Strategic Insights into Integrated Photonics: Core Concepts, Practical Deployments, and Future Outlook

Abstract

1. Introduction

2. Fundamentals of PICs

3. Commercial Availability of Photonic Devices

4. Applications of Integrated Photonics

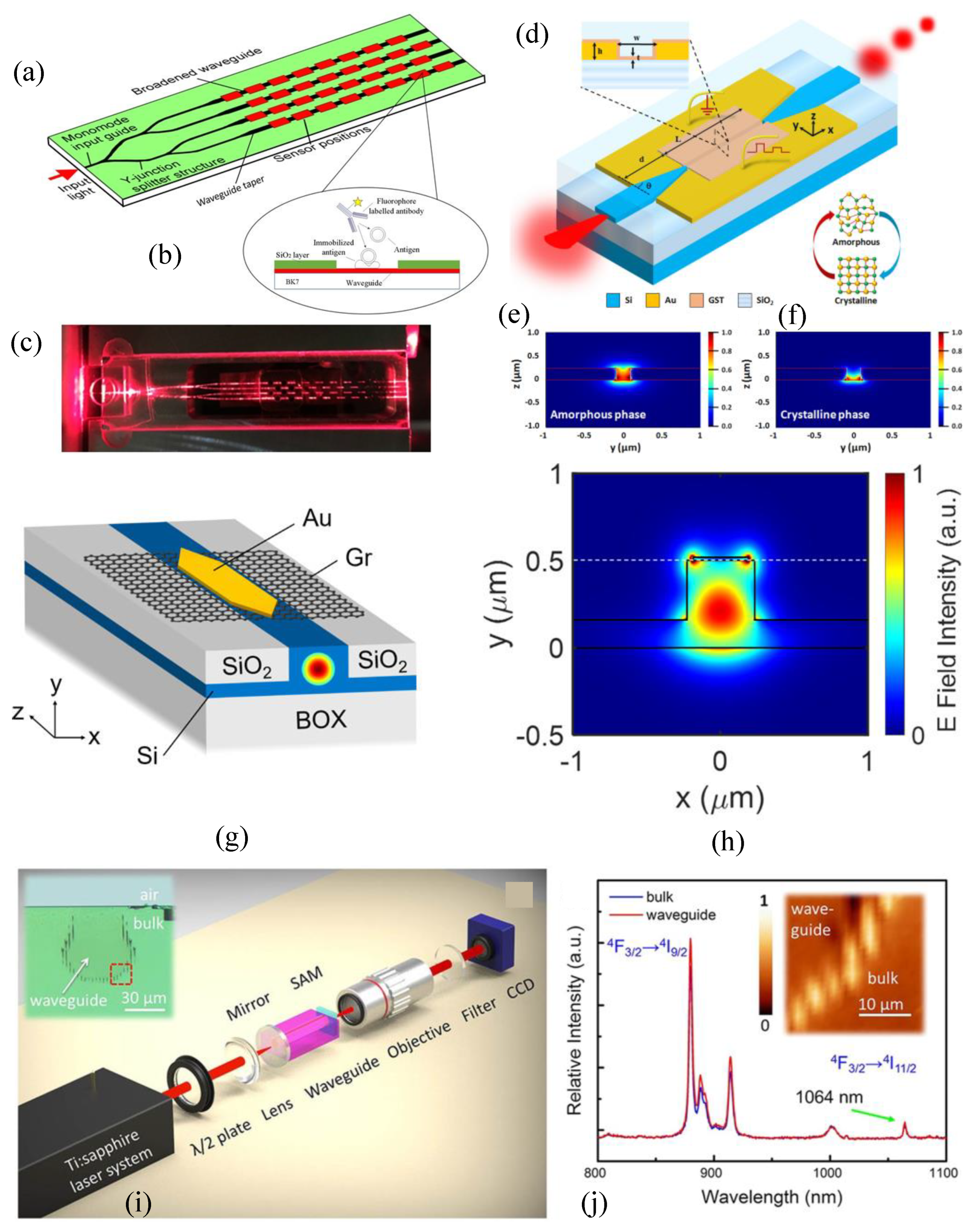

4.1. Sensing Applications

4.2. Optical Switches

4.3. All-Optical Modulators

4.4. WG Lasers

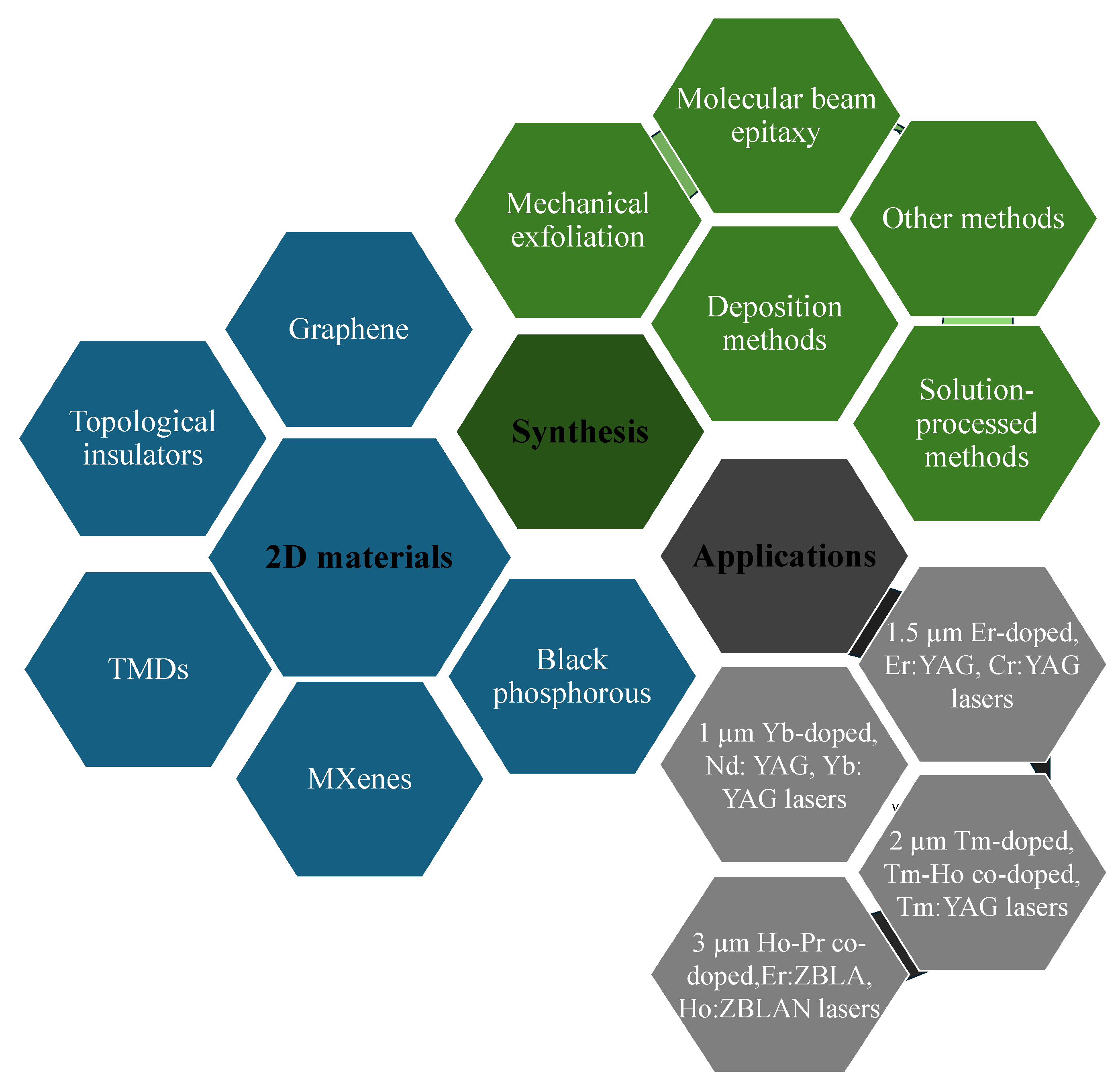

5. Material Platforms for Integrated Photonics

6. Fabrication Techniques and Challenges

7. Role of Artificial Intelligence in the Development of Integrated Photonics

8. Potential Challenges in the Development of PICs

9. Concluding Remarks

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Full form | Abbreviations |

| Photonic integrated circuit | PIC |

| Electronic integrated circuit | EIC |

| Waveguide | WG |

| Electron beam lithography | EBL |

| Nanoimprint lithography | NIL |

| Electro-optic | EO |

| Thermo-optic | TO |

| Complementary metal oxide semiconductor | CMOS |

| Artificial intelligence | AI |

| Artificial neural network | ANN |

| Machine learning | ML |

| Indium phosphide | InP |

| Gallium arsenide | GaAs |

| Silicon nitride | Si3N4 |

| Silicon-on-insulator | SOI |

| Extinction ratio | ER |

| Phase change material | PCM |

| Germanium–Tin | GeSn |

| Photodetector | PD |

References

- Iwai, H.; Ohmi, S. Silicon integrated circuit technology from past to future. Microelectron. Reliab. 2002, 42, 465–491. [Google Scholar] [CrossRef]

- Jin, H. The History, Current Applications and Future of Integrated Circuit. Highlights Sci. Eng. Technol. 2023, 31, 232–238. [Google Scholar] [CrossRef]

- Wang, C.; Li, Z.; Riemensberger, J.; Lihachev, G.; Churaev, M.; Kao, W.; Ji, X.; Zhang, J.; Blesin, T.; Davydova, A.; et al. Lithium tantalate photonic integrated circuits for volume manufacturing. Nature 2024, 629, 784–790. [Google Scholar] [CrossRef]

- Butt, M.A.; Piramidowicz, R. Orthogonal mode couplers for plasmonic chip based on metal–insulator–metal waveguide for temperature sensing application. Sci. Rep. 2024, 14, 3474. [Google Scholar] [CrossRef]

- Homes, C.C.; Carr, G.L.; Lobo, R.P.S.M.; LaVeigne, J.D.; Tanner, D.B. Silicon beam splitter for far-infrared and terahertz spectroscopy. Appl. Opt. 2007, 46, 7884–7888. [Google Scholar] [CrossRef]

- Butt, M.A.; Khonina, S.N.; Kazanskiy, N.L. 2D-Photonic crystal heterostructures for the realization of compact photonic devices. Photonics Nanostruct.-Fundam. Appl. 2021, 44, 100903. [Google Scholar] [CrossRef]

- Eggleton, B.J.; Kerbage, C.; Westbrook, P.S.; Windeler, R.S.; Hale, A. Microstructured optical fiber devices. Opt. Express 2001, 9, 698–713. [Google Scholar] [CrossRef]

- Miller, S.E. Integrated Optics: An Introduction. Bell Syst. Tech. J. 1969, 48, 2059–2069. Available online: https://onlinelibrary.wiley.com/doi/abs/10.1002/j.1538-7305.1969.tb01165.x (accessed on 28 June 2024). [CrossRef]

- 60 years of integrated circuits. Nat. Electron. 2018, 1, 483. [CrossRef]

- Iluz, M.; Cohen, K.; Kheireddine, J.; Hazan, Y.; Rosenthal, A.; Tsesses, S.; Bartal, G. Unveiling the evolution of light within photonic integrated circuits. Optica 2024, 11, 42–47. [Google Scholar] [CrossRef]

- Thylén, L.; Wosinski, L. Integrated photonics in the 21st century. Photonics Res. 2014, 2, 75–81. [Google Scholar] [CrossRef]

- Hermans, A.; Daele, M.V.; Dendooven, J.; Clemmen, S.; Detavernier, C.; Baets, R. Integrated silicon nitride electro-optic modulators with atomic layer deposited overlays. Opt. Lett. 2019, 44, 1112–1115. [Google Scholar] [CrossRef]

- Li, M.; Ling, J.; He, Y.; Javid, U.A.; Xue, S.; Lin, Q. Lithium niobate photonic-crystal electro-optic modulator. Nat. Commun. 2020, 11, 4123. [Google Scholar] [CrossRef]

- Blumenthal, D.J.; Heideman, R.; Geuzebroek, D.; Leinse, A.; Roeloffzen, C. Silicon Nitride in Silicon Photonics. Proc. IEEE 2018, 106, 2209–2231. [Google Scholar] [CrossRef]

- Lin, Y.; Yong, Z.; Luo, X.; Azadeh, S.S.; Mikkelsen, J.C.; Sharma, A.; Chen, H.; Mak, J.C.C.; Lo, P.G.-Q.; Sacher, W.D.; et al. Monolithically integrated, broadband, high-efficiency silicon nitride-on-silicon waveguide photodetectors in a visible-light integrated photonics platform. Nat. Commun. 2022, 13, 6362. [Google Scholar] [CrossRef]

- Lawrence, M. Lithium Niobate Integrated Optics. Rep. Prog. Phys. 1993, 56, 363. Available online: https://iopscience.iop.org/article/10.1088/0034-4885/56/3/001 (accessed on 28 June 2024). [CrossRef]

- Bütow, J.; Sharma, V.; Brandmüller, D.; Eismann, J.S.; Banzer, P. Photonic integrated processor for structured light detection and distinction. Commun. Phys. 2023, 6, 369. [Google Scholar] [CrossRef]

- Kazanskiy, N.L.; Butt, M.A.; Khonina, S.N. Optical Computing: Status and Perspectives. Nanomaterials 2022, 12, 2171. [Google Scholar] [CrossRef]

- Butt, M.A.; Kazanskiy, N.L.; Khonina, S.N.; Voronkov, G.S.; Grakhova, E.P.; Kutluyarov, R.V. A Review on Photonic Sensing Technologies: Status and Outlook. Biosensors 2023, 13, 568. [Google Scholar] [CrossRef]

- London, Y.; Van Vaerenbergh, T.; Ramini, L.; Descos, A.; Buonanno, L.; Youn, J.; Li, C.; Graves, C.E.; Fiorentino, M.; Beausoleil, R.G. Multiplexing in photonics as a resource for optical ternary content-addressable memory functionality. Nanophotonics 2023, 12, 4137–4155. [Google Scholar] [CrossRef]

- Liu, A.; Liao, L.; Chetrit, Y.; Basak, J.; Nguyen, H.; Rubin, D.; Paniccia, M. Wavelength Division Multiplexing Based Photonic Integrated Circuits on Silicon-on-Insulator Platform. IEEE J. Sel. Top. Quantum Electron. 2010, 16, 23–32. [Google Scholar] [CrossRef]

- Melati, D.; Alippi, A.; Melloni, A. Reconfigurable photonic integrated mode (de)multiplexer for SDM fiber transmission. Opt. Express 2016, 24, 12625–12634. [Google Scholar] [CrossRef]

- Sasaki, H. Development of Silicon Photonics Integrated Circuits for Next Generation Optical Access Networks. In Proceedings of the 2019 2nd International Symposium on Devices, Circuits and Systems (ISDCS), Higashi-Hiroshima, Japan, 6–8 March 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Ogura, Y. Spatial Photonic Ising Machine with Time/Space Division Multiplexing. In Photonic Neural Networks with Spatiotemporal Dynamics: Paradigms of Computing and Implementation; Suzuki, H., Tanida, J., Hashimoto, M., Eds.; Springer Nature: Singapore, 2024; pp. 153–174. [Google Scholar] [CrossRef]

- Lu, K.; Chen, Z.; Chen, H.; Zhou, W.; Zhang, Z.; Tsang, H.K.; Tong, Y. Empowering high-dimensional optical fiber communications with integrated photonic processors. Nat. Commun. 2024, 15, 3515. [Google Scholar] [CrossRef]

- Xu, X.; Ren, G.; Feleppa, T.; Liu, X.; Boes, A.; Mitchell, A.; Lowery, A.J. Self-calibrating programmable photonic integrated circuits. Nat. Photonics 2022, 16, 595–602. [Google Scholar] [CrossRef]

- Koren, U. Waveguide Based Photonic Integrated Circuits. In Optoelectronic Integration: Physics, Technology and Applications; Wada, O., Ed.; Springer: Boston, MA, USA, 1994; pp. 233–272. [Google Scholar] [CrossRef]

- Meng, Y.; Chen, Y.; Lu, L.; Ding, Y.; Cusano, A.; Fan, J.A.; Hu, Q.; Wang, K.; Xie, Z.; Liu, Z.; et al. Optical meta-waveguides for integrated photonics and beyond. Light Sci. Appl. 2021, 10, 235. [Google Scholar] [CrossRef]

- Kim, J.T.; Choi, S.-Y. Graphene-based plasmonic waveguides for photonic integrated circuits. Opt. Express 2011, 19, 24557–24562. [Google Scholar] [CrossRef] [PubMed]

- Wu, L. Ultrathin waveguides for 2D photonic integrated circuits. Nat. Rev. Phys. 2023, 5, 634. [Google Scholar] [CrossRef]

- Pawlowski, E.; Ferstl, M.; Hellmich, H.; Kuhlow, B.; Warmuth, C.; Salgueiro, J.R. Fabrication of a multichannel wavelength-division multiplexing–passive optical net demultiplexer with arrayed-waveguide gratings and diffractive optical elements. Appl. Opt. 2022, 38, 3039–3045. [Google Scholar] [CrossRef]

- Afroozeh, A. Analysis of Optical Modulator Based on Silicon Waveguide using FDTD. Silicon 2022, 14, 839–849. [Google Scholar] [CrossRef]

- Ye, L.; Sui, K.; Zhang, Y.; Liu, Q.H. Broadband optical waveguide modulators based on strongly coupled hybrid graphene and metal nanoribbons for near-infrared applications. Nanoscale 2019, 11, 3229–3239. [Google Scholar] [CrossRef]

- Mao, J.; Sato, H.; Bannaron, A.; Hong, J.; Lu, G.-W.; Yokoyama, S. Efficient silicon and side-cladding waveguide modulator with electro-optic polymer. Opt. Express 2022, 30, 1885–1895. [Google Scholar] [CrossRef]

- Low-Power Thermo-Optic Silicon Modulator for Large-Scale Photonic Integrated Systems. Available online: https://opg.optica.org/oe/fulltext.cfm?uri=oe-27-9-13430&id=409370 (accessed on 20 June 2024).

- Ghosh, S.; Mukhopadhyay, B.; Sen, G.; Basu, P.K. Study of Si-Ge-Sn based Heterobipolar Phototransistor (HPT) exploiting Quantum Confined Stark Effect and Franz Keldysh effect with and without resonant cavity. Phys. E Low-Dimens. Syst. Nanostruct. 2019, 106, 62–67. [Google Scholar] [CrossRef]

- Chakraborty, V.; Mukhapadhyay, B.; Basu, P.K. Performance prediction of an electroabsorption modulator at 1550 nm using GeSn/SiGeSn Quantum Well structure. Phys. E Low-Dimens. Syst. Nanostruct. 2013, 50, 67–72. [Google Scholar] [CrossRef]

- Piels, M.; Bowers, J.E. 1—Photodetectors for silicon photonic integrated circuits. In Photodetectors; Nabet, B., Ed.; Woodhead Publishing: Sawston, UK, 2016; pp. 3–20. [Google Scholar] [CrossRef]

- Jiang, F.; Shi, M.; Zhou, J.; Bu, Y.; Ao, J.-P.; Chen, X.S. Integrated Photonic Structure Enhanced Infrared Photodetectors. Adv. Photonics Res. 2021, 2, 2000187. [Google Scholar] [CrossRef]

- Simola, E.T.; Kiyek, V.; Ballabio, A.; Schlykow, V.; Frigerio, J.; Zucchetti, C.; De Iacovo, A.; Colace, L.; Yamamoto, Y.; Capellini, G.; et al. CMOS-Compatible Bias-Tunable Dual-Band Detector Based on GeSn/Ge/Si Coupled Photodiodes. ACS Photonics 2021, 8, 2166–2173. [Google Scholar] [CrossRef]

- On-Chip Mid-Infrared Photothermoelectric Detectors for Full-Stokes Detection|Nature Communications. Available online: https://www.nature.com/articles/s41467-022-32309-w (accessed on 15 July 2024).

- Kita, D.M.; Lin, H.; Agarwal, A.; Richardson, K.; Luzinov, I.; Gu, T.; Hu, J. On-Chip Infrared Spectroscopic Sensing: Redefining the Benefits of Scaling. IEEE J. Sel. Top. Quantum Electron. 2017, 23, 340–349. [Google Scholar] [CrossRef]

- Wang, P.-C.; Huang, P.-R.; Ghosh, S.; Bansal, R.; Jheng, Y.-T.; Lee, K.-C.; Cheng, H.H.; Chang, G.-E. CMOS-compatible Self-powered Short-wave Infrared Imagers Based on GeSn Photodetector Arrays. ACS Photonics 2024, 11, 2659–2666. [Google Scholar] [CrossRef]

- Tran, H.; Pham, T.; Margetis, J.; Zhou, Y.; Dou, W.; Grant, P.C.; Grant, J.M.; Al-Kabi, S.; Sun, G.; Soref, R.A.; et al. Si-Based GeSn Photodetectors toward Mid-Infrared Imaging Applications. ACS Photonics 2019, 6, 2807–2815. [Google Scholar] [CrossRef]

- Halioua, Y.; Bazin, A.; Monnier, P.; Karle, T.J.; Roelkens, G.; Sagnes, I.; Raj, R.; Raineri, F. Hybrid III-V semiconductor/silicon nanolaser. Opt. Express 2011, 19, 9221–9231. [Google Scholar] [CrossRef] [PubMed]

- Jung, Y.; Shim, J.; Kwon, K.; You, J.-B.; Choi, K.; Yu, K. Hybrid integration of III-V semiconductor lasers on silicon waveguides using optofluidic microbubble manipulation. Sci. Rep. 2016, 6, 29841. [Google Scholar] [CrossRef]

- Bondarenko, O.; Fang, C.-Y.; Vallini, F.; Smalley, J.S.T.; Fainman, Y. Extremely compact hybrid III-V/SOI lasers: Design and fabrication approaches. Opt. Express 2015, 23, 2696–2712. [Google Scholar] [CrossRef] [PubMed]

- Ng, W.L.; Lourenço, M.A.; Gwilliam, R.M.; Ledain, S.; Shao, G.; Homewood, K.P. An efficient room-temperature silicon-based light-emitting diode. Nature 2001, 410, 192–194. [Google Scholar] [CrossRef] [PubMed]

- Wu, Q.; Turpin, J.P.; Werner, D.H. Integrated photonic systems based on transformation optics enabled gradient index devices. Light Sci. Appl. 2012, 1, e38. [Google Scholar] [CrossRef]

- Intel® Silicon Photonics. Intel. Available online: https://www.intel.com/content/www/us/en/products/details/network-io/silicon-photonics.html (accessed on 15 July 2024).

- Network Hardware—Interfaces and Modules. Cisco. Available online: https://www.cisco.com/c/en/us/products/interfaces-modules/index.html (accessed on 15 July 2024).

- Optical Networking Innovation at the Speed of Light. Available online: https://www.infinera.com/ (accessed on 15 July 2024).

- Passive Components and Modules|Lumentum Operations LLC. Available online: https://www.lumentum.com/en/optical-communications/products/passive-components-and-modules (accessed on 15 July 2024).

- Photonic Integrated Circuit (PIC) Market, Global Outlook and Forecast 2024–2030. Available online: https://www.24marketreports.com/semiconductor-and-electronics/global-photonic-integrated-circuit-forecast-2024-2030-66 (accessed on 27 March 2024).

- Integrated Photonic Computing Beyond the von Neumann Architecture|ACS Photonics. Available online: https://pubs.acs.org/doi/10.1021/acsphotonics.2c01543 (accessed on 27 March 2024).

- Kutluyarov, R.V.; Zakoyan, A.G.; Voronkov, G.S.; Grakhova, E.P.; Butt, M.A. Neuromorphic Photonics Circuits: Contemporary Review. Nanomaterials 2023, 13, 3139. [Google Scholar] [CrossRef] [PubMed]

- Kazanskiy, N.L.; Khonina, S.N.; Butt, M.A. Advancement in Silicon Integrated Photonics Technologies for Sensing Applications in Near-Infrared and Mid-Infrared Region: A Review. Photonics 2022, 9, 331. [Google Scholar] [CrossRef]

- Butt, M.A.; Mateos, X.; Piramidowicz, R. Photonics Sensors: A Perspective on Current Advancements, Emerging Challenges, and Potential Solutions (Invited). Phys. Lett. A 2024, 516, 129633. Available online: https://www.sciencedirect.com/science/article/pii/S037596012400327X?via%3Dihub (accessed on 28 June 2024). [CrossRef]

- Kaur, S.; Singh, P.; Tripathi, V.; Kaur, R. Recent trends in wireless and optical fiber communication. Glob. Transit. Proc. 2022, 3, 343–348. [Google Scholar] [CrossRef]

- Ghosh, S.; Dar, T.; Viphavakit, C.; Pan, C.; Kejalakshmy, N.; Rahman, B.M.A. Compact Photonic SOI Sensors. In Computational Photonic Sensors; Hameed, M.F.O., Obayya, S., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 343–383. [Google Scholar] [CrossRef]

- Heide, F.; Fu, Q.; Peng, Y.; Heidrich, W. Encoded diffractive optics for full-spectrum computational imaging. Sci. Rep. 2016, 6, 33543. [Google Scholar] [CrossRef] [PubMed]

- Butt, M.A.; Kozłowski, Ł.; Golas, M.; Slowikowski, M.; Filipiak, M.; Juchniewicz, M.; Bieniek-Kaczorek, A.; Dudek, M.; Piramidowicz, R. Numerical and Experimental Demonstration of a Silicon Nitride-Based Ring Resonator Structure for Refractive Index Sensing. Appl. Sci. 2024, 14, 6082. [Google Scholar] [CrossRef]

- Altug, H.; Oh, S.-H.; Maier, S.A.; Homola, J. Advances and applications of nanophotonic biosensors. Nat. Nanotechnol. 2022, 17, 5–16. [Google Scholar] [CrossRef]

- Li, H.; Zhu, Z.; Meng, W.; Cao, L.; Wang, Y.; Lin, Z.; Li, E.; Prades, J.D. Silicon-photonics-based waveguide Bragg grating sensor for blood glucose monitoring. Opt. Express 2022, 30, 41554–41566. [Google Scholar] [CrossRef] [PubMed]

- Aksnes, A. Photonic Sensors for Health and Environmental Monitoring. In Sensors for Environment, Health and Security; Baraton, M.-I., Ed.; Springer: Dordrecht, The Netherlands, 2009; pp. 191–203. [Google Scholar] [CrossRef]

- Butt, M.A.; Voronkov, G.S.; Grakhova, E.P.; Kutluyarov, R.V.; Kazanskiy, N.L.; Khonina, S.N. Environmental Monitoring: A Comprehensive Review on Optical Waveguide and Fiber-Based Sensors. Biosensors 2022, 12, 1038. [Google Scholar] [CrossRef]

- Mahmood, A.I.; Ibrahim, R.K.; Mahmood, A.I.; Ibrahim, Z.K. Design and Simulation of Surface Plasmon Resonance Sensors for Environmental Monitoring. J. Phys. Conf. Ser. 2018, 1003, 012118. [Google Scholar] [CrossRef]

- Ariannejad, M.M.; Akbari, E.; Hanafi, E. Silicon sub-wavelength grating resonator structures for gas sensor. Superlattices Microstruct. 2020, 142, 106506. [Google Scholar] [CrossRef]

- Fabricius, N.; Gauglitz, G.; Ingenhoff, J. A gas sensor based on an integrated optical Mach-Zehnder interferometer. Sens. Actuators B Chem. 1992, 7, 672–676. [Google Scholar] [CrossRef]

- Butt, M.A. Loop-Terminated Mach-Zehnder Interferometer Integrated with Functional Polymer for CO2 Gas Sensing. Preprints 2024. [Google Scholar] [CrossRef]

- Liu, L.; Zhou, X.; Wilkinson, J.S.; Hua, P.; Song, B.; Shi, H. Integrated optical waveguide-based fluorescent immunosensor for fast and sensitive detection of microcystin-LR in lakes: Optimization and Analysis. Sci. Rep. 2017, 7, 3655. [Google Scholar] [CrossRef] [PubMed]

- Moghadas, A.A.; Shadaram, M. Fiber Bragg Grating Sensor for Fault Detection in Radial and Network Transmission Lines. Sensors 2010, 10, 9407. [Google Scholar] [CrossRef] [PubMed]

- Tomita, N. Photonic Sensing Technologies for Fiber Networks. In Optical Fiber Sensors; Optica Publishing Group: Washington, DC, USA, 1996; p. Tu2S1. [Google Scholar] [CrossRef]

- Kurosawa, K. Development of fiber-optic current sensing technique and its applications in electric power systems. Photonic Sens. 2014, 4, 12–20. [Google Scholar] [CrossRef]

- Aslam, N.; Zhou, H.; Urbach, E.K.; Turner, M.J.; Walsworth, R.L.; Lukin, M.D.; Park, H. Quantum sensors for biomedical applications. Nat. Rev. Phys. 2023, 5, 157–169. [Google Scholar] [CrossRef]

- Optimal Metrology with Programmable Quantum Sensors|Nature. Available online: https://www.nature.com/articles/s41586-022-04435-4 (accessed on 20 June 2024).

- Stray, B.; Lamb, A.; Kaushik, A.; Vovrosh, J.; Rodgers, A.; Winch, J.; Hayati, F.; Boddice, D.; Stabrawa, A.; Niggebaum, A.; et al. Quantum sensing for gravity cartography. Nature 2022, 602, 590–594. [Google Scholar] [CrossRef] [PubMed]

- Javaid, M.; Haleem, A.; Singh, R.P.; Rab, S.; Suman, R. Significance of sensors for industry 4.0: Roles, capabilities, and applications. Sens. Int. 2021, 2, 100110. [Google Scholar] [CrossRef]

- Fretty, P. Photonic Sensor Technology Inches towards Consumer Applications. Laser Focus World. Available online: https://www.laserfocusworld.com/test-measurement/article/14292924/photonic-sensor-technology-inches-towards-consumer-applications (accessed on 20 June 2024).

- An Interface between Photonics and Automation. LASER World of PHOTONICS. Available online: https://world-of-photonics.com/en/discover/photonics-industry-portal/detail/interface-between-photonics-and-automation.html (accessed on 20 June 2024).

- Chen, X.; Lin, J.; Wang, K. A Review of Silicon-Based Integrated Optical Switches. Laser Photonics Rev. 2023, 17, 2200571. [Google Scholar] [CrossRef]

- Sun, P.; Reano, R.M. Submilliwatt thermo-optic switches using free-standing silicon-on-insulator strip waveguides. Opt. Express 2010, 18, 8406–8411. [Google Scholar] [CrossRef] [PubMed]

- Extremely-Low-Power-Consumption Thermo-Optic Switch with Silicon-Silica Hybrid Structure|NTT Technical Review. Available online: https://www.ntt-review.jp/archive/ntttechnical.php?contents=ntr201002sf4.html (accessed on 20 June 2024).

- Chu, T.; Yamada, H.; Ishida, S.; Arakawa, Y. Compact 1 × N thermo-optic switches based on silicon photonic wire waveguides. Opt. Express 2005, 13, 10109–10114. [Google Scholar] [CrossRef] [PubMed]

- Zhong, C.; Zhang, Z.; Ma, H.; Wei, M.; Ye, Y.; Wu, J.; Tang, B.; Zhang, P.; Liu, R.; Li, J.; et al. Silicon Thermo-Optic Switches with Graphene Heaters Operating at Mid-Infrared Waveband. Nanomaterials 2022, 12, 1083. [Google Scholar] [CrossRef] [PubMed]

- Yue, W.; Cai, Y.; Yu, M. Review of 2 × 2 Silicon Photonic Switches. Photonics 2023, 10, 564. [Google Scholar] [CrossRef]

- Sun, D. A proposal for digital electro-optic switches with free-carrier dispersion effect and Goos-Hanchen shift in silicon-on-insulator waveguide corner mirror. J. Appl. Phys. 2013, 114, 104502. [Google Scholar] [CrossRef]

- Krückel, C.J.; Becker, H.; Ban, Y.; Heck, M.J.R.; Van Campenhout, J.; Van Thourhout, D. Towards Maximum Energy Efficiency of Carrier-Injection-Based Silicon Photonics. J. Light. Technol. 2021, 39, 2931–2940. [Google Scholar] [CrossRef]

- Miller, K.J.; Hallman, K.A.; Haglund, R.F.; Weiss, S.M. Silicon waveguide optical switch with embedded phase change material. Opt. Express 2017, 25, 26527–26536. [Google Scholar] [CrossRef]

- Ghosh, R.R.; Dhawan, A. Integrated non-volatile plasmonic switches based on phase-change-materials and their application to plasmonic logic circuits. Sci. Rep. 2021, 11, 18811. [Google Scholar] [CrossRef] [PubMed]

- Fang, Z.; Chen, R.; Zheng, J.; Majumdar, A. Non-Volatile Reconfigurable Silicon Photonics Based on Phase-Change Materials. IEEE J. Sel. Top. Quantum Electron. 2022, 28, 1–17. [Google Scholar] [CrossRef]

- Nisar, M.S.; Yang, X.; Lu, L.; Chen, J.; Zhou, L. On-Chip Integrated Photonic Devices Based on Phase Change Materials. Photonics 2021, 8, 205. [Google Scholar] [CrossRef]

- Basiri, A.; Rafique, M.Z.E.; Bai, J.; Choi, S.; Yao, Y. Ultrafast low-pump fluence all-optical modulation based on graphene-metal hybrid metasurfaces. Light. Sci. Appl. 2022, 11, 102. [Google Scholar] [CrossRef] [PubMed]

- Rajput, S.; Kaushik, V.; Babu, P.; Pandey, S.K.; Kumar, M. All optical modulation in vertically coupled indium tin oxide ring resonator employing epsilon near zero state. Sci. Rep. 2023, 13, 18379. [Google Scholar] [CrossRef]

- Dortaj, H.; Faraji, M.; Matloub, S. High-speed and high-contrast two-channel all-optical modulator based on solution-processed CdSe/ZnS quantum dots. Sci. Rep. 2022, 12, 12678. [Google Scholar] [CrossRef] [PubMed]

- Xiao, X.; Li, M.; Wang, L.; Chen, D.; Yang, Q.; Yu, S. High Speed Silicon Photonic Modulators. In Proceedings of the Optical Fiber Communication Conference (2017), Los Angeles, CA, USA, 19–23 March 2017; Optica Publishing Group: Washington, DC, USA, 2017; p. Tu2H.1. [Google Scholar] [CrossRef]

- AlAloul, M.; Rasras, M. Low Insertion Loss Plasmon-Enhanced Graphene All-Optical Modulator. ACS Omega 2021, 6, 7576–7584. [Google Scholar] [CrossRef]

- Gebremichael, W.; Dorrer, C.; Qiao, J. Guiding and lasing comparison of Nd:YAG waveguide lasers fabricated by femtosecond laser inscription at 515 and 1030 nm. J. Laser Appl. 2023, 35, 032014. [Google Scholar] [CrossRef]

- Bai, Z.; Chen, Z.; Xiong, Y.; Liu, H.; Gao, S.; Ren, Y.; Zhao, X.; Liu, F.; Jia, Y.; Chen, F. Tm, Ho:YLF waveguide lasers at 2.05 µm. Opt. Lett. 2024, 49, 1977–1980. [Google Scholar] [CrossRef]

- Zeng, H.-J.; Xue, W.-Z.; Murray, R.T.; Cui, C.; Wang, L.; Pan, Z.; Loiko, P.; Mateos, X.; Yuan, F.; Zhang, G.; et al. In-band pumped Kerr-lens mode-locked Tm,Ho-codoped calcium aluminate laser. Opt. Express 2024, 32, 16083–16089. [Google Scholar] [CrossRef]

- Lin, Z.-L.; Zeng, H.-J.; Pan, Z.; Loiko, P.; Petrov, V.; Mateos, X.; Zhang, G.; Chen, W. Kerr-lens mode-locking of an Yb:SALLO laser generating 25 fs pulses at 1090 nm. Appl. Phys. Lett. 2024, 124, 171102. [Google Scholar] [CrossRef]

- Li, Z.-Q.; Lin, Z.-L.; Loiko, P.; Zeng, H.-J.; Zhang, G.; Nie, H.-Y.; Normani, S.; Benayad, A.; Camy, P.; Mateos, X.; et al. Kerr-Lens Mode-Locked Yb:BaF2 Laser. Photonics 2024, 11, 322. [Google Scholar] [CrossRef]

- Elabedine, G.Z.; Loiko, P.; Normani, S.; Solé, R.M.; Braud, A.; Camy, P.; Dunina, E.; Fomicheva, L.; Kornienko, A.; Chen, W.; et al. Polarized spectroscopy of Ho:YAlO3 crystals for 2 µm and 3 µm lasers. In Proceedings of the Solid State Lasers XXXIII: Technology and Devices, San Francisco, CA, USA, 28–29 January 2024; SPIE: Bellingham, WA, USA, 2024; pp. 209–216. [Google Scholar] [CrossRef]

- Nie, W.; Li, R.; Cheng, C.; Chen, Y.; Lu, Q.; Romero, C.; de Aldana, J.R.V.; Hao, X.; Chen, F. Room-temperature subnanosecond waveguide lasers in Nd:YVO4 Q-switched by phase-change VO2: A comparison with 2D materials. Sci. Rep. 2017, 7, 46162. [Google Scholar] [CrossRef]

- Butt, M.A. Integrated Optics: Platforms and Fabrication Methods. Encyclopedia 2023, 3, 59. [Google Scholar] [CrossRef]

- Margalit, N.; Xiang, C.; Bowers, S.M.; Bjorlin, A.; Blum, R.; Bowers, J.E. Perspective on the future of silicon photonics and electronics. Appl. Phys. Lett. 2021, 118, 220501. [Google Scholar] [CrossRef]

- Roadmapping the Next Generation of Silicon Photonics|Nature Communications. Available online: https://www.nature.com/articles/s41467-024-44750-0 (accessed on 27 March 2024).

- Yoo, S.J.B. Hybrid integrated photonic platforms: Opinion. Opt. Mater. Express 2021, 11, 3528–3534. [Google Scholar] [CrossRef]

- Fischer, I.A.; Brehm, M.; De Seta, M.; Isella, G.; Paul, D.J.; Virgilio, M.; Capellini, G. On-chip infrared photonics with Si-Ge-heterostructures: What is next? APL Photonics 2022, 7, 050901. [Google Scholar] [CrossRef]

- Lasing in Direct-Bandgap GeSn Alloy Grown on Si|Nature Photonics. Available online: https://www.nature.com/articles/nphoton.2014.321 (accessed on 15 July 2024).

- Miao, Y.; Wang, G.; Kong, Z.; Xu, B.; Zhao, X.; Luo, X.; Lin, H.; Dong, Y.; Lu, B.; Dong, L.; et al. Review of Si-Based GeSn CVD Growth and Optoelectronic Applications. Nanomaterials 2021, 11, 2556. [Google Scholar] [CrossRef] [PubMed]

- Evolution of Phases and Their Thermal Stability in Ge–Sn Nanofilms: A Comprehensive In Situ TEM Investigation—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S092583882034127X (accessed on 15 July 2024).

- Chen, X.; Fenrich, C.S.; Xue, M.; Kao, M.-Y.; Zang, K.; Lu, C.-Y.; Fei, E.T.; Chen, Y.; Huo, Y.; Kamins, T.I.; et al. Tensile-strained Ge/SiGe multiple quantum well microdisks. Photonics Res. 2017, 5, B7–B14. [Google Scholar] [CrossRef]

- Khonina, S.N.; Voronkov, G.S.; Grakhova, E.P.; Kazanskiy, N.L.; Kutluyarov, R.V.; Butt, M.A. Polymer Waveguide-Based Optical Sensors—Interest in Bio, Gas, Temperature, and Mechanical Sensing Applications. Coatings 2023, 13, 549. [Google Scholar] [CrossRef]

- Iftikhar, A.; Naseer, N.; Yildiz, S.K.; Gokcen, D.; Fida, A.; Shafique, M.F.; Saka, B. Silicon elastomer as flexible substrate: Dielectric characterization and applications for wearable antenna. Flex. Print. Electron. 2023, 8, 045001. [Google Scholar] [CrossRef]

- Hu, J.; Li, L.; Lin, H.; Zhang, P.; Zhou, W.; Ma, Z. Flexible integrated photonics: Where materials, mechanics and optics meet [Invited]. Opt. Mater. Express 2013, 3, 1313–1331. [Google Scholar] [CrossRef]

- Polyanskiy, M.N. Refractiveindex.info database of optical constants. Sci. Data 2024, 11, 94. [Google Scholar] [CrossRef] [PubMed]

- Leidinger, M.; Fieberg, S.; Waasem, N.; Kühnemann, F.; Buse, K.; Breunig, I. Comparative study on three highly sensitive absorption measurement techniques characterizing lithium niobate over its entire transparent spectral range. Opt. Express 2015, 23, 21690–21705. [Google Scholar] [CrossRef] [PubMed]

- Klein, R.S.; Kugel, G.E.; Maillard, A.; Polgár, K.; Péter, A. Absolute non-linear optical coefficients of LiNbO3 for near stoichiometric crystal compositions. Opt. Mater. 2003, 22, 171–174. [Google Scholar] [CrossRef]

- Process Development for CMOS Fabrication Using Minimal FAB|IEEE Conference Publication|IEEE Xplore. Available online: https://ieeexplore.ieee.org/document/7947527 (accessed on 21 June 2024).

- Mekawey, H.; Elsayed, M.; Ismail, Y.; Swillam, M.A. Optical Interconnects Finally Seeing the Light in Silicon Photonics: Past the Hype. Nanomaterials 2022, 12, 485. [Google Scholar] [CrossRef] [PubMed]

- Shahbaz, M.; Butt, M.A.; Piramidowicz, R. Breakthrough in Silicon Photonics Technology in Telecommunications, Biosensing, and Gas Sensing. Micromachines 2023, 14, 1637. [Google Scholar] [CrossRef] [PubMed]

- Durán-Valdeiglesias, E.; Guerber, S.; Oser, D.; Le Roux, X.; Benedikovic, D.; Pérez-Galacho, D.; Vulliet, N.; Cremer, S.; Monfray, S.; Cassan, E.; et al. Dual-polarization silicon nitride Bragg filters with low thermal sensitivity. Opt. Lett. 2019, 44, 4578–4581. [Google Scholar] [CrossRef] [PubMed]

- Biosensing with Silicon Nitride Microring Resonators Integrated with an On-Chip Filter Bank Spectrometer|ACS Sensors. Available online: https://pubs.acs.org/doi/10.1021/acssensors.2c02276 (accessed on 7 February 2024).

- High-Power Indium Phosphide Semiconductor Lasers|IEEE Conference Publication|IEEE Xplore. Available online: https://ieeexplore.ieee.org/document/893936 (accessed on 20 June 2024).

- Indium Phosphide Particle Detectors|IEEE Journals & Magazine|IEEE Xplore. Available online: https://ieeexplore.ieee.org/abstract/document/34436 (accessed on 20 June 2024).

- Das, A.; Wang, A.; Utéza, O.; Grojo, D. Internal structuring of gallium arsenide using short laser pulses. Opt. Express 2022, 30, 39101–39110. [Google Scholar] [CrossRef]

- Gallium Arsenide Detectors for X-ray and Electron (Beta Particle) Spectroscopy—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S016890021630866X (accessed on 20 June 2024).

- Madabhushi, R. Chapter 6—Lithium Niobate Optical Modulators. In WDM Technologies; Dutta, A.K., Dutta, N.K., Fujiwara, M., Eds.; Academic Press: San Diego, CA, USA, 2002; pp. 207–248. [Google Scholar] [CrossRef]

- Guo, Q.; Sekine, R.; Ledezma, L.; Nehra, R.; Dean, D.J.; Roy, A.; Gray, R.M.; Jahani, S.; Marandi, A. Femtojoule Femtosecond All-Optical Switching in Lithium Niobate Nanophotonics. Nat. Photonics 2022, 16, 625–631. Available online: https://www.nature.com/articles/s41566-022-01044-5 (accessed on 28 June 2024). [CrossRef]

- Chen, J.; Xiong, Y.; Xu, F.; Lu, Y. Silica optical fiber integrated with two-dimensional materials: Towards opto-electro-mechanical technology. Light. Sci. Appl. 2021, 10, 78. [Google Scholar] [CrossRef]

- Kim, S. All-2D material photonic devices. Nanoscale Adv. 2023, 5, 323–328. [Google Scholar] [CrossRef] [PubMed]

- Meng, Y.; Feng, J.; Han, S.; Xu, Z.; Mao, W.; Zhang, T.; Kim, J.S.; Roh, I.; Zhao, Y.; Kim, D.-H.; et al. Photonic van der Waals integration from 2D materials to 3D nanomembranes. Nat. Rev. Mater. 2023, 8, 498–517. [Google Scholar] [CrossRef]

- Tan, H.; Du, L.; Yang, F.; Chu, W.; Zhan, Y. Two-dimensional materials in photonic integrated circuits: Recent developments and future perspectives [Invited]. Chin. Opt. Lett. 2023, 21, 110007. [Google Scholar]

- Graphene-Based Integrated Photonics for Next-Generation Datacom and Telecom|Nature Reviews Materials. Available online: https://www.nature.com/articles/s41578-018-0040-9 (accessed on 15 July 2024).

- Zhang, Y.; Wu, J.; Jia, L.; Qu, Y.; Yang, Y.; Jia, B.; Moss, D.J. Graphene Oxide for Nonlinear Integrated Photonics. Laser Photonics Rev. 2023, 17, 2200512. [Google Scholar] [CrossRef]

- Krasnok, A.; Lepeshov, S.; Alu, A. Nanophotonics with 2D Transition Metal Dichalcogenides [Invited]. Opt. Express 2018, 26, 15972–15994. Available online: https://opg.optica.org/oe/fulltext.cfm?uri=oe-26-12-15972&id=390344 (accessed on 28 June 2024). [CrossRef]

- Engineering Quantum Nanophotonic Components from Hexagonal Boron Nitride—Nonahal—2023—Laser & Photonics Reviews—Wiley Online Library. Available online: https://onlinelibrary.wiley.com/doi/full/10.1002/lpor.202300019 (accessed on 15 July 2024).

- Kim, S.; Fröch, J.E.; Christian, J.; Straw, M.; Bishop, J.; Totonjian, D.; Watanabe, K.; Taniguchi, T.; Toth, M.; Aharonovich, I. Photonic crystal cavities from hexagonal boron nitride. Nat. Commun. 2018, 9, 2623. [Google Scholar] [CrossRef]

- Wu, J.; Ma, H.; Yin, P.; Ge, Y.; Zhang, Y.; Li, L.; Zhang, H.; Lin, H. Two-Dimensional Materials for Integrated Photonics: Recent Advances and Future Challenges. Small Sci. 2021, 1, 2000053. [Google Scholar] [CrossRef]

- Tian, R.; Gan, X.; Li, C.; Chen, X.; Hu, S.; Gu, L.; Van Thourhout, D.; Castellanos-Gomez, A.; Sun, Z.; Zhao, J. Chip-integrated van der Waals PN heterojunction photodetector with low dark current and high responsivity. Light. Sci. Appl. 2022, 11, 101. [Google Scholar] [CrossRef]

- Barbillon, G. Plasmonics and its Applications. Materials 2019, 12, 1502. [Google Scholar] [CrossRef]

- Boltasseva, A.; Atwater, H.A. Low-Loss Plasmonic Metamaterials. Science 2011, 331, 290–291. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, W.O.F.; Mejía-Salazar, J.R. Plasmonics for Telecommunications Applications. Sensors 2020, 20, 2488. [Google Scholar] [CrossRef] [PubMed]

- Giannini, V. Plasmonics: Future and Challenges. Front. Photonics 2020, 1. Available online: https://www.frontiersin.org/articles/10.3389/fphot.2020.621510 (accessed on 17 December 2023). [CrossRef]

- Magno, G.; Yam, V.; Dagens, B. Integration of Plasmonic Structures in Photonic Waveguides Enables Novel Electromagnetic Functionalities in Photonic Circuits. Appl. Sci. 2023, 13, 12551. [Google Scholar] [CrossRef]

- Butt, M.A. Features of the modern development of metal-insulator-metal waveguide based plasmonic sensors. Appl. Res. 2024, e202400069. [Google Scholar] [CrossRef]

- Khurgin, J.B.; Sun, G. Limits of plasmonic enhancement: What if the metal becomes “lossless”? In Proceedings of the Conference on Lasers and Electro-Optics (2016), San Jose, CA, USA, 5–10 June 2016; Optica Publishing Group: Washington, DC, USA, 2016; p. FM1B.1. [Google Scholar] [CrossRef]

- Cunha, J.; Garcia, I.S.; Santos, J.D.; Fernandes, J.; González-Losada, P.; Silva, C.; Gaspar, J.; Cortez, A.; Sampaio, M.; Aguiam, D.E. Assessing tolerances in direct write laser grayscale lithography and reactive ion etching pattern transfer for fabrication of 2.5D Si master molds. Micro Nano Eng. 2023, 19, 100182. [Google Scholar] [CrossRef]

- Bogdanov, A.L.; Lapointe, J.; Schmid, J.H. Electron-beam lithography for photonic waveguide fabrication: Measurement of the effect of field stitching errors on optical performance and evaluation of a new compensation method. J. Vac. Sci. Technol. B 2012, 30, 031606. [Google Scholar] [CrossRef]

- Barcelo, S.; Li, Z. Nanoimprint lithography for nanodevice fabrication. Nano Converg. 2016, 3, 21. [Google Scholar] [CrossRef]

- Grego, S.; Huffman, A.; Lueck, M.; Stoner, B.R.; Lannon, J. Nanoimprint lithography fabrication of waveguide-integrated optical gratings with inexpensive stamps. Microelectron. Eng. 2010, 87, 1846–1851. [Google Scholar] [CrossRef]

- Joyce, B.A. Molecular beam epitaxy-fundamentals and current status. Contemp. Phys. 1990, 31, 195–197. [Google Scholar] [CrossRef]

- Shi, B.; Lau, K.M. Chapter Seven—Growth of III–V semiconductors and lasers on silicon substrates by MOCVD. In Semiconductors and Semimetals; Future Directions in Silicon Photonics; Lourdudoss, S., Bowers, J.E., Jagadish, C., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; Volume 101, pp. 229–282. [Google Scholar] [CrossRef]

- Artel, V.; Ilovitsh, T.; Bakish, I.; Shubely, M.; Shekel, E.; Ben-Ezra, Y.; Sukenik, C.N.; Zadok, A. Wafer bonding techniques for hybrid silicon photonic devices based on surface modifications. In Proceedings of the 2012 14th International Conference on Transparent Optical Networks (ICTON), Coventry, UK, 2–5 July 2012; pp. 1–4. [Google Scholar] [CrossRef]

- Lindenmann, N.; Balthasar, G.; Hillerkuss, D.; Schmogrow, R.; Jordan, M.; Leuthold, J.; Freude, W.; Koos, C. Photonic wire bonding: A novel concept for chip-scale interconnects. Opt. Express 2012, 20, 17667–17677. [Google Scholar] [CrossRef] [PubMed]

- Ferstl, M. Reactive ion etching: A versatile fabrication technique for micro-optical elements. In Diffractive Optics and Micro-Optics (1998); Optica Publishing Group: Washington, DC, USA, 1998; p. DTuD.21. [Google Scholar] [CrossRef]

- Jiao, Y.; de Vries, T.; Unger, R.-S.; Shen, L.; Ambrosius, H.; Radu, C.; Arens, M.; Smit, M.; van der Tol, J. Vertical and Smooth Single-Step Reactive Ion Etching Process for InP Membrane Waveguides. J. Electrochem. Soc. 2015, 162, E90. [Google Scholar] [CrossRef]

- Butt, M.A.; Tyszkiewicz, C.; Karasiński, P.; Zięba, M.; Hlushchenko, D.; Baraniecki, T.; Kazmierczak, A.; Piramidowicz, R.; Guzik, M.; Bachmatiuk, A. Development of a low-cost silica-titania optical platform for integrated photonics applications. Opt. Express 2022, 30, 23678. [Google Scholar] [CrossRef] [PubMed]

- Butt, M.A.; Tyszkiewicz, C.; Karasiński, P.; Zięba, M.; Kaźmierczak, A.; Zdończyk, M.; Duda, Ł.; Guzik, M.; Olszewski, J.; Martynkien, T.; et al. Optical Thin Films Fabrication Techniques—Towards a Low-Cost Solution for the Integrated Photonic Platform: A Review of the Current Status. Materials 2022, 15, 4591. [Google Scholar] [CrossRef] [PubMed]

- Otero, V.V.; Crespo-Monteiro, N.; Gamet, E.; Reynaud, S.; Ollier, N.; Valour, A.; Traynar, M.; Jourlin, Y. Micro-nanostructuring of ZrO2 sol-gel by optical and nanoimprint lithography on various substrate for optical applications. In Novel Patterning Technologies 2023; SPIE: Bellingham, WA, USA, 2023; pp. 252–260. [Google Scholar] [CrossRef]

- Zarkov, A. Sol–Gel Technology Applied to Materials Science: Synthesis, Characterization and Applications. Materials 2024, 17, 462. [Google Scholar] [CrossRef] [PubMed]

- Bae, B.-S. High Photosensitive Sol-Gel Hybrid Materials for Direct Photo-Imprinting of Micro-Optics. J. Sol-Gel Sci. Technol. 2004, 31, 309–315. [Google Scholar] [CrossRef]

- Butt, M.A.; Kaźmierczak, A.; Tyszkiewicz, C.; Karasiński, P.; Piramidowicz, R. Mode Sensitivity Exploration of Silica–Titania Waveguide for Refractive Index Sensing Applications. Sensors 2021, 21, 7452. [Google Scholar] [CrossRef]

- Butt, M.A.; Shahbaz, M.; Piramidowicz, R. Racetrack Ring Resonator Integrated with Multimode Interferometer Structure Based on Low-Cost Silica–Titania Platform for Refractive Index Sensing Application. Photonics 2023, 10, 978. [Google Scholar] [CrossRef]

- Kilicaslan, E.; Butt, M.A.; Kazmierczak, A.; Piramidowicz, R. Technological challenges in the development of silica-titania platform for integrated optics. Photonics Lett. Pol. 2023, 15, 42–44. [Google Scholar] [CrossRef]

- Khonina, S.; Kazanskiy, N.; Efimov, A.; Nikonorov, A.; Oseledets, I.; Skidanov, R.; Butt, M. A perspective on the artificial intelligence’s transformative role in advancing diffractive optics. iScience 2024, 27, 110270. [Google Scholar] [CrossRef]

- Khonina, S.N.; Kazanskiy, N.L.; Skidanov, R.V.; Butt, M.A. Exploring Types of Photonic Neural Networks for Imaging and Computing—A Review. Nanomaterials 2024, 14, 697. [Google Scholar] [CrossRef] [PubMed]

- Alan Turing: How His Universal Machine Became a Musical Instrument—IEEE Spectrum. Available online: https://spectrum.ieee.org/alan-turing-how-his-universal-machine-became-a-musical-instrument (accessed on 4 April 2024).

- Akman, V.; Blackburn, P. Editorial: Alan Turing and Artificial Intelligence. J. Log. Lang. Inf. 2000, 9, 391–395. [Google Scholar] [CrossRef]

- Sharma, S.; Tharani, L.; Sharma, S.; Tharani, L. Photonics for AI and AI for Photonics: Material and Characteristics Integration. In Fiber Optics—Technology and Applications; IntechOpen: London, UK, 2021. [Google Scholar] [CrossRef]

- Hammond, A.M.; Camacho, R.M. Designing integrated photonic devices using artificial neural networks. Opt. Express 2019, 27, 29620–29638. [Google Scholar] [CrossRef] [PubMed]

- Sanchez, M.; Everly, C.; Postigo, P.A. Advances in machine learning optimization for classical and quantum photonics. JOSA B 2024, 41, A177–A190. [Google Scholar] [CrossRef]

- Intelligent Nanophotonics: Merging Photonics and Artificial Intelligence at the Nanoscale. Available online: https://www.degruyter.com/document/doi/10.1515/nanoph-2018-0183/html (accessed on 20 June 2024).

- Zhang, Q.; Yu, H.; Barbiero, M.; Wang, B.; Gu, M. Artificial neural networks enabled by nanophotonics. Light. Sci. Appl. 2019, 8, 42. [Google Scholar] [CrossRef] [PubMed]

- Hegde, R.S. Deep learning: A new tool for photonic nanostructure design. Nanoscale Adv. 2020, 2, 1007–1023. [Google Scholar] [CrossRef] [PubMed]

- Nanophotonic Particle Simulation and Inverse Design Using Artificial Neural Networks|Science Advances. Available online: https://www.science.org/doi/10.1126/sciadv.aar4206 (accessed on 20 June 2024).

- Probabilistic Representation and Inverse Design of Metamaterials Based on a Deep Generative Model with Semi-Supervised Learning Strategy—Ma—2019—Advanced Materials—Wiley Online Library. Available online: https://onlinelibrary.wiley.com/doi/10.1002/adma.201901111 (accessed on 20 June 2024).

- Material Platforms for Integrated Quantum Photonics. Available online: https://opg.optica.org/ome/fulltext.cfm?uri=ome-7-1-111&id=355874 (accessed on 7 February 2024).

- Klamkin, J.; Zhao, H.; Song, B.; Liu, Y.; Isaac, B.; Pinna, S.; Sang, F.; Coldren, L. Indium Phosphide Photonic Integrated Circuits: Technology and Applications. In Proceedings of the 2018 IEEE BiCMOS and Compound Semiconductor Integrated Circuits and Technology Symposium (BCICTS), San Diego, CA, USA, 15–17 October 2018; pp. 8–13. [Google Scholar] [CrossRef]

- Chang, G.-E.; Chang, S.-W.; Chuang, S.L. Strain-Balanced GezSn1−z--SixGeySn1−x−y Multiple-Quantum-Well Lasers. IEEE J. Quantum Electron. 2010, 46, 1813–1820. [Google Scholar] [CrossRef]

- Chang, G.-E.; Cheng, H.H. Optical gain of germanium infrared lasers on different crystal orientations. J. Phys. Appl. Phys. 2013, 46, 065103. [Google Scholar] [CrossRef]

- Hong, H.; Zhang, L.; Qian, K.; An, Y.; Li, C.; Li, J.; Chen, S.; Huang, W.; Wang, J.; Zhang, S. Limitation of bulk GeSn alloy in the application of a high-performance laser due to the high threshold. Opt. Express 2021, 29, 441–453. [Google Scholar] [CrossRef]

- Liang, D.; Roelkens, G.; Baets, R.; Bowers, J.E. Hybrid Integrated Platforms for Silicon Photonics. Materials 2010, 3, 1782. [Google Scholar] [CrossRef]

- Arokiaraj, J.; Vicknesh, S.; Ramam, A. Integration of indium phosphide thin film structures on silicon substrates by direct wafer bonding. J. Phys. Conf. Ser. 2006, 34, 404. [Google Scholar] [CrossRef]

- Dai, D.; Liang, D.; Liu, L. Introduction for the Integrated Photonics: Challenges and Perspectives feature. Photonics Res. 2015, 3, IP1–IP2. [Google Scholar] [CrossRef]

- Feilchenfeld, N.B.; Nummy, K.; Barwicz, T.; Gill, D.; Kiewra, E.; Leidy, R.; Orcutt, J.S.; Rosenberg, J.; Stricker, A.D.; Whiting, C.; et al. Silicon photonics and challenges for fabrication. In Advanced Etch Technology for Nanopatterning VI; SPIE: Bellingham, WA, USA, 2017; p. 101490D. [Google Scholar] [CrossRef]

- Märki, I.; Salt, M.; Herzig, H.P.; Stanley, R.; El Melhaoui, L.; Lyan, P.; Fedeli, J.M. Characterization of buried photonic crystal waveguides and microcavities fabricated by deep ultraviolet lithography. J. Appl. Phys. 2005, 98, 013103. [Google Scholar] [CrossRef]

- Matsui, S.; Kojima, Y.; Ochiai, Y.; Honda, T. High-resolution focused ion beam lithography. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 1991, 9, 2622–2632. [Google Scholar] [CrossRef]

- Gao, G.; Chen, D.; Tao, S.; Zhang, Y.; Zhu, S.; Xiao, X.; Xia, J. Silicon nitride O-band (de)multiplexers with low thermal sensitivity. Opt. Express 2017, 25, 12260–12267. [Google Scholar] [CrossRef]

- Slavík, R.; Marra, G.; Fokoua, E.N.; Baddela, N.; Wheeler, N.V.; Petrovich, M.; Poletti, F.; Richardson, D.J. Ultralow thermal sensitivity of phase and propagation delay in hollow core optical fibres. Sci. Rep. 2015, 5, 15447. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Xu, L.; Mao, D.; D’mello, Y.; Wei, Z.; Li, W.; Plant, D.V. Temperature-insensitive and low-loss single-mode silicon waveguide crossing covering all optical communication bands enabled by curved anisotropic metamaterial. Nanophotonics 2023, 12, 4095–4107. [Google Scholar] [CrossRef]

- Hiraki, T.; Fukuda, H.; Yamada, K.; Yamamoto, T. Small Sensitivity to Temperature Variations of Si-Photonic Mach–Zehnder Interferometer Using Si and SiN Waveguides. Front. Mater. 2015, 2, 26. [Google Scholar] [CrossRef][Green Version]

- Su, Y.; He, Y.; Guo, X.; Xie, W.; Ji, X.; Wang, H.; Cai, X.; Tong, L.; Yu, S. Scalability of Large-Scale Photonic Integrated Circuits. ACS Photonics 2023, 10, 2020–2030. [Google Scholar] [CrossRef]

- Zuo, Y.; Zhao, Y.; Chen, Y.-C.; Du, S.; Liu, J. Scalability of All-Optical Neural Networks Based on Spatial Light Modulators. Phys. Rev. Appl. 2021, 15, 054034. [Google Scholar] [CrossRef]

- Wang, Y.; Jiao, Y.; Williams, K. Scaling photonic integrated circuits with InP technology: A perspective. APL Photonics 2024, 9, 050902. [Google Scholar] [CrossRef]

- Menssen, A.J.; Hermans, A.; Christen, I.; Propson, T.; Li, C.; Leenheer, A.J.; Zimmermann, M.; Dong, M.; Larocque, H.; Raniwala, H.; et al. Scalable photonic integrated circuits for high-fidelity light control. Optica 2023, 10, 1366–1372. [Google Scholar] [CrossRef]

- Marchetti, R.; Lacava, C.; Carroll, L.; Gradkowski, K.; Minzioni, P. Coupling strategies for silicon photonics integrated chips [Invited]. Photonics Res. 2019, 7, 201–239. [Google Scholar] [CrossRef]

- Zaoui, W.S.; Kunze, A.; Vogel, W.; Berroth, M.; Butschke, J.; Letzkus, F.; Burghartz, J. Bridging the gap between optical fibers and silicon photonic integrated circuits. Opt. Express 2014, 22, 1277–1286. [Google Scholar] [CrossRef] [PubMed]

- Wood, M.; Sun, P.; Reano, R.M. Compact cantilever couplers for low-loss fiber coupling to silicon photonic integrated circuits. Opt. Express 2012, 20, 164–172. [Google Scholar] [CrossRef]

- Son, G.; Han, S.; Park, J.; Kwon, K.; Yu, K. High-efficiency broadband light coupling between optical fibers and photonic integrated circuits. Nanophotonics 2018, 7, 1845–1864. [Google Scholar] [CrossRef]

- The Virtuous Circle of AI and Photonics. Available online: https://spie.org/news/photonics-focus/janfeb-2024/exploring-the-ai-photonics-virtuous-circle (accessed on 20 June 2024).

- Xu, Y.; Zhang, X.; Fu, Y.; Liu, Y. Interfacing photonics with artificial intelligence: An innovative design strategy for photonic structures and devices based on artificial neural networks. Photonics Res. 2021, 9, B135–B152. [Google Scholar] [CrossRef]

- Saharia, A.; Choure, K.K.; Mudgal, N.; Pandey, R.; Bhatia, D.; Tiwari, M.; Singh, G. Integrated Photonics for Artificial Intelligence Applications. In VLSI and Hardware Implementations Using Modern Machine Learning Methods; CRC Press: Boca Raton, FL, USA, 2021. [Google Scholar]

| Aspect | PICs | EICs |

|---|---|---|

| Operational mechanism | Utilizes photons (light) for signal transmission | Relies on electrons for signal transmission |

| Medium | Optical fibers, WGs, and photonic crystals | Si or other semiconductor materials |

| Speed | Usually, higher speed | Limited by electron mobility and resistance |

| Energy efficiency | Generally, more energy-efficient | Subject to resistive losses and heat dissipation |

| Bandwidth | Higher bandwidth capabilities | Bandwidth limited by material properties |

| Signal loss | Lower signal loss over long distances | Signal loss over distance in conductors |

| Interference | Less susceptible to EM interference | Susceptible to EM interference |

| Integration density | Limited by photonic component sizes | Can achieve high integration densities |

| Overall cost | Typically, higher costs due to fabrication complexity | Lower cost due to mature manufacturing processes |

| Applications | Optical communication, computing, sensing, imaging | Computing, data processing, control systems |

| Material Platform | Si | Si3N4 | InP | GaAs | Lithium Niobate (LiNbO3) |

|---|---|---|---|---|---|

| Material type | Semiconductor | Dielectric | Semiconductor | Semiconductor | EO crystal |

| Refractive index | ~3.5 [117] | ~2 [117] | ~3.2 [117] | ~3.3 [117] | ~2.2 [117] |

| Transparency range | 1.1 µm to 9 µm | 0.4 µm to 5 µm | 1 µm to 2.6 µm | 0.9 µm to 1.8 µm | 0.35 µm to 5 µm [118] |

| Nonlinear coefficient | Low | Low | High | High | Very high [119] |

| WG loss | Low | Low | Very low | Low | Low |

| Fabrication method | CMOS-compatible [120] | CMOS-compatible [120] | Epitaxial growth | Epitaxial growth | Bulk crystal growth |

| Applications | Optical interconnects, sensors [121,122] | Filters, sensors, modulators [12,123,124] | Lasers, detectors [125,126] | Lasers, detectors [127,128] | Modulators, switches [129,130] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Butt, M.A.; Mateos, X. Strategic Insights into Integrated Photonics: Core Concepts, Practical Deployments, and Future Outlook. Appl. Sci. 2024, 14, 6365. https://doi.org/10.3390/app14146365

Butt MA, Mateos X. Strategic Insights into Integrated Photonics: Core Concepts, Practical Deployments, and Future Outlook. Applied Sciences. 2024; 14(14):6365. https://doi.org/10.3390/app14146365

Chicago/Turabian StyleButt, Muhammad A., and Xavier Mateos. 2024. "Strategic Insights into Integrated Photonics: Core Concepts, Practical Deployments, and Future Outlook" Applied Sciences 14, no. 14: 6365. https://doi.org/10.3390/app14146365

APA StyleButt, M. A., & Mateos, X. (2024). Strategic Insights into Integrated Photonics: Core Concepts, Practical Deployments, and Future Outlook. Applied Sciences, 14(14), 6365. https://doi.org/10.3390/app14146365