Exploring the Distribution Characteristics of High Static Load in the Island Working Face of Extra-Thick Coal Seams with Hard Roof: Addressing the Challenge of Rock Burst Risk

Abstract

1. Introduction

2. High-Stress Appearance of Island Working Face

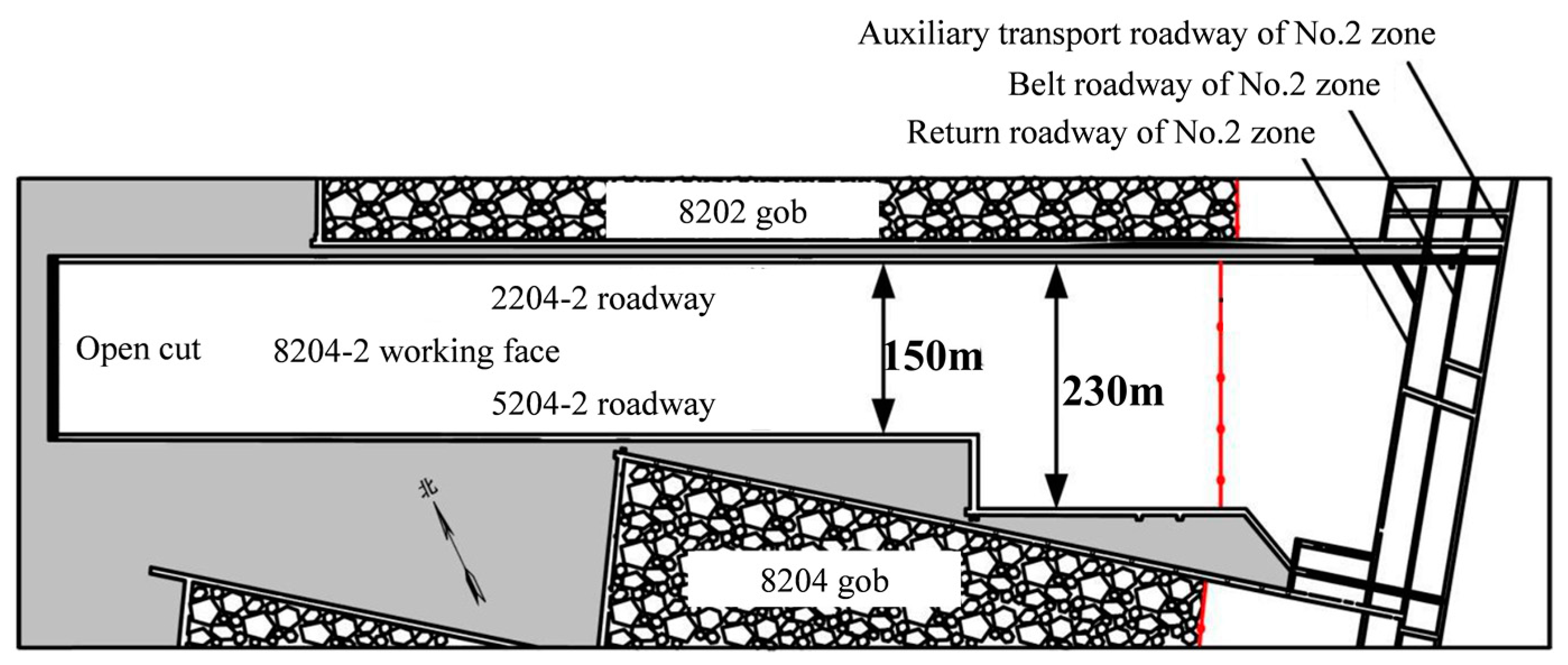

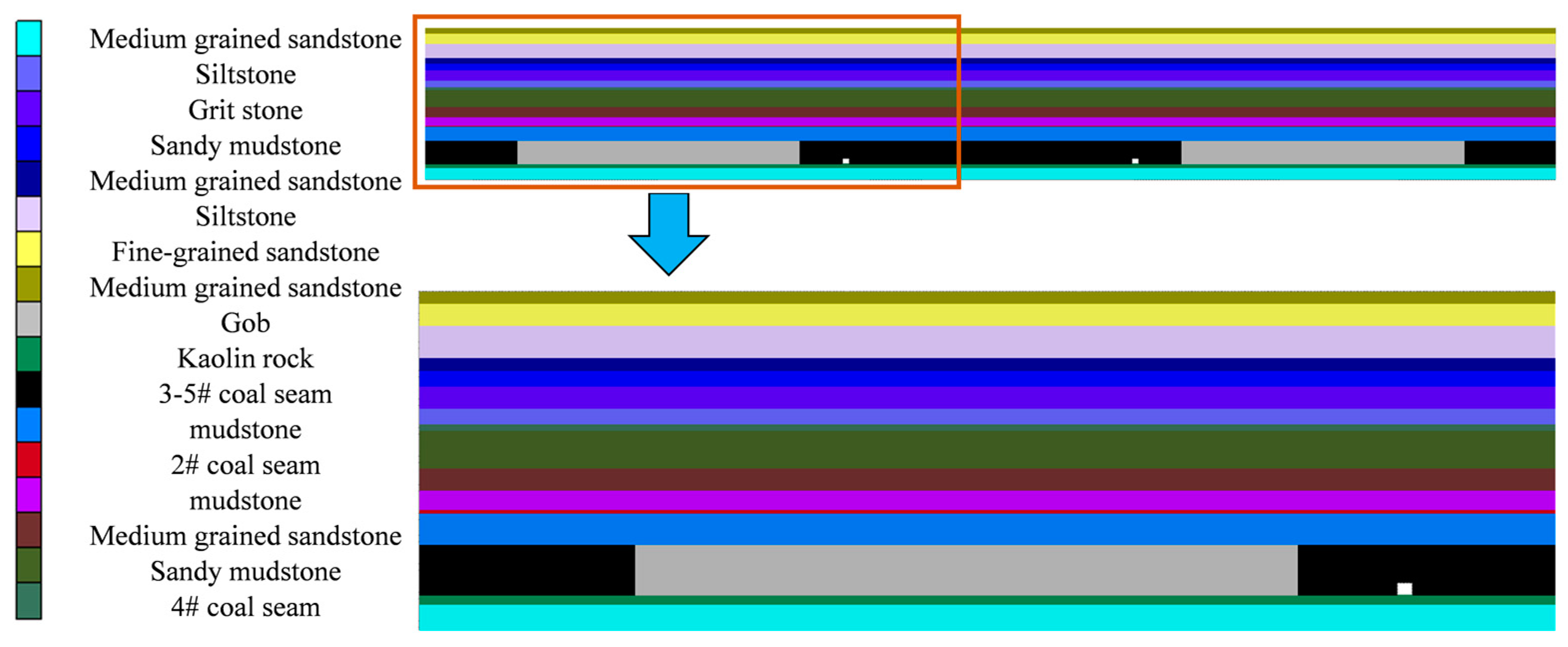

2.1. Engineering Geological Conditions

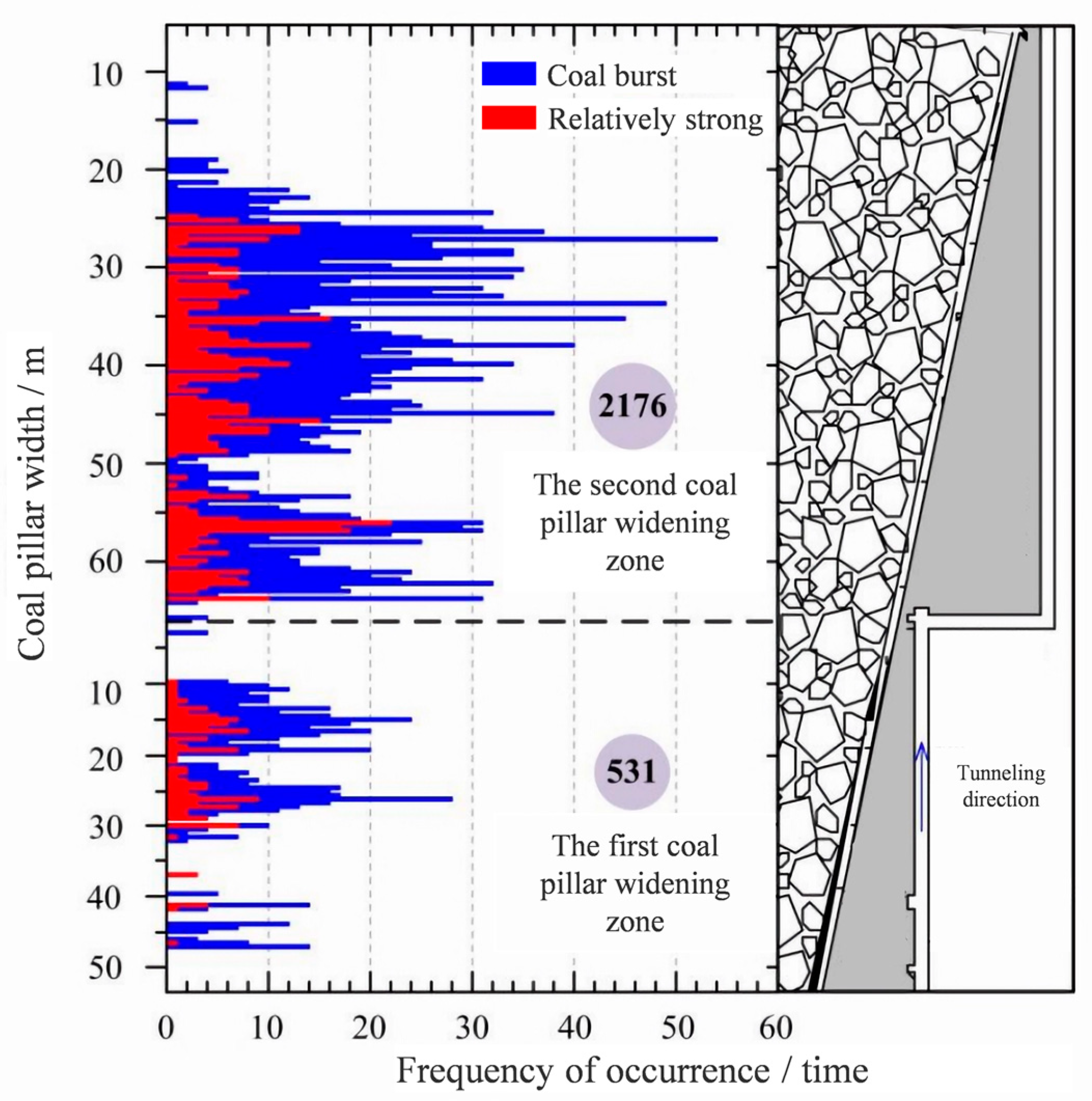

2.2. Appearance of Dynamic Phenomenon

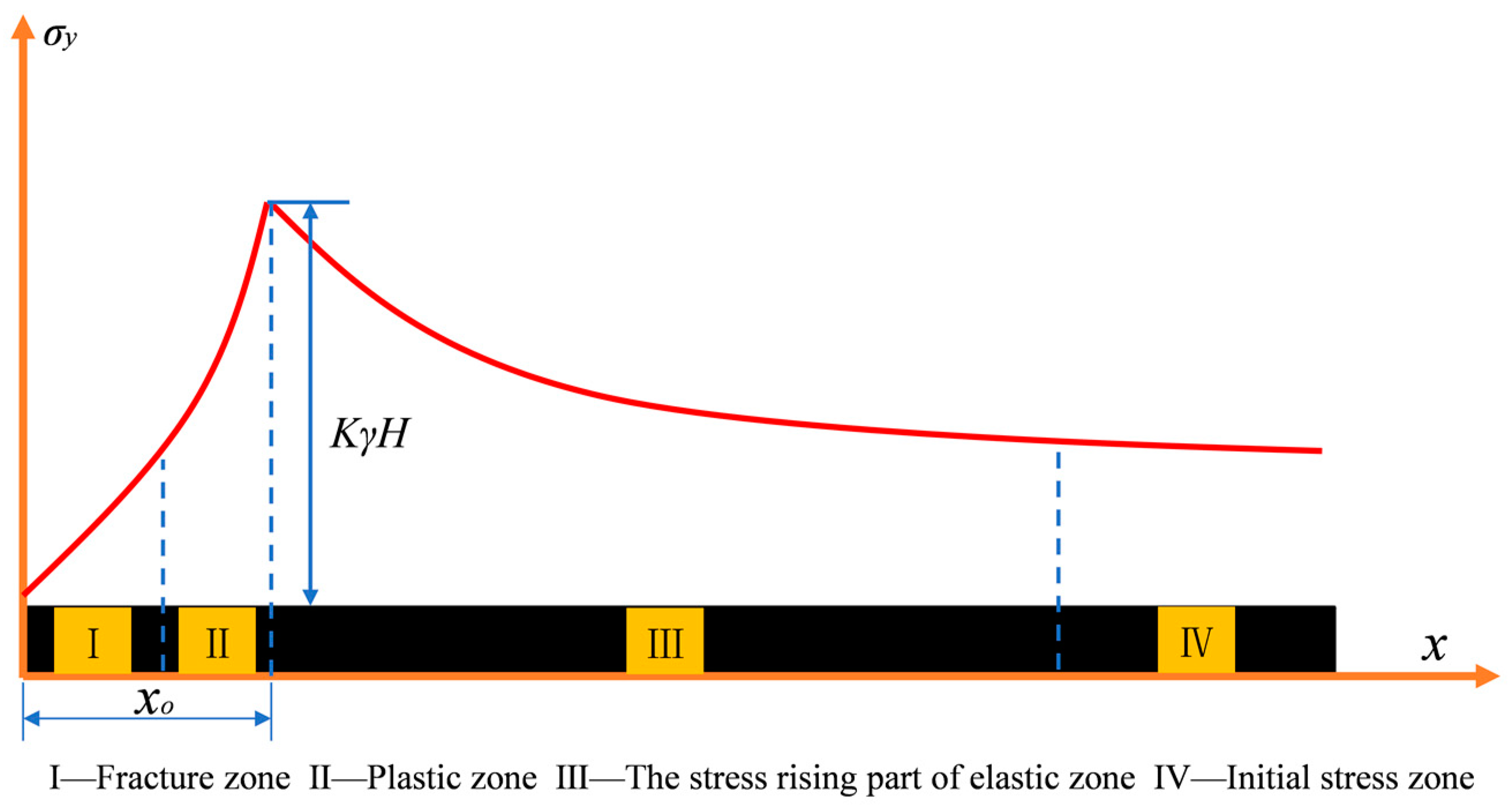

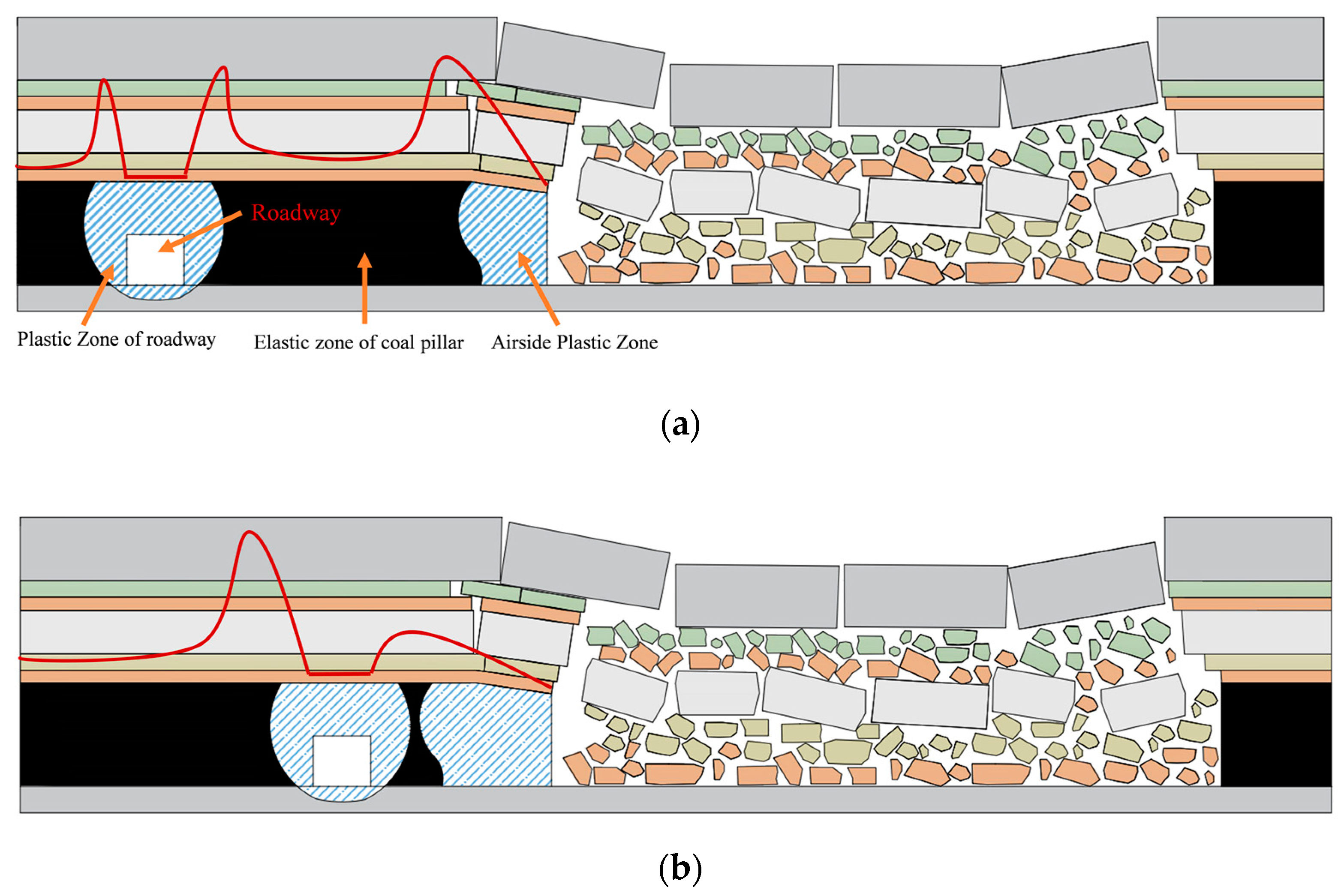

3. Influencing Factors of High Static Load in Island Working Face

4. Stress Distribution Law in Island Working Face

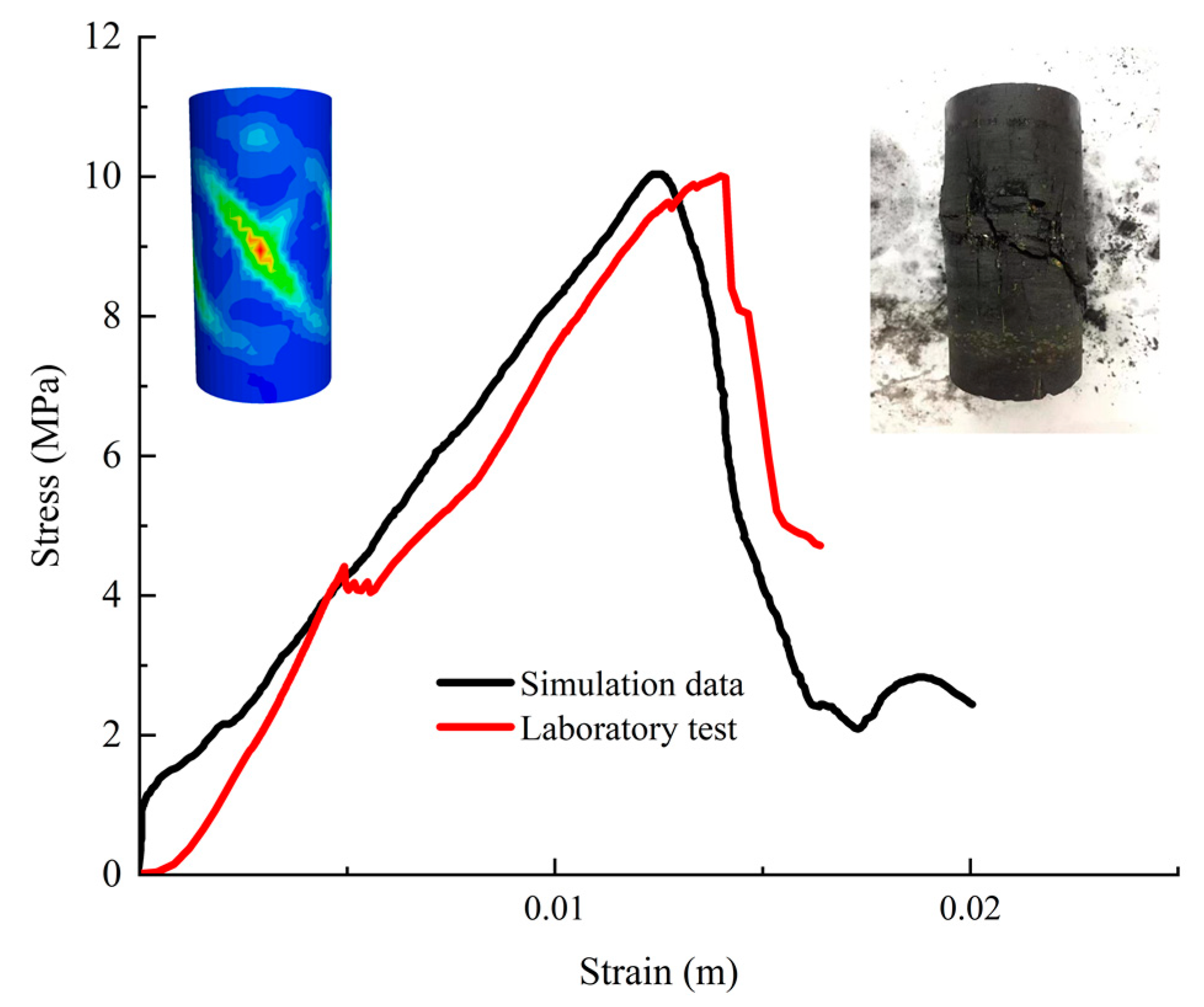

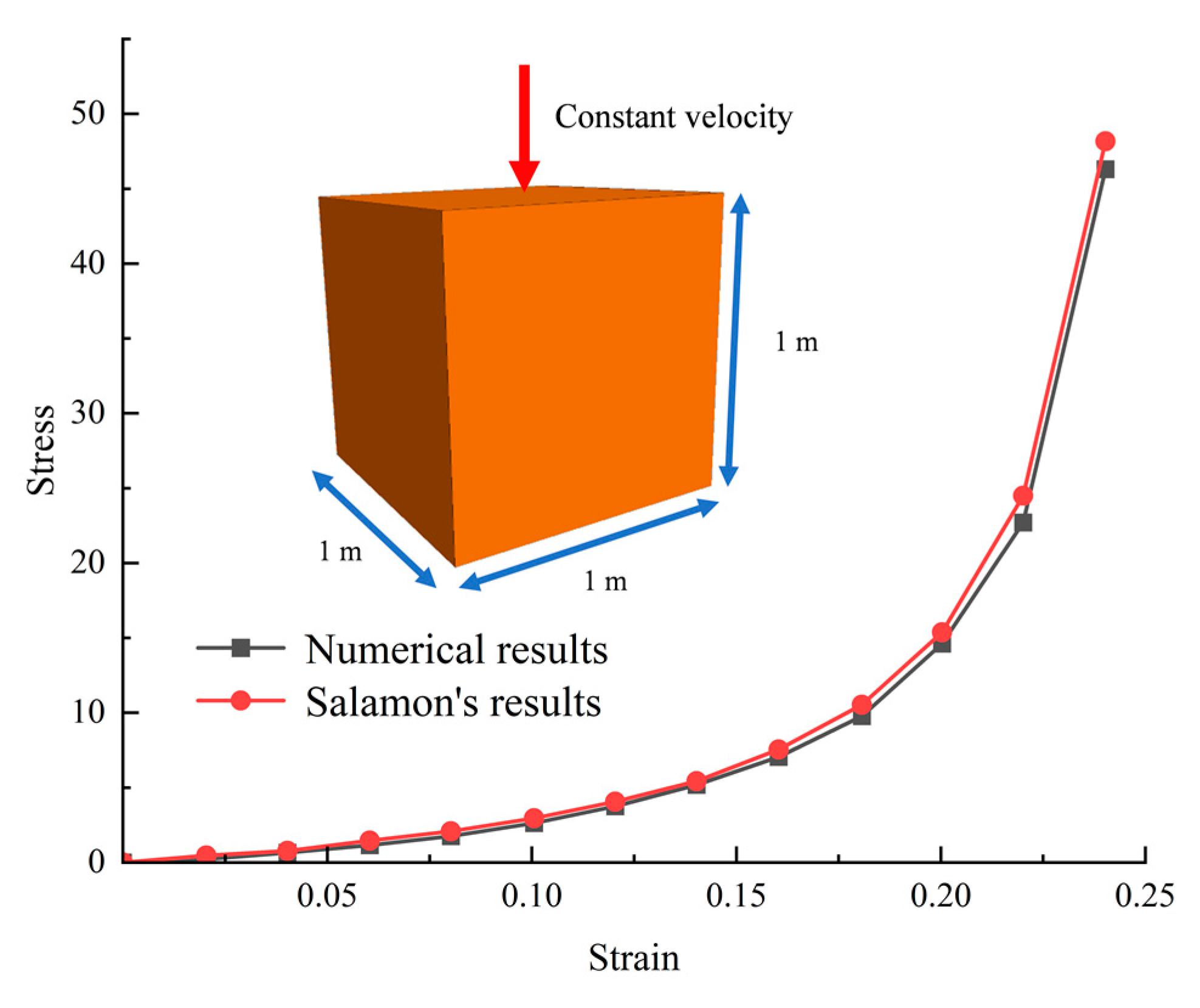

4.1. Construction of Numerical Model

4.2. Numerical Simulation Results Analysis

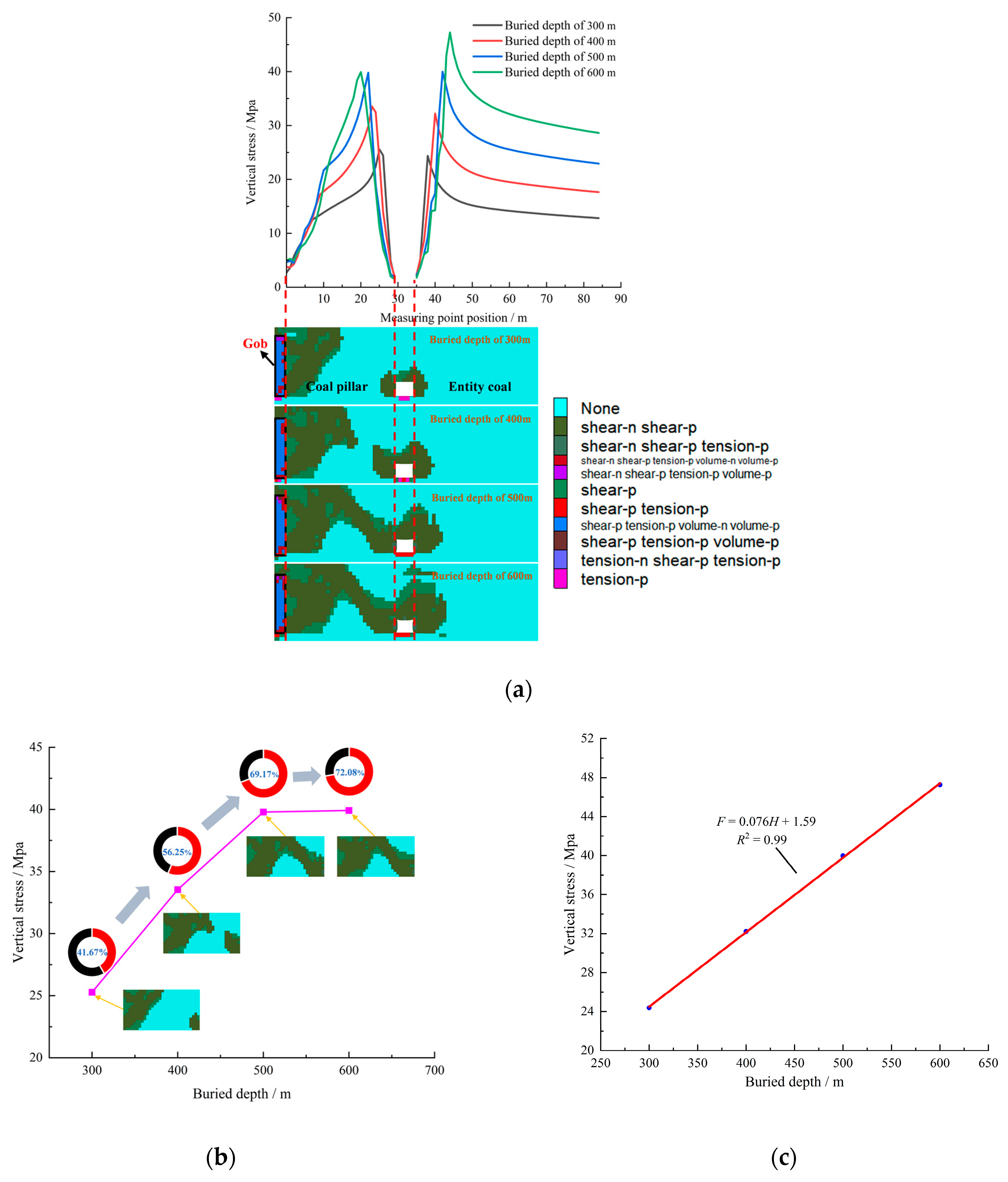

4.2.1. The Stress Distribution Influenced by Buried Depth

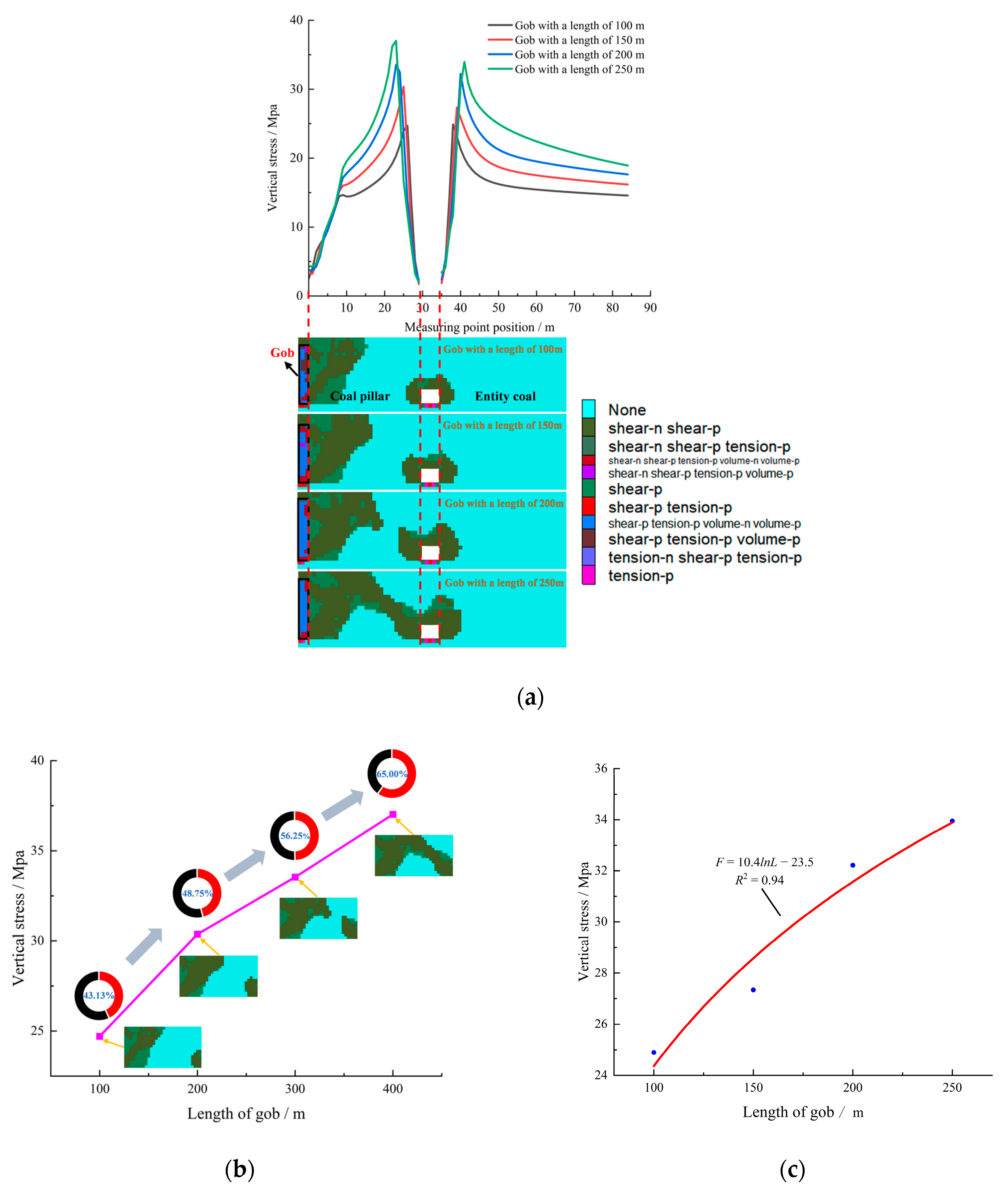

4.2.2. The Stress Distribution Influenced by Adjacent Gob Length

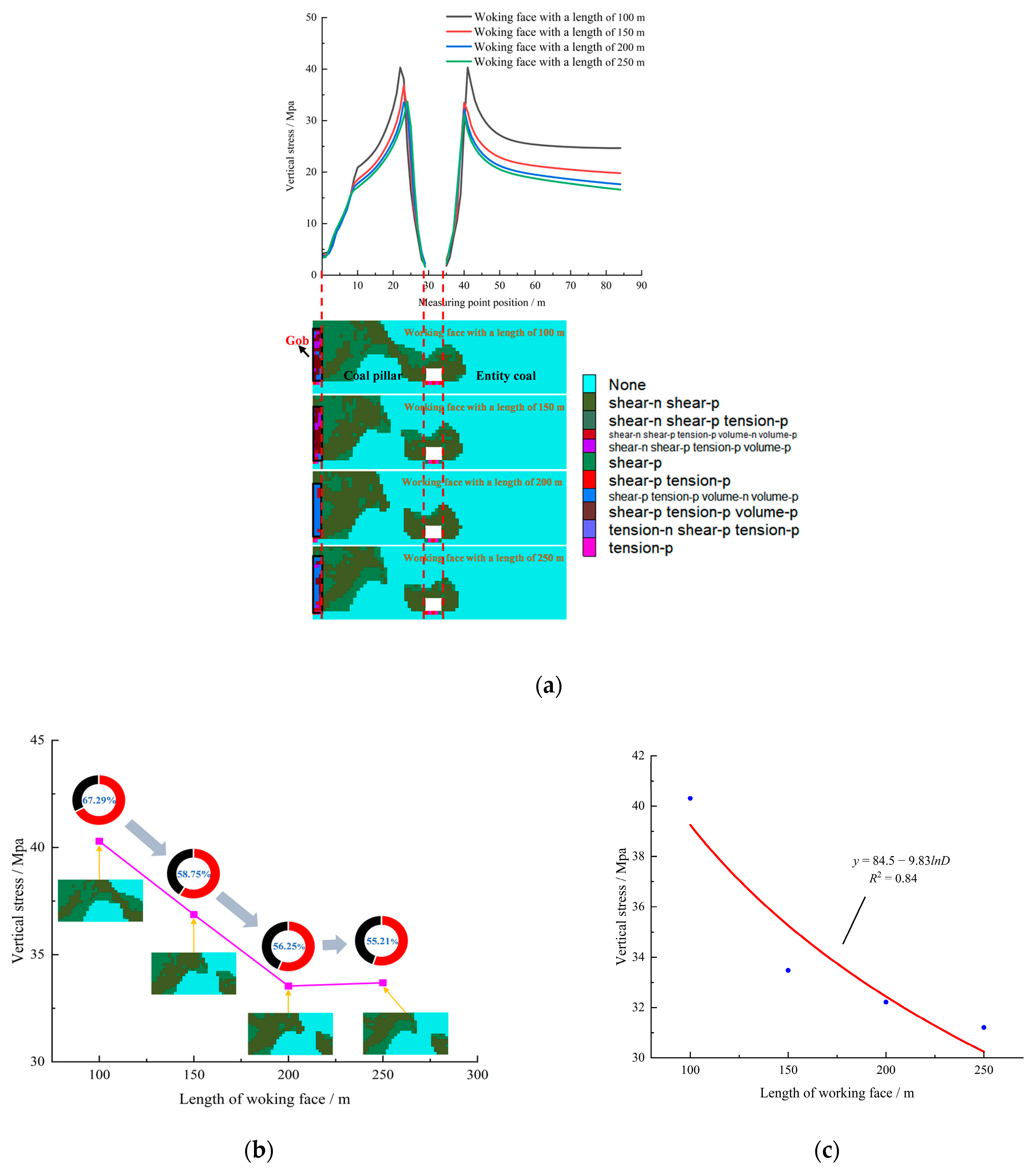

4.2.3. The Stress Distribution Influenced by Working Face Length

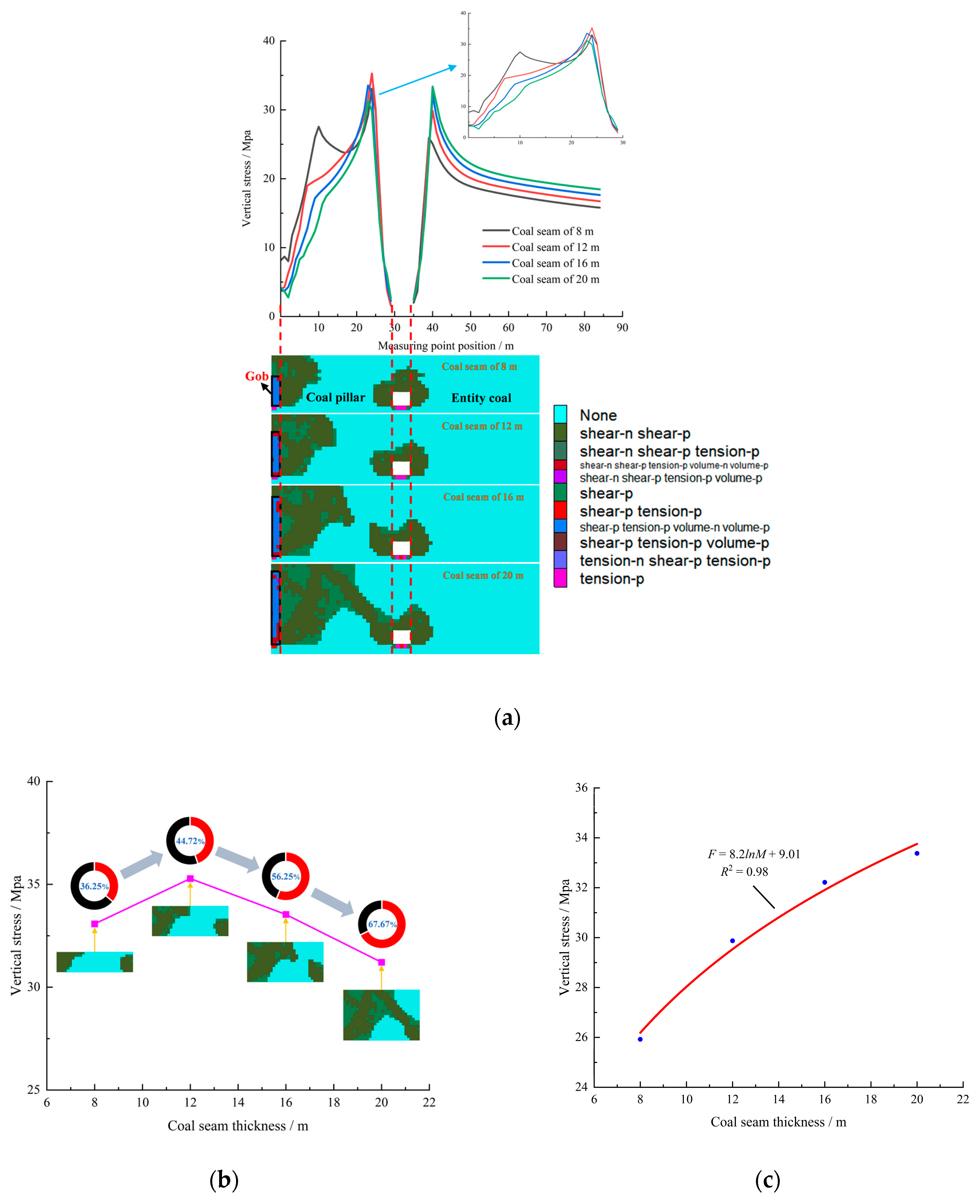

4.2.4. The Stress Distribution Influenced by Coal Seam Thickness

4.2.5. The Stress Distribution Influenced by Coal Pillar Width

5. Discussion

6. Conclusions

- (1)

- Through field investigation, it was shown that the dynamic phenomenon of mine pressure is obvious and there is a high static load in the 8204-2 island working face of an extra-thick coal seam with a hard roof. In the first widened coal pillar area, the coal burst phenomenon mainly occurred in the range of 8.2 m~33.5 m during roadway excavation. In the second widened coal pillar area, the phenomenon of coal burst was more frequent during roadway excavation. In different regions and ranges, there were noticeable variations in the occurrence of coal burst phenomena and strong coal bursts. The high static load on the island working face is influenced by the specific characteristics of each region.

- (2)

- The stress distribution of the island working face was determined to be primarily influenced by five elements through theoretical analysis and mechanical modeling: coal seam thickness, coal pillar width, gob length, buried depth, and working face length. The stress distribution characteristics of the entire island working face, the evolution of the coal pillar’s plastic zone, and the fitting equation for the entity coal’s peak stress were obtained by means of numerical simulation, which also analyzed the stress distribution state of the island working face under various conditions of the five influencing factors.

- (3)

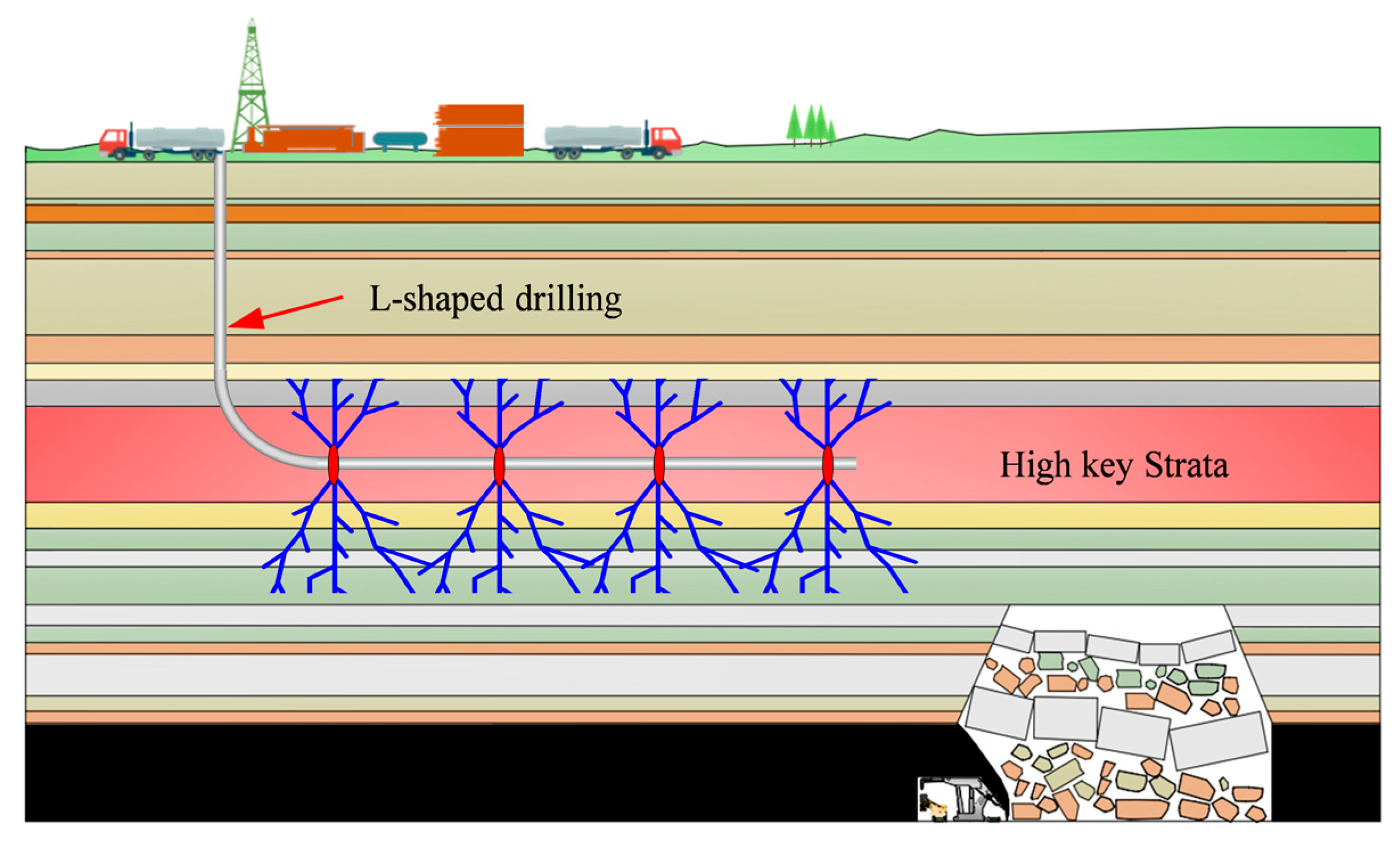

- Preventing and controlling rock bursts poses a significant challenge to coal mine safety. Currently, the primary approach to controlling rock bursts is through defensive measures for underground hazard relief. The primary cause of dynamic disasters is the concentration of stress in the coal body and the disruptive effects of a hard roof breaking. The technical means of fracturing the hard roof on the ground have a positive effect by changing the geological dynamic environment and can prevent and control the dynamic disaster from the source. Applying ground fracturing technology, the hard rock strata are weakened and modified, so that the concentrated stress and energy transfer are released to reduce the risk of rock bursts from the source, the impact mine is changed into no impact, and then the underground mining activities can be safely carried out.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cronshaw, I. World Energy Outlook 2014 Projections to 2040: Natural Gas and Coal Trade, and the Role of China. Aust. J. Agric. Resour. Econ. 2015, 59, 571–585. [Google Scholar] [CrossRef]

- Wang, G.F.; Xu, Y.X.; Ren, H.W. Intelligent and ecological coal mining as well as clean utilization technology in China: Review and prospects. Int. J. Min. Sci. Technol. 2019, 29, 161–169. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, X.F.; Fan, G.W.; Zhang, D.S.; Cui, J.B. Pillar size optimization design of isolated island panel gob-side entry driving in deep inclined coal seam—Case study of Pingmei No. 6 coal seam. J. Geophys. Eng. 2018, 15, 816–828. [Google Scholar] [CrossRef]

- Wen, Y.Y.; Cao, A.Y.; Guo, W.H.; Xue, C.C.; Lv, G.W.; Yan, X.L. Strata Movement and Mining-Induced Stress Identification for an isolated Working Face Surrounded by Two Gobs. Energies 2023, 16, 2839. [Google Scholar] [CrossRef]

- Lan, T.W.; Liu, Y.H.; Yuan, Y.N.; Liu, H.L.; Liu, H.G.; Zhang, S.F.; Wang, S.X. Mine pressure behavior law of isolated island working face under extremely close gob in shallow coal seam. Sci. Rep. 2023, 13, 20597. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.C.; Chen, P.K.; Wang, S. Study of Overlying Rock Structure and Intensive Pressure Control Technology of Island Longwall Panel in Extra-Thick Coal Seams. Processes 2023, 11, 3083. [Google Scholar] [CrossRef]

- Dou, L.M.; He, H. Study of OX-F-T spatial structure evolution of overlying strata in coal mines. Chin. J. Rock Mech. Eng. 2012, 31, 453–460. (In Chinese) [Google Scholar]

- Dou, L.M.; He, J.; Cao, A.Y.; Gong, S.Y.; Cai, W. Rock burst prevention methods based on theory of dynamic and static combined load induced in coal mine. J. China Coal Soc. 2015, 40, 1469–1476. (In Chinese) [Google Scholar]

- Zhu, S.T.; Jiang, F.X.; Liu, J.H.; Ma, Y.Z.; Meng, X.J.; Zhang, X.F.; Jiang, Y.W.; Qu, X.C.; Wang, B.Q. Types, occurrence mechanism and prevention of overall instability induced rock bursts in China coal mines. J. China Coal Soc. 2020, 45, 3667–3677. (In Chinese) [Google Scholar]

- Jiang, Y.D.; Pan, Y.S.; Jiang, F.X.; Dou, L.M.; Ju, Y. State of the art review on mechanism and prevention of coal bumps in China. J. China Coal Soc. 2014, 39, 209–213. (In Chinese) [Google Scholar]

- Jiang, Y.D.; Wang, H.W.; Xue, S.; Zhao, Y.X.; Zhu, J.; Pang, X.F. Assessment and mitigation of coal bump risk during extraction of an island longwall panel. Int. J. Coal Geol. 2015, 95, 20–33. (In Chinese) [Google Scholar] [CrossRef]

- Zhang, W.L.; Li, C.; Jin, J.X.; Qu, X.C.; Fan, S.; Xin, C.W. A new monitoring-while-drilling method of large diameter drilling in underground coal mine and their application. Measurement 2021, 173, 108840. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, Z.; Xu, G.; Gao, X.J.; Liu, Q.J.; Li, Z.J.; Liu, J.C. Lateral abutment pressure distribution and evolution in wide pillars under the first mining effect. Int. J. Min. Sci. Technol. 2023, 33, 309–322. [Google Scholar] [CrossRef]

- Li, C.; Xie, H.P.; Gao, M.Z.; Xie, J.; Deng, G.D.; He, Z.Q. Case study on the mining-induced stress evolution of an extra-thick coal seam under hard roof conditions. Energy Sci. Eng. 2020, 8, 309–322. [Google Scholar] [CrossRef]

- Lehtonen, A.; Cosgrove, J.W.; Hudson, J.A.; Johansson, E. An examination of in situ rock stress estimation using the Kaiser effect. Eng. Geol. 2012, 124, 24–37. [Google Scholar] [CrossRef]

- Bai, X.; Zhang, D.M.; Wang, H.; Li, S.J.; Rao, Z. A novel in situ stress measurement method based on acoustic emission Kaiser effect: A theoretical and experimental study. R. Soc. Open Sci. 2018, 5, 181263. [Google Scholar] [CrossRef] [PubMed]

- Li, X.L.; Wang, E.Y.; Li, Z.H.; Liu, Z.T.; Song, D.Z.; Qiu, L.M. Rock Burst Monitoring by Integrated Microseismic and Electromagnetic Radiation Methods. Rock Mech. Rock Eng. 2016, 49, 4393–4406. [Google Scholar] [CrossRef]

- Lou, Q.; Song, D.Z.; He, X.Q.; Li, Z.L.; Qiu, L.M.; Wei, M.H.; He, S.Q. Correlations between acoustic and electromagnetic emissions and stress drop induced by burst-prone coal and rock fracture. Saf. Sci. 2019, 115, 310–319. (In Chinese) [Google Scholar] [CrossRef]

- Jiang, B.Y.; Wang, L.G.; Lu, Y.L.; Wang, C.Q.; Ma, D. Combined early warning method for rockburst in a Deep Island, fully mechanized caving face. Arab. J. Geosci. 2016, 9, 743. [Google Scholar] [CrossRef]

- He, J.; Dou, L.M.; Gong, S.Y.; Li, J.; Ma, Z.Q. Rock burst assessment and prediction by dynamic and static stress analysis based on micro-seismic monitoring. Int. J. Rock Mech. Min. Sci. 2017, 93, 46–53. [Google Scholar] [CrossRef]

- Ma, K.; Wang, H.Y.; Liao, Z.Y.; Peng, Y.L.; Wang, K.K. Precursor of microseismic energy and stress evolution induced by rockburst in coal mining: A case study from Xiashijie, Shannxi, China. Geomech. Geophys. Geo-Energy Geo-Resour. 2022, 8, 134. [Google Scholar] [CrossRef]

- Ge, M.C. Efficient mine microseismic monitoring. Int. J. Coal Geol. 2005, 64, 44–56. [Google Scholar] [CrossRef]

- Shen, B.; King, A.; Guo, H. Displacement, stress and seismicity in roadway roofs during mining-induced failure. Int. J. Rock Mech. Min. Sci. 2008, 45, 672–688. [Google Scholar] [CrossRef]

- Yu, B.; Zhang, Z.Y.; Kuang, T.J.; Liu, J.R. Stress Changes and Deformation Monitoring of Longwall Coal Pillars Located in Weak Ground. Rock Mech. Rock Eng. 2016, 49, 3293–3305. [Google Scholar] [CrossRef]

- Jia, C.Y.; Wang, H.L.; Sun, X.Z.; Yu, X.B.; Luan, H.J. Study on rockburst prevention technology of isolated working face with thick-hard roof. Geomech. Eng. 2020, 20, 447–459. [Google Scholar]

- Zhu, G.A.; Dou, L.M.; Cao, A.Y.; Cai, W.; Wang, C.B.; Liu, Z.G.; Li, J. Assessment and analysis of strata movement with special reference to rock burst mechanism in island longwall panel. J. Cent. South Univ. 2017, 24, 2951–2960. [Google Scholar] [CrossRef]

- Liu, G.J.; Mu, Z.L.; Chen, J.J.; Yang, J.; Cao, J.L. Rock burst risk in an island longwall coal face by stress field. Geosci. J. 2018, 22, 609–622. [Google Scholar] [CrossRef]

- Xu, Q.Y.; Bai, J.B.; Yan, S.; Wang, R.; Wu, S.X. Numerical Study on Soft Coal Pillar Stability in an Island Longwall Panel. Adv. Civ. Eng. 2021, 2021, 8831778. [Google Scholar] [CrossRef]

- Liu, C.Y.; Huang, B.X.; Meng, X.J.; Yang, P.J.; Chen, L.G. Research on abutment pressure distribution law of overlength isolated fully-mechanized top coal caving face. Chinese J. Rock Mech. Eng. 2007, 26, 2761–2766. (In Chinese) [Google Scholar]

- Wang, H.W.; Jiang, Y.D.; Zhao, Y.X.; Liu, S.; Gao, R.J. Investigation on mechanism of energy explosion during extraction of island longwall panel. Chinese J. Rock Mech. Eng. 2013, 22, 2250–2257. (In Chinese) [Google Scholar]

- Dou, L.M.; Jiang, Y.D.; Cao, A.Y.; Liu, H.S.; Gong, S.Y.; Cai, W.; Zhu, G.A. Monitoring and pre-warning of rockburst hazard with technology of stress field and wave field in underground coalmines. J. Rock Mech. Eng. 2017, 36, 803–811. (In Chinese) [Google Scholar]

- Dou, L.M.; Bai, J.Z.; Li, X.W.; He, H. Study on prevention and control technology of rockburst disaster based on theory of dynamic and static combined load. Coal Sci. Technol. 2018, 46, 1–8. (In Chinese) [Google Scholar]

- Cao, A.Y.; Zhu, L.L.; Li, F.C.; Dou, L.M.; Zhao, Y.L.; Zhang, Z.L. Characteristics of T-type overburden structure and tremor activity in isolated face mining under thick-hard strata. J. China Coal Soc. 2014, 39, 328–335. (In Chinese) [Google Scholar]

- Min, T.; Bu, Q.W.; Fu, B.J.; Wang, Y. Mechanical Analysis of Mining Stress Transfer on isolated Island Face in Extra-Thick Fully Mechanized Top-Coal Caving Mining. Geofluids 2020, 2020, 8834321. [Google Scholar]

- Yu, B.; Zhu, W.B.; Gao, R.; Liu, J.R. Strata structure and its effect mechanism of large space stope for fully-mechanized sublevel caving mining of extremely thick coal seam. J. China Coal Soc. 2016, 41, 571–580. (In Chinese) [Google Scholar]

- Qian, M.G.; Shi, P.W.; Xu, J.L. Mining Pressure and Strata Control, 2nd ed.; China University of Mining and Technology Press: Xuzhou, China, 2010. [Google Scholar]

- Xu, Y.X.; Li, H.M.; Wang, K.L.; Yuan, R.F. Study on Lateral Support Pressure Distribution of Fully—Mechanized Coal Mining Face in Ultra Thick Seam. Coal Sci. Technol. 2014, 42, 26–28. (In Chinese) [Google Scholar]

- Guan, L.G.; Xu, D.; Chen, Z.; Liu, C.; Gao, M.S.; Zhang, D.X. Study on Optimization of Section Coal Pillar Size in Large Mining Height and High Strength Mining Face. Coal Technol. 2022, 41, 29–34. (In Chinese) [Google Scholar]

- He, W.R.; He, F.L.; Zhao, Y.Q. Field and simulation study of the rational coal pillar width in extra-thick coal seams. Energy Sci. Eng. 2020, 8, 627–646. [Google Scholar] [CrossRef]

- Yu, B.; Gao, R.; Xia, B.W.; Kuang, T.J. Ground fracturing technology and application of hard roof in large space. J. China Coal Soc. 2021, 46, 800–811. (In Chinese) [Google Scholar]

- Gao, R. The Mechanism of Ground Pressure Induced by the Breakage of Far-Field Hard Strata and the Control Technology of Ground Fracturing. Ph.D. Thesis, China University of Mining and Technology, Beijing, China, 2018. (In Chinese). [Google Scholar]

- Wang, S.W.; Zhi, B.Y.; Du, T.T.; Yang, G.Y.; Lu, C.; Xia, Y.X. Ground fracturing pre-control technology for potential mine seismic risk of thick and hard roof. Coal Sci. Technol. 2023, 51, 1–11. (In Chinese) [Google Scholar]

| Lithology | Elastic Modulus (GPa) | Poisson Ratio | Friction Angle (°) | Tensile Strength (MPa) | Cohesion (MPa) |

|---|---|---|---|---|---|

| Medium grained sandstone | 17.5 | 0.29 | 22 | 1.1 | 5.4 |

| Fine-grained sandstone | 28.5 | 0.23 | 25 | 5.9 | 6.2 |

| Siltstone | 19.3 | 0.27 | 23 | 2.4 | 6.1 |

| Sandy mudstone | 10.5 | 0.27 | 22 | 2.9 | 5.3 |

| Grit stone | 24.6 | 0.26 | 22 | 3.6 | 5.6 |

| Coal seam | 7.5 | 0.33 | 20 | 1.1 | 4 |

| Mudstone | 8 | 0.32 | 21 | 2.2 | 4.2 |

| Kaolin rock | 17 | 0.22 | 22 | 3.2 | 4.1 |

| Bulk Modulus (MPa) | Shear Modulus (MPa) | Density (kg/m3) | Tensile Strength (MPa) | Friction Angle (°) |

|---|---|---|---|---|

| 5.35 | 1.08 | 1100 | 0 | 28 |

| Scheme | Buried Depth H/m | Gob Length L/m | Working Face Length D/m | Coal Seam Thickness M/m | Coal Pillar Width B/m |

|---|---|---|---|---|---|

| 1 | 300/400/500/600 | 400 | 30 | 16 | 200 |

| 2 | 200 | 100/150/200/250 | 30 | 16 | 200 |

| 3 | 200 | 400 | 100/150/200/250 | 16 | 200 |

| 4 | 200 | 400 | 30 | 8/12/16/20 | 200 |

| 5 | 200 | 400 | 30 | 16 | 10/20/30/40 |

| Origin | Quadratic Sum | Df | Mean Square |

|---|---|---|---|

| Regression | 18,083.561 | 6 | 3013.927 |

| Residual | 14.653 | 10 | 1.465 |

| Uncorrected total | 18,098.214 | 16 | |

| Corrected total | 603.958 | 15 | |

| R2 = 1 − (residual sum of squares)/(corrected sum of squares) = 0.976 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dai, X.; Gao, R.; Gao, W.; Bai, D.; Huang, X. Exploring the Distribution Characteristics of High Static Load in the Island Working Face of Extra-Thick Coal Seams with Hard Roof: Addressing the Challenge of Rock Burst Risk. Appl. Sci. 2024, 14, 1961. https://doi.org/10.3390/app14051961

Dai X, Gao R, Gao W, Bai D, Huang X. Exploring the Distribution Characteristics of High Static Load in the Island Working Face of Extra-Thick Coal Seams with Hard Roof: Addressing the Challenge of Rock Burst Risk. Applied Sciences. 2024; 14(5):1961. https://doi.org/10.3390/app14051961

Chicago/Turabian StyleDai, Xianglin, Rui Gao, Weichen Gao, Dou Bai, and Xiao Huang. 2024. "Exploring the Distribution Characteristics of High Static Load in the Island Working Face of Extra-Thick Coal Seams with Hard Roof: Addressing the Challenge of Rock Burst Risk" Applied Sciences 14, no. 5: 1961. https://doi.org/10.3390/app14051961

APA StyleDai, X., Gao, R., Gao, W., Bai, D., & Huang, X. (2024). Exploring the Distribution Characteristics of High Static Load in the Island Working Face of Extra-Thick Coal Seams with Hard Roof: Addressing the Challenge of Rock Burst Risk. Applied Sciences, 14(5), 1961. https://doi.org/10.3390/app14051961