A Novel Approach to the Production of Printed Patch Antennas

Abstract

1. Introduction

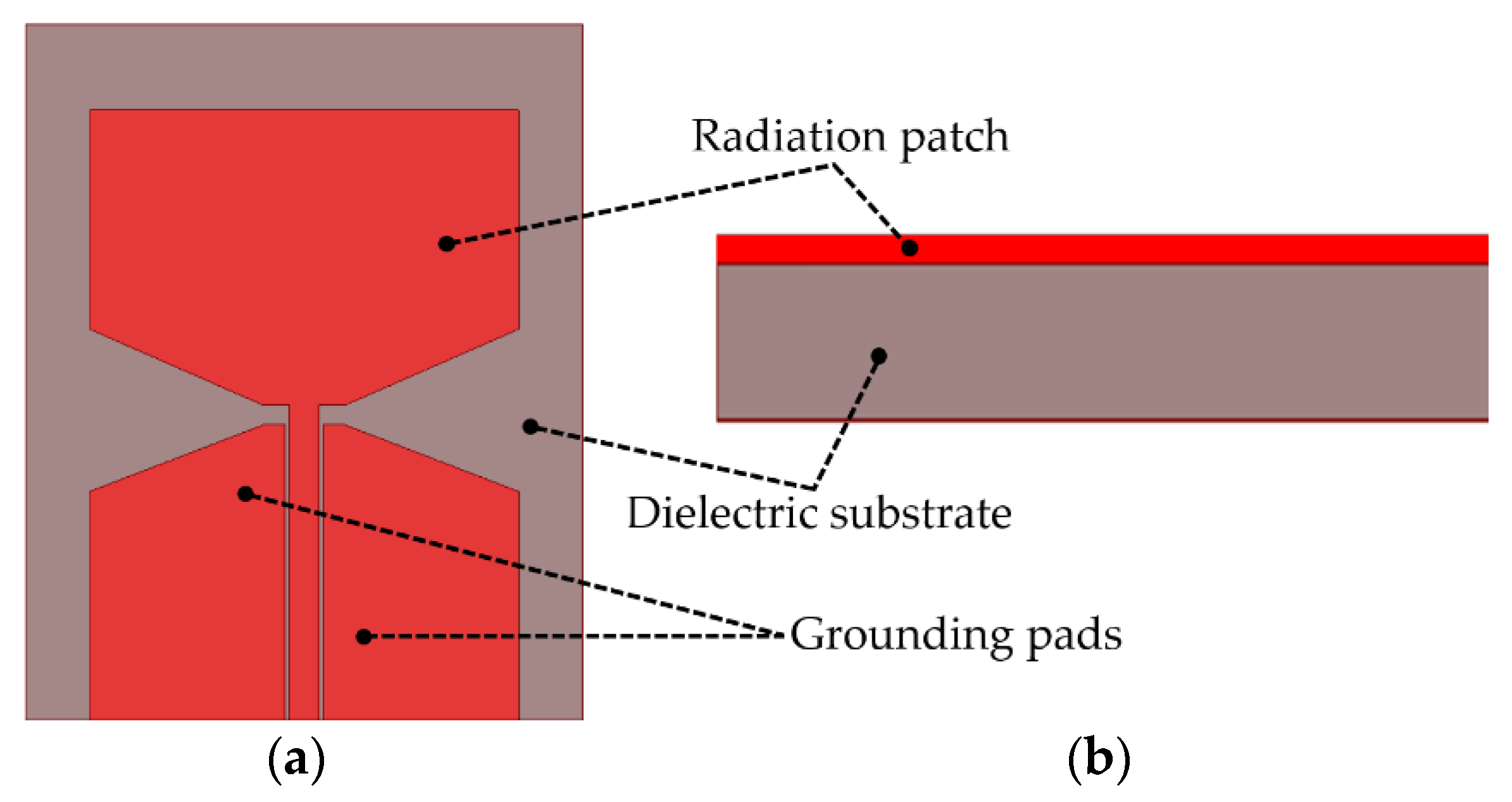

2. Design of the Printed Patch Antenna

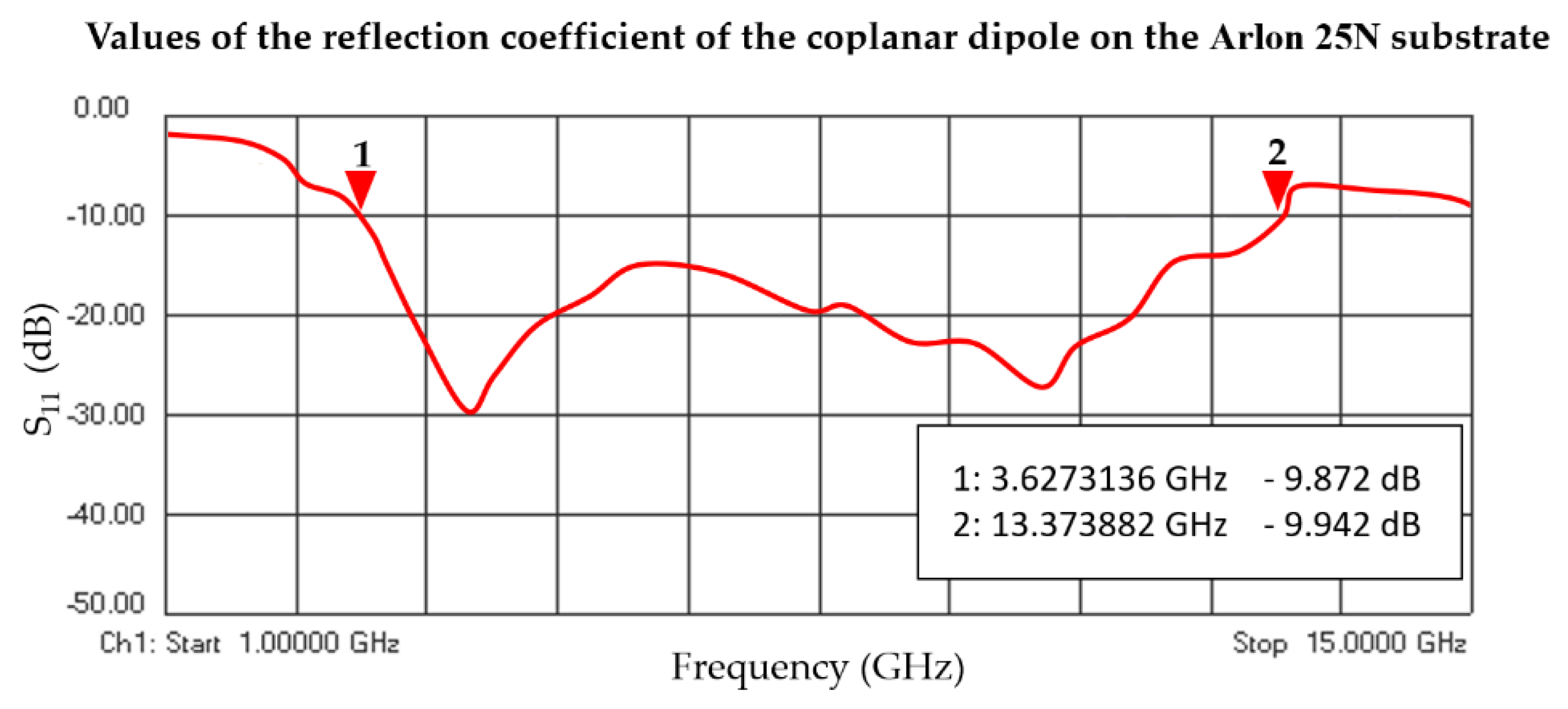

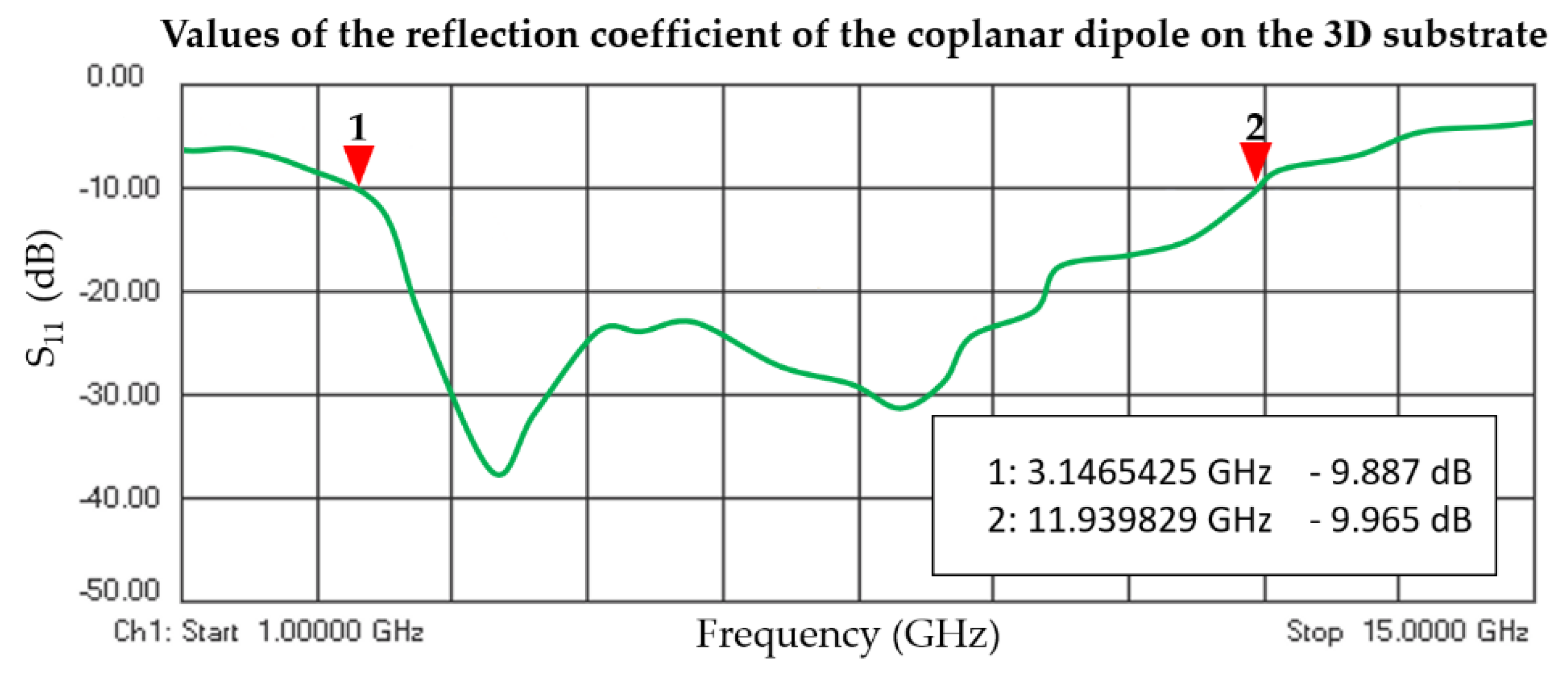

2.1. Substrate Properties of Patch Antennas

2.2. Methods of Feeding Patch Antennas

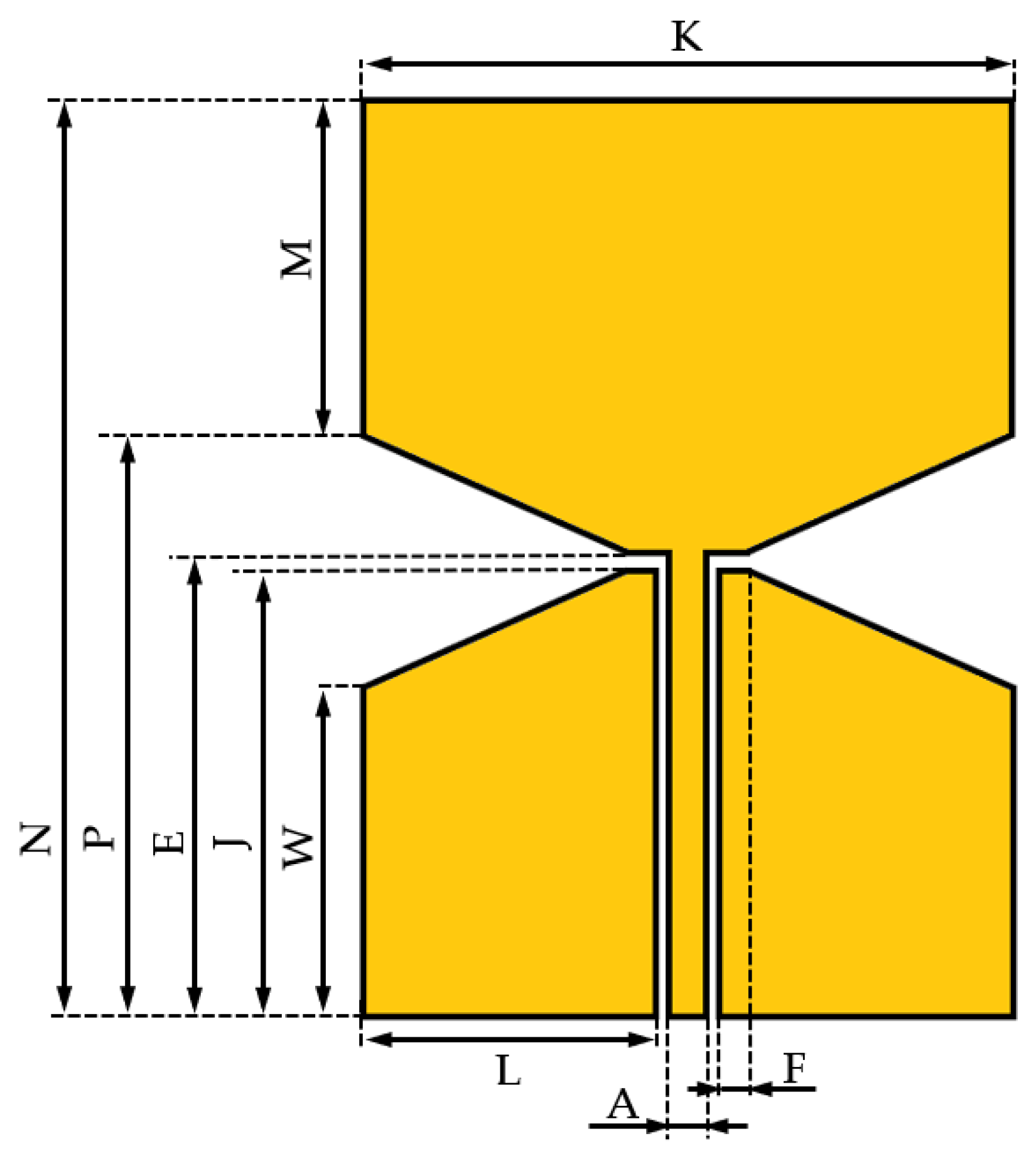

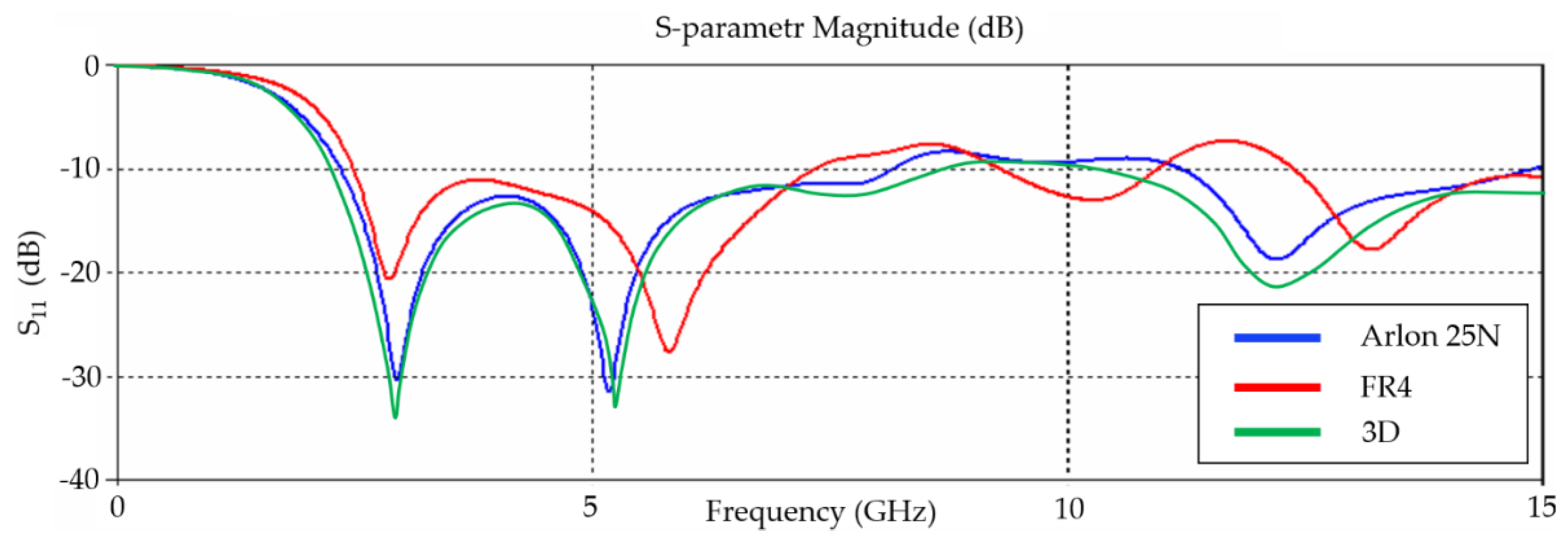

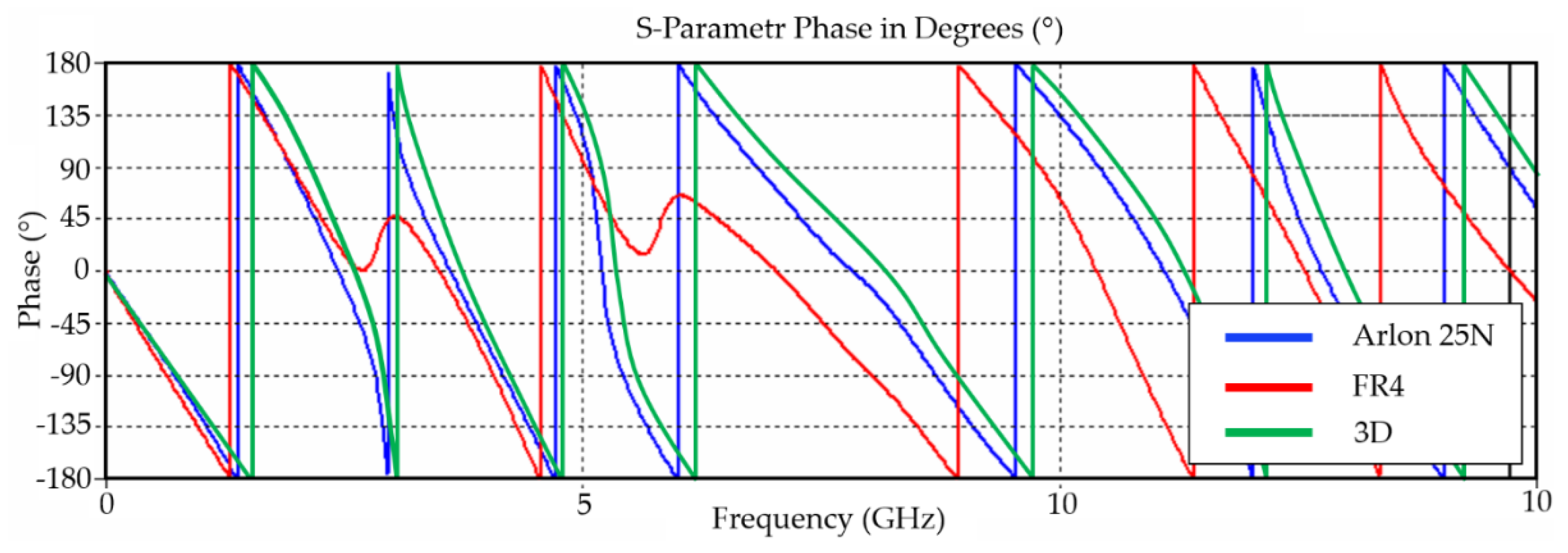

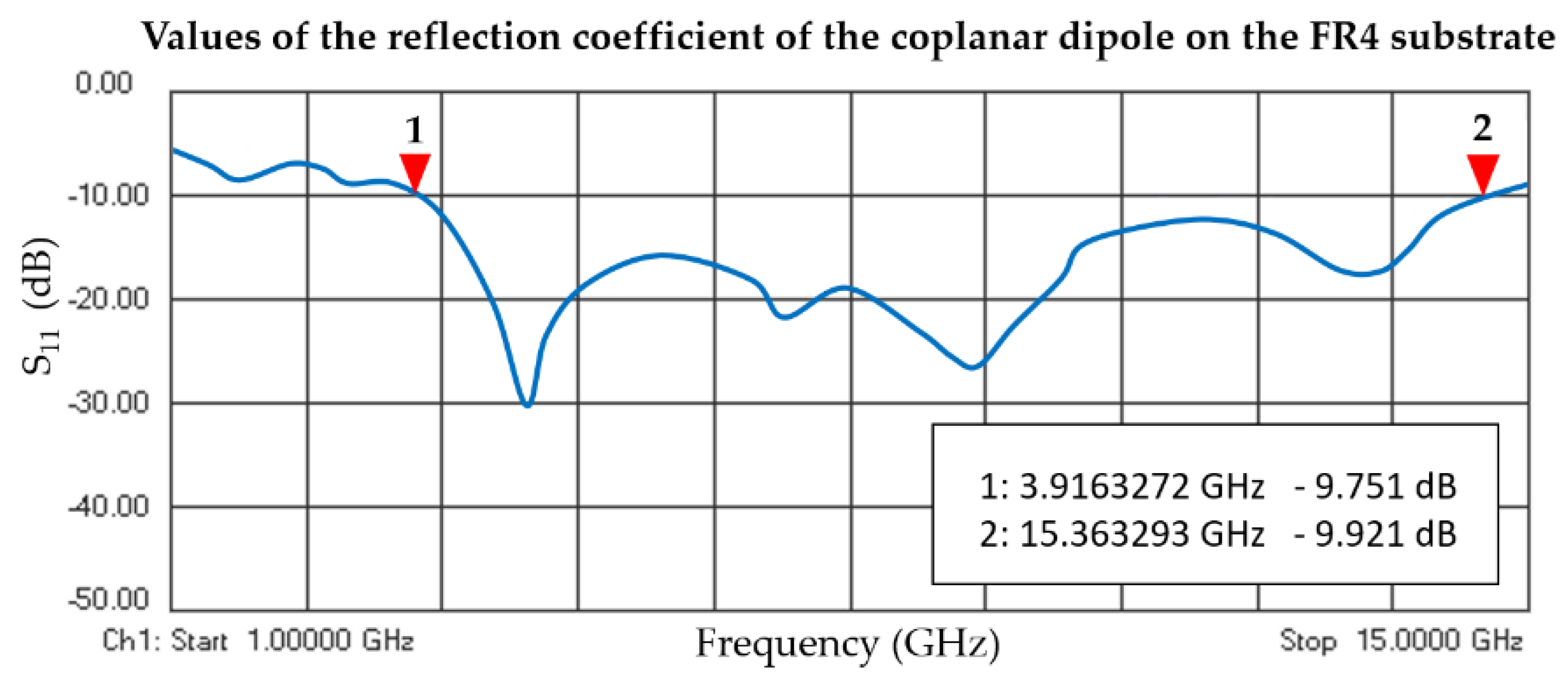

2.3. Design and Analysis of Coplanar Dipole

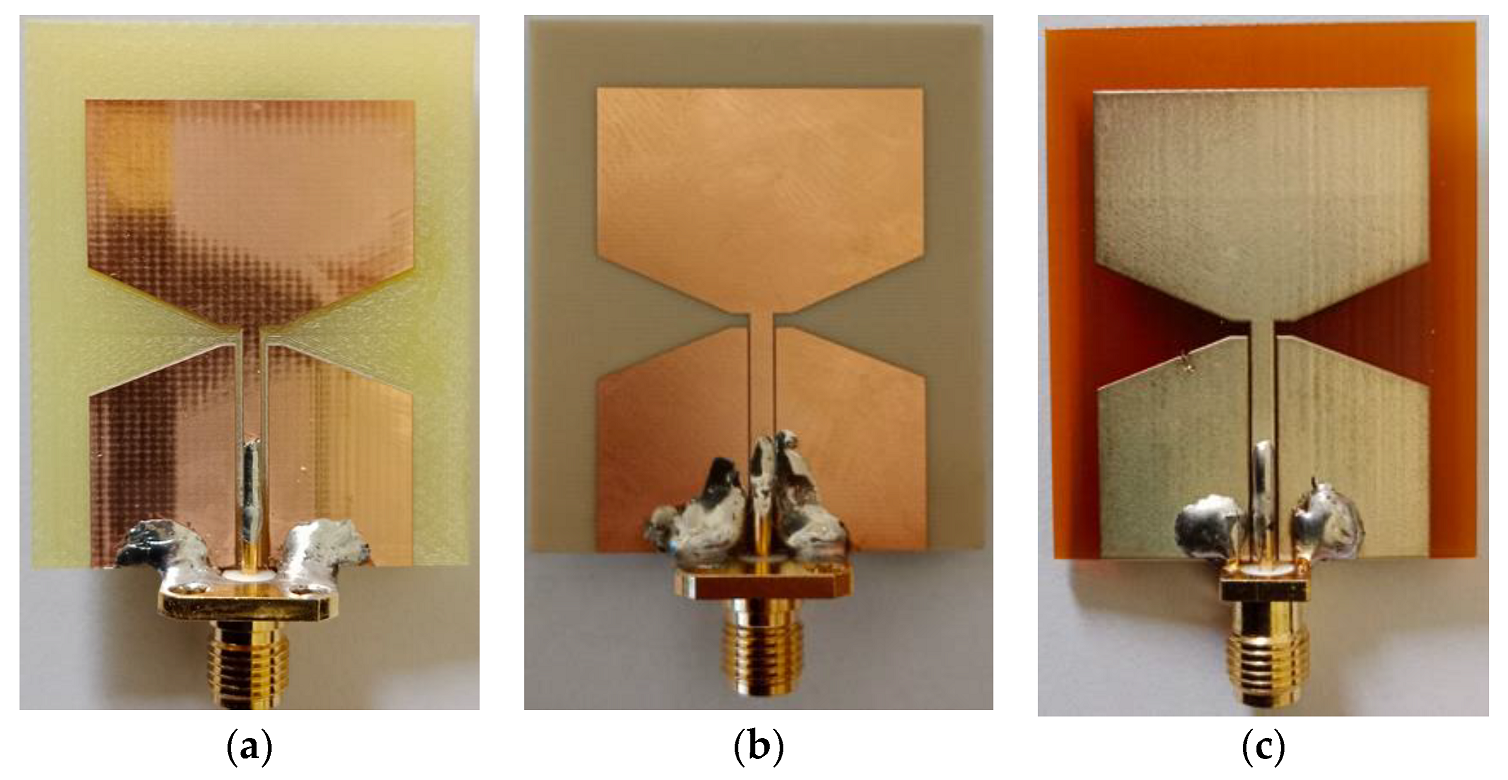

3. Coplanar Dipole Production Technology

3.1. Description of 3D LDM Printing Technology

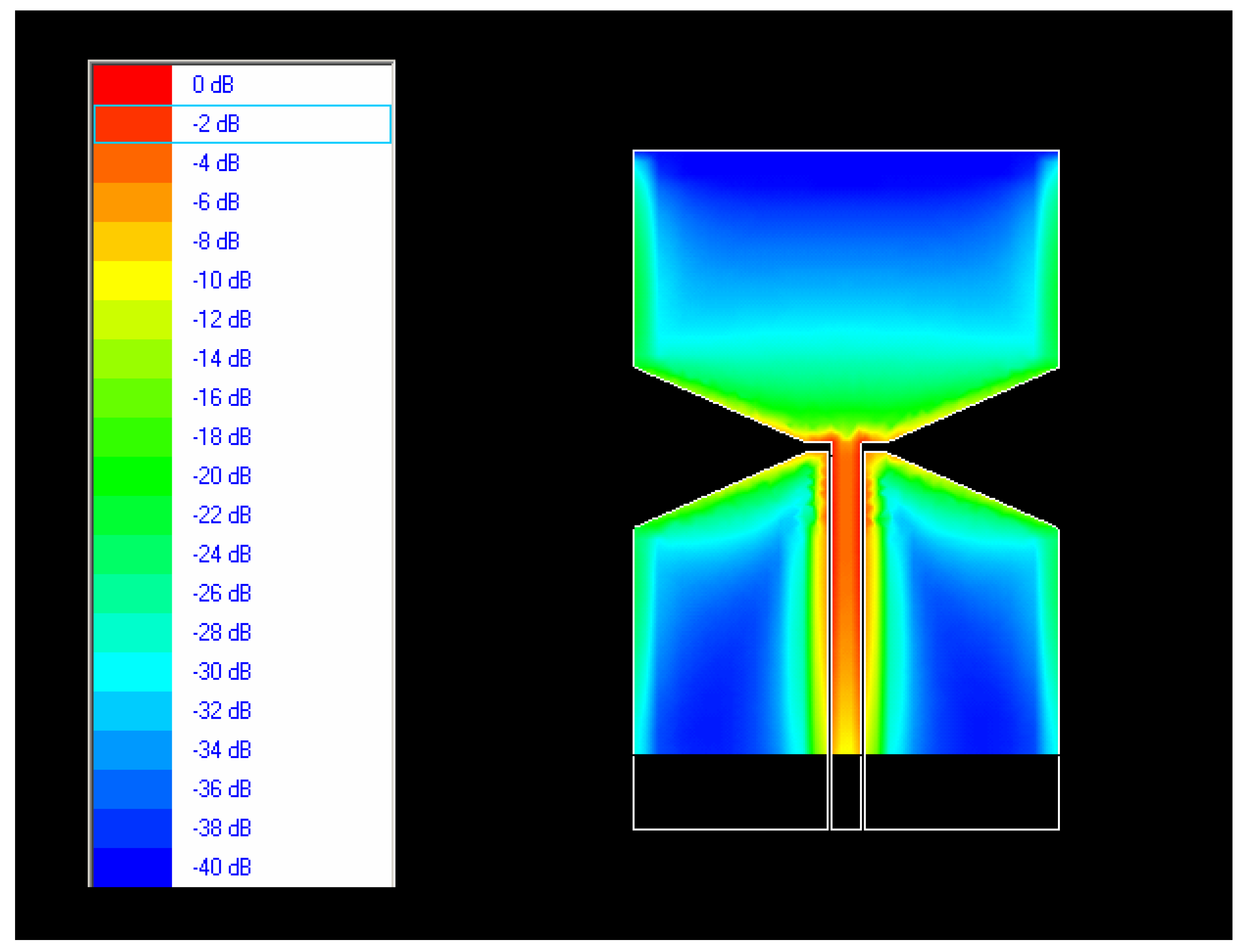

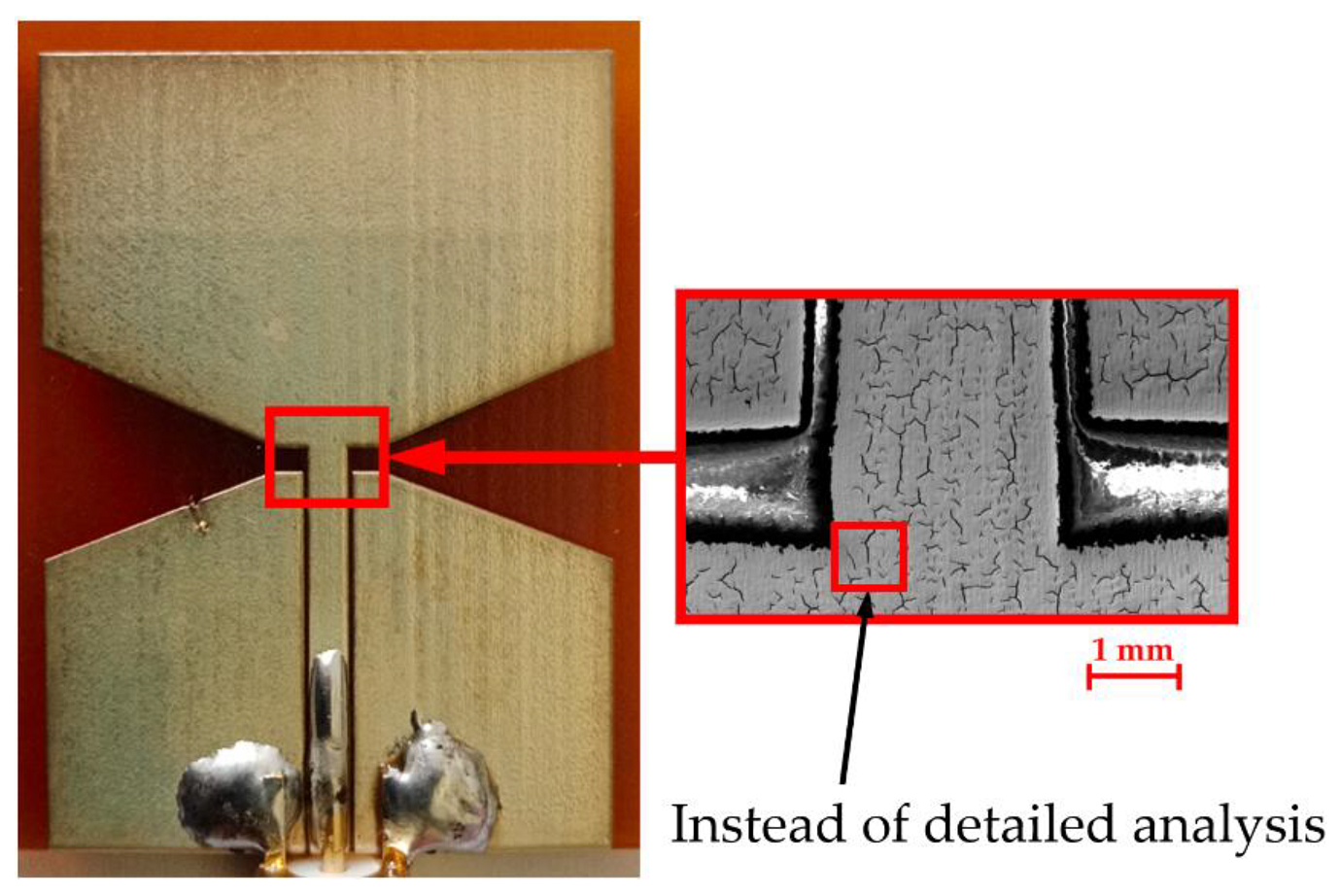

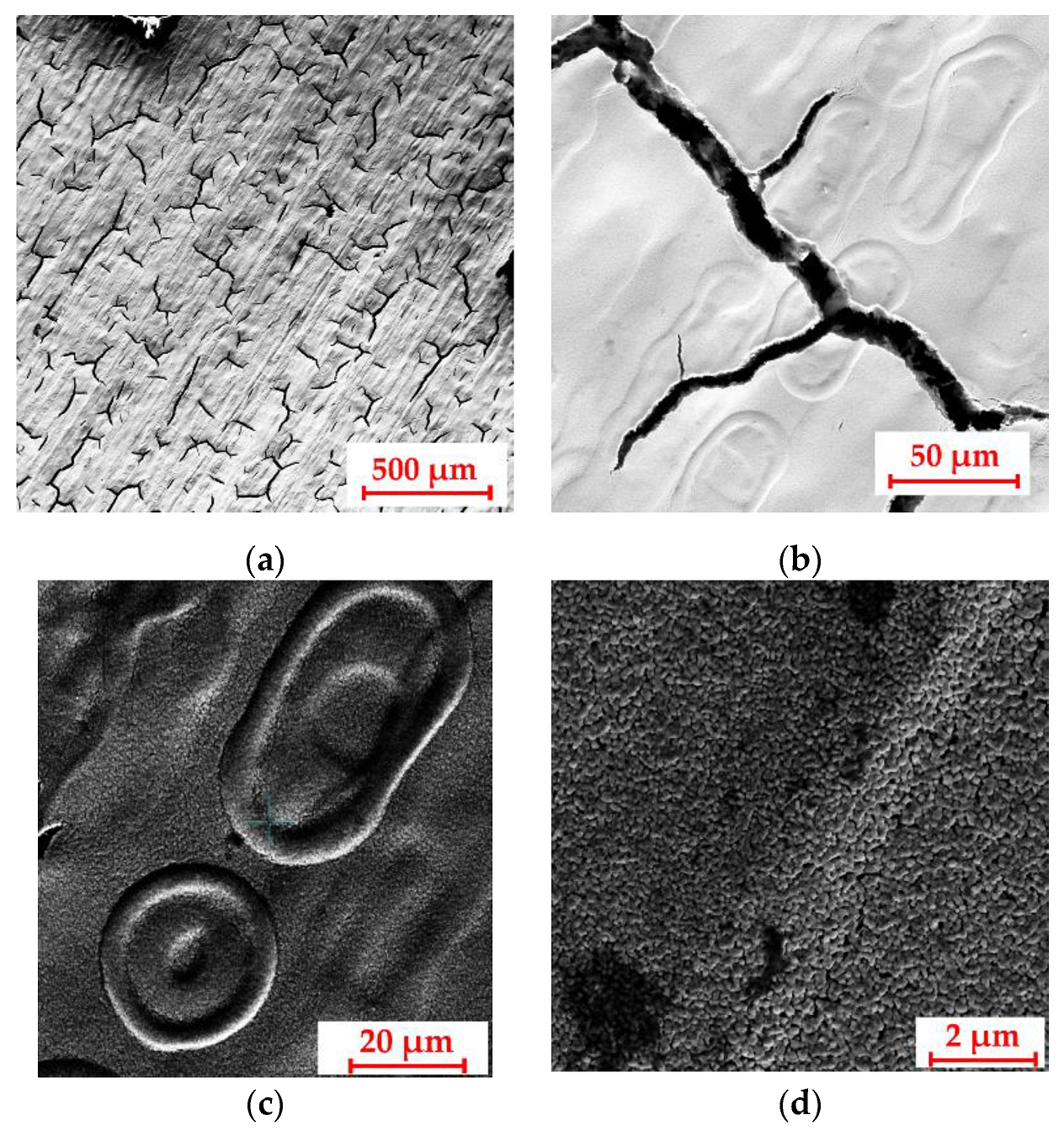

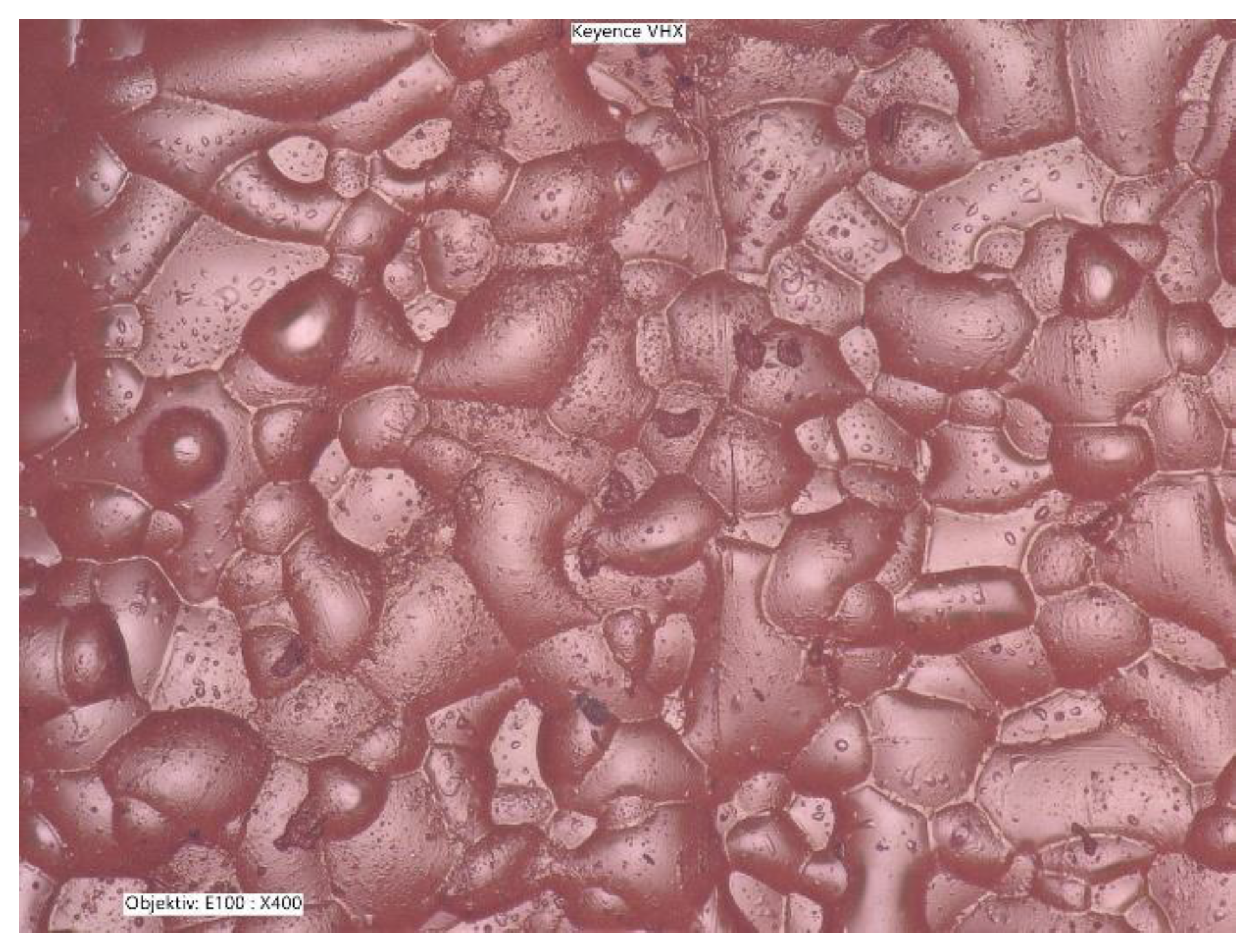

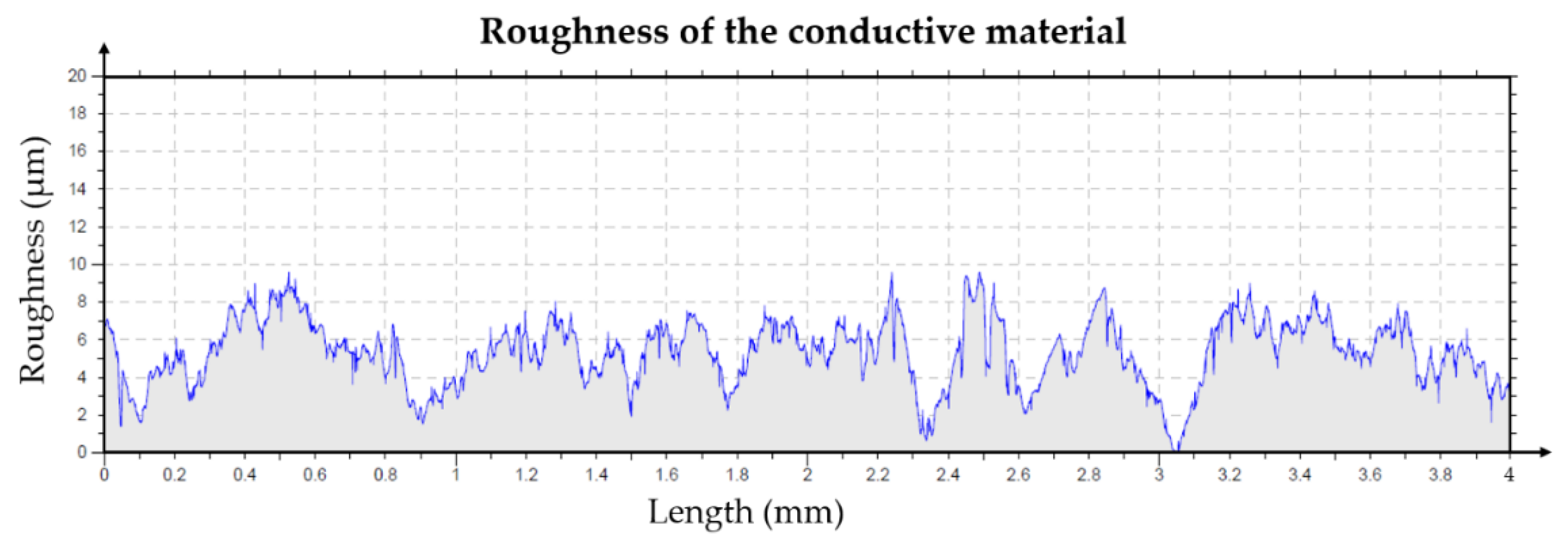

3.2. Technical Analysis of a 3D LDM-Printed Patch Antenna

- -

- Roughness average Ra = 1.15 μm;

- -

- Mean roughness depth Rz = 6.78 μm;

- -

- Total height of the roughness profile Rt = 7.86 μm;

- -

- Arithmetic mean slope Rda = 7.62°;

- -

- Root mean square slope of the assessed profile Rdq = 14.6°.

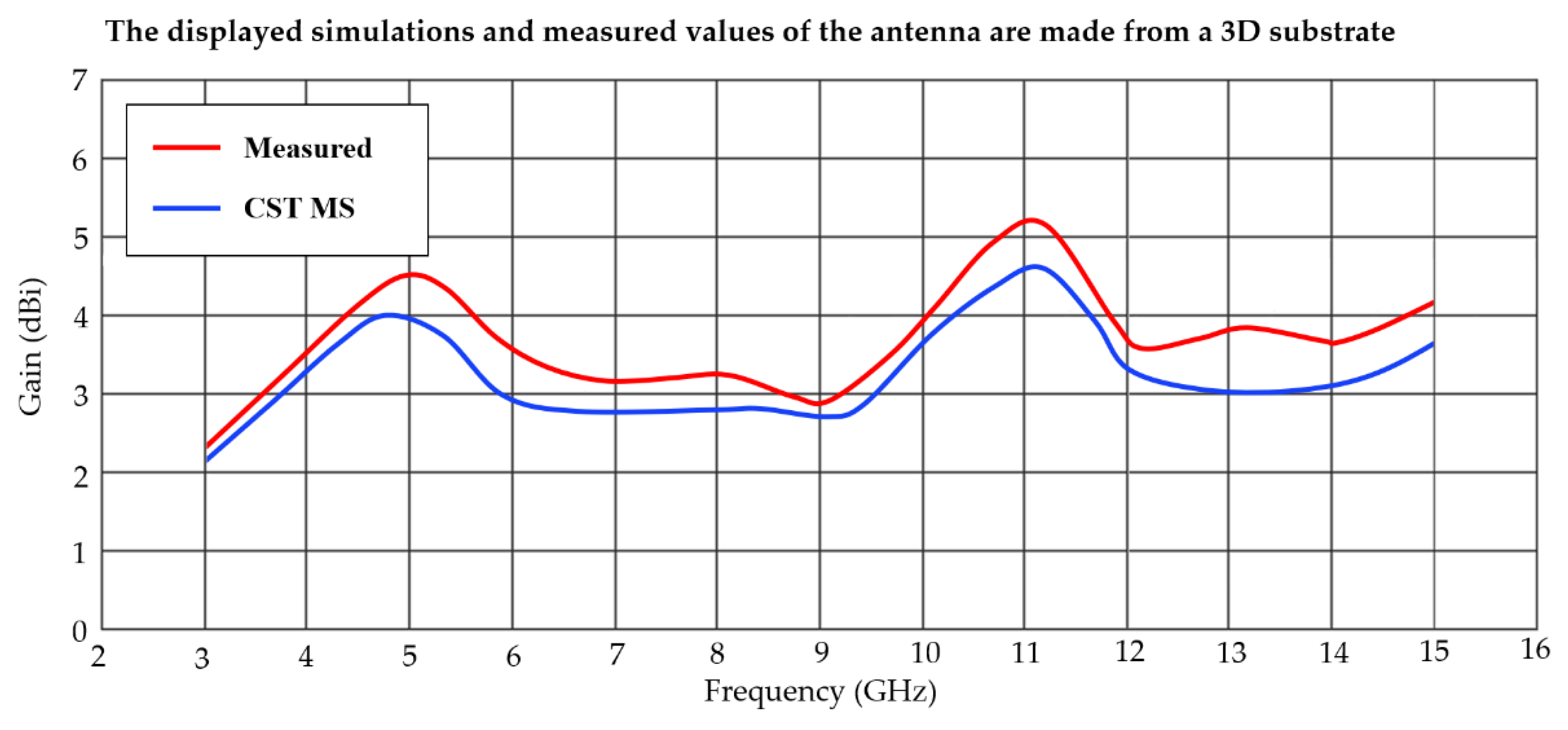

4. Evaluation of 3D LDM Printing Technology

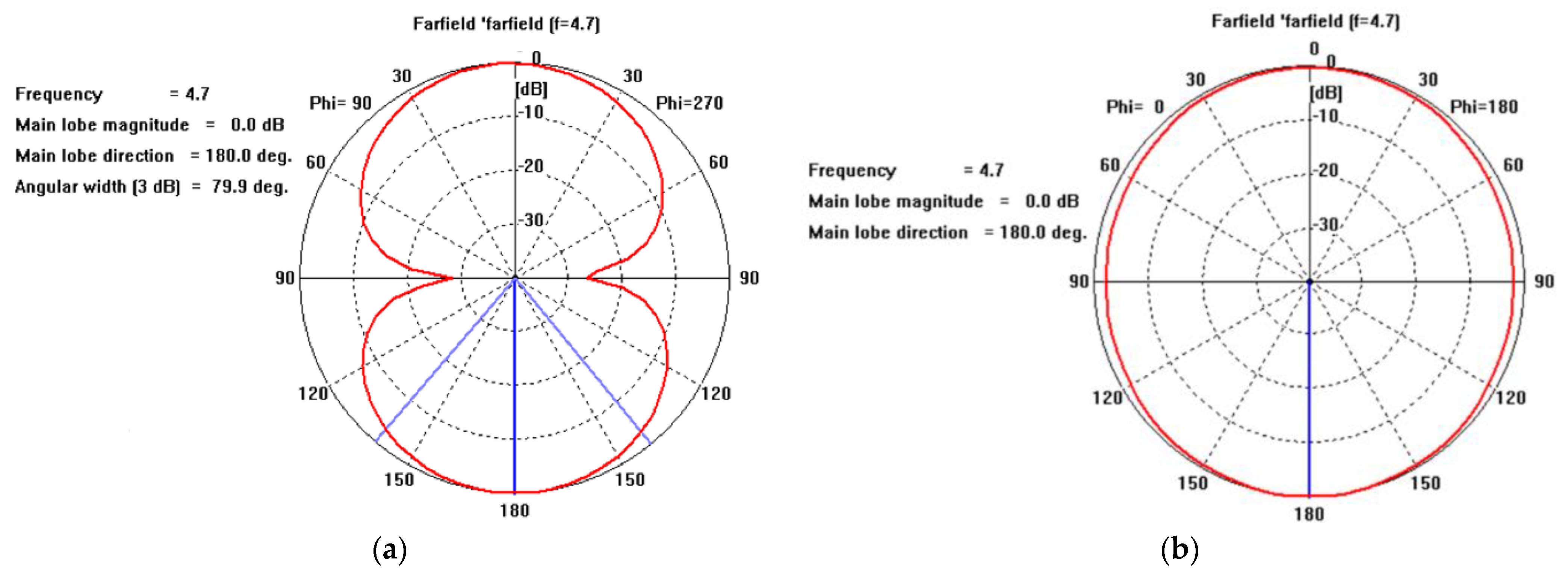

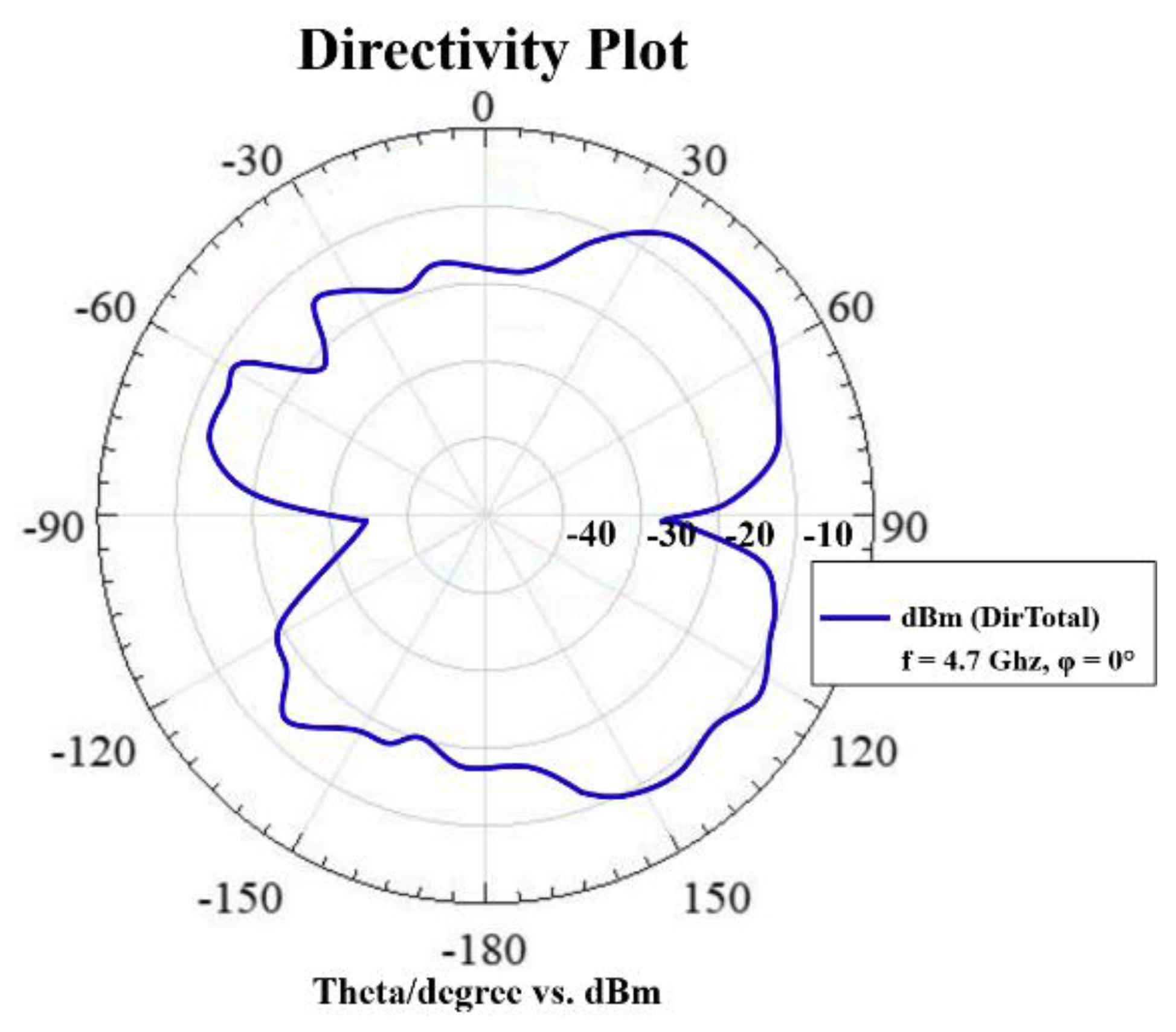

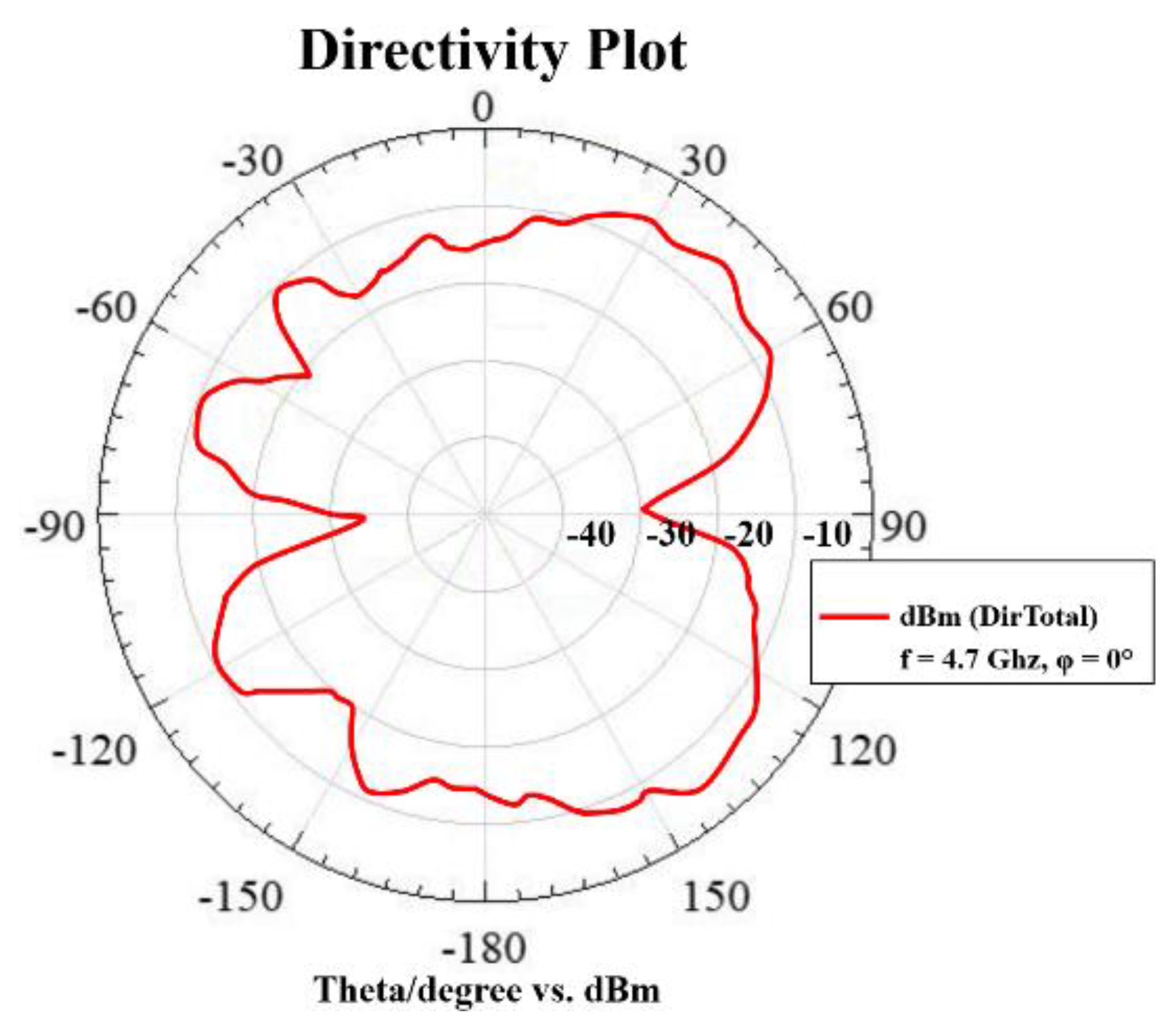

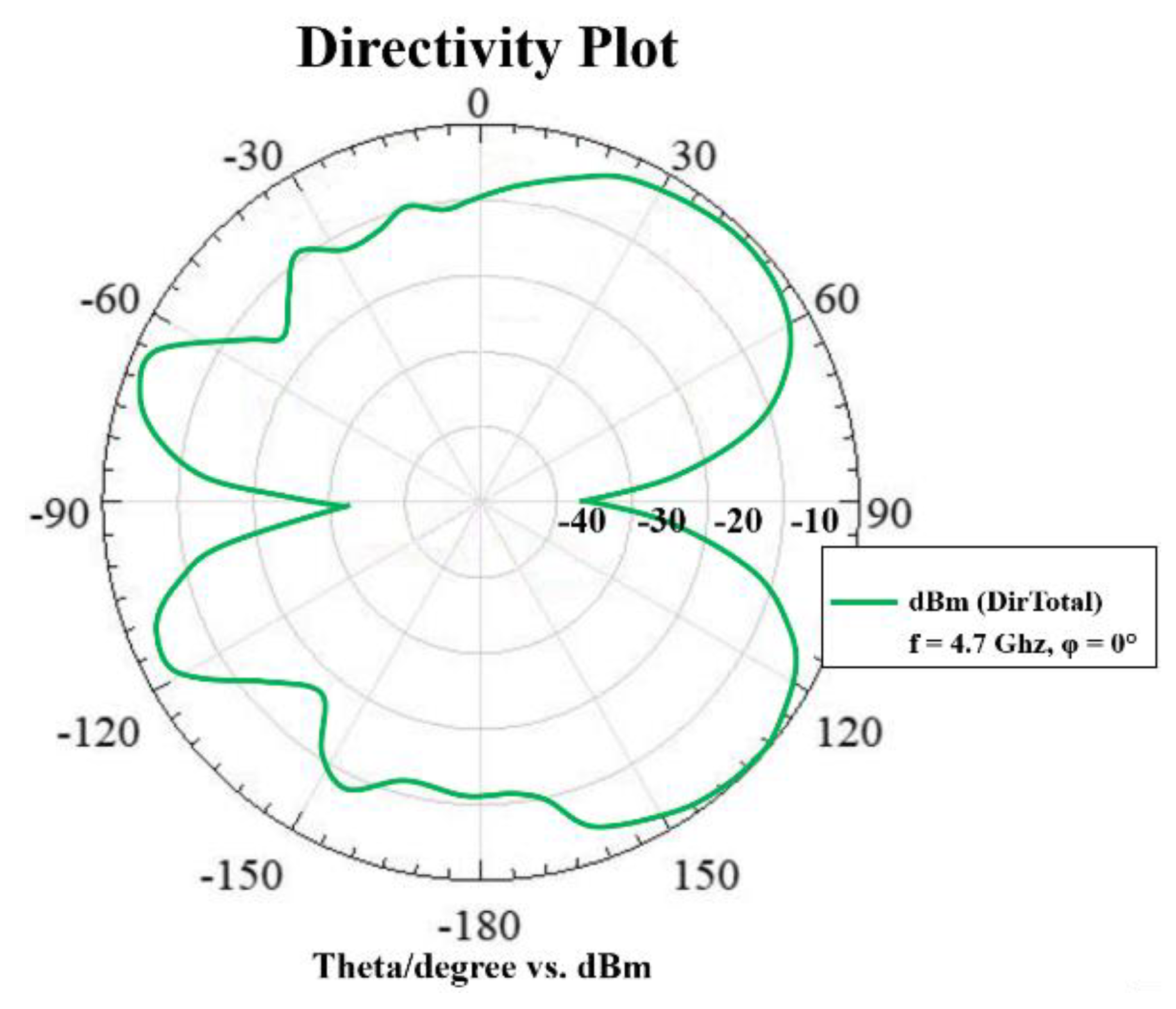

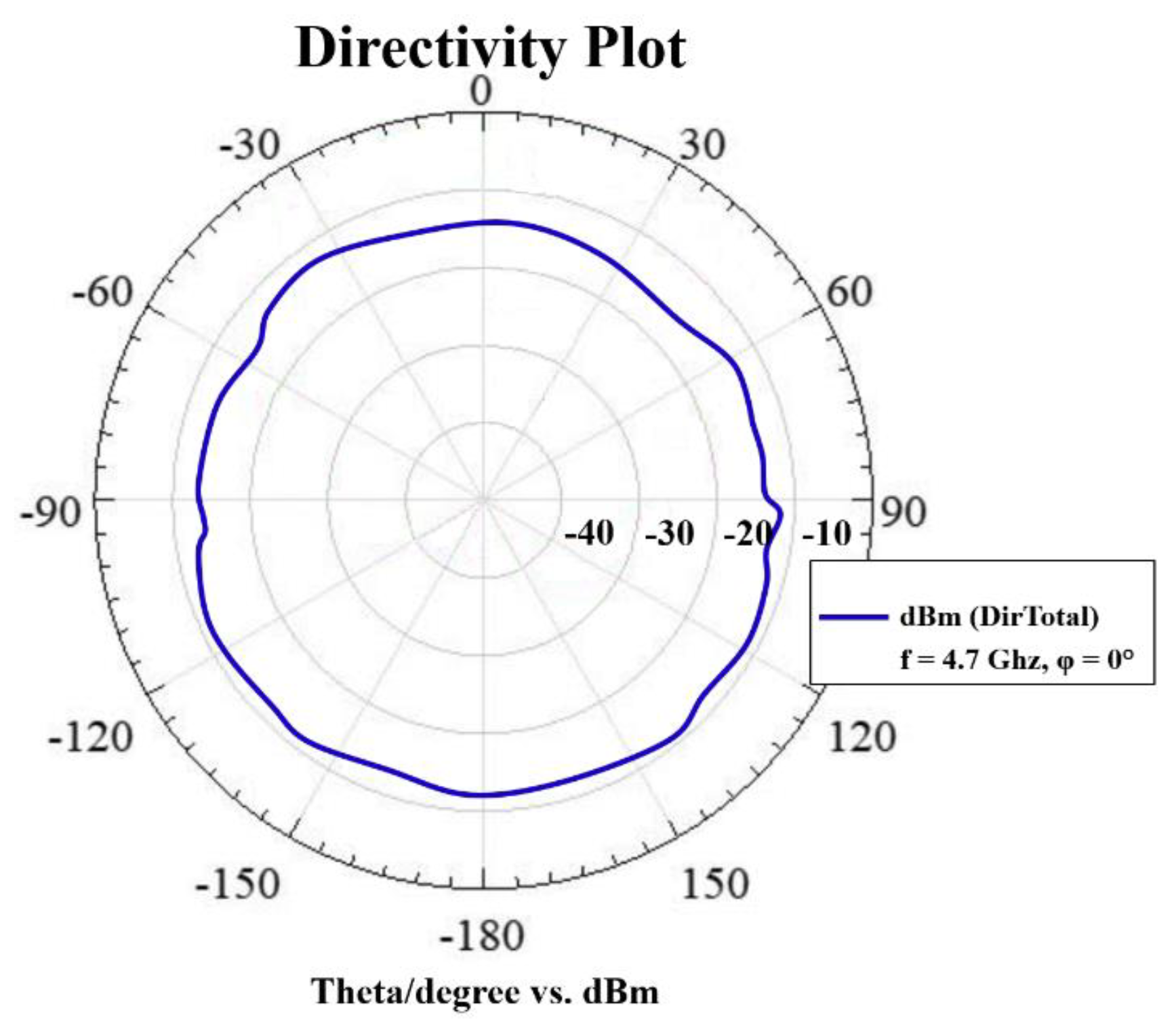

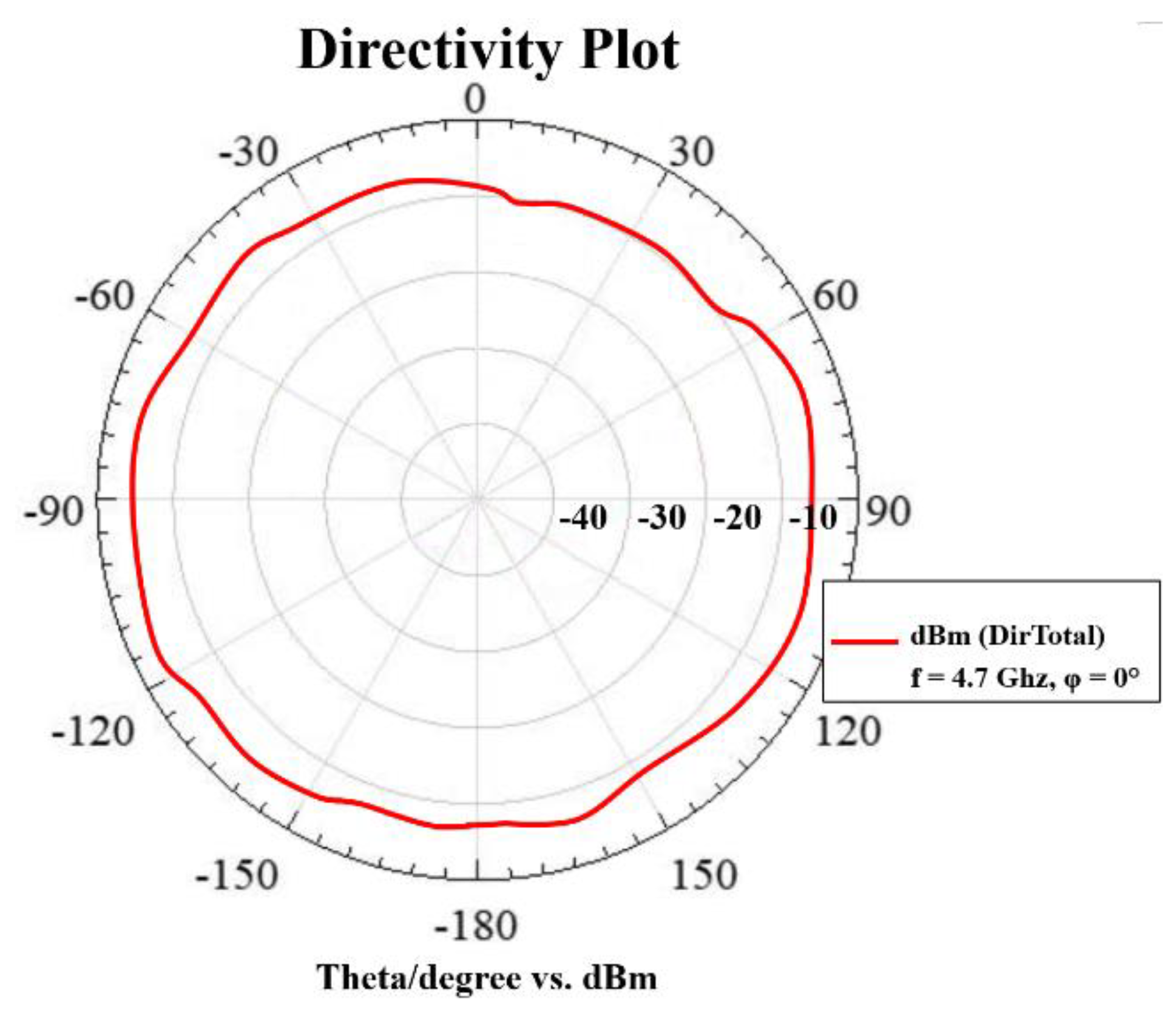

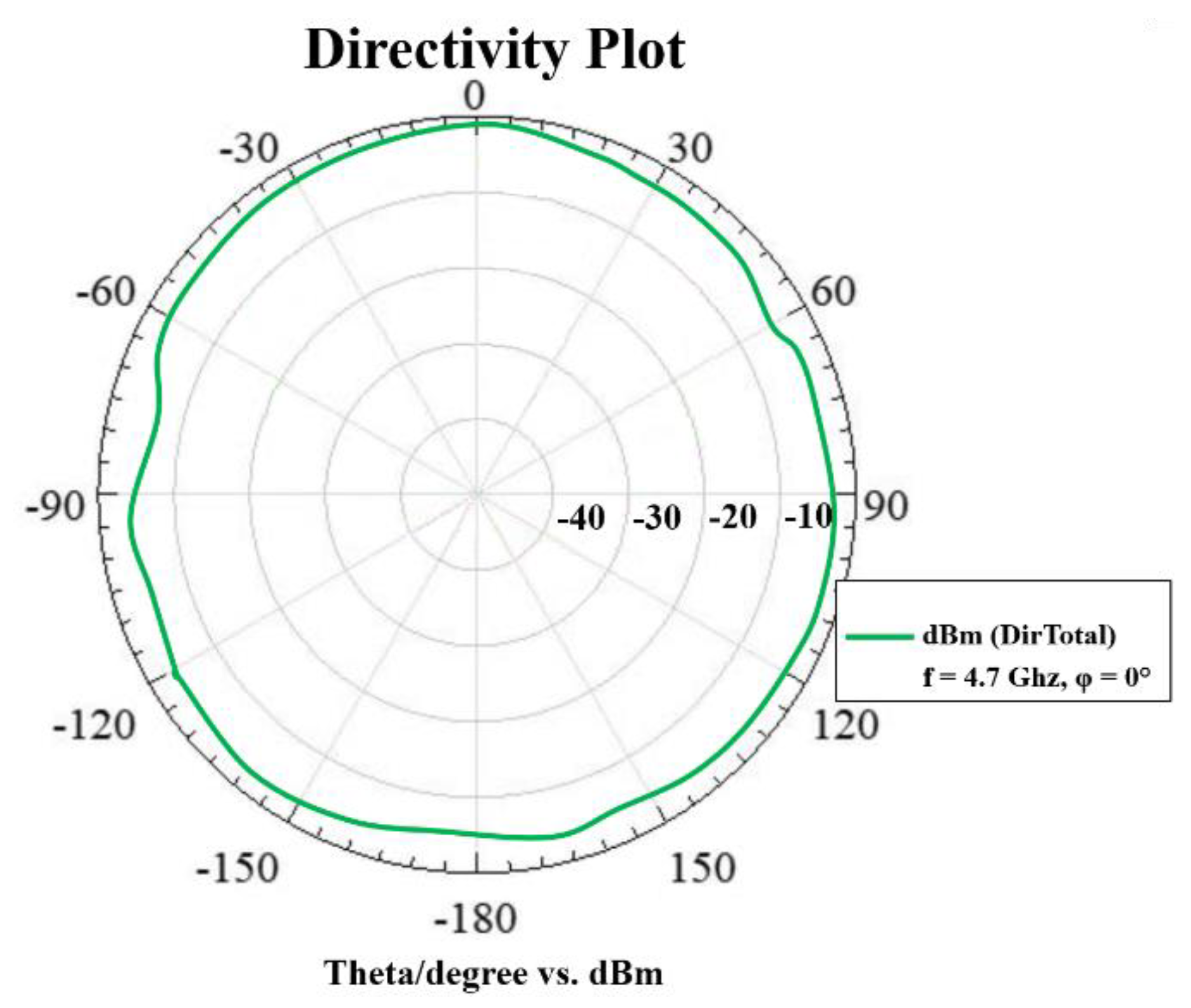

Radiation Patterns of Far-Field Patch Antennas in the E- and H-Planes

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Richterová, M.; Popela, M.; Olivová, J.; Fritz, D. Antennas Based on Metamaterials and Their Application in Modern Communication Technologies; Mechanisms and Machine Science; Springer Science and Business Media: Berlin/Heidelberg, Germany, 2023; ISBN 978-3-031-15757-8. ISSN 2211-0984. [Google Scholar] [CrossRef]

- Popela, M.; Vaněk, S.; Olivová, J.; Vavrečková, K. 3D printing of a patch antenna for 5G network and radio monitoring of UWB signals. In Proceedings of the 9th International Conference on Military Technologies (ICMT), Brno, Czech Republic, 23–26 May 2023; ISBN 979–8-3503-2569-0. [Google Scholar] [CrossRef]

- Olivová, J.; Popela, M.; Richterová, M.; Štefl, E. Use of 3D Printing for Horn Antenna Manufacturing. Electronics 2022, 11, 1539. [Google Scholar] [CrossRef]

- Richterová, M.; Olivová, J.; Popela, M.; Blazek, V. Minkowski Fractal Antenna Based on 3D Printing. In IOP Conference Series: Materials Science and Engineering; Miclaus, S., Ed.; IOP Publishing Ltd.: Sibiu, Romania, 2022; ISSN 1757-8981. [Google Scholar] [CrossRef]

- Hoyack, M.; Bjorgaard, J.; Huber, E.; Mirzaee, M.; Noghanian, S. Connector design for 3D printed antennas. In Proceedings of the 2016 IEEE International Symposium on Antennas and Propagation (APSURSI), Fajardo, PR, USA, 26 June–1 July 2016. [Google Scholar] [CrossRef]

- Toy, Y.C.; Mahouti, P.; Güneş, F.; Belen, M.A. Design and manufactering of an X-band horn antenna using 3D printing technology. In Proceedings of the 8th International Conference on Recent Advances in Space Technologies (RAST), Istanbul, Turkey, 19–22 June 2017. [Google Scholar] [CrossRef]

- Jiménez, J.; Irigoyen, J.; Aresti, M.; Ederra, I.; Bravo, J.; Iriarte, J.C. A New ABS Conductive Material to develop Fully 3D-Printed Patch Antennas. In Proceedings of the 17th European Conference on Antennas and Propagation (EuCAP), Florence, Italy, 26–31 March 2023. [Google Scholar] [CrossRef]

- Balanis, C.A. Antenna Theory: Analysis and Design; John Wiley & Sons: Hoboken, NJ, USA, 2016; ISBN 978-1118642061. [Google Scholar]

- Jeongpyo, K.; Taeyeoul, Y.; Jaemoung, K.; Jaehoon, C. Design of an Ultra Wide-band Printed Monopole Antenna Using FDTD and Genetic Algorithm. IEEE Microw. Wirel. Compon. Lett. 2005, 15, 395–397. [Google Scholar] [CrossRef]

- Noor, S.K.; Jusoh, M.; Sabapathy, T.; Rambe, A.H.; Vettikalladi, H.; Albishi, M.A.; Himdi, M. A Patch Antenna with Enhanced Gain and Bandwidth for Sub-6 GHz and Sub-7 GHz 5G Wireless Applications. Electronics 2023, 12, 2555. [Google Scholar] [CrossRef]

- Raida, Z.; Černohorský, D.; Gala, D.; Goňa, S.; Nováček, Z.; Otevřel, V.; Michálek, V.; Navrátil, V.; Urbanec, T.; Škvor, Z.; et al. Multimedia Textbook. Brno: FEEC VUT Brno. Available online: https://www.radio.feec.vutbr.cz/raida/multimedia/index.php?lang=en (accessed on 1 January 2020).

- Industrial 3DPrinting of Electronics for Manufacturing, A.M.E. NanoDimension. Available online: https://www.nano-di.com (accessed on 19 October 2023).

- Martínez-Lozano, A.; Blanco-Angulo, C.; García-Martínez, H.; Gutiérrez-Mazón, R.; Torregrosa-Penalva, G.; Ávila-Navarro, E.; Sabater-Navarro, J.M. UWB-Printed Rectangular-Based Monopole Antenna for Biological Tissue Analysis. Electronics 2021, 10, 304. [Google Scholar] [CrossRef]

- Jayant, S.; Srivastava, G.; Kumar, S.; Mostafa, H.; Goyal, B.; Choi, H.C.; Kim, K.W. Decoupling Methods in Planar Ultra-Wideband Multiple-Input-Multiple-Output Antennas: A Review of the Design, State-of-the-Art, and Research Challenges. Electronics 2023, 12, 3813. [Google Scholar] [CrossRef]

- Savcı, H.Ş. A Four Element Stringray-Shaped MIMO Antenna System for UWB Applications. Micromachines 2023, 14, 1944. [Google Scholar] [CrossRef] [PubMed]

- Kiani, S.H.; Savci, H.S.; Munir, M.E.; Sedik, A.; Mostafa, H. An Ultra-Wide Band MIMO Antenna System with Enhanced Isolation for Microwave Imaging Applications. Micromachines 2023, 14, 1732. [Google Scholar] [CrossRef] [PubMed]

- Garg, R.; Bhartia, P.; Bahl, I.; Ittipiboon, A. Microstrip Antenna Design Handbook; Artech House, Inc.: Boston, MA, USA; London, UK, 2001; ISBN 0-89006-513-6. [Google Scholar]

- Vavrečková, K.; Olivová, J.; Richterová, M.; Popela, M. Patch Antenna for Monitoring UWB Signals. In Proceedings of the International Conference on Military Technologies (ICMT), Brno, Czech Republic, 8–11 June 2021. [Google Scholar] [CrossRef]

- McMahan, S. 3D Printing Enables ‘Lights-Out Digital Manufacturing’ of Electronic Circuitry. Available online: https://eepower.com/news/3d-printing-of-electronics-with-little-to-no-human-intervention/# (accessed on 23 October 2023).

- Rahyanditya, I.; Rahyanditya, I.; Adit, K. Design and implementation of microstrip antenna array on Ku-Band for satellite TV reception. In Proceedings of the International Telecommunication Networks and Applications Conference (ITNAC), Sydney, NSW, Australia, 18–20 November 2015. [Google Scholar] [CrossRef]

- Storz, V. Nanodimension. Available online: https://www.linkedin.com/pulse/sphere-phased-array-antenna-valentin-storz/ (accessed on 19 October 2023).

- ČSN EN ISO 178 (640607); Plasty—Stanovení Ohybových Vlastností. Český Normalizační Institut: Prague, Czech Republic, 2003. Available online: https://www.technicke-normy-csn.cz/csn-en-iso-178-640607-211909.html (accessed on 19 October 2023).

| 200 MHz | 500 MHz | 1 GHz | 2 GHz | 5 GHz | 10 GHz | 15 GHz | 20 GHz | |

|---|---|---|---|---|---|---|---|---|

| εr | 2.80 | 2.81 | 2.81 | 2.80 | 2.80 | 2.78 | 2.75 | 2.78 |

| tg(δ) | 0.001 | 0.004 | 0.006 | 0.011 | 0.012 | 0.013 | 0.013 | 0.012 |

| Substrate | Dimensions of a Coplanar Dipole | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| εr (-) | h (mm) | W (mm) | L (mm) | A (mm) | J (mm) | N (mm) | M (mm) | P (mm) | E (mm) | G (mm) | K (mm) | |

| FR4 | 4.40 | 1.50 | 11.74 | 10.03 | 1.50 | 15.65 | 31.30 | 11.24 | 20.06 | 16.15 | 0.22 | 22.00 |

| 25N | 3.28 | 1.50 | 13.14 | 11.23 | 1.68 | 16.98 | 35.06 | 12.59 | 22.47 | 18.09 | 0.25 | 24.64 |

| 3D | 2.73 | 1.50 | 16.12 | 12.54 | 1.78 | 18.63 | 39.02 | 15.01 | 24.12 | 20.56 | 0.30 | 27.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Popela, M.; Olivová, J.; Plíva, Z.; Petržílka, L.; Krchová, M.; Joska, Z.; Janů, P. A Novel Approach to the Production of Printed Patch Antennas. Appl. Sci. 2024, 14, 1556. https://doi.org/10.3390/app14041556

Popela M, Olivová J, Plíva Z, Petržílka L, Krchová M, Joska Z, Janů P. A Novel Approach to the Production of Printed Patch Antennas. Applied Sciences. 2024; 14(4):1556. https://doi.org/10.3390/app14041556

Chicago/Turabian StylePopela, Miroslav, Jana Olivová, Zdeněk Plíva, Leoš Petržílka, Michaela Krchová, Zdeněk Joska, and Přemysl Janů. 2024. "A Novel Approach to the Production of Printed Patch Antennas" Applied Sciences 14, no. 4: 1556. https://doi.org/10.3390/app14041556

APA StylePopela, M., Olivová, J., Plíva, Z., Petržílka, L., Krchová, M., Joska, Z., & Janů, P. (2024). A Novel Approach to the Production of Printed Patch Antennas. Applied Sciences, 14(4), 1556. https://doi.org/10.3390/app14041556