Research on Basic Properties of Polymers for Fused Deposition Modelling Technology

Abstract

1. Introduction

2. Materials and Methods

2.1. Characteristics of Printed Materials

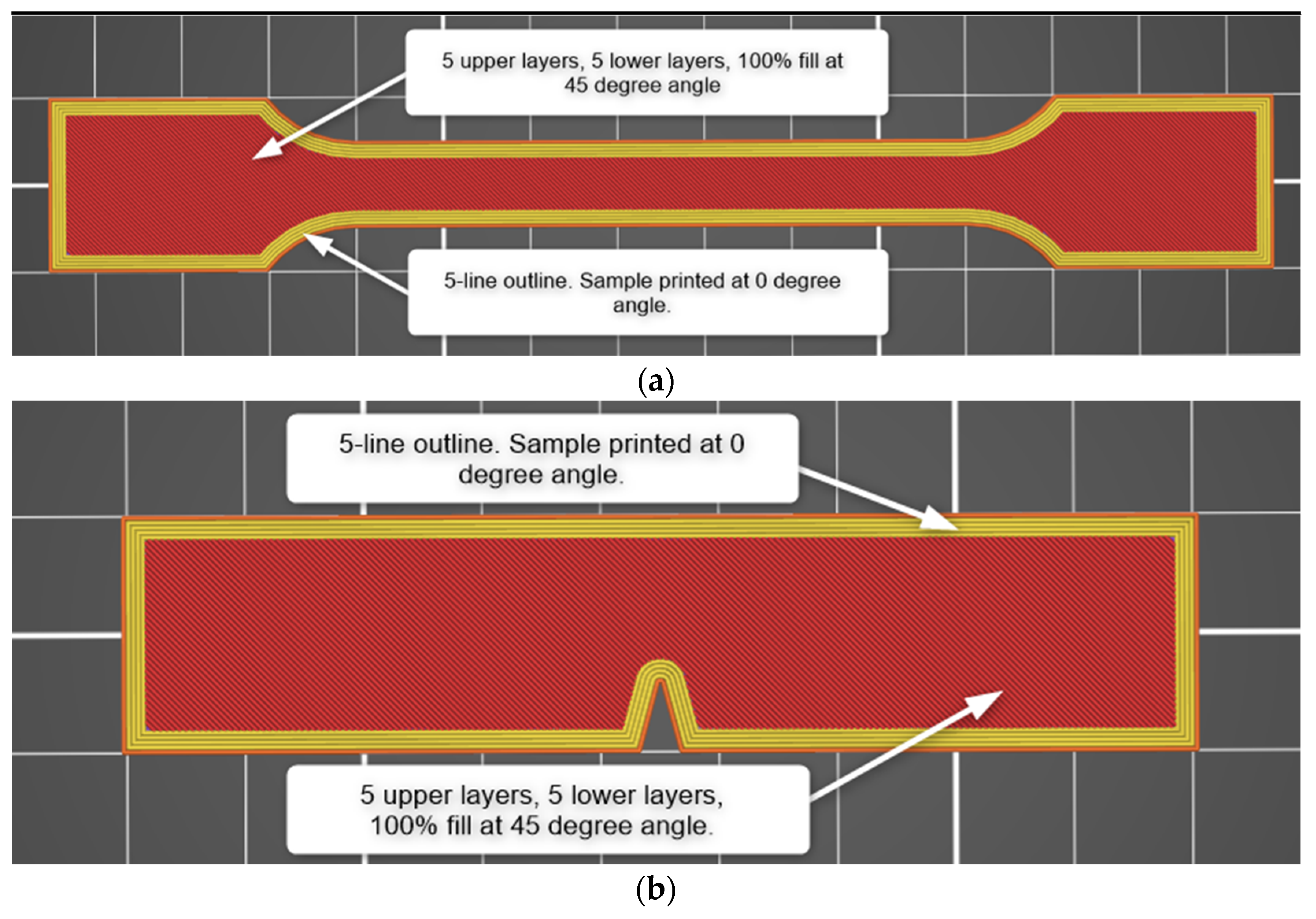

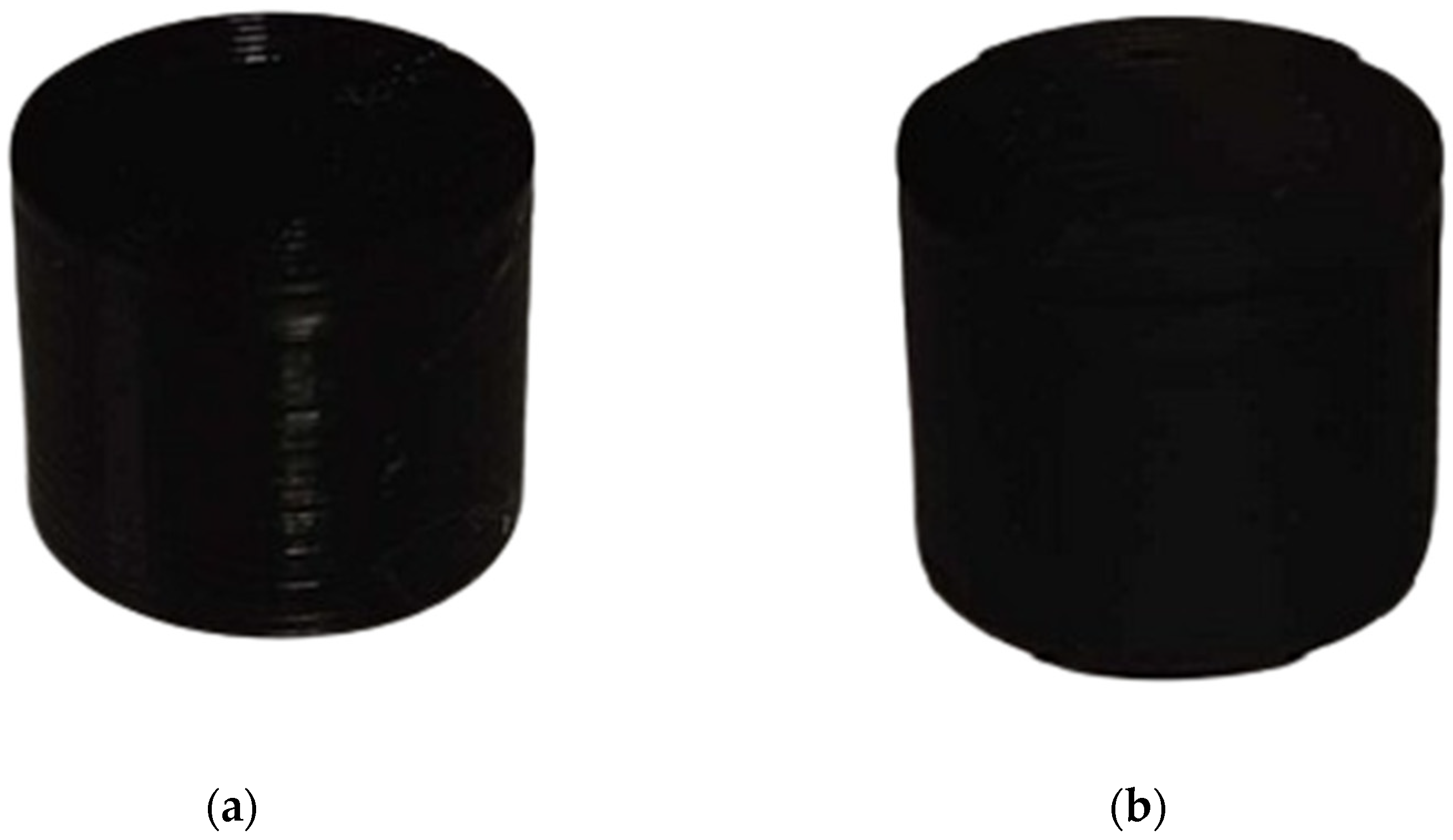

2.2. Fabrication of the Samples

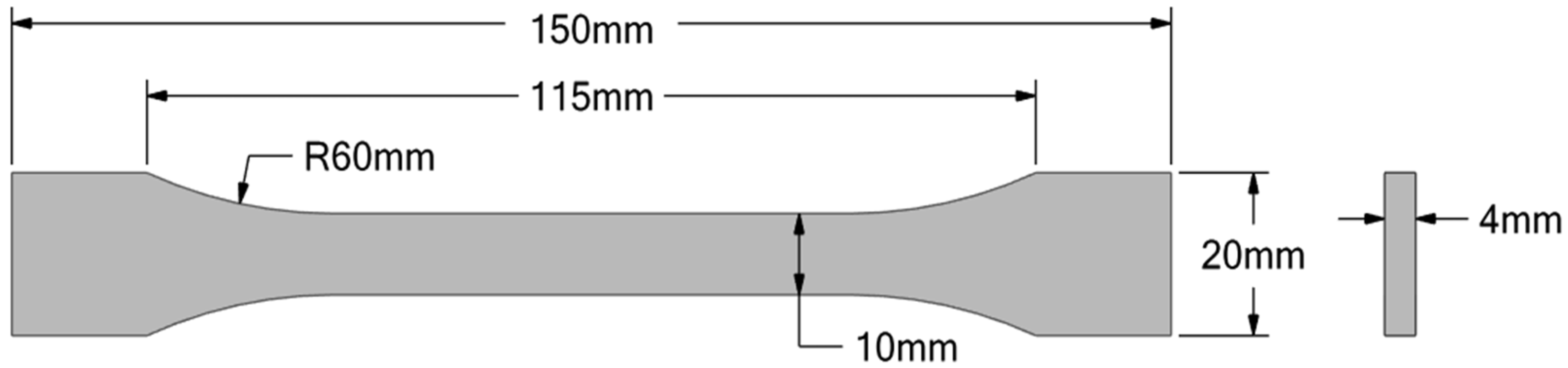

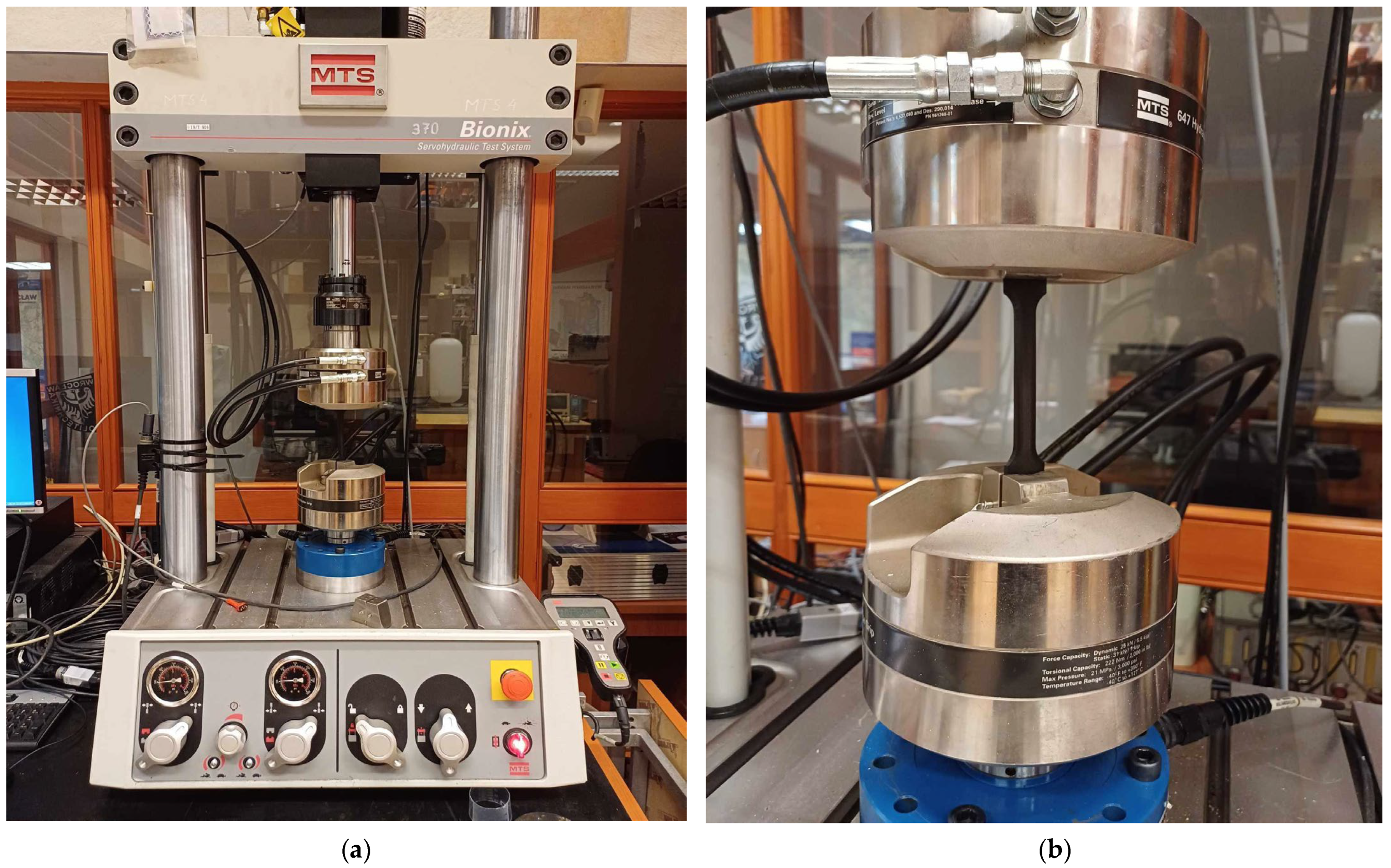

2.3. Testing of Materials Using a Static Tensile Test

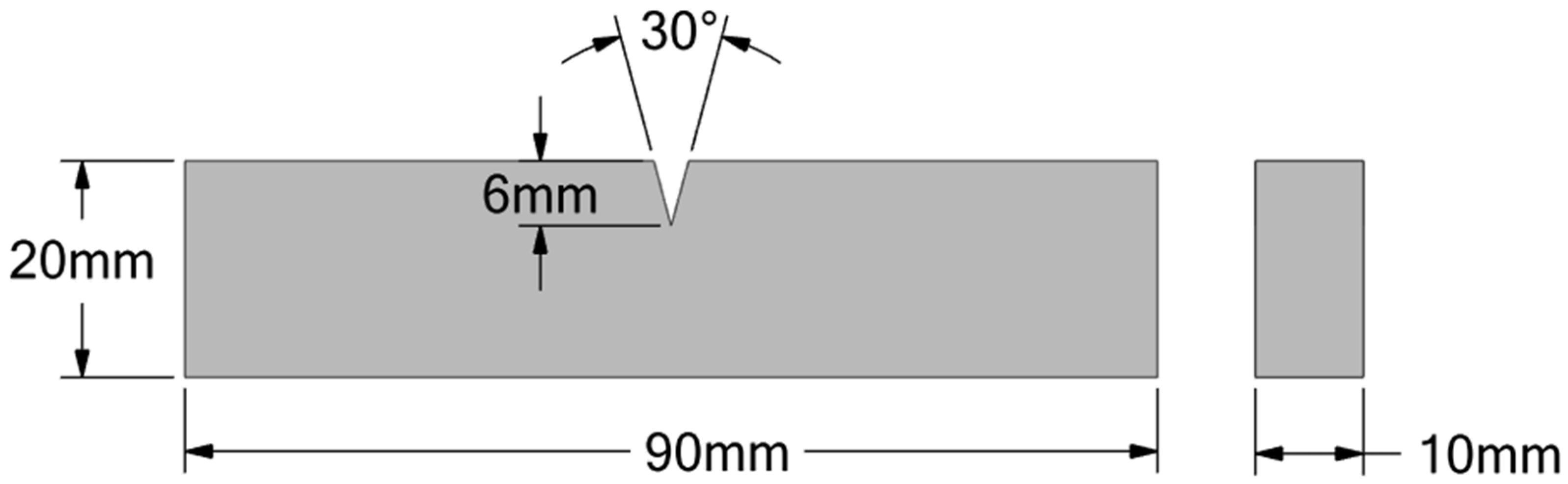

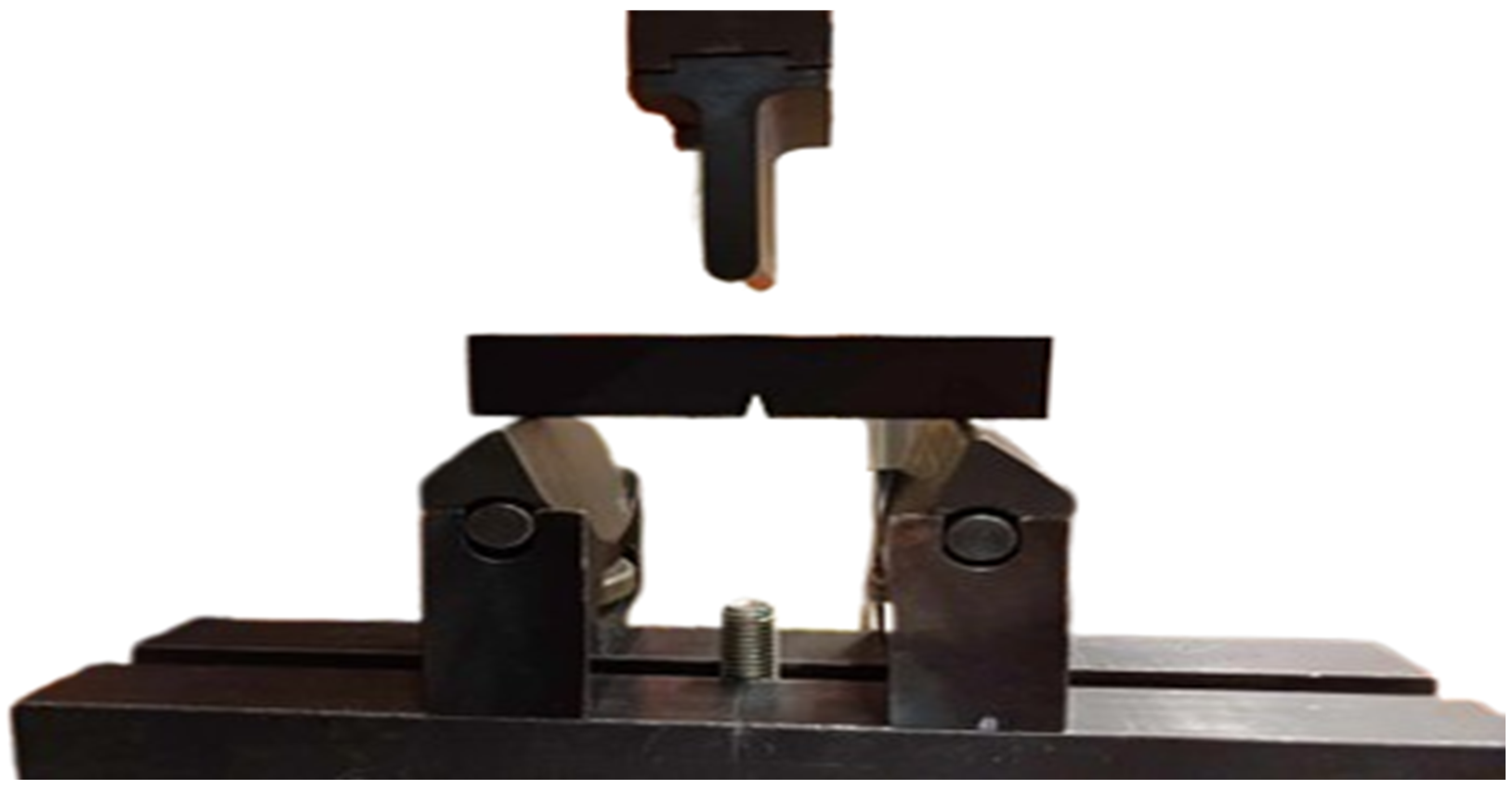

2.4. Testing of Materials Using a Static Three-Point Bending Test

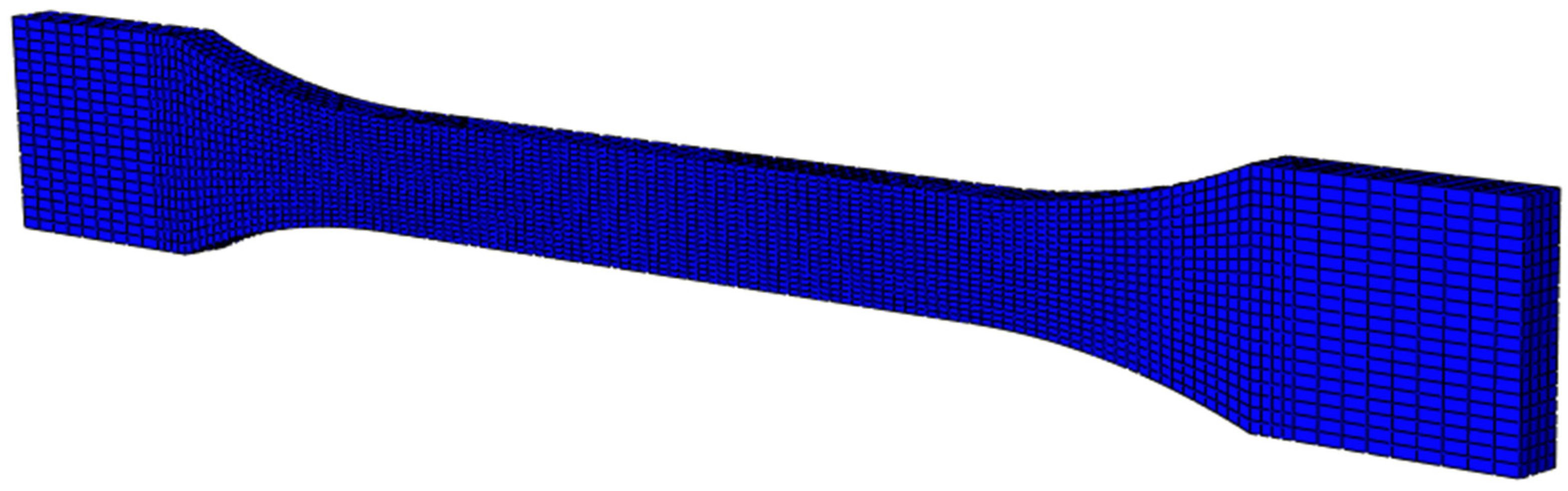

2.5. Methodology of Tensile Test Numerical Simulation

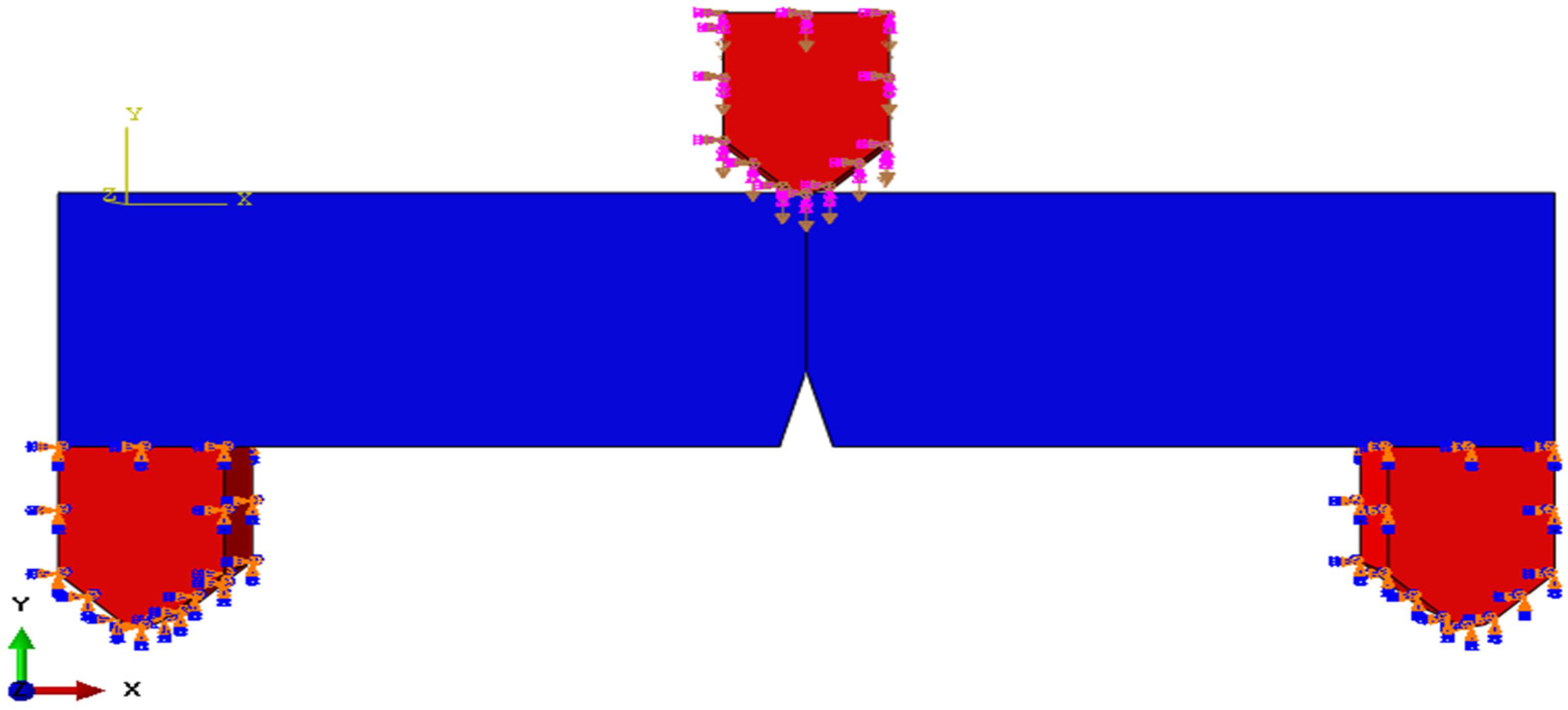

2.6. Methodology of Three-Point Bending Test Numerical Simulation

2.7. Methodology of SEM Observations

2.8. Biological Assessment of Samples

3. Results

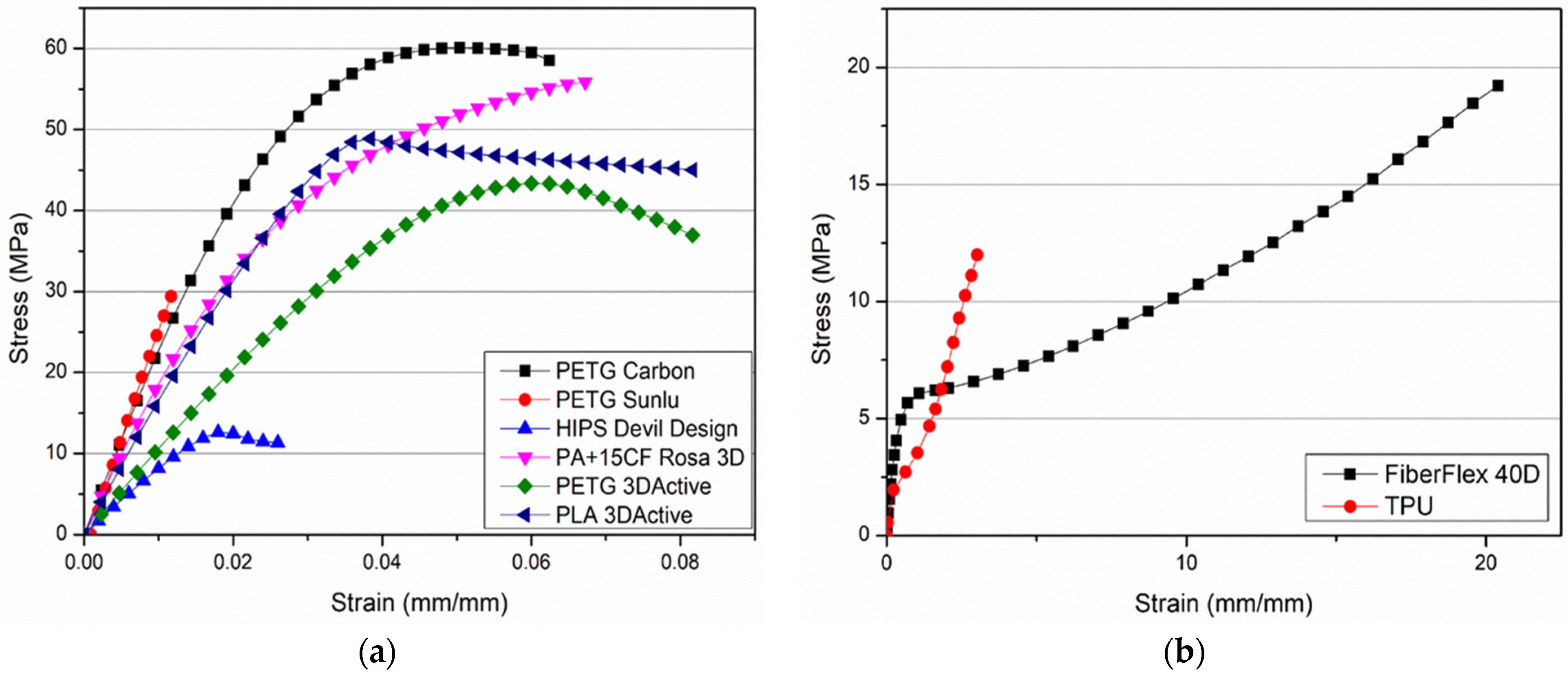

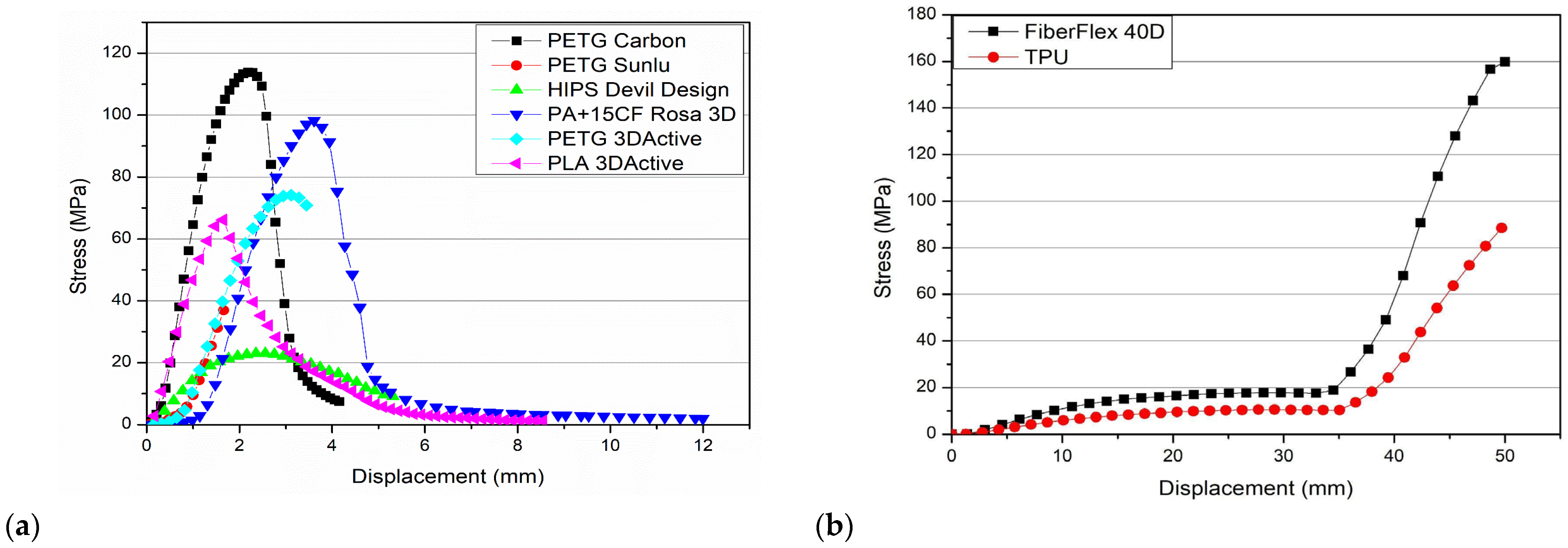

3.1. Tensile Test

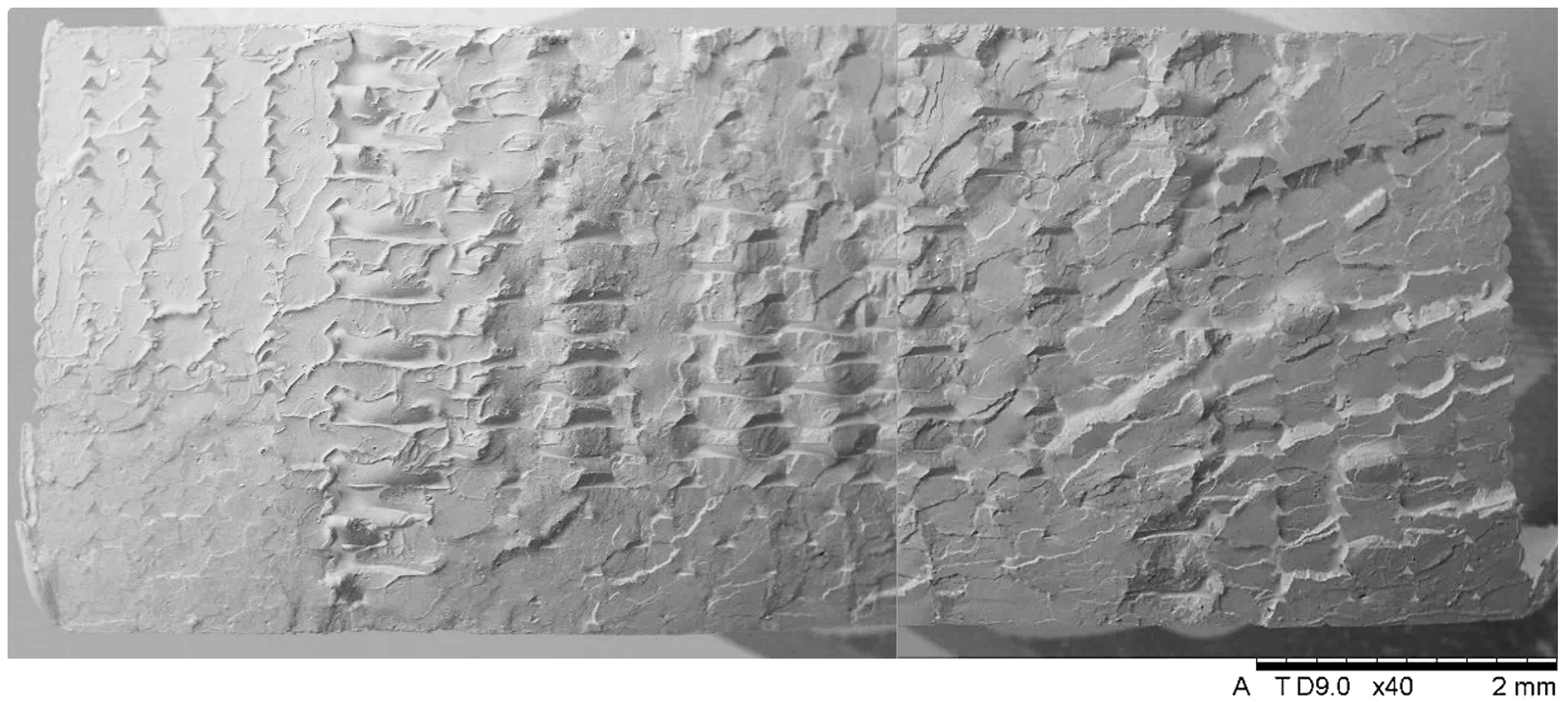

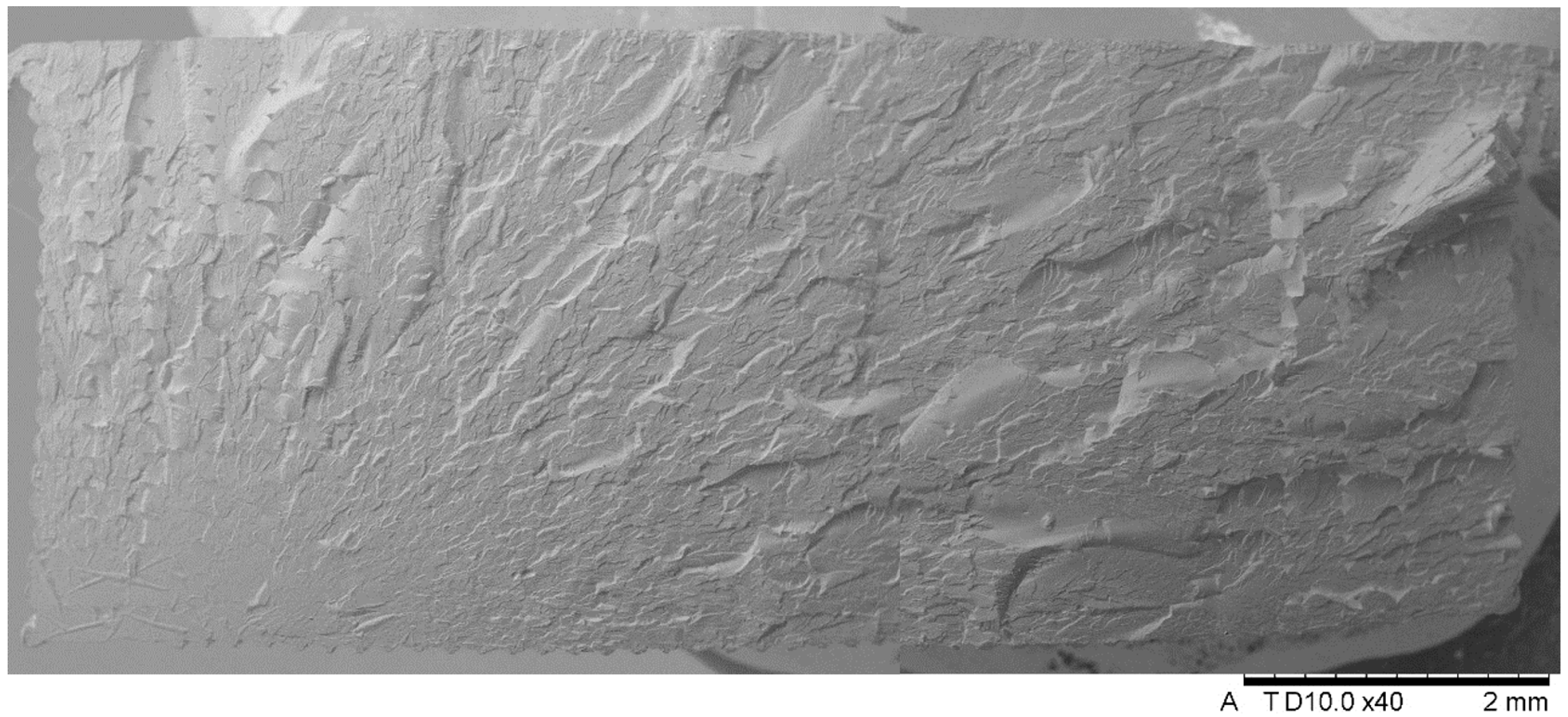

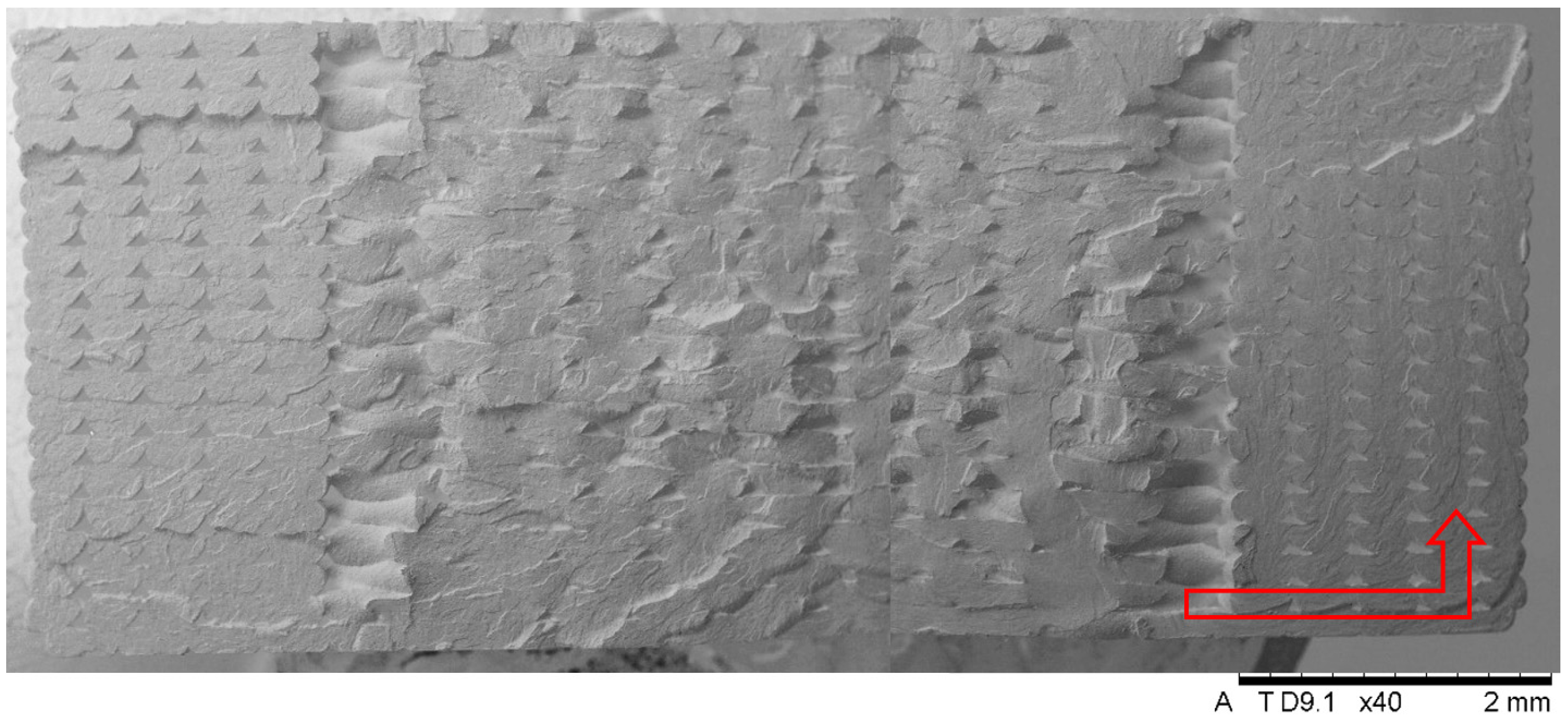

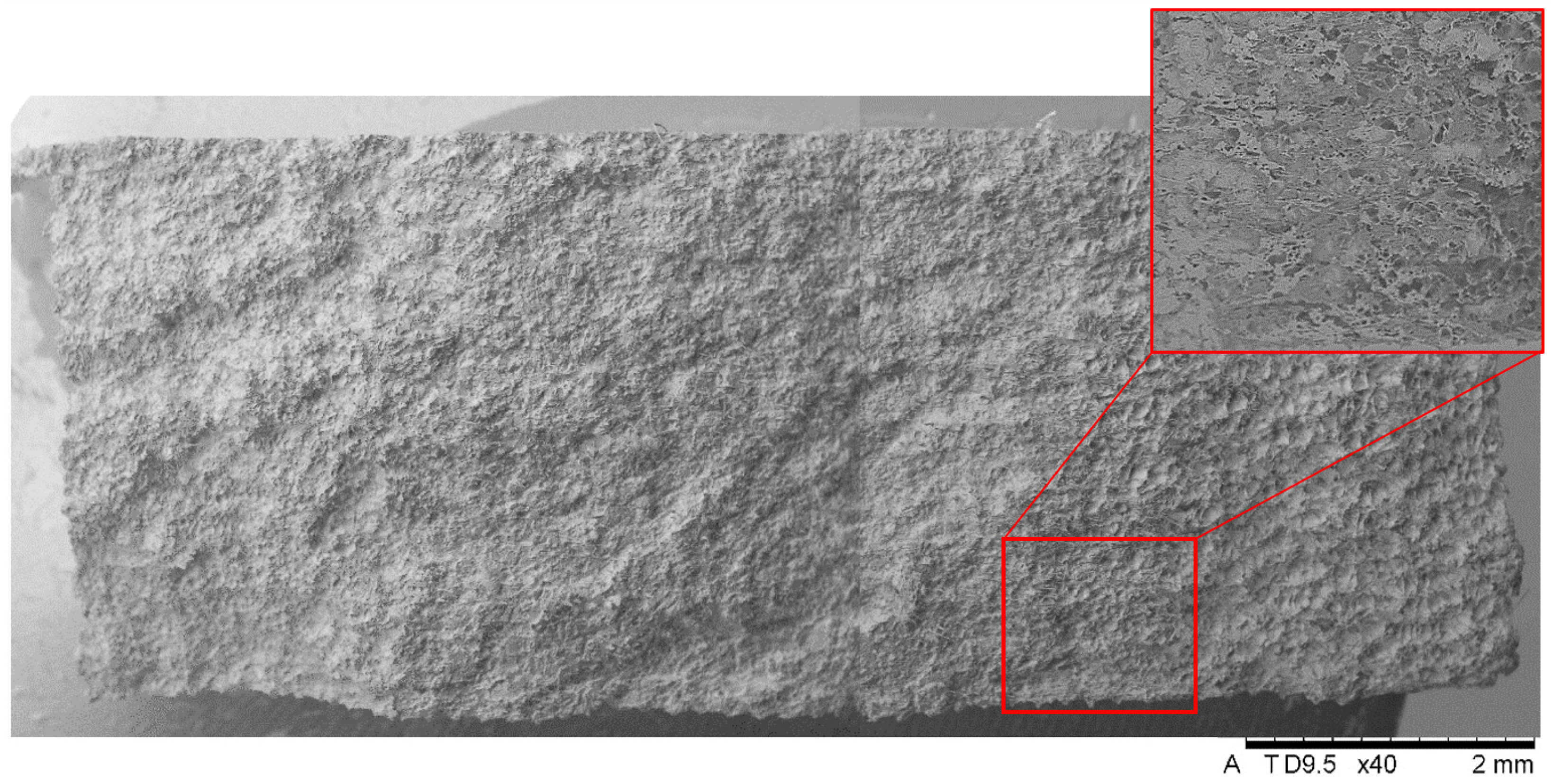

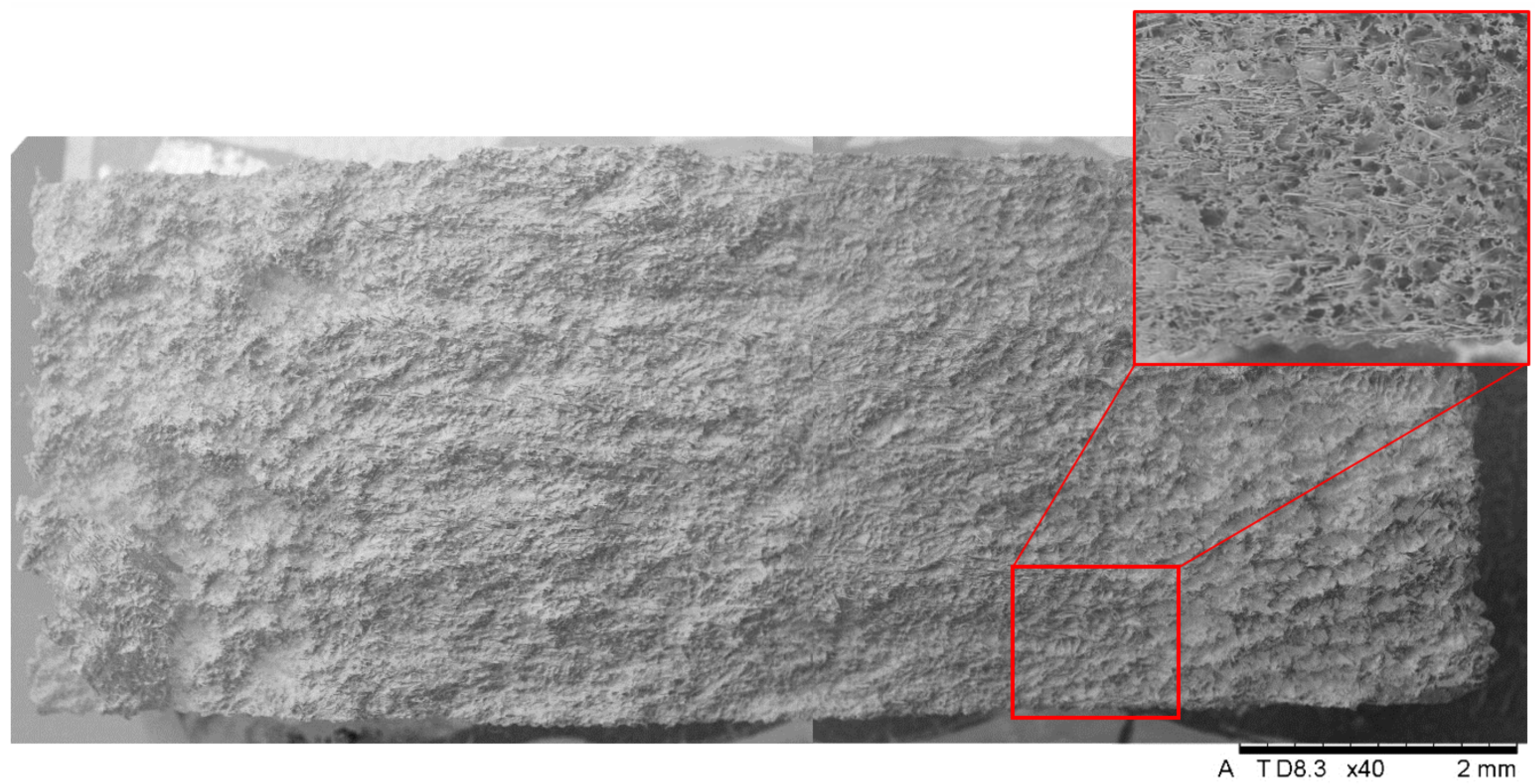

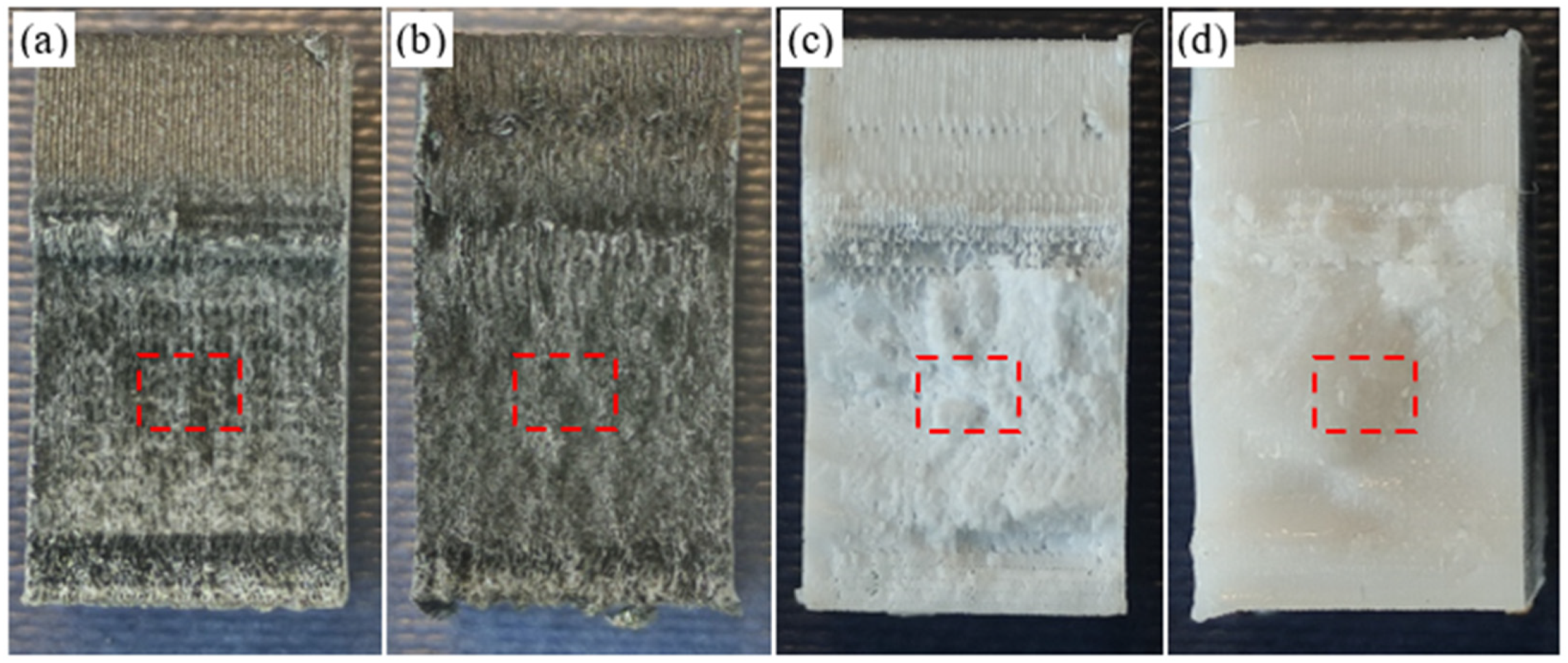

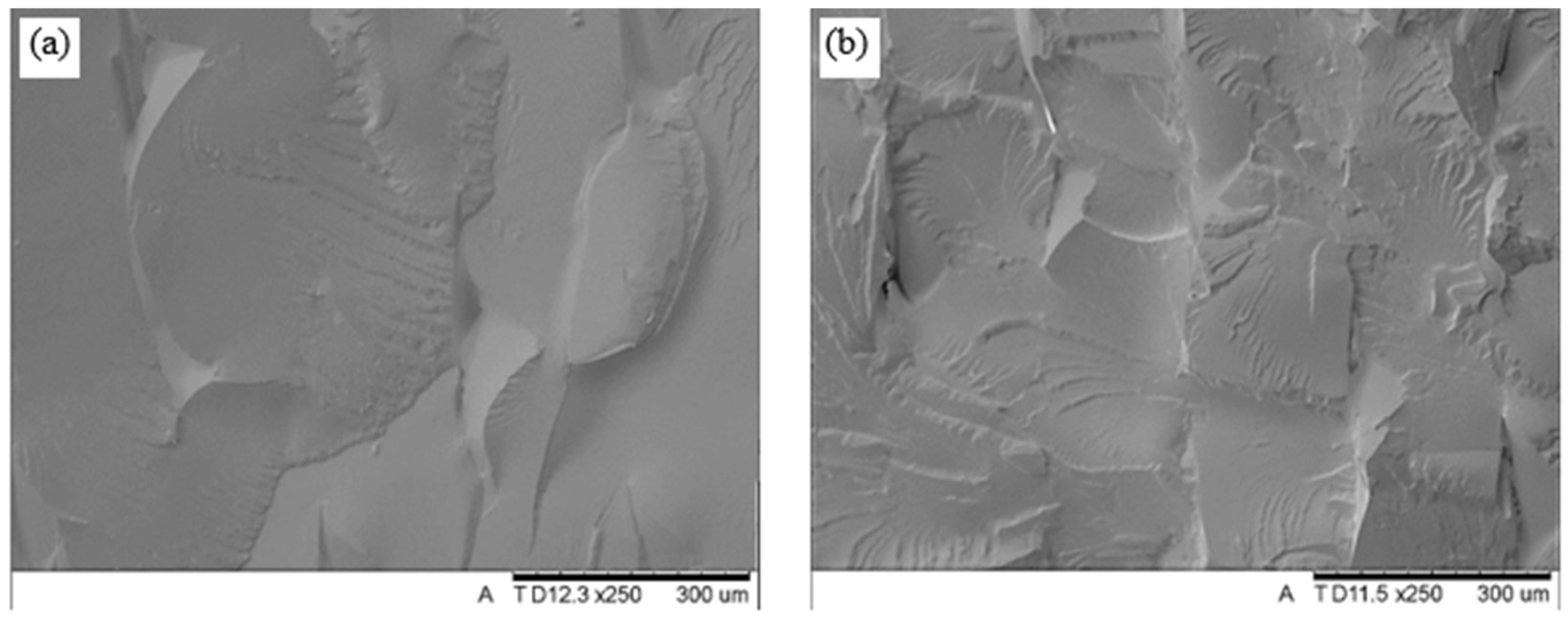

3.2. SEM Scrap Observation After Tensile Test

3.3. Three-Point Bending

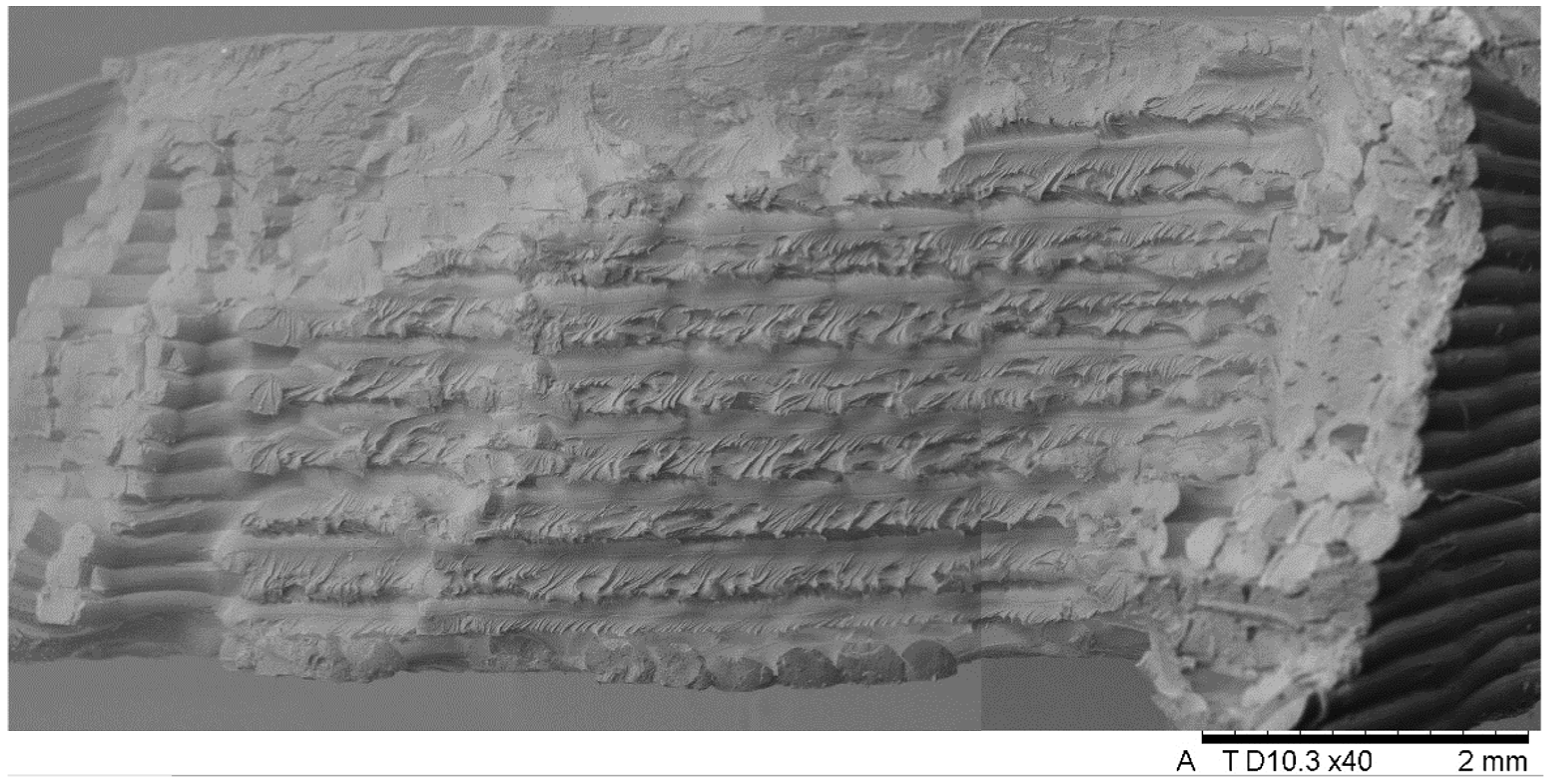

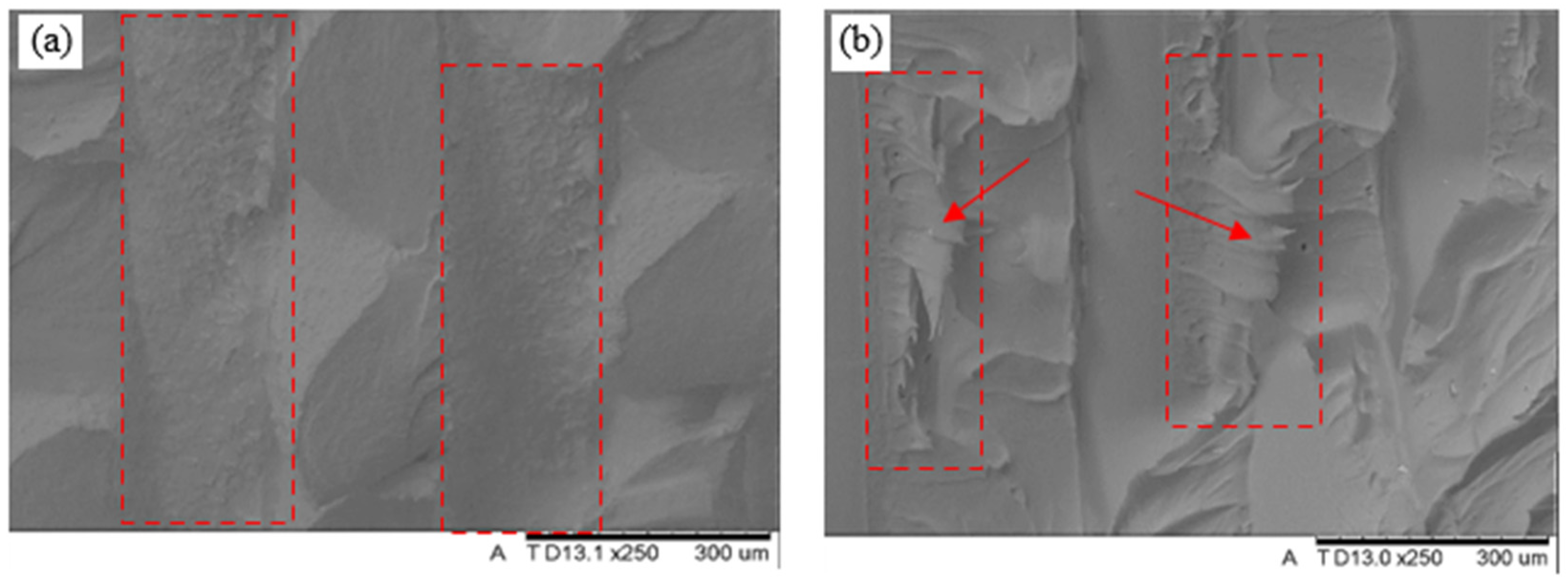

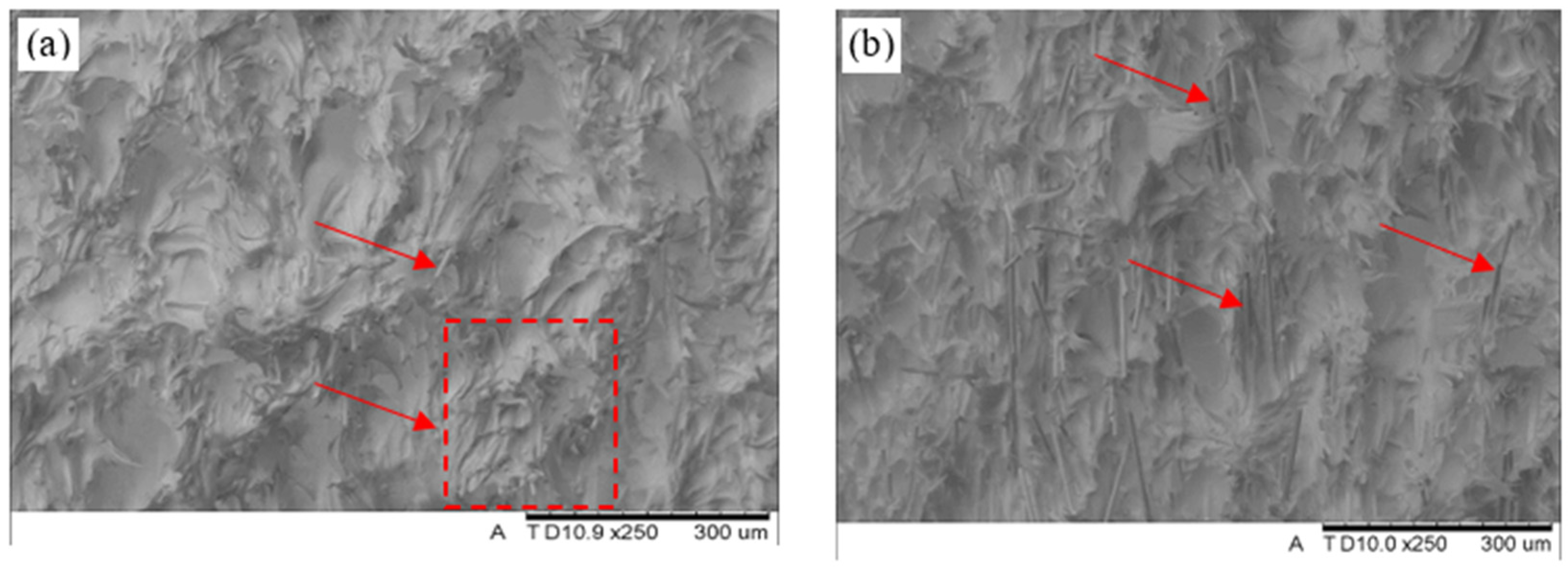

3.4. SEM Scrap Observation After Three-Point Bending Test

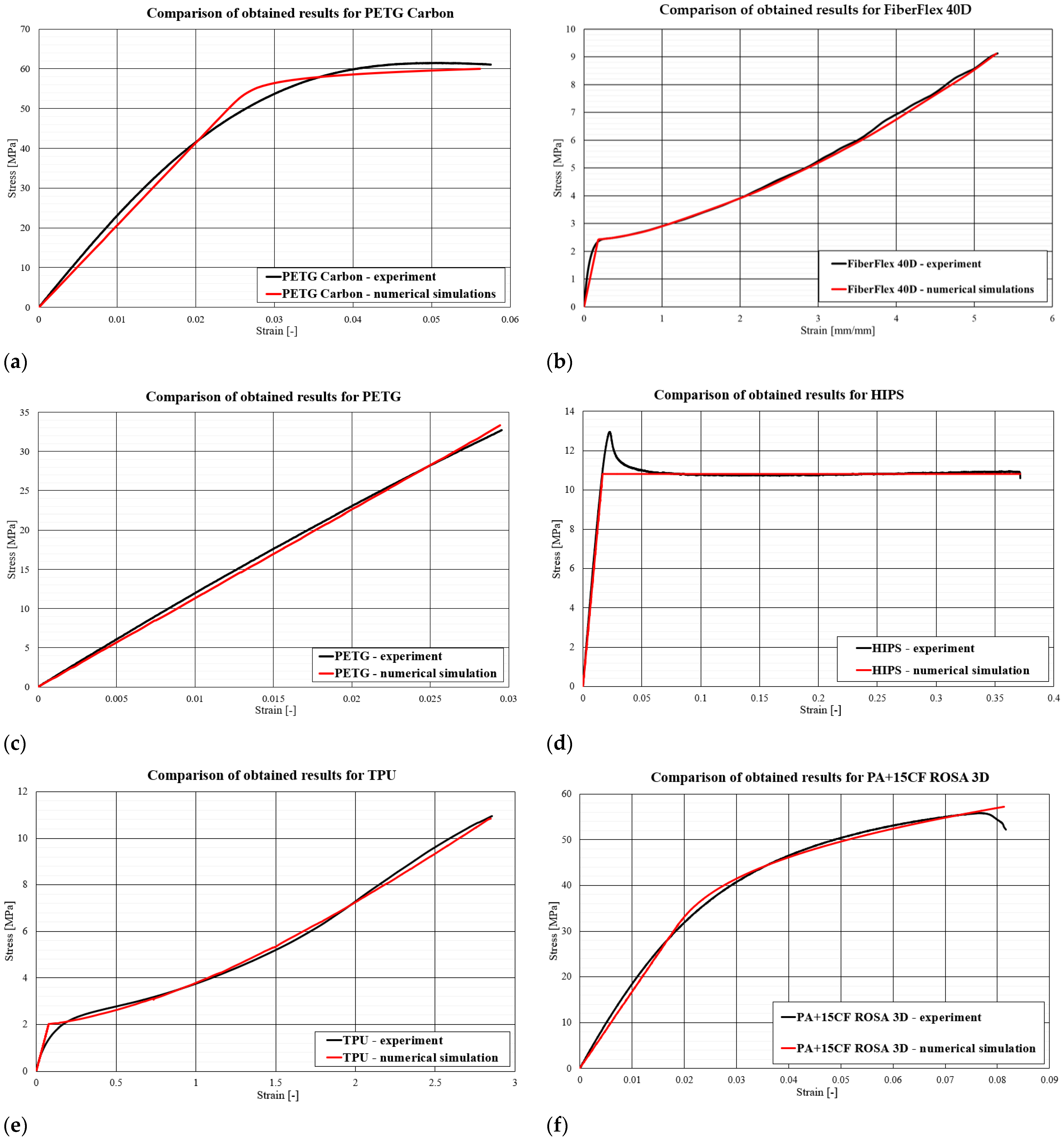

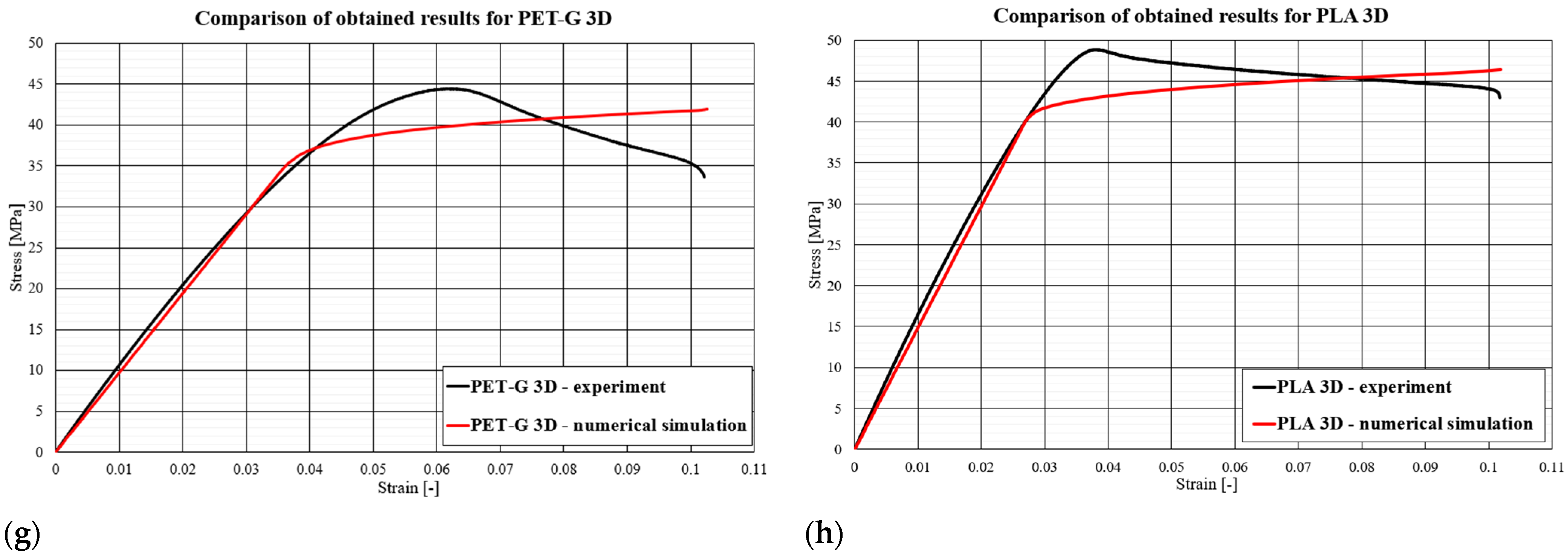

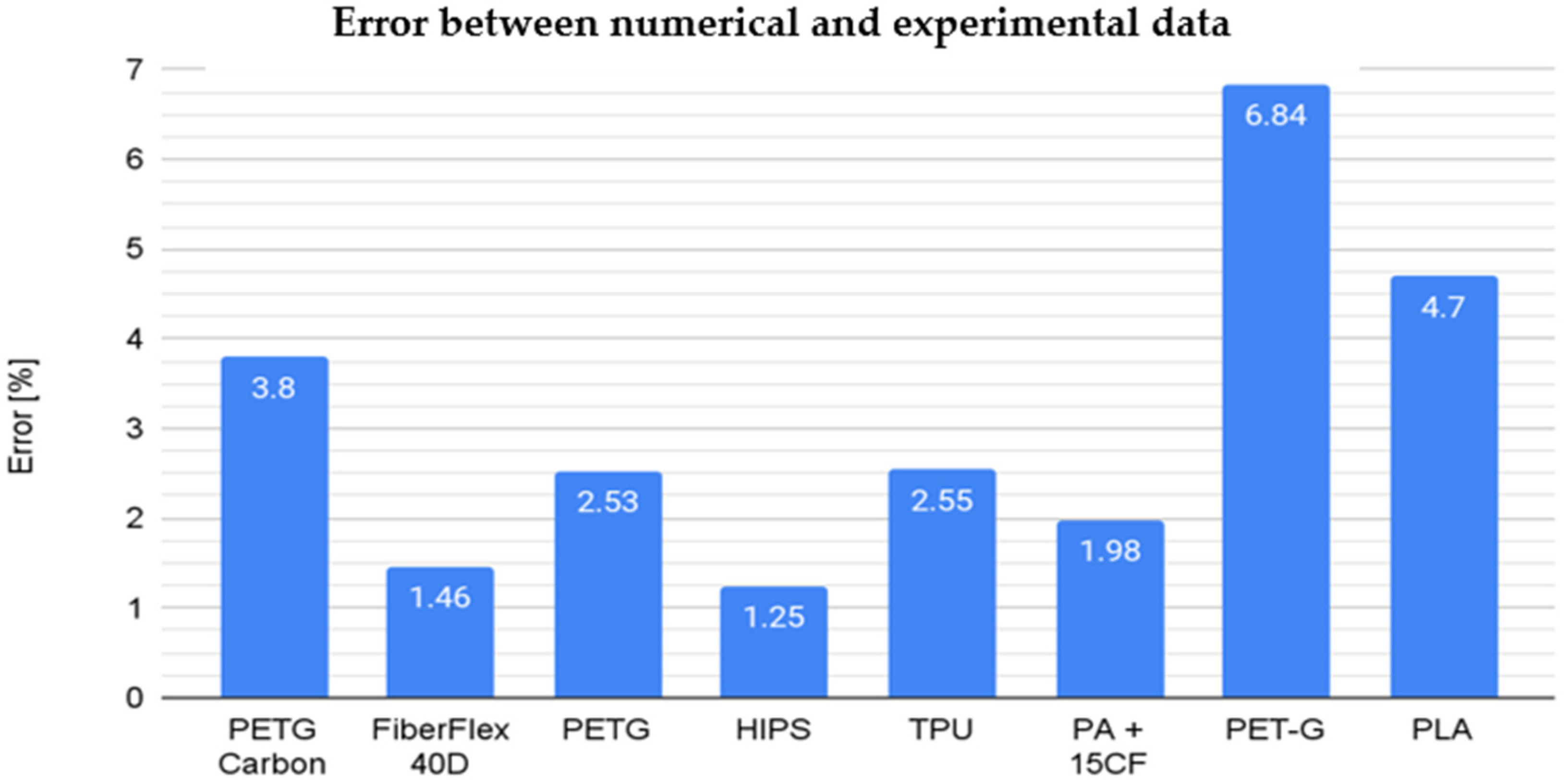

3.5. Numerical Simulations of Tensile Test

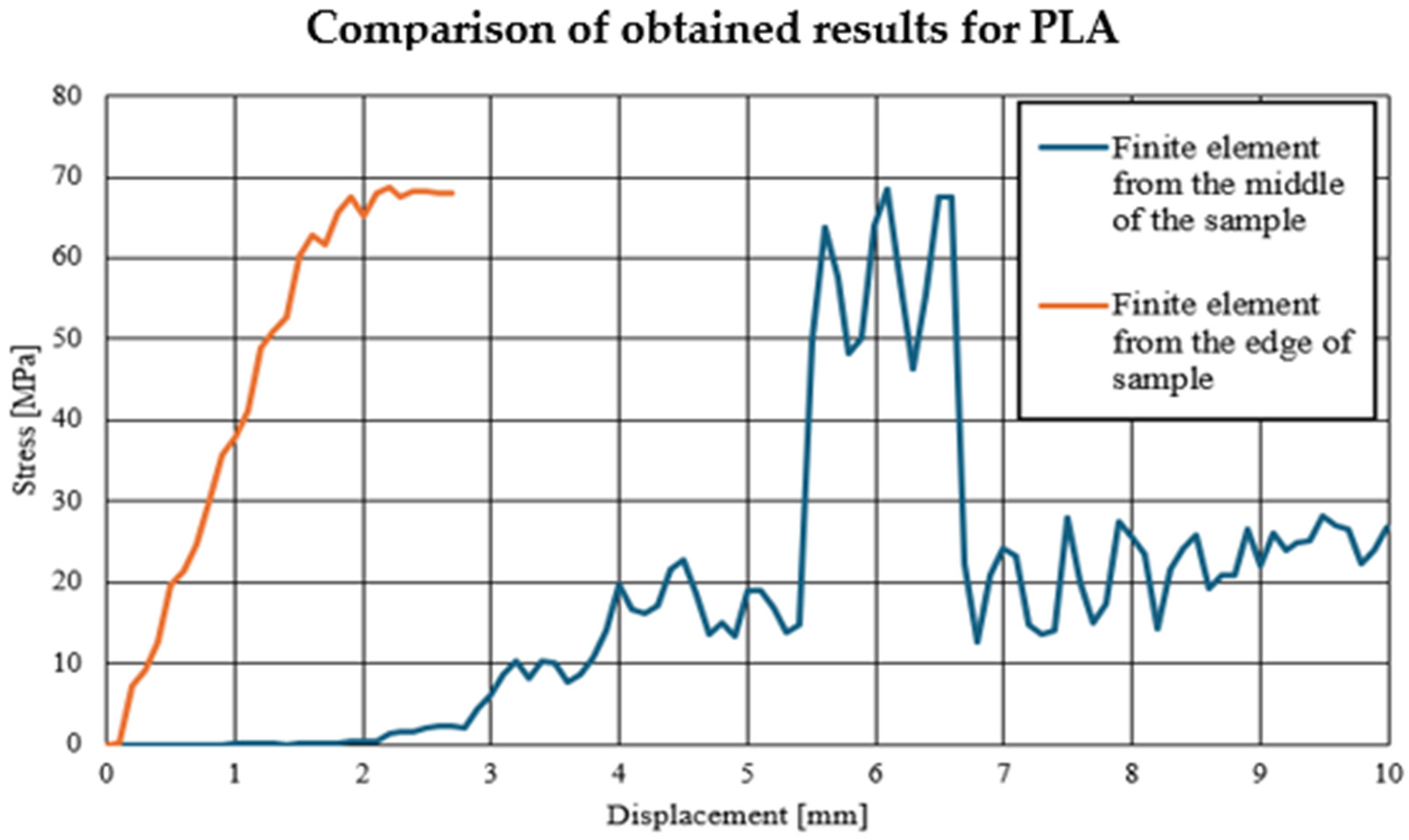

3.6. Numerical Simulations of Three-Point Bending

3.7. Cytotoxicity Tests

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ahmadifar, M.; Benfriha, K.; Shirinbayan, M.; Tcharkhtchi, A. Additive Manufacturing of Polymer-Based Composites Using Fused Filament Fabrication (FFF): A Review. Appl. Compos. Mater. 2021, 28, 1335–1380. [Google Scholar] [CrossRef]

- Kholgh Eshkalak, S.; Rezvani Ghomi, E.; Dai, Y.; Choudhury, D.; Ramakrishna, S. The Role of Three-Dimensional Printing in Healthcare and Medicine. Mater. Des. 2020, 194, 108940. [Google Scholar] [CrossRef]

- Hossain, K.R.; Jami, M.M.; Shyeed, A.; Khatun, K.; Hasan, K.; Cobra, K.; Ahmed, F. Application of 3D Printing in Medicine: Technologies and Challenges. Al-Bahir J. Eng. Pure Sci. 2023, 3, 7. [Google Scholar] [CrossRef]

- Krauel, L.; Valls-Esteve, A.; Tejo-Otero, A.; Fenollosa-Artés, F. 3D-Printing in Surgery: Beyond Bone Structures. A Review. Ann. 3d Print. Med. 2021, 4, 100039. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Paul, R.; Anand, S. Optimal part orientation in Rapid Manufacturing process for achieving geometric tolerances. J. Manuf. Syst. 2011, 30, 214–222. [Google Scholar] [CrossRef]

- Bikas, H.; Stavropoulos, P.; Chryssolouris, G. Additive manufacturing methods and modeling approaches: A critical review. Int. J. Adv. Manuf. Technol. 2016, 83, 389–405. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part. B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Parandoush, P.; Lin, D. A review on additive manufacturing of polymer-fiber composites. Compos. Struct. 2017, 182, 36–53. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef]

- García Plaza, E.; Núñez López, P.J.; Caminero Torija, M.Á.; Chacón Muñoz, J.M. Analysis of PLA geometric properties processed by FFF additive manufacturing: Effects of process parameters and plate-extruder precision motion. Polymers 2019, 11, 1581. [Google Scholar] [CrossRef]

- Yao, T.; Ye, J.; Deng, Z.; Zhang, K.; Ma, Y.; Ouyang, H. Tensile failure strength and separation angle of FDM 3D printing PLA material: Experimental and theoretical analyses. Compos. Part. B Eng. 2020, 188, 107894. [Google Scholar] [CrossRef]

- Es-Said, O.S.; Foyos, J.; Noorani, R.; Mendelson, M.; Marloth, R.; Pregger, B.A. Effect of layer orientation on mechanical properties of rapid prototyped samples. Mater. Manuf. Process. 2000, 15, 107–122. [Google Scholar] [CrossRef]

- Torrado Perez, A.R.; Roberson, D.A.; Wicker, R.B. Fracture surface analysis of 3D-printed tensile specimens of novel ABS-based materials. J. Fail. Anal. Prev. 2014, 14, 343–353. [Google Scholar] [CrossRef]

- Grygier, D.; Kurzawa, A.; Stachowicz, M.; Krawiec, K.; Stępczak, M.; Roszak, M.; Kazimierczak, M.; Aniszewska, D.; Pyka, D. Investigations into the Material Characteristics of Selected Plastics Manufactured Using SLA-Type Additive Methods. Polymers 2024, 16, 1607. [Google Scholar] [CrossRef]

- Liaw, C.-Y.; Guvendiren, M. Current and Emerging Applications of 3D Printing in Medicine. Biofabrication 2017, 9, 024102. [Google Scholar] [CrossRef]

- Lindquist, E.M.; Gosnell, J.M.; Khan, S.K.; Byl, J.L.; Zhou, W.; Jiang, J.; Vettukattil, J.J. 3D Printing in Cardiology: A Review of Applications and Roles for Advanced Cardiac Imaging. Ann. 3d Print. Med. 2021, 4, 100034. [Google Scholar] [CrossRef]

- Oleksy, M.; Dynarowicz, K.; Aebisher, D. Rapid Prototyping Technologies: 3D Printing Applied in Medicine. Pharmaceutics 2023, 15, 2169. [Google Scholar] [CrossRef]

- Vaz, V.M.; Kumar, L. 3D Printing as a Promising Tool in Personalized Medicine. AAPS PharmSciTech 2021, 22, 49. [Google Scholar] [CrossRef]

- Ventola, C.L. Medical Applications for 3D Printing: Current and Projected Uses. Pharm. Ther. 2014, 39, 704–711. [Google Scholar]

- Olivieri, L.J.; Su, L.; Hynes, C.F.; Krieger, A.; Alfares, F.A.; Ramakrishnan, K.; Zurakowski, D.; Marshall, M.B.; Kim, P.C.W.; Jonas, R.A.; et al. “Just-In-Time” Simulation Training Using 3-D Printed Cardiac Models After Congenital Cardiac Surgery. World J. Pediatr. Congenit. Heart Surg. 2016, 7, 164–168. [Google Scholar] [CrossRef]

- Zabala-Travers, S. Biomodeling and 3D Printing: A Novel Radiology Subspecialty. Ann. 3d Print. Med. 2021, 4, 100038. [Google Scholar] [CrossRef]

- Kuo, C.-C.; Liu, L.-C.; Teng, W.-F.; Chang, H.-Y.; Chien, F.-M.; Liao, S.-J.; Kuo, W.-F.; Chen, C.-M. Preparation of Starch/Acrylonitrile-Butadiene-Styrene Copolymers (ABS) Biomass Alloys and Their Feasible Evaluation for 3D Printing Applications. Compos. Part. B Eng. 2016, 86, 36–39. [Google Scholar] [CrossRef]

- Vǎlean, C.; Marşavina, L.; Mǎrghitaş, M.; Linul, E.; Razavi, N.; Berto, F. Effect of manufacturing parameters on tensile properties of FDM printed specimens. Procedia Struct. Integr. 2020, 26, 313–320. [Google Scholar] [CrossRef]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef]

- Jain, P.; Kathuria, H.; Dubey, N. Advances in 3D Bioprinting of Tissues/Organs for Regenerative Medicine and In-Vitro Models. Biomaterials 2022, 287, 121639. [Google Scholar] [CrossRef]

- ISO 527-3:2019-01; Plastics—Determination of Tensile Properties—Part 3: Test Conditions for Films and Plates. ISO: Geneva, Switzerland, 2019.

- ISO 10993-5:2009; Biological Evaluation of Medical Devices—Part 5: Tests for In Vitro Cytotoxicity. ISO: Geneva, Switzerland, 2009.

- Fiberflex 40d. Fiberlogy. Available online: https://fiberlogy.com/en/fiberlogy-filaments/filament-fiberflex-40d/ (accessed on 14 September 2024).

- Filament Hips do Druku, 3D. Opis Produktu: Filame. (n.d.). Available online: https://devildesign.com/download/HIPS_-_karta_produktu.pdf (accessed on 14 September 2024).

- F3dfilament. Strona Główna. (n.d.). Available online: https://f3dfilament.com/product-category/elastyczne/tpu (accessed on 14 September 2024).

- Filamenty Pet-G—WŁAŚCIWOŚCI. 3DActive. (n.d.). Available online: https://3dactive.pl/filamenty-pet-g-wlasciwosci/ (accessed on 14 September 2024).

- Sunlu PETG 3D Printer Filament—SUNLU Official Online Store. Affordable 3D Printing Filaments and Resins. (n.d.). Available online: https://www.sunlu.com/collections/petg?srsltid=AfmBOopy1sTjTszVmrzKJTKx4Q9fI8x1_nA63cWHppyCYF_HkF83rwz5 (accessed on 14 September 2024).

- Kimya Petg Carbon 3D Filament. Kimya PETG Carbon 3D Filament—Kimya.fr. (n.d.). Available online: https://www.kimya.fr/en/product/petg-carbon-3d-filament/ (accessed on 14 September 2024).

- PA12 + CF15 1.75mm 0.5kg. sklep ROSA3D. Available online: https://sklep.rosa3d.pl/product/filament-pa-15cf-175mm/ (accessed on 14 September 2024).

- ISO 10993-12:2021; Sample Preparation and Reference Materials. ISO: Geneva, Switzerland, 2021.

- ISO 178:1998; Plastics—Determination of Flexural Properties. ISO: Geneva, Switzerland, 1998.

- ISO 527-2:2012; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. ISO: Geneva, Switzerland, 2012.

- ISO 527-1:2019; Plastics—Determination of Tensile Properties—Part 1: General Principles. ISO: Geneva, Switzerland, 2019.

- ISO 10993-1:2018; Biological Evaluation of Medical devices—Part 1: Evaluation and Testing Within a Risk Management Process. ISO: Geneva, Switzerland, 2018.

- ISO 14971; Medical Devices—Application of Risk Management to Medical Devices. ISO: Geneva, Switzerland, 2019.

- Chen, G.; Ren, C.; Yu, W.; Yang, X.; Zhang, L. Application of Genetic Algorithms for Optimizing the Johnson–Cook Constitutive Model Parameters. Comput. Mater. Sci. 2012, 64, 221–227. [Google Scholar] [CrossRef]

- Dorogoy, A.; Rittel, D. Determination of the Johnson–Cook Material Parameters Using the Shear Compression Specimen. Exp. Mech. 2009, 49, 881–892. [Google Scholar] [CrossRef]

- Jang, J.; Yoo, S.; Lee, C.; Lee, H. Identification of Plastic Constitutive Johnson-Cook Model Parameters by Optimization-Based Inverse Method. J. Mech. Sci. Technol. 2021, 35, 4457–4466. [Google Scholar] [CrossRef]

- Amani, E.; Faraji, M.; Yousefpour, H. A Non-Ordinary State-Based Peridynamics Formulation for Thermoplastic Fracture. Eng. Fract. Mech. 2016, 168, 102–118. [Google Scholar] [CrossRef]

- Dehgolan, F.; Ramezani, M.; Ghaei, A. Obtaining Constants of Johnson-Cook Material Model Using a Combined Experimental, Numerical Simulation, and Optimization Method. Mater. Des. 2016, 109, 500–506. [Google Scholar] [CrossRef]

- Wittbrodt, B.; Pearce, J. The Effects of PLA Color on Material Properties of 3-D Printed Components. Addit. Manuf. 2015, 8, 110–116. [Google Scholar] [CrossRef]

- Delbart, R.; Papasavvas, A.; Robert, C.; Hoang, T.Q.T.; Martinez-Hergueta, F. An experimental and numerical study of the mechanical response of 3D printed PLA/CB polymers. Compos. Struct. 2023, 319, 117156. [Google Scholar] [CrossRef]

- Licata, J.P.; Slupianek, H.; Rizokulova, S.; Gerstenhaber, J.A.; Lelkes, P.I. Biocompatibility of 3D printed plastics for use in bioreactors. Bioprinting 2024, 40, e00347. [Google Scholar] [CrossRef]

- Burkhardt, F.; Spies, B.C.; Wesemann, C.; Schirmeister, C.G.; Licht, E.H.; Beuer, F.; Steinberg, T. Cytotoxicity of polymers intended for the extrusion-based additive manufacturing of surgical guides. Sci. Rep. 2022, 12, 7391. [Google Scholar] [CrossRef]

| No. | Material | Manufacturer | Density (g/cm3) | Tensile Strength Declared by Producent (MPa) | Hardness (HS) | Volumetric Shrinkage (%) |

|---|---|---|---|---|---|---|

| 1 | PETG Carbon | Kimya | 1.32 | 92.9 | 78.8 | 0.2–1.0 |

| 2 | FiberFlex 40D | Fiberlogy | 1.27 | 26.5 | 40.0 | 0.5–1.0 |

| 3 | PETG | Sunlu | 1.23 | 28.3–101.0 | 71.4 | 0.2–1.0 |

| 4 | HIPS | Devil Design | 1.05 | 37.0 | 75.0 | 0.2–1.0 |

| 5 | TPU | F3D Filament | 1.20 | 28.0–96.0 | 85.0 | 0.5–1.0 |

| 6 | PA+15CF | ROSA 3D | 1.07 | 125.0 | 78.0 | 0.1–0.5 |

| 7 | PETG | 3DActive | 1.26 | 84.6 | 70.0 | 0.2–1.0 |

| 8 | PLA | 3DActive | 1.24 | 45.0 | 87.0 | 0.3–0.5 |

| No. | Material | Producent | Temperature Recommended by the Manufacturer (°C) | Selected Temperature Printing (°C) | Bed Temperature (°C) |

|---|---|---|---|---|---|

| 1 | PETG Carbon | Kimya | 225 | 225 | 90 |

| 2 | FiberFlex 40D | Fiberlogy | 220 | 240 | 60 |

| 3 | PETG | Sunlu | 250 | 240 | 90 |

| 4 | HIPS | Devil Design | 240 | 240 | 110 |

| 5 | TPU | F3D Filament | 230 | 230 | 60 |

| 6 | PA+15CF | ROSA 3D | 290 | 290 | 110 |

| 7 | PETG | 3DActive | 250 | 250 | 90 |

| 8 | PLA | 3DActive | 220 | 220 | 60 |

| Material | E [MPa] | v [-] | ρ [kg/m3] | A [MPa] | B [MPa] | n [-] | Failure Strain [mm/mm] |

|---|---|---|---|---|---|---|---|

| PETG Carbon | 2071 | 0.4 | 1320 | 43.67 | 25.14 | 0.099 | 0.057 |

| FiberFlex 40D | 14 | 0.4 | 1270 | 2.43 | 0.64 | 1.444 | 5.295 |

| PETG | 1130 | 0.4 | 1230 | - | - | - | 0.030 |

| HIPS | 646 | 0.4 | 1050 | 10.80 | - | - | 0.375 |

| TPU | 26 | 0.4 | 1200 | 2.03 | 1.63 | 1.723 | 2.860 |

| PA+15CF ROSA 3D | 1667 | 0.4 | 1070 | 30.04 | 90.17 | 0.392 | 0.082 |

| PET-G | 970 | 0.4 | 1260 | 33.57 | 17.40 | 0.262 | 0.105 |

| PLA | 1488 | 0.4 | 1240 | 40.16 | 16.55 | 0.374 | 0.103 |

| Material | Elastic Limit | Yield Strength | Ultimate Tensile Strength | ||||

|---|---|---|---|---|---|---|---|

| Stress [MPa] | Strain [mm/mm] | Stress [MPa] | Strain [mm/mm] | Stress [MPa] | Strain [mm/mm] | ||

| 1. | PETG Carbon | 20.54 ± 0.48 | 0.008 ± 0.04 | 29.18 ± 0.38 | 0.01 ± 0.01 | 60.09 ± 1.80 | 0.063 ± 0.00 |

| 2. | FiberFlex 40D | 1.31 ± 0.40 | 0.050 ± 0.01 | 2.41 ± 0.03 | 0.22 ± 0.01 | 8.71 ± 0.55 | 5.090 ± 0.30 |

| 3. | PETG Sunlu | 13.18 ± 0.17 | 0.011 ± 0.01 | 15.08 ± 0.18 | 0.01 ± 0.01 | 31.49 ± 1.07 | 0.029 ± 0.01 |

| 4. | HIPS Devil Design | 9.44 ± 0.03 | 0.014 ± 0.01 | 12.73 ± 0.32 | 0.02 ± 0.01 | 10.83 ± 0.17 | 0.366 ± 0.01 |

| 5. | TPU | 0.69 ± 0.15 | 0.043 ± 0.01 | 1.97 ± 0.41 | 0.28 ± 0.02 | 10.96 ± 1.22 | 2.960 ± 0.42 |

| 6. | PA+15CF | 14.71 ± 0.38 | 0.010 ± 0.01 | 20.03 ± 0.38 | 0.01 ± 0.01 | 56.57 ± 1.09 | 0.073 ± 0.01 |

| 7. | PETG 3DActive | 18.01 ± 0.18 | 0.018 ± 0.01 | 22.01 ± 0.24 | 0.02 ± 0.01 | 43.38 ± 0.68 | 0.061 ± 0.01 |

| 8. | PLA 3DActive | 21.95 ± 0.17 | 0.014 ± 0.01 | 48.89 ± 0.89 | 0.03 ± 0.01 | 43.89 ± 1.16 | 0.110 ± 0.02 |

| Material | Ry Yield Stress [MPa] | Elongation at Yield [mm] | Ru Ultimate Tensile Stress [MPa] | Elongation at Break [mm] | |

|---|---|---|---|---|---|

| 1. | PETG Carbon | 113.69 ± 0.52 | 2.14 ± 0.004 | 112.59 ± 0.79 | 2.38 ± 0.001 |

| 2. | FiberFlex 40D | - | - | - | - |

| 3. | PETG Sunlu | 36.55 ± 0.31 | 1.66 ± 0.020 | 2.41 ± 0.03 | 0.22 ± 0.005 |

| 4. | HIPS Devil Design | 22.96 ± 0.73 | 2.33 ± 0.020 | 9.14 ± 0.02 | 5.31 ± 0.010 |

| 5. | TPU | - | - | - | - |

| 6. | PA+15CF | 98.26 ± 0.20 | 3.55 ± 0.040 | 1.99 ± 0.03 | 11.86 ± 0.080 |

| 7. | PETG 3DActive | 74.02 ± 0.08 | 3.12 ±0.020 | 70.77 ± 0.08 | 3.35 ± 0.060 |

| 8. | PLA 3DActive | 66.02 ± 0.10 | 1.56 ± 0.050 | 1.20 ± 0.10 | 8.48 ± 0.150 |

| Sample | PETF Carbon | FiberFlex 40D | PETG | HIPS | TPU | PA+15CF Rosa | PETG 3DActive | PLA |

|---|---|---|---|---|---|---|---|---|

| Blank | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Negative control | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| Positive control | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Test item | Non-cytotoxic | Cytotoxic | Non-cytotoxic | Non-cytotoxic | Non-cytotoxic | Non-cytotoxic | Non-cytotoxic | Non-cytotoxic |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pyka, D.; Słowiński, J.J.; Kurzawa, A.; Roszak, M.; Stachowicz, M.; Kazimierczak, M.; Stępczak, M.; Grygier, D. Research on Basic Properties of Polymers for Fused Deposition Modelling Technology. Appl. Sci. 2024, 14, 11151. https://doi.org/10.3390/app142311151

Pyka D, Słowiński JJ, Kurzawa A, Roszak M, Stachowicz M, Kazimierczak M, Stępczak M, Grygier D. Research on Basic Properties of Polymers for Fused Deposition Modelling Technology. Applied Sciences. 2024; 14(23):11151. https://doi.org/10.3390/app142311151

Chicago/Turabian StylePyka, Dariusz, Jakub J. Słowiński, Adam Kurzawa, Maciej Roszak, Mateusz Stachowicz, Mikołaj Kazimierczak, Maksymilian Stępczak, and Dominika Grygier. 2024. "Research on Basic Properties of Polymers for Fused Deposition Modelling Technology" Applied Sciences 14, no. 23: 11151. https://doi.org/10.3390/app142311151

APA StylePyka, D., Słowiński, J. J., Kurzawa, A., Roszak, M., Stachowicz, M., Kazimierczak, M., Stępczak, M., & Grygier, D. (2024). Research on Basic Properties of Polymers for Fused Deposition Modelling Technology. Applied Sciences, 14(23), 11151. https://doi.org/10.3390/app142311151