Abstract

This study evaluates the effectiveness of an oil-in-water emulsion formulated from water and seed and nut oils as a substitute for butter in the formulation of brioche bread. First, the selected oils were physicochemically characterized. In the brioche, animal fat was fully and partially replaced, and the effects were analyzed at the physical, chemical, and sensory levels. The new formulations exhibited increased lightness, a softer crumb, improved cohesiveness, and greater expansion compared to the control, resulting in fluffier and lighter brioches. Nutritionally, the seed and nut oil brioches showed a lower fat content and lower energy value, but higher protein and carbohydrate levels. The lipid profile was enhanced, with a higher proportion of unsaturated fatty acids, which positively impacted two heart-friendly indices and increased the vitamin E content. This improvement potentially allows the food industry to apply health claims to product labeling. Regarding sensory analysis, in all cases, the reformulated brioches scored higher than the control sample in terms of external appearance, although there remained a preference for the flavor and aroma of the traditional version, which could be mitigated by adding flavor compounds such as diacetyl. This study differs from previous research by using a seed and nut oil emulsion instead of non-emulsified oils, improving the texture and stability of brioche bread, an achievement not consistently reported in prior studies. Additionally, it emphasizes sustainability by offering a plant-based alternative that addresses the growing consumer demand for vegan and eco-friendly products while providing enhanced nutritional benefits that support potential health claims.

1. Introduction

The production of healthier bakery products has advanced significantly in recent years, driven by a growing consumer demand for more nutritious options. However, while the commercialization of value-added foods has flourished in other sectors, it has been less prevalent in the bakery industry, which is often associated with products high in fat and low in nutritional value. In this context, brioche, a bread of French origin known for its high butter content, presents a unique challenge in the field of functional foods. Butter, an essential ingredient, imparts the characteristic texture and flavor that define this bread, but it is also associated with an increasing risk of developing cardiovascular diseases [1]. To address this issue, previous studies have explored the partial or total substitution of butter with healthier alternatives, aiming to preserve the sensory properties of the final product while improving its nutritional profile [2].

One promising alternative is the use of emulsified vegetable oils, which not only provide a more favorable lipid profile but also help reduce the product’s total fat content [3]. Emulsions based on almond, walnut, or hazelnut oils have been successfully used to produce baked goods with the objective of improving the fatty acid profile without compromising the texture or flavor of the bread [4]. Additionally, it has been demonstrated that the use of oil emulsions enables a reduction in the total fat content of bakery products [5].

Vegetable oils are rich in bioactive compounds, such as polyphenols (natural antioxidants found in plants), tocopherols (a type of vitamin E that helps to protect cells from damage), and phytosterols (plant compounds that can help to lower cholesterol levels), which not only improve the lipid profile of the product but also have antioxidant and anti-inflammatory benefits, which could increase oxidative stability and thus potentially extend the shelf life of the bread [6]. These bioactive compounds may also help improve the nutritional value of brioche bread, providing additional health benefits, such as lowering LDL cholesterol and enhancing endothelial function [7].

Butter, due to its high content of saturated fats, has been linked to diverse health risks, particularly concerning cardiovascular health. Saturated fats are known to elevate LDL cholesterol levels, commonly known as “bad” cholesterol, increasing the risk of heart disease and stroke [8]. Replacing saturated fats with healthier alternatives, such as the unsaturated fats found in plant oils, has been shown to improve lipid profiles and may help reduce the risk of cardiovascular diseases [9]. Additionally, butter is calorie-dense, contributing to weight gain when consumed in excess, which further increases the risk of obesity and type 2 diabetes [10].

While butter contains some beneficial nutrients, such as vitamin A and vitamin K2, its overall nutrient profile is less favorable compared to plant-based oils, which provide unsaturated fats, antioxidants, and other beneficial compounds. These oils, such as olive oil and canola oil, are considered healthier fats that promote better heart health and may support long-term wellness [11,12]. Thus, while butter can have a place in a balanced diet, it should be consumed in moderation due to its saturated fat content and its association with long-term health risks.

Moreover, seed and nut oils emerge as promising alternatives, not only for their superior nutritional profile but also for their potential to mitigate the environmental impact associated with food production. Unlike dairy products, vegetable oils are derived from renewable sources and generally require fewer water and land resources for production. They also have a substantially lower environmental foodprint than dairy products such as milk or butter throughout their life cycle [13]. Butter production has significant environmental impacts, involving large-scale water usage (approximately 5 L per kilogram) and greenhouse gas emissions (especially methane from dairy cows). According to the Food and Agriculture Organization (FAO), livestock farming accounts for about 14.5% of global greenhouse gas emissions, with the dairy industry being a substantial part of that [14]. Butter production is also associated with deforestation and land degradation, as land is cleared to grow feed crops for dairy cattle [15]. In contrast, oils from seeds and nuts, such as sunflower oil, canola oil, and olive oil, typically have a lower carbon footprint and require fewer natural resources. Other studies show that vegetable oils not only contribute less to greenhouse gas emissions but also have smaller demands in terms of water usage and land occupation compared to butter and other dairy products [16]. Shifting from butter to plant-based oils can thus play a critical role in reducing the environmental footprint of the food industry, aligning with growing consumer and industry demand for more sustainable food production options. In addition, two seeds (pumpkin and melon) were selected because they are considered waste by industries dedicated to fruit and vegetable processing.

Recent studies on this product have evaluated the incorporation of oils into brioche bread, showing that it is possible to maintain the texture and volume of the product while increasing the unsaturated fatty acid content [17]. Other authors have succeeded in increasing the volume, crumb, and aromatic profile of brioche [18]. It has also been reported that not only does the use of nut-based emulsions enhance the lipid profile, but it can also add bioactive compounds, such as tocopherols and phytoesterols, which are beneficial for cardiovascular health.

Due to the importance of seeking healthier and sustainable alternatives to butter, the aim of this study was to evaluate the partial and total replacement of butter by emulsions based on vegetable oils in the traditional brioche recipe, analyzing the effects on the physical, nutritional, lipid, and sensory parameters. The novelty of this study lies in its innovative approach to replacing traditional animal fat (butter) in brioche bread with a plant-based oil-in-water emulsion derived from seed and nut oils. While previous research has explored fat substitutions in baked goods, this study specifically targets brioche, a rich, buttery bread, which has not been broadly explored. Additionally, it highlights the environmental sustainability of these oils, since plant-based oils typically have a lower environmental footprint than animal fats. Unlike conventional studies, which typically focus on simple substitutions, this research also considers how these changes impact both the sensory experience and consumer acceptance of the product, offering a comprehensive analysis of fat replacement in baking. The findings underline the potential of using such emulsions in industrial-scale food production, presenting a practical solution for manufacturers seeking to reduce the saturated fat content while improving product quality and aligning with growing consumer demand for healthier and more sustainable food options.

2. Material and Methods

2.1. Raw Material

Traditional brioche bread products were purchased at a local supermarket (Albacete, Spain). The emulsifying agents used to prepare the emulsions were obtained from Sosa S.L., a company based in Barcelona, Spain. The emulsifying agents were guar gum (E412), a polysaccharide derived from the seed of the guar plant (Cyamopsis tetragonoloba), consisting of galactose and mannose units connected by β-(1 → 4) glycosidic bonds and inulin, which is a fructan composed of fructose molecules linked by β-(2 → 1) bonds, commercially known as Frutafit® and Orafti®.

Nuts (pistachio, almond, and walnut) and seeds (chia, poppy, pumpkin, and melon) were used to obtain the oils. The nuts and chia and poppy seeds were provided by local suppliers, while the pumpkin and melon seeds were provided by a convenience food industry (Vicente Peris S.A., Albuixech, Spain). The selection of nuts and seeds was based on various criteria, including the nutritional profile, price, availability, and sustainability. However, while the nutritional benefits and sustainability of these oils were key factors, the primary reason for their selection was driven by funding priorities, ensuring that the research aligns with the financial and institutional support provided.

2.2. Oil Extraction

Before extraction, the seeds and nuts were ground for two 20 s cycles at 10,000 rpm using a blade mill (RETSCH model GM 20, Verder Scientific GMbH & Co, KG., Haan, Germany). The ground materials were placed in cloth filters in 200 g fractions for pressing.

The oils were extracted at the pilot plant of the Higher Technical School of Agricultural and Forestry Engineering and Biotechnology in Albacete (Spain). Cold pressing was applied using a hydraulic press (MECAMAQ model DEVF, El Palau D’Anglesola, Spain) to preserve all the nutrients. In each pressing process, 1 kg of ground raw material was pressed at a pressure of 200 bar for 10 min.

After extraction, the oils were centrifuged for 5 min with a CENTRONIC-BL (J.P. Selecta, Abrera, Spain). The oils were then refrigerated and stored in opaque glass bottles until the analyses and the production of the emulsions.

2.3. Emulsion and Brioche Formulation

The first step in reformulating the product was to develop the emulsion to replace the butter. For this purpose, 130 g of water and 60 g of oil were combined with 4 g of guar gum and 6 g of inulin. All these ingredients were placed in a measuring cup and mixed for 3 min using an electric blender. The emulsions were stored in an airtight translucent polypropylene container for 24 h.

A traditional brioche bread was prepared along with 14 new formulations in which butter was partially (50%) and totally substituted by emulsified seed and nut oils.

The traditional recipe was composed of 500 g of strong flour, 200 g of unsalted butter, 100 g of sugar, 200 g of egg, 50 mL of milk, 18 g of fresh yeast, and 2 g of salt. The production method followed a slightly modified version of that described in [19]. For the control sample, the liquid ingredients were mixed with the yeast, while the solid ingredients were mixed separately. The mixture was kneaded for 20 min using a KitchenAid model 5K45SSEWH (Whirpool Corporation, Benton Harbor, MI, USA). Butter, at room temperature, was added in three batches halfway through the kneading process. For the reformulated samples, the emulsion was added to the solid ingredients and kneaded in the same way.

The dough was allowed to rest and ferment for one hour at 30 °C. It was then divided into 80-g portions and left to ferment for another hour. The dough portions were brushed with eggs, as is typical, and baked at 180 °C using a conventional oven (BOSCH OVEN MODEL HBA574ES3, Gerlingen, Germany). Samples intended for sensory evaluation were baked for 12 min, vacuum-packed, and frozen until evaluation. Samples for other analyses were baked for 15 min, and tests were conducted the same day. Figure 1 shows the external appearance of the control brioche and the reformulated samples.

Figure 1.

An external view of the reformulated brioches used for this study.

2.4. Determination of Oil Quality

Three quality parameters of the oil were measured: oxidative stability, color, and viscosity.

Oxidative stability is used to determine the shelf life of oils based on forced oxidation under a continuous air stream of 10 L/h at a temperature of 101.6 °C. A sample of 3 g of oil was used to determine the conductivity of the molecules formed from the oxidation of fatty acids. The equipment used was a Rancimat 743 (Metrohm AG, Herusau, Swizerland).

Additionally, although it is not a direct determinant of oil quality, color is a parameter that is relevant when reformulating foodstuffs as the pigments present in the oil can influence the final appearance of the product. The CIELab system was used for color measurement with a 2° observation angle and a D65 illuminant in a V-530-Jasco spectrophotometer (Jasco Corporation, Tokyo, Japan), with the oil placed in quartz cuvettes.

Finally, viscosity is a physicochemical parameter that indicates the oils’ resistance to flow. To measure this parameter, a rotational viscosimeter, the Visco Basic Plus model (Anton Paar GmbH, Graz, Austria), was used with an LCP spindle at a rotation speed of 10 rpm, with an oil volume of 18 mL, at a temperature of 25 °C.

2.5. The Physical Parameters of the Brioche Samples

The caliber of the samples was measured, assessing the height and width of the brioche breads at three stages of the production process: before fermentation, after fermentation, and after baking. For each formulation, four randomly selected samples were evaluated.

Color was measured using a Minolta CR-200 colorimeter (Minolta Camera Co., Ltd., Osaka, Japan) with a D65 illuminant. For each formulation, four dough samples and four cooked brioche samples were randomly selected. Brioches were sliced horizontally to ensure consistent measurements, and color was measured at four random zones of the internal part. Measuring the internal part of the bread rather than the external crust is preferable for analyzing color because the internal part of the bread is less influenced by the variable factors that affect crust color, such as the Maillard reaction and caramelization, which primarily affect the outer layer during baking. Since the internal color remains more consistent across different samples, it allows for a more reliable comparison of the bread’s raw characteristics, particularly when evaluating changes in the dough itself during processing. The CIELab color coordinates L* (relative lightness), a* (red-green component), and b* (yellow-blue component) were calculated using tristimulus values [20].

To measure the texture of the doughs, a texture profile analysis (TPA) was performed using a TA-XT Plus texture analyzer (Stable Micro Systems, Godalming, UK) equipped with a 50 mm diameter probe at 3.3 mm/s and a 30 kg load cell, compressing the product to 60% of its original height. For each formulation, four randomly selected whole brioches were analyzed. The samples were placed horizontally and subjected to two consecutive compression cycles to simulate the chewing process. The parameters measured were hardness, cohesiveness, chewiness, and elasticity.

2.6. Proximate Composition

The analyzed parameters included moisture content, nitrogen, carbohydrates, crude fiber, total fat, and energy value.

Moisture content was determined by drying the sample in an oven at 105 °C for 24 h until a constant weight was achieved. Ash content was measured by incinerating the samples in a muffle stove at 550 °C until reaching a constant weight [21]. Protein content was determined using the Kjeldahl method, multiplying the nitrogen content by a conversion factor of 6.25 [22].

Fat content was gravimetrically assessed using the filter bag technique with an Ankom XT10 extraction system [23]. Crude fiber content was analyzed using the Weende technique adapted for filter bags that was described by ANKOM [22], and the organic residue remaining after digestion with sulfuric acid and sodium hydroxide solutions was determined with an Ankom 220 analyzer.

Total carbohydrate content was calculated by subtracting the protein, fat, water, and ash contents from the total sample weight [24]. Finally, the total energy value was estimated using Atwater factors, namely 9 kcal/g for fat and 4 kcal/g for both protein and carbohydrates, based on 100 g of sample [25].

2.7. Profile of Fatty Acids, Vitamin E, and Thiobarbutic Acid (TBA)

Fatty acid methyl esters (FAMEs) were obtained by cold transmethylation with methanolic potassium hydroxide, and 2 mL of n-hexane was added to 0.02 g of oil previously extracted from the brioche bread samples using Soxhlet extraction with petroleum ether for three hours. Then, 200 μL of methanolic potassium hydroxide solution (2 mol L−1) was added and mixed vigorously [26]. The supernatant was then transferred to a glass vial and analyzed by gas chromatography using a Shimadzu GC-2010 Plus gas chromatograph equipped with a split-splitless injector, a flame ionization detector, and an automatic sampler (AOC-20i, Shimadzu, Tokyo, Japan).

A CPSil 88 fused silica capillary column (Varian, Middelburg, the Netherlands; 50 m × 0.25 mm inner diameter and 0.20 μm film thickness) was used, with helium as the carrier gas (120 kPa). The program used was as follows: 5 min at 140 °C, followed by an increase of 5 °C per minute from 140 °C to 220 °C, and 220 °C for 15 min. The injector and detector temperatures were set at 250 °C and 270 °C, respectively, with a split ratio of 1:50 and an injection volume of 1 μL. Each FAME was identified by direct comparison with a standard mixture (FAME 37, Supelco, Bellefonte, PA, USA). The analyses were performed in triplicate for each formulation, and the results are expressed as the relative percentage of each fatty acid based on the relative peak areas.

Vitamin E was determined in fat extracted from the food matrix following the same procedure used for the determination of the fatty acid profile. An HPLC device (Jasco, Tokyo, Japan) was used, equipped with an automated injector (AS-2057), a PU-2089, and a diode array detector (DAD) with a multi-wavelength MD-2018 coupled with an FP-2020 fluorescence detector. Components were identified by comparing them with commercial standards [27].

Lipid oxidation was evaluated based on changes in thiobarbituric acid reactive substances (TBAR) during cold storage. The resulting color was measured at 532 nm using a UV/VIS spectrophotometer (Perkin-Elmer Lambda 15, Boston, MA, USA). Results are expressed as mg of malondialdehyde/kg of sample [28].

2.8. Sensory Evaluation

Consumer acceptability was evaluated with a panel comprising 101 participants from the University of Castilla-La Mancha, including professors, administrative staff, technical staff, and students aged 18 to 65. This diverse group provided a broader range of preferences compared to panels composed solely of students. However, this sample may still not fully represent the general population, as university staff and faculty often have different dietary habits and a higher level of health awareness compared to the broader public. Additionally, the group may not reflect the socioeconomic and cultural diversity found in the wider consumer market, which can influence food choices and sensory perceptions [29]. Thus, while this panel offers valuable insights, its findings may not be entirely generalizable to other population groups.

A test to measure the level of satisfaction to determine consumer acceptance or rejection was conducted. The participants responded according to their own personal criteria using a verbal hedonic scale. A 9-point scale was used (−4: I dislike it immensely; 0: I neither like nor dislike it; +4: I like it immensely). The samples were coded with random numbers to ensure unbiased evaluation, and the parameters evaluated were external appearance, aroma, flavor, and texture. The consumers were first informed on the allergens present, namely egg, gluten, and nuts.

The consumer judges evaluated a total of 14 brioche samples over two sessions; in the first session, they compared traditional brioche bread with samples made using nut oils, while in the second, they compared traditional brioche bread with samples made with seed oils. For external appearance, whole baked breads were evaluated as they would appear in supermarkets. For aroma, flavor, and texture, the samples were cut into portions weighing 17.75 g. To ensure an accurate sensory evaluation of the bread, the portions were cut 30 min before analysis. These portions were carefully vacuum sealed at 50% capacity, which helped preserve both the aroma and freshness of the bread, preventing the loss of volatile compounds and avoiding the samples from being squashed or damaged. Additionally, the samples were organized into batches of 10 portions, which is the exact number of consumers that could participate in each round of evaluation. This allowed for optimal control over the analysis conditions, ensuring that each consumer received a fresh and well-preserved portion to evaluate both the aroma and flavor without alterations from handling or loss of volatile compounds.

2.9. Statistical Analysis

All data are presented as means ± standard deviations. Statistical differences were analyzed using analysis of variance (ANOVA) with a significance level of 5% together with Tukey’s test (p < 0.05). All statistical analyses were conducted using SPSS (IBM, Armonk, NY, USA), Version 29.0 for Mac OS.

3. Results and Discussion

3.1. Oil Quality

Table 1 shows the results obtained for the oil parameters analyzed. Chia seeds, well known for their fiber content, also have a significant oil percentage (25–38%) [30]. In this study, the oil yield from chia seeds was 20.07 ± 0.81%, slightly lower than previously reported yields of 28% using a screw press [30] and 23.86% using other methods [31]. These differences can be attributed to the type of press used, since crew presses generate heat that increases yield but can compromise oil quality.

Table 1.

The quality parameters of the oils used to replace butter in the brioche breads.

For pumpkin seeds, oil yield depends heavily on the variety, typically ranging from 28 to 50%. In this study, the yield was significantly lower than those previously reported in the literature, where yields around 30.7% (screw press) and up to 42% (solvent extraction) [31,32] can be found. Melon seeds are another oil source, with lipid levels between 25% and 30.5% [33]. The oil yield obtained in this study was 16.07 ± 0.92%, which is lower than the 26.23% yield obtained when the screw press was used [34], but higher than the 6.80% obtained using a hydraulic press. This higher yield may be attributed to the use of unpeeled seeds.

Nut oils generally have higher extraction yields compared to seed oils. Yields of 31.2% for almond oil, 56% for walnut oil, and 28.6% for pistachio oil have previously been reported using a hydraulic press [34]. The extraction yield obtained in this study closely matched these values since similar extraction parameters and nut varieties were used. Hydraulic press extraction produced sufficiently high oil yields to justify its use in oil production, except for pumpkin seed oil, where alternative methods like screw press, supercritical fluid, or solvent extraction may be used to optimize extraction.

Regarding oxidative stability, significant differences were found across the oils, with pumpkin seed oil showing the highest stability and chia seed oil the lowest. Chia seed oil’s low oxidative stability is attributed to its high content of polyunsaturated fatty acids, which, despite the presence of antioxidant compounds, make it particularly susceptible to oxidation [30].

Among nuts, almond and pistachio oils exhibited similar stability values and were more stable than the seed oils. On the other hand, walnut oil’s stability was like that of poppy oil, consistent with other studies reporting that walnut oil’s stability ranges from 3.9 to 7.8 h depending on the crop type [35]. These differences arise from lipid composition since almonds and pistachios contain higher proportions of oleic acid (ranges of 57.5–78.7% and 54.2–81.17%, respectively) [36,37]. The presence of a single cis-double bond in oleic acid makes this fatty acid less reactive in the presence of oxygen compared to polyunsaturated fatty acids that contain multiple double bonds [38]. Thus, oils with a higher oleic acid content tend to have longer shelf lives under storage and cooking conditions and would be more suitable for use in heat-exposed products like brioche bread.

Additionally, walnut oil is a source of polyunsaturated fatty acids [39], specifically linoleic acid (53.70–63.19%), thus presenting similar stability values to poppy oil. The oxidative stability of oils may impact the stability of the products to be developed, especially those that may be subjected to heat treatment.

Viscosity is related to the processing and quality of oils, the level of saturation, and the triglyceride composition of the vegetable oil [34]. Chia seed and nut oils showed lower values with no significant differences, while pumpkin seed oil was the most viscous.

In summary, the oil yields from pumpkin, chia, and melon seeds were lower than the reported values found in the literature primarily due to the type of press used. In this sense, to obtain higher yields, the use of screw presses or other alternative methods such as supercritical fluids or solvent extraction should be considered. Pumpkin seed oil showed the highest stability, while chia seed oil, due to its high polyunsaturated fatty acid content, had the lowest stability. Nut oils (almond and pistachio) showed higher stability values than seed oils. Pumpkin seed oil was the most viscous, while chia seed and nut oils had similar lower values. All of these characteristics may influence their applications in food products.

3.2. Physical Determinations of Brioche Bread

Table 2 shows the results of the behavior of the brioche breads reformulated with emulsified vegetable oils. It presents the width and height measurements at three critical stages of the production process: before and after fermentation and after baking.

Table 2.

Calibers of the brioche breads at three different stages of the production process.

The control sample exhibited moderate expansion during fermentation but contracted after baking. In contrast, the reformulated samples showed greater expansion during both fermentation and baking, particularly when butter was completely replaced. Both the level of substitution and the type of oil used influenced these changes in the physical dimensions. For instance, melon and pumpkin seed oils yielded better results compared to the chia seed oil.

In gluten-free baking, the use of emulsions combined with gelling agents can significantly improve the dough volume and texture. These agents, such as xanthan gum or guar gum, mimic the structural properties of gluten, enhancing the dough’s ability to trap air and improving its overall consistency. Unlike traditional baking, where liquid oils typically result in denser loaves, these gelling agents allow emulsions to counteract the flattening effects of liquid fats, resulting in bread with better volume and texture. This innovation is especially valuable for developing gluten-free breads, where structure and crumb quality are often difficult to achieve.

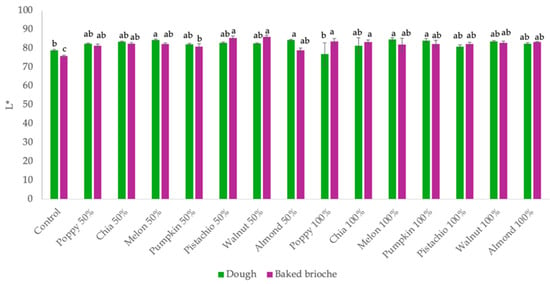

During baking, chemical reactions determine the color of breads and are influenced by the ingredients used in their formulations. Both the color of the dough and the brioche after baking were evaluated to determine pigments’ degradation during baking. In the case of lightness, the use of oil-in-water emulsions with seeds and nuts in the reformulation of functional products has typically been found to darken the samples compared to the traditional product [40,41,42]. The differences in product formulation could explain the observed discrepancy in lightness. While fat replacement in meat products may behave differently due to protein content and fat interaction, baked goods such as bread respond differently due to moisture content and starch interactions during baking. On the other hand, the Maillard reaction behaves differently in baked goods compared to meat products. In meat products, the Maillard reaction often occurs more readily due to the higher protein content, which provides more amino acids that react with reducing sugars, resulting in more intense browning [43]. Meat generally has a lower moisture content compared to bakery products, which also contributes to faster browning. On the other hand, baked goods such as bread have a higher moisture content, and starch is the main macronutrient. These differences in composition influence the degree of browning. In bread, starch gelatinization and water retention during baking can reduce the occurrence of intense Maillard browning, leading to lighter products. In addition, other reactions such as caramelization may also play a role, although usually a less pronounced role than the Maillard reaction in bread.

In the present case, as can be observed in Figure 2, the lightness values are higher in the reformulated samples compared to the control. These results are in agreement with those found in a study on reformulated bread with chia seed mucilage, where the substitution of margarine with such mucilage generated lighter-colored products [44]. Higher lightness values in reformulated products have been associated with a higher moisture content.

Figure 2.

The lightness (L*) of the doughs and brioche breads baked with the total and partial substitution of butter by vegetable oils. Significant differences between samples are indicated by different letters: the letters in the green columns refer to the dough, while the letters in the purple columns refer to the baked brioche. Different letters within each column indicate statistically significant differences (p < 0.05).

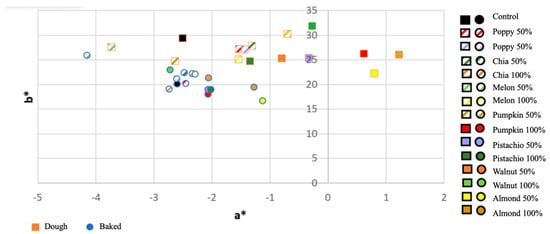

Figure 3 shows the results for parameters a* and b*. The doughs present much more dispersed values compared to the baked breads, whose values, in most cases, are similar to those of the traditional sample. The differences existing in the doughs can be related to the results for the colors of the oils due to the presence of pigments such as carotenes, chlorophylls, and xanthophylls. These pigments are responsible for the yellow, green, and orange hues often observed in oils from sources such as pumpkin [45]. During baking, the Maillard reaction influences the color parameters a* and b*, contributing to the golden-brown tone characteristic of baked products, but it varies depending on factors such as the temperature, pH, type of sugars, and amino acids present [46].

Figure 3.

Parameters a* and b* analyzed in the doughs and cooked brioches formulated with vegetable oil emulsions. The a* parameter represents the green–red color axis, and the b* parameter represents the blue–yellow color axis.

Table 3 summarizes the results obtained for the hardness, cohesiveness, elasticity, and chewiness of the reformulated samples. The inclusion of new ingredients often generates changes in the texture of the reformulated foods compared to the control sample. Specifically, the differences that occur when oils are incorporated may be due to various factors related to the structure of the product, the chemical composition of the fats, or the interaction between the ingredients.

Table 3.

Texture parameters in brioche breads reformulated with partial (50%) and total substitution (100%) of butter by seed and nut oils.

As occurred in a study on puff pastry reformulated using oleogels, the control sample presented higher values since butter forms a barrier around gluten proteins, preventing gluten cross-linking [47,48]. The decrease in hardness is directly related to the percentage of fat substitution, since it is proportional, as can be observed in the results.

As regards elasticity, it has been reported that the use of emulsified oils in baked products helps to improve this parameter since they provide greater hydration and gluten formation [49].

Moreover, the reformulated samples present slightly higher cohesiveness values than the control, a result not observed with the meat products in the previous chapter. Previous studies observed that hardness decreased but cohesiveness increased in cakes reformulated with oleogels [2], because the oleogels generated greater volumes by forming wider air channels, which may be related to the results obtained for caliber.

However, the higher unsaturated fatty acid content and better moisture retention may explain the decreased hardness and increased cohesiveness when oils are used to replace butter in baked products [50].

Chewiness is partly associated with hardness, and thus, the samples with the lowest values are those with larger replacement percentages.

In conclusion, the use of emulsions in bread reformulation significantly improved expansion, volume, and cohesiveness, resulting in a more pleasant and improved texture. The reformulated breads also exhibited higher lightness, suggesting better moisture retention, ultimately improving the overall quality of the product. However, some drawbacks should be considered, such as the pigments in the oils, which could affect the final color of the bread and potentially negatively influence consumer perception.

3.3. Nutritional Composition

Table 4 shows the results of the nutritional composition of the reformulated brioche breads. In general terms, the chemical composition is consistent with the results reported in other studies on similar products [51,52], where the fat content and energy value of the new samples decreased. However, the reduction was smaller than that in this study, as the maximum substitution in the reformulations in the cited products was 15%.

Table 4.

The nutritional compositions of the different brioche samples reformulated with seed and nut oils.

The moisture of the reformulated brioche breads also differed significantly from that of the control sample; the higher the level of replacement of oil-in-water emulsions by butter, the more the moisture content increased. This finding has been reported in other studies using products such as chia seed mucilage to replace fat [45] and oleogels to reduce fat in bread [18].

Total fat intake should constitute 20–25% of a person’s daily caloric intake [53], and it is recommended that saturated fats be limited to less than 10% of the total energy. In this case, the reformulated brioches, particularly those with 100% oil replacement, show a drastic reduction of up to 89.63% in fat content. This reduction is beneficial as it brings the products closer to the target recommended by these guidelines. Furthermore, these brioches could be labeled as low fat according to Regulation (EC) No 1924/2006, which requires at least a 30% reduction in fat to make such claims.

On the other hand, the protein content increased compared to the control sample, and the higher the level, the more the substitution rate increased. As seen in other studies involving vegetable oil emulsions, the use of an inulin- and guar gum-based emulsion helped improve the protein content of all the reformulated products because these substances can affect the protein matrix, integrating proteins and providing greater stability [41,42]. This is consistent with the recommendations of the Dietary Guidelines for Americans (2020–2025), which emphasize the importance of proteins as part of a balanced diet, especially to maintain muscle mass and support metabolic functions. Similarly, the increased carbohydrate content, although linked to the use of emulsifying agents such as inulin and guar gum, reflects a balance with the higher fiber intake recommended by the dietary guidelines to support digestive health [54].

The reformulation of brioche breads with seed and nut oils demonstrates significant improvements in nutritional composition, aligning with global dietary guidelines, especially regarding the fat content. This brings the product closer to the recommended fat intake guidelines set by the WHO and the EU. Furthermore, the reformulated breads exhibited higher protein and carbohydrate contents, reflecting the positive effects of emulsifiers such as inulin and guar gum in integrating a protein matrix. These changes contribute to a more health-conscious product with greater nutritional benefits, supporting public health goals and offering a potential alternative for healthier bakery options, especially in populations with regular bread consumption. However, there are some considerations to be taken into account. The higher carbohydrate content, due to the use of emulsifiers, may not be suitable for individuals following low-carb or ketogenic diets. In addition, while reducing fat is beneficial for reducing saturated fat intake, changing macronutrient ratios could alter the product’s appeal for those seeking higher fat or lower carbohydrate options.

3.4. Lipid Profile, Vitamin E, and TBA

The fatty acid compositions of the brioche bread samples reformulated with seed and nut oils are shown in Table 5, while the total sums of fatty acids, the health-promoting indices, vitamin E, and TBA are shown in Table 6.

Table 5.

Lipid profiles of brioche breads reformulated with emulsified seed and nut oils.

Table 6.

Total sums of fatty acids, atherogenic and thrombogenic indices, vitamin E, and TBA.

Fats have a significant effect on the nutritional value of foods for consumption since fats have a high caloric value compared with other nutrients, such as proteins or carbohydrates. For decades, the World Health Organization (WHO) has advocated limiting fat intake to 20–35% of daily energy, a recommended level exceeded in most developed countries, resulting in a growing number of individuals with overweight and obesity. Moreover, not only is the total fat content important, but also the type, since this also has a notable health impact [55,56].

Due to their crystallizing properties and structuring effect, many of the fats used in bakery and confectionery products contain large amounts of saturated and trans fatty acids, which negatively impact cholesterol and are directly related to the risk of cardiovascular diseases [57].

The reformulation of brioche bread complies with the guidelines established by various governmental entities by significantly reducing the palmitic and stearic acid content and, therefore, the saturated fatty acid content. In this context, the use of vegetable gels as substitutes for animal fat in a range of baked products has been shown to successfully reduce the total fat content by 19 and 46% and the total saturated fatty acid content by 33 and 87% [58].

The differences in fatty acid content are primarily due to the type of oil used. In summary, it can be observed that all the reformulated samples present higher values of unsaturated fatty acid content. Specifically, the highest oleic acid levels are found in the samples with 100% replacement of almond and pistachio oils, while the samples with melon seed and poppy seed oils stand out for their linoleic acid content, and the samples with 100% chia seed oil contain significant amounts of linolenic acid.

In this case, as with the total fat content, it would be possible to include health claims on the packaging, such as, for example, “Replacing saturated fats with unsaturated fats in diet helps maintain normal levels of blood cholesterol” or “Omega-3 fatty acids, such as linolenic acid, contribute to normal health function”.

As regards oxidative stability, there are significant differences between samples. Baked products with a high fat content are prone to oxidative reactions, which compromise quality and functional properties and reduce shelf life [59]. In general terms, it can be observed that the reformulation in which 50% of the butter is replaced by vegetable oils, especially seed oils, makes the brioche breads less susceptible to oxidation compared to the traditional sample, likely due to a better balance between saturated and unsaturated fats [60]. By increasing the percentage of vegetable oils, the samples present higher TBA levels than the control sample.

Two health-related factors were calculated: the thrombogenic index (TI) and the atherogenic index (AI). The atherogenic index is reduced by 95.04% in the 100% almond and chia seed oil samples, and the thrombogenic index is reduced by 91.17% in the case of 100% walnut and almond oils. The atherogenic index is related to the risk of cardiovascular disease and is conditioned by the saturated and monounsaturated fatty acids in the foods consumed [61], while the thrombogenic index determines the potential of the fatty acids in the diet to promote coagulation in blood vessels, increasing the risk of heart attacks and strokes [61]. In both cases, to keep these levels low, sufficient intake of products with monounsaturated and polyunsaturated fatty acid, such as nuts and seeds, is recommended [62,63].

The vitamin E results vary depending on two factors, the replacement level and the type of oil, although the most notable finding is that, in all cases, the reformulated samples present higher values. This vitamin is naturally present in butter, but our results show that combining other seeds and nuts helps to enhance the vitamin E content. The highest levels are observed in the 50% replacements with chia, melon, and pumpkin seed oils as well as the 100% almond and pistachio oil replacements. In addition to its positive health effects, vitamin E is also effective, particularly when encapsulated, in extending the shelf lives of bakery products [64].

The reformulation of brioche breads with vegetable oils results in a healthier product by reducing saturated fatty acids and increasing unsaturated fatty acids, which has a positive impact on cholesterol levels and supports cardiovascular health. Furthermore, the use of vegetable oils instead of butter leads to an increase in vitamin E content, which improves the antioxidant properties of the product. These improvements align with the growing consumer demand for healthier bakery options. Although the reformulated products show better oxidative stability compared to the traditional sample, certain oils can still lead to higher TBA values, which could affect the shelf life if not carefully managed.

3.5. Sensory Analysis

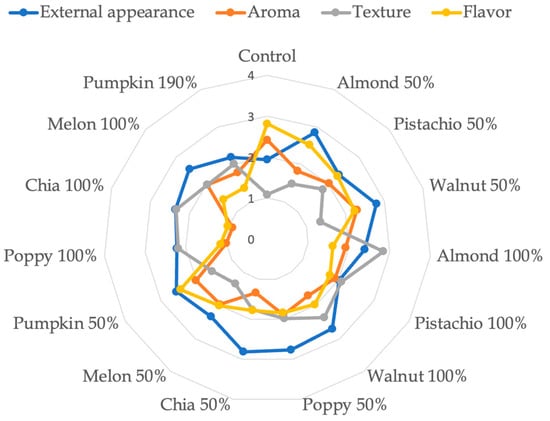

Fat is a key ingredient in baked products since it affects texture, palatability, volume, color, and flavor [48], especially in products such as brioche, where butter is the characteristic ingredient. The acceptability test was chosen to determine whether, despite the differences detected in the other parameters, the new formulations were accepted by consumers. The results are shown in Figure 4.

Figure 4.

The results of the sensory evaluation of the samples of brioche bread reformulated with seeds and nuts.

Differences were found in the evaluation of external appearance. The reformulated samples were rated higher compared to the traditional brioche, a finding directly linked to the caliber results, since the inclusion of emulsified oils improved both the height and width. The same trend was observed when texture was analyzed. Based on the texture profile analysis results, it can be inferred that consumers prefer this type of bread to have softer and spongier textures.

Aroma and flavor are critical parameters in this type of product, where an intense buttery smell is expected, which is reflected in the scores obtained. Reformulation affected these parameters, with the control sample being the best rated. In baked goods, such as cookies, waffles, or cakes, substituting butter with other fats at levels above 25% has been found to alter the perception of a buttery aroma [65]. To enhance this aroma, brioches could be enriched with diacetyl [66]. Other studies have suggested that lower scores in samples reformulated with emulsions may be due to the formation of off-flavors and off-aromas resulting from Maillard reactions [67].

The same applies to flavor, where butter provides these types of bread with a unique taste, leading consumers to rate the traditional sample higher. Additionally, the type of oil affects the acceptability of flavor and aroma, and thus, when chia and poppy seed oils are used, consumers tend to give lower ratings. Both chia and poppy seeds are known for their characteristic flavors, which can range from nutty to slightly earthy or even bitter, and they are strongly linked to their lipidic profiles (Omega-3). These flavors can interfere with the typical sweet and delicate profile of brioche bread. Studies have shown that consumers often prefer more neutral oils as they do not overpower the other ingredients [41].

The substitution of butter with emulsified oils in brioche led to differences in consumer acceptability, particularly in terms of flavor and aroma. Traditional brioche made with butter was preferred due to its characteristic buttery taste, which is essential to the typical sensory experience of this product. The type of oil used also significantly impacted flavor acceptability, with chia and poppy seed oils receiving lower ratings. These oils, known for their distinct, nutty, earthy, or slightly bitter flavors, can interfere with the delicate and sweet flavor profile of brioche. Consumers tend to favor more neutral oils, which do not overpower the bread’s traditional taste.

This study shows that emulsified oils can improve the appearance and texture of brioche but fail to replicate its characteristic butter flavor and aroma. Chia and poppy seed oils negatively affect flavor as their intense flavors interfere with the traditional brioche profile.

3.6. Prospects, Novelty, and Necessity of the Research

This study offers a promising approach to improving both the sustainability and nutritional profile of brioche by replacing animal fats, primarily composed of saturated fatty acids, with more sustainable alternatives derived from seed and nut oils. The findings show that these oils not only improve the texture and appearance of the bread but also reduce its energy and fat content, aligning with current dietary recommendations for healthier food options.

The novelty of this research lies in the evaluation of seed and nut oils as viable alternatives to butter. These oils, rich in unsaturated fatty acids, have the potential to positively influence the lipid profile and promote cardiovascular health. Furthermore, the environmental advantages of using seed and nut oils compared to butter, which requires substantial agricultural, water, and energy resources and contributes to greenhouse gas emissions, highlight the sustainability of this approach.

The use of widely available ingredients, common in other bread and bakery products consumed globally, increases the applicability and scalability of this study’s findings. However, certain aspects still require optimization to develop a product that fully meets all desired attributes. Future research should focus on identifying alternative oils with superior sensory profiles and exploring the potential incorporation of chemical compounds, such as diacetyl, which could help replicate the characteristic taste and aroma of traditional brioche.

3.7. Conclusions

Pumpkin seed, melon seed, and nut oils provided positive results in terms of oxidative stability, which could extend the shelf life of the baked products. In contrast, chia seed oil, with its high content of polyunsaturated fatty acids, showed lower stability. The higher viscosity of pumpkin seed oil might influence the texture of the products, emphasizing the importance of selecting the appropriate oil based on the type of bread.

The use of oils such as pumpkin, melon, and chia seed oils resulted in subtle differences in the color of the final product, with pumpkin seed oil imparting a slightly darker hue compared to the control brioche. However, these color changes were not significant enough to negatively affect consumer acceptance, and the breads still appeared visually appealing.

In terms of texture, the reformulated breads displayed a slightly softer crumb with improved moisture retention compared to the traditional butter brioche. The texture was described as more tender and less crumbly. This improvement is also linked to the results for diameter, as the use of emulsions aids in retaining more gasses during the fermentation process.

The nutritional composition analysis revealed a reduction in the fat content and an increase in protein and carbohydrate levels in the reformulated breads, aligning the product with global dietary recommendations. The lipidic profile was also improved as the content of saturated fatty acids was replaced with unsaturated fatty acids, particularly Omega-3, Omega-6, and Omega-9. Additionally, the vitamin E content increased in all cases compared to the control sample, offering significant health benefits.

Despite these improvements in the physical and chemical analyses, sensory acceptance was highly positive, particularly regarding the external appearance and texture. However, breads made with chia and poppy seed oils had distinctive flavors that some consumers found less favorable. While the reformulation positively impacts the product, further sensory adjustments may be needed to improve taste and aroma.

Author Contributions

Conceptualization, E.M., J.E.P., A.R. and M.Á.-O.; Methodology, M.Á.-O.; Software, A.R.; Formal analysis, M.E.M.-N. and M.Á.-O.; Investigation, E.M.; Data curation, E.M. and M.E.M.-N.; Writing—original draft, E.M.; Supervision, J.E.P. and M.Á.-O.; Project administration, J.E.P.; Funding acquisition, J.E.P. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Castilla-La Mancha Regional Government (FEDER SBPLY/23/180225/000011) and the University of Castilla-La Mancha and the European Regional Development Fund (2022-GRIN-34158 and 2024 – TRAN – 36429). E.M. was funded by the University of Castilla-La Mancha through the European Social Fund Plus (01105PR21.541A).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article; further inquiries can be directed to the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Calder, P.C. Marine omega-3 fatty acids and inflammatory processes: Effects, mechanisms and clinical relevance. Biochim. Biophys. Acta Mol. Cell Biol. Lipids 2015, 1851, 469–484. [Google Scholar] [CrossRef]

- Choo, K.Y.; Lee, M.Y.; Kim, K.W. Optimization of oil-in-water emulsions for improving the quality and shelf-life of reduced-fat baked goods. J. Food Sci. Technol. 2020, 57, 821–828. [Google Scholar]

- Tang, Y.R.; Ghosh, S. Canola protein thermal denaturation improved emulsion-templated oleogelation and its cake-baking application. RSC Adv. 2021, 11, 25141–25157. [Google Scholar] [CrossRef]

- Mamat, H.; Hill, S.E. Effect of fat types on the structural and textural properties of dough and semi-sweet biscuit. J. Food Sci. Technol. 2014, 51, 1998–2005. [Google Scholar] [CrossRef] [PubMed]

- Orthoefer, F.; Kim, D. Applications of Emulsifiers in Baked Foods. In Food Emulsifiers and Their Applications; Hasenhuettl, G., Hartel, R., Eds.; Springer: Chamonix, Switzerland, 2019; pp. 299–321. [Google Scholar]

- Mazzocchi, A.; De Cosmi, V.; Risé, P.; Milani, G.P.; Turolo, S.; Syrén, M.L.; Agostoni, C. Bioactive compounds in edible oils and their role in oxidative stress and inflammation. Front. Physiol. 2021, 12, 659551. [Google Scholar] [CrossRef] [PubMed]

- Polmann, G.; Badia, V.; Danielski, R.; Ferreira, S.R.S.; Block, J.M. Nuts and nut-based products: A meta-analysis from intake health benefits and functional characteristics from recovered constituents. Food Rev. Int. 2023, 39, 5021–5047. [Google Scholar] [CrossRef]

- Mensink, R.P.; Zock, P.L.; Kester, A.D.; Katan, M.B. Effects of dietary fatty acids and carbohydrates on the ratio of serum total to HDL cholesterol and on serum lipids and apolipoproteins: A meta-analysis of 60 controlled trials. Am. J. Clin. Nutr. 2003, 77, 1146–1155. [Google Scholar] [CrossRef]

- Kuipers, R.S.; De Graaf, D.J.; Luxwolda, M.F.; Muskiet, M.H.A.; Dijck-Brouwer, D.A.J.; Muskiet, F.A.J. Saturated fat, carbohydrates and cardiovascular. Complex Acute Med. 2011, 353, 372. [Google Scholar]

- Siri-Tarino, P.W.; Sun, Q.; Hu, F.B.; Krauss, R.M. Saturated fat, carbohydrate, and cardiovascular disease. Am. J. Clin. Nutr. 2010, 91, 502–509. [Google Scholar] [CrossRef]

- Kromhout, D.; Giltay, E.J.; Geleijnse, J.M. n–3 Fatty acids and cardiovascular events after myocardial infarction. N. Engl. J. Med. 2010, 363, 2015–2026. [Google Scholar] [CrossRef]

- Mozaffarian, D.; Micha, R.; Wallace, S. Effects on coronary heart disease of increasing polyunsaturated fat in place of saturated fat: A systematic review and meta-analysis of randomized controlled trials. PLoS Med. 2010, 7, e1000252. [Google Scholar] [CrossRef] [PubMed]

- Craig, W.J.; Messina, V.; Rowland, I.; Frankowska, A.; Bradbury, J.; Smetana, S.; Medici, E. Plant-based dairy alternatives contribute to a healthy and sustainable diet. Nutrients 2023, 15, 3393. [Google Scholar] [CrossRef]

- FAO. The State of Food and Agriculture 2019: Moving Forward on Food Loss and Waste Reduction; Food Agriculture Organization United Nation: Rome, Italy, 2019. [Google Scholar]

- Finnegan, W.; Goggins, J.; Clifford, E.; Zhan, X. Environmental impacts of milk powder and butter manufactured in the Republic of Ireland. Sci. Total Environ. 2017, 579, 159–168. [Google Scholar] [CrossRef]

- Ziarno, M.; Derewiaka, D.; Florowska, A.; Szymańska, I. Comparison of the spreadability of butter and butter substitutes. Appl. Sci. 2023, 13, 2600. [Google Scholar] [CrossRef]

- Huang, L.; Zhao, X.; Zhao, Q.; Zhou, F.; Zhao, M. Recent Progress, Application, and Quality Evaluation of Plant-Based Double Emulsions in Low-Fat Foods. Food Bioprocess Technol. 2024, 17, 1–21. [Google Scholar] [CrossRef]

- Kim, S.H.; Jo, Y.J.; Lee, S.H.; Park, S.H. Development of Oleogel-Based Fat Replacer and Its Application in Pan Bread Making. Foods 2024, 13, 1678. [Google Scholar] [CrossRef] [PubMed]

- Dewidar, O.; El-Kherbawy, G. Nutritional Evaluation of Brioche Bread Made from Egyptian Wheat and Enriched with Garden Cress Seeds (GCS) Powder to be Used as a Functional Food. J. Food Sci. 2021, 6, 27–41. [Google Scholar]

- Martínez, E.; García-Martínez, R.; Álvarez-Ortí, M.; Rabadán, A.; Pardo-Giménez, A.; Pardo, J.E. Elaboration of gluten-free cookies with defatted seed flours: Effects on technological, nutritional, and consumer aspects. Foods 2021, 10, 1213. [Google Scholar] [CrossRef]

- MAPA. Métodos Oficiales de Análisis en la Unión Europea; Tomo, I., Ed.; Ministerio de Agricultura, Pesca y Alimentación; Secretaría General Técnica: Madrid, Spain, 1998; p. 495.

- FAO. Food Analysis: General Techniques, Additives, Contaminants, and Composition. In FAO Food and Nutrition Paper; FAO: Rome, Italy, 1986; Volume 14, pp. 105–109. [Google Scholar]

- ANKOM. Crude fiber analysis in feeds by filter bag technique. In ANKOM Technology Method 7, AOCS Approved Procedure Ba6a-05; ANKOM Technology: Macedon, NY, USA, 2008; p. 3. [Google Scholar]

- Sullivan, D.M. Proximate and Mineral Analysis. In Analysis of Nutrition Labeling; Sullivan, D.M., Carpenter, D.E., Eds.; AOAC International, Springer: Arlington, VA, USA, 1993; pp. 105–109. [Google Scholar]

- Mansour, E.H.; Khalid, A.L. Characteristics of low-fat beefburger as influenced by various types of wheat fibers. Food Res. Int. 1997, 30, 199–205. [Google Scholar] [CrossRef]

- Mendoza, L.G.; Gonzalez-Alvarez, J.; Gonzalo, C.F.; Arias-Abrodo, P.; Altava, B.; Luis, S.V.; Gutiérrez-Álvarez, M.D. Gas chromatographic analysis of fatty acid methyl esters of milk fat by an ionic liquid derived from L-phenylalanine as the stationary phase. Talanta 2015, 143, 212–218. [Google Scholar] [CrossRef]

- Alves, R.C.; Casal, S.; Oliveira, M. Determination of vitamin E in coffee beans by HPLC using a micro-extraction method. Food Sci. Technol. Int. 2009, 15, 57–63. [Google Scholar] [CrossRef]

- Ruiz-Capillas, C.; Herrero, A.; Tahmouzi, S.; Razavi, S.; Triki, M.; Rodríguez-Salas, L.; Samcová, K.; Jiménez-Colmenero, F. Properties of reformulated hot dog sausage without added nitrites during chilled storage. Food Sci. Technol. Int. 2014, 22, 21–30. [Google Scholar] [CrossRef]

- Cohen, D.; Farley, T.A. Eating as an automatic behavior. Prev. Chronic Dis. 2007, 5, A23. [Google Scholar]

- Ixtaina, V.Y.; Martínez, M.L.; Spotorno, V.; Mateo, C.M.; Maestri, D.M.; Diehl, B.W.; Nolasco, S.M.; Tomás, M.C. Characterization of chia seed oils obtained by pressing and solvent extraction. J. Food Compos. Anal. 2011, 24, 166–174. [Google Scholar] [CrossRef]

- Irnawati, I.; Riyanto, S.; Martono, S.; Windarsih, A.; Rohman, A. Physicochemical properties and antioxidant activities of pumpkin seed oil as affected by different origins and extraction methods. J. Appl. Pharm. Sci. 2022, 12, 1–6. [Google Scholar] [CrossRef]

- Rodríguez-Miranda, J.; Hernández-Santos, B.; Herman-Lara, E.; Gómez-Aldapa, C.A.; Garcia, H.S.; Martínez-Sánchez, C.E. Effect of some variables on oil extraction yield from Mexican pumpkin seeds. CyTA-J. Food 2014, 12, 9–15. [Google Scholar] [CrossRef]

- Mallek-Ayadi, B.; Bahloul, N.; Kechaou, N. Chemical composition and bioactive compounds of Cucumis melo L. seeds: Potential source for new trends of plant oils. Process Saf. Environ. Prot. 2018, 113, 68–77. [Google Scholar] [CrossRef]

- Rabadán, A.; Gallardo-Guerrero, L.; Gandul-Rojas, B.; Álvarez-Ortí, M.; Pardo, J.E. Effect of roasting conditions on pigment composition and some quality parameters of pistachio oil. Food Chem. 2018, 264, 49–57. [Google Scholar] [CrossRef]

- Savage, G.P.; Dutta, P.C.; McNeil, D.L. Fatty acid and tocopherol contents and oxidative stability of walnut oils. J. Am. Oil Chem. Soc. 1999, 76, 1059–1063. [Google Scholar] [CrossRef]

- Roncero, J.M.; Álvarez-Ortí, M.; Pardo-Giménez, A.; Gómez, R.; Rabadán, A.; Pardo, J.E. Virgin almond oil: Extraction methods and composition. Grasas y Aceites 2016, 67, e143. [Google Scholar]

- Catalan, L.; Álvarez-Ortí, M.; Pardo-Giménez, A.; Gómez, R.; Rabadán, A.; Pardo, J.E. Pistachio oil: A review on its chemical composition, extraction systems, and uses. Eur. J. Lipid Sci. Technol. 2017, 119, 1600126. [Google Scholar] [CrossRef]

- Blasi, F.; Chiesi, C.; Spogli, R.; Cossignani, L.; Nocchetti, M. Oxidative stability of long-chain fatty acids with different unsaturation degrees into layered double hydroxides. Appl. Sci. 2021, 11, 7035. [Google Scholar] [CrossRef]

- Copolovici, D.; Bungau, S.; Boscencu, R.; Tit, D.M.; Copolovici, L.J.R.C. The fatty acids composition and antioxidant activity of walnut cold press oil. Rev. Chim. 2017, 68, 507–509. [Google Scholar] [CrossRef]

- Tarjuelo, L.; Rabadán, A.; Álvarez-Ortí, M.; Pardo-Giménez, A.; Pardo, J.E. Analysis of nutritional characteristics and willingness to pay of consumers for dry-cured sausages (Salchichón) made with textured seed oils. Foods 2023, 12, 3118. [Google Scholar] [CrossRef]

- Martínez, E.; Vieira Júnior, W.G.; Álvarez-Ortí, M.; Rabadán, A.; Pardo, J.E. Use of different O/W or W/O emulsions as functional ingredients to reduce fat content and improve lipid profile in Spanish cured processed meat product (‘Chorizo’). Foods 2024, 13, 2262. [Google Scholar] [CrossRef]

- Martínez, E.; Pardo, J.E.; Rabadán, A.; Álvarez-Ortí, M. Effects of animal fat replacement by emulsified melon and pumpkin seed oils in deer burgers. Foods 2023, 12, 1279. [Google Scholar] [CrossRef]

- Fellows, P.J. Food Processing Technology: Principles and Practice; Woodhead Publishing: Cambridge, UK, 2022. [Google Scholar]

- Fernandes, S.S.; Mellado, M.D.L.M.S. Development of mayonnaise with substitution of oil or egg yolk by the addition of chia (Salvia hispanica L.) mucilage. J. Food Sci. 2018, 83, 74–83. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Gálvez, A.; Viera, I.; Roca, M. Carotenoids and chlorophylls as antioxidants. Antioxidants 2020, 9, 505. [Google Scholar] [CrossRef]

- Patel, K.N.; Modi, R.B.; Patel, H.G.; Aparnathi, K.D. Browning, its chemistry and implications in dairy products: A review. Indo Am. J. Agric. Vet. Sci. 2013, 1, 1–12. [Google Scholar]

- Wang, Q.; Espert, M.; Salvador, A.; Sanz, T. Shortening replacement by emulsion and foam template hydroxypropyl methylcellulose (HPMC)-based oleogels in puff pastry dough. Rheological and texture properties. Curr. Res. Food Sci. 2023, 7, 100558. [Google Scholar] [CrossRef] [PubMed]

- Espert, M.; Salvador, A.; Sanz, T.; Hernández, M.J. Replacing solid fat in croissant dough using xanthan gum-based oleogels. Impact on rheological properties and final product quality. Food Hydrocoll. 2024, 157, 110472. [Google Scholar] [CrossRef]

- Cappelli, A.; Oliva, N.; Cini, E. A systematic review of gluten-free dough and bread: Dough rheology, bread characteristics, and improvement strategies. Appl. Sci. 2020, 10, 6559. [Google Scholar] [CrossRef]

- Silow, C.; Zannini, E.; Axel, C.; Belz, M.C.; Arendt, E.K. Optimization of fat-reduced puff pastry using response surface methodology. Foods 2017, 6, 15. [Google Scholar] [CrossRef]

- Caggia, C.; Palmeri, R.; Russo, N.; Timpone, R.; Randazzo, C.L.; Todaro, A.; Barbagallo, S. Employ of citrus by-product as fat replacer ingredient for bakery confectionery products. Front. Nutr. 2020, 7, 46. [Google Scholar] [CrossRef] [PubMed]

- Difonzo, G.; Noviello, M.; De Angelis, D.; Porfido, C.; Terzano, R.; Caponio, F. Emulsion filled gels based on inulin and dry-fractionated pulse proteins to produce low-fat baked goods. LWT 2024, 207, 116620. [Google Scholar] [CrossRef]

- World Health Organization (WHO); Consultation, F.E. Diet, nutrition and the prevention of chronic diseases. World Health Organ. Tech. Rep. Ser. 2003, 916, 1–149. [Google Scholar]

- U.S. Department of Agriculture & U.S. Department of Health and Human Services. Dietary Guidelines for Americans, 2020–2025, 9th ed.; U.S. Government Printing Office: Washington, DC, USA, 2020.

- Katan, M.B.; Zock, P.L.; Mensink, R.P. Effects of fats and fatty acids on blood lipids in humans: An overview. Am. J. Clin. Nutr. 1994, 60, 1017–1022. [Google Scholar] [CrossRef] [PubMed]

- Utzschneider, K.M.; Bayer-Carter, J.L.; Arbuckle, M.D.; Tidwell, J.M.; Richards, T.L.; Craft, S. Beneficial effect of a weight-stable, low-fat/low-saturated fat/low-glycaemic index diet to reduce liver fat in older subjects. Br. J. Nutr. 2013, 109, 1096–1104. [Google Scholar] [CrossRef]

- Van den Bremt, K.; Müllendorff, K.; Arnaut, F. Balancing functional and nutritional quality of oils and fats: Current requirements and future trends. Oléagineux Corp. Gras Lipides 2012, 19, 83–88. [Google Scholar] [CrossRef][Green Version]

- Gutiérrez-Luna, K.; Astiasarán, I.; Ansorena, D. Gels as fat replacers in bakery products: A review. Crit. Rev. Food Sci. Nutr. 2022, 62, 3768–3781. [Google Scholar] [CrossRef]

- Daglioglu, O.; Tasan, M.; Gecgel, U.; Daglioglu, F. Changes in oxidative stability of selected bakery products during shelf life. Food Sci. Technol. Res. 2004, 10, 464–468. [Google Scholar] [CrossRef]

- Kairam, N.; Kandi, S.; Sharma, M. Development of functional bread with flaxseed oil and garlic oil hybrid micro-capsules. LWT 2021, 136, 110300. [Google Scholar] [CrossRef]

- Ulbricht, T.L.V.; Southgate, D.A.T. Coronary heart disease: Seven dietary factors. Lancet 1991, 338, 985–992. [Google Scholar] [CrossRef] [PubMed]

- Feldman, E.B. The scientific evidence for a beneficial health relationship between walnuts and coronary heart disease. J. Nutr. 2002, 132, 1062–1101. [Google Scholar] [CrossRef]

- González, C.A.; Salas-Salvadó, J. The potential of nuts in the prevention of coronary heart disease. Br. J. Nutr. 2006, 96, S87–S94. [Google Scholar] [CrossRef]

- Nanditha, B.; Prabhasankar, P. Antioxidants in bakery products: A review. Crit. Rev. Food Sci. Nutr. 2008, 49, 1–27. [Google Scholar] [CrossRef]

- Delicato, C.; Schouteten, J.J.; Dewettinck, K.; Gellynck, X.; Tzompa-Sosa, D.A. Consumers’ perception of bakery products with insect fat as partial butter replacement. Food Qual. Prefer. 2020, 79, 103755. [Google Scholar] [CrossRef]

- Day, G.; LeBouf, R.; Grote, A.; Pendergrass, S.; Cummings, K.; Kreiss, K.; Kullman, G. Identification and measurement of diacetyl substitutes in dry bakery mix production. J. Occup. Environ. Hyg. 2011, 8, 93–103. [Google Scholar] [CrossRef]

- Demirkesen, I.; Mert, B.; Sumnu, G.; Sahin, S. Utilization of chestnut flour in gluten-free bread formulations. J. Food Eng. 2010, 101, 329–336. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).