1. Introduction

The complexity of coal mining conditions in China is on the rise, and the proportion of mining in close-range coal seams is gradually expanding [

1]. In tandem, roadway damage under the influence of dynamic pressure is becoming prominent. Frequent damage phenomena, such as roadway tunnels’ roofs breaking and falling, anchor bolts and cables shearing and detaching, and shoulder corners of the roadways severely squeezing and deforming, require regular repairs and maintenance. This has seriously affected the daily use of roadways and personnel safety, and the situation has gradually attracted the attention of experts and scholars [

2,

3].

Many experts have analyzed and summarized the phenomena of damage to roadways due to the impact of dynamic pressure, revealing the damage mechanisms at work through theoretical derivation and numerical simulation [

4,

5]. Fan et al. [

6] believe that the underlying factor behind significant deformation in deep roadways subjected to dynamic pressure is attributed to the development of precarious plastic regions. The main factor leading to the shift of the plastic zone from a stable state to an unstable one is attributed to external influences, including tectonic stress and mining activities. Rong et al. [

7] found that the stability of the surrounding rock and the large loose circle is often compromised under current support conditions, leading to significant deformation in the rock adjacent to roadways when subjected to dynamic pressure. According to the limit analysis theory, a roadway soft rock failure model was developed by Zhang et al. [

8], and they analyzed the fracture evolution process of surrounding rocks subjected to various mining stresses. Wang et al. [

9] developed a model to analyze the structure of the overlying rock and stress distribution in coal pillars within a goaf roadway subjected to dynamic pressure. They also proposed theoretical criteria for assessing the stability of both the “arch beam” structure and coal pillars in goaf entry roadways subjected to dynamic pressure. Zhao et al. [

10] established models of F-shaped roof structures with long and short arms for various mining stages in the initial working area, and they presented stress calculation approaches for the surrounding rock on the gob side of a roadway. Ma et al. [

11] investigated the mechanism of structural evolution in goaf roof roadways when subjected to dynamic pressure, computed the roof pressure for the short arm beam dynamic pressure model, formulated a calculation formula for identifying roof fractures, and derived a criterion for determining roof fracture occurrence. Wang et al. [

12] employed numerical simulation techniques to examine the instability properties of coal roadways with composite roofs. They uncovered the progressive evolution patterns of fractures, as well as the modes of instability and failure in roadways surrounding rock subjected to multiple dynamic pressures.

In addition, the selection of roadway support under dynamic pressure is intricately intertwined with roadway section shape and surrounding rock condition, which must be met for specific geological and mining conditions [

13], and dynamic loads contribute to the use of a support that is not only more durable but yielding [

14]. Some scholars have improved the support technology of dynamic pressure roadways and proposed targeted support schemes. Ma et al. [

15] observed that the effectiveness of U-shaped steel supports in mitigating deformation and damage to roadways under dynamic pressure was limited. Wang et al. [

16] studied the stress field in a side coal roadway of a goaf under the influence of mining, and they suggested a support scheme that combines “anchor cable + grouting + single pillar”. Zhu et al. [

17] developed a mechanical model to analyze the behavior of rock beams on roadways’ floors subjected to dynamic pressure, quantified the displacement when each load acted independently, and proposed a control method of “bottom crane + bottom corner anchor + floor anchor” to control roadways under dynamic pressure. Sun et al. [

18] studied the deformation and failure mechanism of roadways under dynamic pressure in the entire process from excavation to working face mining, and they proposed a method of combining high pre-stress constant resistance support and roof-cutting technology (HPCR-RC). Jiang et al. [

19] proposed a collaborative approach to control pressure relief during directional roof cutting in strong roadways subjected to dynamic pressure. They also developed a three-dimensional model testing system to compare the effectiveness of their method with the conventional approach. Meng et al. [

20] conducted a theoretical analysis on the radii and displacement deformations occurring in roadway plastic zones subjected to dynamic pressure, and they proposed a support system consisting of “anchor + anchor cable + shotcrete + deep and shallow borehole grouting + invert” to limit the roadway deformation. Xie et al. [

21,

22] conducted an analysis on the damage characteristics of rocks surrounding roadways when subjected to deep dynamic pressure. They innovatively introduced a collaborative control technology involving external anchoring and internal unloading to effectively restrict significant deformations in the roadway. Lv et al. [

23] introduced a control strategy of “slow production, long–short control” for roadways under dynamic pressure affected by mining, and they designed a “high-strength yield bolt (cable) + steel belt” coupling support scheme.

Although the above studies have produced certain scientific results, few scholars have analyzed the impact of the dynamic pressure coefficient on the plastic zone of the surrounding rock during the study of the mechanisms of changes. Moreover, most of the support improvement solutions for roadways under dynamic pressure are still active supports, and these support solutions can play a certain supporting role in dynamic pressure roadways. However, under the influence of multiple strong dynamic pressures, there is still a risk of the anchor bolt and anchor cable being sheared and broken, and there is a potential for localized instability of the rock adjacent to the roadway, which does not effectively address the issue of controlling the surrounding rock.

Therefore, we have focused on investigating the influence coefficient of roadways when subjected to dynamic pressure. As a result, we have derived an implicit equation that describes the boundary of the plastic zone surrounding a roadway under dynamic pressure and with a nonuniform stress field. Additionally, our study has examined how the influence coefficient affects both the shape and extent of this plastic zone. Simultaneously, the effect of support resistance on the plastic zone of a roadway under dynamic pressure was analyzed, and based on this, a joint support scheme comprising an anchor cable and channel steel beam–CFST column combined bracket is proposed to achieve the protection of rocks surrounding roadways under dynamic pressure.

3. Damage Mechanisms of the Roadway’s Surrounding Rock under Dynamic Pressure

3.1. Roadway Mechanics Model

From its excavation to the completion of its service life, Malan Coal Mine’s gas drainage roadway is subject to disturbances caused by both excavation activities and the mining pressure exerted from the upper coal seam. The surrounding rock experiences a relatively intricate stress state as a consequence of this process. To effectively unpick its workings and facilitate theoretical calculations, the following assumptions were made:

- (1)

We simplified the roadway into a circle, assuming uniform properties of the surrounding rock throughout its length;

- (2)

We considered that the roadway was surrounded by a linear elastic body that was both homogeneous and isotropic in nature;

- (3)

The original rock stresses in both horizontal and vertical directions were approximated as uniform stresses;

- (4)

The mining influence coefficient

K was introduced to indicate the degree of influence of coal seam mining on the stress of the surrounding rock, and it was divided into the vertical mining influence coefficient

K1 and the horizontal mining influence coefficient

K2 [

25].

Based on the above assumptions, it was possible to analyze the stress distribution of the roadway’s surrounding rock as a problem involving plane strain. This made it possible to construct a mechanical model for this roadway under dynamic pressure, as depicted in

Figure 2.

3.2. Boundary Equation of the Plastic Zone

Based on the principles of elastic mechanics, when calculating the stress of the roadway surrounding rock under two-way non-isobaric conditions, the load can be decomposed into two parts, that is, the stress of the surrounding rock shown in

Figure 2 is decomposed into the two parts in

Figure 3a,b. Each situation is calculated separately, and finally, the stress component under the original load can be obtained by superimposing the two parts of the solution [

26].

As shown in

Figure 3a, the static equilibrium equation and geometric equation are

And the constitutive equation is

At the same moment, the boundary circumstances of the rock encircling the roadway are

By combining Formulas (1)–(3), part one of the stress state at any point in the rock surrounding the roadway is [

26]

Then, as shown in

Figure 3b, the stress boundary condition at an infinite distance from the roadway is

The expression for converting the stress components in the Cartesian coordinate system into the polar coordinate system is

In addition, the inner boundary of the roadway meets the following conditions:

By combining Formulas (5)–(7), part two of the stress state at any point in the rock surrounding the roadway is [

26]

In these formulas, σr, σθ, and τrθ represent the radial stress, hoop stress, and shear stress, respectively, at any point of the rock surrounding the roadway in polar coordinates, MPa; σx and σy represent the horizontal stress and vertical stress, respectively, at any point of the rock surrounding the roadway in Cartesian coordinates, MPa; r is the distance from the point to the roadway center, m; θ represents the deviation between the line connecting the point and the center of the roadway and the horizontal direction, (°); λ represents the lateral pressure coefficient; and r0 is the roadway radius, m.

By superimposing the two parts of the solution, the stress field of the rock surrounding the two-way non-isobaric roadway under the action of dynamic pressure can be obtained. The stress expression at any point of the rock surrounding the roadway is as follows [

26]:

As shown in Formula (10), the principal stresses in surrounding rock can be determined in the polar coordinate system by transforming stress equations from the cartesian coordinate system [

25].

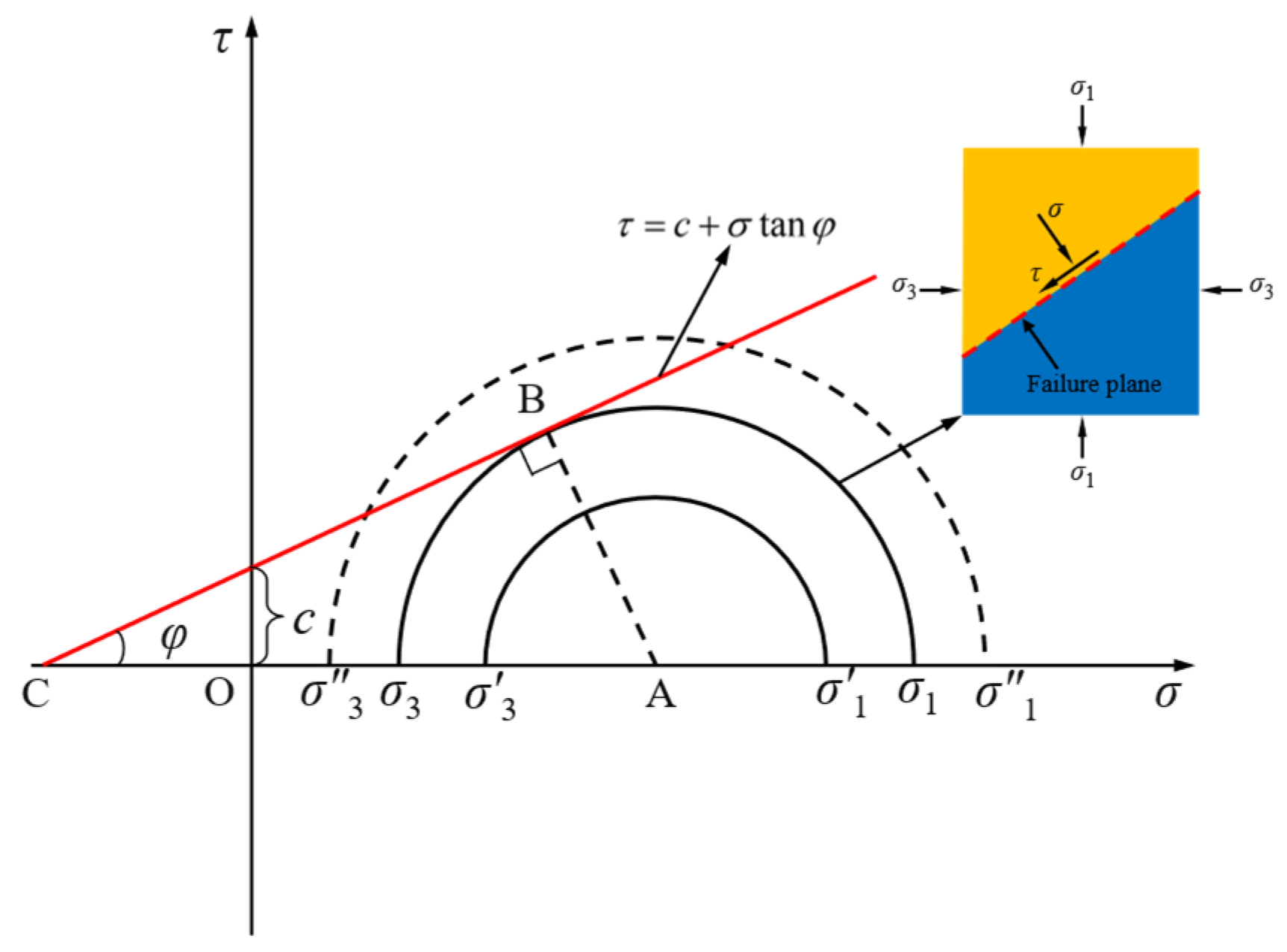

Assume that the rock surrounding the roadway can continuously transition to an ideal plastic state, as shown in

Figure 4. According to the Mohr-Coulomb yield criterion, when the ratio of shear stress to normal stress on the rock shear surface reaches the maximum value, the rock is in a limited equilibrium state and is about to undergo yield failure [

27]. The relationship between the maximum principal stress and the minimum principal stress at this time is shown in Formula (11) and is simplified to Formula (12) [

28].

In the formula, σ1 represents the maximum principal stress, σ3 represents the minimum principal stress, c represents the cohesion force, and φ represents the internal friction angle.

Then, according to Formulas (10) and (12), the polar coordinate expression of the Mohr-Coulomb yield criterion can be obtained, as shown in Formula (13) [

28] as follows:

Substituting Formula (9) into Formula (13) for calculation, the binary implicit function about

r and

θ can be obtained, and the expression is as shown in Formula (14) [

28] as follows:

When the above function f (θ, r) = 0, an implicit equation of the boundary of the plastic zone of the rock surrounding the nonuniform stress field of the dynamic pressure roadway can be obtained. According to this equation, the distribution shape and evolution of the plastic zone of the surrounding rock can be studied.

3.3. Distribution Shape and Evolution of Plastic Zones

According to the boundary equation of the plastic zone of the rock surrounding the roadway under dynamic pressure, the shape of the plastic zone is related to the dynamic pressure coefficient, original rock stress, lateral pressure coefficient, roadway radius, internal friction angle, cohesion, and other factors. When the size of the roadway under dynamic pressure and the mechanical properties of the surrounding rock remain unchanged, the size and boundary of the plastic zone depend on the size of the dynamic pressure coefficient. Hence, an analysis was conducted on roadways with varying coefficients of lateral pressure to investigate the impact of vertical and horizontal mining activities on the boundary of the plastic zone of surrounding rock.

When the roadway is located below the mining working face, the roadway will be affected by vertical mining. Taking three common lateral pressure coefficients λ = 0.8, λ = 1.0, and λ = 1.5 as examples,

Figure 5 shows the distribution of the plastic zone of the surrounding rock under the influence of vertical dynamic pressure.

Figure 5a shows the plastic zone of the roadway’s surrounding rock when

λ is 0.8. When

K1 is 1.0, the shape of the plastic zone of the surrounding rock is elliptical, and the roadway is under the action of static load and is not affected by dynamic pressure. The plastic zones at the sides of the roadway are larger, and the plastic zones of the roof and floor are smaller. When

K1 increases to 1.5, the plastic zone expands from the upper part to the deep part of the surrounding rock, and the zone becomes roughly butterfly shaped. As

K1 further increases, the plastic zone gradually expands in the four directions of the top and bottom corners of the roadway, and the butterfly shape becomes more obvious.

Figure 5b shows the plastic zone of the roadway’s surrounding rock when

λ is 1.0. When

K1 is 1.0, the shape of the plastic zone of the roadway under static load is circular. As

K1 increases, the shape evolution pattern is similar to that in

Figure 5a, and the distribution shape evolves from circular to butterfly. However, the influence of

K1 is relatively weakened. As shown in

Figure 5c, when

K1 is 1.0, the shape of the plastic zone of the roadway under static load is elliptical, and the shape of the plastic zone changes from an ellipse to a rounded rectangle as

K1 increases. The plastic zones at the sides of the roadway gradually increase, while the plastic zones at the roof and floor weaken slightly. As

λ increases, the influence of

K1 on the distribution shape and range of the plastic zone gradually weakens.

When the roadway and the mining face are in the same coal seam, the rock surrounding the roadway will be affected by horizontal mining. The corresponding plastic zone of the surrounding rock is shown in

Figure 6.

Figure 6a shows the distribution shape of the plastic zone when

λ is 0.8. As

K2 increases, the shape of the plastic zone changes from elliptical to butterfly. The scope of the plastic zone gradually increases and extends toward the roof and floor of the roadway, while the plastic zones at both sides of the roadway gradually weaken.

When

λ is 1.0 or 1.5, the plastic zone of the roadway’s surrounding rock is as shown in

Figure 6b,c. As

K2 increases, the radius of the plastic zone increases significantly, gradually extending to the four corners of the roadway’s surrounding rock, and the butterfly shape becomes more obvious. As

λ increases, the influence of

K2 on the distribution shape and range of the plastic zone becomes increasingly obvious.

Through the above analysis and combined with the plastic zone distribution shape, we have identified four distinct types for delineating the boundaries of the plastic zone in the rock surrounding the roadway subjected to dynamic pressure.

Circle: Under bidirectional isobaric conditions, the plastic zone boundary of the roadway forms a standard circle;

Elliptical shape: Under bidirectional anisobaric conditions, the plastic zone boundary of the roadway is similar to an elliptical shape;

Rounded rectangle: Under bidirectional anisobaric conditions, a shape similar to a rounded rectangle will appear during the transformation process of the plastic zone boundary of the roadway from an ellipse to a butterfly shape;

Butterfly shape: Under bidirectional anisobaric conditions, as the value of K and λ change, the boundary of the plastic zone gradually transforms from an elliptical shape to a butterfly shape.

3.4. Analysis of the Damage Mechanism of the Roadway’s Surrounding Rock under Dynamic Pressure

By establishing a mechanical model of a roadway under nonuniform, dynamic pressure, a more in-depth study was conducted of the morphological evolution and distribution range of the surrounding rock’s plastic zone under the influence of mining. Combined with the deformation characteristics of roadways under dynamic pressure, we have inferred that the primary factors contributing to significant deformation and failure of roadways subjected to dynamic pressure are as follows:

- (1)

Original rock stress conditions. The gas drainage roadway is buried approximately 400 m deep and is subject to relatively large stress on the original rock. After the excavation of the roadway, there has been a shift in the stress state of the surrounding rock from three-dimensional to unidirectional. Consequently, the surrounding rock is susceptible to damage and displays indications of localized fragmentation and loosening.

- (2)

Development of fissures in surrounding rocks. The fractures in the broken surrounding rock develop rapidly under the influence of mining, eventually causing severe plastic damage. In addition, there are often various interlayers inside coal seams. The shear and tensile properties of the interlayers are low, and they are prone to damage and sliding, resulting in layered protrusions.

- (3)

Surrounding rock stress environment. During the mining process of close coal seams, the severe mine pressure caused by the excavation of the upper group of coal will seriously damage the stability of the gas drainage roadway and cause serious plastic damage. Under the influence of the advanced support pressure of the mining working face, the rock surrounding the roadway will be seriously damaged, and anchor cables cannot resist the pressure. In addition, the interlayer dislocation of broken surrounding rock will most likely shear anchor cables and other supporting components, leading to support failure and ultimately causing overall roadway instability and damage.

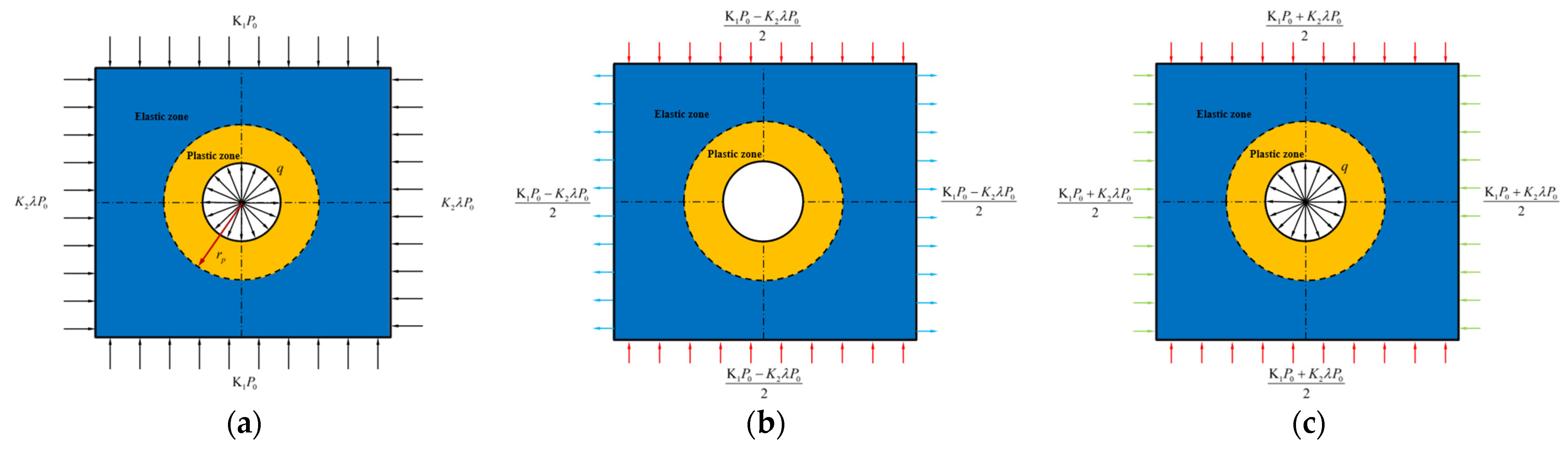

4. Effect of Supporting Force on the Plastic Zone of the Surrounding Rock

An implicit equation for the plastic zone boundary of the rock surrounding the roadway in a nonuniform stress field under dynamic pressure and subject to the action of supporting force can be deduced after following the steps outlined in

Section 3. First, a roadway under a dynamic pressure mechanical model considering supporting force is established, as shown in

Figure 7a, and then decomposed into two situations, as shown in

Figure 7b,c. Through calculation, the binary implicit function of

r and

θ can be obtained as shown in Formula (15).

In the formula, P1 = (K1 P0 + K2λP0)/ 2, and P2 = (K1 P0 − K2λP0)/ 2.

When f (θ, r) = 0, an implicit equation for the boundary of the plastic zone of the rock surrounding the roadway under dynamic pressure and in a nonuniform stress field subject to supporting force can be obtained.

When using the existing technology and equipment, the supporting force is not of the same order of magnitude as the resistance needed to completely control the deformation of the surrounding rock. The supporting force applies to active types of support that can exert preload force, including anchor bolts and anchor cables, and it is approximately a few percent of the in situ stress. For example, the supporting force range of anchor bolts is 0.05~0.8 MPa, and the maximum support resistance that hydraulic supports can provide is only 0.6 MPa [

28]. At the same time, in the current situation, the maximum support resistance provided by support equipment materials generally does not exceed 1 MPa. Therefore, the distribution range and change rules of the plastic zone boundary of the rock surrounding the roadway under dynamic pressure were studied when the supporting forces were 0, 0.3 MPa, 0.5 MPa, 0.8 MPa, and 1.0 MPa, respectively.

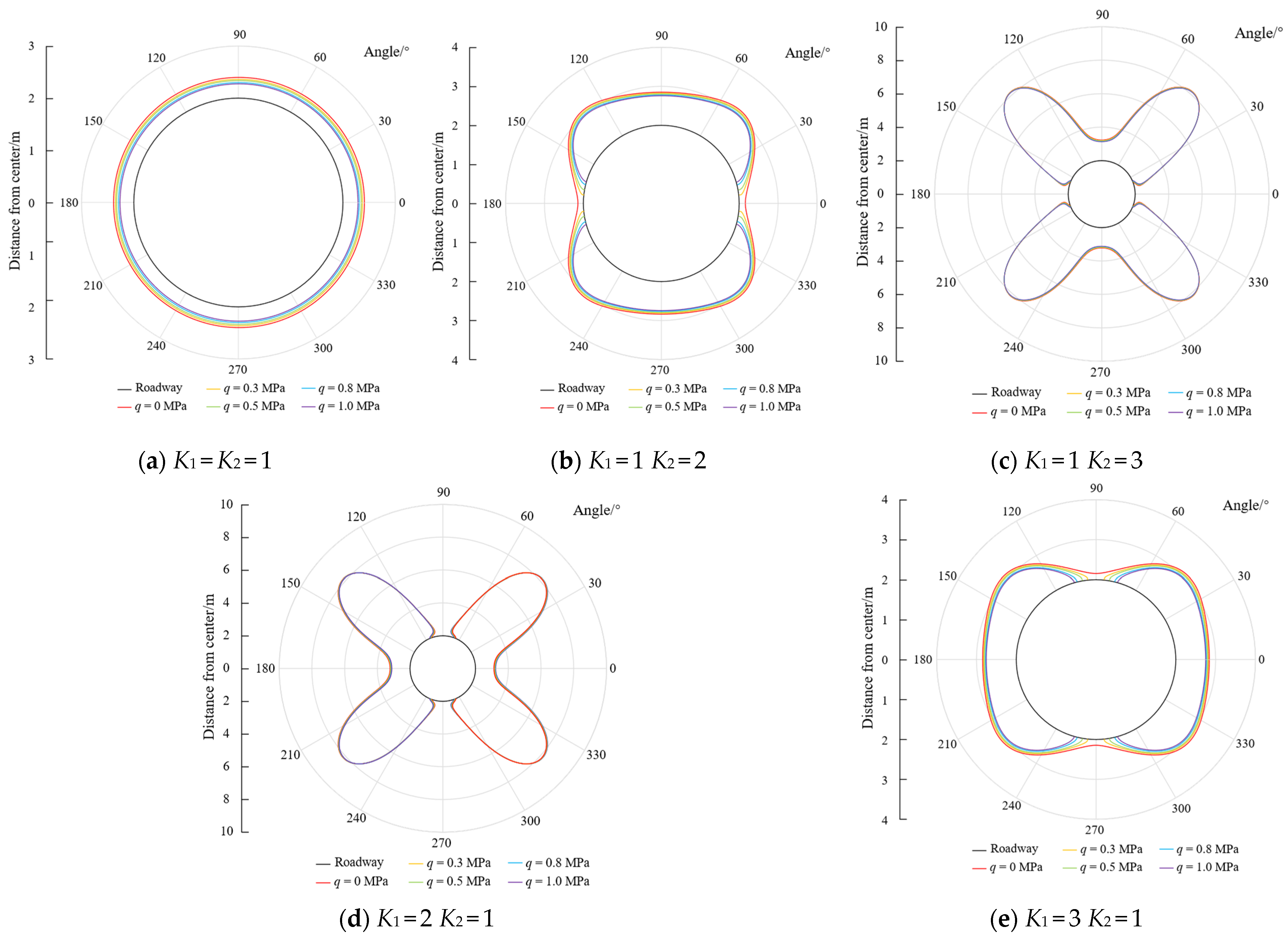

When

λ is 0.8, the relationship between the supporting force and the boundary of the plastic zone of the surrounding rock is shown in

Figure 8. When the roadway is not affected by mining, the shape of the plastic zone is elliptical, with larger plastic zones at both sides of the roadway and smaller plastic zones at the roof and floor. As the supporting force increases, there is a certain reduction in the size of the plastic zone, but the decrease is very small, as shown in

Figure 8a. When the roadway is only affected by horizontal mining, the shape of the plastic zone is shown in

Figure 8b,c. As the horizontal mining influence coefficient increases, the shape of the plastic zone changes from elliptical to butterfly, and the plastic zone gradually expands to the roof and floor corners of the roadway. As the supporting force increases, the plastic zone decreases slightly, but its shape does not change. When the roadway is only affected by vertical mining, the shape of the plastic zone is shown in

Figure 8d. It is butterfly shaped, and the two butterfly wings are symmetrical. As the supporting force increases, the plastic zone gradually decreases, but the decrease is very small.

When

λ is 1.0, the relationship between the supporting force and the plastic zone of the surrounding rock is shown in

Figure 9. When the roadway is not affected by mining, the shape of the plastic zone forms a uniform circle. With the application of supporting force, the shape of the plastic zone does not change, though its radius decreases slightly, as shown in

Figure 9a.

Figure 9b,c show the distribution shape of the plastic zone when the roadway is only affected by horizontal mining. It is butterfly shaped but facing horizontally, and the two butterfly wings are symmetrical. With the increase in the horizontal mining influence coefficient, the scope of the plastic zone gradually increases, and the butterfly shape gradually appears, but the scope of the plastic zone does not significantly shrink with the increase in supporting force.

Figure 9d,e show the distribution shape of the plastic zone when the roadway is only affected by vertical mining. It is still butterfly shaped, and the two butterfly wings are symmetrically distributed. The plastic zone is mainly distributed in the upper part of the roadway, and the supporting force has little impact on its distribution range.

Figure 10 shows the relationship between the supporting force and the plastic zone of the surrounding rock when

λ is 1.5. As shown in

Figure 10a, when the roadway is not affected by mining, the shape of the plastic zone is elliptical, and it is distributed mainly at the roof and floor of the roadway. As the supporting force increases, the scope of the plastic zone decreases slightly, but the shape is still elliptical.

Figure 10b presents the roadway when only affected by horizontal mining. The plastic zone of the surrounding rock is butterfly shaped and concentrated at the top and bottom of the roadway. The increase in support resistance has a smaller impact on the reduction in the plastic zone.

Figure 10c,d show the distribution pattern of the plastic zone of the roadway’s surrounding rock when the roadway is only affected by vertical mining. This time, the plastic zone is mainly located at the two sides of the roadway, and as the vertical mining influence coefficient increases, its shape changes from elliptical to butterfly. At the same time, the radius of the plastic zone decreases to a certain extent as the support resistance increases, but the amplitude is small.

6. Engineering Site

6.1. Original Roadway Support Scheme

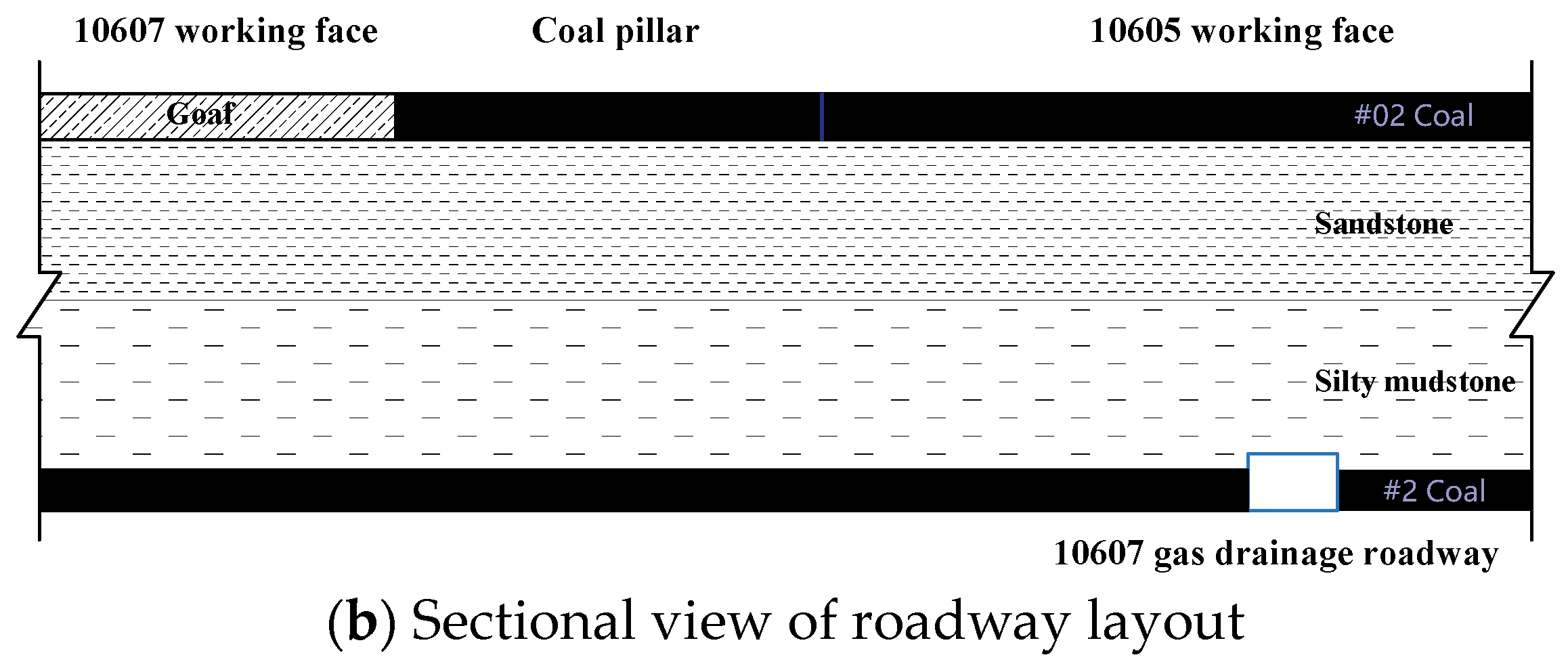

The 10607 gas drainage roadway, located in the #2 coal seam, is utilized for the extraction of gas from both the 10607 and 10605 working faces of the #02 coal seam. Furthermore, it will serve as a mining roadway during the mining of the #2 coal seam, thus realizing a multipurpose function (Shan et al. [

24]).

Figure 18 displays the layout of the 10607 gas drainage roadway.

The 10607 gas drainage roadway features a rectangular shape with dimensions of 4200 mm in width and 2600 mm in height. The original support scheme consists of anchor bolts and anchor cables, and the design is based on the predicted load of the roadway roof. The roof adopts

Φ20 × 2000 mm rebar anchor bolts + metal diamond mesh + reinforced steel belt +

Φ21.6 × 52,000 mm anchor cables + pressed pallet joint support, and the two sides use

Φ20 × 2000 mm rebar anchors + W pallets + metal diamond mesh for joint support [

24], as illustrated in

Figure 19.

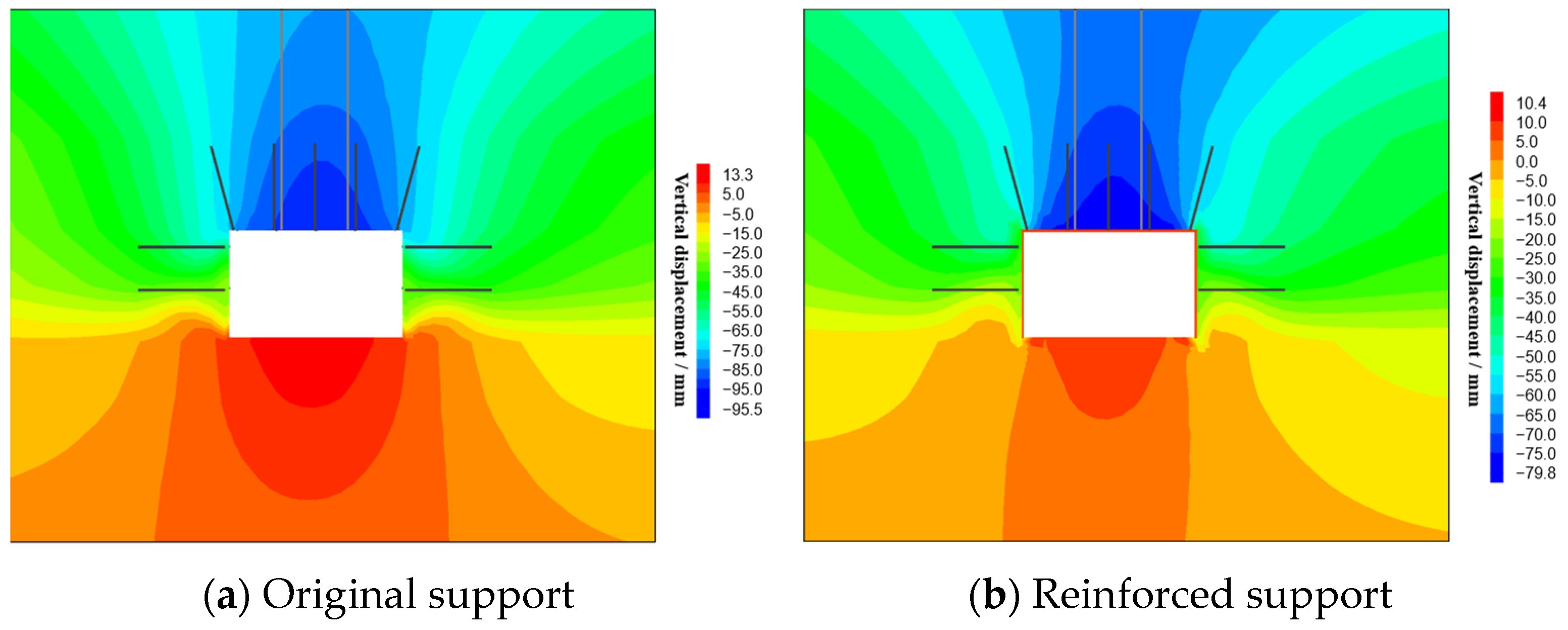

6.2. Roadway Reinforcement Design

Based on our analysis of the damage mechanisms of roadways under dynamic pressure, an overall active and passive support technology has been proposed, comprising an anchor cable and channel steel beam–CFST column combined bracket, and the reliability of this support technology has been verified using numerical simulation software. This has shown that since the 10607 gas drainage roadway only has conventional anchor cable supports, the roadway surrounding rock will suffer damage as a result of mining activities. Therefore, the roadway needs to be reinforced in advance to ensure that it can maintain the stability of the surrounding rock under the influence of mining.

As shown in

Figure 20, the reinforcement support scheme uses a channel steel beam–CFST column combined bracket to passively support the surrounding rock, and this is combined with the active support of the anchor cables used in the original scheme to jointly cope with the impact of mining the 10605 working face. To guarantee the durability and stability of the roadway under various dynamic pressures, a combination bracket with a substantial support reaction force is employed in the design scheme.

The CFST columns are made of Φ194 × 8 mm seamless steel pipes, the channel steel is made of the 14#b model, and we employ C40 fast-hardening concrete. The anchor bolts and anchor cables have breaking loads of 200 kN and 180 kN, respectively, while the ultimate bearing capacity of the CFST columns is 1954 kN. Considering that the roadway has a long service life and will need to withstand many mining disturbances, the design distance between the brackets is 1000 mm.

6.3. On-Site Support Effect Analysis

When taking into account the geological composition of the 10607 gas drainage roadway and its specific site conditions, it can be observed that the middle section of the roadway is composed of silty mudstone for its roof, siltstone for its floor, silty mudstone for its upper sides, and #2 coal for its lower sides. The slope of the floor in this section is small and gentle, which facilitates the installation of the combined bracket and the mixing of concrete on-site. Therefore, this section was selected as the support reinforcement test section, and the on-site support effect is shown in

Figure 21.

To assess the impact of the reinforcement scheme on support effectiveness, it was imperative to monitor the roadway deformation in relation to that observed under the original support scheme. In this case, we established two sets of measuring stations along the roadway, termed Y# and A#. The Y# measuring station monitored the roadway with the original support scheme, and A# monitored the roadway with the reinforcement scheme. During on-site monitoring, the cross-point method was used, and tools such as laser ranging instruments, steel tapes, hooks, and height gauges were applied to determine the vertical distance between the roof and floor, as well as the horizontal distance between both sides.

According to the on-site monitoring findings, the maximum displacements of the roof, side walls, and floor for which the excavation remains functional are 410 mm, 350 mm, and 80 mm, respectively. As depicted in

Figure 22, the mining-induced impact resulted in a maximum roof subsidence of 520 mm for the original support section, while the reinforced support section experienced a maximum roof subsidence of 271 mm. The displacement of the two sides of the original support section reached a maximum of 435 mm, while the reinforced support section exhibited a maximum displacement of 241 mm. It is evident that the reinforcement support scheme significantly enhanced the effectiveness of mitigating roof subsidence and lateral displacement by 47.9% and 44.6%, respectively, when compared with the original scheme, and the surrounding rock deformation control effect was more obvious.