Abstract

This study aims to develop a framework to incorporate Waste Cooking Oil (WCO) into asphalt mixtures. Such a framework utilizes a Balanced Mix Design (BMD) approach to ensure adequate resistance to cracking and rutting. Transportation agencies can use the proposed framework to incorporate recycled materials such as used cooking oils and reclaimed asphalt pavements into asphalt mixtures, which promotes sustainability in asphalt pavement construction. This study evaluated the cracking and rutting performance of the control and modified asphalt mixtures with different WCO dosages (i.e., 2, 3, 4, 5, and 7% by the weight of the binder) using the Indirect Tensile Asphalt Cracking (IDEAL) and High-temperature Indirect Tensile (High-IDT) Rutting Assessment Tests, respectively. The results demonstrated that WCO improved the cracking resistance of the control balanced mixture but reduced its resistance to rutting. A statistically significant effect was observed at high WCO dosages. Furthermore, the interaction plot indicates that the overall performance of WCO-modified asphalt becomes softer and more flexible with the increase in WCO dosage. Thus, the designed balanced control mixture becomes unbalanced when using WCO oil at any dosage. This study proposed several approaches to design a more economically balanced WCO-modified balance asphalt mixture.

1. Introduction

Flexible pavements undergo various types of field distress (e.g., cracking and rutting) [1,2]. The characteristics of pavement materials (i.e., binder, aggregates, and asphalt mixture) are one of the main factors affecting this distress [3]. Several approaches are investigated to enhance the mixture’s performance, including modifying components or implementing new performance assessment tests, specifications, and design approaches.

Asphalt binder modifiers are additives added to the binder to enhance its resistance to specific distresses (i.e., fatigue cracking, rutting, and thermal cracking) [4]. Although it is an old practice, several concerns encourage the asphalt community to differentiate, implement, and optimize the use of such modifiers, including (1) the increasing demand for using flexible pavements (e.g., high traffic volumes and loads), (2) reduction in crude oil supply, (3) development of new binder specifications (i.e., SuperPave binder specifications), and (4) environmental and economic concerns (i.e., pressure to recycle waste materials) [5].

Researchers investigated numerous types of modifiers, including elastomer (e.g., Styrene butadiene), plastomer (e.g., ethylene propylene diene monomer), anti-strip (e.g., fatty amido amines), hydrocarbons (e.g., paraffinic), antioxidants (e.g., hydrated lime), extenders (e.g., Sulfur), and fillers (e.g., Mineral filler, lime, Portland cement, fly ash) [5,6,7,8]. These modifiers differ in their interacting mechanism and impact on binder performance (i.e., enhancing/declining resistance to cracking/rutting, composition and physical nature, and source (i.e., natural, manufactured, or waste modifiers)).

Waste modifiers (i.e., modifiers derived from waste materials) are believed to have several benefits over other modifiers, including (1) they are free or inexpensive, which reduces production expenses of conventional mixtures; (2) they reduce environmental pollution; and (3) they assess in saving the natural resources. Several waste modifiers were proposed, including tire rubber, glass, oil shale ash, polystyrene, medical ash, electric arc furnace dust, rubber seed oil, palm oil, clinker fine, engine oil, dates seed, and vegetable oil [4,9,10,11,12,13,14,15].

The recycling of Waste Cooking Oil (WCO) has garnered considerable interest. WCO has become one of the major pollutants nationally [16]. It has a low recoverability rate, many metals, viruses, and bacteria, and it is a potential source of soil, water, and air pollution. It has been used in different applications to mitigate its environmental impacts, such as biodiesel, biogas, grease, animal food, soaps, and detergent productions [17,18,19]. However, massive amounts are still illegally dumped into landfills [16].

Several researchers explored the applicability of recycling WCO oil into asphalt binders or mixtures. It has mainly been used as a modifier or rejuvenator for virgin and aged binders. Recently, various research studies have documented the state of knowledge of recycling the WCO into asphalt binder and mixture asphalt materials [20,21,22,23,24,25,26]. It was found that WCO was able to affect the physical (i.e., penetration, softening point, viscosity) and rheological (i.e., phase angle [δ], complex shear modulus [G*]) properties of asphalt binders. In addition, it influences the mixture performance (e.g., workability, rutting, low-temperature cracking, stability, flow, and creep stiffness). The literature review findings highlight the feasibility of using WCO as an asphalt binder modifier or rejuvenator. It was observed that adding WCO increases the penetration and viscosity, and δ, while decreasing the softening point and G* of an aged binder. Furthermore, it enhanced rutting and low-temperature cracking, stability, and resistance. However, several concerns have been raised.

Previous studies mainly used the results of physical binder tests (e.g., penetration, viscosity, softening point, flash point, Fraass Breaking Point, and ductility test) to assess the effectiveness of WCO and determine its suitable dosage (or optimum). However, such empirical binder assessment tests do not represent any performance criteria of the studied binders and may provide inconsistent results. For instance, Joni et al. (2019) and Sun et al. (2016) recommended the optimum WCO dosage to be 1% and 15% of binder weight, respectively, although they relied on the same binder tests (penetration, softening point, and ductility tests) to determine the optimum dosage [21,27,28]. Similarly, there was a wide range of recommended optimum WCO dosages in the literature (i.e., from 1% to 33% [20,21]). Although other factors contribute to determining the optimum WCO dosage, such a wide range of recommended dosages would negatively affect the performance of asphalt mixtures. In fact, Elahi et al. (2021) and Khedaywi and Melhem (2022), in their review, highlighted the importance of addressing this issue [20,26,29].

In addition, the currently implemented asphalt mix design methods (i.e., SuperPave and Marshall) lack the capability to design modified asphalt mix properly. These methods rely on volumetric parameters (i.e., design air voids (Va) and volume of effective binder (Vbe)) to determine the optimum binder content (OBC). However, these parameters do not provide any indication of the interaction between the virgin binder and modifiers [28]. Therefore, the impact of such modifiers (enhance/decline) on the designed mix’s performance (e.g., resistance to cracking) cannot be appropriately assessed. The review studies indicated that limited studies assessed the performance of modified asphalt mixtures [26,29]. For instance, Elahi et al. (2021) [26] stated that limited studies examined WCO-modified asphalt mixtures’ cracking resistance.

Nowadays, greater emphasis is placed on utilizing asphalt mixture performance assessment tests [30]. The primary objective of such tests is to discern mixtures that exhibit inadequate performance (e.g., rutting, cracking) during the mix design or production phases using well-established performance thresholds. Several studies have proved the ability of such tests to assess the performance of asphalt mixtures [31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48].

A new design concept called “Balanced Mix Design (BMD)” is being developed. The BMD overcomes the current volumetric methods (i.e., SuperPave and Marshall) by incorporating performance assessment tests, indicators, and specifications during the mix design process. It is defined as “Asphalt mix design using performance tests on appropriately conditioned specimens that address multiple modes of distress taking into consideration mix aging, traffic, climate, and location within the pavement structure” [49]. There is a national interest in implementing the BMD approach [2,30].

In light of the previous discussion, there is a need to utilize the BMD approach to address the raised concerns with WCO-modified asphalt mixtures. It would enhance our understanding of the impact of WCO on asphalt mixture performance. Such findings would optimize the usage of WCO without declaring the mixture performance, which would offer a sustainable, cost-effective, and performance-enhancing solution for road construction, contributing to waste reduction, resource conservation, and environmental protection.

2. Objectives

The present study aims to develop a framework to incorporate Waste Cooking Oil (WCO) into asphalt mixtures. Such a framework utilizes a Balanced Mix Design (BMD) approach to ensure adequate resistance to cracking and rutting. The proposed framework can be used by transportation agencies to incorporate recycled materials such as used cooking oils and reclaimed asphalt pavements into asphalt mixtures, which promotes sustainability in asphalt pavement construction.

3. Laboratory Experimental Program

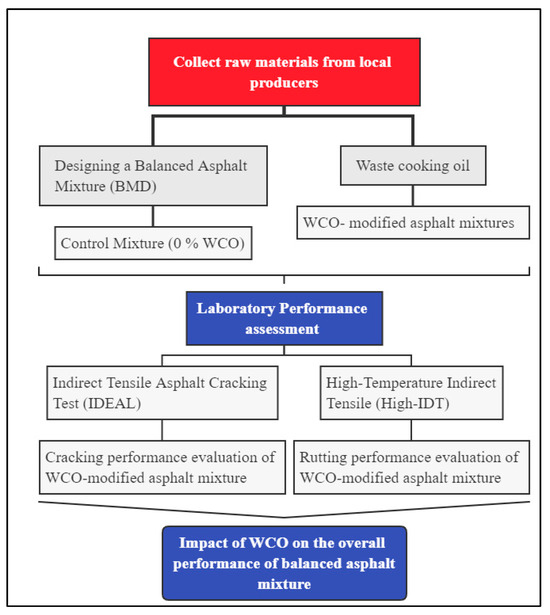

Figure 1 presents the designed experiment plan. First, raw materials were collected (i.e., virgin binder, aggregates, and waste cooking oil (WCO)). Next, the most promising cracking and rutting performance assessment tests, indicators, and thresholds have been selected. Then, a balanced asphalt mixture was designed using the virgin binder and aggregates. Later, the BMD mix was modified with different dosages of WCO. Finally, the BMD performance assessment tools were used to examine the cracking and rutting resistance of the WCO-modified balanced mixtures. Finally, the impact of WCO on the overall performance of a balanced asphalt mixture was assessed using an interaction plot. The following sections discuss the cracking and rutting performance assessment tests selection, properties of raw materials, sample preparation, and testing procedure.

Figure 1.

Laboratory experimental program.

3.1. Properties of Raw Materials

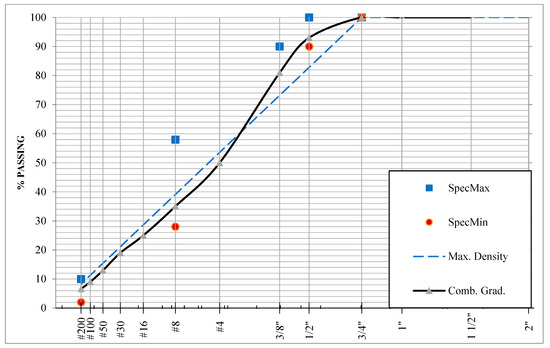

An 85/100 binder grade and basalt aggregates were collected from local producers and delivered to the pavement materials laboratory at Hashemite University. Table 1 presents the physical properties of virgin asphalt binder. The aggregate gradation was selected to meet the 12.5 mm Nominal Maximum Aggregate Size (NMAS) requirement following AASHTO M323 [50] (Figure 2). In addition, the selected Waste Cooking Oil (WCO) was a palm olein vegetable oil collected from a local fast-food restaurant. The collected oil was purified through a #200 sieve (0.075 mm) [13].

Table 1.

Properties of virgin asphalt binder as collected from the supplier.

Figure 2.

Selected aggregate gradation.

3.2. Selection of Performance Assessment Tests and Indicators

3.2.1. Performance Assessment Tests

Several performance assessment tests were proposed and evaluated to assess asphalt mixtures’ cracking and rutting resistance [31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48]. In this study, the authors selected two of the most promising monotonic cracking and rutting assessment tests: the Indirect Tensile Asphalt Cracking Test (IDEAL) and the High-temperature Indirect Tensile (High-IDT) Rutting Assessment Test, respectively.

The IDEAL and High-IDT were performed following ASTM D8225 and the Virginia Department of Transportation (VDOT) recommended procedures by Boz et al. [56], respectively. Both tests involve the application of a constant axial rate of 50 mm/min on the test specimen. The test temperatures were 25 °C and 54.4 °C for the IDEAL and High-IDT, respectively. The load and displacement measurements are gathered throughout the experiment in order to produce the Load–Displacement (L–D) relationship.

3.2.2. Performance Assessment Indicators

The IDEAL Cracking Resistance (CTIndex) and the indirect tensile strength (HI-IDTStrength) performance assessment indicators were used to explain the change in the L-D curve obtained from the IDEAL and High-IDT, respectively. The CTIndex standardizes the fracture energy by adjusting it in relation to the post-peak slope. (Equation (1)) [42]. The post-peak slope is defined by the tangent slope at 75% of the peak load on the post-peak curve () (Equation (2)). Higher CTIndex demonstrates better resistance to cracking [42,57,58]. The HI-IDTStrength is an expression of the standardization of the maximum applied load (P100%) in relation to the configuration of the specimen (i.e., diameter (D) and height (t)) (Equation (3)). Higher HI-IDTStrength demonstrates better resistance to rutting [45,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77].

The BMD implements the performance assessment specifications to assess mixture performance. It is defined as “pre-determined thresholds/limits that need to be achieved for a given performance indicator obtained from a given performance assessment test to assess mix resistance to a specific distress” [48]. Several thresholds were proposed for CTIndex and HI-IDTStrength indicators [48,78,79]. In this study, a mixture shall have a minimum value of 26.4 and 110 KPa of CTIndex and HI-IDTStrength, respectively, to be approved [48,56].

where is the IDEAL cracking test index indicator, is the total fracture energy (J/m2), and are the slope and deformation (displacement) at 75% of the maximum (peak) load on the post-peak curve, respectively. P65% and L65% are the load and deformation (displacement) at 65% of the maximum (peak) load on the post-peak curve, respectively. P85% and L85% are the load and deformation (displacement) at 85% of the maximum (peak) load on the post-peak curve, respectively. is the tensile strength (kPa), is the peak (maximum) applied load (KN) on the test specimen (curve peak), and t and D are specimen thickness (mm) and diameter (mm), respectively.

3.3. WCO-Modified Binder Preparation

In this study, the virgin binder (i.e., 85/100) and the filtered WCO oil were heated in the oven to 145 °C. The WCO oil was heated to remove the moisture completely [80]. Next, the required amount of binder was poured into a container and placed on a hot plate. The filtered WCO was progressively added and mixed to the virgin binder using a high-shear mixer. The mixing was performed at a constant speed of 1600 rpm for 10 min at 145 °C. Later, the modified binder was used to prepare the modified asphalt mixtures.

3.4. Specimen Preparation, Conditioning, and Testing

The unmodified mixtures were prepared by mixing the raw materials (i.e., virgin binder and aggregates) using a planetary mixer at the specified laboratory mixing temperature of 165 °C. Loose samples were scooped from the prepared mixtures to measure the theoretical maximum specific gravity (Gmm) following AASHTO T 209 [81]. The remaining materials were short-term aged following AASHTO R30 [82], then compacted using a SuperPave gyratory compactor. The fabricated test specimens were 150 mm in diameter by 62 mm in height for both tests. At least two specimens have been fabricated for each test. After that, the bulk specific gravity (Gmb) was measured following AASHTO T312 [83]. Later, specimens were checked to achieve the target air void content (i.e., 7 ± 1.5%). Then, it was conditioned at the desired testing temperature (i.e., 25 °C and 54.5 °C for IDEAL and High-IDT, respectively) for 2 h ± 10 min before testing. Finally, the specimens were tested at a 50 mm/min loading rate using Marshall testing equipment.

A similar approach has been followed for the modified WCO asphalt mixtures, except for replacing the virgin binder with the modified WCO asphalt binder. The literature review showed that researchers prepared the modified binder by mixing the required dosage of WCO oil with the virgin binder using a high-shear mixer. However, it was conducted at varied speed (200–4000 revolutions per minute (rpm)), time (15–120 min), and temperature (120–190 °C) [22,26].

4. Results and Discussions

4.1. Designing Balanced Asphalt Mixture (BMD)

The Balanced Asphalt Mixture (BMD) design approach is a meticulous process encompassing several stages, including material characterization, performance testing, mixture optimization, and validation [30]. The primary objective of this methodology is to ensure that asphalt mixtures exhibit the desired performance characteristics. This process begins with a comprehensive evaluation of raw materials, particularly asphalt binders and aggregates, to determine their mechanical and physical properties. Afterward, lab-based performance assessment tests and indicators are carried out to assess the resistance of asphalt mixtures to various types of distress, such as rutting, cracking, and moisture damage [30].

The information obtained from material characterization and performance testing is then utilized in the optimization phase of BMD. This phase identifies the range of binder content that yields the desired performance characteristics. Following this approach, asphalt mixtures can be optimized to achieve the desired performance characteristics while meeting the relevant specifications and standards. Four different approaches were proposed to implement the BMD method, namely (A) Volumetric Design with Performance Verification, (B) Volumetric Design with Performance Optimization, (C) Performance-modified Volumetric Design, and (D) Performance Design [30,84].

This study followed approach “D”, which starts with an initial selection of virgin binder grade and aggregate gradation. Then, the performance of the initial mix design is evaluated at three or more binder contents varied in increments of 0.3 to 0.5%. Firstly, several mixtures were prepared by mixing the selected virgin binder (85/100) and aggregate gradation (Figure 2) at four different binder contents (i.e., 4.0, 4.5, 5.5, and 6.0%). Then, the test specimens were prepared and tested to evaluate the prepared mixtures’ performance (i.e., cracking and rutting resistance) using CTIndex and HI-IDTStrength indicators.

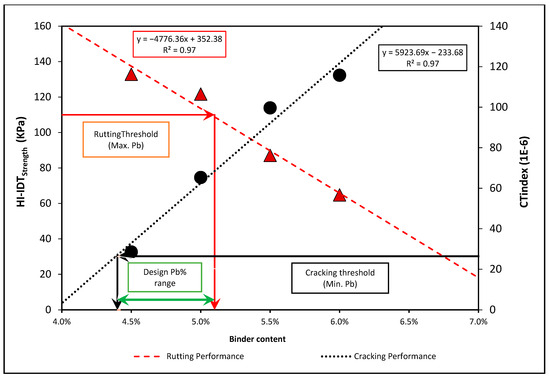

Figure 3 presents the testing results of prepared asphalt mixtures. It can be observed that CTIndex and HI-IDTStrength indicators increased and decreased, respectively, with the increase in binder content. Both indicators have an excellent linear relationship with the variation binder content (i.e., coefficient of determination (R2) of 0.97). These findings agree with the reported results in the literature [43,56]. Such relationships indicated that the CTIndex is increased by 59.2 (i.e., CTIndex = 5923.69 [Pb%] − 233.68), and the HI-IDTStrength is decreased by −47.7 KPa (i.e., HI-IDTStrength = −4776.36 [Pb%] + 352.38) for each 1% increment in binder content.

Figure 3.

Designed balanced asphalt mixtures.

CTIndex and HI-IDTStrength assessment thresholds were used to determine the balanced binder content range. The rutting threshold for HI-IDTStrength (i.e., a minimum of 110 KPa) was used to determine the maximum accepted binder content since increased binder content declined mixture resistance to rutting. It was observed that a binder content of 5.1% satisfies this threshold. Similarly, the cracking threshold for CTIndex (i.e., a minimum of 26.4) was used to determine the minimum required binder content since the decrease in the binder content declined mixture resistance to cracking. It was observed that a binder content of 4.4% satisfies this threshold. Therefore, the designed balanced binder range was 4.4–5.1%. The Balanced Optimum Binder Content (BOBC) was selected as the midpoint of this range (i.e., 4.75%) (Figure 3).

4.2. Performance Assessment of Waste Cooking Oil on Balanced Asphalt Mixtures

In this study, the IDEAL and High-IDT tests were used to investigate the impact of Waste Cooking Oil (WCO) on the performance of asphalt mixtures. The virgin binder was modified by adding the WCO at three different dosages (i.e., 3, 5, and 7% by the weight of the binder). In addition, the performance of unmodified binder (i.e., 0% WCO) asphalt mixture was tested. It was used to verify the performance of the selected BOBC (i.e., 4.75%) and to examine the influence of WCO on the performance of a balanced mixture.

In addition, a statistical examination was conducted to analyze the type, magnitude, and importance impact of the WCO modification on cracking and rutting indicators (i.e., CTIndex and HI-IDTStrength). This study employed three distinct analysis modes: regression analysis, Analysis of Variance (ANOVA), and Tukey’s range test (HSD). ANOVA and Tukey’s tests were both performed with a confidence level of 95% (i.e., a = 0.05). Furthermore, the strength of the relationship was determined by utilizing the coefficient of determination (R2). Additionally, the repeatability and reliability of testing results were examined using the Coefficient of Variation (COV) [85].

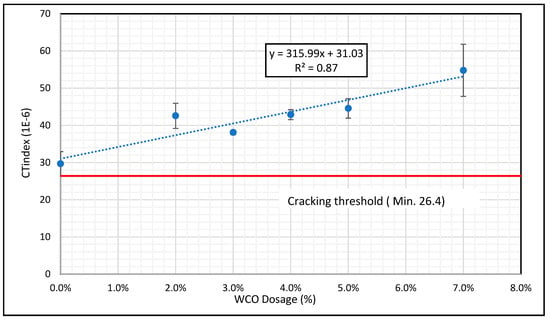

4.2.1. Cracking Performance Evaluation of WCO-Modified Asphalt Mixture

Figure 4 presents the average results of CTIndex for all tested specimens with the cracking threshold (i.e., a minimum of 26.4). The error bars indicate a plus/minus one standard deviation. It can be observed that the control mixture (i.e., 0% WCO) had an average CTIndex of 29.7, which satisfies the performance threshold. The data showed that CTIndex has an excellent direct linear relationship (i.e., CTIndex = 315.99 [WCO%] + 31.03) with the variation WCO dosage (i.e., R2 of 0.87). Such relationships indicated that CTIndex increased by 3.15 for each 1% increment in WCO dosage. The WCO dosages of 0%, 2%, 3%, 4%, 5%, and 7% had CTIndex of 29.7, 42.5, 38,0, 42.8, 44.5, and 54.8, respectively. Such findings indicate that the mixture resistance to cracking improved with the increment in WCO dosages. ANOVA and Tukey’s analysis indicated a statistically significant difference between the control and modified mixtures with high WCO dosages (e.g., 5% and 7%). Furthermore, the data showed a low variability with an average COV of less than 15%. This finding agrees with reported results in the literature [24,86,87].

Figure 4.

Cracking performance evaluation of WCO-modified asphalt mixture.

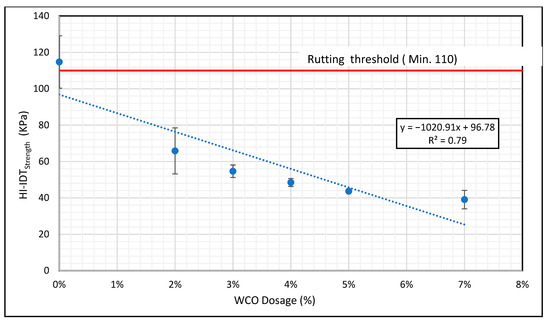

4.2.2. Rutting Performance Evaluation of WCO-Modified Asphalt

Figure 5 presents the mean results of HI-IDTStrength with the rutting threshold (i.e., a minimum of 110 KPa). The error bars indicate a plus/minus one standard deviation. It can be observed that the control mixture (i.e., 0% WCO) had an average HI-IDTStrength of 114 KPa, which satisfies the performance threshold. The data showed that HI-IDTStrength has a good indirect linear relationship (i.e., HI-IDTStrength = −1020[WCO%] + 96.78) with the variation WCO dosage (i.e., R2 of 0.73). Such relationships indicated that HI-IDTStrength decreased by 10.20 KPa for each 1% increment in WCO dosage. The WCO dosages of 0%, 2%, 3%, 4%, 5%, and 7% had HI-IDTStrength of 114.7, 65.8, 54.6, 48.4, 43.6, and 39.0, respectively. Such findings indicate that mixture resistance to rutting declined with the increment in WCO dosages. ANOVA and Tukey’s tests revealed a statistically significant discrepancy between the control mixture and all modified mixtures. However, no significant difference existed between consecutive WCO dosages (i.e., 2% vs. 3% vs. 4% vs. 5% vs. 7%). Furthermore, the data showed a low variability (i.e., average COV less than 15%). This finding agrees with reported results in the literature [24,86,87].

Figure 5.

Rutting performance evaluation of WCO-modified asphalt mixture.

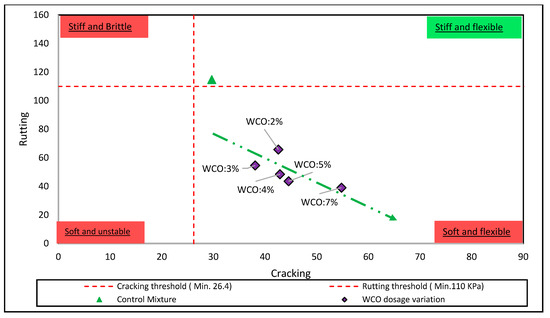

4.3. Impact of WCO on Overall Performance of Balanced Asphalt Mixture

The variation in the overall performance of WCO-modified asphalt mixtures can be examined using the interaction plot. It defines the overall mixture performance by four quadrants: stiff and brittle, stiff and flexible, soft and flexible, and soft and unstable [40]. Stiff and brittle mixtures are expected to have poor cracking resistance (i.e., low CTIndex) but good rutting resistance (i.e., high HI-IDTStrength). Stiff and flexible mixtures are expected to have good cracking and rutting resistance. Soft and flexible mixtures have good cracking resistance but poor rutting resistance. The soft and unstable mixtures have very poor cracking and rutting resistance.

The authors created an interaction plot between the CTIndex and HI-IDTStrength for the tested mixtures, as presented in Figure 6. The CTIndex and HI-IDTStrength values are shown in the X and Y axes, respectively, along with their associated pass/fail performance assessment thresholds. Stiff and brittle mixtures are expected to have CTIndex < 26.4 and HI-IDTStrength >110 KPa (i.e., poor and good cracking rutting resistance, respectively). Stiff and flexible mixtures are expected to have CTIndex > 26.4 and high HI-IDTStrength > 110 KPa. Soft and Flexible mixtures have CTIndex > 26.4 and HI-IDTStrength < 110Kpa, while the soft and unstable mixtures have CTIndex < 26.4 and HI-IDTStrength < 110Kpa. The designed mixture was designed as stiff and flexible mixtures to satisfy the BMD requirements (i.e., the green area).

Figure 6.

Interaction plot between CTIndex and HI-IDTStrength for the evaluated mixtures.

The interaction plot is used to study the overall performance of a given mixture and to track the effect of variation in mix proportions (i.e., binder content) or modifier dosage (i.e., WCO oil) on mixture performance. It can be observed that the performance control mixture (i.e., unmodified [0% WCO]) was stiff and flexible, which had a good rutting and cracking resistance. The increase in WCO dosage improves the mixture’s resistance to cracking resistance but declines its resistance to rutting. A significant effect can be observed at high WCO dosages. For instance, the modified mixture with 7% WCO increases the cracking resistance of the control mixture by 85% (i.e., from 29.7 to 54.8) but decreases its rutting resistance by 66% (from 114 KPa to 39 KPa).

The variation trend indicates that the mixture becomes softer and more flexible with the increase in WCO dosage, as evidenced by its movement to the lower left quadrant (Figure 6). Thus, the designed balanced control mixture becomes unbalanced when using WCO oil at any dosage. Therefore, it shall be redesigned to account for the WCO effect.

Several approaches can be implemented to adjust the mixture performance. For example, it is well known that the overall mixture performance relies on the proportions and properties of raw materials. Therefore, adjusting such properties of the control asphalt mixture would address the effect of WCO oil. For instance, performing the following modification would enhance asphalt mixture resistance to rutting using lower binder content, harder virgin binder, higher filler content, higher coarse and fine aggregate angularity, stronger aggregates, higher surface texture aggregates, more cubical shape aggregates, larger nominal maximum aggregate size, higher recycled asphalt pavement content (RAP) [88].

Using a compound modifier consisting of WCO with another modifier would reduce the WCO impact on the performance of the designed asphalt mixture (i.e., enhancing the rutting resistance). Several modifiers are proofed to enhance asphalt mixture resistance to rutting, including polymers (styrene–butadiene–styrene (SBS), ethylene vinyl acetate, polyethylene), ground tire rubber (GTR), rock asphalt, and nanomaterials (e.g., nano clay (NC), nano silica, carbon nanofiber, carbon nanotubes (CNT), carbon black (CB), graphene, nano-ZnO, and nano-TiO2) [26,89]. Such compound modifiers enhanced the physical and rheological properties of asphalt binders.

5. Conclusions and Recommendations

The main goal of this research is to assess the performance of Waste Cooking Oil (WCO)-modified asphalt mixtures using the Balanced Mix Design (BMD) approach. The following conclusions can be made:

- Mixture resistance to cracking was improved with the increment in WCO dosages. CTIndex has an excellent direct linear relationship with the variation WCO dosage (i.e., R2 of 0.87). A statistically significant discrepancy was found between the control and modified mixtures with high WCO dosages (e.g., 5% and 7%).

- HI-IDTStrength has a good indirect linear relationship with the variation WCO dosage (i.e., R2 of 0.79). A statistically significant discrepancy was found between the control mixture and all modified mixtures.

- WCO was able to improve the cracking resistance of the control balanced mixture, but it declined its resistance to rutting. However, a significant effect can be observed at high WCO dosages. For instance, the modified mixture with 7% WCO increases the cracking resistance of the control mixture by 85% (i.e., from 29.7 to 54.8) but decreases its rutting resistance by 66% (from 114 KPa to 39 KPa).

- The interaction plot indicates that the overall performance of WCO-modified asphalt becomes softer and more flexible with the increase in WCO dosage. Thus, the designed balanced control mixture becomes unbalanced when using WCO oil at any dosage.

- Future research is recommended to investigate the ability to use a compound modifier consisting of WCO with other waste modifiers (e.g., ground tire rubber, plastic) to reduce its negative impact on mixture rutting resistance. Such an approach would lead to a more economically balanced WCO-modified balance asphalt mixture.

- WCO enhanced mixture resistance to cracking; thus, the authors recommend further investigating the potential of using WCO as a rejuvenator for asphalt mixtures modified with Recycled Asphalt Pavement (RAP) or Recycled Asphalt Shingles (RAS).

Author Contributions

Conceptualization, H.A. and E.K.; Formal Analysis, H.A., M.B., A.A. and F.A.; Methodology, H.A., E.K., K.A.A. and M.B.; Supervision, H.A. and E.K.; Writing—Original Draft, H.A., E.K., K.A.A., M.B., A.A. and F.A.; Writing—Review and Editing, H.A., E.K., K.A.A., M.B., A.A. and F.A. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by Deanship of Scientific Research at Hashemite University (grant number 63/2020).

Data Availability Statement

All data, models, or codes supporting this study’s findings are available from the corresponding author upon reasonable request.

Acknowledgments

The authors are thankful to the Deanship of Scientific Research at Hashemite University for funding this work (Grant No. 63/2020). Also, the authors appreciate the technical help provided by Eng Mohammad Shafiq at the Hashemite University and Eng. Shaymaa Al-Dlabeeh.

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Zhou, F.; Hu, S.; Scullion, T.; Zhou, T.S.F. Development and verification of the overlay tester based fatigue cracking prediction approach. Asph. Paving Technol. 2007, 76, 627–662. [Google Scholar]

- West, R.; Rodezno, C.; Leiva, F.; Yin, F. Development of a Framework for Balanced Mix Design; NCHRP project 20-07/task 406; National Center for Asphalt Technology at Auburn University: Auburn, AL, USA, 2018. [Google Scholar]

- Tamrakar, N.K. Overview on causes of flexible pavement distresses. Bull. Nepal Geol. Soc. 2019, 36, 245–250. [Google Scholar]

- Ghuzlan, K.; Al-Khateeb, G.; Abu Damrah, A. Using oil shale ash waste as a modifier for asphalt binders. J. Mater. Cycles Waste Manag. 2013, 15, 522–529. [Google Scholar] [CrossRef]

- Mundt, D.J.; Adams, R.C.; Marano, K.M. A historical review of additives and modifiers used in paving asphalt refining processes in the United States. J. Occup. Environ. Hyg. 2009, 6, 705–713. [Google Scholar] [CrossRef] [PubMed]

- Islam, T.; Hossain, K. Development of Improved Asphalt Mixture for the City of St. John’s: A Literature Review on Asphalt Binder Additives and Modifiers. 2020. Available online: https://www.researchgate.net/publication/339945825_Development_of_Improved_Asphalt_Mixture_for_the_City_of_St_John’s_A_Literature_Review_on_Asphalt_Binder_Additives_and_Modifiers (accessed on 22 December 2023).

- Daly, W.H. NCHRP Synthesis 511: Relationship between Chemical Makeup of Binders and Engineering Performance; The National Academies Press: Washington, DC, USA, 2017. [Google Scholar] [CrossRef]

- Bahia, H.U.; Hanson, D.I.; Zeng, M.; Zhai, H.; Khatri, M.A.; Anderson, R.M. NCHRP Report 459: Characterization of Modified Asphalt Binder in Superpave Mix Design; The National Academies Press: Washington, DC, USA, 2001. [Google Scholar]

- Alsheyab, M.A.; Khedaywi, T.S. Effect of electric arc furnace dust (EAFD) on properties of asphalt cement mixture. Resour. Conserv. Recycl. 2013, 70, 38–43. [Google Scholar] [CrossRef]

- Al-Khateeb, G.G.; Khedaywi, T.S.; Irfaeya, M.F. Shear properties of waste glass-asphalt mastics. Int. J. Pavement Res. Technol. 2019, 12, 307–314. [Google Scholar] [CrossRef]

- Saeed, S.M.; Sutanto, M.H.; Napiah, M.; Usman, A.; Batari, A.; Aman, M.Y.; Yaro, N.S.A. Optimization of rubber seed oil content as bio-oil rejuvenator and total water content for cold recycled asphalt mixtures using response surface methodology. Case Stud. Constr. Mater. 2021, 15, e00561. [Google Scholar] [CrossRef]

- Yaro, N.S.A.; Bin Napiah, M.; Sutanto, M.H.; Usman, A.; Saeed, S.M. Modeling and optimization of mixing parameters using response surface methodology and characterization of palm oil clinker fine modified bitumen. Constr. Build. Mater. 2021, 298, 123849. [Google Scholar] [CrossRef]

- Al-Omari, A.A.; Khedaywi, T.S.; Khasawneh, M.A. Laboratory characterization of asphalt binders modified with waste vegetable oil using superpave specifications. Int. J. Pavement Res. Technol. 2018, 11, 68–76. [Google Scholar] [CrossRef]

- Nassar, I.M.; Kabel, K.I.; Ibrahim, I.M. Evaluation of the effect of waste polystyrene on performance of asphalt binder. ARPN J. Sci. Technol. 2012, 2, 927–935. [Google Scholar]

- Kheder, S.; Alkhedher, M.; Alshraiedeh, K.A. The effect of using activated dates seed on hot mix asphalt performance. Constr. Build. Mater. 2020, 269, 121239. [Google Scholar] [CrossRef]

- Asli, H.; Ahmadinia, E.; Zargar, M.; Karim, M.R. Investigation on physical properties of waste cooking oil—Rejuvenated bitumen binder. Constr. Build. Mater. 2012, 37, 398–405. [Google Scholar] [CrossRef]

- Gui, M.; Lee, K.; Bhatia, S. Technologies for biodiesel production from used cooking oil—A review. Energy Sustain. Dev. 2010, 14, 339–345. [Google Scholar] [CrossRef]

- Gui, M.M.; Lee, K.T.; Bhatia, S. Feasibility of edible oil vs. non-edible oil vs. waste edible oil as biodiesel feedstock. Energy 2008, 33, 1646–1653. [Google Scholar] [CrossRef]

- Talens Peiró, L.; Lombardi, L.; Villalba Méndez, G.; Gabarrell i Durany, X. Life cycle assessment (LCA) and exergetic life cycle assessment (ELCA) of the production of biodiesel from used cooking oil (UCO). Energy 2010, 35, 889–893. [Google Scholar] [CrossRef]

- Khedaywi, T.; Melhem, M. Effect of waste vegetable oil on properties of asphalt cement and asphalt concrete mixtures: An overview. Int. J. Pavement Res. Technol. 2022, 17, 280–290. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, K. Review on performance of asphalt and asphalt mixture with waste cooking oil. Materials 2023, 16, 1341. [Google Scholar] [CrossRef]

- Li, H.; Feng, Z.; Ahmed, A.T.; Yombah, M.; Cui, C.; Zhao, G.; Guo, P.; Sheng, Y. Repurposing waste oils into cleaner aged asphalt pavement materials: A critical review. J. Clean. Prod. 2022, 334, 130230. [Google Scholar] [CrossRef]

- Rahman, T.; Mohajerani, A.; Giustozzi, F. Recycling of Waste Materials for Asphalt Concrete and Bitumen: A Review. Materials 2020, 13, 1495. [Google Scholar] [CrossRef]

- Azahar, W.N.A.W.; Bujang, M.; Jaya, R.P.; Hainin, M.R.; Mohamed, A.; Ngad, N.; Jayanti, D.S. The potential of waste cooking oil as bio-asphalt for alternative binder—An overview. J. Teknol. 2016, 78, 111–116. [Google Scholar] [CrossRef]

- Ahmed, R.B.; Hossain, K. Waste cooking oil as an asphalt rejuvenator: A state-of-the-art review. Constr. Build. Mater. 2020, 230, 116985. [Google Scholar] [CrossRef]

- Elahi, Z.; Jakarni, F.M.; Muniandy, R.; Hassim, S.; Ab Razak, M.S.; Ansari, A.H.; Ben Zair, M.M. Waste cooking oil as a sustainable bio modifier for asphalt modification: A review. Sustainability 2021, 13, 11506. [Google Scholar] [CrossRef]

- Sun, Z.; Yi, J.; Huang, Y.; Feng, D.; Guo, C. Properties of asphalt binder modified by bio-oil derived from waste cooking oil. Constr. Build. Mater. 2016, 102, 496–504. [Google Scholar] [CrossRef]

- Joni, H.H.; Al-Rubaee, R.H.; Al-Zerkani, M.A. Rejuvenation of aged asphalt binder extracted from reclaimed asphalt pavement using waste vegetable and engine oils. Case Stud. Constr. Mater. 2019, 11, e00279. [Google Scholar] [CrossRef]

- Zahoor, M.; Nizamuddin, S.; Madapusi, S.; Giustozzi, F. Sustainable asphalt rejuvenation using waste cooking oil: A comprehensive review. J. Clean. Prod. 2021, 278, 123304. [Google Scholar] [CrossRef]

- Yin, F.; West, R.C. Balanced Mix Design Resource Guide; National Asphalt Pavement Association (NAPA): Washington, DC, USA, 2021. [Google Scholar]

- Bayomy, F.; Mull-Aglan, M.A.; Abdo, A.A.; Santi, M.J. Evaluation of hot mix asphalt (HMA) fracture resistance using the critical strain energy release rate, Jc. In Proceedings of the Transportation Research Board 85th Annual Meeting, Washington, DC, USA, 22–26 January 2006. [Google Scholar]

- Buttlar, W.G.; Roque, R.; Kim, N. Accurate asphalt mixture tensile strength. In Proceedings of the Materials Engineering Conference, Washington, DC, USA, 10–14 November 1996. [Google Scholar]

- AASHTO 322; Standard Method of Test for Determining the Creep Compliance and Strength of Hot Mix Asphalt (HMA) Using the Indirect Tensile Test Device. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2011.

- Molenaar AA, A.; Scarpas, A.; Liu, X.; Erkens SM, J.G. Semi-circular bending test; simple but useful. Asph. Paving Technol. Assoc. Asph. Paving Technol. 2002, 71, 794–815. [Google Scholar]

- Mitchell, M.R.; Link, R.E.; Huang, L.; Cao, K.; Zeng, M. Evaluation of semicircular bending test for determining tensile strength and stiffness modulus of asphalt mixtures. J. Test. Eval. 2009, 37, 122–128. [Google Scholar] [CrossRef]

- Hofman, R.; Oosterbaan, B.; Erkens, S.M.J.G.; Van der Kooij, J. Semi-circular bending test to assess the resistance against crack growth. In Proceedings of the 6th International Rilem Symposium, Zurich, Switzerland, 14–16 April 2003; pp. 257–263. [Google Scholar]

- West, R.C.; Copeland, A. High RAP Asphalt Pavements: Japan practice-lessons learned. Natl. Asph. Pavement Assoc. 2015, 139, 62. [Google Scholar]

- Kaseer, F.; Yin, F.; Arámbula-Mercado, E.; Martin, A.E.; Daniel, J.S.; Salari, S. Development of an index to evaluate the cracking potential of asphalt mixtures using the semi-circular bending test. Constr. Build. Mater. 2018, 167, 286–298. [Google Scholar] [CrossRef]

- West, R.C.; Winkle, C.V.; Maghsoodloo, S.; Dixon, S. Relationships between simple asphalt mixture cracking tests using ndesign specimens and fatigue cracking at fhwa’s accelerated loading facility. Road Mater. Pavement Des. 2017, 86, 579–602. [Google Scholar] [CrossRef]

- Al-Qadi, I.L.; Ozer, H.; Lambros, J.; Khatib, A.E.; Singhvi, P.; Khan, T.; Rivera-Perez, J.; Doll, B. Testing Protocols to Ensure Performance of High Asphalt binder Replacement Mixes Using RAP and RAS; Illinois Center for Transportation: Rantoul, IL, USA, 2015. [Google Scholar]

- Majidifard, H.; Jahangiri, B.; Rath, P.; Buttlar, W.G. Development of a balanced cracking index for asphalt mixtures tested in semi-circular bending with load-LLD measurements. Measurement 2021, 173, 108658. [Google Scholar] [CrossRef]

- Zhou, F.; Im, S.; Sun, L.; Scullion, T. Development of an IDEAL cracking test for asphalt mix design and QC/QA. Road Mater. Pavement Des. 2017, 86, 549–577. [Google Scholar] [CrossRef]

- Alkuime, H.; Tousif, F.; Kassem, E.; Bayomy, F.M. Review and evaluation of intermediate temperature monotonic cracking performance assessment testing standards and indicators for asphalt mixes. Constr. Build. Mater. 2020, 263, 120121. [Google Scholar] [CrossRef]

- Alkuime, H.; Kassem, E.; Al-Rousan, T.; Mujalli, R.O.; Alshraiedeh, K.A. Accounting for the effect of air voids on asphalt mix monotonic cracking testing results. J. Test. Eval. 2023, 51, 3662–3681. [Google Scholar] [CrossRef]

- Alkuime, H. Impact of testing and specimen configurations on monotonic high-temperature indirect tensile (high-IDT) rutting assessment test. Int. J. Pavement Res. Technol. 2023. [Google Scholar] [CrossRef]

- Alkuime, H.; Kassem, E.; Bayomy, F.M.; Nielsen, R.J. Development of a multi-stage semi-circle bending cyclic test to evaluate the cracking resistance of asphalt mixtures. Road Mater. Pavement Des. 2022, 23, 1–21. [Google Scholar] [CrossRef]

- Alkuime, H.; Kassem, E. Comprehensive evaluation of wheel-tracking rutting performance assessment tests. Int. J. Pavement Res. Technol. 2020, 13, 334–347. [Google Scholar] [CrossRef]

- Alkuime, H.; Kassem, E.; Bayomy, F.M.S.; Nielsen, R.J. Evaluation and development of performance-engineered specifications for monotonic loading cracking performance assessment tests and indicators. J. Test. Eval. 2021, 49, 4151–4169. [Google Scholar] [CrossRef]

- Buchanan, S. Asphalt Mix ETG: Balanced Mix Design Task Force: Update of Activities. In Proceedings of the Asphalt Mixture Expert Task Group (ETG) Meeting, Salt Lake City, UT, USA, 25–27 April 2016. [Google Scholar]

- AASHTO M323; Standard Specification for Superpave Volumetric Mix Design, AASHTO Specifications and Test Method. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2015.

- ASTM D5; ASTM, Standard Test Method for Penetration of Bituminous Materials. ASTM: West Conshohocken, PA, USA, 2005.

- ASTM D92; ASTM, Standard Test Method for Flash and Fire Points by Cleveland Open Cup Tester. ASTM: West Conshohocken, PA, USA, 2005.

- ASTM D36; ASTM, Standard Test Method for Softening Point of Bitumen (Ring-Ball Apparatus). ASTM: West Conshohocken, PA, USA, 2005.

- ASTM D113; ASTM, Standard Test Method for Ductility of Bituminous Materials. ASTM: West Conshohocken, PA, USA, 2005.

- ASTM D2042; ASTM, Standard Test Method for Solubility of Asphalt Materials in Trichloroethylene. ASTM: West Conshohocken, PA, USA, 2005.

- Boz, I.; Habbouche, J.; Diefenderfer, S.D.; Coffey, G.P.; Ozbulut, O.E.; Seitllari, A. Simple and Practical Tests for Rutting Evaluation of Asphalt Mixtures in the Balanced Mix Design Process; Virgina Transportation Research Council: Charlottesville, VA, USA, 2023. [Google Scholar]

- Dong, W.; Charmot, S. Proposed Tests for Cold Recycling Balanced Mixture Design with Measured Impact of Varying Emulsion and Cement Contents. J. Mater. Civ. Eng. 2019, 2, 1–8. [Google Scholar] [CrossRef]

- Bennert, T.; Haas, E.; Wass, E. Indirect Tensile Test (IDT) to Determine Asphalt Mixture Performance Indicators during Quality Control Testing in New Jersey. Transp. Res. Rec. J. Transp. Res. Board 2018, 2672, 394–403. [Google Scholar] [CrossRef]

- Christensen, D.W.; Bonaquist, R.; Jack, D.P. Evaluation of Triaxial Strength as a Simple Test for Asphalt Concrete Rut Resistance; The National Academies Press: Washington, DC, USA, 2000. [Google Scholar]

- Thiessen, M.; Shalaby, A.; Kavanagh, L. Strength Testing of In-Service Asphalt Pavements in Manitoba and Correlation to Rutting. Proc. Can. Tech. Asph. Assoc. 2000, 45, 203–227. [Google Scholar]

- Brown, E.R.; Kandhal, P.S.; Zhang, J. Performance Testing for Hot Mix Asphalt. National Center for Asphalt Technology, National Center for Asphalt Technology; Report No. NCAT 2001-05; NCAT: Greensboro, NC, USA, 2001. [Google Scholar]

- Anderson, R.M.; Christensen, D.W.; Bonaquist, R. Estimating the rutting potential of asphalt mixtures using superpave gyratory compaction properties and indirect tensile strength, in: Asphalt Paving Technology: Association of Asphalt Paving Technologists. In Proceedings of the Technical Sessions, Lexington, KY, USA, 11–15 October 2003; pp. 1–26. [Google Scholar]

- Zaniewski, J.P.; Srinivasan, G. Evaluation of Indirect Tensile Strength to Identify Asphalt Concrete Rutting Potential; West Virginia University: Morgantown, WV, USA, 2004; Volume 73. [Google Scholar]

- Christensen, D.W.; Bonaquist, R.; Anderson, D.A.; Gokhale, S. Transportation Research Circular E-C068: Indirect Tension Strength as a Simple Performance Test; Performance Tests for Asphalt Mixes, Transportation Research Board, of the National Academies: Washington, DC, USA, 2004; pp. 44–57. [Google Scholar]

- Pellinen, T.K.; Xiao, S. FHWA/IN/JTRP-2005/20 Report: Stiffness of Hot Mix Asphalt; INDOT Division of Research: West Lafayette, IN, USA, 2005. [Google Scholar]

- Christensen, D.W.; Bonaquist, R. Transportation Research Circular E-C124: Using the Indirect Tensile Test to Evaluate Rut Resistance in Developing Hot-Mix Asphalt Designs. In Practical Approaches to Hot-Mix Asphalt Mix Design and Production Quality Control Testing; Transportation Research Board: Washington, DC, USA, 2007. [Google Scholar]

- Khosla, N.P.; Harikrishnan, K.I. Tensile Strength-a Design and Evaluation Tool for Superpave Mixtures. 2007. Available online: https://connect.ncdot.gov/projects/research/pages/ProjDetails.aspx?ProjectID=2005-14 (accessed on 22 December 2023).

- Zhu, F. Developing Simple Lab Test to Evaluate HMA Resistance to Moisture, Rutting, Thermal Cracking Distress. Ph.D. Thesis, The University of Akron, Akron, OH, USA, 2008. [Google Scholar]

- Wen, H.; Bhusal, S. A Laboratory Study to Predict the Rutting and Fatigue Behavior of Asphalt Concrete Using the Indirect Tensile Test. J. Test. Eval. 2013, 41, 20120004. [Google Scholar] [CrossRef]

- Tran, N.T.; Takahashi, O. Evaluating the Rutting Resistance of Wearing Course Mixtures with Different Fine Aggregate Sources Using the Indirect Tensile Strength Test. J. Test. Eval. 2018, 48, 2865–2879. [Google Scholar] [CrossRef]

- Zieliński, P. Indirect Tensile Test as A Simple Method for Rut Resistance Evaluation of Asphalt Mixtures–Polish Experience. Arch. Civ. Eng. 2019, 65, 31–44. [Google Scholar] [CrossRef]

- Divandari, H. Predict of Asphalt Rutting Potential Based on IDT and Validation with ANN. J. Appl. Eng. Sci. 2019, 9, 131–138. [Google Scholar] [CrossRef]

- Yin, F.; Taylor, A.J.; Tran, N. Performance Testing for Quality Control and Acceptance of Balanced Mix Design; NCAT: Greensboro, NC, USA, 2020; Volume 30. [Google Scholar]

- Alsalihi, M. Quantification of the Role of The Effective Binder in the Performance of RAP—WMA Mixtures. Ph.D. Thesis, Temple University, Philadelphia, PA, USA, 2020. [Google Scholar]

- Nascimento, F.A.C.; Guimarães, A.C.R.; Castro, C.D. Comparative study on permanent deformation in asphalt mixtures from indirect tensile strength testing and laboratory wheel tracking. Constr. Build. Mater. 2021, 305, 124736. [Google Scholar] [CrossRef]

- Meroni, F.; Flintsch, G.W.; Habbouche, J.; Diefenderfer, B.K.; Giustozzi, F. Three-level performance evaluation of high RAP asphalt surface mixes. Constr. Build. Mater. 2021, 309, 125164. [Google Scholar] [CrossRef]

- Zieliński, P. Indirect tensile test as a simple method for rut resistance evaluation of asphalt mixtures—Polish experience. Road Mater. Pavement Des. 2022, 23, 112–128. [Google Scholar] [CrossRef]

- Diefenderfer, S.D.; Bowers, B.F. Initial Approach to Performance (Balanced) Mix Design: The Virginia Experience. Transp. Res. Board 2019, 2673, 335–345. [Google Scholar] [CrossRef]

- Boz, I.; Coffey, G.P.; Habbouche, J.; Diefenderfer, S.D.; Ozbulut, O.E. A critical review of monotonic loading tests to evaluate rutting potential of asphalt mixtures. Constr. Build. Mater. 2022, 335. [Google Scholar] [CrossRef]

- Niu, D.; Xie, X.; Zhang, Z.; Niu, Y.; Yang, Z. Influence of binary waste mixtures on road performance of asphalt and asphalt mixture. J. Clean. Prod. 2021, 298, 126842. [Google Scholar] [CrossRef]

- AASHTO T2; Standard Method of Test for Theoretical Maximum Specific Gravity (Gmm) and Density of Hot-Mix Asphalt (HMA), AASHTO Specifications and Test Method. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2012.

- AASHTO R30; Standard Practice for Mixture Conditioning of Hot Mix Asphalt (AASHTO R30), AASHTO Specifications and Test Method. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2015.

- ASTM D2726; ASTM, Standard Test Method for Bulk Specific Gravity and Density of Non-Absorptive Compacted Bituminous Mixtures. ASTM: West Conshohocken, PA, USA, 2005.

- Wang, Y.D.; Liu, J.; Liu, J. Integrating Quality Assurance in Balance Mix Designs for Durable Asphalt Mixtures: State-of-the-Art Literature Review. J. Transp. Eng. Part B Pavements 2023, 149, 03122004. [Google Scholar] [CrossRef]

- Salkind, N.J. Encyclopedia of Research Design; SAGE: Newbury Park, CA, USA, 2010. [Google Scholar]

- Yan, K.; Lan, H.; Duan, Z.; Liu, W.; You, L.; Wu, S.; Miljković, M. Mechanical performance of asphalt rejuvenated with various vegetable oils. Constr. Build. Mater. 2021, 293, 123485. [Google Scholar] [CrossRef]

- Maharaj, R.; Ramjattan-Harry, V.; Mohamed, N. Rutting and Fatigue Cracking Resistance of Waste Cooking Oil Modified Trinidad Asphaltic Materials. Sci. World J. 2015, 2015, 1–7. [Google Scholar] [CrossRef]

- Zaumanis, M.; Poulikakos, L.; Partl, M. Performance-based design of asphalt mixtures and review of key parameters. Mater. Des. 2018, 141, 185–201. [Google Scholar] [CrossRef]

- Li, Y.; Hao, P.; Zhao, C.; Ling, J.; Wu, T.; Li, D.; Liu, J.; Sun, B. Anti-rutting performance evaluation of modified asphalt binders: A review. J. Traffic Transp. Eng. 2021, 8, 339–355. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).