Exchange Flows in Inclined Pipes with Different Viscosity Ratios

Abstract

1. Introduction

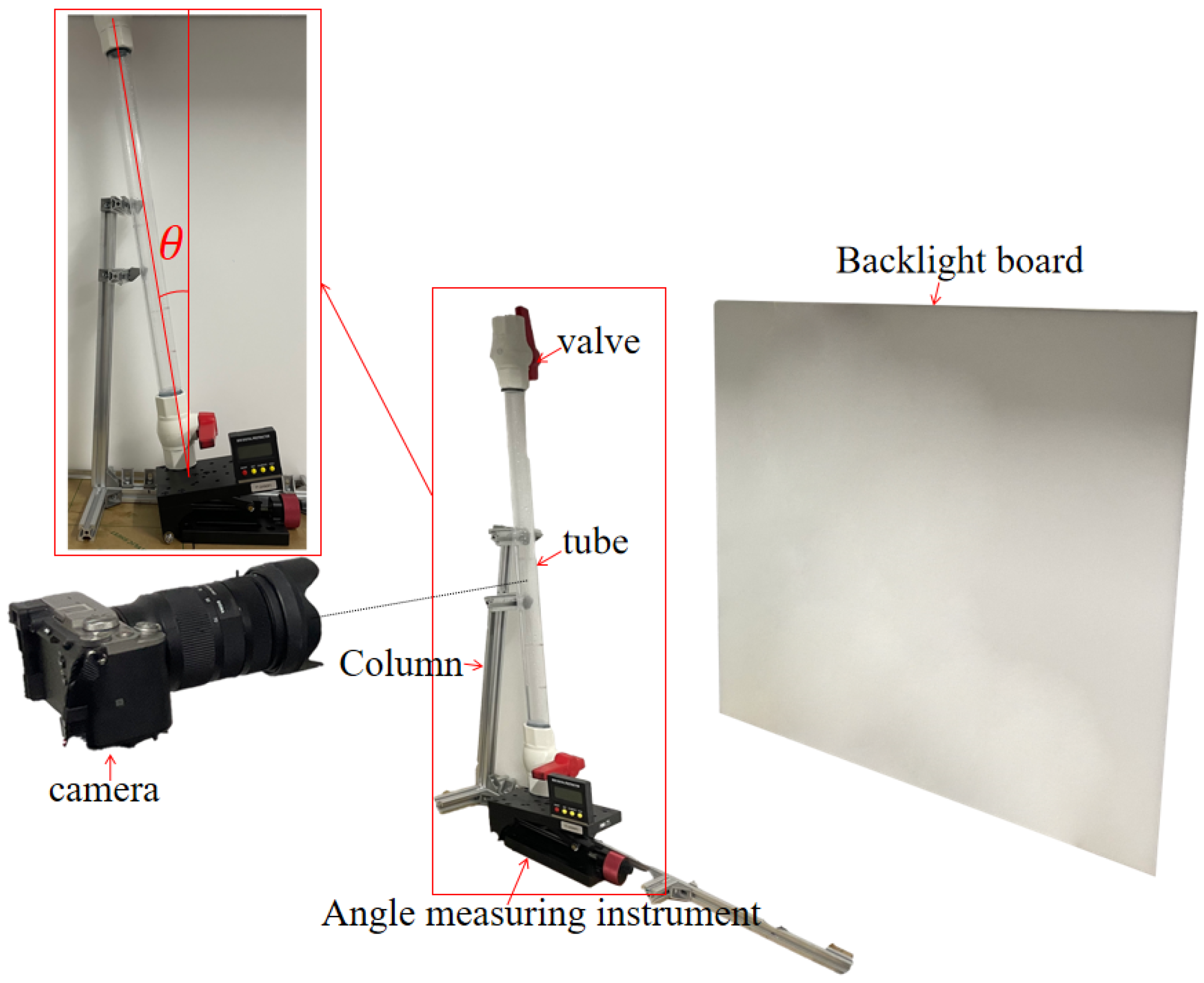

2. Materials and Methods

2.1. Research Program

2.2. Range of Experimental Parameters

3. Results and Discussion

3.1. Exchange Flow Experiments in Pipes

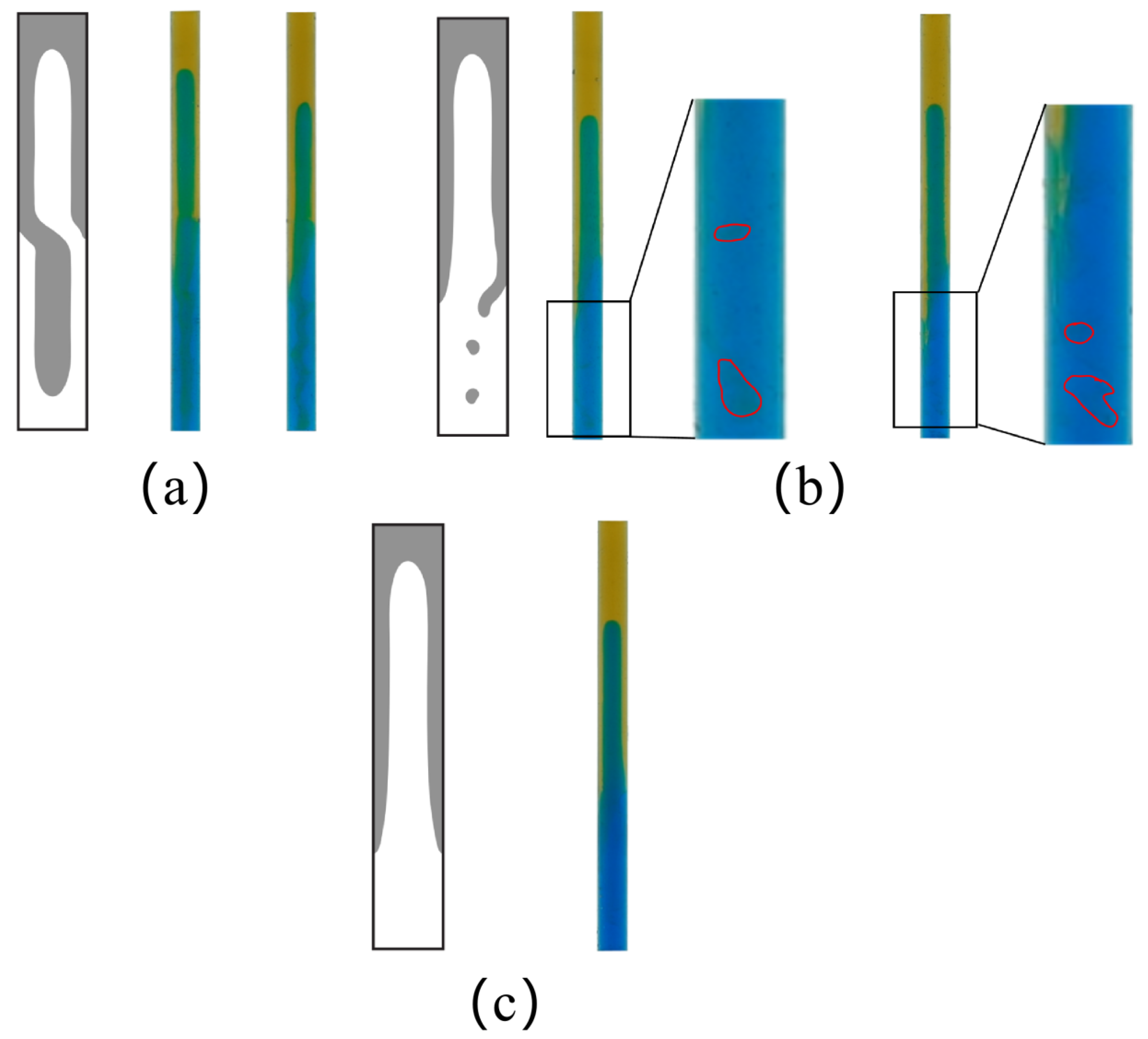

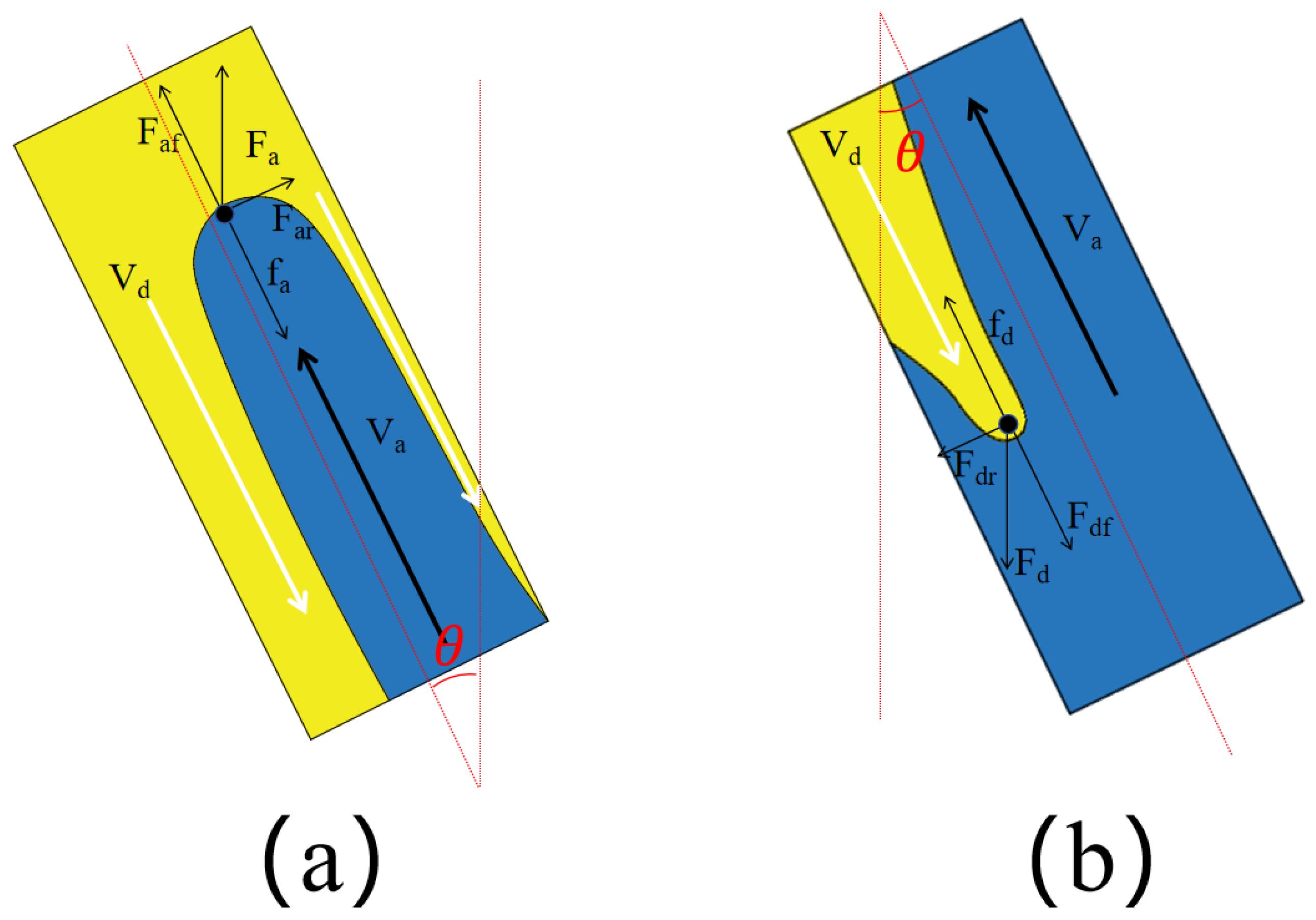

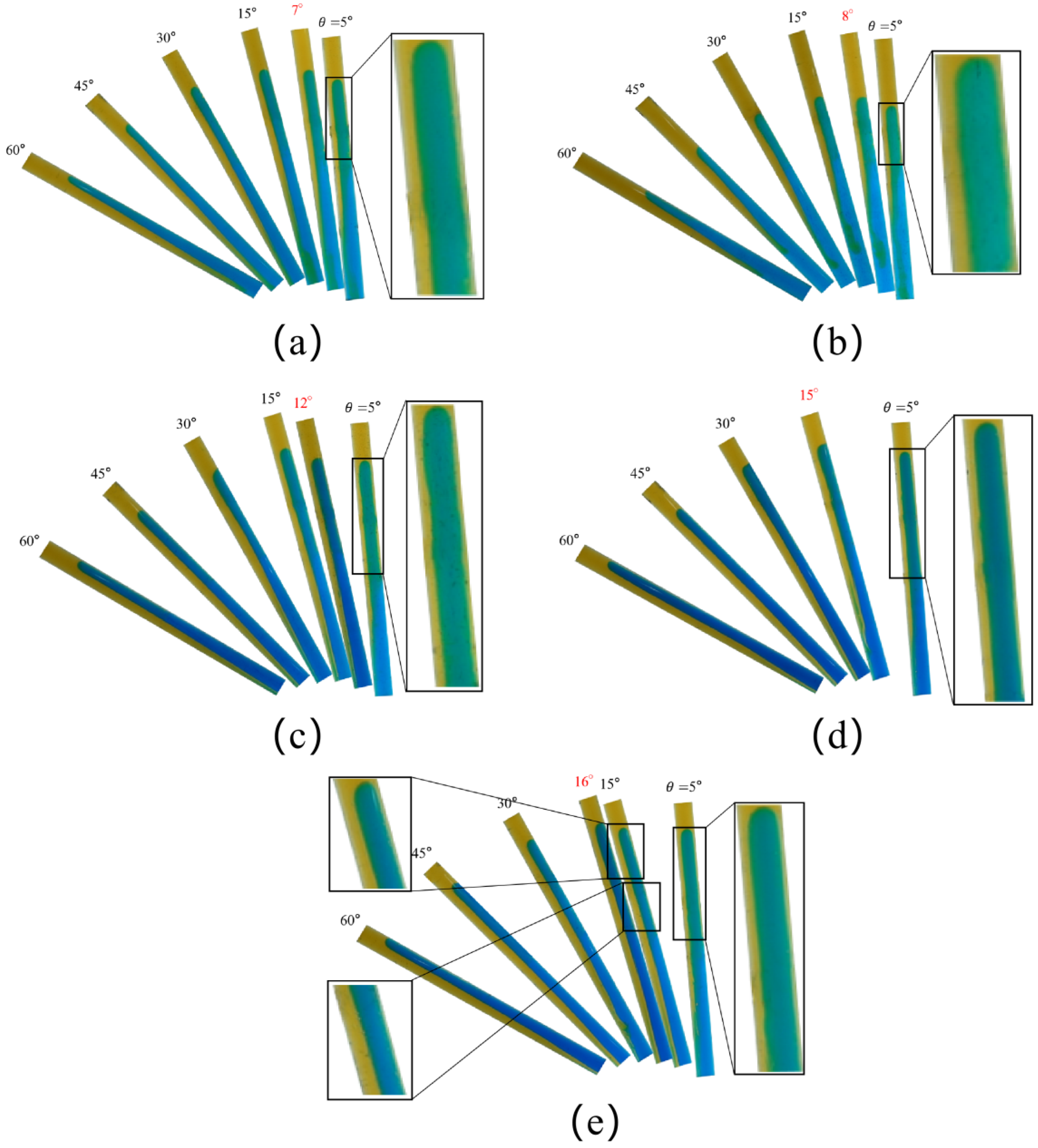

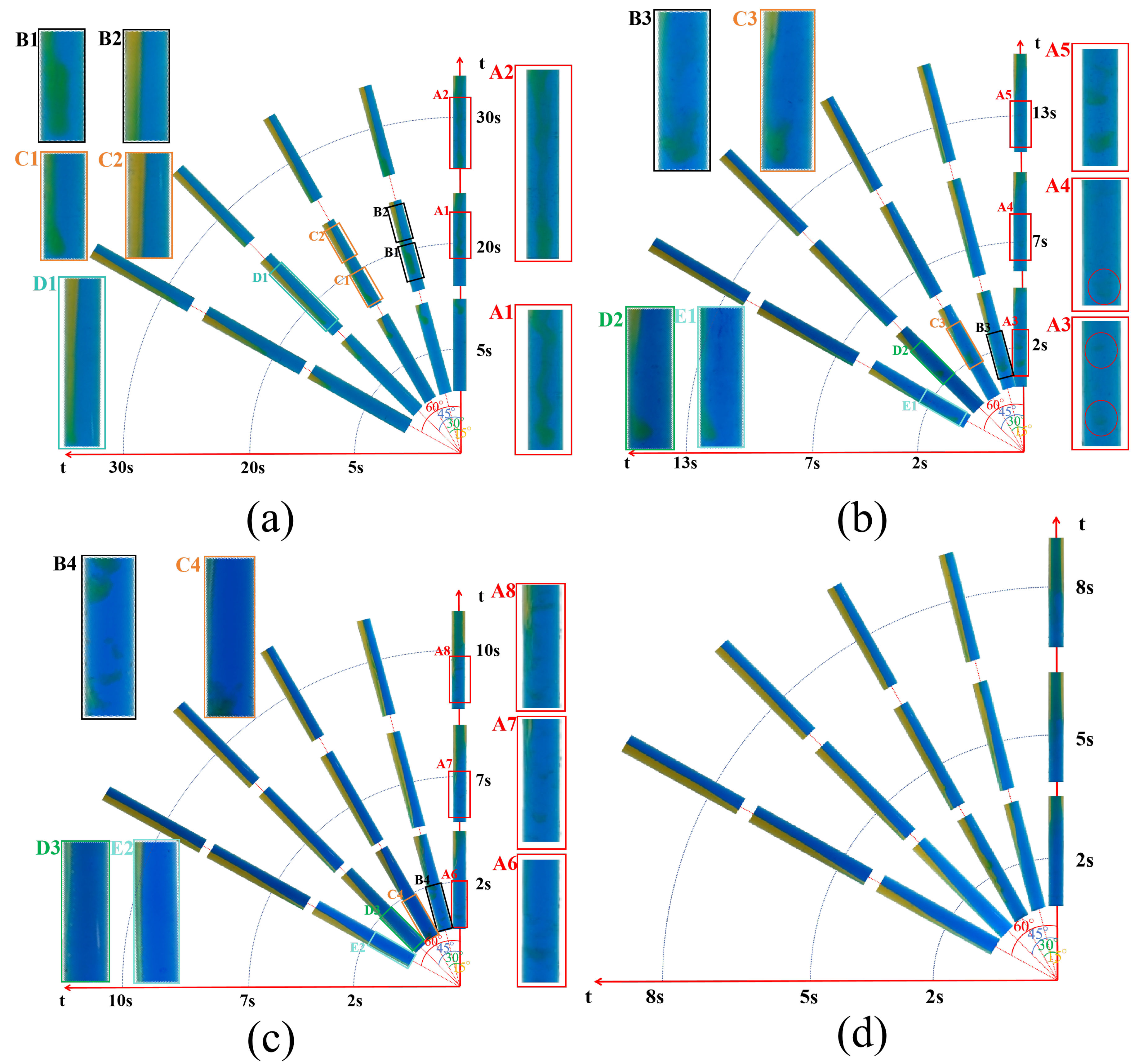

3.1.1. Changes in the Flow Regime of Light Fluids

3.1.2. Changes in the Flow Regime of Aqueous Maltose Solution (Heavy Fluids)

3.2. Velocity Changes

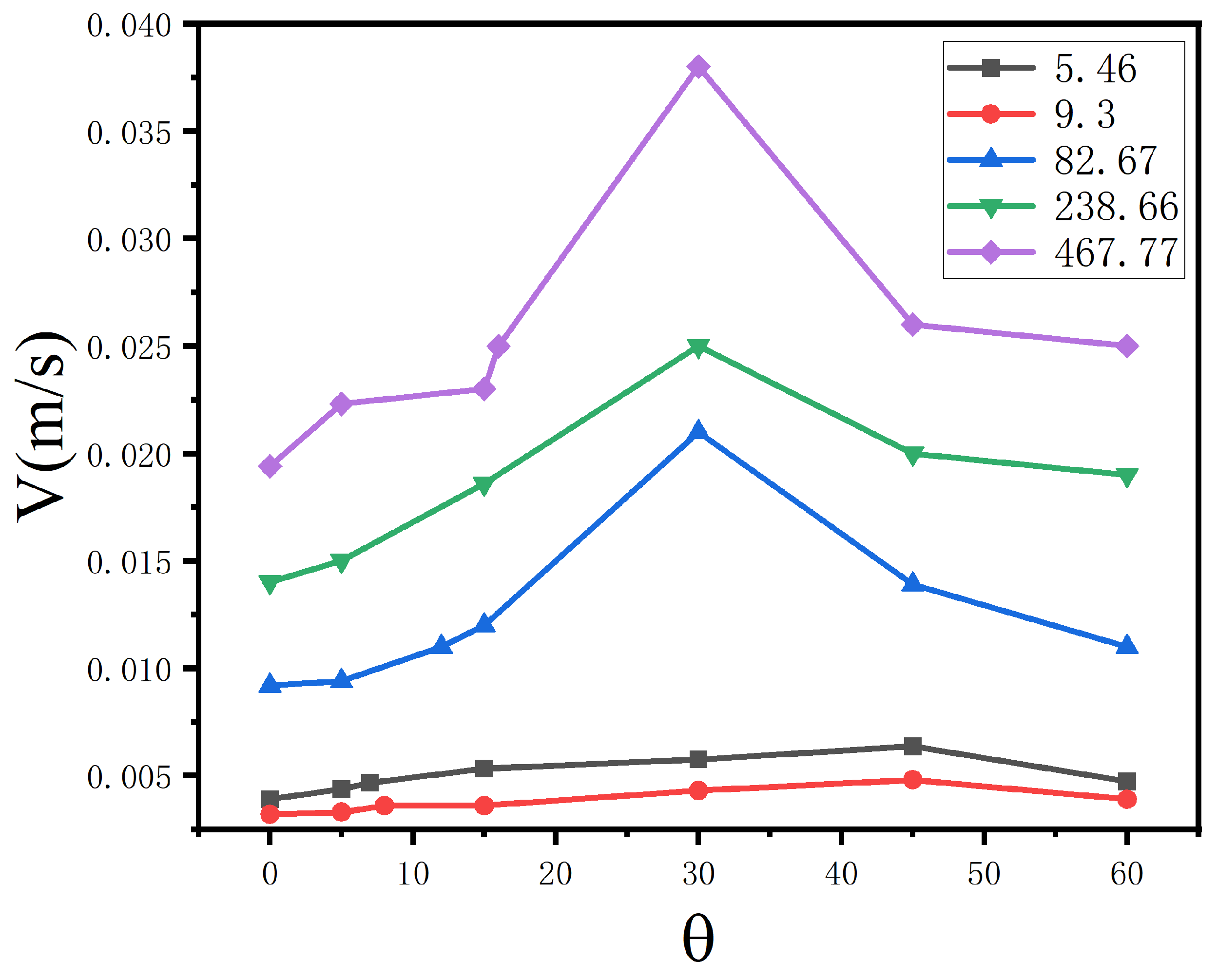

3.2.1. Light Fluid Velocity Changes

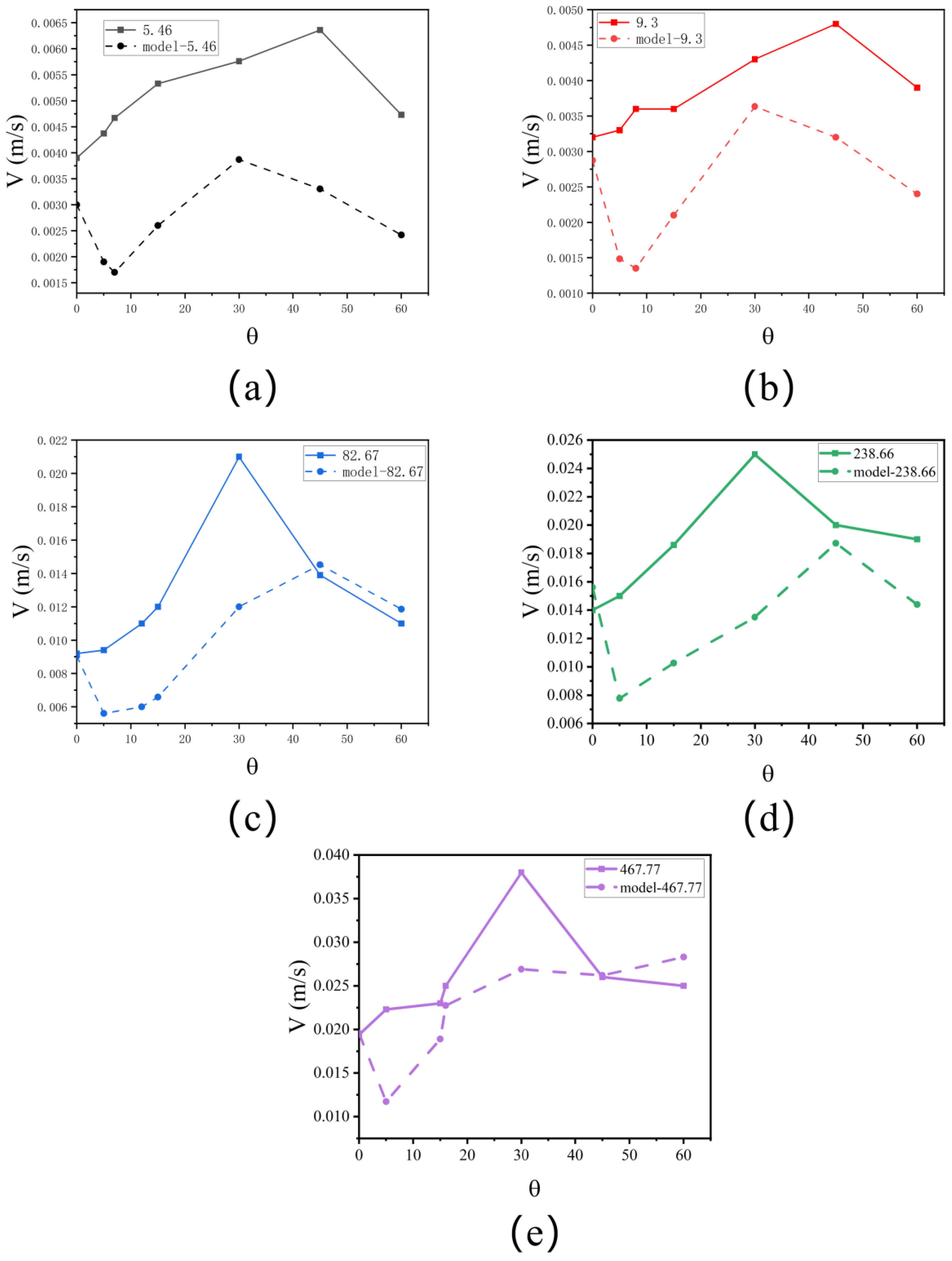

3.2.2. Comparison of Experimental and Theoretical Model Velocities for Light Fluids

- (1)

- First, of all, we found that in the velocity results of the model, as the pipe is tilted, the velocity becomes smaller and then larger, whereas this did not happen in the velocities measured in our experiments. This is because after the pipe is tilted, as mentioned above, the becomes larger and then smaller, whereas, in our model, where we kept the boundary conditions unchanged, the velocity becomes smaller as the and the become larger so that there is a decrease in the velocity in the model. However, in the experiment, after the pipe was tilted, the light fluid did not move in the centre of the pipe; at this time, the shear force (viscous force) was not the same on both sides of the light fluid. When the light fluid moves against the wall, meaning only one side is subjected to shear force, and the closer it is to the wall, the smaller the subjection to resistance. This leads to the velocity becoming larger first when the pipe is tilted in the experiment. This results in inconsistencies regarding the results predicted by the model.

- (2)

- We also find that the model predicted velocities are generally smaller than the experimentally measured velocities. This is because a portion of the shear force exerted on the light fluid in the experiment acts on the change in direction of the light fluid flow. In that case, the role of inertial forces on the change in velocity in the experiment will be large as a percentage. This is not taken into account in our model, so the experimental velocity is greater than the modelled velocity. However, from Figure 8c,e, we observe that the model velocity is greater than the experimentally measured velocity at = and = for both . In Figure 8e, we observe a tendency for the velocity to become larger at = , which is attributed to the smaller value of the measured due to the interfacial instability.

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Stevenson, D.S.; Blake, S. Modelling the dynamics and thermodynamics of volcanic degassing. Bull. Volcanol. 1998, 60, 307–317. [Google Scholar] [CrossRef]

- Dalziel, S.B. Maximal exchange in channels with nonrectangular cross sections. J. Phys. Oceanogr. 1992, 22, 1188–1206. [Google Scholar] [CrossRef][Green Version]

- Jaluria, Y.; Lee, S.K.; Mercier, G.; Tan, Q. Transport processes across a horizontal vent due to density and pressure differences. Exp. Therm. Fluid Sci. 1998, 16, 260–273. [Google Scholar] [CrossRef]

- Joseph, D.D.; Bai, R.; Chen, K.; Renardy, Y.Y. Core-annular flows. Annu. Rev. Fluid Mech. 1997, 29, 65–90. [Google Scholar] [CrossRef]

- Debacq, M.; Hulin, J.P.; Salin, D.; Perrin, B.; Hinch, E.J. Buoyant mixing of miscible fluids of varying viscosities in vertical tubes. Phys. Fluids 2003, 15, 3846–3855. [Google Scholar] [CrossRef]

- d’Olce, M.; Martin, J.; Rakotomalala, N.; Salin, D.; Talon, L. Pearl and mushroom instability patterns in two miscible fluids’ core annular flows. Phys. Fluids 2008, 20, 024104. [Google Scholar] [CrossRef]

- Martin, J.; Rakotomalala, N.; Salin, D.; Talon, L. Convective/absolute instability in miscible core-annular flow. Part 1: Experiments. J. Fluid Mech. 2009, 618, 305–322. [Google Scholar]

- Huppert, H.E.; Hallworth, M.A. Bi-directional flows in constrained systems. J. Fluid Mech. 2007, 578, 95–112. [Google Scholar] [CrossRef]

- Beckett, F.; Mader, H.; Phillips, J.; Rust, A.; Witham, F. An experimental study of low-Reynolds-number exchange flow of two Newtonian fluids in a vertical pipe. J. Fluid Mech. 2011, 682, 652–670. [Google Scholar] [CrossRef]

- Kerswell, R. Exchange flow of two immiscible fluids and the principle of maximum flux. J. Fluid Mech. 2011, 682, 132–159. [Google Scholar] [CrossRef][Green Version]

- Suckale, J.; Qin, Z.; Picchi, D.; Keller, T.; Battiato, I. Bistability of buoyancy-driven exchange flows in vertical tubes. J. Fluid Mech. 2018, 850, 525–550. [Google Scholar] [CrossRef]

- Picchi, D.; Suckale, J.; Battiato, I. Taylor drop in a closed vertical pipe. J. Fluid Mech. 2020, 902, A19. [Google Scholar] [CrossRef]

- Joseph, D.D.; Renardy, M.; Renardy, Y. Instability of the flow of two immiscible liquids with different viscosities in a pipe. J. Fluid Mech. 1984, 141, 309–317. [Google Scholar] [CrossRef]

- Meiburg, E.; Vanaparthy, S.H.; Payr, M.D.; Wilhelm, D. Density-Driven Instabilities of Variable-Viscosity Miscible Fluids in a Capillary Tube. Ann. N. Y. Acad. Sci. 2004, 1027, 383–402. [Google Scholar] [CrossRef] [PubMed]

- Everage, A., Jr. Theory of stratified bicomponent flow of polymer melts. I. Equilibrium Newtonian tube flow. Trans. Soc. Rheol. 1973, 17, 629–646. [Google Scholar] [CrossRef]

- Bendiksen, K.H. On the motion of long bubbles in vertical tubes. Int. J. Multiph. Flow 1985, 11, 797–812. [Google Scholar] [CrossRef]

- Zukoski, E. Influence of viscosity, surface tension, and inclination angle on motion of long bubbles in closed tubes. J. Fluid Mech. 1966, 25, 821–837. [Google Scholar] [CrossRef]

- Weber, M.E.; Alarie, A.; Ryan, M.E. Velocities of extended bubbles in inclined tubes. Chem. Eng. Sci. 1986, 41, 2235–2240. [Google Scholar] [CrossRef]

- Séon, T.; Hulin, J.P.; Salin, D.; Perrin, B.; Hinch, E. Buoyancy driven miscible front dynamics in tilted tubes. Phys. Fluids 2005, 17, 031702. [Google Scholar] [CrossRef]

- Alba, K.; Taghavi, S.; Frigaard, I. Miscible density-unstable displacement flows in inclined tube. Phys. Fluids 2013, 25, 067101. [Google Scholar] [CrossRef]

- Lefauve, A.; Linden, P. Buoyancy-driven exchange flows in inclined ducts. J. Fluid Mech. 2020, 893, A2. [Google Scholar] [CrossRef]

| Material | (kg/m3) | (mpa.s) |

|---|---|---|

| Syrup | 1323 | 818.6 |

| 80 wt% glycerol-syrup | 1270 | 150.1 |

| Dil.syrup | 1285 | 88 |

| Dil.syrup | 1224.3 | 9.9 |

| Dil.syrup | 1174.1 | 3.43 |

| v.dil.syrup | 1100 | 1.75 |

| Notation | Hidden Meaning | Unit |

|---|---|---|

| Viscosity of rising fluid (light fluid). | mpa.s | |

| Viscosity of downward flowing fluids (heavy fluids). | mpa.s | |

| Density of light fluids. | kg/m3 | |

| Density of heavy fluids. | kg/m3 | |

| Viscosity ratio (ratio of high viscosity to low viscosity). | ||

| Density difference (high density minus low density). | kg/m3 | |

| The ratio of the width of the light fluid to the diameter of the pipe. | ||

| Ratio of minimum width of heavy fluid to pipe diameter. | ||

| Inertial force on a light fluid. | ||

| Inertial force on heavy fluid. | ||

| Axial inertia forces on light fluids. | ||

| Radial force on light fluid. | ||

| Axial inertia force on heavy fluid. | ||

| Radial force on heavy fluid. | ||

| Viscous resistance to light fluids. | ||

| Viscous resistance to heavy fluids. | ||

| u | Experimentally measured rate of ascent of a light fluid. | m/s |

| V | Rising velocity of light fluid calculated by theoretical model. | m/s |

| Q | Fluid flow. | m3/s |

| (kg/m3) | (°) | u (m/s) | V (m/s) | Q (m3/s) | |||

|---|---|---|---|---|---|---|---|

| 5.43 | 53 | 0 | 0.59 | 0.0039 | 0.003 | 0.0052 | |

| 5 | 0.66 | 0.00437 | 0.0019 | 0.0072 | |||

| 7 | 0.67 | 0.00467 | 0.0017 | 0.0080 | |||

| 15 | 0.61 | 0.00533 | 0.0026 | 0.0075 | |||

| 30 | 0.49 | 0.00576 | 0.00387 | 0.0053 | |||

| 45 | 0.47 | 0.00636 | 0.0033 | 0.0053 | |||

| 60 | 0.45 | 0.00473 | 0.00242 | 0.0036 | |||

| 9.3 | 38 | 0 | 0.58 | 0.0032 | 0.00287 | 0.0041 | |

| 5 | 0.67 | 0.0033 | 0.00148 | 0.0056 | |||

| 8 | 0.68 | 0.0036 | 0.00135 | 0.0063 | |||

| 15 | 0.62 | 0.0036 | 0.0021 | 0.0053 | |||

| 30 | 0.5 | 0.0043 | 0.00363 | 0.0041 | |||

| 45 | 0.48 | 0.0048 | 0.0032 | 0.0042 | |||

| 60 | 0.45 | 0.0039 | 0.0024 | 0.003 | |||

| 82.67 | 98.7 | 0 | 0.61 | 0 | 0.0092 | 0.00903 | 0.013 |

| 5 | 0.66 | 0 | 0.0094 | 0.0056 | 0.016 | ||

| 12 | 0.65 | 0 | 0.011 | 0.006 | 0.018 | ||

| 15 | 0.64 | 0 | 0.012 | 0.00658 | 0.019 | ||

| 30 | 0.56 | 0 | 0.021 | 0.012 | 0.025 | ||

| 45 | 0.51 | 0 | 0.0139 | 0.01452 | 0.014 | ||

| 60 | 0.49 | 0 | 0.011 | 0.01186 | 0.01 | ||

| 238.66 | 148.9 | 0 | 0.6 | 0 | 0.014 | 0.0156 | 0.019 |

| 5 | 0.67 | 0 | 0.015 | 0.00777 | 0.026 | ||

| 15 | 0.64 | 0 | 0.0186 | 0.01026 | 0.029 | ||

| 30 | 0.57 | 0 | 0.025 | 0.0135 | 0.034 | ||

| 45 | 0.54 | 0.005 | 0.02 | 0.01872 | 0.022 | ||

| 60 | 0.53 | 0.14 | 0.019 | 0.0144 | 0.020 | ||

| 467.77 | 223 | 0 | 0.62 | 0.0194 | 0.01956 | 0.028 | |

| 5 | 0.67 | 0.0223 | 0.01172 | 0.038 | |||

| 15 | 0.62 | 0.023 | 0.01889 | 0.034 | |||

| 16 | 0.6 | 0.025 | 0.02274 | 0.034 | |||

| 30 | 0.575 | 0.038 | 0.0269 | 0.047 | |||

| 45 | 0.55 | 0.026 | 0.0262 | 0.03 | |||

| 60 | 0.5 | 0.025 | 0.02829 | 0.024 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, Z.; Huang, W.; Ning, Z.; Hu, K. Exchange Flows in Inclined Pipes with Different Viscosity Ratios. Appl. Sci. 2024, 14, 1573. https://doi.org/10.3390/app14041573

Qin Z, Huang W, Ning Z, Hu K. Exchange Flows in Inclined Pipes with Different Viscosity Ratios. Applied Sciences. 2024; 14(4):1573. https://doi.org/10.3390/app14041573

Chicago/Turabian StyleQin, Zhipeng, Wei Huang, Zhipeng Ning, and Kang Hu. 2024. "Exchange Flows in Inclined Pipes with Different Viscosity Ratios" Applied Sciences 14, no. 4: 1573. https://doi.org/10.3390/app14041573

APA StyleQin, Z., Huang, W., Ning, Z., & Hu, K. (2024). Exchange Flows in Inclined Pipes with Different Viscosity Ratios. Applied Sciences, 14(4), 1573. https://doi.org/10.3390/app14041573