this Study

2. Theoretical Background and Literature Review

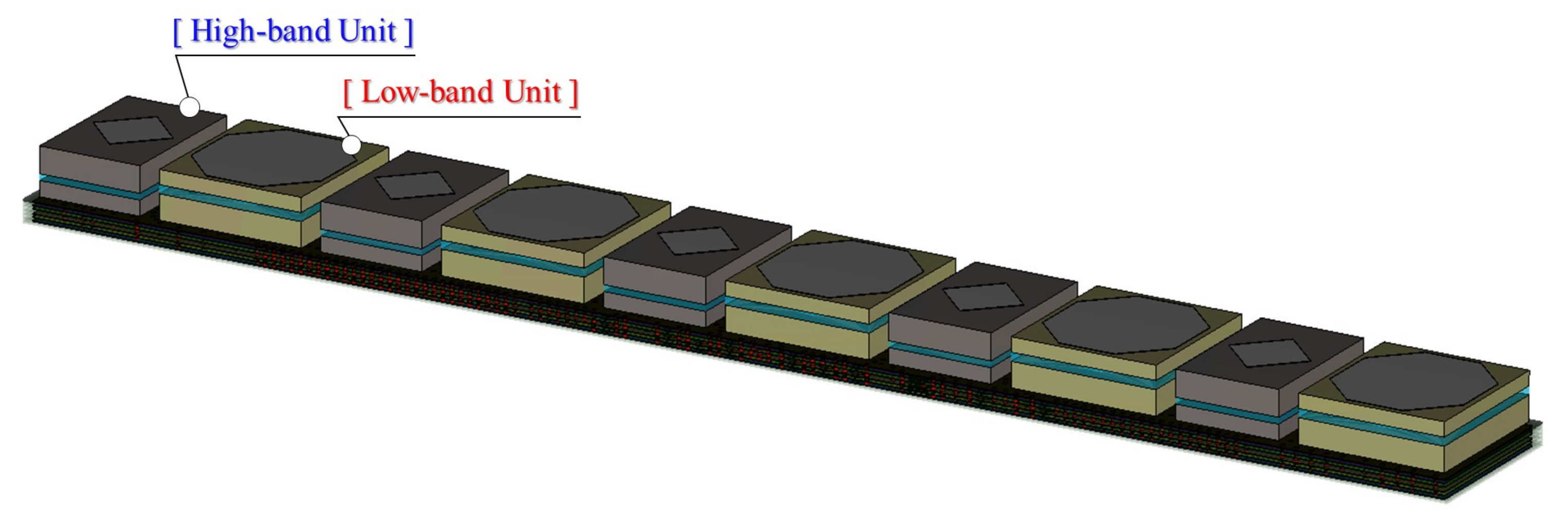

2.1. The Core of 5G Networks: Advanced Ceramic Antenna Technologies

2.1.1. Overview of 5G Communications and the Significance of Antenna Technology

2.1.2. Advantages of 5G Ceramic Antennas and Comparison with PCB Antennas

2.2. Blockchain and Smart Contracts

2.2.1. Blockchain Technology: The Theoretical Foundation

2.2.2. Blockchain Algorithm: Hyperledger Fabric

2.2.3. Detailed Blockchain Configuration

2.2.4. Smart Contracts: Automating Trust in Blockchain

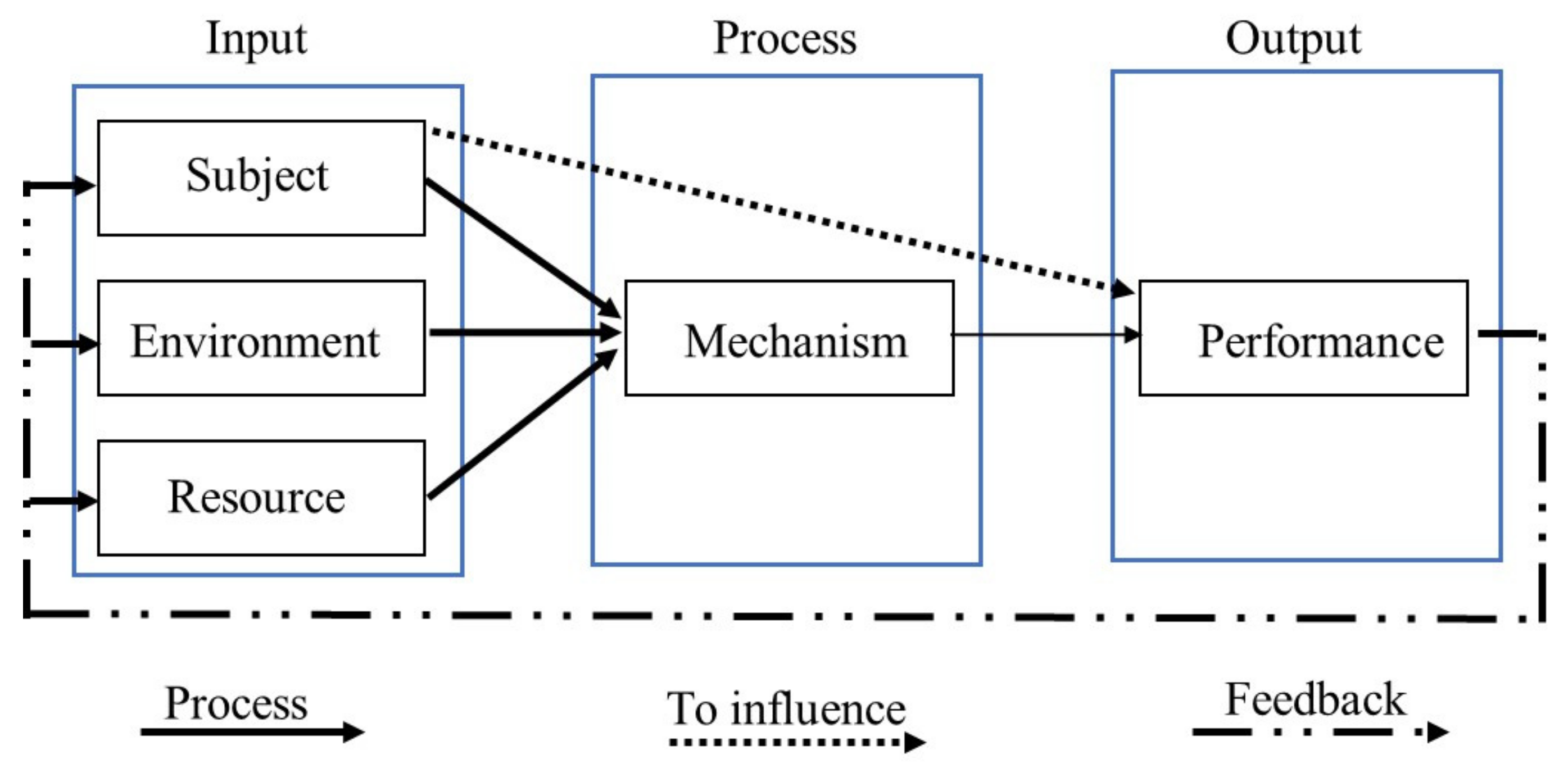

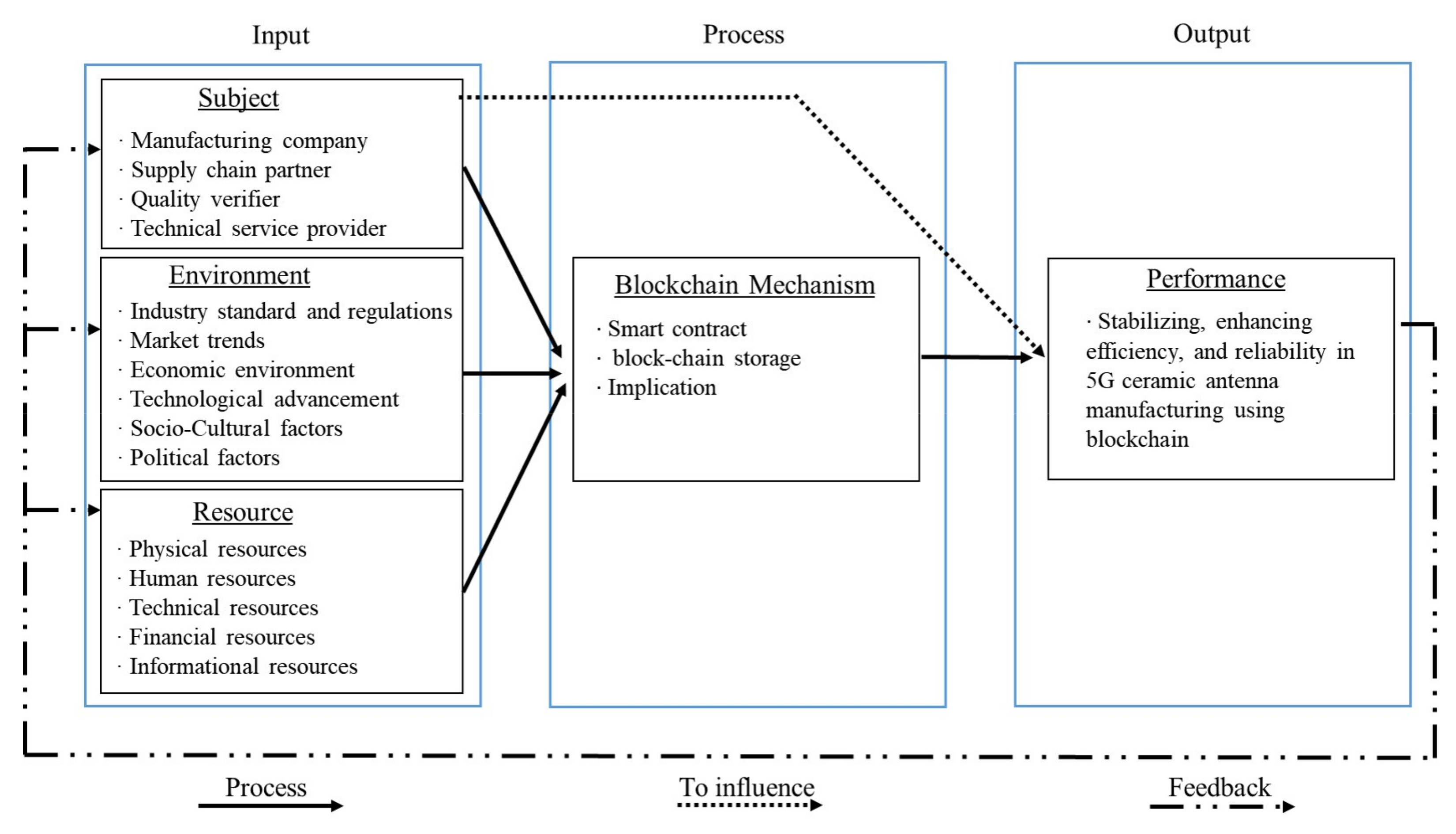

2.3. SER-M Model

2.4. Analytic Hierarchy Process (AHP)

3. Research Design and Methodology, and Model Integration

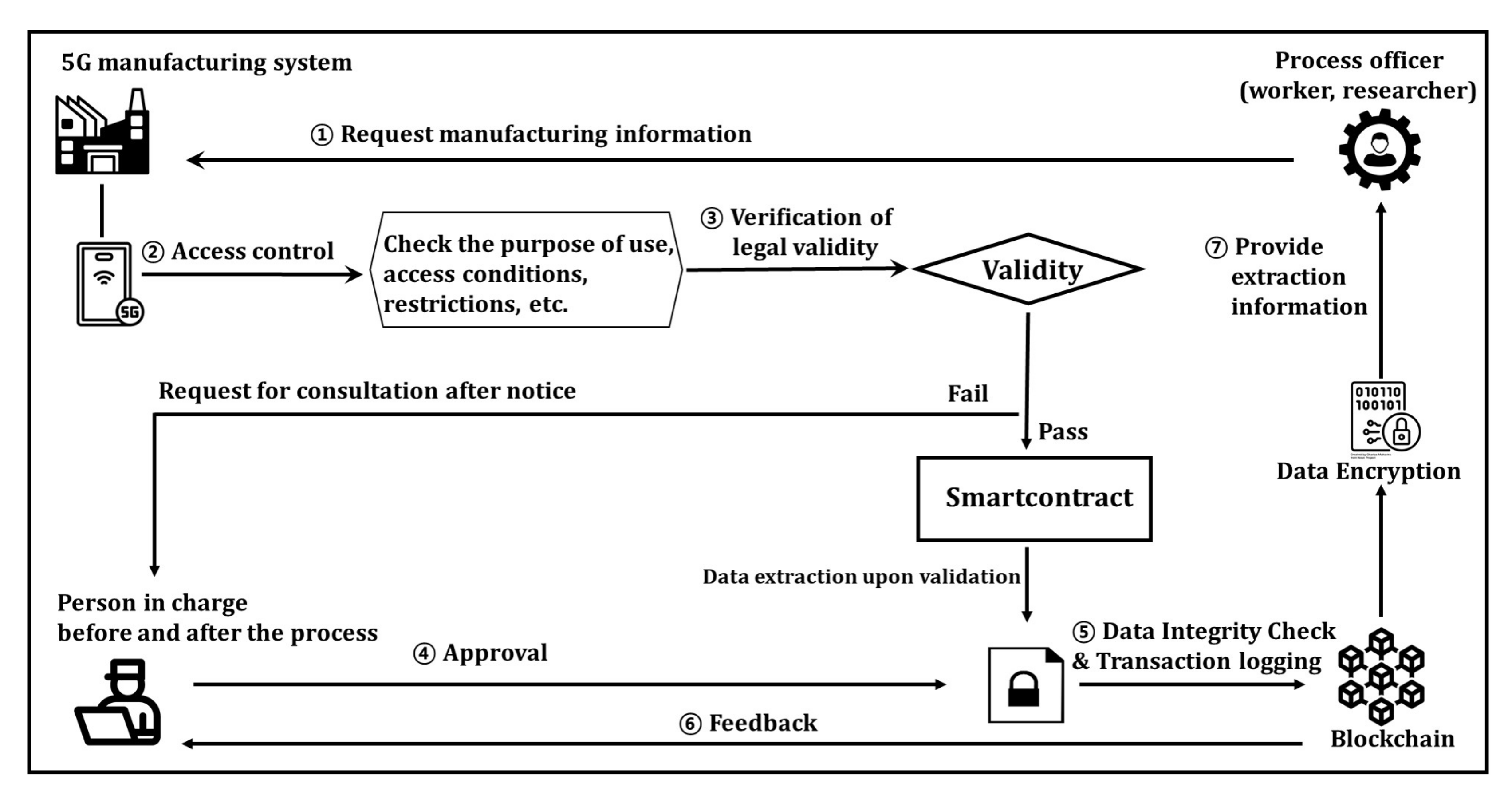

3.1. System Configuration

3.2. Blockchain-Based Business Model Proposal

3.3. Blockchain-Based SER-M (B-SER-M) Model

3.4. Research Design Description

3.5. AHP Analysis

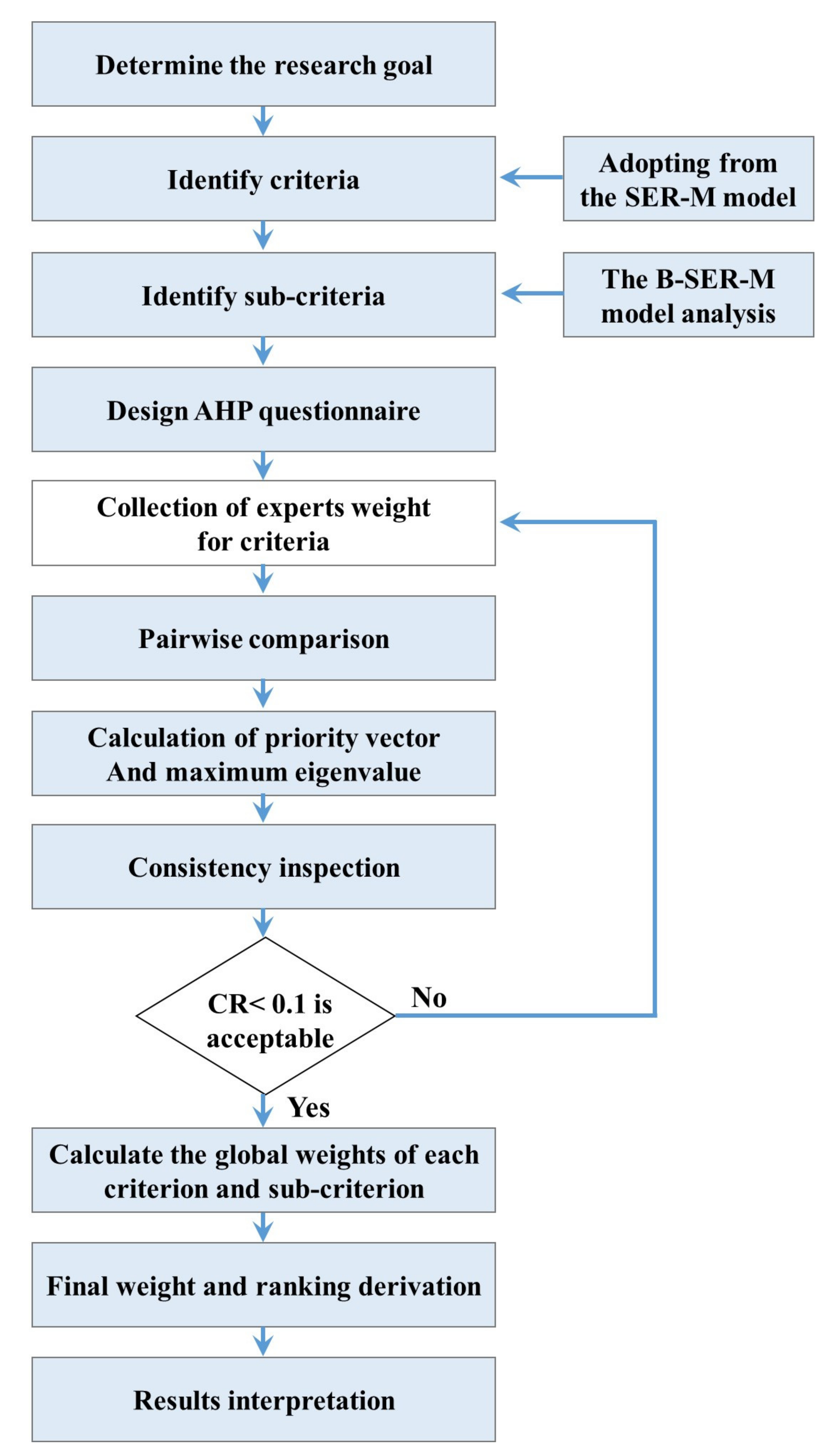

3.6. AHP Analysis Research Process and Data Collection

4. Results and Discussion

5. Conclusions

5.1. Key Insights and Implications

5.2. Research Limitation and Future Plans

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Matenga, A.E.; Mpofu, K. Blockchain-Based Cloud Manufacturing SCM System for Collaborative Enterprise Manufacturing: A Case Study of Transport Manufacturing. Appl. Sci. 2022, 12, 8664. [Google Scholar] [CrossRef]

- Khan, S.N.; Loukil, F.; Ghedira-Guegan, C.; Benkhelifa, E.; Bani-Hani, A. Blockchain smart contracts: Applications, Challenges, and future trends. Peer-Peer Netw. Appl. 2021, 14, 2901–2925. [Google Scholar] [CrossRef] [PubMed]

- Alqarni, M.A.; Alkatheiri, M.S.; Chauhdary, S.H.; Saleem, S. Use of Blockchain-Based Smart Contracts in Logistics and Supply Chains. Electronics 2023, 12, 1340. [Google Scholar] [CrossRef]

- Wang, D.; Zhao, D.; Chen, F. Research on Financing Strategy of Green Energy-Efficient Supply Chain Based on Blockchain Technology. Energies 2023, 16, 2985. [Google Scholar] [CrossRef]

- Kang, Y.; Shi, X.; Yue, X.; Zhang, W.; Liu, S.S. Enhancing Traceability in Wine Supply Chain through Blockchain: A Stackelberg Game-Theoretical Analysis. J. Theor. Appl. Electron. Commer. Res. 2023, 18, 2142–2162. [Google Scholar] [CrossRef]

- Ayan, B.; Güner, E.; Son-Turan, S. Blcokchain Technology and Sustainability in Supply Chains and a Closer Look at Different Industries: A Mixed Method Approach. Logistics 2022, 6, 85. [Google Scholar] [CrossRef]

- Sung, Y.; Song, X.; Fang, X.; Guo, J. Self-Built or Third-Party Blockchain Traceability Strategy in a Dual-Channel Supply Chain Considering Consumers’ Traceability Awareness. Mathematics 2023, 11, 4312. [Google Scholar]

- Yang, T.; Li, C.; Bian, Z. Recycling Strategies in a Collector-Led Remanufacturing Supply Chain under Blockchain and Uncertain Demand. Process 2023, 11, 1426. [Google Scholar] [CrossRef]

- Guo, X.; Zhang, G.; Zhang, Y. A Comprehensive Review of Blockchain Technology-Enabled Smart Manufacturing: A Framework, Challenges and Future Research Directions. Sensors 2023, 23, 155. [Google Scholar] [CrossRef]

- Li, S.; Zhou, T.; Yang, H.; Wang, P. Blockchain-Based Secure Storage and Access Control Scheme for Supply Chain Ecological Business Data: A Case Study of the Automotive Industry. Sensors 2023, 23, 7036. [Google Scholar] [CrossRef]

- Oliveira, M.; Chauhan, S.; Pereira, F.; Felgueiras, C.; Carvalho, D. Blockchain Protocols and Edge Computing Targeting Industry 5.0 Needs. Sensors 2023, 23, 9174. [Google Scholar] [CrossRef] [PubMed]

- Watanabe, A.O.; Ali, M.; Sayeed, S.Y.B.; Tummala, R.R.; Pulugurtha, M.R. A Review of 5G Front-End Systems Package Integration. IEEE Trans. Compon. Packag. Manuf. Technol. 2021, 11, 118–133. [Google Scholar] [CrossRef]

- Mafakheri, B.; Heider-Aviet, A.; Riggio, R.; Goratti, L. Smart Contracts in the 5G Roaming Architecture: The Fusion of Blockchain with 5G Networks. IEEE Commun. Mag. 2021, 59, 77–83. [Google Scholar] [CrossRef]

- William, A.D.J.; Rajendran, S.; Pranam, P.; Berry, Y.; Sreedharan, A.; Gul, J.; Paul, A. Blockchain Technologies: Smart Contracts for Consumber Electtonics Data Sharing and Secure Payment. Electronics 2023, 12, 208. [Google Scholar] [CrossRef]

- Kaur, K.; Kumar, S.; Baliyan, A. 5G: A new era of wireless communication. Int. J. Inf. Technol. 2018, 12, 619–624. [Google Scholar] [CrossRef]

- Nahar, T.; Rawat, S. Efficiency enhancement techniques of microwave and millimeter-wave antennas for 5G communication: A survey. Trans. Emerg. Telecommun. Technol. 2022, 33, 4530. [Google Scholar] [CrossRef]

- Mansour, R.; Rioual, S.; Lescop, B.; Talbot, P.; Abboud, M.; Farah, W.; Tanné, G. Development of a Resonant Microwave Sensor for Sediment Density Characterization. Sensors 2020, 20, 1058. [Google Scholar] [CrossRef]

- Ikram, M. 5G/B5G Internet of Things MIMO Antenna Design. Signals 2022, 3, 29–37. [Google Scholar] [CrossRef]

- Ullah, H.; Abutarboush, F.; Rashid, A.; Tahir, F.A. A Compact Low-Profile Antenna for Millimeter-Wave 5G Mobile Phones. Electronics 2022, 11, 3256. [Google Scholar] [CrossRef]

- Kumar, N.; Kumar, P.; Sharma, M. Reconfigurable Antenna and Performance Optimization Approach. Wirel. Pers. Commun. 2020, 112, 2187–2212. [Google Scholar] [CrossRef]

- Ellul, J.; Galea, J.; Ganado, M.; Mccarthy, S.; Pace, G.J. Regulating Blockchain, DLT and Smart Contracts: A technology regulator’s perspective. ERA Forum 2020, 21, 209–220. [Google Scholar] [CrossRef]

- Sanda, O.; Pavlidis, M.; Polatidis, N. A Regulatory Readiness Assessment Framework for Blockchain Adoption in Healthcare. Digital 2022, 2, 65–87. [Google Scholar] [CrossRef]

- Seo, J.; Yon, I.; Jung, J.; Ryoo, J.; Park, J.; Lee, W.; Ko, D.; Oh, J. Miniaturized Dual-Band Broadside/Endfire Antenna-in-Package for 5G Smartphone. IEEE Trans. Antennas Propag. 2021, 69, 8100. [Google Scholar] [CrossRef]

- Attaran, M. The impact of 5G on the evolution of intelligent automation and industry digitization. J. Ambient Intell. Humaniz. Comput. 2023, 14, 5977–5993. [Google Scholar] [CrossRef]

- Elfergani, I.; Hussaini, A.S.; Rodriguez, J.; Abd-Alhameed, R.A. Recent Advances in Antenna Design for 5G Heterogeneous Networks. Electronics 2022, 11, 146. [Google Scholar] [CrossRef]

- Shakir, M.; Aslam, S.; Adnan, M.; Khan, M.R. Performance evaluation and design of 5G communication-based millimeter wave antenna. J. Wirel. Commun. Netw. 2021, 2021, 179. [Google Scholar] [CrossRef]

- Kumar, S.; Dixit, A.S.; Malekar, R.R.; Raut, H.D.; Shevada, L.K. Fifth Generation Antennas: A Comprehensive Review of Design and Performance Enhancement Techniques. IEEE Access 2020, 8, 163568–163593. [Google Scholar] [CrossRef]

- Tung, W.S.; Chiang, W.Y.; Liu, C.K.; Chen, C.A.; Rao, P.Z.; Abu, P.A.R.; Chen, W.M.; Asadi, F.; Chen, S.L. Low Cost AIP Design in 5G Flexible Antenna Phase Array System Application. Micromachines 2020, 11, 851. [Google Scholar] [CrossRef]

- Hao, H.; Hui, D.; Lau, D. Material advancement in technologogical development for the 5G wireless communications. Nanotechnol. Rev. 2020, 9, 683–699. [Google Scholar] [CrossRef]

- Ahmad, I.; Tan, W.; Ali, Q.; Sun, H. Latest Performance Improvement Strategies and Techniques Used in 5G Antenna Designing Technology, a Comprehensive Study. Micromachines 2022, 13, 717. [Google Scholar] [CrossRef]

- Alazab, M.; Alhyari, S. Industry 4.0 Innovation: A Systematic Literature Review on the Role of Blockchain Technology in Creating Smart and Sustainable Manufacturing Facilities. Information 2024, 15, 78. [Google Scholar] [CrossRef]

- Prashar, D.; Jha, N.; Jha, S.; Joshi, G.P.; Seo, C. Integrating IoT and Blockchain for Ensuring Road Safety: An Unconventional Approach. Sensors 2020, 20, 3296. [Google Scholar] [CrossRef]

- Huang, Z.; Li, L.; Qiao, J. Trace additive enhances microwave dielectric performance significantly to facilitate 5G communications. J. Am. Ceram. Soc. 2022, 105, 7426–7437. [Google Scholar] [CrossRef]

- Zhou, Y. Material Foundation for Future 5G Technology. Acc. Mater. Res. 2021, 2, 306–310. [Google Scholar] [CrossRef]

- Imbert, M.; Romeu, J.; Baquero-Wscudero, M.; Martinez-Ingles, M.T.; Molina-Garcia-Pardo, J.M.; Jofre, L. Assessment of LTCC-Based Dielectric Flat Lens Antennas and Switched-Beam Arrays for Future 5G Millimeter-Wave Communication Systems. IEEE Trans. Antennas Propag. 2017, 64, 6453–6473. [Google Scholar] [CrossRef]

- Hong, W. Solving the 5G Mobile Antenna Puzzle. IEEE Microw. Mag. 2017, 18, 86–102. [Google Scholar] [CrossRef]

- Mohammed, A.S.B.; Kamal, S.; Ain, M.F.B.; Hussin, R.; Ahmad, Z.A.; Ullah, U.; Othman, M.; Rahman, M.F.A. Mathematical Modelling on the Effects of Conductive Material and Substrate Thickness for Air Substrate Microstrip Patch Antenna. ACES J. 2020, 35, 674–683. [Google Scholar]

- An, S.Y.; Ngayo, G.; Hong, S.P. Efficient 5G Ceramic Antenna Manufacturing Architecture using Blockchain and Smart Contracts. J. Adv. Navig. Technol. 2023, 27, 594–609. [Google Scholar]

- Raj, T.; Mishra, R.; Kumar, P.; Kapoor, A. Advances in MIMO Antenna Design for 5G: A Comprehensive Review. Sensors 2023, 23, 6329. [Google Scholar] [CrossRef]

- Michael, D.; Cruickshank, D.B. Ceramic materials for 5G wireless communication system. Am. Ceram. Soc. Bull. 2019, 98, 20. [Google Scholar]

- Lee, J.; Hong, Y.K.; Bae, S.; Abo, G.S.; Seong, W.M.; Kim, G.H. Miniature Long-Term Evolution (LTE) MIMO Ferrite Antenna. IEEE Antennas Wirel. Propag. Lett. 2011, 10, 603–606. [Google Scholar]

- Lee, W.; Hong, Y.K.; Park, J.; LaRochelle, G.; Lee, J. Low-loss Z-type hexaferrite (Ba3Co2Fe24O41) for GHz antenna applications. J. Magn. Magn. Mater. 2016, 414, 194–197. [Google Scholar] [CrossRef]

- Hansen, R.C.; Burke, M. Nakamoto, Antennas with Magneto-Dielectrics. Microw. Opt. Technol. Lett. 2000, 26, 75–78. [Google Scholar] [CrossRef]

- An, S.Y.; Kim, B. Smallest form-factor multi-stacked ceramic patch antenna on package for 5G millimeter-wave mobile applications. Photonics Nanostructures—Fundam. Appl. 2023, 57, 101189. [Google Scholar] [CrossRef]

- Nakamoto, S. Bitcoin: A Peer-to-Peer Electronic Cash System. Available online: https://bitcoin.org/en/bitcoin-paper (accessed on 14 January 2024).

- Ballandies, M.C.; Dapp, M.M.; Pournaras, E. Decrypting distributed ledger design—Taxonomy, classification and blockchain community evaluation. Clust. Comput. 2022, 25, 1817–1838. [Google Scholar] [CrossRef]

- Romano, D.; Schmid, G. Beyond Bitcoin: Recent Trends and Perspectives in Distributed Ledger Technology. Cryptography 2021, 5, 36. [Google Scholar] [CrossRef]

- Yadav, A.S.; Singh, N.; Kushwaha, D.S. Evolution of Blockchain and consensus mechanisms & its real-world applications. Multimed. Tools Appl. 2023, 82, 34363–34408. [Google Scholar]

- Huang, Y.; Chen, J. Analysis of Development of Blockchain Technology Supply Chain Finance Based on PEST-SWOT Model. Acad. J. Bus. Manag. 2023, 5, 27–33. [Google Scholar]

- Yusuf, M.; Hakim, L.; Hendra, J.; Kamar, K.; Idawati, W.; Winarso, E.; Meiden, C.; Fahlevi, M. Blockchain technology for corporate governance and IT governance: A financial perspective. Int. J. Data Netw. Sci. 2023, 7, 927–932. [Google Scholar] [CrossRef]

- Rejeb, A.; Rejeb, K.; Simske, S.; Keogh, J.G. Exploring Blockchain Research in Supply Chain Management: A Latent Dirichlet Allocation-Driven Systematic Review. Information 2023, 14, 557. [Google Scholar] [CrossRef]

- Radmanesh, S.A.; Haji, A.; Valilai, O.F. Blockchain-Based Architecture for a Sustainable Supply Chain in Cloud Architecture. Sustainability 2023, 15, 9072. [Google Scholar] [CrossRef]

- Elvas, L.B.; Serrao, C.; Ferreira, J.C. Sharing Health Information Using a Blockchain. Healthcare 2023, 11, 170. [Google Scholar] [CrossRef]

- Hussain, S.; Rahman, H.; Abdulsaheb, G.M.; Al-Khawaja, H.; Khalaf, O.I. A Blockchain-Based Approach for Healthcare Data Interoperability. Int. J. Adv. Soft Compu. Appl. 2023, 15, 85–98. [Google Scholar]

- Mohammed, Z.H.; Chankaew, K.; Vallabhuni, R.R.; Sonawane, V.R.; Ambala, S.; Markkandan, S. Blockchain-enabled bioacoustics signal authentication for cloud-based electronic medical records. Meas. Sens. 2023, 26, 100706. [Google Scholar] [CrossRef]

- Ciriello, R.F.; Torbensen, A.C.G.; Hansen, M.R.P.; Muller-Bloch, C. Blockchain-based digital rights management systems: Design principles for the music industry. Electron. Mark. 2023, 33, 5. [Google Scholar] [CrossRef]

- Assiri, B. A Modified and Effective Blockchain Model for E-Healthcare Systems. Appl. Sci. 2023, 13, 12630. [Google Scholar] [CrossRef]

- Chentouf, F.Z.; Bouchkaren, S. Security and privacy in smart city: A secure e-voting system based on blockchain. Int. J. Electr. Comput. Eng. 2023, 13, 1848–1857. [Google Scholar] [CrossRef]

- Alves, J.; Pinto, A. On the Implementation of a Blockchain-Assisted Academic Council Electronic Vote System. Smart Cities 2023, 6, 291–315. [Google Scholar] [CrossRef]

- Siyal, A.A.; Junejo, A.Z.; Zawish, M.; Ahmed, K.; Khalil, A.; Soursou, G. Applications of Blockchain Technology in Medicine and Healthcare: Challenges and Future Perspectives. Cryptography 2019, 3, 3. [Google Scholar] [CrossRef]

- Sonmez, R.; Sonmez, F.O.; Ahmadisheykhsarmast, S. Blockchain in project management: A systematic review of use cases and a design decision framework. J. Ambient Intell. Humaniz. Comput. 2023, 14, 8433–8447. [Google Scholar] [CrossRef]

- Smith, S.S.; Castonguay, J.J. Blockchain and Accounting Governance: Emerging Issues and Considerations for Accounting and Assurance Professionals. J. Emerg. Technol. Account. 2020, 17, 119–131. [Google Scholar] [CrossRef]

- Grida, M.O.; Elrahman, S.A.; Eldrandaly, K.A. Critical Success Factors Evaluation for Blockchain’s Adoption and Implementing. Systems 2023, 11, 2. [Google Scholar] [CrossRef]

- Mishra, L.; Kaushik, V. Application of blockchain in dealing with sustainability issues and challenges of financial sector. J. Sustain. Financ. Invest. 2023, 13, 1. [Google Scholar] [CrossRef]

- Alkafaji, B.K.A.; Dashtbayaz, M.L.; Salehi, M. The impact of Blockchain on the Quality of Accounting information: An Iraqi Case Study. Risks 2023, 11, 58. [Google Scholar] [CrossRef]

- Singh, S.; Babu, C.R.; Ramana, K.; Ra, I.H.; Yoon, B. BENS-B5G: Blockchain-Enabled Network Slicing in 5G and Beyond-5G (B5G) Networks. Sensors 2022, 22, 6068. [Google Scholar] [CrossRef]

- Hameed, K.; Bajwa, I.S.; Sarwar, N.; Anwar, W.; Mushtag, Z.; Rashid, T. Integration of 5G and Block-Chain Technologiees in Smart Telemedicine Using IoT. J. Healthc. Eng. 2021, 2021, 8814364. [Google Scholar] [CrossRef]

- Mishra, A.K.; Wazid, M.; Singh, D.P.; Das, A.K.; Singh, J.; Vasilakos, A.V. Secure Blockchain-Enabled Authentication Key Management Framework with Big Data Analytics for Drones in Networks Beyond 5G Applications. Drones 2023, 7, 508. [Google Scholar] [CrossRef]

- Muntaha, S.T.; Lazaridis, P.I.; Hafeez, M.; Ahmed, Q.Z.; Khan, F.A.; Zaharis, Z.D. Blockchain for Dynamic Spectrum Access and Network Slicing: A Review. IEEE Access 2023, 11, 17922–17944. [Google Scholar] [CrossRef]

- Biswas, A.; Wang, H.C. Autonomous Vehicles Enabled by the Integration of IoT, Edge Intelligence, 5G, and Blockchain. Sensors 2023, 23, 1963. [Google Scholar] [CrossRef]

- Karim, S.M.; Habbal, A.; Chaudhry, S.A.; Irshad, Z. BSDCE-IoV: Blockchain-Based Secure Data Collection and Exchange Scheme for IoV in 5G Environment. IEEE Access 2023, 11, 36158–36175. [Google Scholar] [CrossRef]

- Rathod, T.; Jadav, N.K.; Tanwar, S.; Sharma, R.; Tolba, A.; Raboaca, M.S.; Marina, V.; Said, W. Blockchain-Driven Intelligent Scheme for IoT-Based Public Safety System beyond 5G Networks. Sensors 2023, 23, 969. [Google Scholar] [CrossRef]

- Maroufi, M.; Abdolee, R.; Tazekand, B.M.; Mortezavi, A.M. Lightweight Blockchain-Based Architecture for 5G Enabled Iot. IEEE Access 2023, 11, 60225–60239. [Google Scholar] [CrossRef]

- Szabo, N. Smartcontracts. 1994. Available online: https://nakamotoinstitute.org/smart-contracts/ (accessed on 13 January 2024).

- Xu, Y.; Chong, H.Y.; Chi, M. A Review of Smart Contracts Applications in Various Industries: A Procurement Perspective. Adv. Civ. Eng. 2021, 2021, 5530755. [Google Scholar] [CrossRef]

- Rouhani, S.; Deters, R. Security, Performance, and Applications of Smart Contracts: A Systematic Survey. IEEE Access 2019, 7, 50759–50779. [Google Scholar] [CrossRef]

- Ye, X.; Zeng, N.; König, M. Systematic literature review on smart contracts in the construction industry: Potentials, benefits, and challenges. Front. Eng. Manag. 2022, 9, 196–213. [Google Scholar] [CrossRef]

- Taherdoost, H. Smart Contracts in Blockchain Technology: A Critical Review. Information 2023, 14, 117. [Google Scholar] [CrossRef]

- Rustiana, D.; Ramadhan, D.; Wibowo, L.; Nugroho, A.W.; Mahardika, A.G. State of the Art Blockchain Enabled Smart Contact Applications in the University. Blockchain Front. Technol. 2023, 2, 70–80. [Google Scholar] [CrossRef]

- Rana, S.K.; Rana, A.K.; Rana, S.K.; Sharama, V.; Lilhore, U.K.; Khalaf, O.I.; Galletta, A. Decentralized Model to Protect Digital Evidence via Smart Contracts Using Layer 2 Polygon Blockchain. IEEE Access 2023, 11, 83289–83300. [Google Scholar] [CrossRef]

- Toderean, L.; Chifu, V.R.; Cioara, T.; Anghel, I. Cooperative Game Over Blockchain and Smart Contracts for Self-Sufficient Eneergy Communities. IEEE Access 2023, 11, 73982–73999. [Google Scholar] [CrossRef]

- Chowdhury, E.K.; Stasi, A.; Pellegrino, A. Blockchain Technology in Financial Accounting: Emerging Regulatory Issues. Rev. Econ. Financ. 2023, 21, 862–868. [Google Scholar]

- Cho, D.S.; Lee, D.H. A new paradigm in strategy theory: Ser-M. Monash Mt Eliza Bus. Rev. 1998, 1, 82–96. [Google Scholar]

- Cho, D.S.; Ku, S.W. Case study on convergence strategies of high-technology companies. Bus. Stud. 2007, 8, 53–84. [Google Scholar]

- Cho, D.S. Mechanism-Based View: A New Strategy Paradigm for Holistics Management; Seoul Econoic Management Publishing Co.: Seoul, Republic of Korea, 2014. [Google Scholar]

- Kim, B.; Kim, H. A Case Study of Design-driven Startup Companies in South Korea. Arch. Des. Res. 2018, 31, 51–65. [Google Scholar] [CrossRef]

- Kim, D.K.; Kim, B.Y. Small and Medium Enterprise Management Consulting System and Performance Creation Mechanism. Int. J. Manag. 2020, 11, 222–234. [Google Scholar]

- Schmidt, K.; Aumann, I.; Hollander, I.; Damm, K.; Graf, J.M.; Schulenburg, G.V.D. Applying the Analytic Hierarchy Process in healthcare research: A systematic literature review and evaluation of reporting. BMC Med. Inform. Decis. Mak. 2015, 15, 112. [Google Scholar] [CrossRef]

- Madzík, P.; Falát, L. State-of-the-art on analytic hierarchy process in the last 40 years: Literature revew based on Latent Dirichlet Allocation topic modelling. PLoS ONE 2022, 17, e0268777. [Google Scholar] [CrossRef]

- Li, X.; Mo, X. Application of AHP Based on Mathematical Operational Research in Teaching Evaluation System. J. Phys. Conf. Ser. 2020, 1650, 032015. [Google Scholar] [CrossRef]

- Subramanian, N.; Ramanathan, R.A. Review of applications of Analytic Hierarchy Process in operations management. Int. J. Prod. Econ. 2012, 138, 215–241. [Google Scholar] [CrossRef]

- Lee, H.; Kim, B. Invigorating Care Farm Ecosystem Based on Public Service Innovation: Case of South Korea. Adm. Sci. 2022, 12, 58. [Google Scholar] [CrossRef]

- Ahn, B.; Kim, B. A Decision-Making Model for Selecting Product Suppliers in Crop Protection Retail Sector. Adm. Sci. 2023, 13, 97. [Google Scholar] [CrossRef]

- Lee, B.; Kim, B.; Ivan, U.V. Enhancing the Competitiveness of AI Technology-Based Startups in the Digital Era. Adm. Sci. 2024, 14, 6. [Google Scholar] [CrossRef]

- Cho, W.C.; Atukeren, E.; Yim, H. Overseas Market Expansion Strategy of the Global Electronic Components Company Based on the AHP Analysis of Factors in Technology, Organization, and Environment Context: A Case of Samsung Electro-Mechanics. Systems 2023, 11, 532. [Google Scholar] [CrossRef]

- Lee, M.; Majer, M.; Kim, B. Critical Factors Affecting Sustainable Success of Social Service Systems. J. Open Innov. Technol. Mark. Complex 2019, 5, 77. [Google Scholar] [CrossRef]

- Kurek, K.A.; Heijman, W.; Ophem, J.V.; Gedek, S.; Strojny, J. Measuring local competitiveness: Comparing and integrating two methods PCA and AHP. Qual. Quant. 2022, 56, 1371–1389. [Google Scholar] [CrossRef]

- Xiao, H.; Zhang, Y.; Kou, G.; Zhang, S.; Branke, J. Ranking and selection for pairwise comparison. Nav. Res. Logist. 2023, 70, 284–302. [Google Scholar] [CrossRef]

- Choi, J.R.; Sung, J.H.; Kang, D.H.; Choo, K.S.; Kim, B.S. A Study on the Priority Selection Method for Underground Dam Installation Considering Humanities and Social Factors Using Fuzzy Analytic Hierarchy Process in Korea. Water 2023, 15, 3296. [Google Scholar] [CrossRef]

- Purwayudhaningsari, R.; Oetomo, W.; Tjendani, H.T.; Rumihin, O.F. Risk and Cost Analysis Study Occupational Health and Safety (K3) on Passenger Terminal Building Works New Mentawai Airport Development Project. J. Econ. Technol. Bus. 2023, 2, 590–603. [Google Scholar] [CrossRef]

- Dozic, S.; Babic, D.; Kalic, M.; Zivojinovic, S. An AHP approach to airport choice by freight forwarder. Sustain. Futures 2023, 5, 100106. [Google Scholar] [CrossRef]

- Liu, J.; Du, Z.; Ma, L.; Liu, C. Identification and Assessment of Subway Construction Risk: An Integration of AHP and Experts Grading Method. Adv. Civ. Eng. 2021, 2021, 6661099. [Google Scholar] [CrossRef]

- Pereira, R.C.A.; Silva, O.S.D.; Bandeira, J.R.A.D.; Santos, M.M.D.; Rocha, C.D.S.J.; Castillo, C.D.S.; Gomes, C.F.S.; Pereira, D.A.D.M.; Muradas, F.M. Evaluation of Smart Sensors for Subway Electric Motor Escalators through AHP-Gaussian Method. Sensors 2023, 23, 4131. [Google Scholar] [CrossRef]

- Razi, P.Z.; Ali, M.I.; Ramli, N.I. AHP-based Analysis of the Risk Assessment Delay Case Study of Public Road Construction Project: An Empirical Study. J. Eng. Sci. Technol. 2019, 14, 875–891. [Google Scholar]

- Samanaseh, V.; Noor, Z.Z.; Mazlan, M.A. The application of analytic hierarchy process for innovative solution: A review. IOP Conf. Ser. Earth Environ. Sci. 2023, 1143, 012022. [Google Scholar] [CrossRef]

- Moslem, S.; Saraji, M.K.; Mardani, A.; Alkharabsheh, A.; Duleba, S.; Esztergar-Kiss, D. A Systematic Review of Analytic Hierarchy Process Applications to Solve Transportation Problems: From 2003 to 2022. IEEE Access 2023, 11, 11973. [Google Scholar] [CrossRef]

- Liberatore, M.J. An Extension of the Analytic Hierarchy Process for Industrial R&D Project Selection and Resource Allocation. IEEE Trans. Eng. Manag. 1987, 34, 12–18. [Google Scholar]

- Tavana, M.; Soltanifar, M.; Santos-Arteaga, F.J. Analytical hierarchy process: Revolution and evolution. Ann. Oper. Res. 2023, 326, 879–907. [Google Scholar] [CrossRef]

- Liang, W.Y. The analytic hierarchy process in project evaluation An R&D case study in Taiwan. Benchmarking Int. J. 2003, 10, 445–456. [Google Scholar]

- Kim, K.; Kim, B. Decision-Making Model for Reinforcing Digital Transformation Strategies Based on Artificial Intelligence Technology. Information 2022, 13, 253. [Google Scholar] [CrossRef]

- Chen, C.; Huang, H.; Zhao, B.; Shu, D.; Wang, Y. The Research of AHP-Based Credit Rating System on a Blockchain Application. Electronics 2023, 12, 887. [Google Scholar] [CrossRef]

- Javaherikhah, A.; Lopez, M.V. Effective Factors for Implementing Building Information Modeling Using Fuzzy Method to Manage Buildings on Mars. Buildings 2023, 13, 2991. [Google Scholar] [CrossRef]

- Priya, B.; Malhotra, J. 5GAuNetS: An autonomous 5G network selection framework for Industry 4.0. Soft Comput. 2020, 24, 9507–9523. [Google Scholar] [CrossRef]

- Kim, H.; Hong, S.; Marko, M. Smart contract-based Business Model for growth of Korea Fabless System Semiconductor. J. Adv. Navig. Technol. 2023, 27, 235–246. [Google Scholar]

- Saaty, T. Decision making with the analytic hierarchy process. Int. J. Serv. Sci. 2008, 1, 83–98. [Google Scholar] [CrossRef]

- Saaty, T. Fundamentals of Decision Making and Priority Theory with the Analytic Hierarchy Process; RWS Publications: Pittsburgh, PA, USA, 2000; ISBN 978-0962031762. [Google Scholar]

- Taherdoost, H. Decision Making Using the Analytic Hierarchy Process (AHP); A Step by Step Approach. Int. J. Econ. Manag. Syst. 2017, 2, 244–246. [Google Scholar]

- Ossadnik, W.; Schinke, S.; Kaspar, R.H. Group Aggregation Techniques for Analytic Hierarchy Process and Analytic Network Process: A Comparative Analysis. Group Decis. Negot. 2016, 25, 421–457. [Google Scholar] [CrossRef]

| Configuration Aspect | Details |

|---|---|

| Blockchain Platform | Ethereum for smart contracts; Hyperledger for private blockchain operations |

| Consensus Mechanism | Proof of Authority (PoA) for efficiency and control within manufacturing ecosystem |

| Smart Contract Language | Solidity for Ethereum-based contracts |

| Network Type | Consortium blockchain for collaboration between manufacturing partners |

| Node Configuration | Full nodes operated by major stakeholders for integrity and consensus; light nodes for supply chain participants for verification purposes |

| Security Protocols | AES encryption for data security; SSL/TLS for secure communication channels |

| Data Storage | On-chain for critical manufacturing data and smart contract states; off-chain for bulky data storage using IPFS |

| Interoperability Features | APIs for integration with existing ERP and supply chain management systems |

| Scalability Solutions | Layer 2 scaling solutions (e.g., state channels) for enhanced transaction throughput |

| Component | Description | Technology Used |

|---|---|---|

| Blockchain platform | Core infrastructure for decentralized data management. | Ethereum, Hyperledger Fabric |

| Smart contracts | Automated contracts for process efficiency and integrity. | Solidity, chaincode |

| Manufacturing system | System integration blockchain for tracking, verification, and management of production. | IoT devices, ERP systems |

| Analytic tools | Tools for AHP analysis and decision-making support. | AHP software, custom scripts |

| Security and compliance | Mechanisms ensuring data integrity, privacy, and regulatory adherence. | Encryption, access controls |

| Intensity of Importance | Definition | Explanation |

|---|---|---|

| 1 2 | Equal importance Weak or slight | Two activities contribute equally to the objective |

| 3 | Moderate importance | Experience and judgement slightly favor one activity over another |

| 4 | Moderate plus | |

| 5 | Strong importance | Experience and judgement strongly favor one activity over another |

| 6 | Strong plus | |

| 7 | Very strong or Demonstrated importance | An activity is favored very strongly over another; its dominance demonstrated in practice |

| 8 | Very, very strong | |

| 9 | Extreme importance | The evidence favoring one activity over another is of the highest possible order of affirmation |

| Reciprocals of above | If activity i has one of the above non-zero numbers assigned to it when compared with activity j, then j has the reciprocal value when compared with i | A reasonable assumption |

| 1.1–1.9 | If the activities are very close | May be difficult to assign the best value but when compared with other contrasting activities, the size of the small numbers would not be too noticeable, yet they can still indicate the relative importance of the activities. |

| n | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| RI | 0 | 0 | 0.58 | 0.9 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 | 1.49 |

| Section | Characters | Frequency | Ratio (%) |

|---|---|---|---|

| Gender | Male | 25 | 71.4 |

| Female | 10 | 28.6 | |

| Total | 35 | 100 | |

| Age | 30s | 9 | 25.7 |

| 40s | 16 | 45.7 | |

| 50s | 10 | 28.6 | |

| Total | 30 | 100 | |

| Work experience in the related field | 10–15 years | 8 | 22.9 |

| 15–20 years | 21 | 60.0 | |

| Over 20 years | 6 | 17.1 | |

| Total | 35 | 100 | |

| Professional area | Blockchain technology | 7 | 20.0 |

| 5G technology | 7 | 20.0 | |

| Artificial intelligence | 6 | 17.1 | |

| Manufacturing | 9 | 25.8 | |

| Supply chain management | 6 | 17.1 | |

| Total | 30 | 100 |

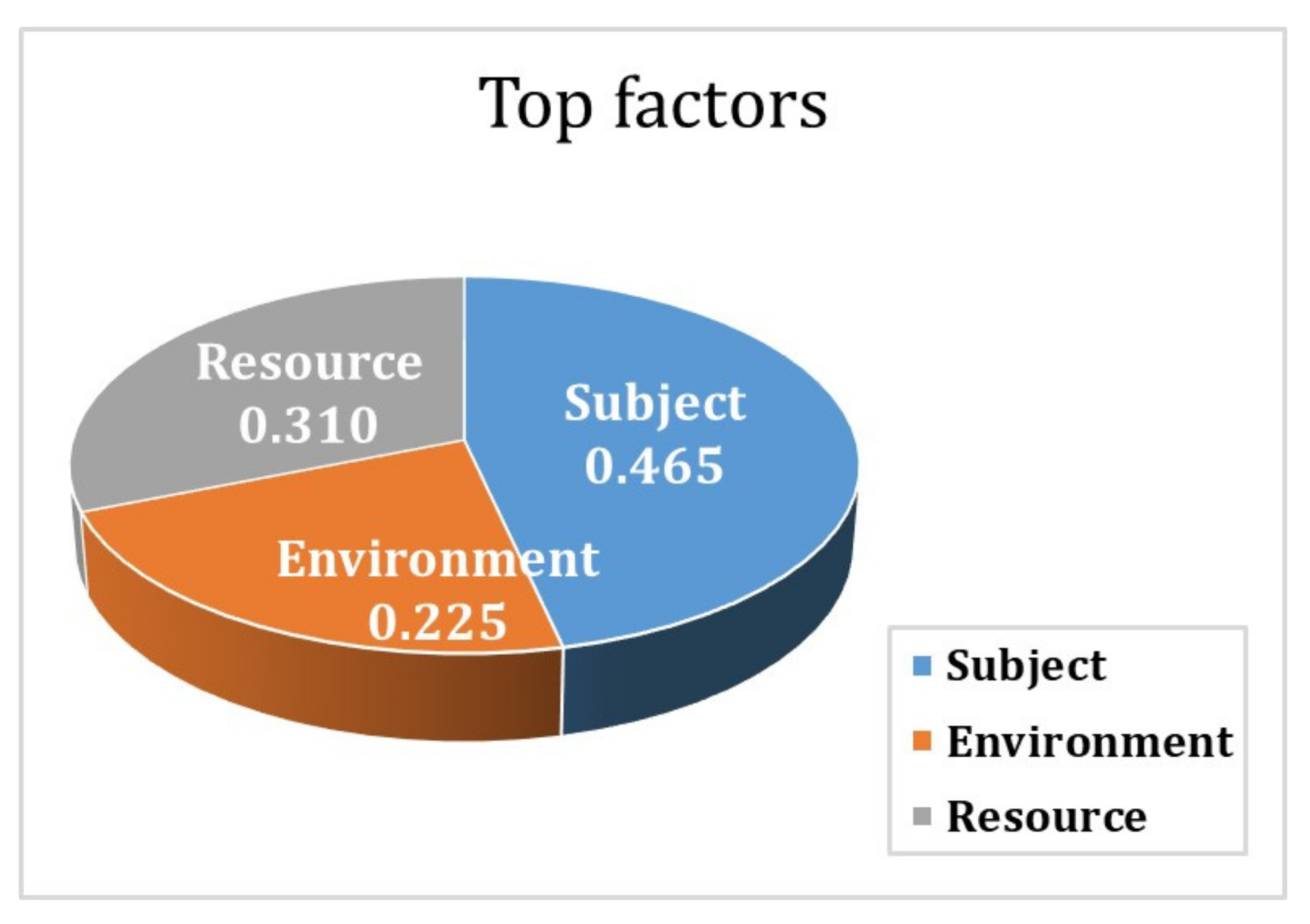

| Top Factor | Weight | Rank | CI | CR | λmax |

|---|---|---|---|---|---|

| Subject | 0.465 | 1 | 0.016 | 0.031 | 3.031 |

| Environment | 0.225 | 3 | |||

| Resource | 0.310 | 2 |

| Sub-Factors | Rank | Weight |

|---|---|---|

| Manufacturing Company | 1 | 0.443 |

| Supply Chain Partner | 4 | 0.112 |

| Quality Verifier | 3 | 0.129 |

| Technical Service Provider | 2 | 0.316 |

| SUM | 1.000 | |

| CI | 0.028 | |

| CR | 0.031 | |

| λmax | 4.084 | |

| Sub-Factors | Rank | Weight |

|---|---|---|

| Industry Standards and Regulations | 6 | 0.069 |

| Market Trends | 3 | 0.135 |

| Economic Environment | 2 | 0.282 |

| Technological Advancement | 1 | 0.297 |

| Socio-Cultural Factors | 5 | 0.108 |

| Political Factors | 4 | 0.109 |

| SUM | 1.000 | |

| CI | 0.041 | |

| CR | 0.033 | |

| λmax | 6.205 | |

| Sub-Factors | Rank | Weight |

|---|---|---|

| Physical Resources | 5 | 0.075 |

| Human Resources | 1 | 0.335 |

| Technical Resources | 3 | 0.218 |

| Financial Resources | 4 | 0.148 |

| Informational Resources | 2 | 0.224 |

| SUM | 1.000 | |

| CI | 0.041 | |

| CR | 0.037 | |

| λmax | 5.164 | |

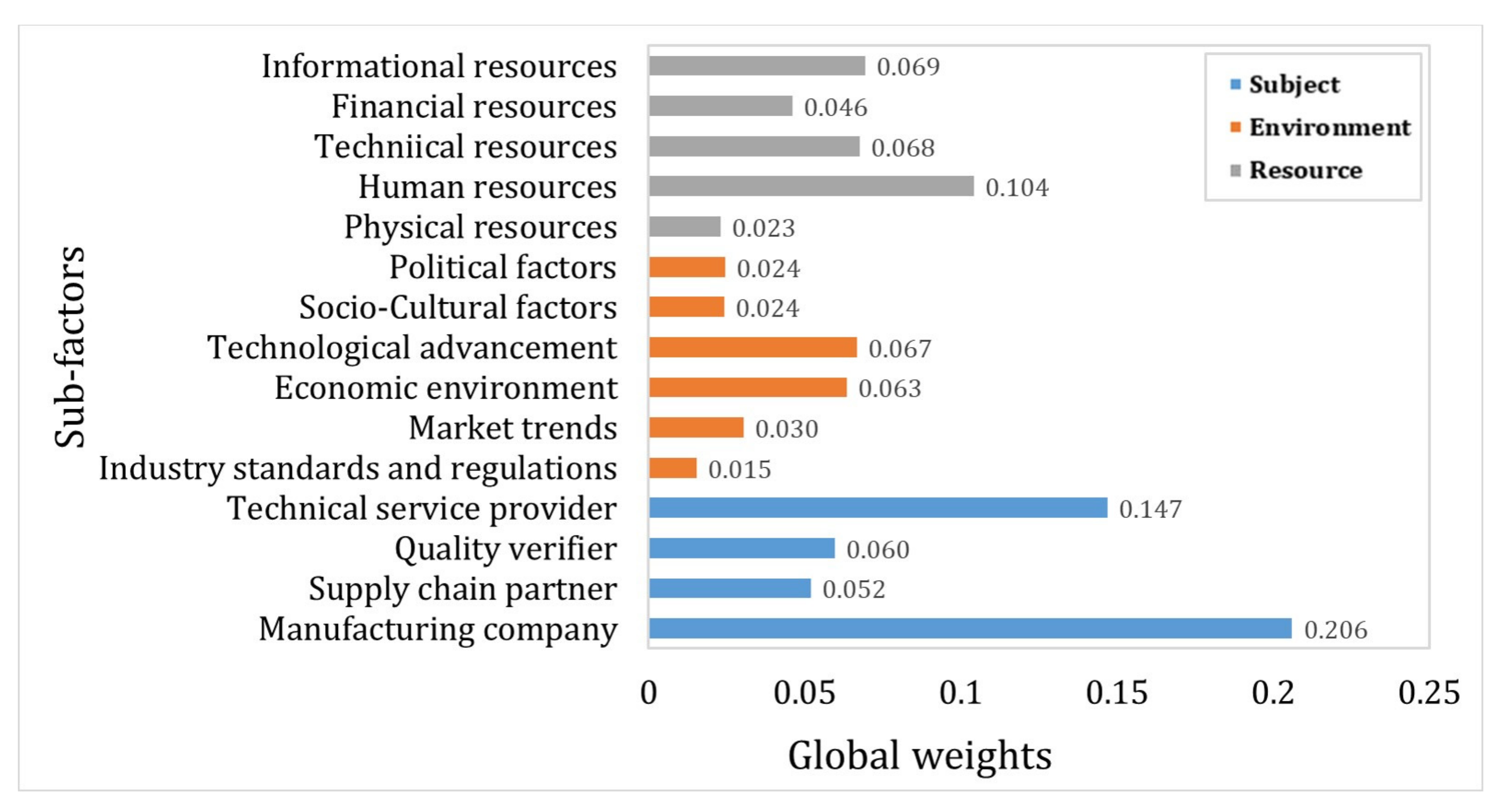

| Top Factors | Weight | Sub-Factors | Local Weight | Global Weight | Global Rank |

|---|---|---|---|---|---|

| Security | 0.3465 | Manufacturing Company | 0.443 | 0.206 | 1 |

| Supply Chain Partner | 0.112 | 0.052 | 9 | ||

| Quality Verifier | 0.129 | 0.060 | 8 | ||

| Technical Service Provider | 0.316 | 0.147 | 2 | ||

| Standards and Regulation | 0.225 | Industry Standards and Regulations | 0.069 | 0.015 | 15 |

| Market Trends | 0.135 | 0.030 | 11 | ||

| Economic Environment | 0.282 | 0.063 | 7 | ||

| Technological Advancement | 0.297 | 0.067 | 6 | ||

| Socio-Cultural Factors | 0.108 | 0.024 | 13 | ||

| Political Factors | 0.109 | 0.024 | 12 | ||

| Efficiency | 0.310 | Physical Resources | 0.075 | 0.023 | 14 |

| Human Resources | 0.335 | 0.104 | 3 | ||

| Technical Resources | 0.218 | 0.068 | 5 | ||

| Financial Resources | 0.148 | 0.046 | 10 | ||

| Informational Resources | 0.224 | 0.069 | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

An, S.Y.; Ngayo, G.; Hong, S.-P. Enhancing 5G Antenna Manufacturing Efficiency and Reliability through Blockchain and Smart Contract Integration: A Comprehensive AHP Analysis. Appl. Sci. 2024, 14, 2507. https://doi.org/10.3390/app14062507

An SY, Ngayo G, Hong S-P. Enhancing 5G Antenna Manufacturing Efficiency and Reliability through Blockchain and Smart Contract Integration: A Comprehensive AHP Analysis. Applied Sciences. 2024; 14(6):2507. https://doi.org/10.3390/app14062507

Chicago/Turabian StyleAn, Sung Yong, Guy Ngayo, and Seng-Phil Hong. 2024. "Enhancing 5G Antenna Manufacturing Efficiency and Reliability through Blockchain and Smart Contract Integration: A Comprehensive AHP Analysis" Applied Sciences 14, no. 6: 2507. https://doi.org/10.3390/app14062507

APA StyleAn, S. Y., Ngayo, G., & Hong, S.-P. (2024). Enhancing 5G Antenna Manufacturing Efficiency and Reliability through Blockchain and Smart Contract Integration: A Comprehensive AHP Analysis. Applied Sciences, 14(6), 2507. https://doi.org/10.3390/app14062507