Experimental Study and Bearing Capacity Calculation of Compression-Reinforced Concrete Columns Strengthened with Ultra-High-Performance Concrete

Abstract

1. Introduction

2. Experimental Design

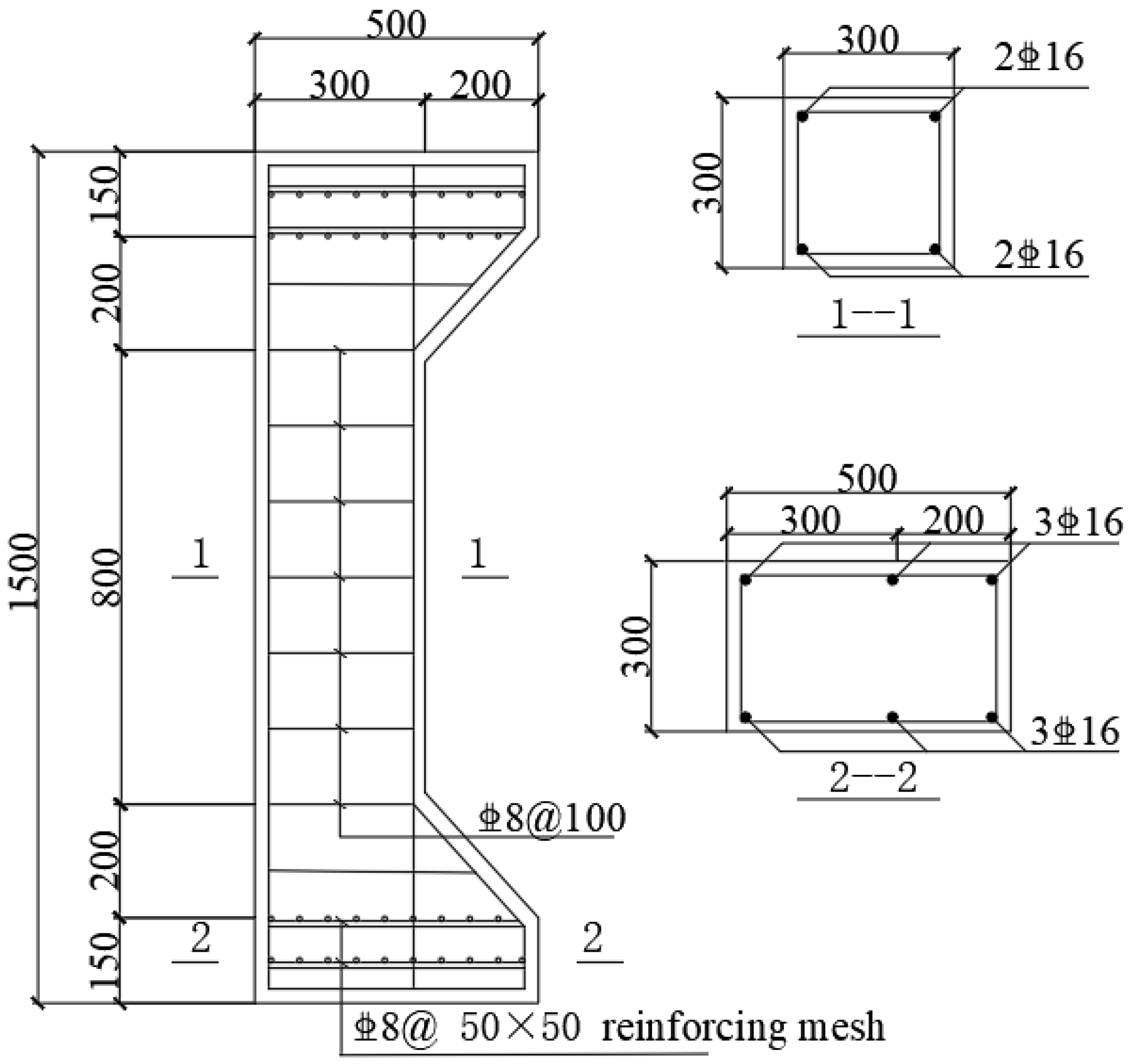

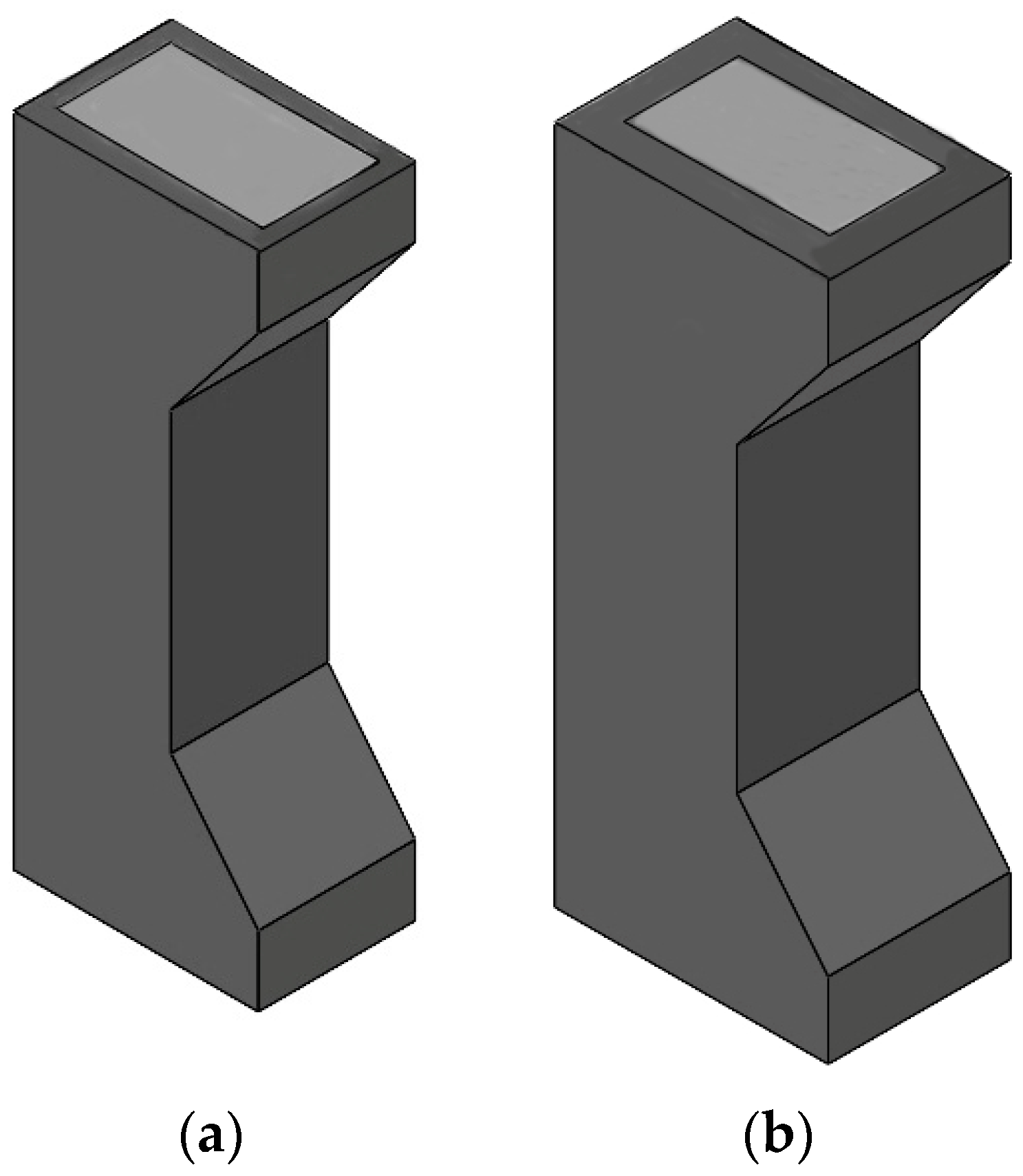

2.1. Specimen Design

2.2. Reinforcement Program

2.3. Mechanical Properties of Concrete and Steel Reinforcement

2.4. Test Setup and Content

3. Results and Discussion

3.1. Specimen Crack Development and Damage Pattern

3.1.1. Damage Patterns of Eccentric Compression Specimens

3.1.2. Damage Patterns of High-Eccentric-Compression Specimens

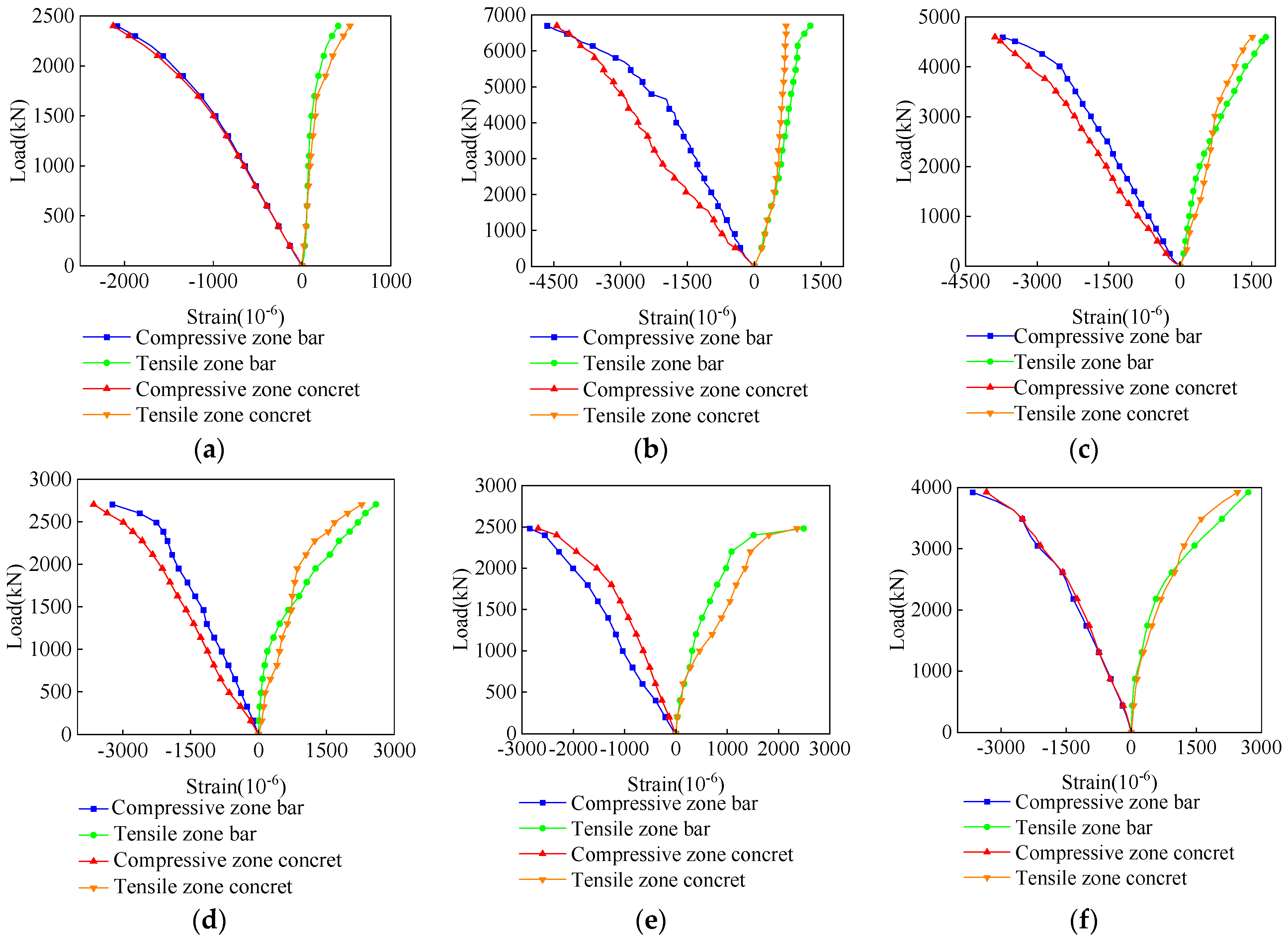

3.2. Strain Distribution

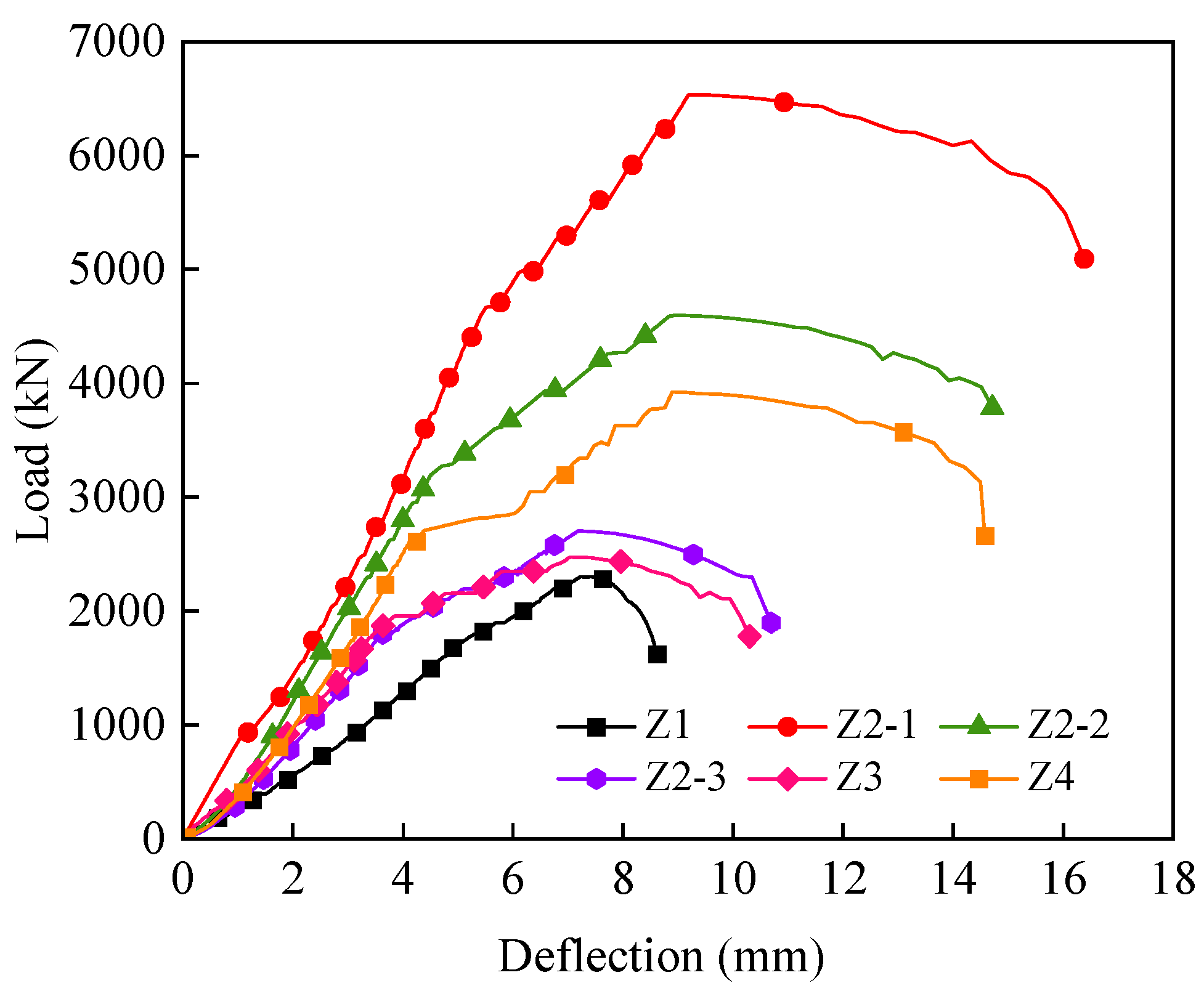

3.3. Load–Lateral Displacement Curves

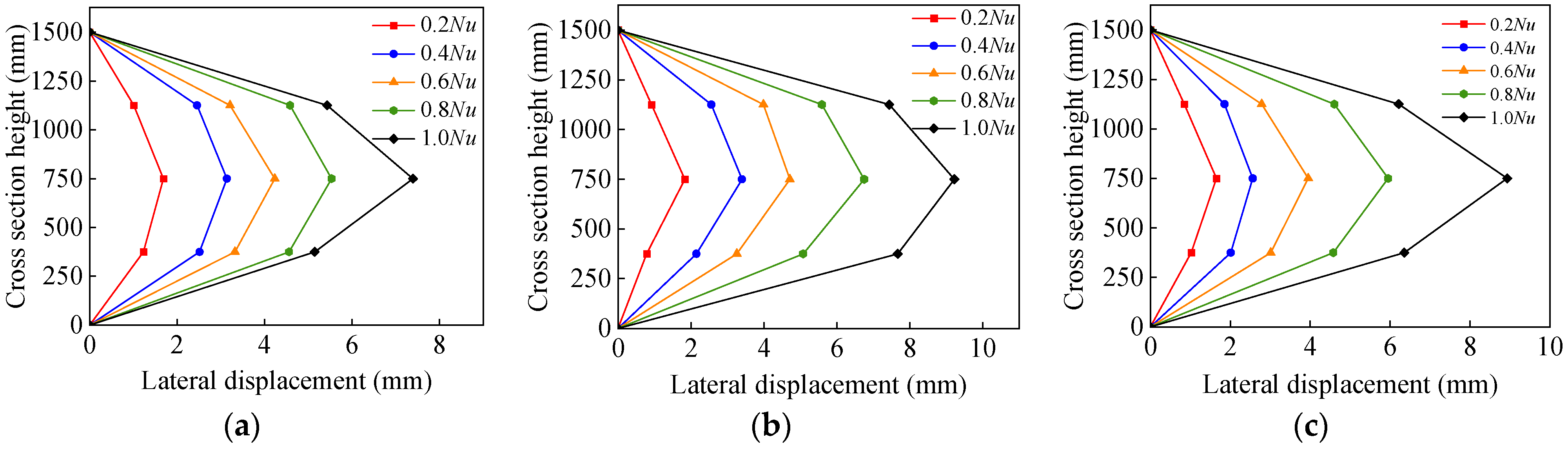

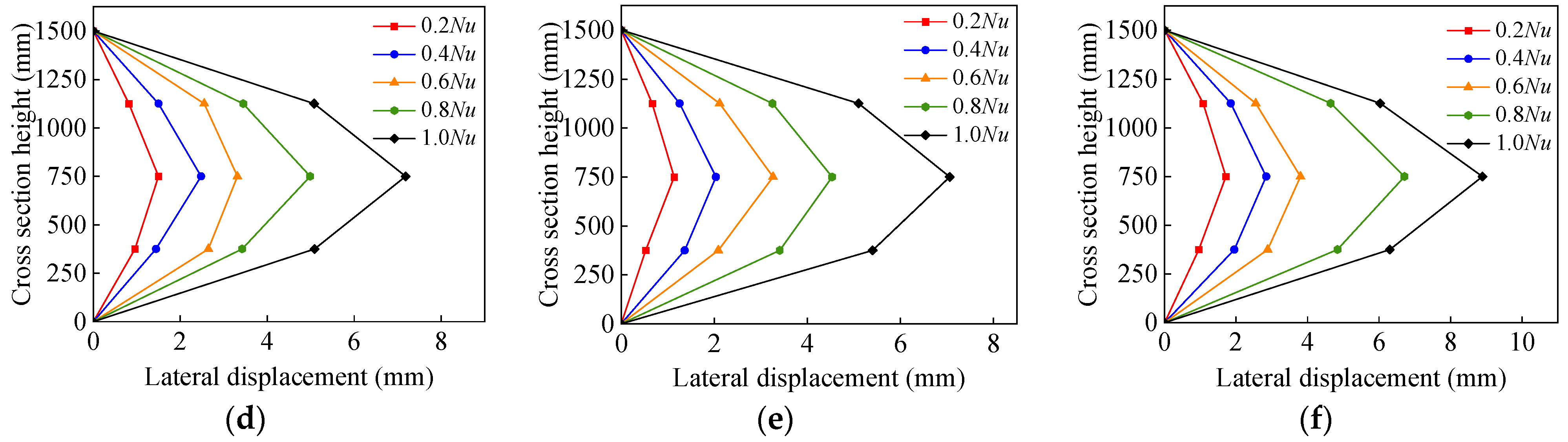

3.4. Lateral Deformation of Specimens

3.5. Mechanical Properties Analysis

3.5.1. Load-Bearing Capacity Analysis

- (1)

- Comparison of test pieces Z1 and Z2-1 (50 mm eccentricity)

- (2)

- Reinforced specimens Z2-1, Z2-2, and Z2-3 (reinforcement thickness of 30 mm)

- (3)

- Reinforced specimens Z2-3 and Z3 (reinforcement thickness 30 mm)

- (4)

- Reinforced specimens Z2-3 and Z4 (2% steel fiber)

3.5.2. Ductility Analysis

3.6. Calculation of Compressive Bearing Capacity in Positive Section

3.6.1. Basic Assumptions

- The strains in the UHPC reinforcement, plain concrete, and stressed longitudinal bars satisfied the flat section assumption;

- Without considering the tensile action of the concrete in the original structure, the stress–strain relationship model between the concrete under compression and the longitudinal reinforcement from the concrete structure design code was adopted;

- The relative slip of the UHPC to the original structural concrete was not considered;

- Due to the high tensile strength of UHPC, the role of the tensile properties of UHPC in the tensile zone was considered in the calculation of the bearing capacity of the UHPC columns, and the bearing capacity of the UHPC at the sides was considered.

3.6.2. Calculation of Bearing Capacity of UHPC-Reinforced Eccentrically Compressed Columns

3.6.3. Calculation Formulae for Bearing Capacity of UHPC High-Eccentric-Compression Specimens

3.6.4. Calculation Formulae for Bearing Capacity of UHPC low-Eccentric-Compression Specimens

4. Analysis of Calculation Results

5. Conclusions

- UHPC reinforcement improved the load carrying capacity and ductility of eccentrically compressed columns; however, their ultimate load carrying capacity gradually decreased as the eccentricity increased.

- The stress performance of the UHPC-reinforced eccentric compression columns was greatly improved. The ultimate load capacity and ductility coefficient of the UHPC-reinforced specimens increased by 172.30% and 56.24%, respectively, compared with the comparison RC columns under low eccentric compression.

- The thickness of the UHPC reinforcement layer had a greater effect on the reinforcement effect. When the eccentricity was 50 mm, the ultimate bearing capacity and ductility coefficient of the reinforcement layer thickness of 50 mm were increased by 45.11% and 9.08%, respectively, compared with an eccentricity of 30 mm.

- When the volume of the UHPC steel fiber dosage was within a suitable range, the steel fiber dosage impacted the reinforcement effect. The ultimate load-carrying capacity and ductility coefficient of the columns with 2% UHPC steel fiber by volume were increased by 8.96% and 2.60%, respectively, compared with the columns with 1% UHPC steel fiber by volume.

- Based on the limit equilibrium theory and considering the tensile contribution of UHPC, the formula for calculating the ultimate bearing capacity of eccentrically compressed RC columns reinforced with UHPC was provided, and the error of the calculation results is small, which can be used as a reference in the design of reinforcements.

- Using UHPC both for reinforcement and new construction has many shortcomings. For example, the cost of UHPC raw materials is approximately 10–15 times that of ordinary concrete, resulting in a high cost of material use. The imperfections in the theory of UHPC structural design make it difficult to apply on a large scale in the main structure of a building or a bridge. The roughness of the UHPC interface affects the interfacial adhesion of the base material in the repair and reinforcement, resulting in the detachment of some parts of the interface over a long period when the load is being held. Nevertheless, UHPC still represents a sustainable development of new reinforcement materials. The application of UHPC in the repair and reinforcement of new bridges at home and abroad and existing bridges is an exponentially growing trend. With the deepening of the study of materials and structures, it can be predicted that the development of relevant norms and standards will propel the applications of UHPC.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Huang, X.; Liu, T.; Ding, Q. A review of UHPC research. Concrete 2019, 9, 36–38. [Google Scholar]

- Sanjuán, M.A.; Andrade, C. Reactive powder concrete: Durability and applications. Appl. Sci. 2021, 11, 5629. [Google Scholar] [CrossRef]

- Cheng, Y. Experimental Study on Flexural and Axial Compression Performance of UHPC RC Members; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Lin, S.; Tao, Z.; Xia, Z. Experimental study on axial compressive performance of RC piers and columns with different UHPC reinforcement measures. World Bridge 2022, 50, 102–108. [Google Scholar]

- Wang, B.; Zhou, J. Study on axial compressive load capacity of UHPC reinforced RC columns. J. Ofilin Univ. Archit. 2022, 39, 354. [Google Scholar]

- Zhang, Y.; Dang, Q.; Mu, C. Experimental study on bending performance of UHPC reinforced box girder top slab. J. Hunan Univ. (Nat. Sci. Ed.) 2017, 44, 8–18. [Google Scholar]

- Brüdwiler, E. UHPFRC technology to enhance the performance of existing concrete bridges. In Maintenance, Safety, Risk, Management and Life-Cycle Performance of Bridges; Taylor & Francis Group: Boca Raton, FL, USA, 2018. [Google Scholar]

- Brühwiler, E.; Denarié, E. Rehabilitation of Concrete Structures Using Ultra-High Performance Fiber Reinforced Concrete; University of Kassel: Kassel, Germany, 2008. [Google Scholar]

- Noshiravani, T.; Bruehwiler, E. Analytical model for predicting response and flexure-shear resistance of composite beams combining reinforced ultrahigh performance fiber-reinforced concrete and reinforced concrete. J. Struct. Eng. 2014, 140, 1299–1328. [Google Scholar] [CrossRef]

- Noshiravani, T.; Bruhwiller, E. Experimental investigation on reinforced ultra-high-performance fiber-reinforced concrete composite beams subjected to combined bending and shear. ACI Struct. J. 2013, 110, 251–261. [Google Scholar]

- Bache, H.H. Densified Cement/Ultrafine Particle-Based Materials. In Proceedings of the International Conference on Superplasticizers in Concrete, Ottawa, ON, Canada, 10–12 June 1981. [Google Scholar]

- Larrard, F.D.; Sedran, T. Optimization of ultra-high-performance concrete by the use of a packing model. Cem. Concr. Res. 1994, 24, 997–1009. [Google Scholar] [CrossRef]

- Huang, Z. Experimental study on 200MPa ultra-high strength steel fiber concrete. Concrete 1993, 8, 5. [Google Scholar]

- Cui, B.; Wang, J.; Liu, G. Progress of UHPC bridge research and analysis of technical path for large-scale application. China Highw. J. 2023, 36, 1–19. [Google Scholar]

- Caluk, N.; Mantawy, I.M.; Azizinamini, A. Cyclic test of concrete bridge Column utilizing ultra-high performance concrete shell. Transp. Res. Rec. J. Transp. Res. Board 2020, 2674, 6088. [Google Scholar] [CrossRef]

- Amran, M.; Murali, G.; Makul, N.; Tang, W.C.; Alluqmani, A.E. Sustainable development of eco-friendly ultra-high performance concrete (UHPC): Cost, carbon emission, and structural ductility. Constr. Build. Mater. 2023, 398, 132477. [Google Scholar] [CrossRef]

- Garto, M.A.; Caforio, A.; Falegnami, A.; Tomassi, A.; Romano, E. Shape the EU future citizen. Environmental education on the European Green Deal. Energy Rep. 2023, 9, 340–354. [Google Scholar] [CrossRef]

- Bu, L.; Yuan, C.; Lu, C. Experimental study on bias performance of RC columns reinforced with polyvinyl alcohol fibre cement mortar reinforcing mesh. Build. Struct. 2013, 43, 82–88+9. [Google Scholar]

- Lu, C.; Ou, Y.; Wang, Q. Experimental study on axial compressive properties of UHPC-RC columns. Build. Sci. 2023, 39, 108–117. [Google Scholar]

- Li, L.Z.; Bai, Y.; Yu, K.Q.; Yu, J.-T.; Lu, Z.D. Reinforced high-strength engineered cementitious composite (ECC) columns under eccentric compression: Experiment and theoretical model. Eng. Struct. 2019, 198, 109541. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, Y.; Wang, L. Study on compressive performance of RC columns with Small eccentricity reinforced by high strength strand mesh/ECC. J. Build. Mater. 2023, 26, 29–36+44. [Google Scholar]

- Zhang, D.; Yu, J.; Wu, H.; Jaworska, B.; Ellis, B.R.; Li, V.C. Discontinuous micro-fibers as intrinsic reinforcement for ductile Engineered Cementitious Composites (ECC). Compos. Part B Eng. 2020, 184, 107741. [Google Scholar] [CrossRef]

- Ramezani, M.; Dehghani, A.; Sherif, M.M. Carbon nanotube reinforced cementitious composites: A comprehensive review. Constr. Build. Mater. 2022, 315, 125100. [Google Scholar] [CrossRef]

- GB 50367-2013; Design Code for Reinforcement of Concrete Structures. Sichuan Academy of Building Research: Sichuan, China, 2014.

- GB/T50081-2002; Standard Test Methods for Mechanical Properties of Ordinary Concrete. China Construction Industry Press: Beijing, China, 2007.

- 228.1-2021 GT; Methods of Room Temperature Tensile Tests for Metallic Materials. China Standard Press: Beijing, China, 2021.

- GB/T 50152-2012; B5 Standard for Test Methods for Concrete Structures. China Academy of Building Research: Beijing, China, 2012; 130p.

- Donnini, J.; Lancioni, G.; Chiappini, G.; Corinaldesi, V. Uniaxial tensile behavior of ultra-high performance fiber-reinforced concrete (Uhpfrc): Experiments and Modeling. Compos. Struct. 2020, 258, 113433. [Google Scholar] [CrossRef]

- Ma, K.; Ma, Y.; Liu, B. Experimental Study on Eccentric Compression Behavior of Ultra-high Performance Concrete Columns. Eng. Sci. Technol. 2018, 50, 201–208. [Google Scholar]

- Yoo, D.-L.; Yoon, Y.-S. Structural performance of ultra-high-performance concrete beams with different steel fibers. Eng. Struct. 2015, 102, 409–423. [Google Scholar] [CrossRef]

- Singh, M.; Sheikh, A.H.; Ali, M.S.; Visintin, P.; Griffith, M.C. Experimental and numerical study of the flexural behaviour of ultra-high performance fibre reinforced concrete beams. Constr. Build. Mater. 2017, 138, 12–25. [Google Scholar] [CrossRef]

- Wang, J.; Liu, J.; Wang, Z.; Liu, T.; Kiu, J.; Zhang, J. Cost-effective UHPC for accelerated bridge construction: Material properties, structural elements, and structural applications. J. Bridge Eng. 2020, 26, 04020117. [Google Scholar] [CrossRef]

- Liu, J.; Liu, J.; Han, F. Research progress and application of coarse aggregate ultra-high performance concrete based on lightweighting of steel-concrete composite structures. J. Build. Struct. 2022, 43, 9. [Google Scholar]

| Specimen | Initial Eccentricity (mm) | Thickness of UHPC (mm) | Steel Fiber Dosage (%) |

|---|---|---|---|

| Z1 | 50 | - | - |

| Z2-1 | 50 | 30 | 2% |

| Z2-2 | 100 | 30 | 2% |

| Z2-3 | 150 | 30 | 2% |

| Z3 | 150 | 30 | 1% |

| Z4 | 150 | 50 | 2% |

| Concrete Type | (MPa) | (MPa) | (MPa) | (GPa) | (MPa) |

|---|---|---|---|---|---|

| C40 | 42.52 | 28.70 | 3.94 | 31.97 | - |

| UHPC (1%) | 128.30 | 108.37 | 21.60 | 44.52 | 10.42 |

| UHPC (2%) | 134.80 | 116.74 | 25.90 | 45.01 | 11.31 |

| Diameter (d/mm) | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) |

|---|---|---|---|

| 8 mm | 528.60 | 652 | 22 |

| 16 mm | 457.30 | 627.60 | 26.30 |

| Specimen Number | (kN) | (kN) | (mm) | (mm) | Ductility Factor |

|---|---|---|---|---|---|

| Z1 | 1037.70 | 2401.40 | 7.394 | 8.232 | 1.113 |

| Z2-1 | 2078.40 | 6539.20 | 9.222 | 16.040 | 1.739 |

| Z2-2 | 1532.60 | 4596.30 | 8.931 | 14.512 | 1.625 |

| Z2-3 | 1314.30 | 2703.90 | 7.184 | 10.201 | 1.420 |

| Z3 | 1022.40 | 2481.50 | 7.059 | 9.770 | 1.384 |

| Z4 | 1538.90 | 3923.70 | 8.892 | 13.772 | 1.549 |

| Specimen Number | (kN) | (kN) | |

|---|---|---|---|

| Z1 | 2401.40 | 1902.50 | 1.260 |

| Z2-1 | 6539.20 | 6068.30 | 1.080 |

| Z2-2 | 4596.30 | 4167.50 | 1.103 |

| Z2-3 | 2703.90 | 2912.10 | 0.930 |

| Z3 | 2481.50 | 2703.60 | 0.920 |

| Z4 | 3923.70 | 4396.20 | 0.890 |

| Average value | - | - | 1.031 |

| Standard deviation | - | - | 0.32 |

| Coefficient of variation | - | - | 0.31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Pan, M.; Li, W.; Jing, C.; Chang, W.; Zhang, H. Experimental Study and Bearing Capacity Calculation of Compression-Reinforced Concrete Columns Strengthened with Ultra-High-Performance Concrete. Appl. Sci. 2024, 14, 1911. https://doi.org/10.3390/app14051911

Liu X, Pan M, Li W, Jing C, Chang W, Zhang H. Experimental Study and Bearing Capacity Calculation of Compression-Reinforced Concrete Columns Strengthened with Ultra-High-Performance Concrete. Applied Sciences. 2024; 14(5):1911. https://doi.org/10.3390/app14051911

Chicago/Turabian StyleLiu, Xianhui, Meiqing Pan, Weizhao Li, Chenggui Jing, Wenlong Chang, and Haoyang Zhang. 2024. "Experimental Study and Bearing Capacity Calculation of Compression-Reinforced Concrete Columns Strengthened with Ultra-High-Performance Concrete" Applied Sciences 14, no. 5: 1911. https://doi.org/10.3390/app14051911

APA StyleLiu, X., Pan, M., Li, W., Jing, C., Chang, W., & Zhang, H. (2024). Experimental Study and Bearing Capacity Calculation of Compression-Reinforced Concrete Columns Strengthened with Ultra-High-Performance Concrete. Applied Sciences, 14(5), 1911. https://doi.org/10.3390/app14051911