Continuous Wave Mode Test of Conduction-Cooled Nb3Sn Radio Frequency Superconducting Cavities at Peking University

Abstract

1. Introduction

2. Experimental Descriptions

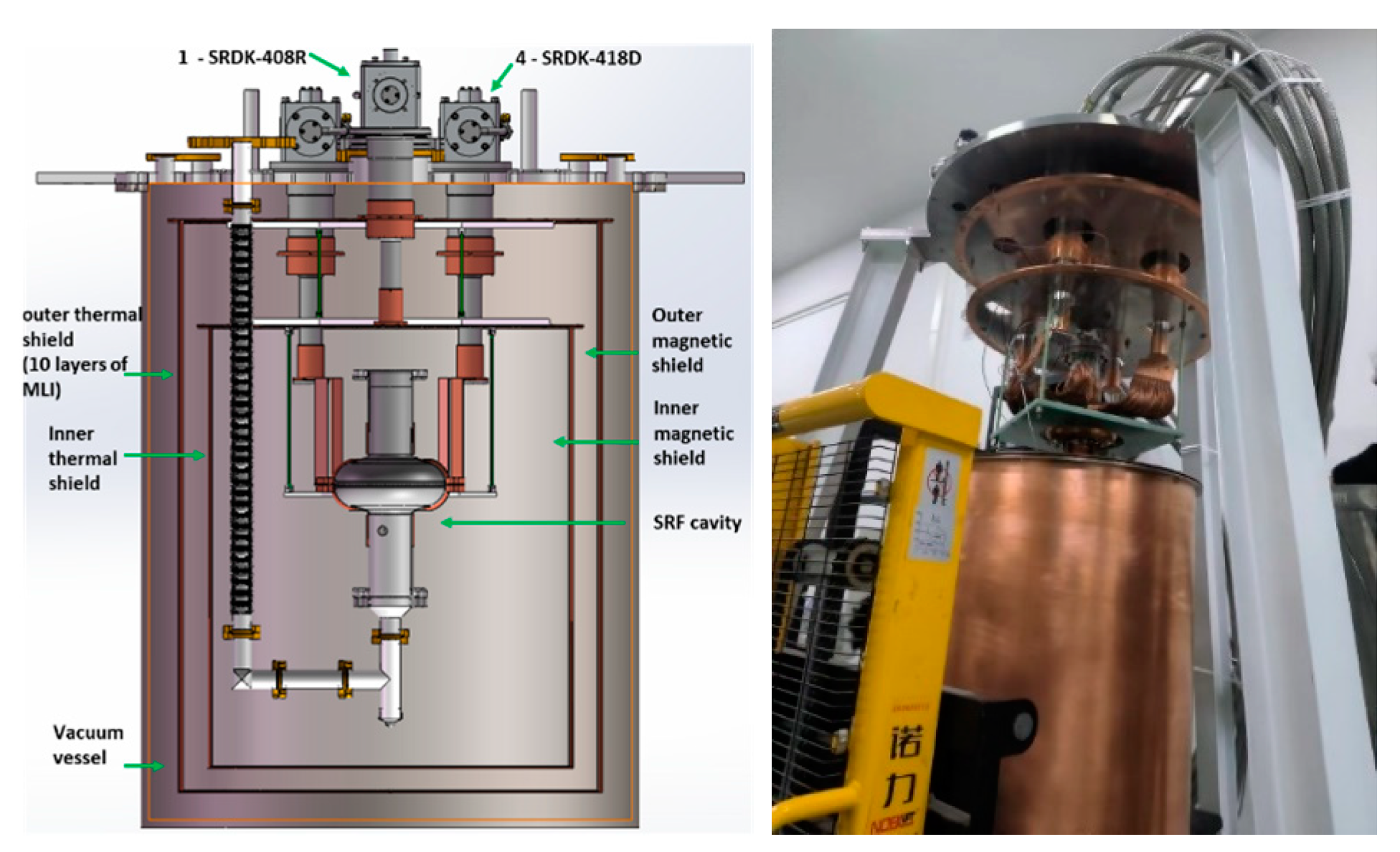

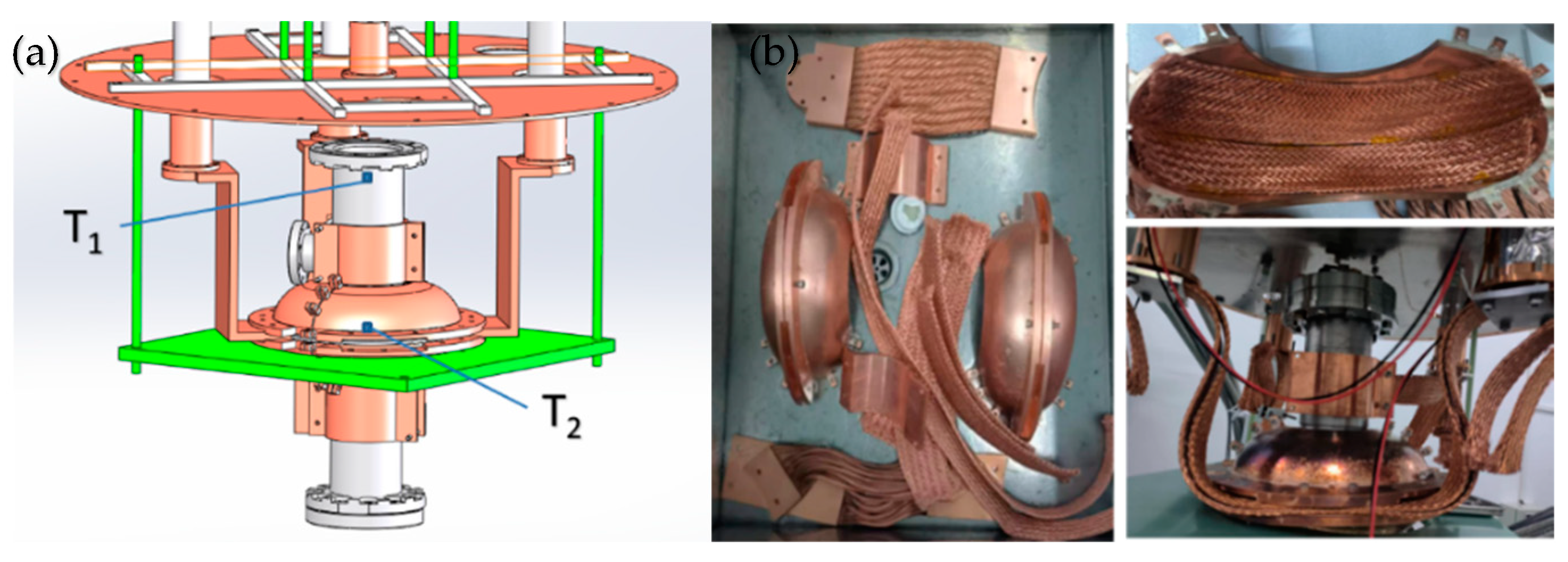

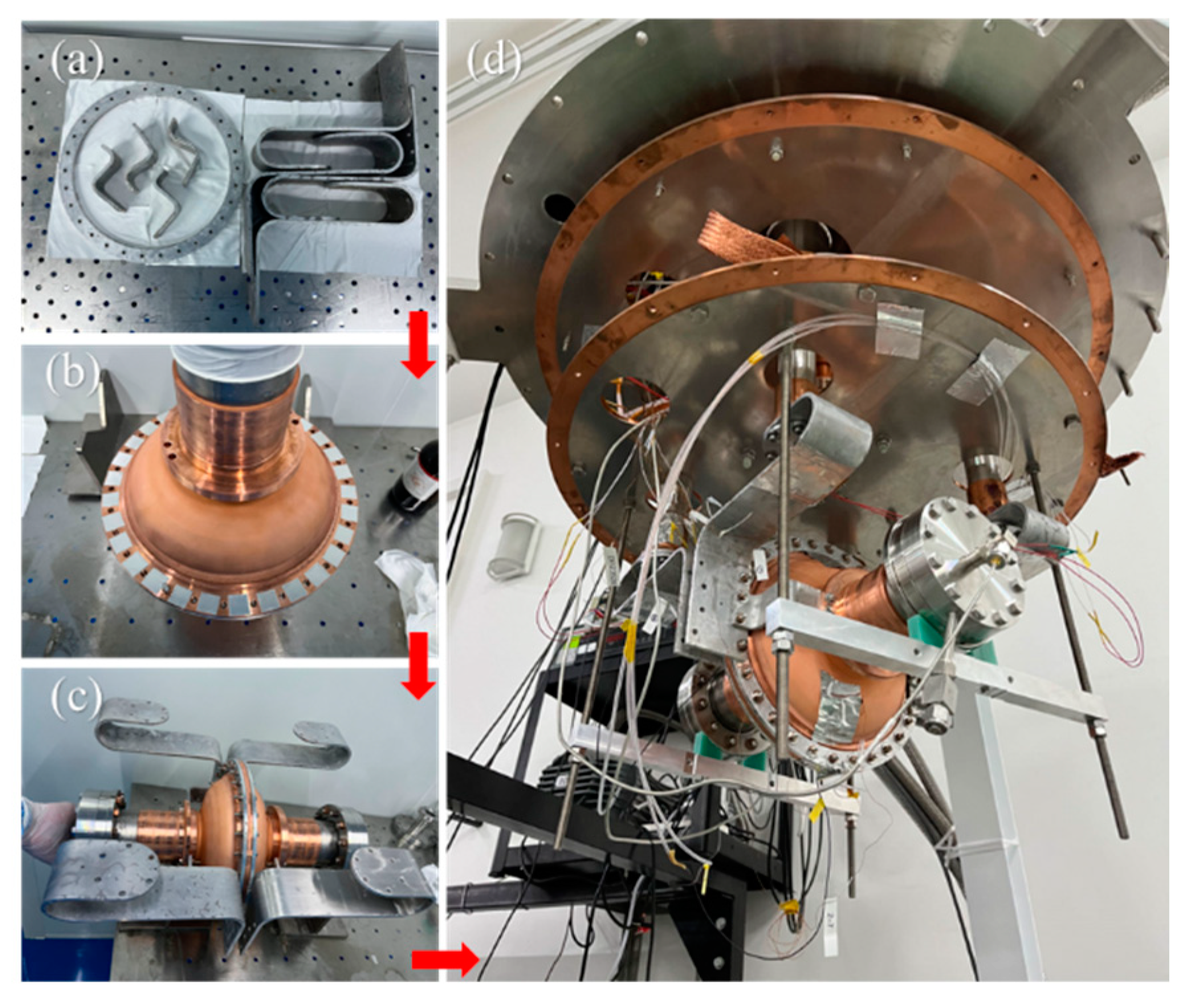

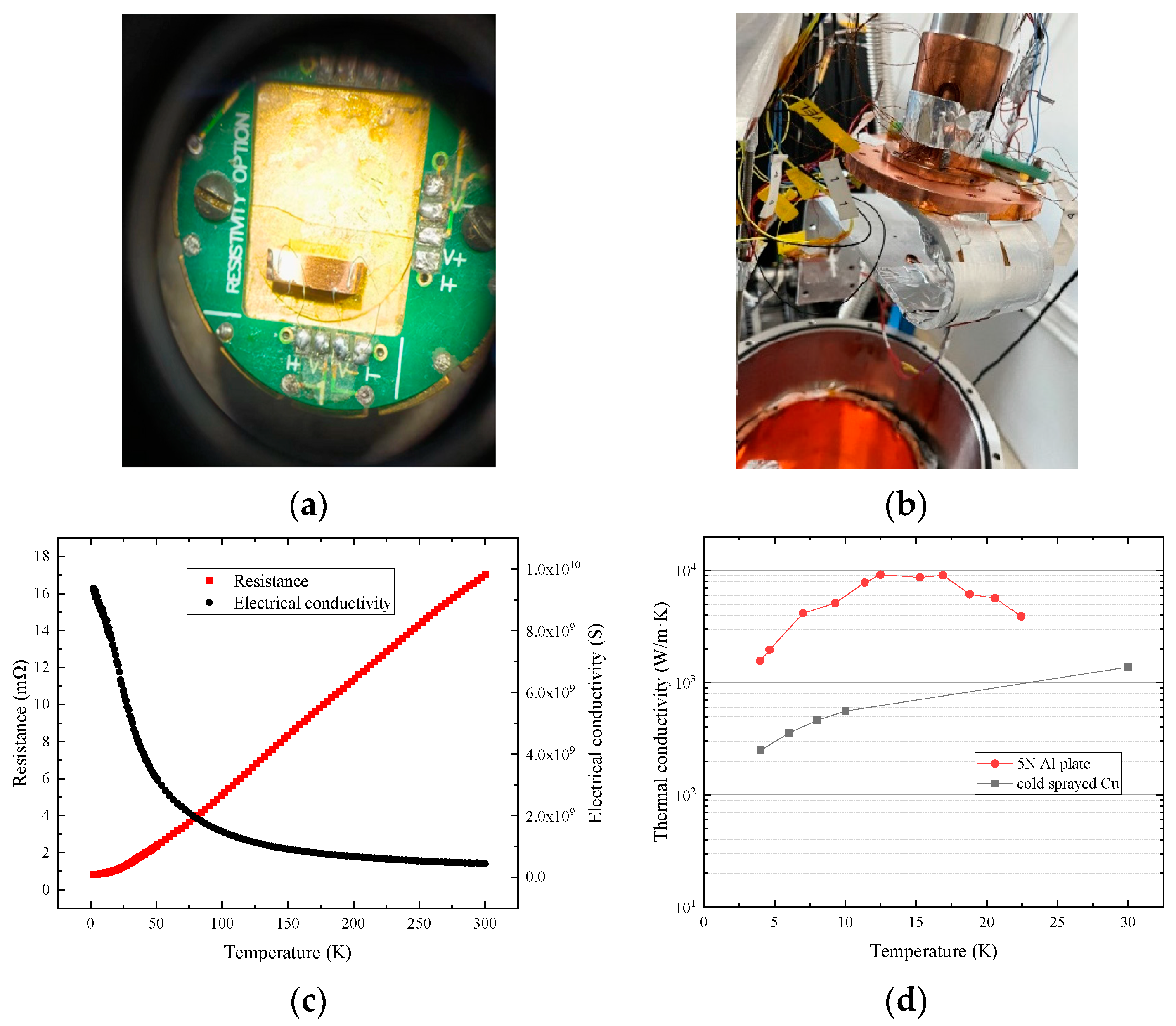

2.1. Cryostat Design

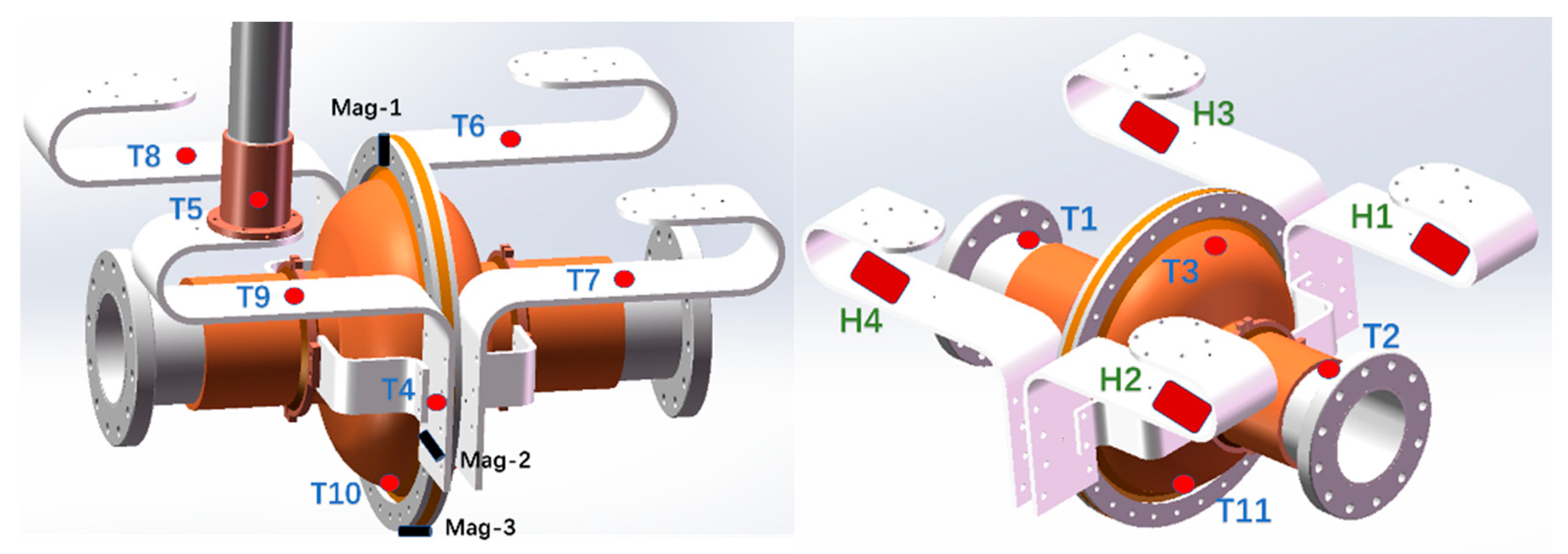

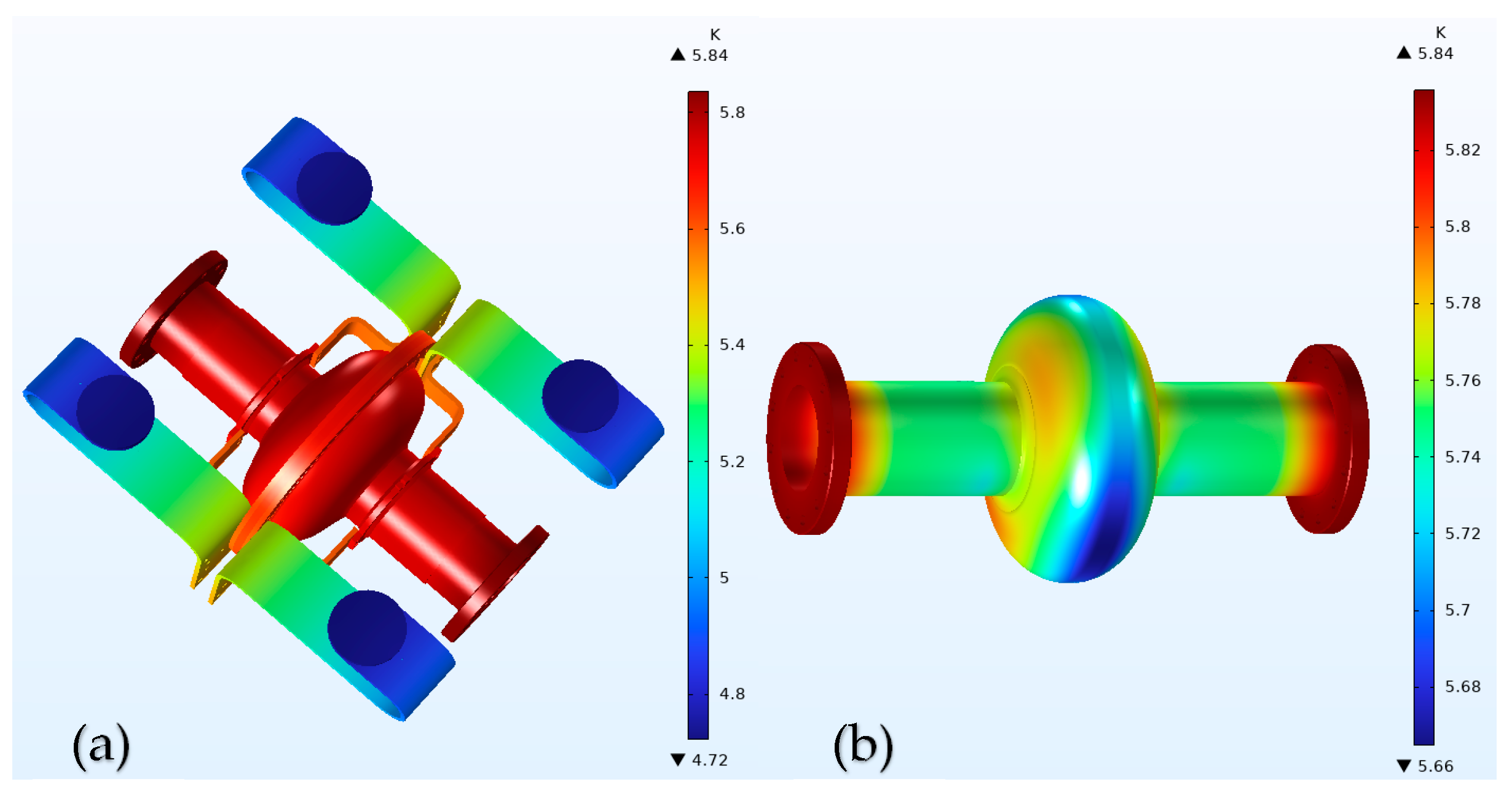

2.1.1. Temperature Distribution and Heat Leakage Calculations

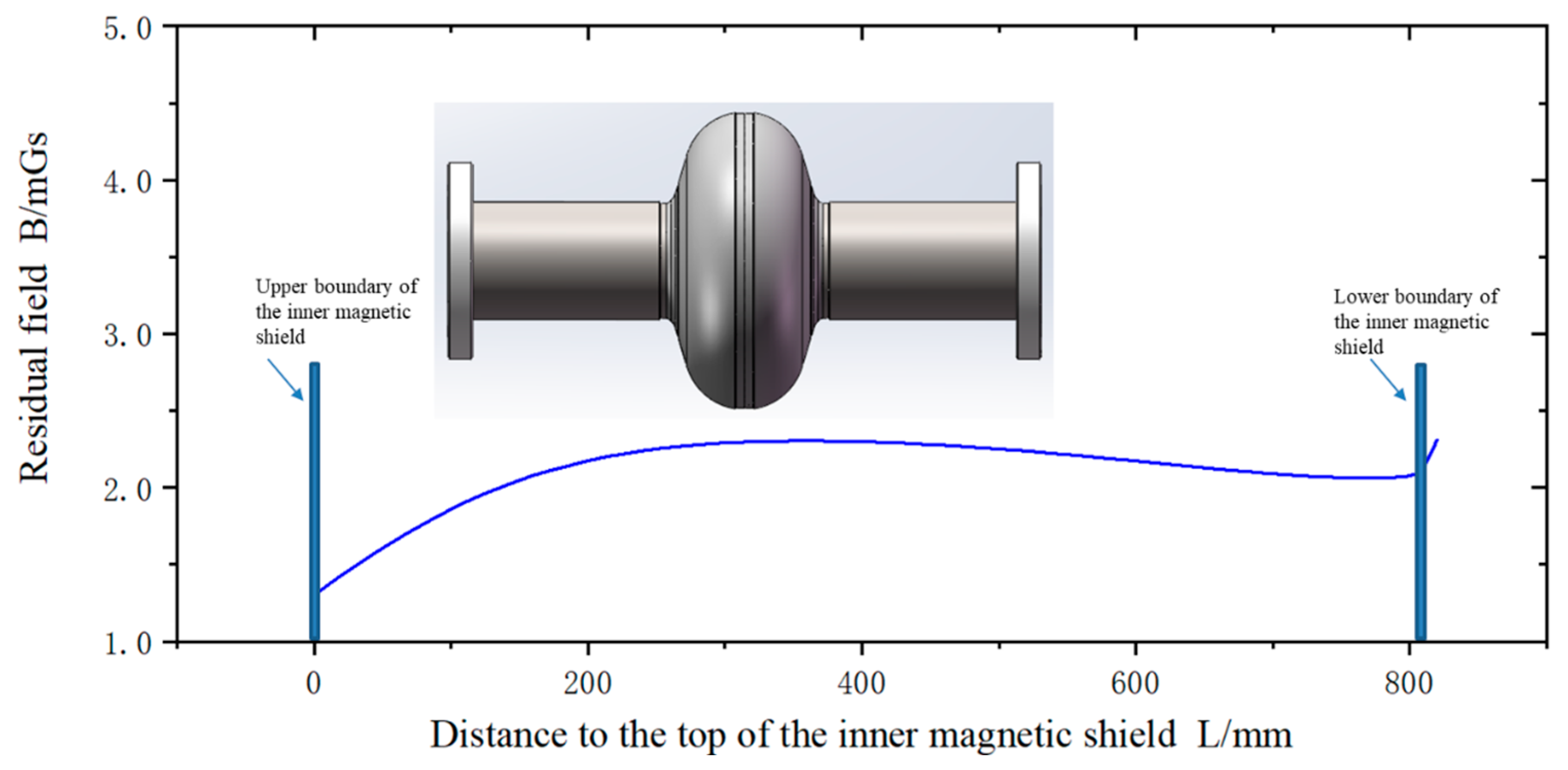

2.1.2. Residual Magnetic Field Simulation

2.2. Superconducting Cavities Treatment

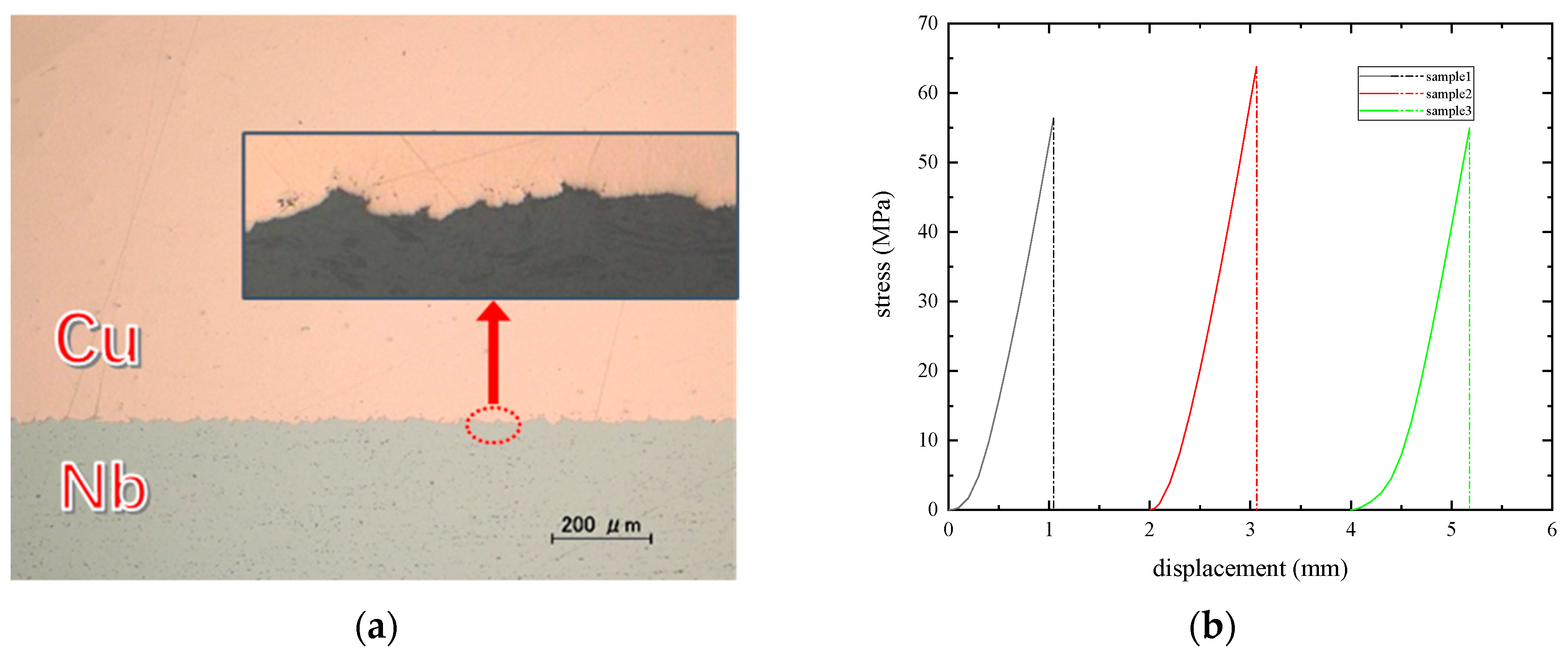

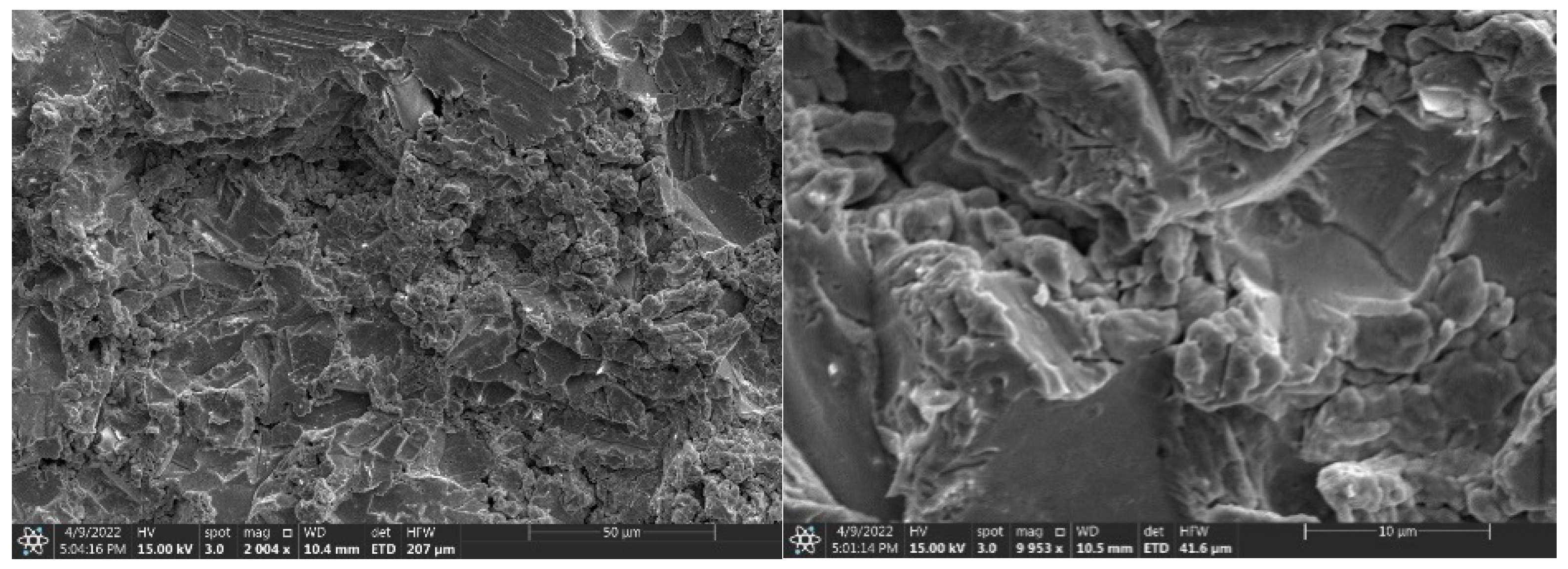

2.2.1. Nb3Sn Inner Coating

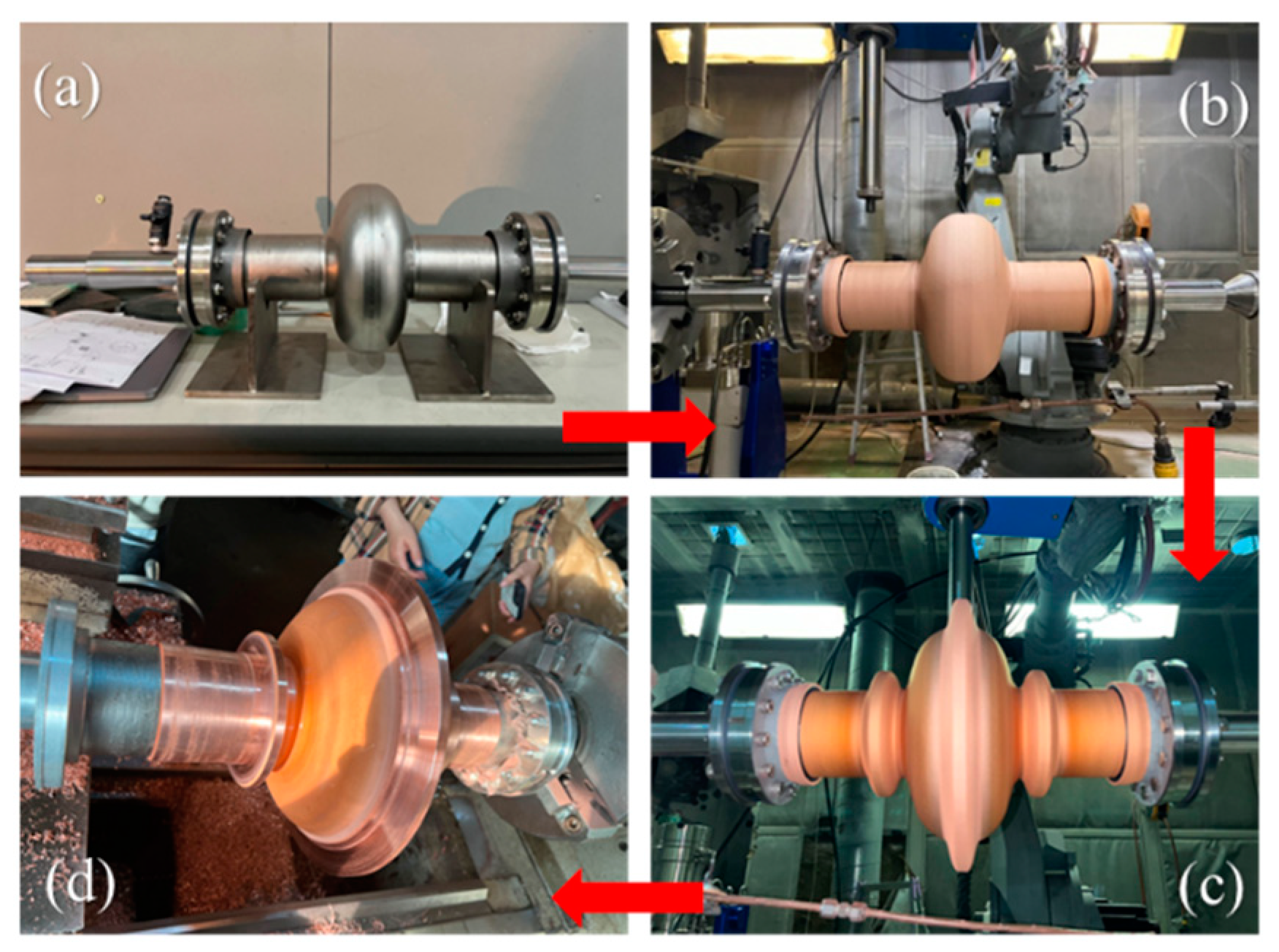

2.2.2. Surface Treatment outside the NS04 Cavity

2.2.3. Surface Treatment outside the NS03 Cavity

3. Results Analysis

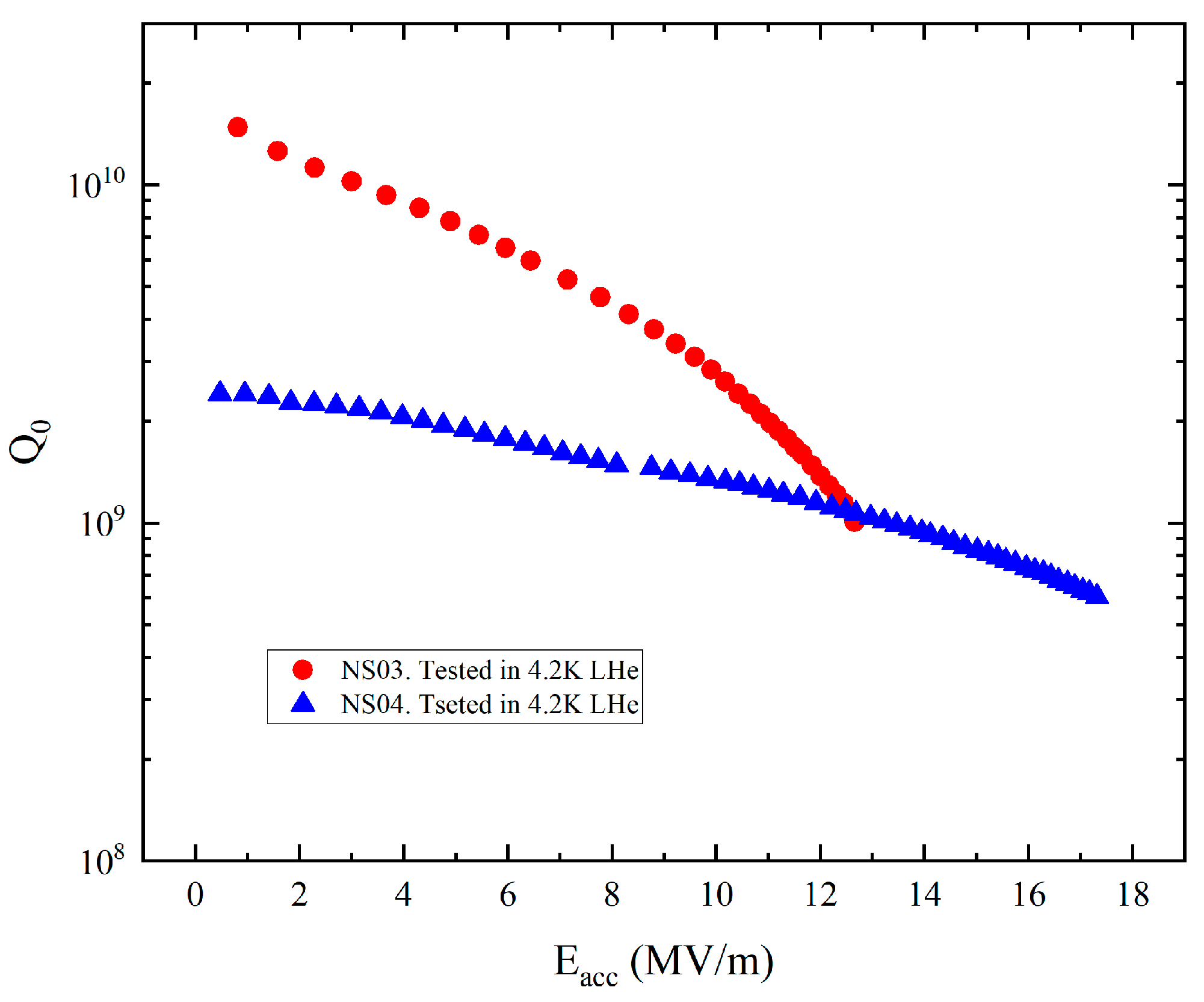

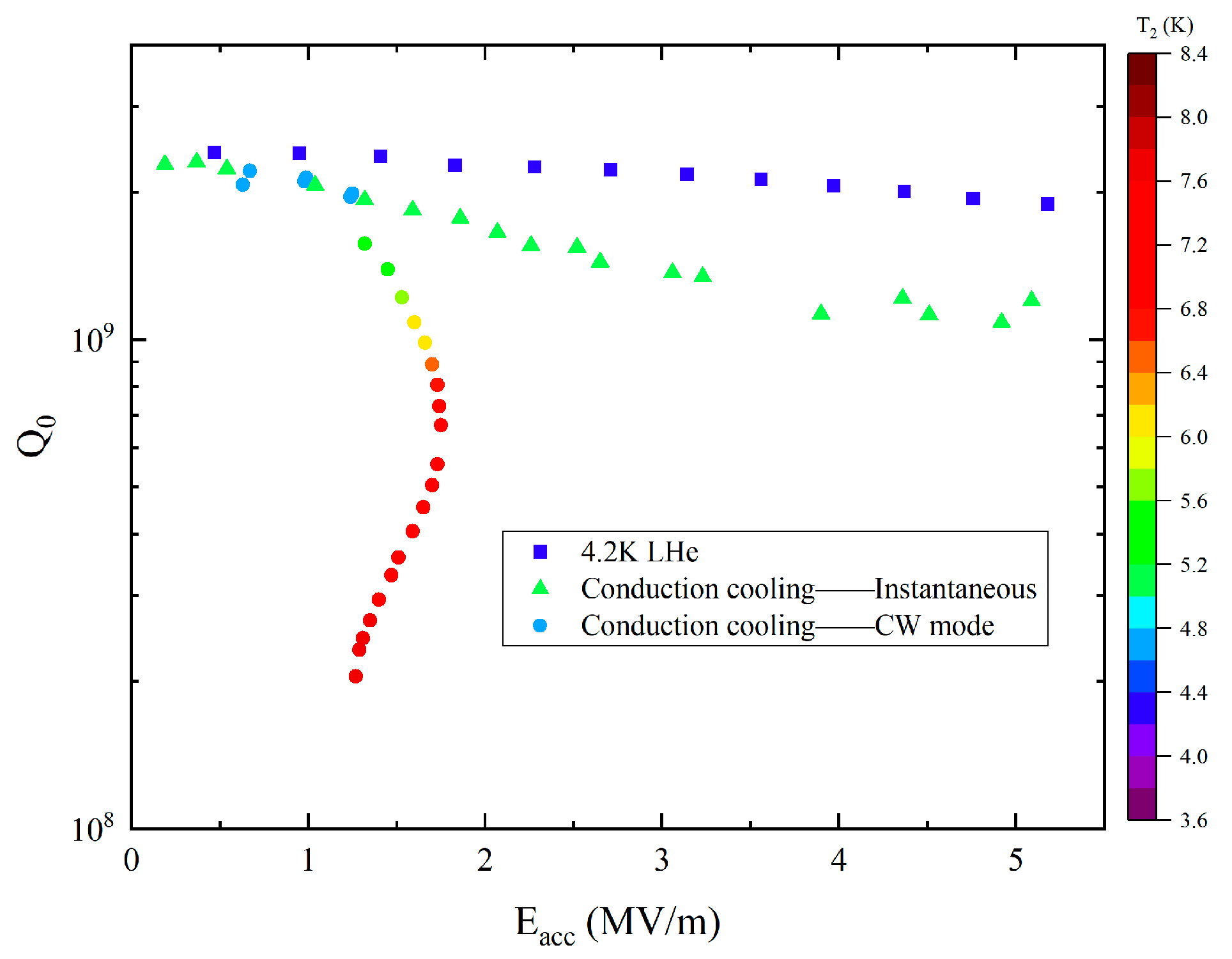

3.1. NS04 Cavity Test Results

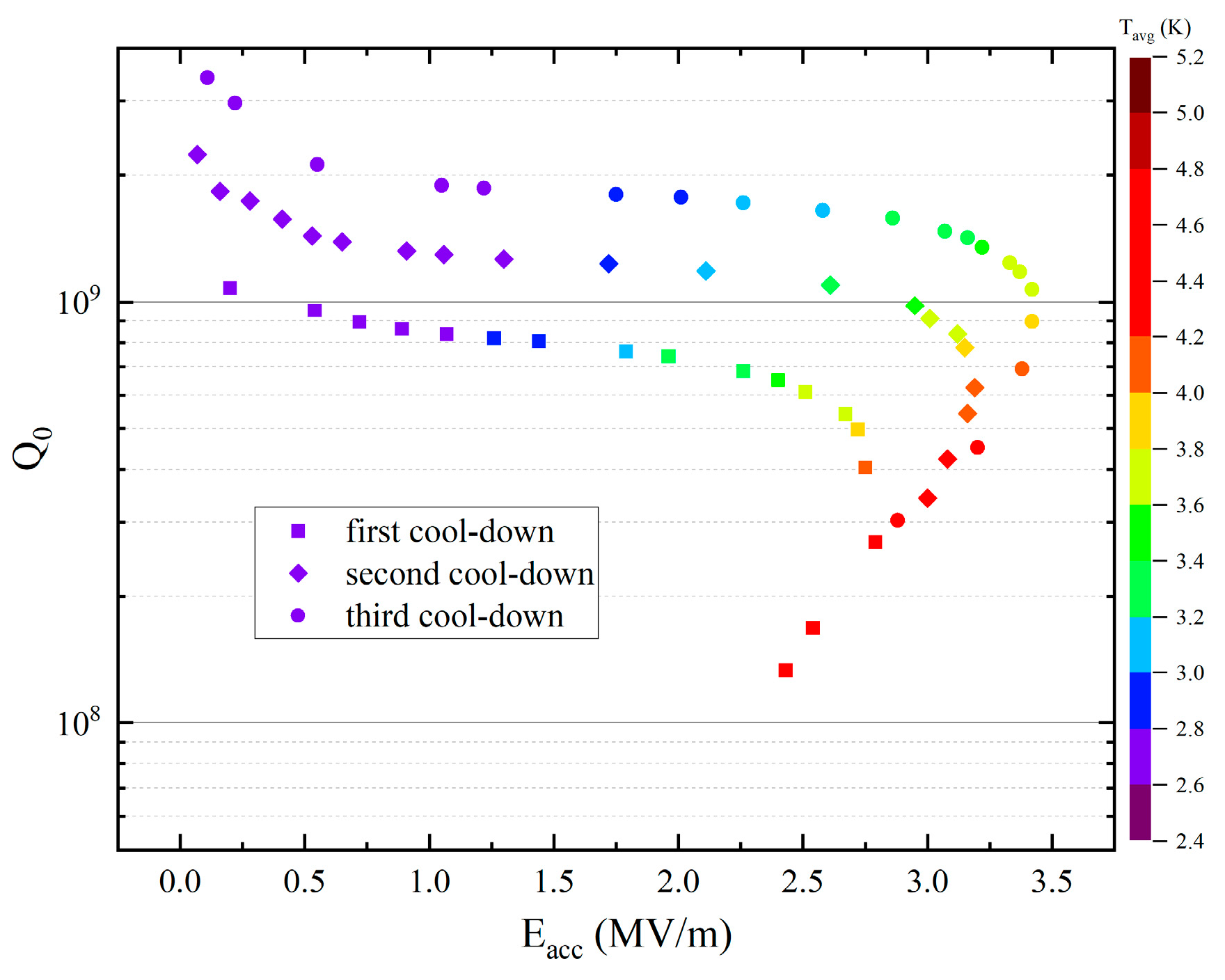

3.2. NS03 Cavity Test Results

4. Discussion

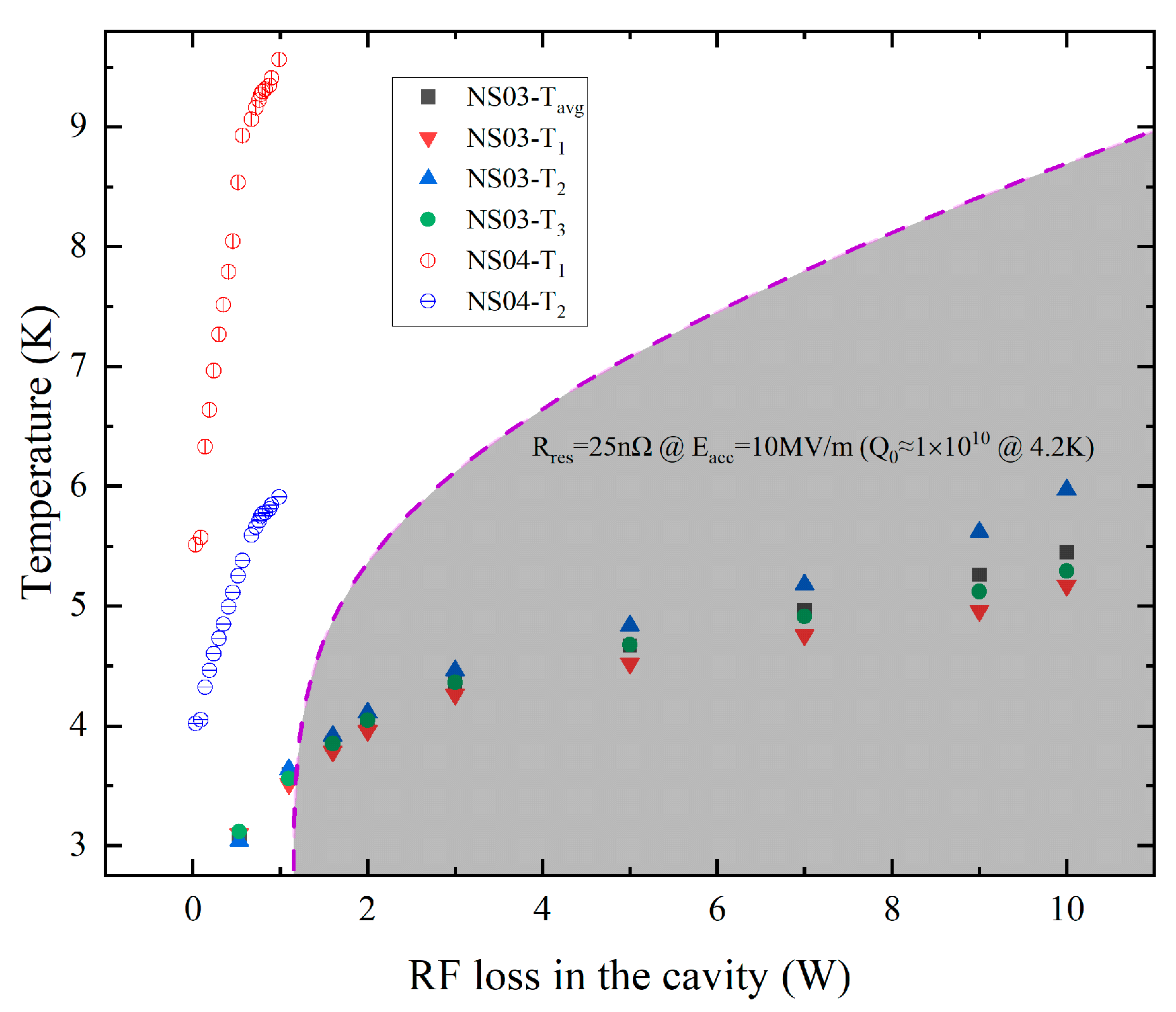

4.1. Thermal Stability and Uniformity

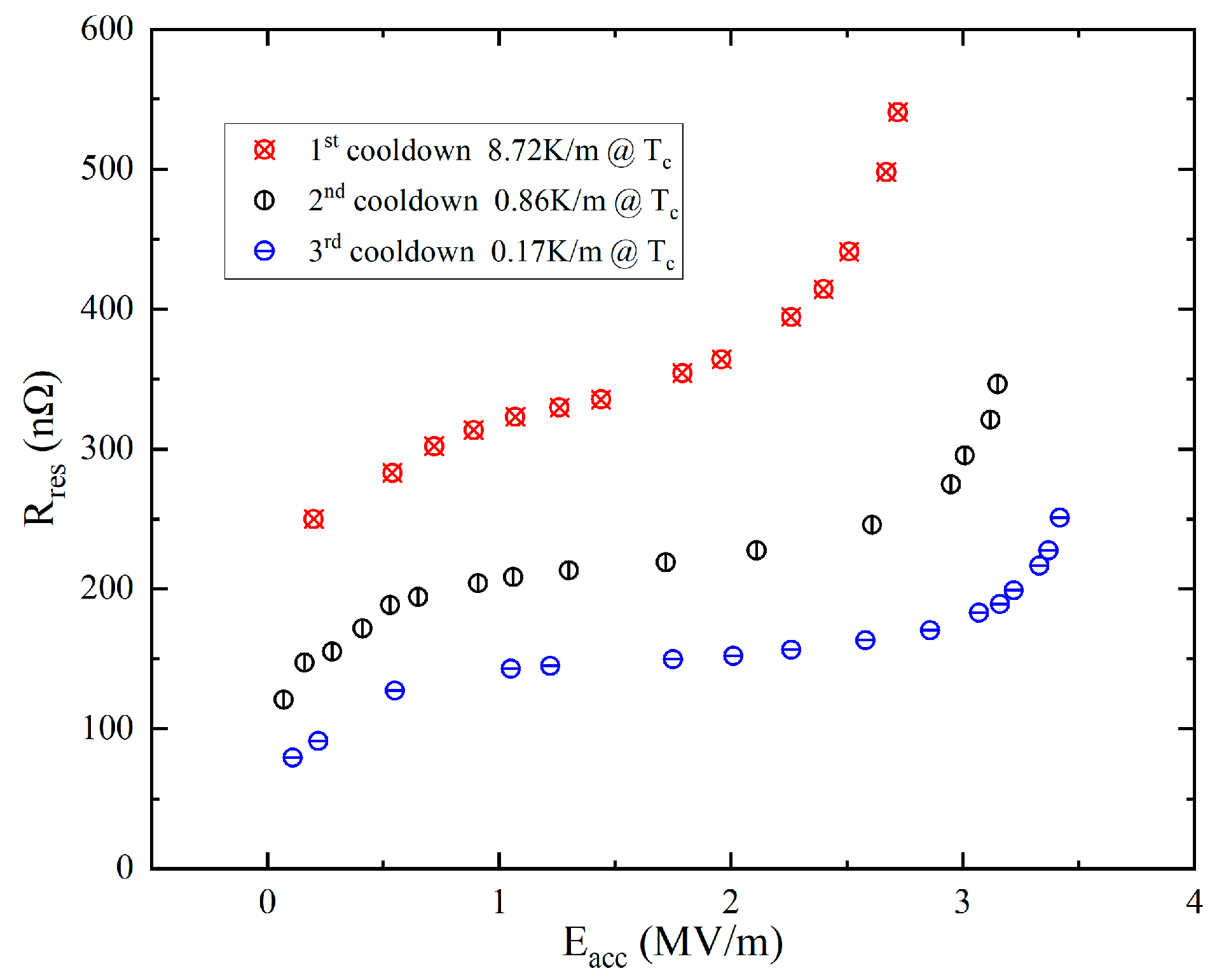

4.2. Effect of Cooling Rate on RF Performance of Nb3Sn Cavity

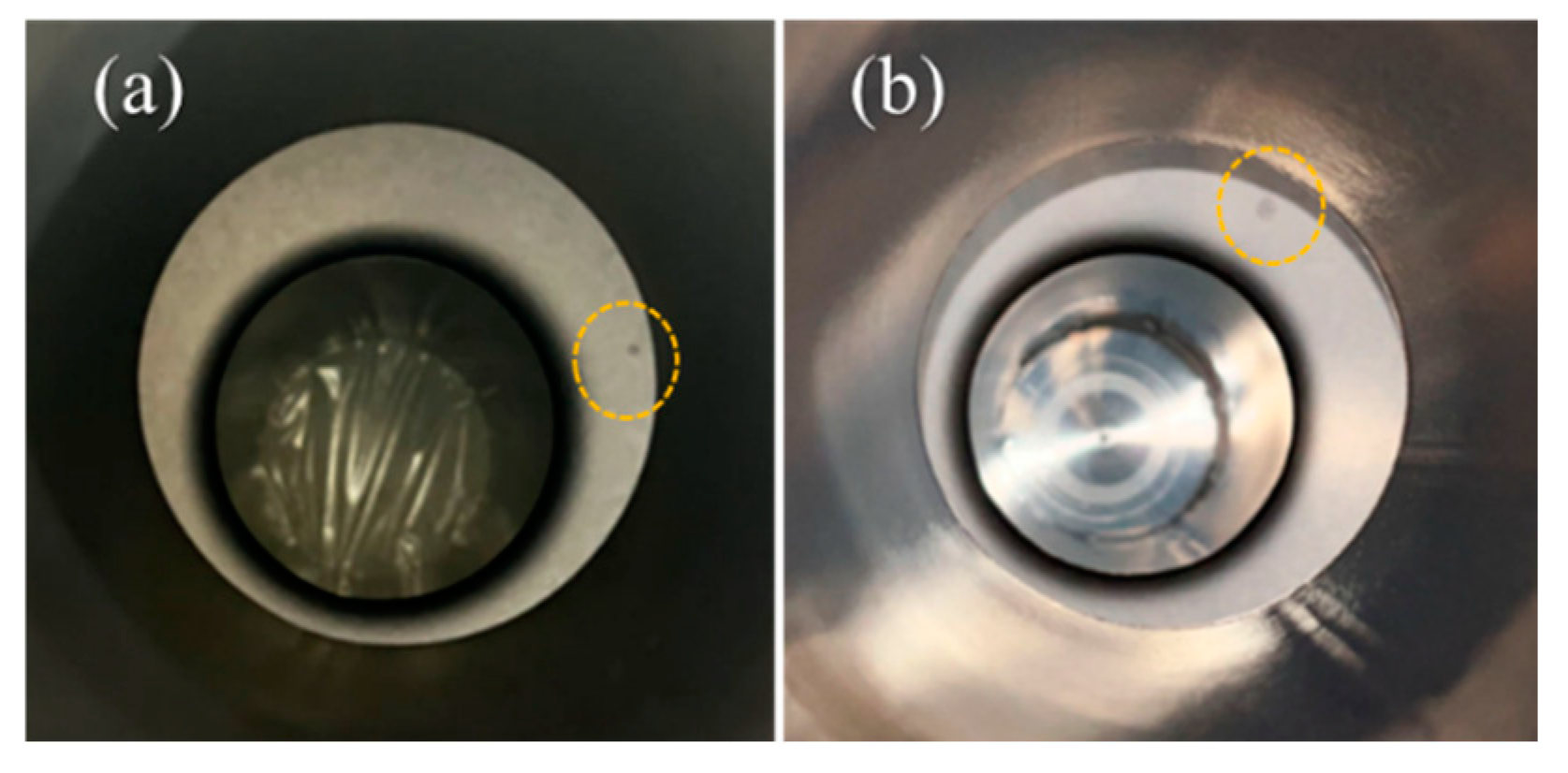

4.3. Causes of Performance Degradation of NS03 Cavity

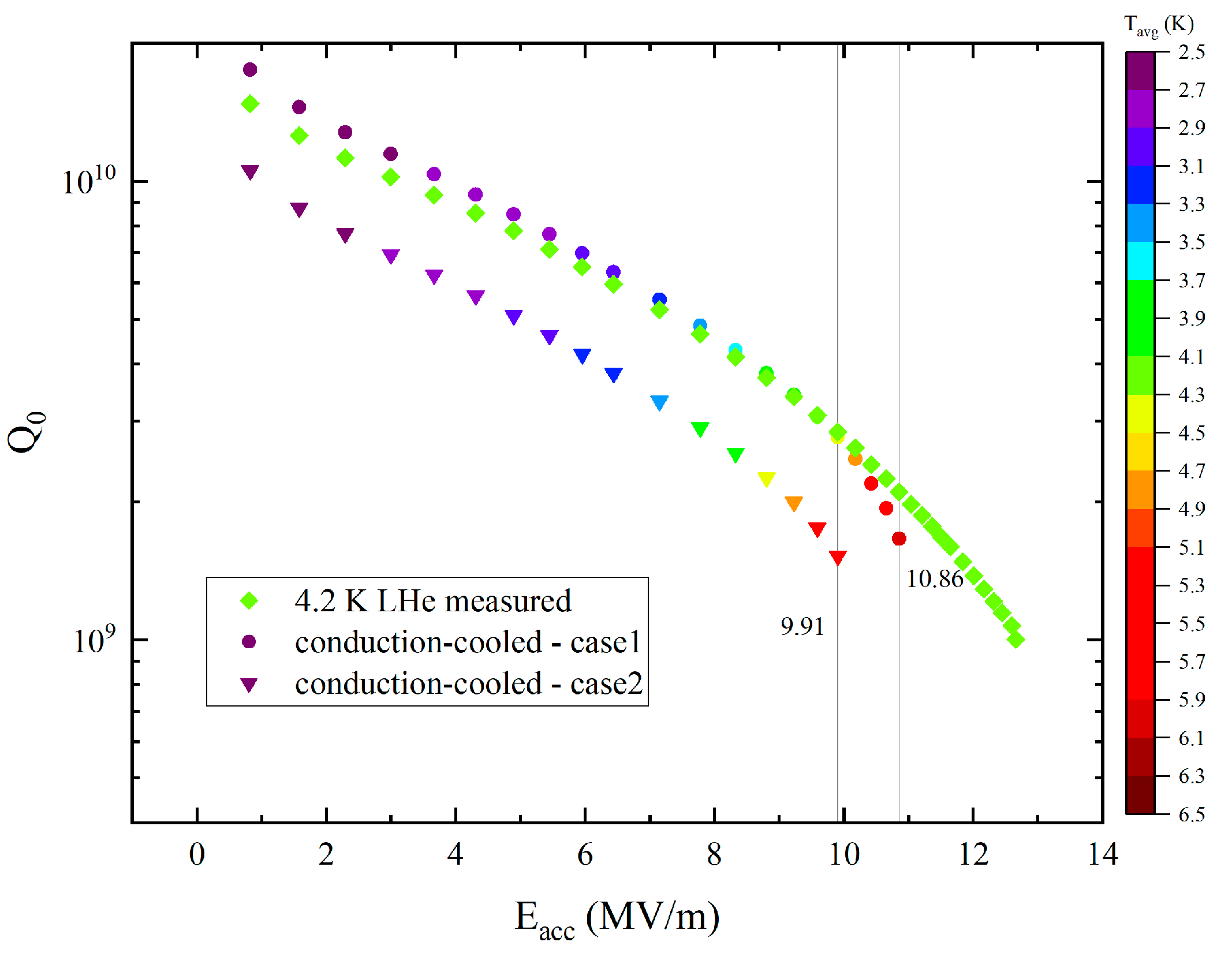

4.4. Simulation of RF Performance of NS03 Cavity

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Workshop on Energy and Environmental Applications of Accelerators. 2015. Available online: https://www.osti.gov/biblio/1358082 (accessed on 20 July 2024).

- Henning, W.; Shank, C. Accelerators for America’s Future. 2010. Available online: https://science.osti.gov/-/media/hep/pdf/files/pdfs/Accel_for_Americas_Future_final_report.pdf (accessed on 20 July 2024).

- Chmielewski, A.G. Electron Accelerators for Environmental Protection. Rev. Accel. Sci. Technol. 2011, 4, 147–159. [Google Scholar] [CrossRef]

- Schoenlein, R.; Elsaesser, T.; Holldack, K.; Huang, Z.; Kapteyn, H.; Murnane, M.; Woerner, M. Recent Advances in Ultrafast X-Ray Sources. Philos. Trans. R. Soc. A 2019, 377, 20180384. [Google Scholar] [CrossRef] [PubMed]

- Dohmae, T.; Umemori, K.; Yamanaka, M.; Watanabe, Y.; Inoue, H. Investigation of In-House Superconducting Radio-Frequency 9-Cell Cavity Made of Large Grain Niobium at KEK. Nucl. Instrum. Methods Phys. Res. A 2017, 875, 1–9. [Google Scholar] [CrossRef]

- Reschke, D.; Gubarev, V.; Schaffran, J.; Steder, L.; Walker, N.; Wenskat, M.; Monaco, L. Performance in the Vertical Test of the 832 Nine-Cell 1.3 GHz Cavities for the European X-Ray Free Electron Laser. Phys. Rev. Accel. Beams 2017, 20, 042004. [Google Scholar] [CrossRef]

- Gonnella, D.; Aderhold, S.; Burrill, A.; Daly, E.; Davis, K.; Grassellino, A.; Grimm, C.; Khabiboulline, T.; Marhauser, F.; Melnychuk, O.; et al. Industrialization of the Nitrogen-Doping Preparation for SRF Cavities for LCLS-II. Nucl. Instrum. Methods Phys. Res. A 2018, 883, 143–150. [Google Scholar] [CrossRef]

- McGee, K.; Kim, S.; Elliott, K.; Ganshyn, A.; Hartung, W.; Metzgar, E.; Ostroumov, P.; Popielarski, L.; Popielarski, J.; Taylor, A.; et al. Medium-Velocity Superconducting Cavity for High Accelerating Gradient Continuous-Wave Hadron Linear Accelerators. Phys. Rev. Accel. Beams 2021, 24, 112003. [Google Scholar] [CrossRef]

- Belomestnykh, S. Superconducting Radio-Frequency Systems for High-β Particle Accelerators. Rev. Accel. Sci. Technol. 2012, 5, 147–184. [Google Scholar] [CrossRef]

- Kelly, M. Superconducting Radio-Frequency Cavities for Low-Beta Particle Accelerators. Rev. Accel. Sci. Technol. 2012, 5, 185–203. [Google Scholar] [CrossRef]

- Pudasaini, U.; Ciovati, G.; Eremeev, G.; Kelley, M.; Parajuli, I.; Reece, C. Recent Results from Nb3Sn-Coated Single-Cell Cavities Combined with Sample Studies at Jefferson Lab. In Proceedings of the 10th International Particle Accelerator Conference (IPAC2019), Melbourne, Australia, 19–24 May 2019; JACOW Publishing: Geneva, Switzerland, 2019; pp. 3066–3069. [Google Scholar]

- Hillenbrand, B. The Preparation of Superconducting Nb3Sn Surfaces for RF Applications. 1980. Available online: https://accelconf.web.cern.ch/srf80/papers/srf80-3.pdf (accessed on 20 July 2024).

- Work on Nb3Sn Cavities at Wuppertal. In Proceedings of the Third Workshop on RF Superconductivity, Argonne, IL, USA, 14–18 September 1987; JACoW Publishing: Geneva, Switzerland, 1987; pp. 503–532.

- Mueller, G.; Kneisel, P.; Mansen, D.; Piel, H.; Pouryamout, J.; Roeth, R.W. Nb3Sn Layers on High-Purity Nb Cavities with Very High Quality Factors and Accelerating Gradients. In Proceedings of the 5th European Particle Accelerator Conference (EPAC*96), Sitges, Spain, 10–14 June 1996; JACoW Publishing: Geneva, Switzerland, 1996; pp. 2085–2087. [Google Scholar]

- Posen, S.; Liepe, M. Advances in Development of Nb3Sn Superconducting Radio-Frequency Cavities. Phys. Rev. Spec. Top.-Accel. Beams 2014, 17, 112001. [Google Scholar] [CrossRef]

- Posen, S.; Liepe, M.; University, C. Nb3Sn-Present Status and Potential as an Alternative SRF Material. In Proceedings of the 27th Linear Accelerator Conference, LINAC2014, Geneva, Switzerland, 31 August–5 September 2014; JACOW Publishing: Geneva, Switzerland, 2014; pp. 431–436. [Google Scholar]

- Porter, R.; Arias, T.; Cueva, P.; Hall, D.; Liepe, M.; Maniscalco, J.; Muller, D.; Sitaraman, N. Next Generation Nb3Sn SRF Cavities for Linear Accelerators. In Proceedings of the 29th Linear Accelerator Conference (LINAC’18), Beijing, China, 16–21 September 2018; JACOW Publishing: Geneva, Switzerland, 2019; pp. 462–465. [Google Scholar]

- Posen, S.; Lee, J.; Seidman, D.N.; Romanenko, A.; Tennis, B.; Melnychuk, O.S.; Sergatskov, D.A. Advances in Nb 3 Sn Superconducting Radiofrequency Cavities towards First Practical Accelerator Applications. Supercond. Sci. Technol. 2021, 34, 025007. [Google Scholar] [CrossRef]

- Yang, Z.; Huang, S.; He, Y.; Lu, X.; Guo, H.; Li, C.; Niu, X.; Xiong, P.; Song, Y.; Wu, A.; et al. Low-Temperature Baking Effect of the Radio-Frequency Nb 3 Sn Thin Film Superconducting Cavity. Chin. Phys. Lett. 2021, 38, 092901. [Google Scholar] [CrossRef]

- Jiang, G.; Wu, S.; Yang, Z.; He, Y.; Ye, Y.; Guo, H.; Li, C.; Xiong, P.; Li, L.; Huang, S.; et al. Understanding and Optimization of the Coating Process of the Radio-Frequency Nb3Sn Thin Film Superconducting Cavities Using Tin Vapor Diffusion Method. Appl. Surf. Sci. 2024, 643, 158708. [Google Scholar] [CrossRef]

- Dong, C.; Lin, Z.; Sha, P.; Liu, B.; Ye, L.; He, X. Preliminary Research of Niobium Cavity Coating with Nb3Sn Film at IHEP. Phys. C Supercond. Its Appl. 2022, 600, 1354107. [Google Scholar] [CrossRef]

- Chen, Q.; Zong, Y.; Wang, Z.; Xing, S.; Wu, J.; Dong, P.; Zhao, M.; Wu, X.; Rong, J.; Chen, J. First Results of Nb3Sn Coated Cavity by Vapor Diffusion Method at SARI. Coatings 2024, 14, 581. [Google Scholar] [CrossRef]

- Wang, G.; Quan, S.; Lin, L.; Ren, M.; Hao, J.; Wang, F.; Jiao, F.; Zhu, F.; Huang, S.; Yan, X.; et al. Nb3Sn Cavities Coated by Tin Vapor Diffusion Method at Peking University. Appl. Sci. 2023, 13, 8618. [Google Scholar] [CrossRef]

- Takahashi, K.; Ito, H.; Kako, E.; Konomi, T.; Okada, T.; Sakai, H.; Umemori, K. First Nb3Sn Coating and Cavity Performance Result at KEK. In Proceedings of the 20th International Conference on RF Superconductivity (SRF’21), East Lansing, MI, USA, 28 June–2 July 2021; JACOW Publishing: Geneva, Switzerland, 2022; pp. 27–31. [Google Scholar]

- Dhuley, R.C.; Posen, S.; Geelhoed, M.I.; Prokofiev, O.; Thangaraj, J.C.T. First Demonstration of a Cryocooler Conduction Cooled Superconducting Radiofrequency Cavity Operating at Practical Cw Accelerating Gradients. Supercond. Sci. Technol. 2020, 33, 06LT01. [Google Scholar] [CrossRef]

- Ciovati, G.; Anderson, J.; Balachandran, S.; Cheng, G.; Coriton, B.; Daly, E.; Dhakal, P.; Gurevich, A.; Hannon, F.; Harding, K.; et al. Development of a Prototype Superconducting Radio-Frequency Cavity for Conduction-Cooled Accelerators. Phys. Rev. Accel. Beams 2023, 26, 044701. [Google Scholar] [CrossRef]

- Ciovati, G.; Cheng, G.; Pudasaini, U.; Rimmer, R.A. Multi-Metallic Conduction Cooled Superconducting Radio-Frequency Cavity with High Thermal Stability. Supercond. Sci. Technol. 2020, 33, 07LT01. [Google Scholar] [CrossRef]

- Stilin, N.A.; Holic, A.; Liepe, M.; Porter, R.D.; Sears, J.; Sun, Z. RF and Thermal Studies on Conduction Cooled Nb3Sn SRF Cavity. Eng. Res. Express 2023, 5, 025078. [Google Scholar] [CrossRef]

- Dhuley, R.C.; Gonin, I.; Kazakov, S.; Khabiboulline, T.; Sukhanov, A.; Yakovlev, V.; Saini, A.; Solyak, N.; Sauers, A.; Thangaraj, J.C.T.; et al. Design of a 10 MeV, 1000 kW Average Power Electron-Beam Accelerator for Wastewater Treatment Applications. Phys. Rev. Accel. Beams 2022, 25, 041601. [Google Scholar] [CrossRef]

- Ciovati, G.; Anderson, J.; Coriton, B.; Guo, J.; Hannon, F.; Holland, L.; LeSher, M.; Marhauser, F.; Rathke, J.; Rimmer, R.; et al. Design of a Cw, Low-Energy, High-Power Superconducting Linac for Environmental Applications. Phys. Rev. Accel. Beams 2018, 21, 091601. [Google Scholar] [CrossRef]

- Stilin, N.; Conklin, H.; Gruber, T.; Holic, A.; Liepe, M.; O’Connell, T.; Quigley, P.; Sears, J.; Shemelin, V.; Turco, J. Conduction-Cooled SRF Cavities: Opportunities and Challenges. In Proceedings of the 21th International Conference on RF Superconductivity (SRF’23), Grand Rapids, MI, USA, 25–30 June 2023; JACOW Publishing: Geneva, Switzerland, 2023; pp. 973–977. [Google Scholar]

- Kubiczek, K.; Durandetto, P.; Capra, P.P.; Francese, C.; Lanzillotti, M.; Roncaglione, L.; Kampik, M.; Sosso, A. Direct Calibration of a True-Rms Ac Voltmeter against a He-Free Pulsed Josephson Standard. Measurement 2024, 236, 114981. [Google Scholar] [CrossRef]

- Padamsee, H.; Knobloch, J.; Hays, T.; Wilson, P.B. RF Superconductivity for Accelerators; Wiley: Hoboken, NJ, USA, 1998; Volume 52, ISBN 0-471-15432-6. [Google Scholar]

- Woodcraft, A.L. Recommended Values for the Thermal Conductivity of Aluminium of Different Purities in the Cryogenic to Room Temperature Range, and a Comparison with Copper. Cryogenics 2005, 45, 626–636. [Google Scholar] [CrossRef]

- Didschuns, I.; Woodcraft, A.L.; Bintley, D.; Hargrave, P.C. Thermal Conductance Measurements of Bolted Copper to Copper Joints at Sub-Kelvin Temperatures. Cryogenics 2004, 44, 293–299. [Google Scholar] [CrossRef]

- Dhuley, R.C.; Ruschman, M.; Link, J.T.; Eyre, J. Thermal Conductance Characterization of a Pressed Copper Rope Strap between 0.13 K and 10 K. Cryogenics 2017, 86, 17–21. [Google Scholar] [CrossRef]

- Hall, D.L. New Insights into the Limitations on the Efficiency and Achievable Gradients in Nb3Sn SRF Cavities. Ph.D. Thesis, Cornell University, Ithaca, NY, USA, 2017. [Google Scholar]

- Miyazaki, A.; Delsolaro, W.V. Two Different Origins of the Q-Slope Problem in Superconducting Niobium Film Cavities for a Heavy Ion Accelerator at CERN. Phys. Rev. Accel. Beams 2019, 22, 073101. [Google Scholar] [CrossRef]

| Pathway | Position | 50 K | 10 K | 4 K |

|---|---|---|---|---|

| Radiation | Vacuum vessel—outer thermal shield | 42.4 | - | |

| Outer thermal shield—inner thermal shield | 0.393 | |||

| Inner thermal shield—SRF cavity | 0.001 | |||

| Conduction | G10 or titanium rods | 0.3 | 0.24 | 0.003 |

| RF cables | 0.6 | 0.17 | 0.013 | |

| Thermometer leads | 0.1 | 0.006 | 0.001 | |

| Total | 43.4 | 0.809 | 0.018 |

| Cavity | Tin Weights/g | Tin Chloride Weights/g | Nucleation Temperature/°C | Nucleation Time/min | Coating Temperature/°C | Coating Time/min | Annealing Temperature/°C | Annealing Time/min |

|---|---|---|---|---|---|---|---|---|

| NS04 | 0.6 + 0.8 + 1.0 | 3 | 500 | 270 | 1150 | 80 | 1100 | 60 |

| NS03 | 0.2 + 0.5 + 0.8 | 3 | 500 | 300 | 1200 | 180 | 1100 | 60 |

| Cooldown | Cooling Rate/ K/min | Temperature Gradient/K/m | /mG | /mG | /mG |

|---|---|---|---|---|---|

| 1 | 2.55 | 8.72 | 4.04 | 6.71 | −2.47 |

| 2 | 12.39 | 0.86 | 9.79 | −1.60 | −1.35 |

| 3 | 0.06 | 0.17 | 10.15 | −1.08 | −0.81 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, M.; Lin, L.; Hao, J.; Wang, G.; Wang, Z.; Wang, D.; Shen, H.; Quan, S.; Wang, F.; Feng, L.; et al. Continuous Wave Mode Test of Conduction-Cooled Nb3Sn Radio Frequency Superconducting Cavities at Peking University. Appl. Sci. 2024, 14, 6350. https://doi.org/10.3390/app14146350

Ren M, Lin L, Hao J, Wang G, Wang Z, Wang D, Shen H, Quan S, Wang F, Feng L, et al. Continuous Wave Mode Test of Conduction-Cooled Nb3Sn Radio Frequency Superconducting Cavities at Peking University. Applied Sciences. 2024; 14(14):6350. https://doi.org/10.3390/app14146350

Chicago/Turabian StyleRen, Manqian, Lin Lin, Jiankui Hao, Gai Wang, Ziyu Wang, Deyang Wang, Haoyu Shen, Shengwen Quan, Fang Wang, Liwen Feng, and et al. 2024. "Continuous Wave Mode Test of Conduction-Cooled Nb3Sn Radio Frequency Superconducting Cavities at Peking University" Applied Sciences 14, no. 14: 6350. https://doi.org/10.3390/app14146350

APA StyleRen, M., Lin, L., Hao, J., Wang, G., Wang, Z., Wang, D., Shen, H., Quan, S., Wang, F., Feng, L., Jiao, F., Zhu, F., Zhu, K., Yan, X., & Huang, S. (2024). Continuous Wave Mode Test of Conduction-Cooled Nb3Sn Radio Frequency Superconducting Cavities at Peking University. Applied Sciences, 14(14), 6350. https://doi.org/10.3390/app14146350