Estimation of the Compressive Strength of Cardboard Boxes Including Packaging Overhanging on the Pallet

Abstract

1. Introduction

2. Materials and Methods

2.1. Workflow of the Study

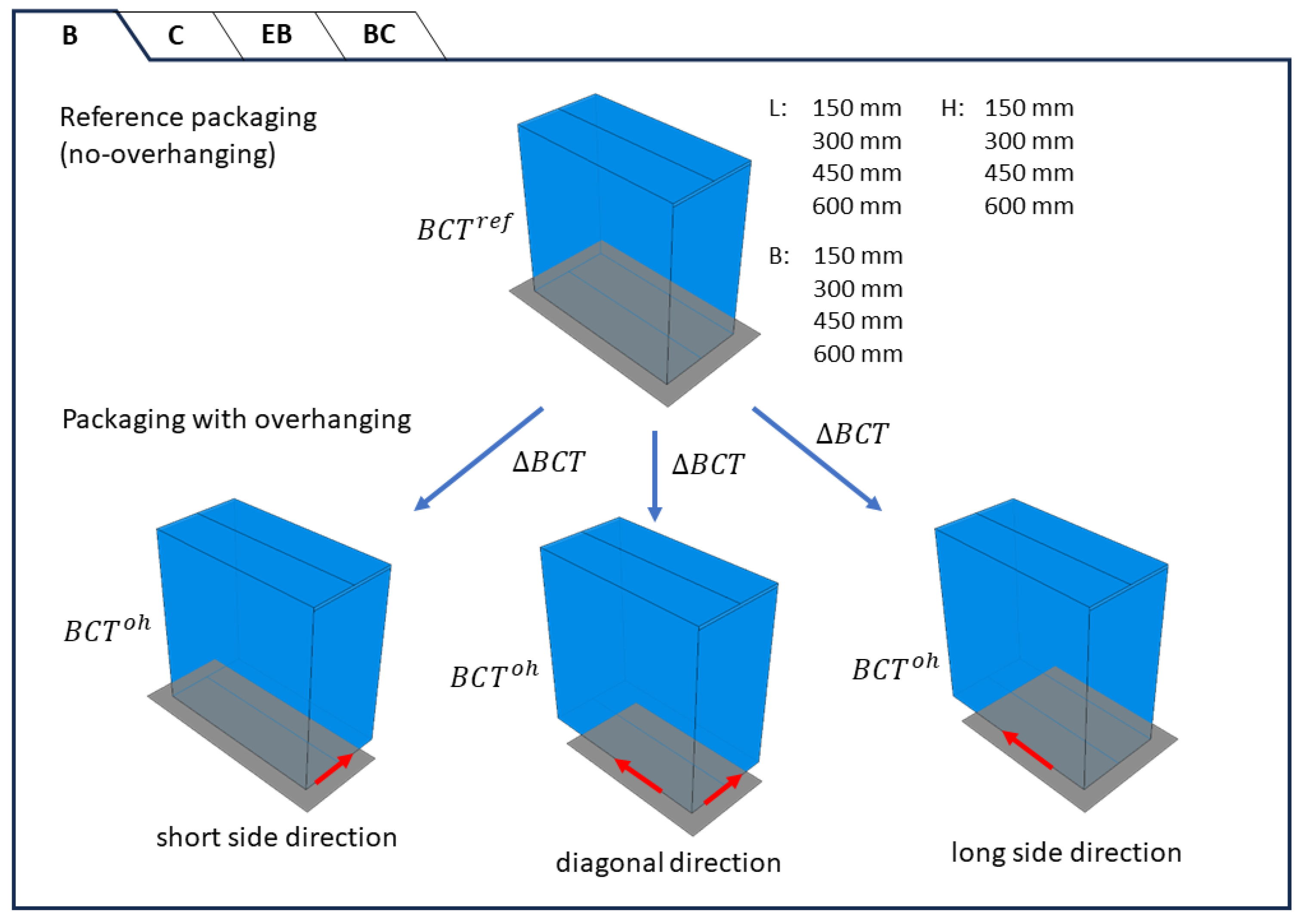

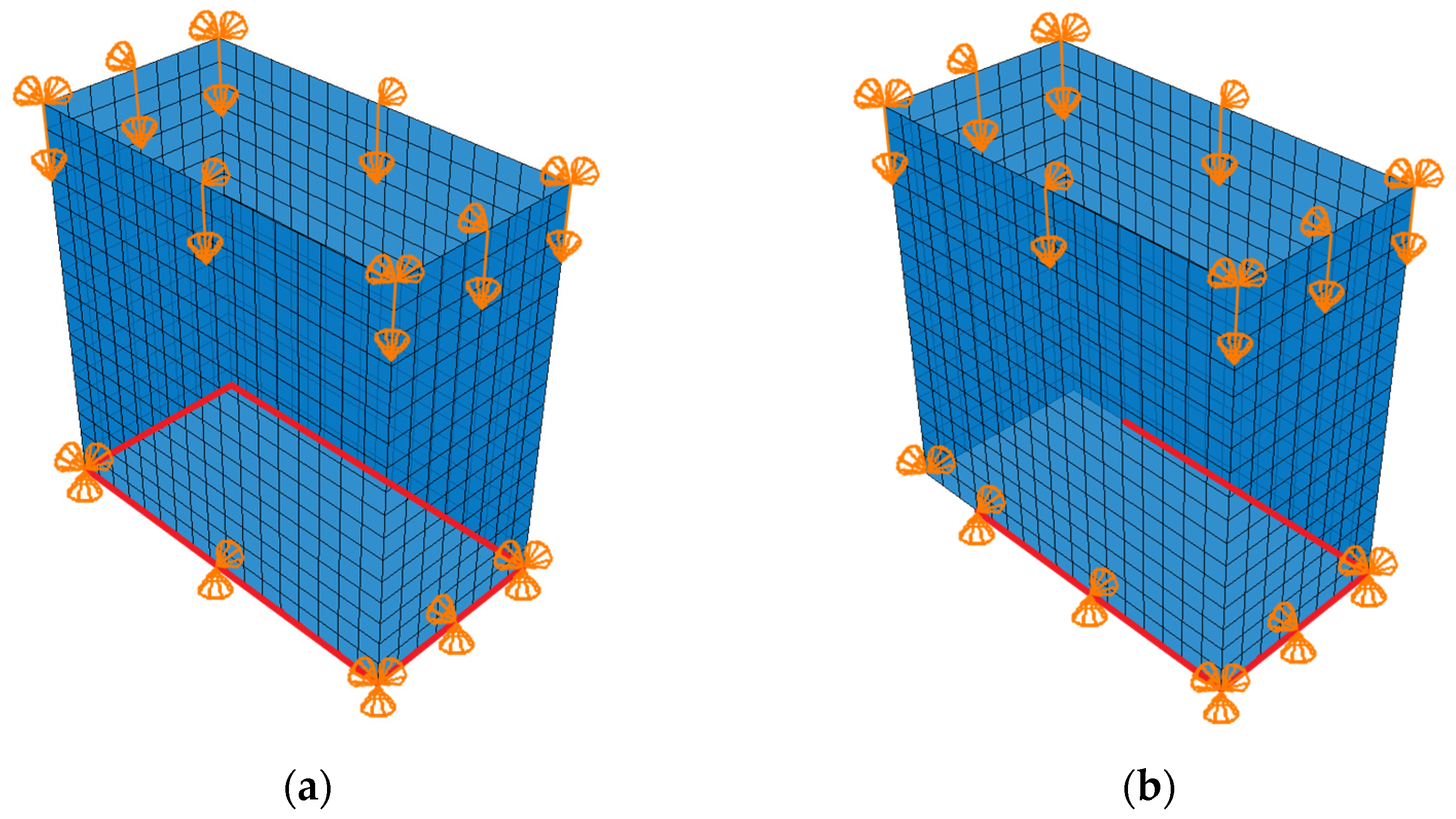

2.2. Numerical Modeling of Corrugated Board Packaging including Overhanging

3. Results

3.1. Validation of Numerical Model of Corrugated Board Packaging

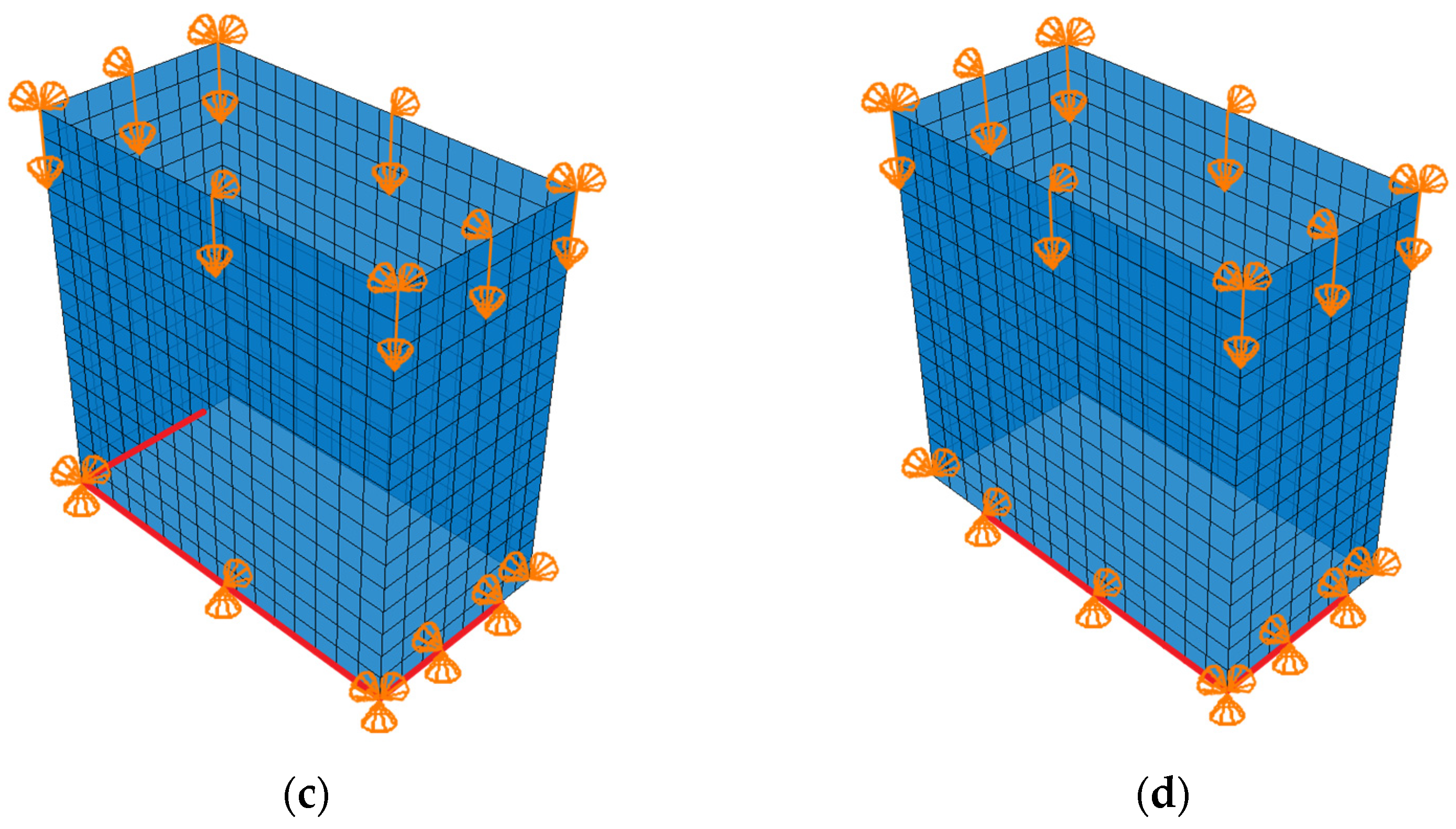

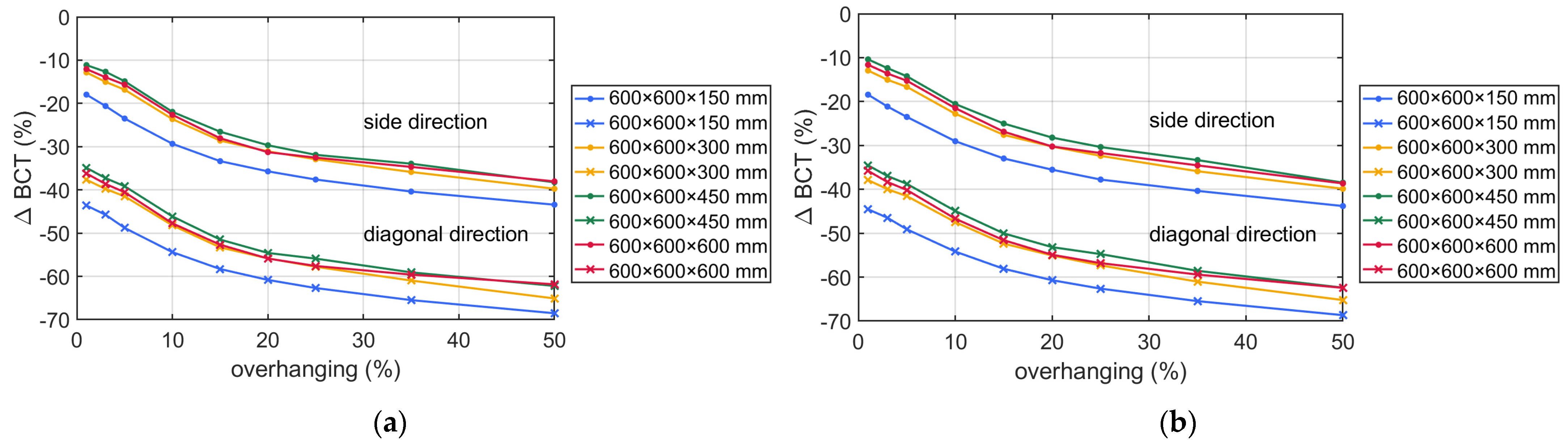

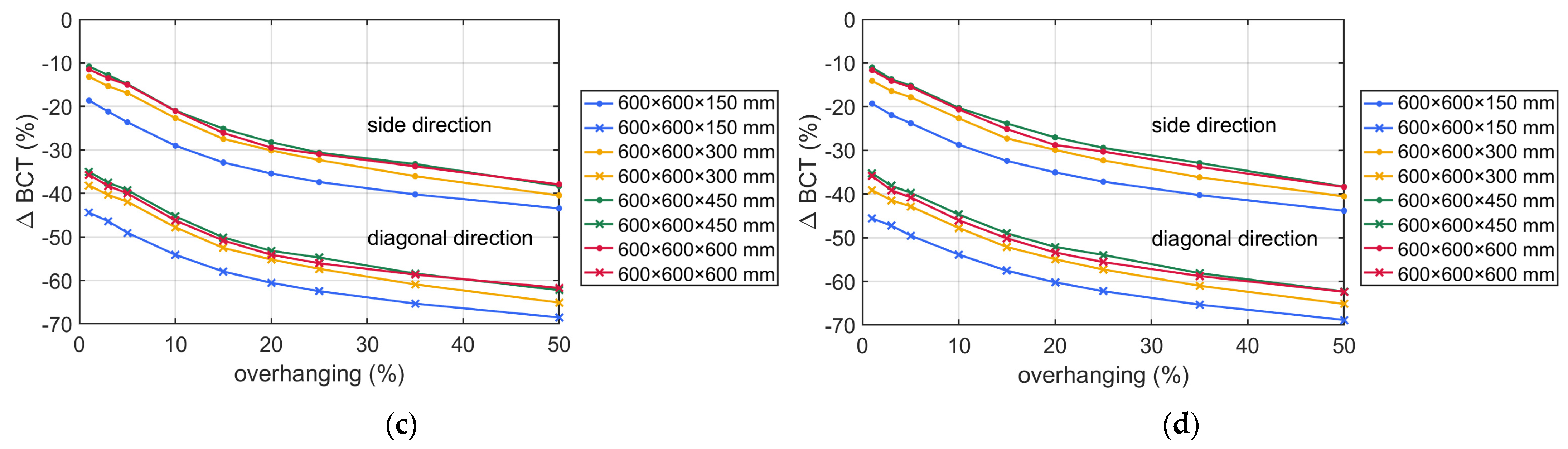

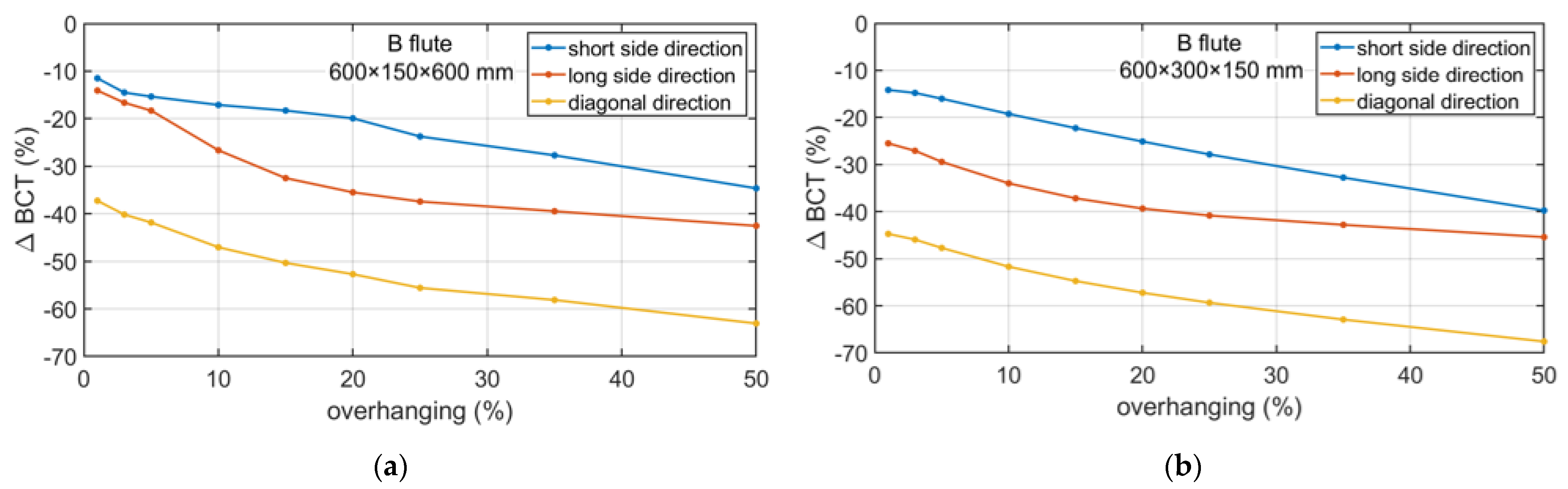

3.2. The Influence of Packaging Overhanging on the Load-Bearing Capacity of the Packaging

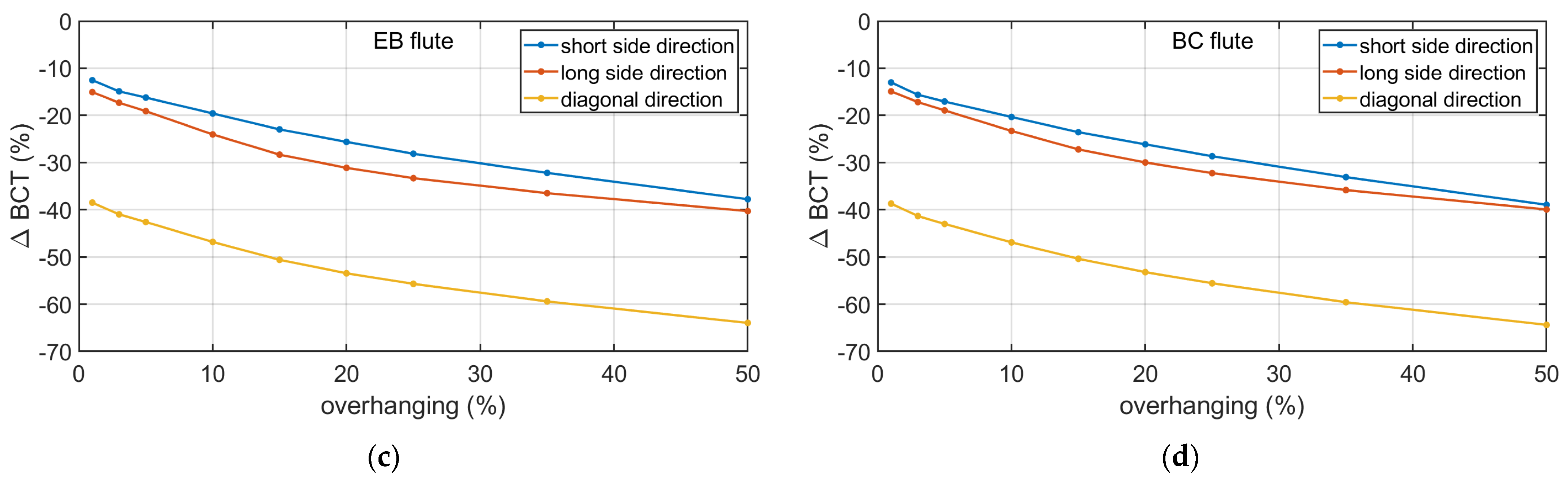

3.3. Influence of the Type of Corrugated Board

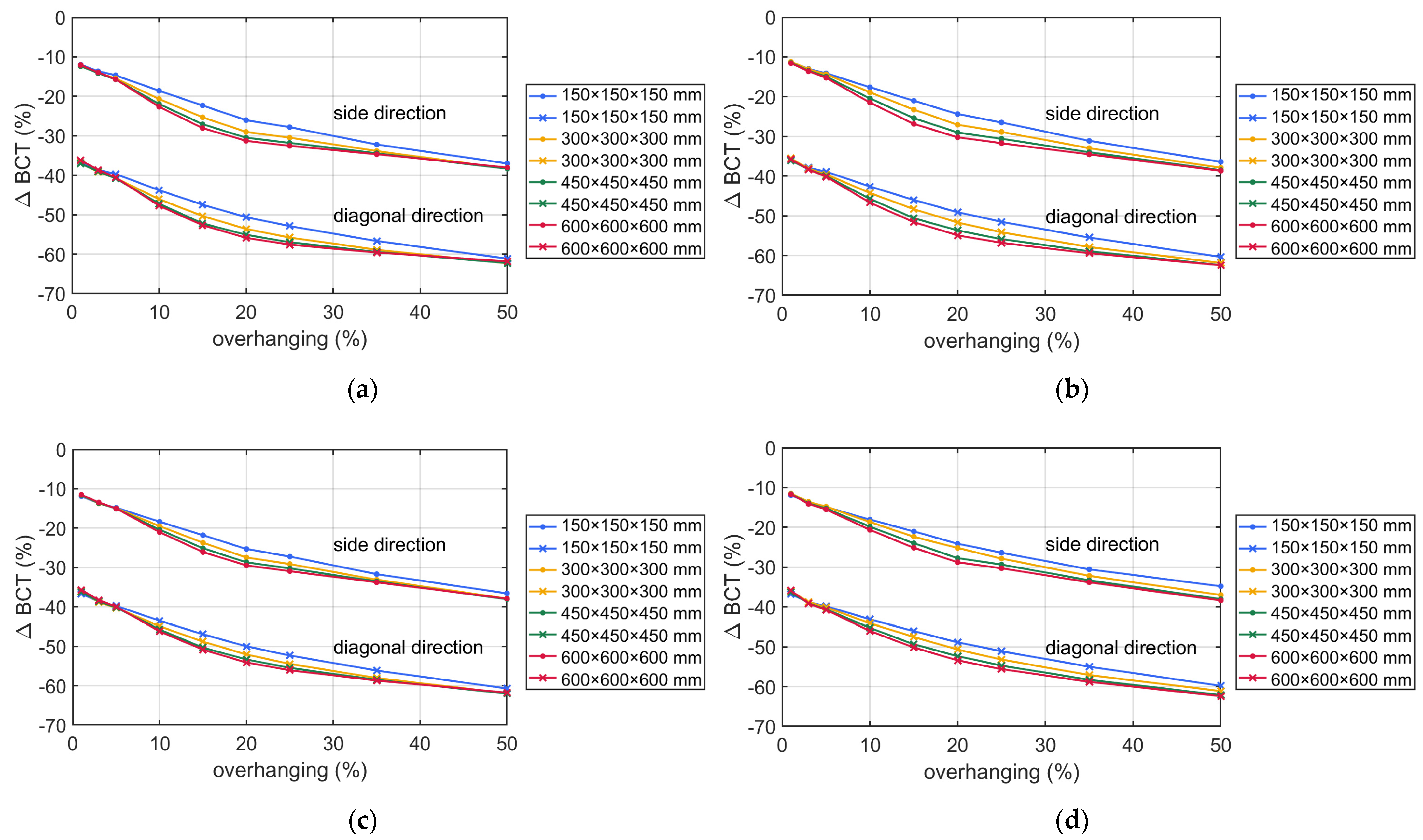

3.4. Cubic Packaging

3.5. Column Type Packaging with a Square Base

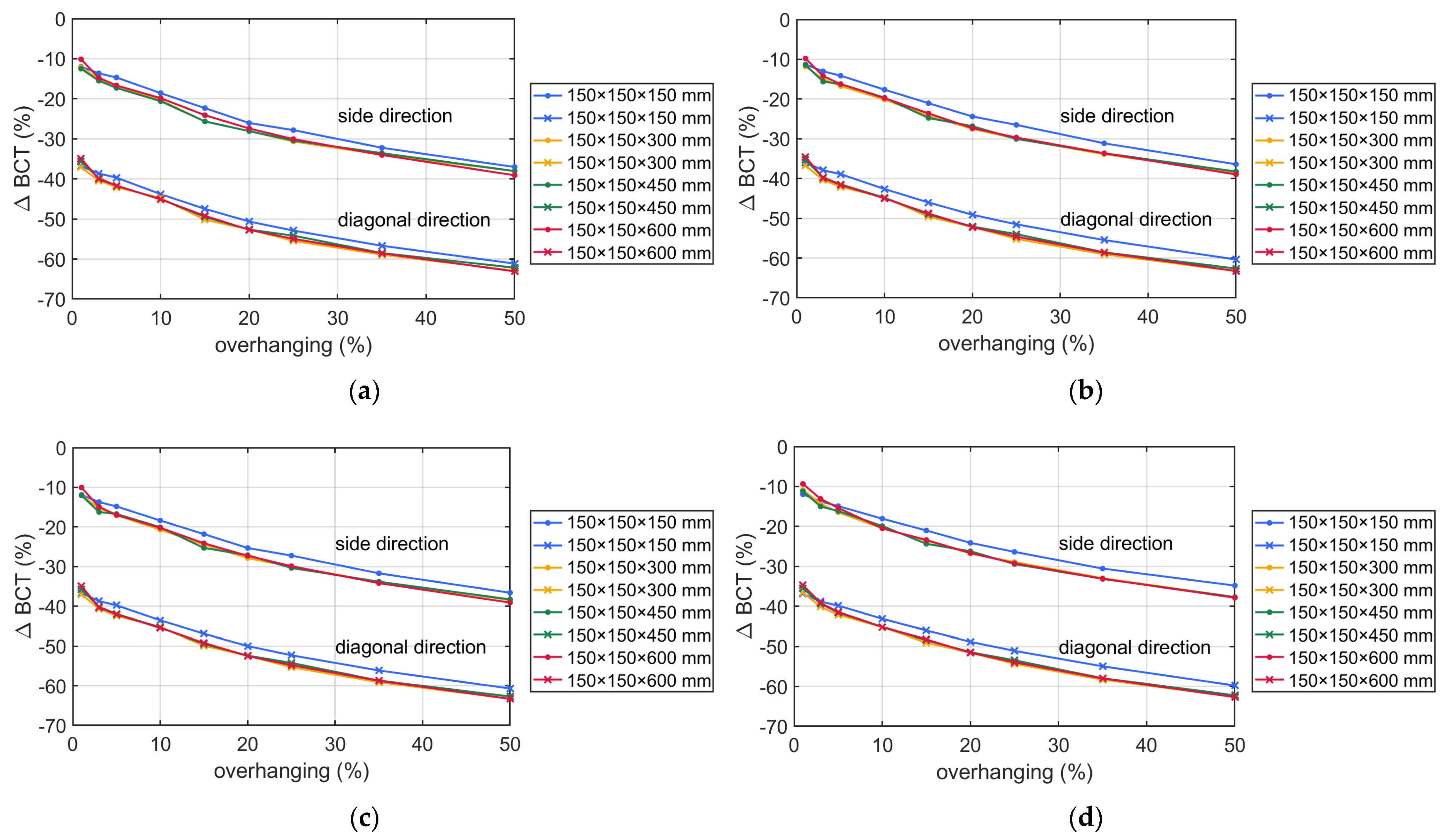

3.6. Flat Type Packaging with a Square Base

3.7. Special Cases

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Box | BCT (N) | |||

|---|---|---|---|---|

| B-Flute | C-Flute | EB-Flute | BC-Flute | |

| 150 × 150 × 150 | 1324 | 1700 | 1733 | 2622 |

| 150 × 150 × 300 | 1199 | 1587 | 1612 | 2437 |

| 150 × 150 × 450 | 1236 | 1637 | 1663 | 2534 |

| 150 × 150 × 600 | 1271 | 1670 | 1702 | 2547 |

| 300 × 150 × 150 | 2333 | 3005 | 2993 | 4364 |

| 300 × 150 × 300 | 1839 | 2417 | 2380 | 3675 |

| 300 × 150 × 450 | 2194 | 2933 | 2911 | 4276 |

| 300 × 150 × 600 | 2086 | 2702 | 2715 | 4025 |

| 300 × 300 × 150 | 1934 | 2585 | 2595 | 4082 |

| 300 × 300 × 300 | 2060 | 2607 | 2689 | 4046 |

| 300 × 300 × 450 | 1982 | 2526 | 2592 | 3942 |

| 300 × 300 × 600 | 1887 | 2505 | 2530 | 3862 |

| 450 × 150 × 150 | 2823 | 3669 | 3634 | 5338 |

| 450 × 150 × 300 | 2804 | 3465 | 3500 | 5066 |

| 450 × 150 × 450 | 2268 | 2809 | 2861 | 4147 |

| 450 × 150 × 600 | 2782 | 3400 | 3482 | 4948 |

| 450 × 300 × 150 | 3225 | 4512 | 4394 | 6881 |

| 450 × 300 × 300 | 2876 | 3750 | 3795 | 5926 |

| 450 × 300 × 450 | 2316 | 3643 | 3775 | 5683 |

| 450 × 300 × 600 | 2899 | 3747 | 3808 | 5901 |

| 450 × 450 × 150 | 2487 | 3415 | 3389 | 5462 |

| 450 × 450 × 300 | 2526 | 3206 | 3294 | 5034 |

| 450 × 450 × 450 | 2715 | 3370 | 3513 | 5211 |

| 450 × 450 × 600 | 2557 | 3774 | 3310 | 5962 |

| 600 × 150 × 150 | 3173 | 4148 | 4100 | 5942 |

| 600 × 150 × 300 | 3112 | 3788 | 3870 | 5496 |

| 600 × 150 × 450 | 3285 | 3917 | 4048 | 5648 |

| 600 × 150 × 600 | 2654 | 3195 | 3290 | 4619 |

| 600 × 300 × 150 | 4043 | 5652 | 5469 | 8345 |

| 600 × 300 × 300 | 3500 | 4601 | 4645 | 7082 |

| 600 × 300 × 450 | 3560 | 4559 | 4691 | 6996 |

| 600 × 300 × 600 | 2799 | 4469 | 4753 | 6832 |

| 600 × 450 × 150 | 4254 | 6140 | 5931 | 9425 |

| 600 × 450 × 300 | 3420 | 4529 | 4563 | 7189 |

| 600 × 450 × 450 | 3458 | 4382 | 4512 | 6813 |

| 600 × 450 × 600 | 3471 | 4324 | 4576 | 6665 |

| 600 × 600 × 150 | 3043 | 4265 | 4203 | 6875 |

| 600 × 600 × 300 | 2958 | 3795 | 3875 | 5978 |

| 600 × 600 × 450 | 3137 | 3901 | 4040 | 6046 |

| 600 × 600 × 600 | 3347 | 4096 | 4299 | 6269 |

| Box | BCT (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1% | 3% | 5% | 10% | 15% | 20% | 25% | 35% | 50% | |

| 150 × 150 × 150 | −12.0 | −13.6 | −14.7 | −18.6 | −22.3 | −26.0 | −27.8 | −32.2 | −37.0 |

| 150 × 150 × 300 | −12.1 | −15.0 | −16.7 | −20.3 | −25.7 | −28.1 | −30.6 | −34.0 | −38.0 |

| 150 × 150 × 450 | −12.5 | −15.5 | −17.3 | −20.6 | −25.6 | −28.1 | −30.4 | −33.6 | −38.0 |

| 150 × 150 × 600 | −10.1 | −14.8 | −16.7 | −19.8 | −24.1 | −27.4 | −30.1 | −34.0 | −39.1 |

| 300 × 150 × 150 | −12.9 | −14.4 | −15.6 | −18.5 | −20.7 | −23.7 | −25.7 | −31.6 | −38.7 |

| 300 × 150 × 300 | −8.1 | −10.6 | −11.6 | −14.1 | −18.4 | −19.9 | −22.9 | −27.0 | −34.0 |

| 300 × 150 × 450 | −11.9 | −13.9 | −15.0 | −17.1 | −20.2 | −22.6 | −24.9 | −29.8 | −36.5 |

| 300 × 150 × 600 | −11.0 | −13.4 | −14.4 | −16.6 | −18.6 | −22.1 | −24.5 | −29.2 | −34.6 |

| 300 × 300 × 150 | −14.4 | −16.3 | −17.8 | −22.9 | −27.4 | −30.0 | −32.2 | −35.7 | −39.7 |

| 300 × 300 × 300 | −12.4 | −14.1 | −15.4 | −20.7 | −25.3 | −29.0 | −30.5 | −33.9 | −38.3 |

| 300 × 300 × 450 | −12.5 | −15.0 | −16.7 | −21.0 | −26.1 | −28.4 | −30.7 | −33.7 | −38.0 |

| 300 × 300 × 600 | −10.8 | −14.2 | −17.0 | −19.2 | −27.3 | −28.8 | −31.8 | −34.4 | −37.3 |

| 450 × 150 × 150 | −17.3 | −19.3 | −20.0 | −21.0 | −24.8 | −26.2 | −29.9 | −35.1 | −41.9 |

| 450 × 150 × 300 | −14.4 | −15.9 | −17.0 | −18.6 | −21.5 | −23.5 | −25.5 | −30.5 | −37.6 |

| 450 × 150 × 450 | −10.5 | −13.1 | −14.0 | −15.9 | −17.7 | −20.9 | −23.1 | −27.6 | −33.3 |

| 450 × 150 × 600 | −13.4 | −15.8 | −16.9 | −18.7 | −20.3 | −21.4 | −25.4 | −29.5 | −36.7 |

| 450 × 300 × 150 | −13.3 | −14.3 | −15.5 | −19.0 | −22.3 | −25.4 | −28.0 | −32.5 | −38.1 |

| 450 × 300 × 300 | −9.9 | −11.0 | −11.9 | −15.5 | −18.1 | −21.1 | −23.6 | −27.7 | −33.7 |

| 450 × 300 × 450 | −9.4 | −11.5 | −12.5 | −17.0 | −20.0 | −23.2 | −25.2 | −29.0 | −34.2 |

| 450 × 300 × 600 | −10.2 | −11.8 | −12.8 | −15.3 | −19.1 | −21.8 | −24.6 | −28.6 | −33.8 |

| 450 × 450 × 150 | −15.8 | −17.8 | −20.7 | −26.2 | −30.1 | −33.8 | −35.0 | −38.1 | −41.9 |

| 450 × 450 × 300 | −11.2 | −13.5 | −14.7 | −20.6 | −25.5 | −28.6 | −30.7 | −34.0 | −38.6 |

| 450 × 450 × 450 | −12.3 | −14.2 | −15.7 | −21.9 | −27.1 | −30.5 | −31.8 | −34.4 | −38.4 |

| 450 × 450 × 600 | −12.3 | −14.5 | −16.0 | −22.8 | −26.8 | −29.5 | −31.3 | −34.3 | −38.7 |

| 600 × 150 × 150 | −20.5 | −22.3 | −22.9 | −24.5 | −27.4 | −28.6 | −32.2 | −37.0 | −43.3 |

| 600 × 150 × 300 | −16.8 | −18.7 | −19.7 | −21.3 | −22.3 | −25.8 | −27.7 | −32.5 | −39.2 |

| 600 × 150 × 450 | −16.0 | −18.3 | −19.1 | −20.5 | −21.9 | −24.9 | −26.5 | −30.0 | −36.5 |

| 600 × 150 × 600 | −11.5 | −14.5 | −15.4 | −17.1 | −18.3 | −19.9 | −23.7 | −27.7 | −34.7 |

| 600 × 300 × 150 | −14.2 | −14.8 | −16.0 | −19.2 | −22.3 | −25.1 | −27.9 | −32.8 | −39.8 |

| 600 × 300 × 300 | −10.9 | −11.8 | −12.7 | −15.6 | −18.2 | −21.0 | −23.3 | −27.7 | −33.8 |

| 600 × 300 × 450 | −9.9 | −10.8 | −11.6 | −13.5 | −16.8 | −18.8 | −21.4 | −25.3 | −31.1 |

| 600 × 300 × 600 | −9.7 | −11.3 | −12.3 | −14.9 | −18.6 | −21.1 | −23.6 | −27.0 | −32.4 |

| 600 × 450 × 150 | −13.3 | −14.7 | −16.4 | −20.7 | −24.5 | −27.5 | −30.3 | −34.9 | −40.9 |

| 600 × 450 × 300 | −10.6 | −12.0 | −13.4 | −17.5 | −21.3 | −24.3 | −26.9 | −31.0 | −36.6 |

| 600 × 450 × 450 | −9.9 | −11.1 | −12.5 | −16.6 | −19.8 | −23.0 | −25.3 | −29.4 | −34.6 |

| 600 × 450 × 600 | −12.1 | −13.6 | −15.0 | −19.0 | −22.3 | −25.3 | −27.0 | −30.6 | −34.8 |

| 600 × 600 × 150 | −18.0 | −20.6 | −23.5 | −29.3 | −33.4 | −35.7 | −37.6 | −40.4 | −43.4 |

| 600 × 600 × 300 | −12.9 | −15.0 | −16.8 | −23.6 | −28.6 | −31.1 | −32.9 | −35.9 | −39.7 |

| 600 × 600 × 450 | −11.1 | −12.7 | −14.9 | −22.0 | −26.6 | −29.7 | −31.9 | −33.9 | −38.3 |

| 600 × 600 × 600 | −12.1 | −14.0 | −15.7 | −22.6 | −28.1 | −31.3 | −32.6 | −34.7 | −38.0 |

| Box | BCT (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1% | 3% | 5% | 10% | 15% | 20% | 25% | 35% | 50% | |

| 150 × 150 × 150 | −12.0 | −13.6 | −14.7 | −18.6 | −22.3 | −25.1 | −27.8 | −32.2 | −37.0 |

| 150 × 150 × 300 | −12.1 | −15.0 | −16.7 | −19.3 | −25.7 | −27.2 | −30.6 | −34.0 | −37.8 |

| 150 × 150 × 450 | −12.5 | −16.2 | −17.3 | −19.7 | −24.9 | −27.4 | −30.3 | −33.7 | −38.5 |

| 150 × 150 × 600 | −10.1 | −14.0 | −15.9 | −19.8 | −23.6 | −27.4 | −30.2 | −34.0 | −38.3 |

| 300 × 150 × 150 | −20.2 | −21.4 | −23.4 | −27.7 | −30.9 | −33.5 | −35.5 | −38.6 | −41.9 |

| 300 × 150 × 300 | −17.7 | −19.7 | −21.1 | −26.8 | −31.3 | −33.8 | −35.5 | −38.5 | −41.6 |

| 300 × 150 × 450 | −19.4 | −21.3 | −22.5 | −27.7 | −31.7 | −34.0 | −36.0 | −38.6 | −42.2 |

| 300 × 150 × 600 | −17.1 | −19.1 | −20.8 | −26.3 | −30.4 | −33.4 | −35.4 | −37.7 | −41.5 |

| 300 × 300 × 150 | −14.4 | −16.3 | −17.6 | −22.6 | −27.4 | −29.8 | −32.2 | −36.0 | −40.4 |

| 300 × 300 × 300 | −12.4 | −14.1 | −15.4 | −20.7 | −25.3 | −28.2 | −30.5 | −33.9 | −38.3 |

| 300 × 300 × 450 | −12.5 | −15.0 | −16.7 | −21.0 | −26.1 | −28.4 | −30.2 | −33.7 | −38.0 |

| 300 × 300 × 600 | −10.8 | −14.2 | −15.9 | −18.2 | −26.2 | −28.0 | −31.2 | −34.1 | −37.1 |

| 450 × 150 × 150 | −20.3 | −22.1 | −24.6 | −29.1 | −33.0 | −35.6 | −38.1 | −40.4 | −43.5 |

| 450 × 150 × 300 | −13.8 | −15.5 | −18.0 | −23.3 | −27.9 | −31.1 | −33.3 | −36.5 | −39.9 |

| 450 × 150 × 450 | −15.5 | −17.9 | −19.6 | −26.8 | −32.1 | −34.9 | −36.7 | −39.0 | −42.6 |

| 450 × 150 × 600 | −14.4 | −16.3 | −18.4 | −24.4 | −29.0 | −31.7 | −34.2 | −36.8 | −40.9 |

| 450 × 300 × 150 | −23.8 | −25.3 | −27.5 | −31.8 | −35.1 | −37.4 | −39.1 | −41.8 | −44.3 |

| 450 × 300 × 300 | −14.4 | −16.7 | −18.3 | −23.7 | −28.4 | −31.4 | −33.3 | −36.1 | −39.7 |

| 450 × 300 × 450 | −15.4 | −17.7 | −19.4 | −27.4 | −31.9 | −34.5 | −35.9 | −38.7 | −42.1 |

| 450 × 300 × 600 | −15.7 | −17.7 | −19.4 | −25.1 | −29.6 | −32.3 | −34.1 | −36.8 | −40.2 |

| 450 × 450 × 150 | −15.8 | −17.8 | −20.7 | −26.2 | −30.1 | −33.7 | −34.9 | −38.1 | −41.5 |

| 450 × 450 × 300 | −11.2 | −13.5 | −14.7 | −20.6 | −25.5 | −28.6 | −30.7 | −34.0 | −37.6 |

| 450 × 450 × 450 | −12.3 | −14.2 | −15.7 | −21.9 | −27.1 | −29.8 | −31.8 | −34.4 | −38.4 |

| 450 × 450 × 600 | −12.3 | −14.5 | −16.0 | −22.8 | −26.0 | −29.5 | −31.5 | −34.3 | −38.4 |

| 600 × 150 × 150 | −19.5 | −21.7 | −24.5 | −30.4 | −34.4 | −36.5 | −38.4 | −41.6 | −44.0 |

| 600 × 150 × 300 | −13.2 | −15.2 | −18.2 | −24.4 | −29.2 | −32.3 | −34.4 | −37.7 | −41.7 |

| 600 × 150 × 450 | −10.9 | −12.8 | −15.8 | −22.3 | −27.7 | −31.2 | −33.4 | −36.2 | −40.1 |

| 600 × 150 × 600 | −14.1 | −16.7 | −18.3 | −26.7 | −32.5 | −35.5 | −37.4 | −39.5 | −42.5 |

| 600 × 300 × 150 | −25.5 | −27.1 | −29.4 | −34.0 | −37.2 | −39.4 | −40.8 | −42.8 | −45.4 |

| 600 × 300 × 300 | −17.0 | −18.8 | −21.4 | −27.4 | −31.5 | −34.2 | −35.9 | −38.7 | −42.1 |

| 600 × 300 × 450 | −13.7 | −15.5 | −18.0 | −24.2 | −29.0 | −32.5 | −34.4 | −36.7 | −39.8 |

| 600 × 300 × 600 | −15.2 | −17.7 | −19.1 | −27.9 | −33.2 | −35.8 | −37.3 | −39.1 | −42.3 |

| 600 × 450 × 150 | −26.7 | −28.2 | −30.4 | −34.7 | −37.7 | −39.8 | −41.3 | −43.2 | −45.7 |

| 600 × 450 × 300 | −16.5 | −18.7 | −21.0 | −26.6 | −30.8 | −33.5 | −35.3 | −38.2 | −41.6 |

| 600 × 450 × 450 | −13.5 | −15.5 | −17.2 | −23.6 | −28.8 | −31.8 | −33.7 | −35.9 | −38.9 |

| 600 × 450 × 600 | −15.0 | −17.0 | −18.7 | −25.9 | −31.0 | −33.8 | −35.2 | −37.2 | −39.4 |

| 600 × 600 × 150 | −18.0 | −20.6 | −23.5 | −29.3 | −33.4 | −35.7 | −37.8 | −40.4 | −43.7 |

| 600 × 600 × 300 | −12.9 | −15.0 | −16.5 | −23.1 | −28.2 | −30.8 | −32.8 | −36.1 | −40.4 |

| 600 × 600 × 450 | −11.1 | −12.7 | −14.9 | −22.0 | −26.6 | −29.7 | −31.6 | −33.9 | −38.3 |

| 600 × 600 × 600 | −12.1 | −14.0 | −15.7 | −22.6 | −28.1 | −30.7 | −32.6 | −34.7 | −38.0 |

| Box | BCT (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1% | 3% | 5% | 10% | 15% | 20% | 25% | 35% | 50% | |

| 150 × 150 × 150 | −36.8 | −38.6 | −39.7 | −43.8 | −47.5 | −50.6 | −52.9 | −56.7 | −61.1 |

| 150 × 150 × 300 | −37.0 | −40.4 | −42.0 | −44.8 | −50.2 | −52.6 | −55.5 | −58.9 | −62.9 |

| 150 × 150 × 450 | −35.6 | −39.8 | −41.7 | −45.1 | −49.5 | −52.7 | −54.2 | −58.5 | −62.2 |

| 150 × 150 × 600 | −34.9 | −40.0 | −41.7 | −45.1 | −49.2 | −52.7 | −55.0 | −58.6 | −63.1 |

| 300 × 150 × 150 | −41.4 | −42.9 | −44.4 | −47.9 | −50.7 | −53.5 | −55.6 | −60.2 | −65.4 |

| 300 × 150 × 300 | −37.5 | −40.1 | −41.8 | −45.9 | −49.5 | −52.2 | −54.1 | −57.9 | −62.6 |

| 300 × 150 × 450 | −39.8 | −42.0 | −43.6 | −46.8 | −49.5 | −53.3 | −54.9 | −59.2 | −64.3 |

| 300 × 150 × 600 | −38.9 | −41.4 | −42.8 | −46.7 | −49.6 | −52.9 | −54.8 | −58.5 | −62.9 |

| 300 × 300 × 150 | −39.5 | −41.3 | −42.6 | −47.7 | −52.2 | −54.9 | −57.2 | −60.9 | −65.1 |

| 300 × 300 × 300 | −37.0 | −39.2 | −40.7 | −46.1 | −50.3 | −53.6 | −55.8 | −58.9 | −62.3 |

| 300 × 300 × 450 | −37.2 | −39.6 | −41.2 | −46.6 | −50.7 | −53.8 | −55.6 | −59.0 | −63.2 |

| 300 × 300 × 600 | −36.1 | −39.1 | −41.3 | −44.0 | −51.7 | −53.8 | −56.6 | −59.4 | −62.7 |

| 450 × 150 × 150 | −43.6 | −45.5 | −47.1 | −50.1 | −53.9 | −55.9 | −58.8 | −62.8 | −67.7 |

| 450 × 150 × 300 | −38.7 | −40.6 | −42.2 | −45.7 | −49.3 | −52.1 | −54.3 | −58.5 | −63.9 |

| 450 × 150 × 450 | −37.7 | −40.3 | −41.8 | −46.5 | −50.2 | −53.1 | −55.0 | −58.4 | −62.8 |

| 450 × 150 × 600 | −38.8 | −41.0 | −42.6 | −46.6 | −49.6 | −51.9 | −55.0 | −58.2 | −64.0 |

| 450 × 300 × 150 | −43.4 | −44.8 | −46.5 | −50.4 | −53.7 | −56.4 | −58.6 | −62.1 | −66.2 |

| 450 × 300 × 300 | −37.0 | −38.5 | −39.7 | −44.2 | −47.9 | −51.0 | −53.4 | −57.1 | −61.8 |

| 450 × 300 × 450 | −37.5 | −39.8 | −41.1 | −46.9 | −51.2 | −54.1 | −55.9 | −59.2 | −63.5 |

| 450 × 300 × 600 | −38.0 | −39.7 | −41.1 | −45.3 | −49.5 | −52.2 | −54.5 | −57.8 | −62.3 |

| 450 × 450 × 150 | −41.4 | −43.3 | −46.1 | −51.5 | −55.5 | −58.8 | −60.3 | −63.6 | −67.0 |

| 450 × 450 × 300 | −36.1 | −38.0 | −39.8 | −45.8 | −50.6 | −53.7 | −55.8 | −59.0 | −63.2 |

| 450 × 450 × 450 | −37.1 | −39.1 | −40.8 | −47.2 | −52.2 | −55.1 | −57.0 | −59.4 | −62.3 |

| 450 × 450 × 600 | −36.2 | −38.5 | −40.5 | −46.8 | −51.4 | −54.4 | −55.7 | −59.1 | −62.9 |

| 600 × 150 × 150 | −45.2 | −47.0 | −48.5 | −52.2 | −55.7 | −58.0 | −60.3 | −64.1 | −68.7 |

| 600 × 150 × 300 | −39.9 | −41.8 | −43.7 | −47.6 | −50.7 | −53.9 | −55.9 | −60.0 | −65.3 |

| 600 × 150 × 450 | −38.3 | −40.2 | −42.0 | −46.0 | −49.5 | −52.9 | −54.8 | −58.3 | −63.4 |

| 600 × 150 × 600 | −37.3 | −40.2 | −41.8 | −47.0 | −50.3 | −52.7 | −55.6 | −58.1 | −63.1 |

| 600 × 300 × 150 | −44.7 | −45.9 | −47.7 | −51.7 | −54.7 | −57.2 | −59.4 | −62.9 | −67.6 |

| 600 × 300 × 300 | −38.9 | −40.3 | −42.1 | −46.3 | −49.7 | −52.5 | −54.5 | −58.3 | −63.0 |

| 600 × 300 × 450 | −36.6 | −38.0 | −39.3 | −43.5 | −47.7 | −50.5 | −52.8 | −56.2 | −60.7 |

| 600 × 300 × 600 | −36.7 | −39.0 | −40.7 | −46.2 | −50.7 | −53.6 | −54.7 | −58.4 | −61.7 |

| 600 × 450 × 150 | −44.9 | −46.5 | −48.4 | −52.8 | −56.2 | −58.7 | −60.8 | −64.1 | −68.2 |

| 600 × 450 × 300 | −38.6 | −40.2 | −42.2 | −47.1 | −51.1 | −53.9 | −56.2 | −59.7 | −64.2 |

| 600 × 450 × 450 | −36.0 | −37.8 | −39.4 | −44.5 | −48.9 | −52.3 | −54.5 | −57.7 | −61.9 |

| 600 × 450 × 600 | −37.6 | −39.7 | −41.2 | −47.2 | −51.4 | −53.9 | −56.2 | −59.0 | −62.4 |

| 600 × 600 × 150 | −43.6 | −45.8 | −48.8 | −54.4 | −58.3 | −60.8 | −62.7 | −65.5 | −68.5 |

| 600 × 600 × 300 | −37.7 | −39.8 | −41.5 | −48.2 | −53.3 | −55.8 | −57.8 | −61.0 | −65.1 |

| 600 × 600 × 450 | −34.9 | −37.3 | −39.2 | −46.1 | −51.5 | −54.6 | −55.9 | −59.1 | −62.2 |

| 600 × 600 × 600 | −36.2 | −38.6 | −40.5 | −47.7 | −52.7 | −55.9 | −57.6 | −59.6 | −61.9 |

| Box | BCT (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1% | 3% | 5% | 10% | 15% | 20% | 25% | 35% | 50% | |

| 150 × 150 × 150 | −11.3 | −13.0 | −14.1 | −17.7 | −21.1 | −24.4 | −26.5 | −31.1 | −36.4 |

| 150 × 150 × 300 | −11.8 | −15.0 | −16.7 | −20.1 | −24.2 | −27.5 | −29.9 | −33.9 | −38.4 |

| 150 × 150 × 450 | −11.4 | −15.6 | −16.2 | −19.7 | −24.8 | −26.8 | −30.0 | −33.6 | −38.2 |

| 150 × 150 × 600 | −9.8 | −14.2 | −16.2 | −19.8 | −23.6 | −27.3 | −29.7 | −33.7 | −39.0 |

| 300 × 150 × 150 | −13.1 | −14.8 | −15.8 | −20.1 | −22.4 | −25.5 | −28.0 | −33.9 | −41.9 |

| 300 × 150 × 300 | −5.7 | −9.6 | −11.4 | −14.8 | −18.0 | −20.7 | −23.7 | −27.2 | −35.2 |

| 300 × 150 × 450 | −12.5 | −14.8 | −16.1 | −18.5 | −21.3 | −23.7 | −26.1 | −31.3 | −38.8 |

| 300 × 150 × 600 | −10.1 | −12.9 | −14.1 | −16.5 | −19.1 | −21.9 | −24.3 | −29.2 | −36.0 |

| 300 × 300 × 150 | −15.4 | −17.1 | −18.6 | −23.1 | −27.3 | −30.2 | −32.7 | −36.6 | −40.9 |

| 300 × 300 × 300 | −11.2 | −13.1 | −14.4 | −18.9 | −23.3 | −27.1 | −28.9 | −33.0 | −37.9 |

| 300 × 300 × 450 | −11.3 | −14.4 | −16.1 | −20.1 | −24.8 | −27.2 | −29.9 | −33.4 | −38.1 |

| 300 × 300 × 600 | −10.5 | −13.6 | −16.8 | −19.0 | −26.2 | −27.9 | −31.2 | −34.5 | −37.8 |

| 450 × 150 × 150 | −19.3 | −22.5 | −23.2 | −23.4 | −27.8 | −28.3 | −32.8 | −37.7 | −43.4 |

| 450 × 150 × 300 | −15.2 | −17.2 | −18.1 | −21.0 | −22.8 | −25.8 | −26.7 | −32.6 | −38.7 |

| 450 × 150 × 450 | −9.0 | −12.1 | −13.3 | −15.6 | −17.5 | −20.6 | −22.9 | −27.8 | −34.0 |

| 450 × 150 × 600 | −12.5 | −15.4 | −16.6 | −18.5 | −20.2 | −21.4 | −25.3 | −29.3 | −36.7 |

| 450 × 300 × 150 | −14.1 | −14.8 | −16.1 | −19.2 | −22.4 | −25.5 | −28.2 | −33.1 | −39.5 |

| 450 × 300 × 300 | −9.5 | −11.1 | −11.8 | −15.2 | −17.7 | −20.8 | −23.5 | −28.0 | −34.5 |

| 450 × 300 × 450 | −11.0 | −12.7 | −13.9 | −17.4 | −20.1 | −23.2 | −25.2 | −29.1 | −34.2 |

| 450 × 300 × 600 | −9.4 | −11.6 | −12.6 | −15.2 | −18.7 | −21.4 | −24.4 | −28.8 | −34.3 |

| 450 × 450 × 150 | −16.5 | −18.4 | −20.8 | −26.0 | −29.9 | −33.9 | −35.2 | −38.1 | −42.0 |

| 450 × 450 × 300 | −11.1 | −13.2 | −14.8 | −19.7 | −24.3 | −27.5 | −29.8 | −33.8 | −37.7 |

| 450 × 450 × 450 | −11.5 | −13.5 | −15.0 | −20.5 | −25.4 | −29.0 | −30.6 | −34.0 | −38.5 |

| 450 × 450 × 600 | −11.3 | −13.1 | −15.5 | −19.2 | −23.2 | −27.4 | −28.6 | −32.3 | −37.3 |

| 600 × 150 × 150 | −22.9 | −25.4 | −26.0 | −27.4 | −30.2 | −30.6 | −34.7 | −39.2 | −44.5 |

| 600 × 150 × 300 | −16.5 | −18.9 | −19.7 | −22.5 | −22.8 | −26.9 | −28.8 | −33.5 | −39.1 |

| 600 × 150 × 450 | −15.1 | −18.0 | −18.6 | −20.8 | −22.1 | −25.1 | −26.6 | −29.7 | −36.3 |

| 600 × 150 × 600 | −10.3 | −13.8 | −14.9 | −16.8 | −18.5 | −19.9 | −23.5 | −27.5 | −34.6 |

| 600 × 300 × 150 | −16.1 | −16.6 | −17.7 | −20.9 | −23.8 | −26.8 | −29.1 | −35.3 | −42.8 |

| 600 × 300 × 300 | −11.0 | −12.5 | −13.4 | −16.3 | −18.7 | −21.7 | −24.0 | −29.2 | −35.7 |

| 600 × 300 × 450 | −10.3 | −11.6 | −12.5 | −14.3 | −17.6 | −19.7 | −22.6 | −27.0 | −32.9 |

| 600 × 300 × 600 | −11.4 | −13.1 | −13.8 | −16.0 | −19.5 | −21.3 | −24.2 | −28.1 | −34.3 |

| 600 × 450 × 150 | −13.5 | −14.7 | −16.1 | −20.2 | −24.0 | −27.1 | −30.0 | −34.9 | −41.8 |

| 600 × 450 × 300 | −10.8 | −12.0 | −13.3 | −17.1 | −20.7 | −23.8 | −26.6 | −31.0 | −36.2 |

| 600 × 450 × 450 | −9.2 | −10.3 | −11.6 | −15.4 | −18.6 | −21.9 | −24.4 | −29.0 | −34.6 |

| 600 × 450 × 600 | −10.8 | −12.7 | −14.0 | −17.6 | −20.8 | −24.0 | −26.0 | −30.2 | −35.0 |

| 600 × 600 × 150 | −18.4 | −21.1 | −23.5 | −29.0 | −33.0 | −35.5 | −37.8 | −40.4 | −43.8 |

| 600 × 600 × 300 | −12.9 | −15.0 | −16.7 | −22.8 | −27.6 | −30.3 | −32.4 | −35.9 | −39.9 |

| 600 × 600 × 450 | −10.4 | −12.4 | −14.3 | −20.6 | −25.0 | −28.2 | −30.4 | −33.3 | −38.5 |

| 600 × 600 × 600 | −11.6 | −13.6 | −15.3 | −21.5 | −26.9 | −30.3 | −31.7 | −34.6 | −38.7 |

| Box | BCT (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1% | 3% | 5% | 10% | 15% | 20% | 25% | 35% | 50% | |

| 150 × 150 × 150 | −11.3 | −13.0 | −14.8 | −18.3 | −21.8 | −23.8 | −26.5 | −31.1 | −36.4 |

| 150 × 150 × 300 | −11.8 | −15.0 | −16.7 | −19.6 | −24.2 | −26.8 | −29.9 | −33.9 | −38.1 |

| 150 × 150 × 450 | −11.4 | −15.6 | −16.2 | −20.2 | −24.8 | −26.8 | −30.0 | −33.6 | −38.3 |

| 150 × 150 × 600 | −9.8 | −13.9 | −15.8 | −20.2 | −23.6 | −27.0 | −29.8 | −34.0 | −38.4 |

| 300 × 150 × 150 | −18.9 | −21.3 | −23.2 | −26.0 | −29.3 | −33.0 | −35.3 | −37.6 | −42.3 |

| 300 × 150 × 300 | −18.0 | −20.8 | −22.1 | −26.5 | −30.3 | −33.6 | −34.6 | −38.7 | −41.2 |

| 300 × 150 × 450 | −19.3 | −21.3 | −22.4 | −26.9 | −30.6 | −33.1 | −35.3 | −38.4 | −42.1 |

| 300 × 150 × 600 | −16.9 | −19.2 | −20.7 | −25.4 | −29.2 | −32.3 | −34.2 | −37.6 | −41.2 |

| 300 × 300 × 150 | −15.4 | −17.1 | −18.5 | −23.1 | −27.3 | −30.1 | −32.5 | −36.3 | −40.2 |

| 300 × 300 × 300 | −11.2 | −13.1 | −14.4 | −18.9 | −23.3 | −26.3 | −28.9 | −33.0 | −37.9 |

| 300 × 300 × 450 | −11.3 | −14.4 | −16.1 | −20.1 | −24.8 | −27.2 | −29.3 | −33.4 | −37.9 |

| 300 × 300 × 600 | −10.5 | −13.6 | −16.0 | −18.3 | −25.1 | −27.1 | −30.6 | −34.1 | −37.5 |

| 450 × 150 × 150 | −19.3 | −21.0 | −24.4 | −27.9 | −32.0 | −34.8 | −37.0 | −39.9 | −43.2 |

| 450 × 150 × 300 | −13.6 | −15.4 | −16.9 | −22.4 | −26.2 | −30.0 | −32.5 | −36.4 | −40.8 |

| 450 × 150 × 450 | −14.1 | −16.7 | −19.0 | −25.4 | −30.5 | −33.3 | −34.7 | −38.4 | −41.3 |

| 450 × 150 × 600 | −13.1 | −14.6 | −16.4 | −21.9 | −26.9 | −29.4 | −32.1 | −36.0 | −39.9 |

| 450 × 300 × 150 | −25.6 | −26.9 | −28.8 | −32.5 | −35.7 | −38.1 | −39.8 | −42.3 | −45.0 |

| 450 × 300 × 300 | −15.6 | −17.2 | −18.9 | −23.6 | −27.8 | −30.8 | −32.9 | −36.1 | −39.9 |

| 450 × 300 × 450 | −15.2 | −17.1 | −18.4 | −23.7 | −28.7 | −32.0 | −33.9 | −37.3 | −41.1 |

| 450 × 300 × 600 | −16.1 | −18.1 | −19.7 | −24.6 | −28.8 | −31.5 | −33.5 | −36.6 | −40.5 |

| 450 × 450 × 150 | −16.5 | −18.4 | −20.8 | −26.0 | −29.9 | −33.7 | −34.9 | −38.1 | −41.6 |

| 450 × 450 × 300 | −11.1 | −13.2 | −14.8 | −19.7 | −24.3 | −27.5 | −29.8 | −33.8 | −38.7 |

| 450 × 450 × 450 | −11.5 | −13.5 | −15.0 | −20.5 | −25.4 | −28.3 | −30.6 | −34.0 | −38.5 |

| 450 × 450 × 600 | −12.3 | −14.4 | −15.5 | −20.8 | −24.9 | −27.4 | −29.6 | −32.9 | −37.3 |

| 600 × 150 × 150 | −17.9 | −21.6 | −22.6 | −28.4 | −32.5 | −35.4 | −37.4 | −40.4 | −43.7 |

| 600 × 150 × 300 | −11.1 | −13.1 | −16.5 | −21.6 | −27.0 | −30.3 | −32.9 | −36.8 | −40.0 |

| 600 × 150 × 450 | −9.1 | −11.1 | −13.8 | −19.8 | −25.3 | −28.9 | −31.3 | −35.0 | −39.5 |

| 600 × 150 × 600 | −12.0 | −14.7 | −16.7 | −24.6 | −30.2 | −33.1 | −35.1 | −37.9 | −41.7 |

| 600 × 300 × 150 | −26.7 | −28.1 | −29.6 | −33.9 | −37.4 | −39.0 | −40.6 | −42.9 | −45.4 |

| 600 × 300 × 300 | −18.5 | −20.2 | −22.4 | −27.2 | −31.1 | −33.8 | −35.8 | −38.9 | −42.7 |

| 600 × 300 × 450 | −15.0 | −17.5 | −18.2 | −23.5 | −29.4 | −31.7 | −33.9 | −37.1 | −41.2 |

| 600 × 300 × 600 | −16.6 | −18.6 | −19.3 | −26.2 | −31.3 | −34.2 | −36.0 | −38.1 | −41.2 |

| 600 × 450 × 150 | −28.6 | −29.5 | −31.3 | −35.0 | −38.0 | −39.9 | −41.4 | −43.8 | −45.8 |

| 600 × 450 × 300 | −18.1 | −19.8 | −22.1 | −26.8 | −30.7 | −33.4 | −35.5 | −38.5 | −41.9 |

| 600 × 450 × 450 | −13.7 | −15.6 | −17.3 | −22.9 | −27.8 | −30.9 | −32.9 | −35.7 | −39.1 |

| 600 × 450 × 600 | −14.8 | −16.9 | −18.4 | −24.9 | −30.0 | −32.8 | −34.4 | −36.8 | −39.7 |

| 600 × 600 × 150 | −18.4 | −21.1 | −23.5 | −29.0 | −33.0 | −35.5 | −37.5 | −40.4 | −43.6 |

| 600 × 600 × 300 | −12.9 | −15.0 | −16.6 | −22.4 | −27.6 | −30.0 | −32.3 | −36.2 | −40.6 |

| 600 × 600 × 450 | −10.4 | −12.4 | −14.3 | −20.6 | −25.0 | −28.2 | −30.4 | −33.3 | −38.5 |

| 600 × 600 × 600 | −11.6 | −13.6 | −15.3 | −21.5 | −26.9 | −29.6 | −31.7 | −34.6 | −38.7 |

| Box | BCT (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1% | 3% | 5% | 10% | 15% | 20% | 25% | 35% | 50% | |

| 150 × 150 × 150 | −35.9 | −37.9 | −38.9 | −42.6 | −46.0 | −49.1 | −51.5 | −55.5 | −60.4 |

| 150 × 150 × 300 | −36.7 | −40.3 | −42.1 | −44.8 | −49.6 | −52.2 | −55.2 | −59.0 | −63.3 |

| 150 × 150 × 450 | −35.3 | −39.7 | −41.5 | −44.8 | −49.0 | −52.1 | −54.0 | −58.6 | −62.6 |

| 150 × 150 × 600 | −34.6 | −39.8 | −41.6 | −45.0 | −48.8 | −52.2 | −54.6 | −58.6 | −63.2 |

| 300 × 150 × 150 | −41.3 | −43.0 | −45.2 | −48.5 | −51.3 | −54.3 | −56.6 | −61.3 | −67.1 |

| 300 × 150 × 300 | −35.7 | −39.4 | −41.4 | −45.8 | −49.1 | −52.1 | −53.5 | −58.7 | −63.2 |

| 300 × 150 × 450 | −40.2 | −42.7 | −44.0 | −47.4 | −50.3 | −53.4 | −55.5 | −59.8 | −65.4 |

| 300 × 150 × 600 | −37.8 | −40.8 | −42.3 | −46.1 | −49.1 | −52.2 | −54.3 | −58.4 | −63.5 |

| 300 × 300 × 150 | −40.5 | −42.3 | −43.5 | −48.1 | −52.4 | −55.1 | −57.6 | −61.5 | −65.5 |

| 300 × 300 × 300 | −35.6 | −38.1 | −39.6 | −44.3 | −48.3 | −51.7 | −54.2 | −57.9 | −61.9 |

| 300 × 300 × 450 | −36.2 | −39.2 | −40.8 | −45.6 | −49.5 | −52.8 | −54.8 | −58.8 | −63.2 |

| 300 × 300 × 600 | −35.4 | −39.2 | −41.2 | −43.9 | −50.7 | −53.0 | −56.0 | −59.4 | −63.2 |

| 450 × 150 × 150 | −44.2 | −46.8 | −48.3 | −50.6 | −55.0 | −56.5 | −60.0 | −64.0 | −68.3 |

| 450 × 150 × 300 | −38.5 | −40.8 | −42.4 | −46.2 | −49.5 | −52.4 | −54.6 | −59.0 | −64.6 |

| 450 × 150 × 450 | −36.4 | −39.6 | −41.3 | −45.7 | −49.2 | −52.1 | −54.5 | −58.1 | −63.0 |

| 450 × 150 × 600 | −37.6 | −40.4 | −41.7 | −45.6 | −48.8 | −51.0 | −54.1 | −57.8 | −63.8 |

| 450 × 300 × 150 | −44.5 | −45.7 | −47.3 | −50.8 | −53.9 | −56.7 | −58.9 | −62.6 | −67.3 |

| 450 × 300 × 300 | −37.5 | −39.0 | −40.1 | −44.1 | −47.5 | −50.6 | −53.1 | −57.3 | −62.3 |

| 450 × 300 × 450 | −38.1 | −39.9 | −41.0 | −45.5 | −49.4 | −52.6 | −54.6 | −58.3 | −62.7 |

| 450 × 300 × 600 | −37.7 | −39.9 | −41.2 | −45.1 | −48.9 | −51.8 | −54.1 | −58.0 | −62.8 |

| 450 × 450 × 150 | −42.3 | −44.1 | −46.6 | −51.5 | −55.3 | −58.8 | −60.4 | −63.7 | −67.2 |

| 450 × 450 × 300 | −35.9 | −38.0 | −39.6 | −44.9 | −49.5 | −52.6 | −54.9 | −58.7 | −63.2 |

| 450 × 450 × 450 | −36.1 | −38.3 | −40.0 | −45.7 | −50.6 | −53.7 | −55.9 | −58.9 | −62.4 |

| 450 × 450 × 600 | −35.9 | −38.3 | −39.8 | −44.9 | −49.2 | −52.2 | −53.9 | −58.1 | −62.3 |

| 600 × 150 × 150 | −46.2 | −48.0 | −49.4 | −52.9 | −56.4 | −58.0 | −61.1 | −64.9 | −69.1 |

| 600 × 150 × 300 | −38.9 | −41.2 | −43.0 | −47.2 | −49.9 | −53.5 | −55.7 | −60.0 | −64.9 |

| 600 × 150 × 450 | −36.8 | −39.3 | −41.1 | −44.9 | −48.4 | −51.8 | −53.8 | −57.5 | −62.9 |

| 600 × 150 × 600 | −35.7 | −39.0 | −40.8 | −45.9 | −49.4 | −51.9 | −54.6 | −57.7 | −63.2 |

| 600 × 300 × 150 | −46.1 | −47.2 | −48.8 | −52.4 | −55.4 | −58.0 | −59.9 | −64.2 | −69.1 |

| 600 × 300 × 300 | −39.7 | −41.3 | −42.8 | −46.7 | −49.8 | −52.7 | −54.9 | −59.2 | −64.2 |

| 600 × 300 × 450 | −37.4 | −38.9 | −40.1 | −43.7 | −47.8 | −50.6 | −53.1 | −57.1 | −62.0 |

| 600 × 300 × 600 | −37.9 | −40.0 | −41.3 | −45.4 | −49.8 | −52.7 | −54.2 | −58.3 | −62.1 |

| 600 × 450 × 150 | −45.7 | −47.2 | −48.8 | −52.7 | −56.1 | −58.6 | −60.8 | −64.2 | −68.8 |

| 600 × 450 × 300 | −39.3 | −40.8 | −42.6 | −46.9 | −50.7 | −53.6 | −56.0 | −59.8 | −64.3 |

| 600 × 450 × 450 | −35.8 | −37.7 | −39.1 | −43.7 | −47.9 | −51.3 | −53.6 | −57.4 | −62.1 |

| 600 × 450 × 600 | −37.0 | −39.2 | −40.7 | −46.0 | −50.2 | −52.9 | −55.3 | −58.7 | −62.7 |

| 600 × 600 × 150 | −44.6 | −46.5 | −49.1 | −54.2 | −58.1 | −60.7 | −62.6 | −65.5 | −68.7 |

| 600 × 600 × 300 | −37.9 | −40.0 | −41.6 | −47.5 | −52.4 | −55.1 | −57.3 | −61.0 | −65.2 |

| 600 × 600 × 450 | −34.5 | −37.0 | −38.8 | −44.9 | −50.0 | −53.2 | −54.8 | −58.6 | −62.4 |

| 600 × 600 × 600 | −35.8 | −38.3 | −40.2 | −46.7 | −51.6 | −54.9 | −56.8 | −59.4 | −62.5 |

| Box | BCT (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1% | 3% | 5% | 10% | 15% | 20% | 25% | 35% | 50% | |

| 150 × 150 × 150 | −11.3 | −13.0 | −14.1 | −17.7 | −21.1 | −24.4 | −26.5 | −31.1 | −36.4 |

| 150 × 150 × 300 | −11.8 | −15.0 | −16.7 | −20.1 | −24.2 | −27.5 | −29.9 | −33.9 | −38.4 |

| 150 × 150 × 450 | −11.4 | −15.6 | −16.2 | −19.7 | −24.8 | −26.8 | −30.0 | −33.6 | −38.2 |

| 150 × 150 × 600 | −9.8 | −14.2 | −16.2 | −19.8 | −23.6 | −27.3 | −29.7 | −33.7 | −39.0 |

| 300 × 150 × 150 | −13.1 | −14.8 | −15.8 | −20.1 | −22.4 | −25.5 | −28.0 | −33.9 | −41.9 |

| 300 × 150 × 300 | −5.7 | −9.6 | −11.4 | −14.8 | −18.0 | −20.7 | −23.7 | −27.2 | −35.2 |

| 300 × 150 × 450 | −12.5 | −14.8 | −16.1 | −18.5 | −21.3 | −23.7 | −26.1 | −31.3 | −38.8 |

| 300 × 150 × 600 | −10.1 | −12.9 | −14.1 | −16.5 | −19.1 | −21.9 | −24.3 | −29.2 | −36.0 |

| 300 × 300 × 150 | −15.4 | −17.1 | −18.6 | −23.1 | −27.3 | −30.2 | −32.7 | −36.6 | −40.9 |

| 300 × 300 × 300 | −11.2 | −13.1 | −14.4 | −18.9 | −23.3 | −27.1 | −28.9 | −33.0 | −37.9 |

| 300 × 300 × 450 | −11.3 | −14.4 | −16.1 | −20.1 | −24.8 | −27.2 | −29.9 | −33.4 | −38.1 |

| 300 × 300 × 600 | −10.5 | −13.6 | −16.8 | −19.0 | −26.2 | −27.9 | −31.2 | −34.5 | −37.8 |

| 450 × 150 × 150 | −19.3 | −22.5 | −23.2 | −23.4 | −27.8 | −28.3 | −32.8 | −37.7 | −43.4 |

| 450 × 150 × 300 | −15.2 | −17.2 | −18.1 | −21.0 | −22.8 | −25.8 | −26.7 | −32.6 | −38.7 |

| 450 × 150 × 450 | −9.0 | −12.1 | −13.3 | −15.6 | −17.5 | −20.6 | −22.9 | −27.8 | −34.0 |

| 450 × 150 × 600 | −12.5 | −15.4 | −16.6 | −18.5 | −20.2 | −21.4 | −25.3 | −29.3 | −36.7 |

| 450 × 300 × 150 | −14.1 | −14.8 | −16.1 | −19.2 | −22.4 | −25.5 | −28.2 | −33.1 | −39.5 |

| 450 × 300 × 300 | −9.5 | −11.1 | −11.8 | −15.2 | −17.7 | −20.8 | −23.5 | −28.0 | −34.5 |

| 450 × 300 × 450 | −11.0 | −12.7 | −13.9 | −17.4 | −20.1 | −23.2 | −25.2 | −29.1 | −34.2 |

| 450 × 300 × 600 | −9.4 | −11.6 | −12.6 | −15.2 | −18.7 | −21.4 | −24.4 | −28.8 | −34.3 |

| 450 × 450 × 150 | −16.5 | −18.4 | −20.8 | −26.0 | −29.9 | −33.9 | −35.2 | −38.1 | −42.0 |

| 450 × 450 × 300 | −11.1 | −13.2 | −14.8 | −19.7 | −24.3 | −27.5 | −29.8 | −33.8 | −37.7 |

| 450 × 450 × 450 | −11.5 | −13.5 | −15.0 | −20.5 | −25.4 | −29.0 | −30.6 | −34.0 | −38.5 |

| 450 × 450 × 600 | −11.3 | −13.1 | −15.5 | −19.2 | −23.2 | −27.4 | −28.6 | −32.3 | −37.3 |

| 600 × 150 × 150 | −22.9 | −25.4 | −26.0 | −27.4 | −30.2 | −30.6 | −34.7 | −39.2 | −44.5 |

| 600 × 150 × 300 | −16.5 | −18.9 | −19.7 | −22.5 | −22.8 | −26.9 | −28.8 | −33.5 | −39.1 |

| 600 × 150 × 450 | −15.1 | −18.0 | −18.6 | −20.8 | −22.1 | −25.1 | −26.6 | −29.7 | −36.3 |

| 600 × 150 × 600 | −10.3 | −13.8 | −14.9 | −16.8 | −18.5 | −19.9 | −23.5 | −27.5 | −34.6 |

| 600 × 300 × 150 | −16.1 | −16.6 | −17.7 | −20.9 | −23.8 | −26.8 | −29.1 | −35.3 | −42.8 |

| 600 × 300 × 300 | −11.0 | −12.5 | −13.4 | −16.3 | −18.7 | −21.7 | −24.0 | −29.2 | −35.7 |

| 600 × 300 × 450 | −10.3 | −11.6 | −12.5 | −14.3 | −17.6 | −19.7 | −22.6 | −27.0 | −32.9 |

| 600 × 300 × 600 | −11.4 | −13.1 | −13.8 | −16.0 | −19.5 | −21.3 | −24.2 | −28.1 | −34.3 |

| 600 × 450 × 150 | −13.5 | −14.7 | −16.1 | −20.2 | −24.0 | −27.1 | −30.0 | −34.9 | −41.8 |

| 600 × 450 × 300 | −10.8 | −12.0 | −13.3 | −17.1 | −20.7 | −23.8 | −26.6 | −31.0 | −36.2 |

| 600 × 450 × 450 | −9.2 | −10.3 | −11.6 | −15.4 | −18.6 | −21.9 | −24.4 | −29.0 | −34.6 |

| 600 × 450 × 600 | −10.8 | −12.7 | −14.0 | −17.6 | −20.8 | −24.0 | −26.0 | −30.2 | −35.0 |

| 600 × 600 × 150 | −18.4 | −21.1 | −23.5 | −29.0 | −33.0 | −35.5 | −37.8 | −40.4 | −43.8 |

| 600 × 600 × 300 | −12.9 | −15.0 | −16.7 | −22.8 | −27.6 | −30.3 | −32.4 | −35.9 | −39.9 |

| 600 × 600 × 450 | −10.4 | −12.4 | −14.3 | −20.6 | −25.0 | −28.2 | −30.4 | −33.3 | −38.5 |

| 600 × 600 × 600 | −11.6 | −13.6 | −15.3 | −21.5 | −26.9 | −30.3 | −31.7 | −34.6 | −38.7 |

| Box | BCT (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1% | 3% | 5% | 10% | 15% | 20% | 25% | 35% | 50% | |

| 150 × 150 × 150 | −11.3 | −13.0 | −14.8 | −18.3 | −21.8 | −23.8 | −26.5 | −31.1 | −36.4 |

| 150 × 150 × 300 | −11.8 | −15.0 | −16.7 | −19.6 | −24.2 | −26.8 | −29.9 | −33.9 | −38.1 |

| 150 × 150 × 450 | −11.4 | −15.6 | −16.2 | −20.2 | −24.8 | −26.8 | −30.0 | −33.6 | −38.3 |

| 150 × 150 × 600 | −9.8 | −13.9 | −15.8 | −20.2 | −23.6 | −27.0 | −29.8 | −34.0 | −38.4 |

| 300 × 150 × 150 | −18.9 | −21.3 | −23.2 | −26.0 | −29.3 | −33.0 | −35.3 | −37.6 | −42.3 |

| 300 × 150 × 300 | −18.0 | −20.8 | −22.1 | −26.5 | −30.3 | −33.6 | −34.6 | −38.7 | −41.2 |

| 300 × 150 × 450 | −19.3 | −21.3 | −22.4 | −26.9 | −30.6 | −33.1 | −35.3 | −38.4 | −42.1 |

| 300 × 150 × 600 | −16.9 | −19.2 | −20.7 | −25.4 | −29.2 | −32.3 | −34.2 | −37.6 | −41.2 |

| 300 × 300 × 150 | −15.4 | −17.1 | −18.5 | −23.1 | −27.3 | −30.1 | −32.5 | −36.3 | −40.2 |

| 300 × 300 × 300 | −11.2 | −13.1 | −14.4 | −18.9 | −23.3 | −26.3 | −28.9 | −33.0 | −37.9 |

| 300 × 300 × 450 | −11.3 | −14.4 | −16.1 | −20.1 | −24.8 | −27.2 | −29.3 | −33.4 | −37.9 |

| 300 × 300 × 600 | −10.5 | −13.6 | −16.0 | −18.3 | −25.1 | −27.1 | −30.6 | −34.1 | −37.5 |

| 450 × 150 × 150 | −19.3 | −21.0 | −24.4 | −27.9 | −32.0 | −34.8 | −37.0 | −39.9 | −43.2 |

| 450 × 150 × 300 | −13.6 | −15.4 | −16.9 | −22.4 | −26.2 | −30.0 | −32.5 | −36.4 | −40.8 |

| 450 × 150 × 450 | −14.1 | −16.7 | −19.0 | −25.4 | −30.5 | −33.3 | −34.7 | −38.4 | −41.3 |

| 450 × 150 × 600 | −13.1 | −14.6 | −16.4 | −21.9 | −26.9 | −29.4 | −32.1 | −36.0 | −39.9 |

| 450 × 300 × 150 | −25.6 | −26.9 | −28.8 | −32.5 | −35.7 | −38.1 | −39.8 | −42.3 | −45.0 |

| 450 × 300 × 300 | −15.6 | −17.2 | −18.9 | −23.6 | −27.8 | −30.8 | −32.9 | −36.1 | −39.9 |

| 450 × 300 × 450 | −15.2 | −17.1 | −18.4 | −23.7 | −28.7 | −32.0 | −33.9 | −37.3 | −41.1 |

| 450 × 300 × 600 | −16.1 | −18.1 | −19.7 | −24.6 | −28.8 | −31.5 | −33.5 | −36.6 | −40.5 |

| 450 × 450 × 150 | −16.5 | −18.4 | −20.8 | −26.0 | −29.9 | −33.7 | −34.9 | −38.1 | −41.6 |

| 450 × 450 × 300 | −11.1 | −13.2 | −14.8 | −19.7 | −24.3 | −27.5 | −29.8 | −33.8 | −38.7 |

| 450 × 450 × 450 | −11.5 | −13.5 | −15.0 | −20.5 | −25.4 | −28.3 | −30.6 | −34.0 | −38.5 |

| 450 × 450 × 600 | −12.3 | −14.4 | −15.5 | −20.8 | −24.9 | −27.4 | −29.6 | −32.9 | −37.3 |

| 600 × 150 × 150 | −17.9 | −21.6 | −22.6 | −28.4 | −32.5 | −35.4 | −37.4 | −40.4 | −43.7 |

| 600 × 150 × 300 | −11.1 | −13.1 | −16.5 | −21.6 | −27.0 | −30.3 | −32.9 | −36.8 | −40.0 |

| 600 × 150 × 450 | −9.1 | −11.1 | −13.8 | −19.8 | −25.3 | −28.9 | −31.3 | −35.0 | −39.5 |

| 600 × 150 × 600 | −12.0 | −14.7 | −16.7 | −24.6 | −30.2 | −33.1 | −35.1 | −37.9 | −41.7 |

| 600 × 300 × 150 | −26.7 | −28.1 | −29.6 | −33.9 | −37.4 | −39.0 | −40.6 | −42.9 | −45.4 |

| 600 × 300 × 300 | −18.5 | −20.2 | −22.4 | −27.2 | −31.1 | −33.8 | −35.8 | −38.9 | −42.7 |

| 600 × 300 × 450 | −15.0 | −17.5 | −18.2 | −23.5 | −29.4 | −31.7 | −33.9 | −37.1 | −41.2 |

| 600 × 300 × 600 | −16.6 | −18.6 | −19.3 | −26.2 | −31.3 | −34.2 | −36.0 | −38.1 | −41.2 |

| 600 × 450 × 150 | −28.6 | −29.5 | −31.3 | −35.0 | −38.0 | −39.9 | −41.4 | −43.8 | −45.8 |

| 600 × 450 × 300 | −18.1 | −19.8 | −22.1 | −26.8 | −30.7 | −33.4 | −35.5 | −38.5 | −41.9 |

| 600 × 450 × 450 | −13.7 | −15.6 | −17.3 | −22.9 | −27.8 | −30.9 | −32.9 | −35.7 | −39.1 |

| 600 × 450 × 600 | −14.8 | −16.9 | −18.4 | −24.9 | −30.0 | −32.8 | −34.4 | −36.8 | −39.7 |

| 600 × 600 × 150 | −18.4 | −21.1 | −23.5 | −29.0 | −33.0 | −35.5 | −37.5 | −40.4 | −43.6 |

| 600 × 600 × 300 | −12.9 | −15.0 | −16.6 | −22.4 | −27.6 | −30.0 | −32.3 | −36.2 | −40.6 |

| 600 × 600 × 450 | −10.4 | −12.4 | −14.3 | −20.6 | −25.0 | −28.2 | −30.4 | −33.3 | −38.5 |

| 600 × 600 × 600 | −11.6 | −13.6 | −15.3 | −21.5 | −26.9 | −29.6 | −31.7 | −34.6 | −38.7 |

| Box | BCT (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1% | 3% | 5% | 10% | 15% | 20% | 25% | 35% | 50% | |

| 150 × 150 × 150 | −35.9 | −37.9 | −38.9 | −42.6 | −46.0 | −49.1 | −51.5 | −55.5 | −60.4 |

| 150 × 150 × 300 | −36.7 | −40.3 | −42.1 | −44.8 | −49.6 | −52.2 | −55.2 | −59.0 | −63.3 |

| 150 × 150 × 450 | −35.3 | −39.7 | −41.5 | −44.8 | −49.0 | −52.1 | −54.0 | −58.6 | −62.6 |

| 150 × 150 × 600 | −34.6 | −39.8 | −41.6 | −45.0 | −48.8 | −52.2 | −54.6 | −58.6 | −63.2 |

| 300 × 150 × 150 | −41.3 | −43.0 | −45.2 | −48.5 | −51.3 | −54.3 | −56.6 | −61.3 | −67.1 |

| 300 × 150 × 300 | −35.7 | −39.4 | −41.4 | −45.8 | −49.1 | −52.1 | −53.5 | −58.7 | −63.2 |

| 300 × 150 × 450 | −40.2 | −42.7 | −44.0 | −47.4 | −50.3 | −53.4 | −55.5 | −59.8 | −65.4 |

| 300 × 150 × 600 | −37.8 | −40.8 | −42.3 | −46.1 | −49.1 | −52.2 | −54.3 | −58.4 | −63.5 |

| 300 × 300 × 150 | −40.5 | −42.3 | −43.5 | −48.1 | −52.4 | −55.1 | −57.6 | −61.5 | −65.5 |

| 300 × 300 × 300 | −35.6 | −38.1 | −39.6 | −44.3 | −48.3 | −51.7 | −54.2 | −57.9 | −61.9 |

| 300 × 300 × 450 | −36.2 | −39.2 | −40.8 | −45.6 | −49.5 | −52.8 | −54.8 | −58.8 | −63.2 |

| 300 × 300 × 600 | −35.4 | −39.2 | −41.2 | −43.9 | −50.7 | −53.0 | −56.0 | −59.4 | −63.2 |

| 450 × 150 × 150 | −44.2 | −46.8 | −48.3 | −50.6 | −55.0 | −56.5 | −60.0 | −64.0 | −68.3 |

| 450 × 150 × 300 | −38.5 | −40.8 | −42.4 | −46.2 | −49.5 | −52.4 | −54.6 | −59.0 | −64.6 |

| 450 × 150 × 450 | −36.4 | −39.6 | −41.3 | −45.7 | −49.2 | −52.1 | −54.5 | −58.1 | −63.0 |

| 450 × 150 × 600 | −37.6 | −40.4 | −41.7 | −45.6 | −48.8 | −51.0 | −54.1 | −57.8 | −63.8 |

| 450 × 300 × 150 | −44.5 | −45.7 | −47.3 | −50.8 | −53.9 | −56.7 | −58.9 | −62.6 | −67.3 |

| 450 × 300 × 300 | −37.5 | −39.0 | −40.1 | −44.1 | −47.5 | −50.6 | −53.1 | −57.3 | −62.3 |

| 450 × 300 × 450 | −38.1 | −39.9 | −41.0 | −45.5 | −49.4 | −52.6 | −54.6 | −58.3 | −62.7 |

| 450 × 300 × 600 | −37.7 | −39.9 | −41.2 | −45.1 | −48.9 | −51.8 | −54.1 | −58.0 | −62.8 |

| 450 × 450 × 150 | −42.3 | −44.1 | −46.6 | −51.5 | −55.3 | −58.8 | −60.4 | −63.7 | −67.2 |

| 450 × 450 × 300 | −35.9 | −38.0 | −39.6 | −44.9 | −49.5 | −52.6 | −54.9 | −58.7 | −63.2 |

| 450 × 450 × 450 | −36.1 | −38.3 | −40.0 | −45.7 | −50.6 | −53.7 | −55.9 | −58.9 | −62.4 |

| 450 × 450 × 600 | −35.9 | −38.3 | −39.8 | −44.9 | −49.2 | −52.2 | −53.9 | −58.1 | −62.3 |

| 600 × 150 × 150 | −46.2 | −48.0 | −49.4 | −52.9 | −56.4 | −58.0 | −61.1 | −64.9 | −69.1 |

| 600 × 150 × 300 | −38.9 | −41.2 | −43.0 | −47.2 | −49.9 | −53.5 | −55.7 | −60.0 | −64.9 |

| 600 × 150 × 450 | −36.8 | −39.3 | −41.1 | −44.9 | −48.4 | −51.8 | −53.8 | −57.5 | −62.9 |

| 600 × 150 × 600 | −35.7 | −39.0 | −40.8 | −45.9 | −49.4 | −51.9 | −54.6 | −57.7 | −63.2 |

| 600 × 300 × 150 | −46.1 | −47.2 | −48.8 | −52.4 | −55.4 | −58.0 | −59.9 | −64.2 | −69.1 |

| 600 × 300 × 300 | −39.7 | −41.3 | −42.8 | −46.7 | −49.8 | −52.7 | −54.9 | −59.2 | −64.2 |

| 600 × 300 × 450 | −37.4 | −38.9 | −40.1 | −43.7 | −47.8 | −50.6 | −53.1 | −57.1 | −62.0 |

| 600 × 300 × 600 | −37.9 | −40.0 | −41.3 | −45.4 | −49.8 | −52.7 | −54.2 | −58.3 | −62.1 |

| 600 × 450 × 150 | −45.7 | −47.2 | −48.8 | −52.7 | −56.1 | −58.6 | −60.8 | −64.2 | −68.8 |

| 600 × 450 × 300 | −39.3 | −40.8 | −42.6 | −46.9 | −50.7 | −53.6 | −56.0 | −59.8 | −64.3 |

| 600 × 450 × 450 | −35.8 | −37.7 | −39.1 | −43.7 | −47.9 | −51.3 | −53.6 | −57.4 | −62.1 |

| 600 × 450 × 600 | −37.0 | −39.2 | −40.7 | −46.0 | −50.2 | −52.9 | −55.3 | −58.7 | −62.7 |

| 600 × 600 × 150 | −44.6 | −46.5 | −49.1 | −54.2 | −58.1 | −60.7 | −62.6 | −65.5 | −68.7 |

| 600 × 600 × 300 | −37.9 | −40.0 | −41.6 | −47.5 | −52.4 | −55.1 | −57.3 | −61.0 | −65.2 |

| 600 × 600 × 450 | −34.5 | −37.0 | −38.8 | −44.9 | −50.0 | −53.2 | −54.8 | −58.6 | −62.4 |

| 600 × 600 × 600 | −35.8 | −38.3 | −40.2 | −46.7 | −51.6 | −54.9 | −56.8 | −59.4 | −62.5 |

| Box | BCT (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1% | 3% | 5% | 10% | 15% | 20% | 25% | 35% | 50% | |

| 150 × 150 × 150 | −12.0 | −13.8 | −14.9 | −18.1 | −21.0 | −24.1 | −26.4 | −30.6 | −34.8 |

| 150 × 150 × 300 | −10.9 | −14.3 | −16.5 | −20.5 | −23.5 | −26.8 | −28.9 | −33.0 | −37.7 |

| 150 × 150 × 450 | −11.2 | −15.0 | −16.2 | −19.9 | −24.4 | −26.2 | −29.4 | −33.2 | −37.7 |

| 150 × 150 × 600 | −9.4 | −13.1 | −15.4 | −20.5 | −23.4 | −26.7 | −29.2 | −33.1 | −37.9 |

| 300 × 150 × 150 | −14.9 | −17.1 | −18.2 | −21.1 | −23.3 | −26.2 | −31.0 | −34.3 | −44.1 |

| 300 × 150 × 300 | −0.4 | −5.4 | −8.1 | −14.1 | −16.3 | −19.9 | −22.5 | −31.7 | −40.8 |

| 300 × 150 × 450 | −12.7 | −16.0 | −17.7 | −20.5 | −23.0 | −25.5 | −26.1 | −33.1 | −39.0 |

| 300 × 150 × 600 | −9.1 | −12.6 | −14.3 | −17.3 | −21.2 | −22.4 | −25.0 | −30.0 | −38.8 |

| 300 × 300 × 150 | −16.7 | −18.6 | −19.8 | −23.8 | −27.6 | −30.3 | −32.9 | −36.8 | −41.0 |

| 300 × 300 × 300 | −11.5 | −13.6 | −14.8 | −18.7 | −22.4 | −25.2 | −27.9 | −32.2 | −37.0 |

| 300 × 300 × 450 | −11.1 | −14.6 | −16.4 | −20.4 | −23.9 | −26.9 | −29.0 | −32.5 | −37.3 |

| 300 × 300 × 600 | −10.7 | −14.2 | −16.6 | −19.8 | −25.4 | −27.3 | −30.6 | −34.2 | −37.8 |

| 450 × 150 × 150 | −21.5 | −24.1 | −27.2 | −26.5 | −31.4 | −31.0 | −35.8 | −40.1 | −44.8 |

| 450 × 150 × 300 | −18.1 | −20.5 | −21.6 | −23.5 | −26.1 | −28.0 | −29.9 | −34.4 | −40.8 |

| 450 × 150 × 450 | −8.0 | −13.2 | −13.7 | −16.8 | −21.0 | −21.8 | −24.4 | −29.4 | −37.9 |

| 450 × 150 × 600 | −14.0 | −17.2 | −18.9 | −21.1 | −22.9 | −25.5 | −27.6 | −31.6 | −38.6 |

| 450 × 300 × 150 | −15.1 | −16.4 | −17.4 | −20.4 | −23.4 | −26.4 | −29.2 | −34.5 | −42.7 |

| 450 × 300 × 300 | −10.5 | −12.4 | −13.4 | −16.5 | −18.9 | −21.9 | −24.7 | −29.5 | −36.0 |

| 450 × 300 × 450 | −10.8 | −12.8 | −13.7 | −16.9 | −19.3 | −22.4 | −24.6 | −29.1 | −35.1 |

| 450 × 300 × 600 | −9.5 | −12.4 | −13.3 | −15.9 | −19.0 | −21.7 | −25.0 | −29.5 | −35.2 |

| 450 × 450 × 150 | −17.7 | −19.4 | −21.6 | −26.1 | −29.8 | −33.7 | −35.0 | −38.4 | −42.1 |

| 450 × 450 × 300 | −12.2 | −14.4 | −15.9 | −20.2 | −24.1 | −27.2 | −29.8 | −33.5 | −38.8 |

| 450 × 450 × 450 | −11.6 | −14.0 | −15.3 | −19.8 | −24.0 | −27.8 | −29.4 | −33.3 | −38.1 |

| 450 × 450 × 600 | −12.2 | −14.4 | −16.7 | −19.6 | −23.2 | −27.1 | −28.8 | −32.8 | −37.8 |

| 600 × 150 × 150 | −23.3 | −27.6 | −28.2 | −29.5 | −32.0 | −31.8 | −36.0 | −39.9 | −44.2 |

| 600 × 150 × 300 | −18.6 | −21.3 | −22.4 | −24.2 | −27.1 | −28.4 | −30.2 | −34.5 | −41.3 |

| 600 × 150 × 450 | −17.7 | −20.2 | −21.5 | −23.2 | −24.5 | −27.2 | −28.7 | −32.4 | −37.9 |

| 600 × 150 × 600 | −11.3 | −14.6 | −16.4 | −18.8 | −20.4 | −22.1 | −25.4 | −29.5 | −36.6 |

| 600 × 300 × 150 | −19.8 | −20.5 | −21.4 | −24.3 | −27.1 | −29.9 | −31.3 | −38.1 | −45.0 |

| 600 × 300 × 300 | −12.1 | −14.1 | −15.2 | −18.0 | −20.4 | −23.4 | −26.3 | −31.3 | −39.6 |

| 600 × 300 × 450 | −11.3 | −13.3 | −14.3 | −16.1 | −19.3 | −21.5 | −24.6 | −29.5 | −36.4 |

| 600 × 300 × 600 | −11.9 | −14.1 | −14.9 | −17.0 | −20.2 | −22.3 | −25.4 | −29.6 | −36.5 |

| 600 × 450 × 150 | −15.4 | −16.4 | −17.6 | −21.2 | −24.5 | −27.4 | −30.3 | −35.1 | −42.7 |

| 600 × 450 × 300 | −11.5 | −13.5 | −14.6 | −18.1 | −21.3 | −24.3 | −27.0 | −31.2 | −36.6 |

| 600 × 450 × 450 | −9.4 | −11.3 | −12.5 | −15.7 | −18.6 | −21.6 | −24.2 | −28.9 | −34.4 |

| 600 × 450 × 600 | −10.4 | −12.6 | −13.8 | −17.2 | −20.0 | −23.1 | −25.2 | −29.7 | −34.7 |

| 600 × 600 × 150 | −19.3 | −21.9 | −23.8 | −28.7 | −32.4 | −35.1 | −37.2 | −40.3 | −43.8 |

| 600 × 600 × 300 | −14.1 | −16.4 | −17.8 | −22.7 | −27.3 | −29.9 | −32.3 | −36.2 | −40.6 |

| 600 × 600 × 450 | −11.0 | −13.7 | −15.2 | −20.3 | −23.9 | −27.0 | −29.4 | −32.9 | −38.4 |

| 600 × 600 × 600 | −11.7 | −14.1 | −15.5 | −20.6 | −25.2 | −28.8 | −30.3 | −33.8 | −38.4 |

| Box | BCT (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1% | 3% | 5% | 10% | 15% | 20% | 25% | 35% | 50% | |

| 150 × 150 × 150 | −12.0 | −13.8 | −14.9 | −18.1 | −21.0 | −23.6 | −26.1 | −30.3 | −35.6 |

| 150 × 150 × 300 | −10.9 | −14.3 | −16.5 | −19.8 | −23.5 | −26.1 | −28.9 | −33.0 | −37.3 |

| 150 × 150 × 450 | −11.2 | −15.0 | −16.2 | −19.9 | −24.4 | −26.2 | −29.4 | −33.2 | −37.5 |

| 150 × 150 × 600 | −9.4 | −13.4 | −16.0 | −20.5 | −22.9 | −26.2 | −29.0 | −33.1 | −38.2 |

| 300 × 150 × 150 | −17.4 | −18.8 | −20.6 | −25.7 | −28.9 | −31.6 | −34.0 | −37.8 | −41.5 |

| 300 × 150 × 300 | −17.6 | −19.9 | −21.2 | −25.3 | −28.6 | −31.0 | −32.9 | −37.9 | −41.7 |

| 300 × 150 × 450 | −15.7 | −16.8 | −17.9 | −22.8 | −26.3 | −28.0 | −30.5 | −35.1 | −38.4 |

| 300 × 150 × 600 | −16.1 | −18.6 | −20.1 | −24.1 | −27.4 | −30.5 | −32.5 | −36.2 | −40.2 |

| 300 × 300 × 150 | −16.7 | −18.6 | −19.8 | −23.8 | −27.6 | −30.2 | −32.6 | −36.4 | −40.4 |

| 300 × 300 × 300 | −11.5 | −13.6 | −14.8 | −18.7 | −22.4 | −26.1 | −27.9 | −32.2 | −37.0 |

| 300 × 300 × 450 | −11.1 | −14.6 | −16.4 | −20.4 | −23.9 | −26.9 | −28.3 | −32.5 | −37.0 |

| 300 × 300 × 600 | −10.7 | −14.2 | −16.6 | −18.8 | −24.3 | −26.4 | −29.9 | −33.6 | −37.3 |

| 450 × 150 × 150 | −19.2 | −19.4 | −21.6 | −26.0 | −30.0 | −33.0 | −35.4 | −38.9 | −42.7 |

| 450 × 150 × 300 | −12.1 | −14.0 | −15.9 | −20.3 | −24.3 | −28.4 | −31.0 | −34.1 | −40.0 |

| 450 × 150 × 450 | −12.5 | −15.6 | −18.4 | −23.0 | −28.4 | −30.1 | −32.2 | −35.6 | −40.9 |

| 450 × 150 × 600 | −11.5 | −13.9 | −14.7 | −19.6 | −24.5 | −27.5 | −29.6 | −34.3 | −38.3 |

| 450 × 300 × 150 | −25.3 | −26.0 | −28.3 | −31.6 | −34.6 | −37.0 | −38.3 | −41.6 | −44.5 |

| 450 × 300 × 300 | −17.6 | −19.2 | −20.4 | −24.3 | −27.8 | −30.6 | −32.8 | −36.5 | −40.7 |

| 450 × 300 × 450 | −16.1 | −17.7 | −19.5 | −24.0 | −27.3 | −30.3 | −32.6 | −36.3 | −39.4 |

| 450 × 300 × 600 | −16.9 | −19.4 | −20.7 | −24.7 | −28.2 | −30.8 | −32.9 | −36.2 | −40.2 |

| 450 × 450 × 150 | −17.7 | −19.4 | −21.6 | −26.1 | −29.7 | −33.4 | −34.7 | −38.4 | −41.8 |

| 450 × 450 × 300 | −12.2 | −14.4 | −15.9 | −20.2 | −24.1 | −27.2 | −29.8 | −33.5 | −37.8 |

| 450 × 450 × 450 | −11.6 | −14.0 | −15.3 | −19.8 | −24.0 | −26.9 | −29.4 | −33.3 | −38.1 |

| 450 × 450 × 600 | −12.2 | −15.5 | −16.7 | −21.0 | −24.6 | −27.1 | −29.5 | −33.1 | −37.5 |

| 600 × 150 × 150 | −14.2 | −16.6 | −20.0 | −25.4 | −29.8 | −33.0 | −35.4 | −37.9 | −43.1 |

| 600 × 150 × 300 | −9.6 | −12.6 | −15.2 | −19.4 | −24.8 | −28.3 | −31.1 | −35.3 | −39.9 |

| 600 × 150 × 450 | −7.7 | −9.6 | −12.1 | −17.3 | −22.1 | −25.7 | −28.5 | −32.8 | −36.8 |

| 600 × 150 × 600 | −9.8 | −13.0 | −15.8 | −22.6 | −27.8 | −30.1 | −32.3 | −35.6 | −39.7 |

| 600 × 300 × 150 | −25.0 | −27.2 | −29.1 | −32.3 | −36.1 | −37.7 | −39.5 | −42.9 | −45.1 |

| 600 × 300 × 300 | −19.0 | −20.7 | −22.9 | −27.0 | −30.5 | −32.9 | −35.3 | −38.1 | −42.3 |

| 600 × 300 × 450 | −15.7 | −17.5 | −18.9 | −23.4 | −27.7 | −30.4 | −32.6 | −35.8 | −39.6 |

| 600 × 300 × 600 | −16.3 | −18.2 | −19.9 | −25.0 | −28.9 | −32.0 | −34.2 | −37.0 | −41.4 |

| 600 × 450 × 150 | −28.0 | −29.1 | −30.8 | −34.1 | −37.0 | −39.1 | −40.7 | −43.1 | −45.7 |

| 600 × 450 × 300 | −20.0 | −21.5 | −23.5 | −27.5 | −30.9 | −33.5 | −35.6 | −38.5 | −41.8 |

| 600 × 450 × 450 | −14.9 | −16.9 | −18.3 | −22.9 | −27.0 | −29.9 | −32.0 | −35.1 | −38.9 |

| 600 × 450 × 600 | −15.2 | −17.7 | −19.0 | −24.3 | −28.5 | −31.3 | −33.1 | −36.1 | −39.4 |

| 600 × 600 × 150 | −19.3 | −21.9 | −23.8 | −28.7 | −32.4 | −35.1 | −37.4 | −40.3 | −43.9 |

| 600 × 600 × 300 | −14.1 | −16.4 | −18.0 | −23.0 | −27.1 | −30.0 | −32.3 | −35.9 | −39.8 |

| 600 × 600 × 450 | −11.0 | −13.7 | −15.2 | −20.3 | −24.6 | −27.5 | −29.7 | −32.9 | −38.4 |

| 600 × 600 × 600 | −11.7 | −14.1 | −15.5 | −20.6 | −25.2 | −28.0 | −30.3 | −33.8 | −38.4 |

| Box | BCT (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1% | 3% | 5% | 10% | 15% | 20% | 25% | 35% | 50% | |

| 150 × 150 × 150 | −36.8 | −38.8 | −39.8 | −43.1 | −46.1 | −48.9 | −51.1 | −55.0 | −59.8 |

| 150 × 150 × 300 | −36.6 | −40.1 | −42.1 | −45.2 | −49.1 | −51.6 | −54.4 | −58.3 | −62.7 |

| 150 × 150 × 450 | −35.5 | −39.3 | −41.6 | −45.2 | −48.4 | −51.4 | −53.5 | −58.0 | −62.2 |

| 150 × 150 × 600 | −34.7 | −39.2 | −41.5 | −45.2 | −48.3 | −51.6 | −54.0 | −58.0 | −62.7 |

| 300 × 150 × 150 | −41.4 | −43.5 | −45.1 | −48.3 | −51.1 | −53.9 | −57.5 | −60.9 | −67.8 |

| 300 × 150 × 300 | −30.5 | −35.6 | −38.7 | −46.5 | −47.2 | −52.5 | −53.7 | −59.8 | −64.4 |

| 300 × 150 × 450 | −37.8 | −40.9 | −42.7 | −45.4 | −48.8 | −51.4 | −53.6 | −58.4 | −64.5 |

| 300 × 150 × 600 | −36.5 | −39.9 | −41.8 | −45.7 | −49.2 | −51.5 | −53.9 | −58.2 | −64.5 |

| 300 × 300 × 150 | −41.8 | −43.7 | −44.8 | −48.8 | −52.6 | −55.3 | −57.7 | −61.6 | −65.6 |

| 300 × 300 × 300 | −36.1 | −38.8 | −40.1 | −44.1 | −47.5 | −50.7 | −53.2 | −57.1 | −61.1 |

| 300 × 300 × 450 | −36.2 | −39.5 | −41.2 | −45.2 | −48.8 | −51.8 | −54.0 | −58.0 | −62.5 |

| 300 × 300 × 600 | −35.8 | −39.8 | −41.9 | −44.6 | −49.9 | −52.2 | −55.3 | −59.0 | −63.0 |

| 450 × 150 × 150 | −44.1 | −46.7 | −49.5 | −51.2 | −55.8 | −57.0 | −60.7 | −64.6 | −68.7 |

| 450 × 150 × 300 | −39.4 | −41.9 | −43.6 | −46.9 | −50.0 | −52.8 | −55.5 | −59.3 | −65.2 |

| 450 × 150 × 450 | −35.1 | −38.7 | −41.0 | −45.9 | −49.1 | −52.1 | −54.7 | −58.8 | −64.4 |

| 450 × 150 × 600 | −37.5 | −40.5 | −41.9 | −45.8 | −49.2 | −51.4 | −54.2 | −58.2 | −64.1 |

| 450 × 300 × 150 | −45.3 | −46.5 | −47.8 | −51.0 | −54.0 | −56.7 | −59.0 | −63.0 | −68.6 |

| 450 × 300 × 300 | −38.8 | −40.7 | −41.9 | −45.3 | −48.3 | −51.2 | −53.7 | −57.8 | −63.3 |

| 450 × 300 × 450 | −38.2 | −40.5 | −41.5 | −45.5 | −48.7 | −51.7 | −53.8 | −57.9 | −62.6 |

| 450 × 300 × 600 | −37.8 | −40.7 | −42.1 | −45.6 | −48.9 | −51.7 | −54.0 | −58.1 | −63.3 |

| 450 × 450 × 150 | −43.5 | −45.2 | −47.3 | −51.6 | −55.1 | −58.5 | −60.2 | −63.7 | −67.3 |

| 450 × 450 × 300 | −37.2 | −39.5 | −40.9 | −45.4 | −49.3 | −52.4 | −54.8 | −58.7 | −63.3 |

| 450 × 450 × 450 | −36.4 | −39.1 | −40.6 | −45.3 | −49.4 | −52.3 | −54.7 | −58.3 | −62.1 |

| 450 × 450 × 600 | −36.7 | −39.7 | −41.1 | −45.2 | −49.0 | −52.0 | −53.9 | −58.4 | −62.8 |

| 600 × 150 × 150 | −45.8 | −47.8 | −49.1 | −52.5 | −55.9 | −58.4 | −60.7 | −64.5 | −68.6 |

| 600 × 150 × 300 | −39.1 | −41.6 | −43.5 | −47.2 | −50.8 | −53.3 | −55.6 | −59.8 | −65.0 |

| 600 × 150 × 450 | −37.2 | −39.7 | −41.6 | −45.3 | −48.5 | −51.7 | −53.9 | −57.5 | −63.0 |

| 600 × 150 × 600 | −35.1 | −38.5 | −40.7 | −45.7 | −49.4 | −51.8 | −54.4 | −58.2 | −63.5 |

| 600 × 300 × 150 | −47.4 | −48.5 | −49.9 | −53.3 | −56.2 | −58.8 | −60.4 | −65.1 | −70.1 |

| 600 × 300 × 300 | −40.5 | −42.5 | −44.1 | −47.5 | −50.5 | −53.3 | −55.8 | −59.9 | −65.9 |

| 600 × 300 × 450 | −38.3 | −40.3 | −41.5 | −44.7 | −48.4 | −51.0 | −53.7 | −57.9 | −63.3 |

| 600 × 300 × 600 | −38.5 | −41.2 | −42.5 | −46.1 | −49.9 | −52.6 | −54.2 | −58.5 | −63.3 |

| 600 × 450 × 150 | −46.5 | −47.8 | −49.2 | −52.7 | −55.8 | −58.3 | −60.6 | −64.1 | −69.2 |

| 600 × 450 × 300 | −40.7 | −42.5 | −44.0 | −47.7 | −51.0 | −53.8 | −56.3 | −60.0 | −64.5 |

| 600 × 450 × 450 | −36.7 | −38.9 | −40.2 | −44.1 | −47.4 | −50.7 | −53.1 | −57.1 | −61.8 |

| 600 × 450 × 600 | −37.3 | −40.0 | −41.3 | −45.7 | −49.2 | −51.9 | −54.3 | −58.1 | −62.4 |

| 600 × 600 × 150 | −45.6 | −47.3 | −49.5 | −53.9 | −57.6 | −60.2 | −62.3 | −65.3 | −68.8 |

| 600 × 600 × 300 | −39.2 | −41.4 | −42.9 | −47.8 | −52.2 | −54.9 | −57.3 | −61.0 | −65.2 |

| 600 × 600 × 450 | −35.3 | −38.2 | −39.7 | −44.7 | −49.0 | −52.1 | −54.0 | −58.1 | −62.3 |

| 600 × 600 × 600 | −35.9 | −39.2 | −40.8 | −46.0 | −50.2 | −53.4 | −55.6 | −58.8 | −62.4 |

References

- Garbowski, T. Optimal corrugated board—What does it mean? Przegląd Pap. 2022, 78, 517–524. [Google Scholar] [CrossRef]

- Garbowski, T. The most common mistakes when estimating the load-bearing capacity of corrugated board packaging. Przegląd Pap. 2023, 79, 485–488. [Google Scholar] [CrossRef]

- Garbowski, T. Safety Factors in the Design of Corrugated Board Packaging. Packag. Rev. 2023, 3, 16–22. [Google Scholar]

- Garbowski, T. The use of artificial intelligence for the optimal production of corrugated board. Przegląd Pap. 2023, 79, 279–288. [Google Scholar] [CrossRef]

- FEMat Systems: BSE System. Available online: http://fematsystems.pl/bse-system_en/ (accessed on 18 December 2023).

- Sohrabpour, V.; Hellström, D. M odels and software for corrugated board and box design. In Proceedings of the 18th International Conference on Engineering Design (ICED 11), Copenhagen, Denmark, 15–18 October 2011. [Google Scholar]

- Kellicutt, K.; Landt, E. Development of design data for corrugated fiberboard shipping containers. Tappi J. 1952, 35, 398–402. [Google Scholar]

- Maltenfort, G. Compression strength of corrugated containers. Fibre Contain 1956, 41, 106–121. [Google Scholar]

- McKee, R.C.; Gander, J.W.; Wachuta, J.R. Compression strength formula for corrugated boxes. Paperboard Packag. 1963, 48, 149–159. [Google Scholar]

- Allerby, I.M.; Laing, G.N.; Cardwell, R.D. Compressive strength—From components to corrugated containers. Appita Conf. Notes 1985, 1, 11. [Google Scholar]

- Schrampfer, K.E.; Whitsitt, W.J.; Baum, G.A. Combined Board Edge Crush (ECT) Technology; Institute of Paper Chemistry: Appleton, WI, USA, 1987. [Google Scholar]

- Batelka, J.J.; Smith, C.N. Package Compression Model; Institute of Paper Science and Technology: Atlanta, GA, USA, 1993. [Google Scholar]

- Urbanik, T.J.; Frank, B. Box compression analysis of world-wide data spanning 46 years. Wood Fiber Sci. 2006, 38, 399–416. [Google Scholar]

- Garbowski, T. Digitization of corrugated board. Przegląd Pap. 2022, 78, 683–686. [Google Scholar] [CrossRef]

- Garbowski, T.; Gajewski, T.; Grabski, J.K. The role of buckling in the estimation of compressive strength of corrugated cardboard boxes. Materials 2020, 13, 4578. [Google Scholar] [CrossRef]

- Urbanik, T.J.; Saliklis, E.P. Finite element corroboration of buckling phenomena observed in corrugated boxes. Wood Fiber Sci. 2003, 35, 322–333. [Google Scholar]

- Nordstrand, T. Basic Testing and Strength Design of Corrugated Board and Containers. Ph.D. Thesis, Lund University, Lund, Sweden, 2003. [Google Scholar]

- Suarez, B.; Muneta, M.L.M.; Sanz-Bobi, J.D.; Romero, G. Application of homogenization approaches to the numerical analysis of seating made of multi-wall corrugated cardboard. Compos. Struct. 2021, 262, 113642. [Google Scholar] [CrossRef]

- Fadiji, T.; Ambaw, A.; Coetzee, C.J.; Berry, T.M.; Opara, U.L. Application of finite element analysis to predict the mechanical strength of ventilated corrugated paperboard packaging for handling fresh produce. Biosyst. Eng. 2018, 174, 260–281. [Google Scholar]

- ISO 12048:1994; Packaging Complete, Filled Transport Packages. Compression and Stacking Tests Using a Compression Tester. ISO: Geneva, Switzerland, 1994.

- ISO 3037:2022; Corrugated Fibreboard, Determination of Edgewise Crush Resistance (Non-Waxed Edge Method). ISO: Geneva, Switzerland, 2022.

- Avilés, F.; Carlsson, L.A.; May-Pat, A. A shear-corrected formulation of the sandwich twist specimen. Exp. Mech. 2012, 52, 17–23. [Google Scholar] [CrossRef]

- Garbowski, T.; Gajewski, T. Transverse shear modulus in corrugated materials. Przegląd Pap. 2020, 76, 103–108. [Google Scholar] [CrossRef]

- Nordstrand, T.; Carlsson, L. Evaluation of transverse shear stiffness of structural core sandwich plates. Comp. Struct. 1997, 37, 145–153. [Google Scholar] [CrossRef]

- Pozorski, Z.; Wojciechowski, S. The influence of symmetrical boundary conditions on the structural behaviour of sandwich panels subjected to torsion. Symmetry 2020, 12, 2093. [Google Scholar]

- Yan, J.; Wang, G.; Li, Q.; Zhang, L.; Yan, J.D.; Chen, C.; Fang, Z. A comparative study on damage mechanism of sandwich structures with different core materials under lightning strikes. Energies 2017, 10, 1594. [Google Scholar] [CrossRef]

- Zhang, X.; Jin, X.; Xie, G.; Yan, H. Thermo-fluidic comparison between sandwich panels with tetrahedral lattice cores fabricated by casting and metal sheet folding. Energies 2017, 10, 906. [Google Scholar]

- Duan, Y.; Zhang, H.; Sfarra, S.; Avdelidis, N.P.; Loutas, T.H.; Sotiriadis, G.; Kostopoulos, V.; Fernandes, H.; Petrescu, F.I.; Ibarra-Castanedo, C.; et al. On the use of infrared thermography and acousto-ultrasonics NDT techniques for ceramic-coated sandwich structures. Energies 2019, 12, 2537. [Google Scholar] [CrossRef]

- Hohe, J. A direct homogenization approach for determination of the stiffness matrix for microheterogeneous plates with application to sandwich panels. Compos. Part B 2003, 34, 615–626. [Google Scholar]

- Buannic, N.; Cartraud, P.; Quesnel, T. Homogenization of corrugated core sandwich panels. Comp. Struct. 2003, 59, 299–312. [Google Scholar]

- Biancolini, M.E. Evaluation of equivalent stiffness properties of corrugated board. Comp. Struct. 2005, 69, 322–328. [Google Scholar] [CrossRef]

- Abbès, B.; Guo, Y.Q. Analytic homogenization for torsion of orthotropic sandwich plates: Application. Comp. Struct. 2010, 92, 699–706. [Google Scholar]

- Marek, A.; Garbowski, T. Homogenization of sandwich panels. Comput. Assist. Methods Eng. Sci. 2015, 22, 39–50. [Google Scholar]

- Garbowski, T.; Marek, A. Homogenization of corrugated boards through inverse analysis. In Proceedings of the 1st International Conference on Engineering and Applied Sciences Optimization, Kos Island, Greece, 4–6 June 2014; pp. 1751–1766. [Google Scholar]

- Kim, S.; Horvath, L.; Molina, E.; Frank, B.; Johnson, S.; Johnson, A. Predicting the effect of pallet overhang on the box compression strength. Packag. Technol. Sci. 2023, 36, 927–939. [Google Scholar] [CrossRef]

- TAPPI T402 sp-21; Standard Conditioning and Testing Atmospheres for Paper, Board, Pulp Handsheets, and Related Products, Test Method TAPPI/ANSI T 402 sp-21. TAPPI Press: Atlanta, GA, USA, 2021.

- Abaqus Unified FEA® Software. Available online: https://www.3ds.com/products-services/simulia/products/abaqus (accessed on 18 December 2023).

- Hill, R. A theory of the yielding and plastic flow in anisotropic metals. Proc. R. Soc. London Ser. A Math. Phys. Sci. 1948, 193, 281–297. [Google Scholar] [CrossRef]

| Board | ||||||||

|---|---|---|---|---|---|---|---|---|

| (MPa) | (MPa) | (–) | (MPa) | (MPa) | (MPa) | (MPa) | (–) | |

| B | 2317 | 969 | 0.46 | 3348 | 3 | 5 | 1.833 | 0.857 |

| C | 1420 | 833 | 0.39 | 3516 | 3 | 5 | 1.538 | 0.701 |

| EB | 954 | 585 | 0.38 | 2344 | 4 | 8 | 1.363 | 0.800 |

| BC | 1176 | 684 | 0.39 | 2397 | 4 | 6 | 1.720 | 0.800 |

| Board | Grammage ± | Compression Strength of F201 Box ± | |

|---|---|---|---|

| (g) | (N/mm) | (N) | |

| 32 ECT C-flute [35] | 468 | 5.60 | 2390 ± 158 |

| C flute | 458 ± 2 | 5.47 ± 0.07 | 2495 (4.4%) |

| 48 ECT BC-flute [35] | 707 | 8.40 | 3970 ± 246 |

| BC flute | 730 ± 53 | 8.25 ± 0.34 | 4006 (0.9%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mrówczyński, D.; Gajewski, T.; Pośpiech, M.; Garbowski, T. Estimation of the Compressive Strength of Cardboard Boxes Including Packaging Overhanging on the Pallet. Appl. Sci. 2024, 14, 819. https://doi.org/10.3390/app14020819

Mrówczyński D, Gajewski T, Pośpiech M, Garbowski T. Estimation of the Compressive Strength of Cardboard Boxes Including Packaging Overhanging on the Pallet. Applied Sciences. 2024; 14(2):819. https://doi.org/10.3390/app14020819

Chicago/Turabian StyleMrówczyński, Damian, Tomasz Gajewski, Michał Pośpiech, and Tomasz Garbowski. 2024. "Estimation of the Compressive Strength of Cardboard Boxes Including Packaging Overhanging on the Pallet" Applied Sciences 14, no. 2: 819. https://doi.org/10.3390/app14020819

APA StyleMrówczyński, D., Gajewski, T., Pośpiech, M., & Garbowski, T. (2024). Estimation of the Compressive Strength of Cardboard Boxes Including Packaging Overhanging on the Pallet. Applied Sciences, 14(2), 819. https://doi.org/10.3390/app14020819