Optimizing Assembly in Wiring Boxes Using API Technology for Digital Twin

Abstract

1. Introduction

2. The State of the Art

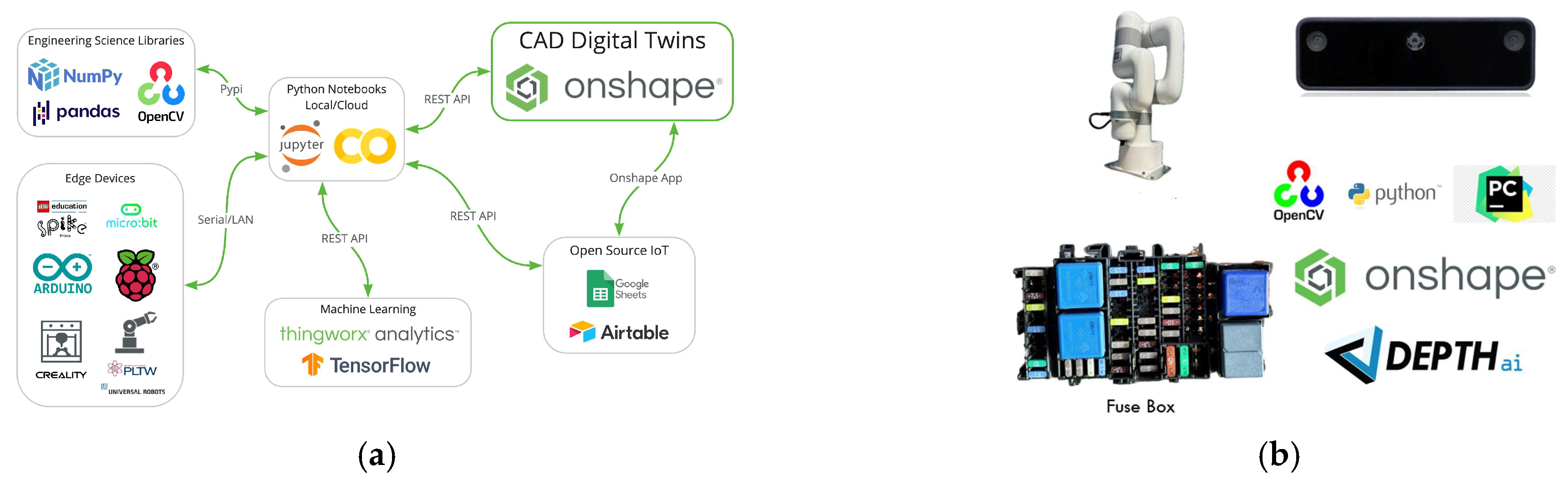

3. Overview of the System Architecture

3.1. Technical Specification for Ufactory Lite 6 Robot

3.2. Kinematics of Robotic Arm

3.2.1. Denavit–Hartenberg Parameters for Lite 6

3.2.2. Homogeneous and Combined Transformation Matrices

3.3. Methodology

3.3.1. Implementation Phases

- Creating the digital twin model using API Technology;

- Configuring and integrating the Ufactory Lite 6 robot (Ufactory, Shenzhen, Guangdong, China);

- Testing and calibrating the system using computer vision and digital twin.

3.3.2. Tools and Software Used

- Onshape is a SAS (Software as a Service);

- PyCharm IDE (Python) 3.12.2;

- Ufactory Studio 1.0.1;

- Open CV 4.10.0.84;

- Depth AI 3.5.0.

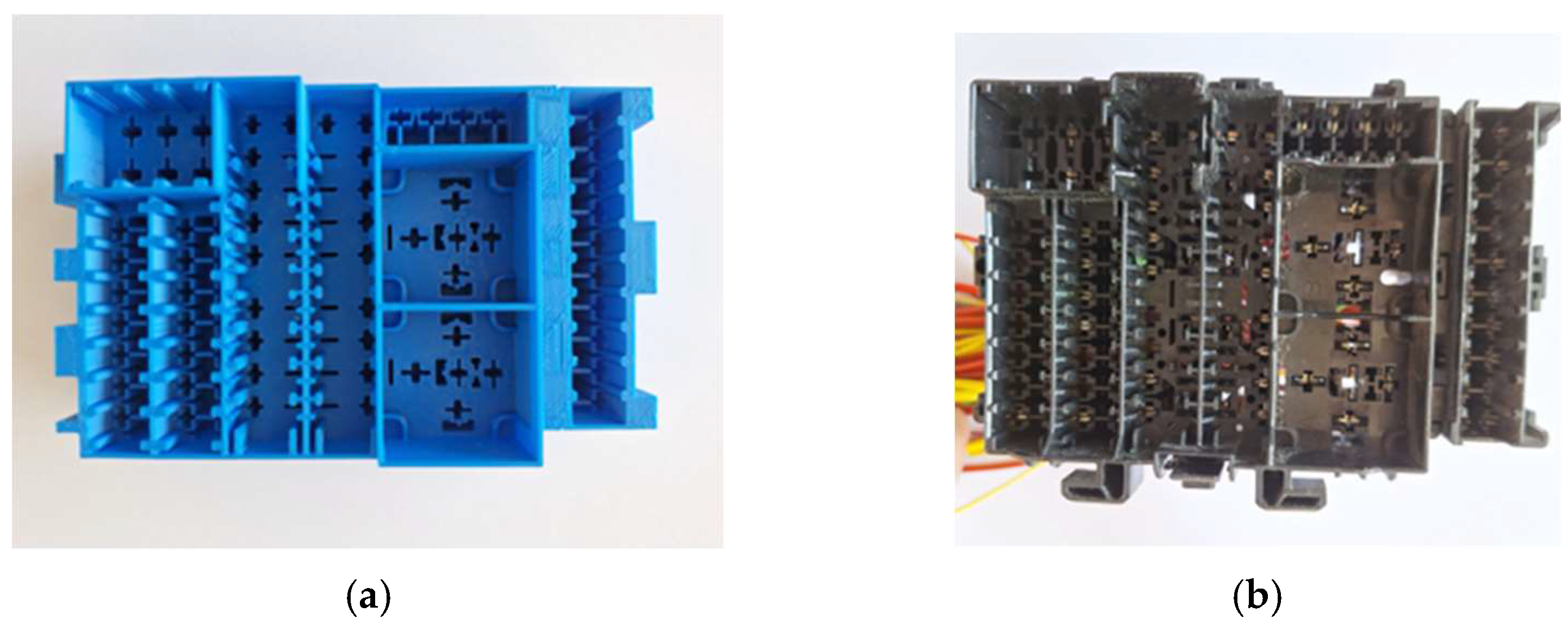

- Creating the digital twin model using API technology: In this initial phase, a virtual replica of the wiring box assembly is created. The digital twin model is crucial for simulating and monitoring the assembly process in real time. Tools like Onshape are used for 3D modeling, enabling the reverse engineering of the physical wiring box to generate its digital counterpart.

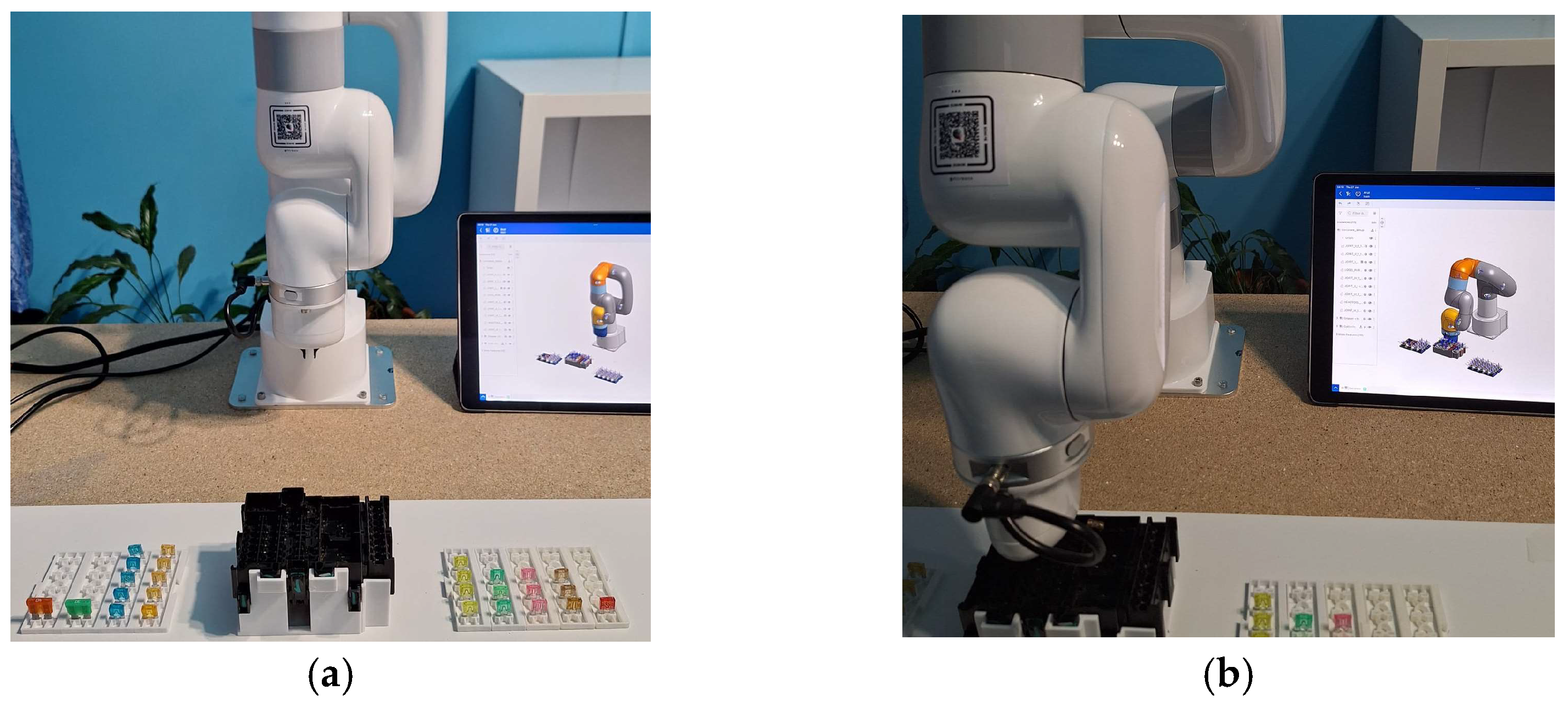

- Configuring and integrating the Ufactory Lite 6 robot: In this phase, the robotic arm is set up, including the calibration of the custom gripper and the initialization of the arm’s position. The precise configuration of the robot is essential to ensure the accurate assembly of fuses. Software like Ufactory Studio is used to configure the robot, while Python is employed to develop control programs that synchronize the robot’s movements with the digital twin.

- Testing and calibrating the system using computer vision and digital twin: After configuring the robot and digital twin, this phase focuses on testing the system’s accuracy and efficiency. OpenCV and DepthAI are used for image processing, allowing the robot to leverage computer vision to identify and correctly position the fuses. Calibration ensures that the robot applies the right amount of force during insertion, preventing errors.

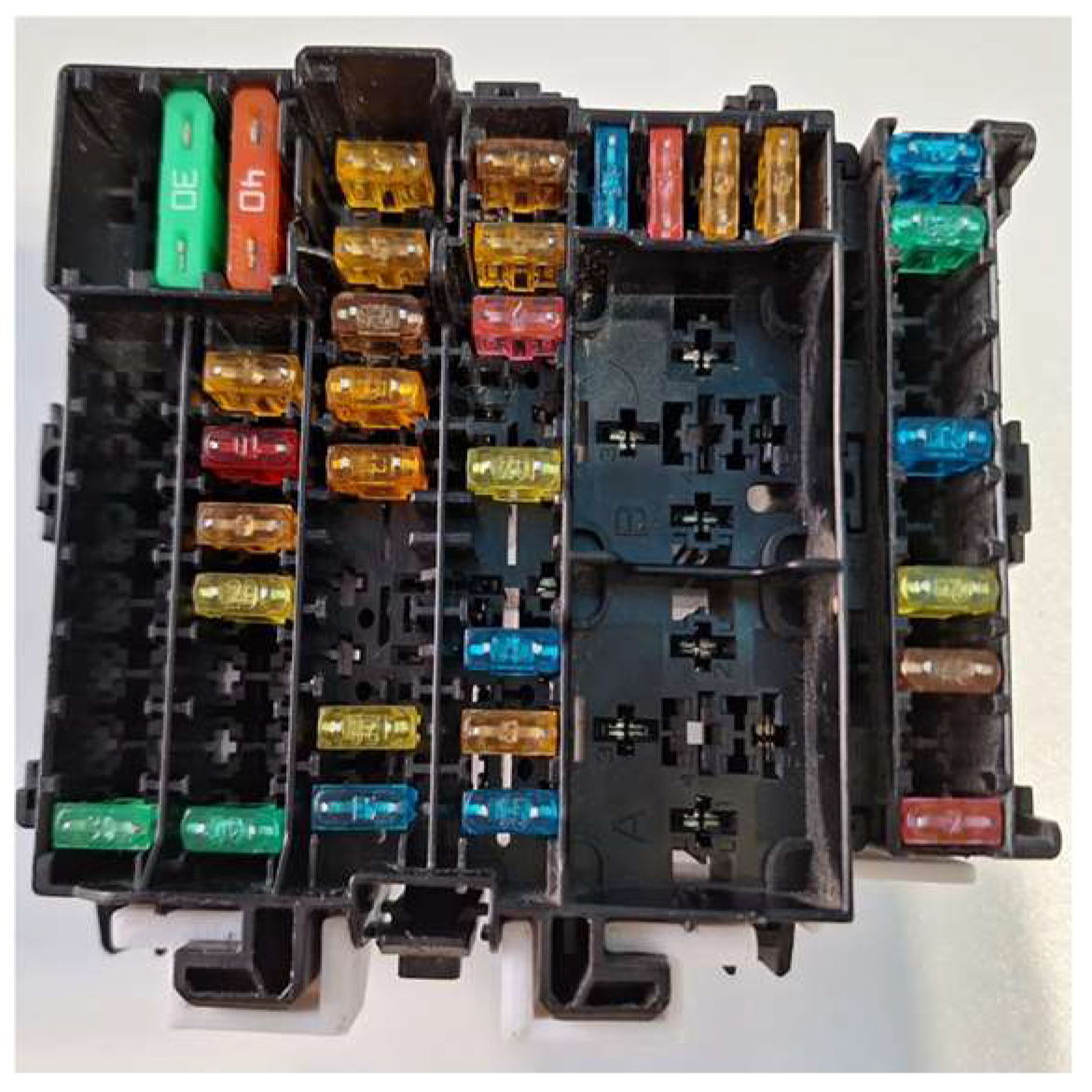

4. Proof of Concept for Optimizing Assembly in Wiring Boxes

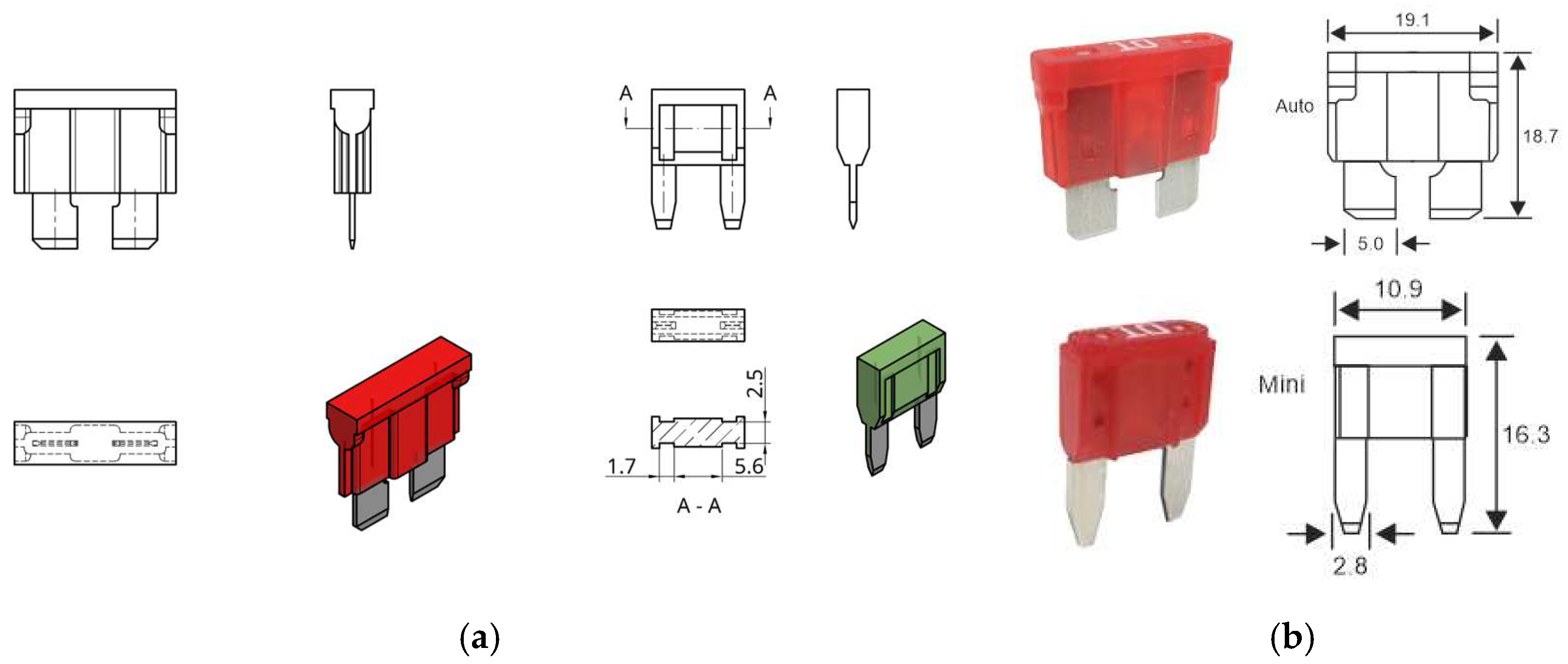

- 10 mini blade fuses 5A;

- 3 mini blade fuses 7.5A;

- 1 mini blade fuse 10A;

- 6 mini blade fuses 15A;

- 4 mini blade fuses 20A;

- 3 mini blade fuses 25A;

- 3 mini blade fuses 30A;

- 1 auto blade fuse 30A;

- 1 auto blade fuse 40A.

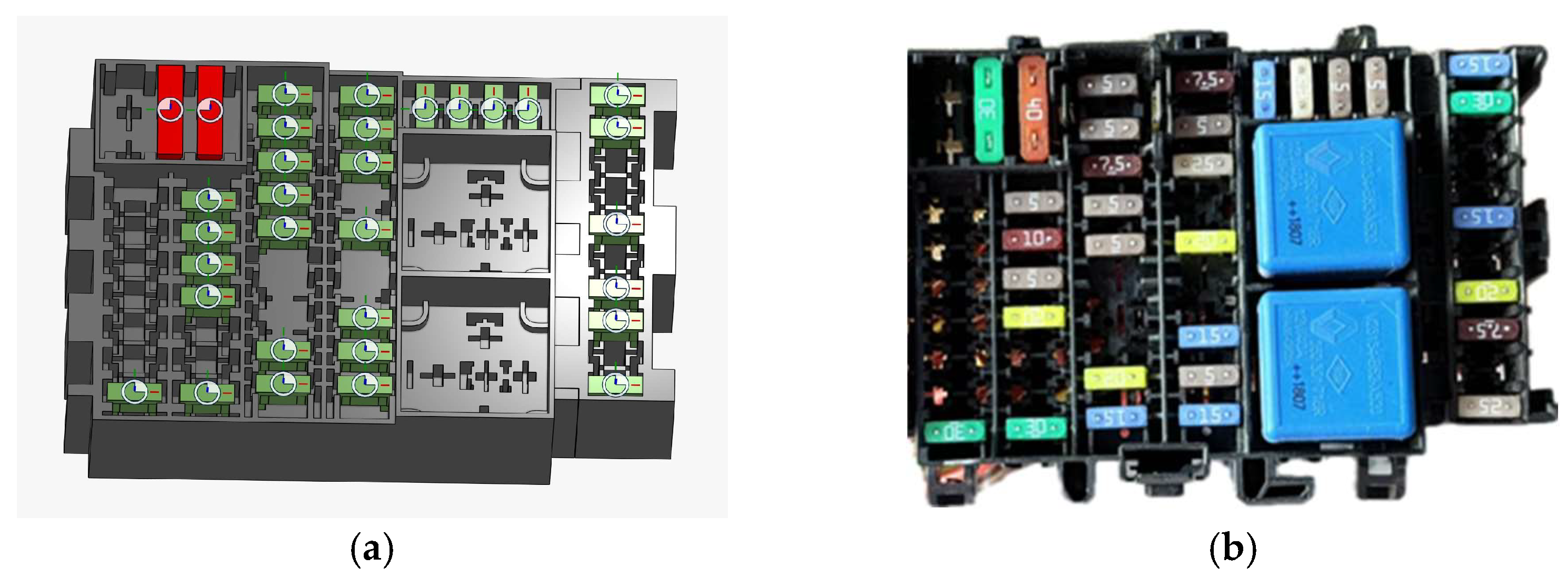

4.1. Creating the Digital Twin Model Using API Technology

- The local coordinates of each mate connector on the fuse within the fuse’s local coordinate system.

- Transforming the local coordinates of the fuse into global coordinates (relative to the origin).

- is the position of a mate connector on the fuse in local coordinates. The coordinates of the point in the fuse’s coordinate system (which is at the center).

- is the transformation matrix (including rotation and translation) that converts the fuse’s local coordinates into global coordinates.

- is the position of a mate connector on the fuse in global coordinates.

- is the rotation matrix that defines the orientation of the fuse in the global system.

- is the translation vector that defines the position of the fuse’s center in the global system.

4.2. Configuring and Integrating the Ufactory Lite 6 Robot

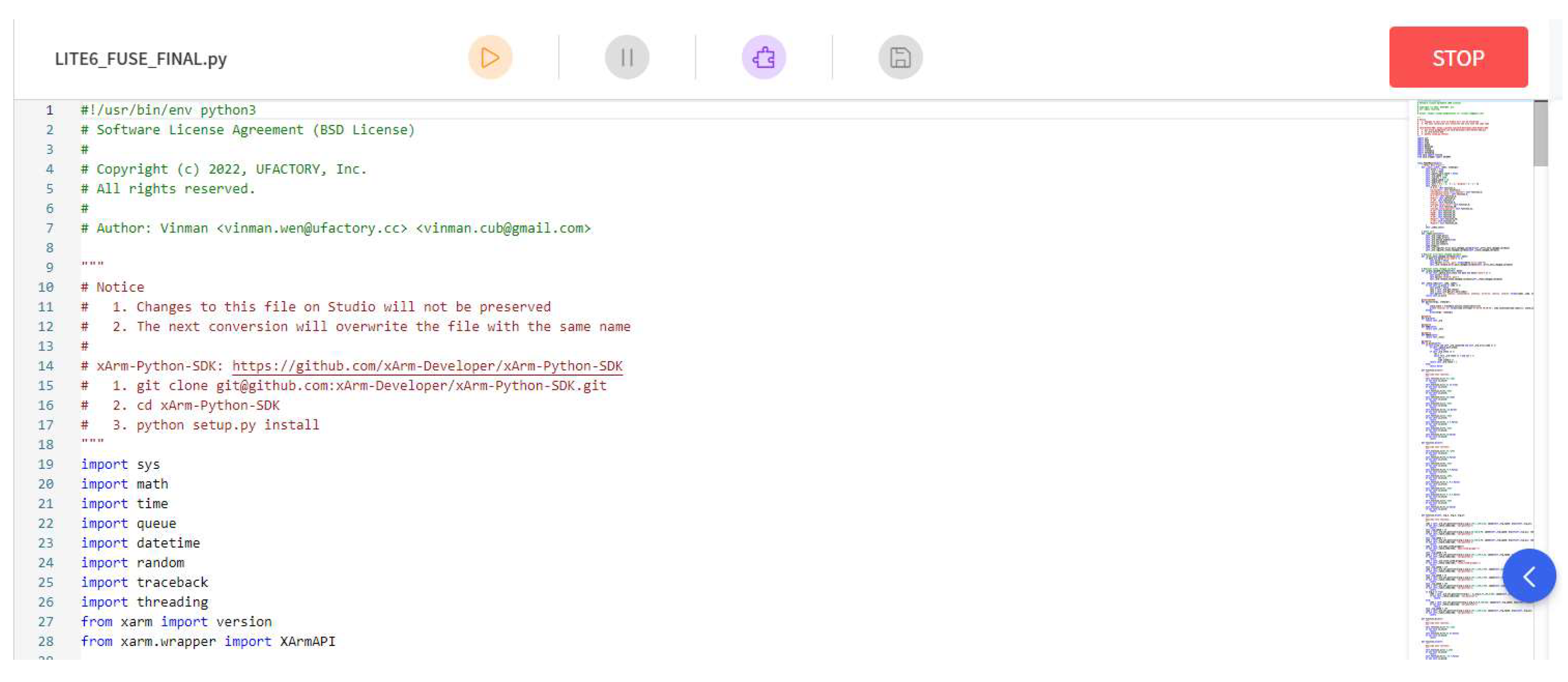

- Fuse assembly program: This program handles the precise assembly of fuses, ensuring that each step is executed with accuracy. The program is sent to the robot using the Ufactory Studio 1.0.1. interface, Figure 10.

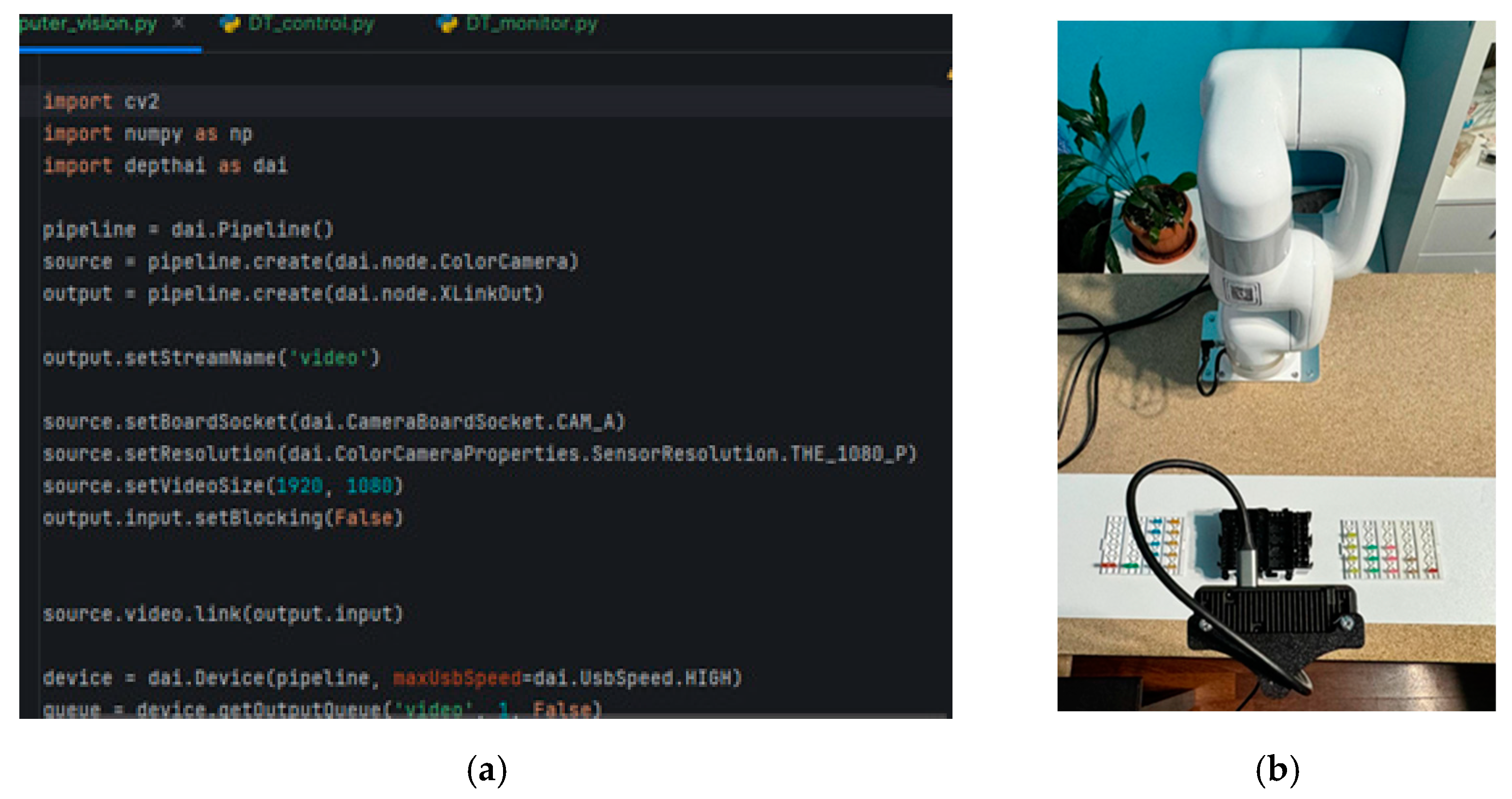

- Computer vision program: Using an Oak-D Lite camera (Luxonis Holding Corporation, Littleton, CO 80127, USA) can identify the fuses in the storage location. This program is sent to the robot using the Pycharm platform, Figure 11.

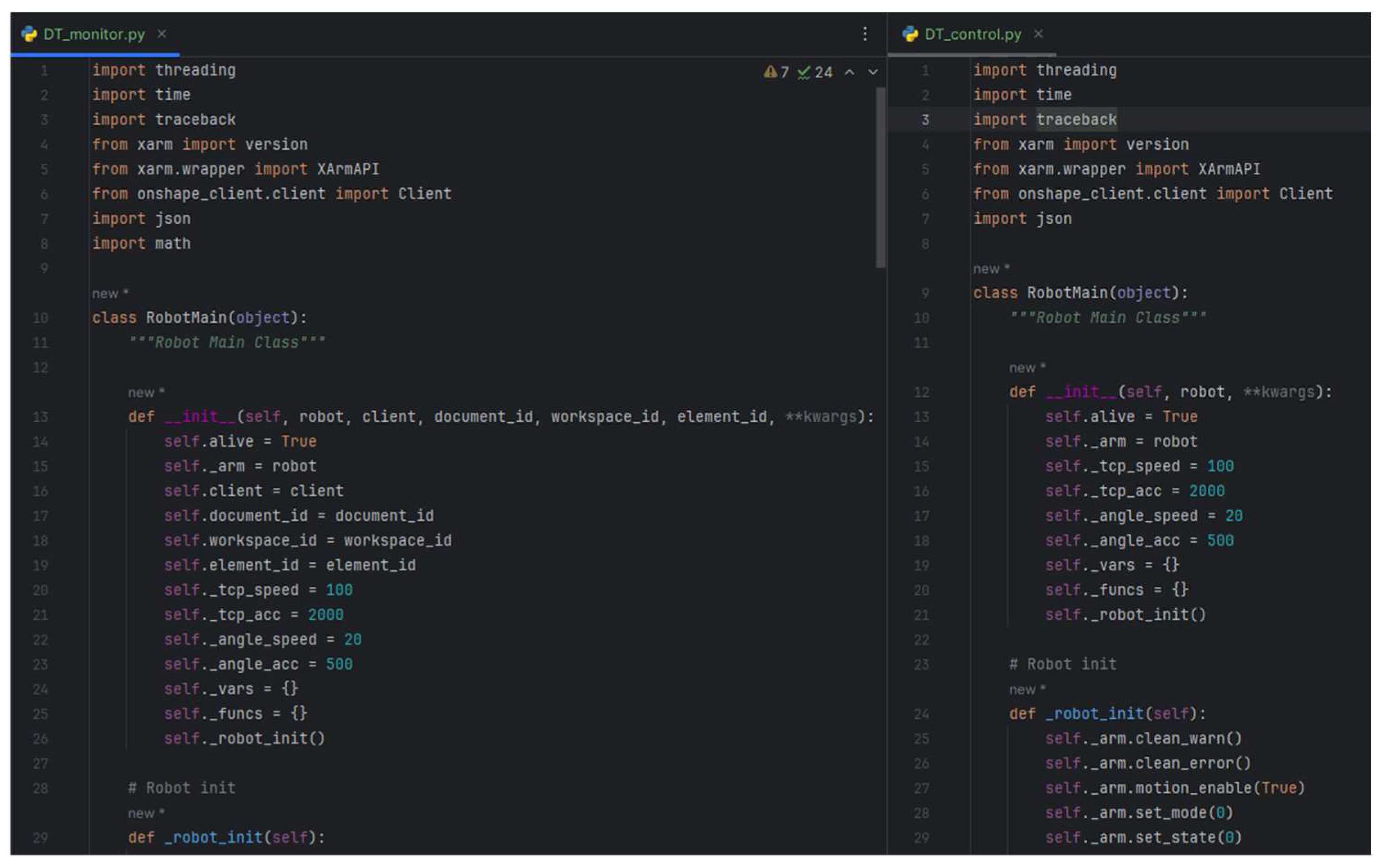

- Digital twin monitoring program: This program monitors the robot’s activity during assembly. It is sent to the robot using the Pycharm platform, Figure 12.

- Digital twin control program: This program allows us to control the robot’s activity from CAD environment on a computer. It is sent to the robot using the Pycharm platform, Figure 13.

- DepthAI pipeline configuration: configuring the video source and output for video capture.

- Video capture: initializing video capture from the default camera.

- Image processing: applying filters to detect colors and identify fuses in boxes.

- Object identification and marking: identifying and marking the positions of fuses in the video frame.

- xArm API—for controlling the robotic arm.

- Onshape API—for monitoring and updating the digital model.

- from xarm.wrapper import XArmAPI

- arm = XArmAPI(‘Robot ID’, baud_checkset = False)

- arm.connect()

- arm.motion_enable(enable = True)

- arm.set_mode(0)

- arm.set_state(0)

- def sync_movements(self, joint_positions):

- def monitor_robot(self):

- def update_onshape(self, joint_positions):

- def continuous_sync(client, arm, document_id, workspace_id, element_id, interval = 5):

4.3. Testing and Calibrating the System Using Computer Vision and Digital Twin

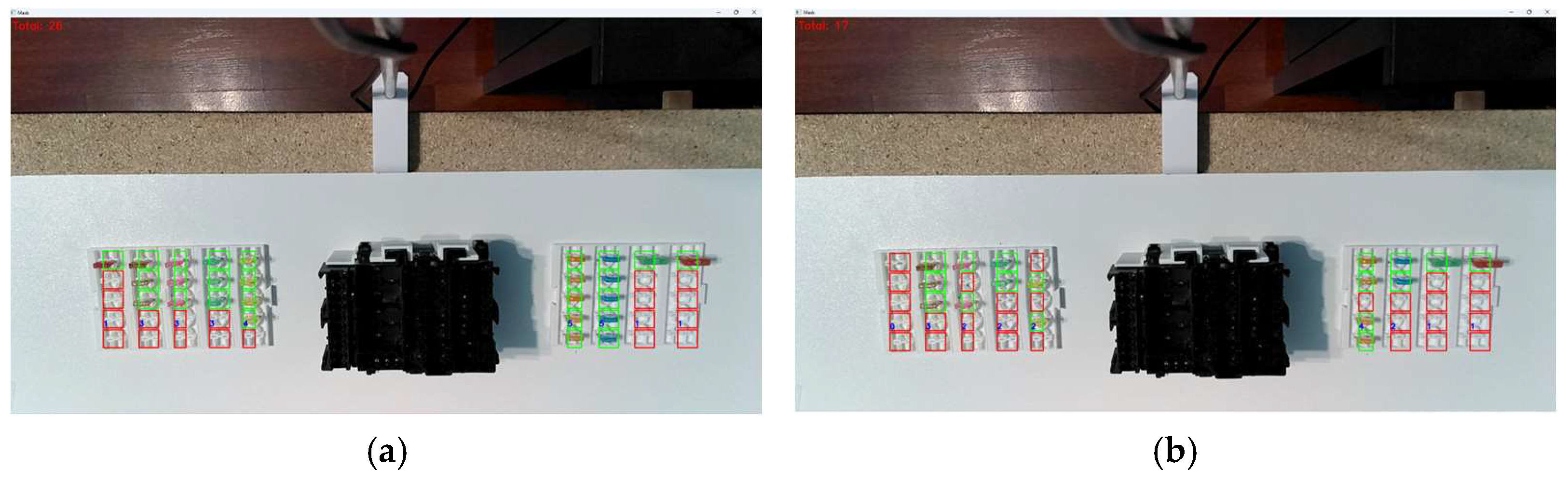

- Fuses: The fuses are organized in a grid-like pattern, with red and green indicators. The red color indicates the absence of a fuse, while the green color indicates the presence of a fuse.

- Wiring box: The black component in the middle is likely the main housing for the cable connections, serving as the central point for the fuse assembly.

- Workspace: The assembly takes place on a white surface, providing a clear and contrasting background for image processing.

- Real-time monitoring: the digital twin mirrors the real-world setup, providing continuous feedback and ensuring the assembly process is on track.

- Simulation and optimization: by simulating the assembly process, potential issues can be predicted and addressed before they occur in the real world.

5. Results

- Novelty of the approach: this study is the first to apply a fully automated, digitally controlled process for fuse insertion, Figure 15, which solves existing quality and performance issues.

- Accuracy and precision: The robotic system, integrated with digital twin technology, achieved a fuse insertion accuracy rate of 99.5%. This represents a significant improvement over manual insertion, which often results in misalignments such as angled or incomplete insertion, leading to a suboptimal electrical contact and potential rework. By utilizing real-time feedback from the digital twin, the automated system consistently ensured that fuses were inserted at the correct angle and depth, mitigating the common errors associated with manual assembly.

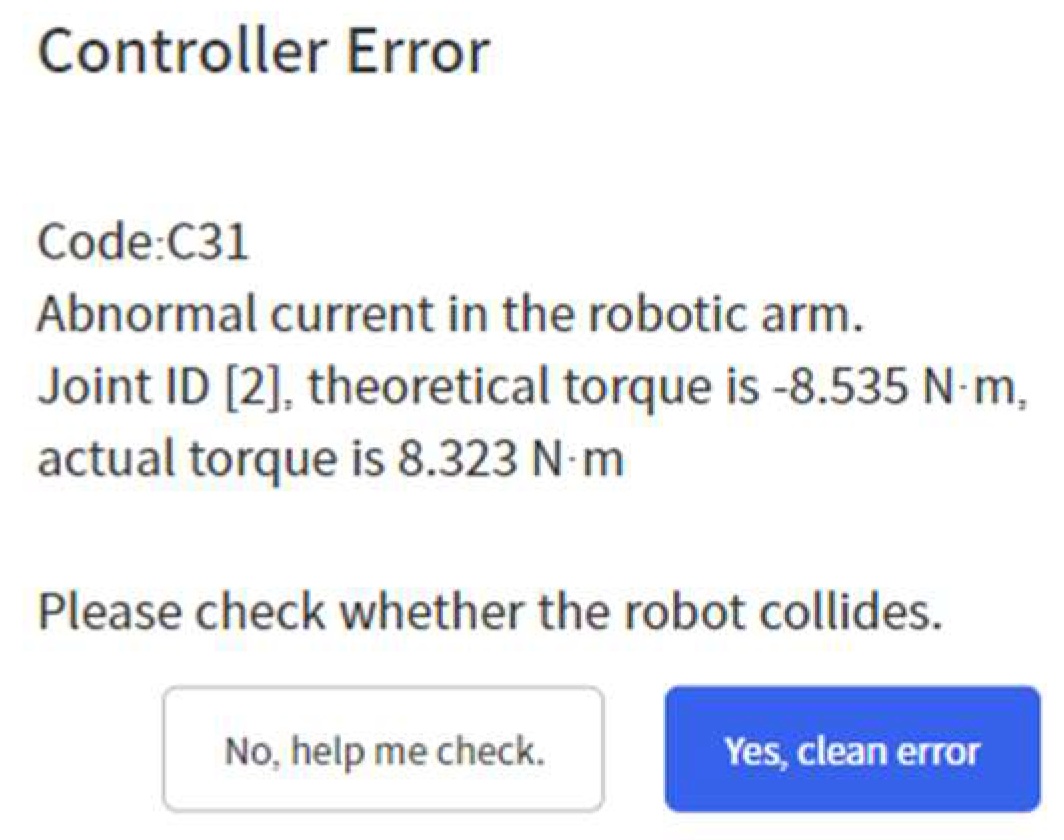

- Force control and component integrity: Another critical factor in the automation process was the precise control of insertion force. The system applied just enough pressure to secure the fuse without causing damage, Figure 16. This is an improvement over manual processes, where excessive or insufficient force often leads to defects or damaged components. The force applied by the robotic arm was consistently measured and controlled, ensuring the reliable and secure insertion of each fuse, thus enhancing the quality and reliability of the wiring box assembly.

- Time efficiency: The cycle time for manual fuse insertion typically ranged between 40 and 45 s per fuse, depending on the operator’s skill and the complexity of the fuse box. With the automated system, this time was significantly reduced to 22–25 s per fuse, reflecting a nearly 50% improvement in efficiency. This reduction in cycle time was achieved without compromising accuracy or quality, making the automated process both faster and more reliable than manual alternatives.

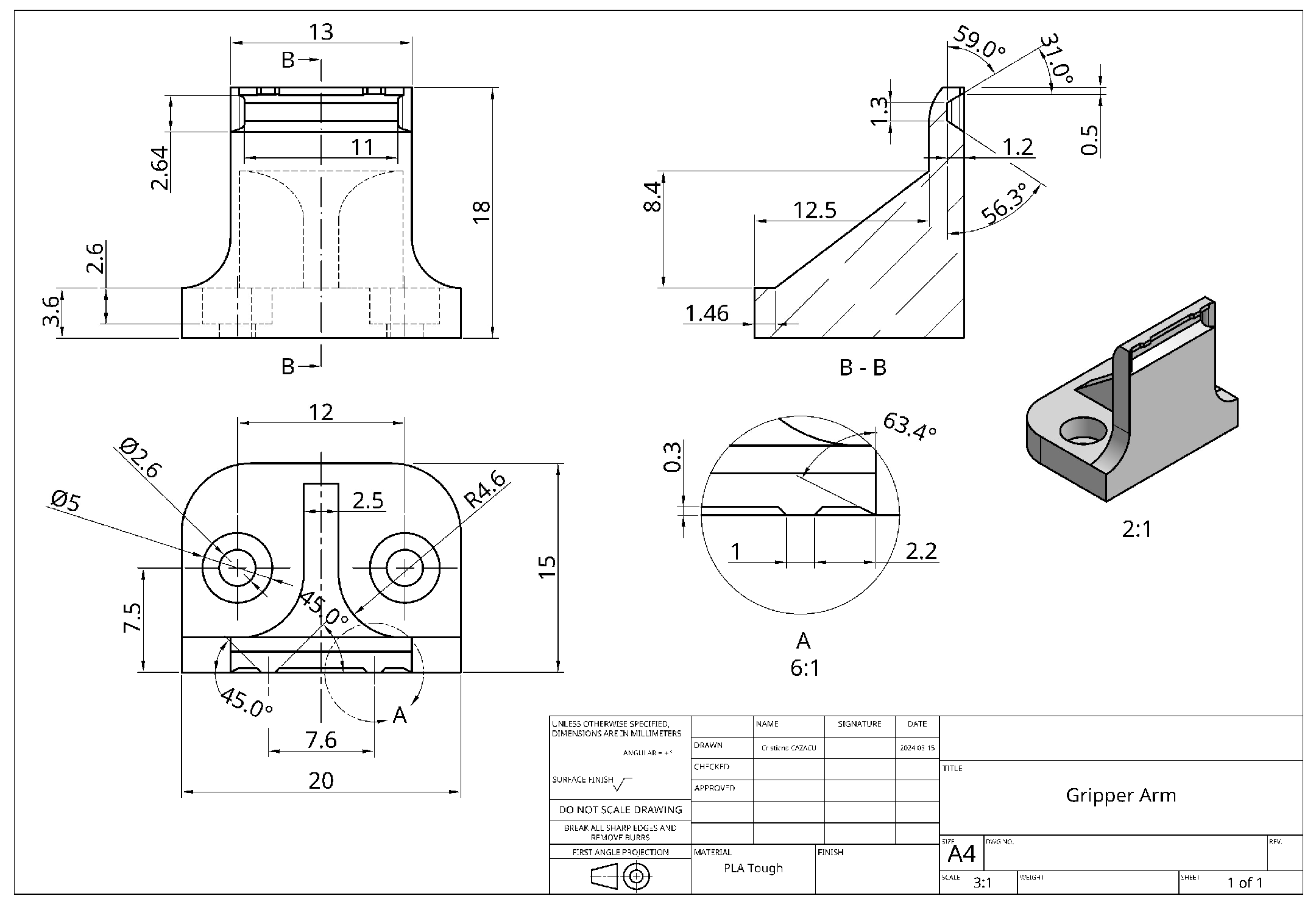

- System flexibility: The system demonstrated the flexibility to handle slight variations in fuse dimensions and box configurations. The combination of computer vision and digital twin technology allowed the system to adapt to these variations without requiring extensive recalibration or adjustments, showcasing its potential for handling different fuse box designs in dynamic production environments. The gripper design, optimized through iterative testing, enabled the robotic arm to handle delicate components with a minimal risk of damage.

- Continuous operation and reliability: During extended testing, the system demonstrated high reliability, operating continuously over long periods without significant faults or errors. This robustness is crucial for its potential application in full-scale production environments, where continuous, uninterrupted operation is necessary to maintain productivity. The real-time monitoring capabilities of the digital twin allowed for ongoing adjustments to be made, ensuring optimal performance throughout the assembly process.

- Gripper design optimization: The design of the gripper was optimized through multiple iterations to ensure that it could securely grasp the fuses without causing damage. The adjustments to the gripper’s shape and the force it applied were crucial for handling the small, sensitive components involved in the assembly process. This iterative testing led to a gripper design capable of maintaining a firm hold on each fuse while allowing precise control during insertion.

- Scalability and adaptability: The system’s adaptability to different box configurations was another significant advantage. The automated process proved scalable and capable of handling various wiring box setups with minimal adjustments, making it suitable for a wide range of automotive applications. This scalability was further enhanced by the digital twin’s simulation capabilities, which allowed for the virtual testing of multiple scenarios, reducing the need for physical prototypes.

- Statistical validation: The results were validated through multiple test cycles, typically ranging from 20 to 30 cycles per setup, to ensure consistency and reliability. Statistical methods, including mean and standard deviation calculations, were applied to metrics such as cycle time, insertion accuracy, and the force applied by the gripper. This rigorous approach ensured that the results were representative and not outliers, confirming the system’s high performance.

6. Conclusions

- The paper proposes a novel approach to automate the insertion of fuses and relays using a robotic arm integrated with API technology for digital twin simulation and optimization. The main scientific contribution is the integration of a digitally real-time monitored, fully adaptive robotic system that ensures precise insertion angles and force application.

- This research introduces a novel methodological framework in which a digital twin not only simulates but actively controls the assembly process through real-time data feedback. This reduces reliance on post-production quality checks, thus enhancing both production speed and product reliability. The study also introduces a new scientific framework for real-time process adjustment using digital twin models.

- This work significantly contributes to the broader field of smart manufacturing and Industry 4.0. It demonstrates how integrating API technology with robotic systems can yield adaptive, real-time production systems. This paves the way for future studies to apply similar concepts to other complex manual assembly processes, potentially revolutionizing the field.

- Expand automation to handle diverse box types with adaptable algorithms and robotic systems for increased flexibility and scalability.

- Predictive maintenance is a key area for further development, as it was not fully implemented in this study but was identified as a promising application of digital twin technology. Future work could focus on integrating predictive maintenance to improve the system’s ability to monitor wear and tear on robotic components, predict potential failures, and proactively schedule maintenance tasks. This would help reduce downtime and enhance overall system reliability.

- Integrate digital twin and IoT for real-time monitoring, optimizing operational efficiency, predictive maintenance, and assembly line optimization.

- Enhance robotic gripper design to improve delicate component handling, experimenting with materials and designs for better reliability.

- Implement continuous improvement through iterative testing, refining the automated system based on performance data to meet evolving industry needs.

- In this study, the robot was programmed offline, using API technology and digital twin integration to simulate and optimize the assembly process before its physical implementation. This approach allowed us to test multiple scenarios and refine the robot’s movements without disrupting the production process. While offline programming provided the advantage of optimizing complex operations in a controlled environment, we recognize that online programming, which allows for real-time adjustments directly on the robot, could offer greater flexibility and faster on-site modifications.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Eheim, M.; Kaiser, D.; Weil, R. On Automation Along the Automotive Wire Harness Value Chain. In Advances in Automotive Production Technology—Theory and Application; Weißgraeber, P., Heieck, F., Ackermann, C., Eds.; ARENA2036; Springer: Berlin/Heidelberg, Germany, 2021; pp. 178–186. [Google Scholar] [CrossRef]

- Govoni, A.; Laudante, G.; Mirto, M.; Natale, C.; Pirozzi, S. Towards the Automation of Wire Harness Manufacturing: A Robotic Manipulator with Sensorized Fingers. In Proceedings of the 9th International Conference on Control, Decision and Information Technologies (CoDIT), Rome, Italy, 3–6 July 2023. [Google Scholar] [CrossRef]

- Ștefan, I.; Popescu, A.C.; Popa, L.C.; Dobrescu, T.G.; Coteț, C.E. Research regarding assembly flow optimization of wiring harness in automotive industry. MATEC Web Conf. 2021, 343, 02003. [Google Scholar] [CrossRef]

- Heisler, P.; Steinmetz, P.; Yoo, I.S.; Franke, J. Automatization of the Cable-Routing-Process within the Automated Production of Wiring Systems. Appl. Mech. Mater. 2017, 871, 186–192. [Google Scholar] [CrossRef]

- Heisler, P.; Kuhn, M.; Süß-Wolf, R.; Franke, J. Innovative Solutions for the Covering Process in the Manufacturing of Wire Harnesses to Increase the Automation Degre. In Proceedings of the IEEE 11th International Conference on Mechanical and Intelligent Manufacturing Technologies (ICMIMT), Cape Town, South Africa, 20–22 January 2020. [Google Scholar] [CrossRef]

- Bi, Z.; Pomalaza-Ráe, C.; Hershberger, D.; Dawson, J.; Lehman, A.; Yurek, J.; Ball, J. Automation of Electrical Cable Harnesses Testing. Robotics 2018, 7, 1. [Google Scholar] [CrossRef]

- Salunkhe, O.; Stahre, J.; Romero, D.; Li, D.; Johansson, B. Specifying Task Allocation in Automotive Wire Harness Assembly Stations for Human-Robot Collaboration. Comput. Ind. Eng. 2023, 184, 109572. [Google Scholar] [CrossRef]

- Navas-Reascos, G.; Romero, D.; Stahre, J.; Caballero-Riuz, A. Wire Harness Assembly Process Supported by Collaborative Robots: Literature Review and Call for R&D. Robotics 2022, 11, 65. [Google Scholar] [CrossRef]

- Román-Ibáñez, V.; Pujol, F.A. Collaborative robotics in wire harnesses spot taping process. Comput. Ind. 2021, 125, 103370. [Google Scholar] [CrossRef]

- Thelen, A.; Zhang, X.; Fink, O.; Lu, Y.; Ghosh, S.; Youn, B.D.; Todd, M.D.; Mahadevan, S.; Hu, C.; Hu, Z. A comprehensive review of digital twin—Part 1: Modeling and twinning enabling technologies. Struct. Multidiscip. Optim. 2022, 65, 354. [Google Scholar] [CrossRef]

- Thelen, A.; Zhang, X.; Fink, O.; Lu, Y.; Ghosh, S.; Youn, B.D.; Todd, M.D.; Mahadevan, S.; Hu, C.; Hu, Z. A Comprehensive Review of Digital Twin—Part 2: Roles of Uncertainty Quantication and Optimization, a Battery Digital Twin, and Perspectives. Struct. Multidiscip. Optim. 2022, 66, 1. [Google Scholar] [CrossRef]

- Garg, G.; Kuts, V.; Anbarjafari, G. Digital Twin for FANUC Robots: Industrial Robot Programming and Simulation Using Virtual Reality. Sustainability 2021, 13, 10336. [Google Scholar] [CrossRef]

- Barricelli, B.R.; Casiraghi, E.; Fogli, D. A Survey on Digital Twin: Definitions, Characteristics, Applications, and Design Implications. IEEE Access 2019, 7, 167653–167671. [Google Scholar] [CrossRef]

- Erdei, T.I.; Krakó, R.; Husi, G. Design of a Digital Twin Training Centre for an Industrial Robot Arm. Appl. Sci. 2022, 12, 8862. [Google Scholar] [CrossRef]

- Popescu, D.; Dragomir, M.; Popescu, S.; Dragomir, D. Building Better Digital Twins for Production Systems by Incorporating Environmental Related Functions—Literature Analysis and Determining Alternatives. Appl. Sci. 2022, 12, 8857. [Google Scholar] [CrossRef]

- Iliuță, M.E.; Moisescu, M.A.; Pop, E.; Ioniță, A.D.; Caramihai, S.I.; Mitulescu, T.C. Digital Twin—A Review of the Evolution from Concept to Technology and Its Analytical Perspectives on Applications in Various Fields. Appl. Sci. 2024, 14, 5454. [Google Scholar] [CrossRef]

- Ufactory Lite 6—User Manual V2.0.0. Available online: https://www.ufactory.cc/wp-content/uploads/2023/05/Lite6-User-Manual-V2.0.0.pdf (accessed on 3 February 2024).

- Ufactory Lite 6—DH Parameters. Available online: https://www.ufactory.cc/wp-content/uploads/2023/04/Kinematic-and-Dynamic-Parameters-of-UFACTORY-Lite-6.pdf (accessed on 2 February 2024).

- Modi, P.P.; Sunny, M.S.H.; Khan, M.M.R.; Ahmed, H.U.; Rahman, M.H. Interactive IIoT-based 5DOF Robotic Arm for Upper Limb Telerehabilitation. IEEE Access 2022, 10, 114919–114928. [Google Scholar] [CrossRef]

- Onshape Digital Twins|Digital Transformation in Education. Available online: https://ptc-education.github.io/docs/solutions/onshapedx (accessed on 4 February 2024).

- Swe-Check—Blade Fuse Sizes. Available online: https://www.swe-check.com.au/editorials/blade_fuse_sizes.php (accessed on 15 February 2024).

- Onshape—Mate Connectors. Available online: https://cad.onshape.com/help/Content/mateconnector.htm (accessed on 4 March 2024).

| Parameter | Value |

|---|---|

| DoF | 6 |

| Reach | 440 mm |

| Payload | 600 g |

| Repeatability | 0.5 mm |

| Speed | 500 mm/s |

| EOAT | ISO9409-1-50 [17] |

| Motor type | DC Brushless |

| Control box | Build-in/Integrated |

| I/O Parts (Base) | 8 |

| I/O Parts (EOAT) | 4 |

| Robot communication | Private TCP |

| Developing Environment | Python 3.12.2 /ROS/C++ |

| GUI | Ufactory Studio |

| Weight | 7.2 kg |

| Maximum speed | 180°/s |

| Joint 1 | ±360° |

| Joint 2 | ±150° |

| Joint 3 | −3.5°–300° |

| Joint 4 | ±360° |

| Joint 5 | ±124° |

| Joint 6 | ±360° |

| Joint (i) | α (deg) | a (mm) | d (mm) | θ (deg) * |

|---|---|---|---|---|

| 1 | 0 | 0 | 243.3 | 0 |

| 2 | −90 | 0 | 0 | −90 |

| 3 | 180 | 200 | 0 | −90 |

| 4 | 90 | 87 | 227.6 | 0 |

| 5 | 90 | 0 | 0 | 0 |

| 6 | −90 | 0 | 61.5 | 0 |

| Joint (i) | α (deg) | a (mm) | d (mm) | θ (deg) |

|---|---|---|---|---|

| 1 | −90 | 0 | 243.3 | 0 |

| 2 | 180 | 200 | 0 | −90 |

| 3 | 90 | 87 | 0 | −90 |

| 4 | 90 | 0 | 227.6 | 0 |

| 5 | −90 | 0 | 0 | 0 |

| 6 | 0 | 0 | 61.5 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cazacu, C.-C.; Iorga, I.; Parpală, R.C.; Popa, C.L.; Coteț, C.E. Optimizing Assembly in Wiring Boxes Using API Technology for Digital Twin. Appl. Sci. 2024, 14, 9483. https://doi.org/10.3390/app14209483

Cazacu C-C, Iorga I, Parpală RC, Popa CL, Coteț CE. Optimizing Assembly in Wiring Boxes Using API Technology for Digital Twin. Applied Sciences. 2024; 14(20):9483. https://doi.org/10.3390/app14209483

Chicago/Turabian StyleCazacu, Carmen-Cristiana, Ioana Iorga, Radu Constantin Parpală, Cicerone Laurențiu Popa, and Costel Emil Coteț. 2024. "Optimizing Assembly in Wiring Boxes Using API Technology for Digital Twin" Applied Sciences 14, no. 20: 9483. https://doi.org/10.3390/app14209483

APA StyleCazacu, C.-C., Iorga, I., Parpală, R. C., Popa, C. L., & Coteț, C. E. (2024). Optimizing Assembly in Wiring Boxes Using API Technology for Digital Twin. Applied Sciences, 14(20), 9483. https://doi.org/10.3390/app14209483