A Study on Three-Dimensional Multi-Cluster Fracturing Simulation under the Influence of Natural Fractures

Abstract

1. Introduction

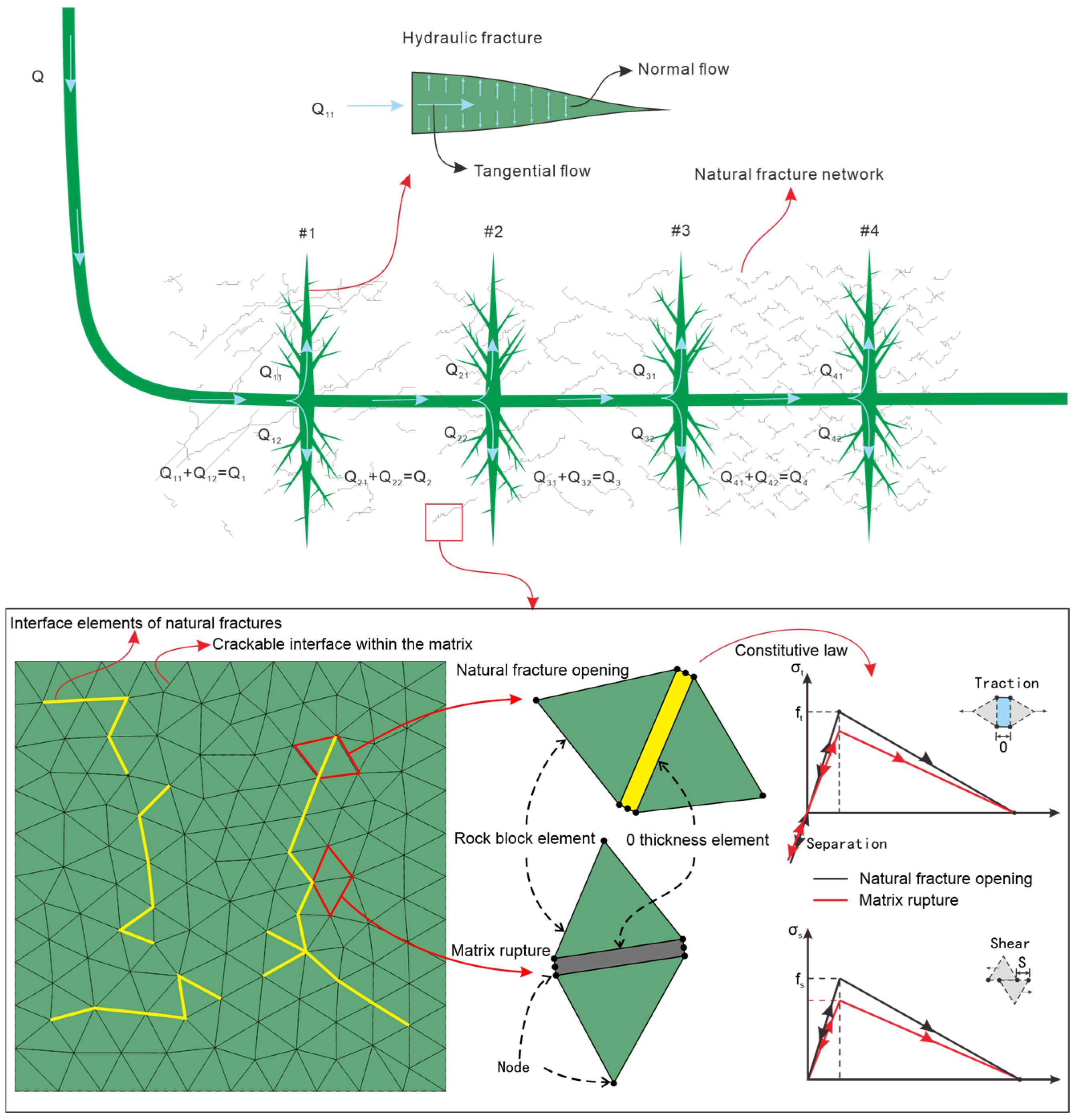

2. Numerical Model

2.1. Simulation Method

2.2. Model Setup

3. Results and Analysis

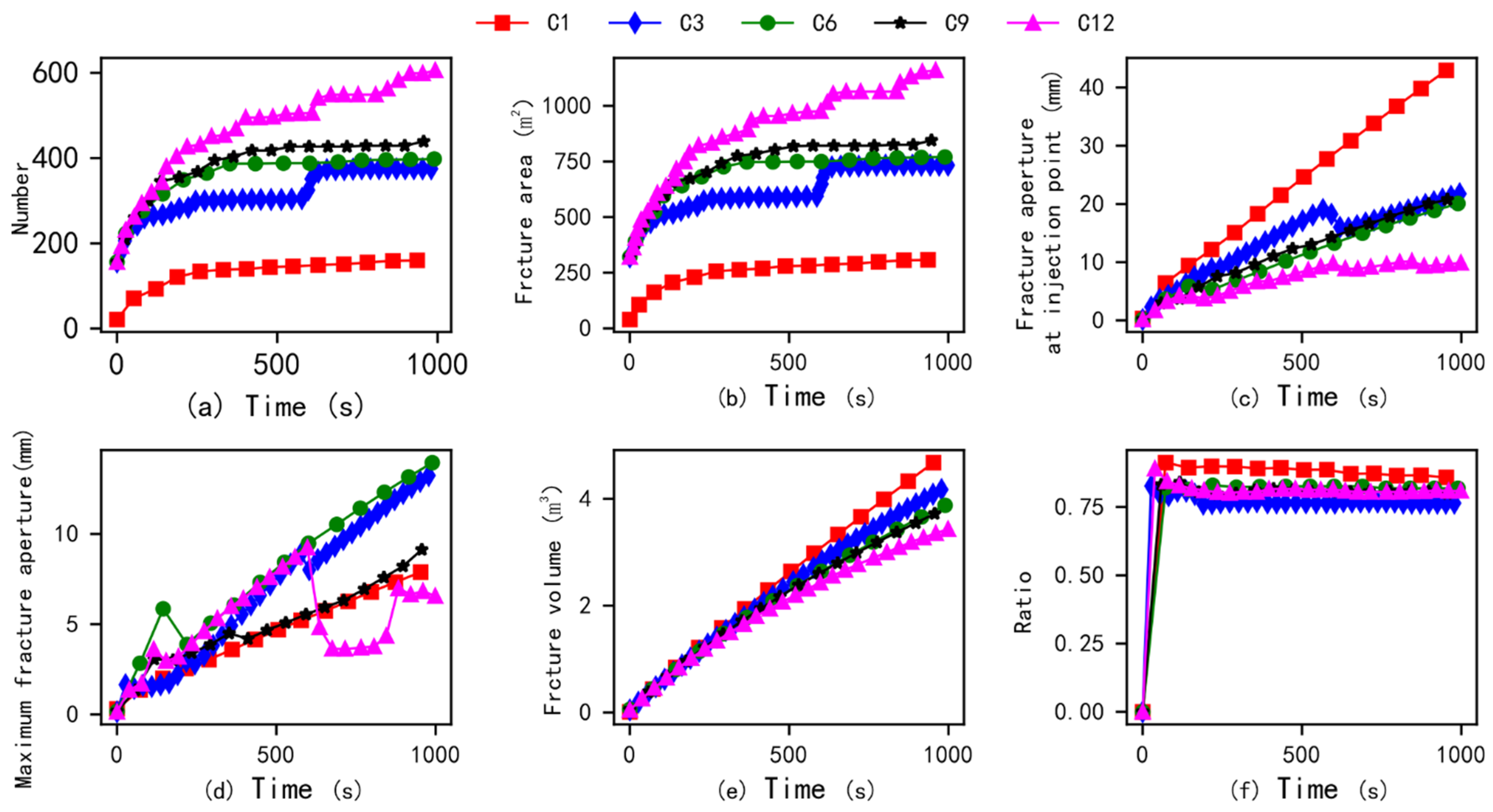

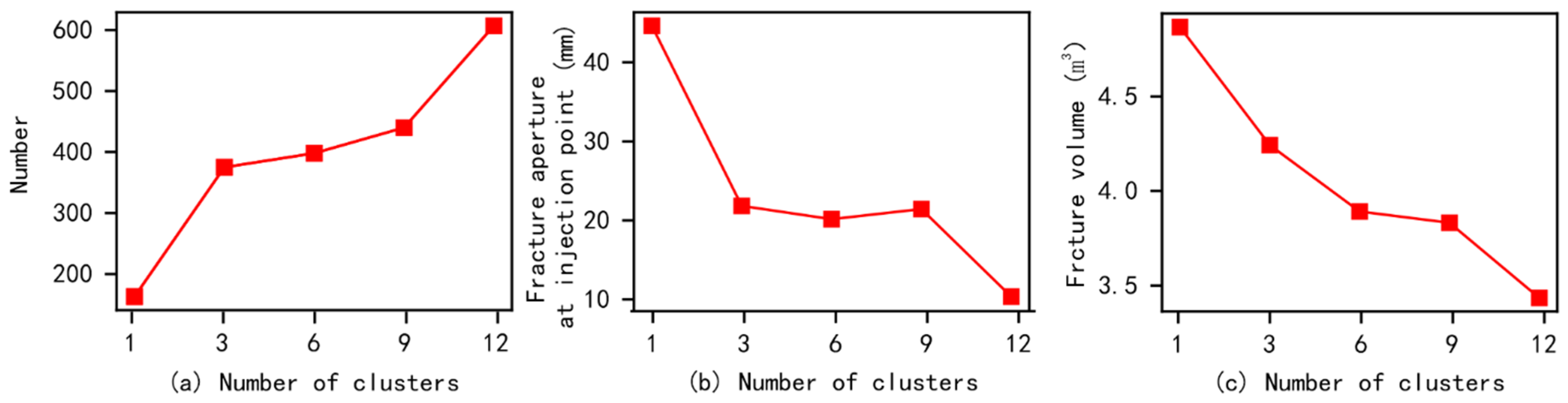

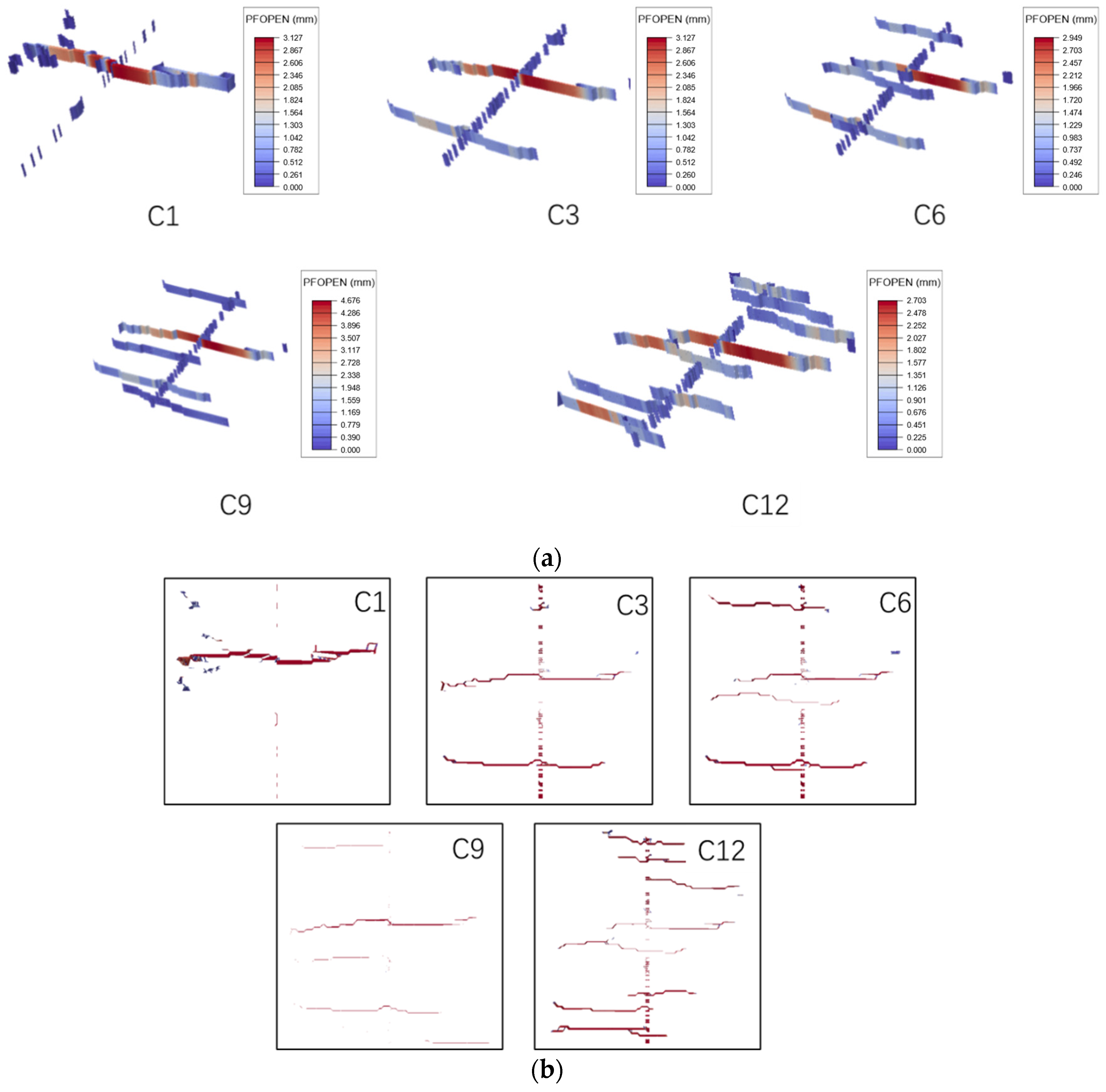

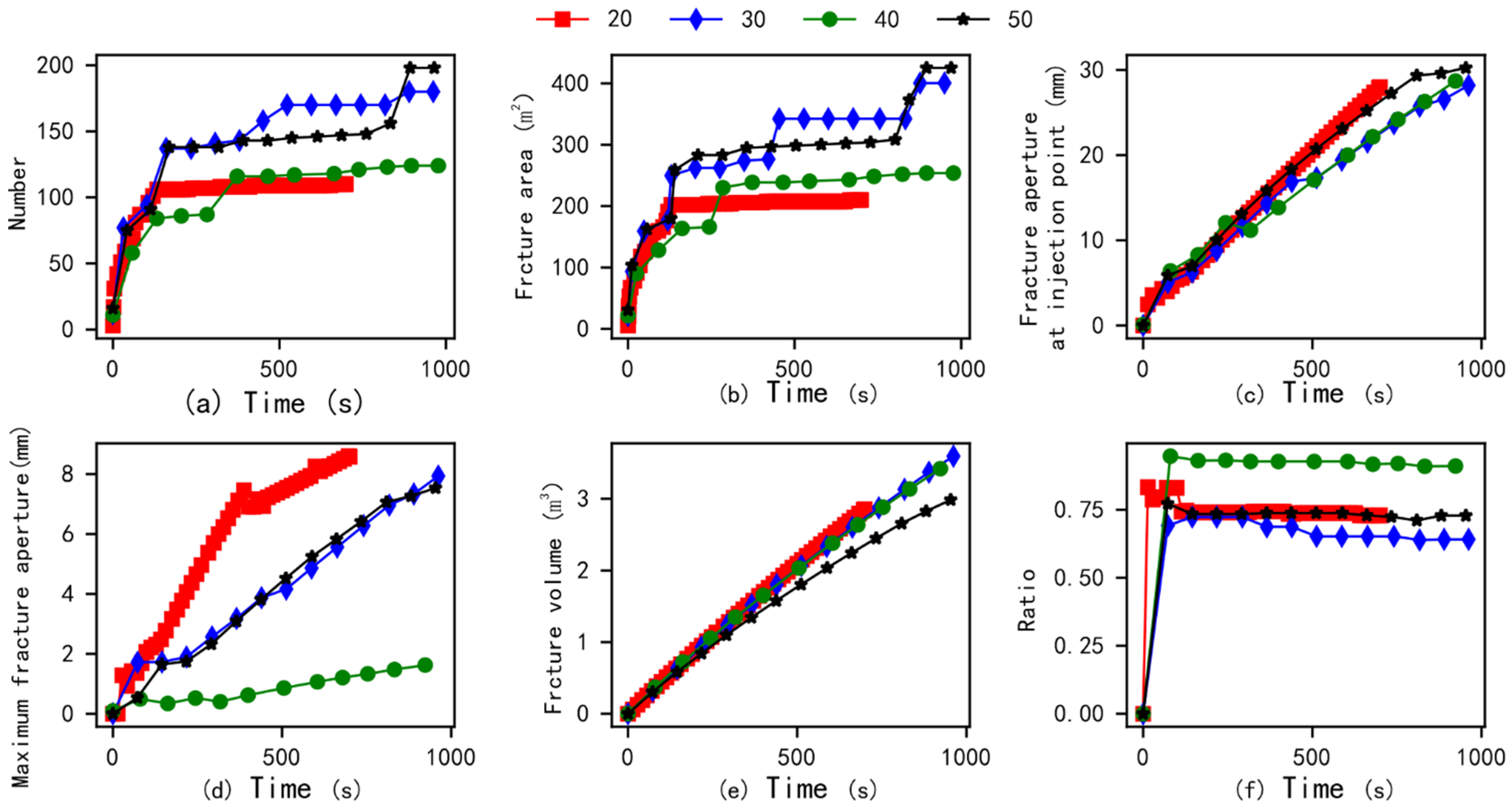

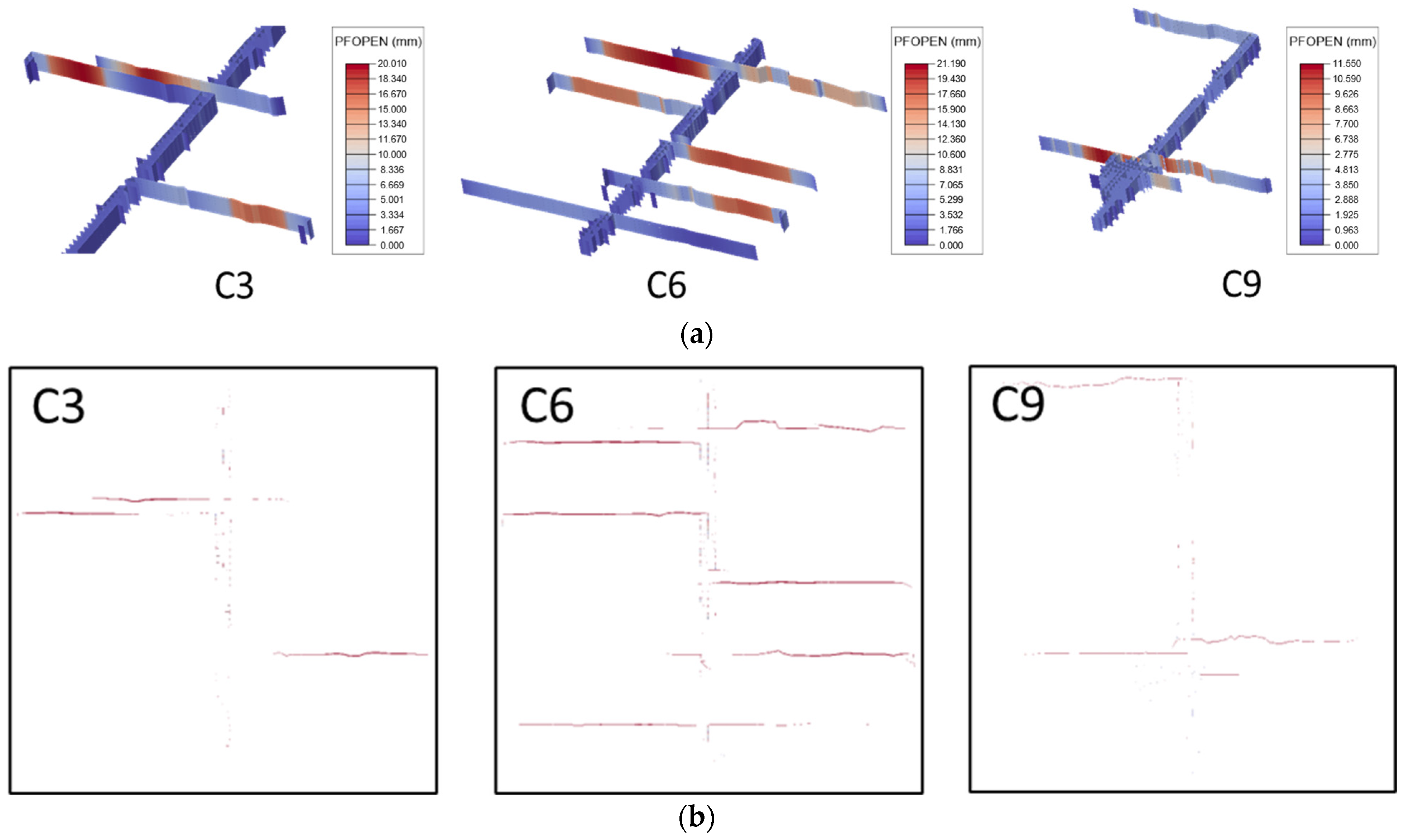

3.1. Effect of Fracturing Cluster Number

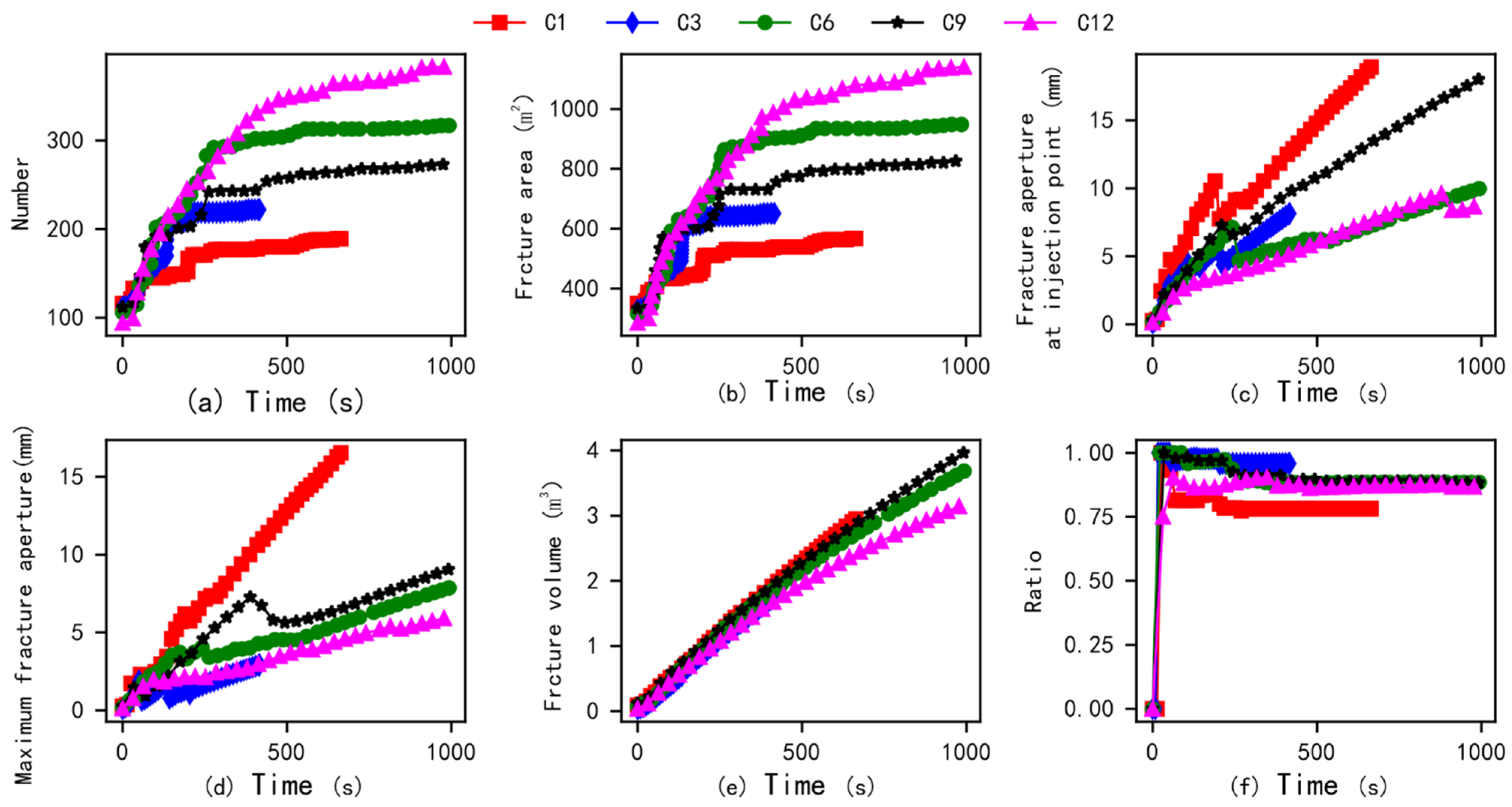

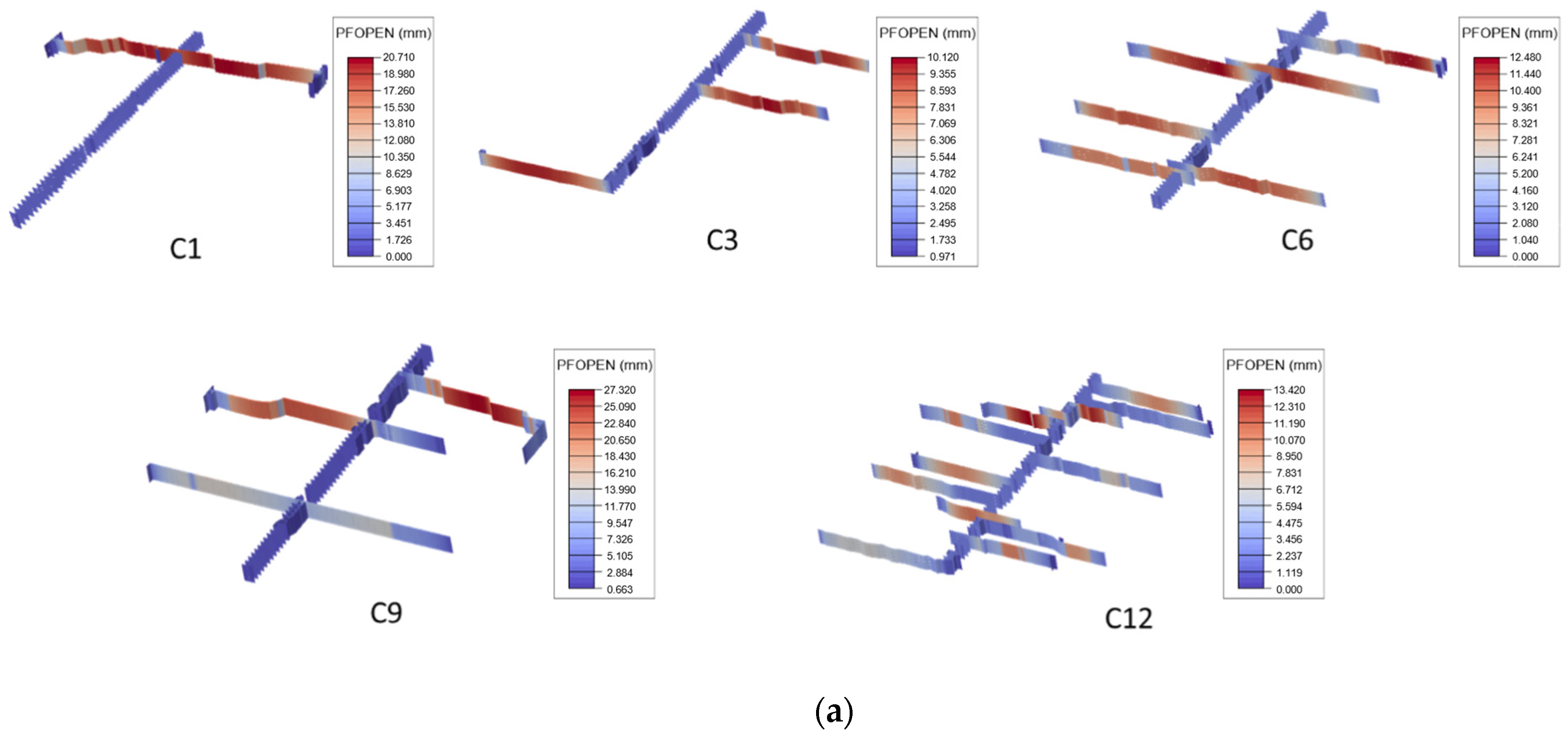

3.2. Effect of Number of Natural Fractures

3.3. Comprehensive Impact Analysis

4. Conclusions

- (1)

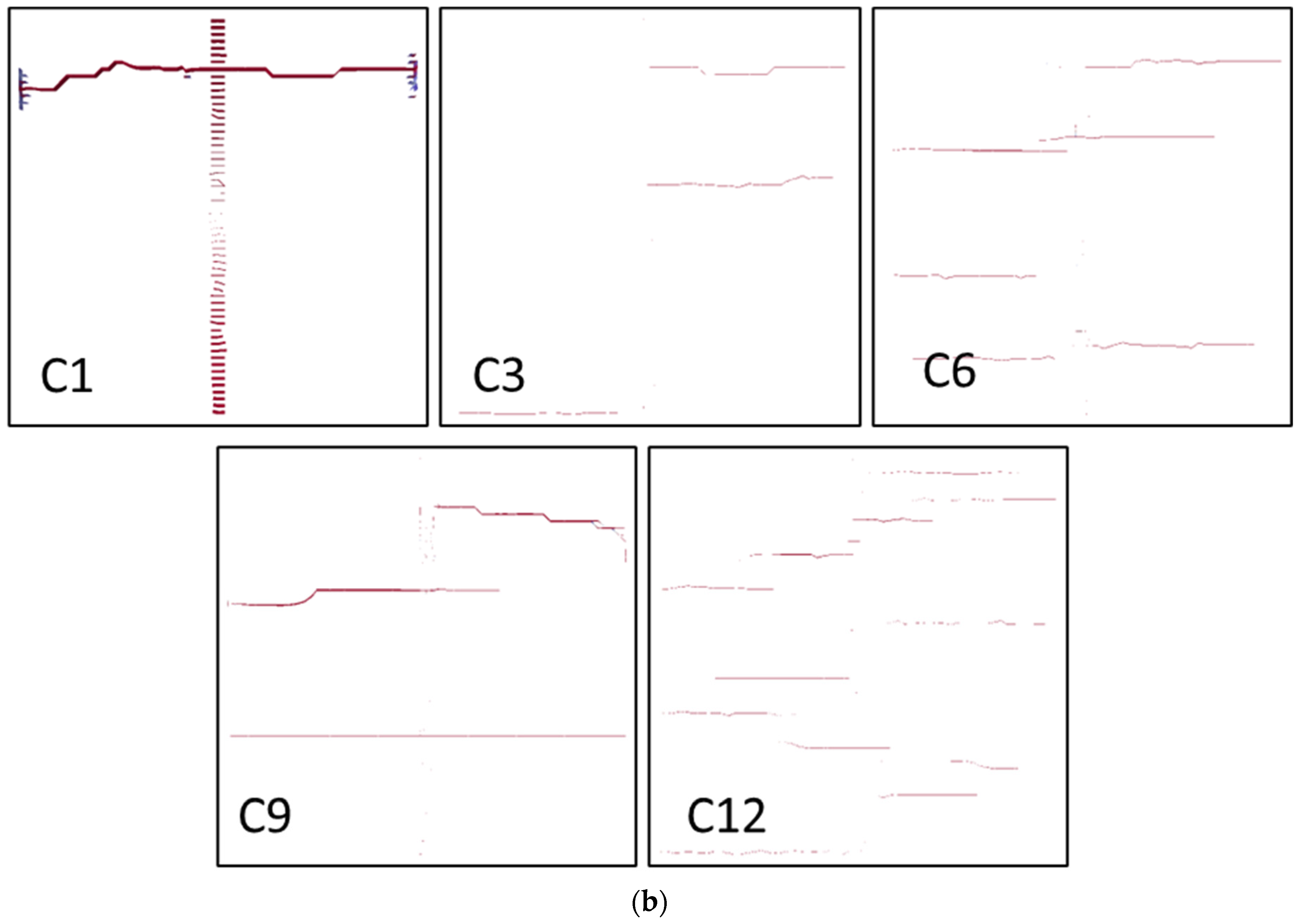

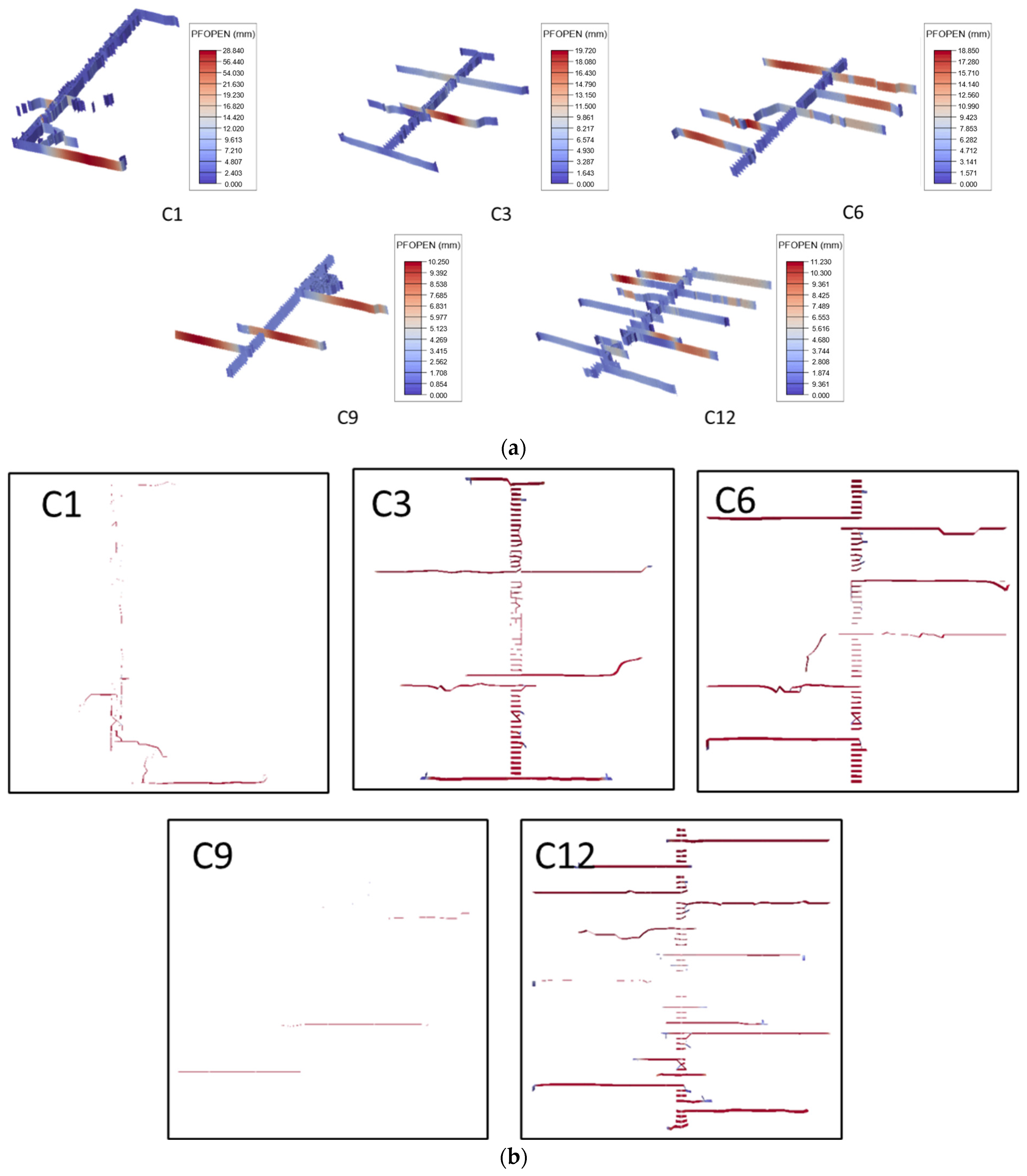

- As the number of fracturing clusters increases, the number of artificial main fractures formed in the target block shows a significant increasing trend. However, when affected by the distribution of natural fractures, geo-stress, and other factors, it may also be difficult to form multiple main fractures through multi-cluster fracturing in the target block (Figure 9). Therefore, obtaining data on the spatial location and orientation of natural fractures may be more helpful in accurately estimating the fracturing effect of the target block.

- (2)

- Due to the influence of the original random fracturing path and natural fractures of the reservoir, shear stimulation phenomena are prone to occur. Under these conditions, artificial fractures in the reservoir are prone to bending, branching, and other phenomena. When further affected by multiple construction methods, the artificial main fracture will be more prone to single-wing expansion rather than double-wing expansion.

- (3)

- Multi-cluster fracturing construction may promote an increase in artificial fracture networks, but under the same injection amount, the aperture of artificial fractures will decrease. Therefore, increasing the injection rate appropriately during multi-cluster construction will be more conducive to the pumping of proppants and other materials.

- (4)

- The increase in the number of natural fractures in the target block will help to obtain a more complex artificial fracture network. When the number of natural fractures reaches a certain threshold, even using a single-cluster fracturing construction process may form an artificial fracture network connected by multiple main fractures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wu, M.; Liu, J.; Lv, X.; Shi, D.; Zhu, Z. A study on homogenization equations of fractal porous media. J. Geophys. Eng. 2018, 15, 2388–2398. [Google Scholar] [CrossRef]

- Zheng, Y.; He, R.; Huang, L.; Bai, Y.; Wang, C.; Chen, W.; Wang, W. Exploring the effect of engineering parameters on the penetration of hydraulic fractures through bedding planes in different propagation regimes. Comput. Geotech. 2022, 146, 104736. [Google Scholar] [CrossRef]

- Liu, Q.; Li, J.; Liang, B.; Liu, J.; Sun, W.; He, J.; Lei, Y. Complex wettability behavior triggering mechanism on imbibition: A model construction and comparative study based on analysis at multiple scales. Energy 2023, 275, 127434. [Google Scholar] [CrossRef]

- Song, R.; Liu, J.; Cui, M. A new method to reconstruct structured mesh model from micro-computed tomography images of porous media and its application. Int. J. Heat Mass Transf. 2017, 109, 705–715. [Google Scholar] [CrossRef]

- Wang, L.; Zhou, J.; Guo, Y.; Song, X.; Guo, W. Laboratory investigation and evaluation of the hydraulic fracturing of marine shale considering multiple geological and engineering factors. Front. Earth Sci. 2022, 10, 952655. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, J.; Li, Z.; Hu, H.; Mei, Y. Numerical Simulation of Multi-cluster Fracturing Using the Triaxiality Dependent Cohesive Zone Model in a Shale Reservoir with Mineral Heterogeneity. Rock Mech. Rock Eng. 2023, 57, 325–349. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Lee, J.H.; Elraies, K.A. A review of PKN-type modeling of hydraulic fractures. J. Pet. Sci. Eng. 2020, 195, 107607. [Google Scholar] [CrossRef]

- Yew, C.H.; Weng, X. Chapter 1—Fracturing of a wellbore and 2D fracture models. In Mechanics of Hydraulic Fracturing, 2nd ed.; Gulf Professional Publishing: Boston, MA, USA, 2015; pp. 1–22. [Google Scholar]

- Dontsov, E.V.; Peirce, A.P. Proppant transport in hydraulic fracturing: Crack tip screen-out in KGD and P3D models. Int. J. Solids Struct. 2015, 63, 206–218. [Google Scholar] [CrossRef]

- Santillán, D.; Juanes, R.; Cueto-Felgueroso, L. Phase field model of fluid-driven fracture in elastic media: Immersed-fracture formulation and validation with analytical solutions. J. Geophys. Res. Solid Earth 2017, 122, 2565–2589. [Google Scholar] [CrossRef]

- Song, R.; Liu, J.; Yang, C.; Sun, S. Study on the multiphase heat and mass transfer mechanism in the dissociation of methane hydrate in reconstructed real-shape porous sediments. Energy 2022, 254, 124421. [Google Scholar] [CrossRef]

- Song, R.; Wang, Y.; Ishutov, S.; Zambrano-Narvaez, G.; Hodder, K.J.; Chalaturnyk, R.J.; Sun, S.; Liu, J.; Gamage, R.P. A Comprehensive Experimental Study on Mechanical Behavior, Microstructure and Transport Properties of 3D-printed Rock Analogs. Rock Mech. Rock Eng. 2020, 53, 5745–5765. [Google Scholar] [CrossRef]

- Guo, C.; Xu, J.; Wei, M.; Jiang, R. Experimental study and numerical simulation of hydraulic fracturing tight sandstone reservoirs. Fuel 2015, 159, 334–344. [Google Scholar] [CrossRef]

- Moghadasi, R.; Rostami, A.; Hemmati-Sarapardeh, A. Application of nanofluids for treating fines migration during hydraulic fracturing: Experimental study and mechanistic understanding. Adv. Geo-Energy Res. 2019, 3, 100–111. [Google Scholar] [CrossRef]

- Yang, R.; Wang, Y.; Song, G.; Shi, Y. Fracturing and thermal extraction optimization methods in enhanced geothermal systems. Adv. Geo-Energy Res. 2023, 8, 136–140. [Google Scholar] [CrossRef]

- Chen, B.; Barboza, B.R.; Sun, Y.; Bai, J.; Thomas, H.R.; Dutko, M.; Cottrell, M.; Li, C. A Review of Hydraulic Fracturing Simulation. Arch. Comput. Methods Eng. 2022, 29, 1–58. [Google Scholar] [CrossRef]

- Yuan, J.; Jiang, R.; Zhang, W. The workflow to analyze hydraulic fracture effect on hydraulic fractured horizontal well production in composite formation system. Adv. Geo-Energy Res. 2018, 2, 319–342. [Google Scholar] [CrossRef]

- Esfandiari, M.; Pak, A. XFEM modeling of the effect of in-situ stresses on hydraulic fracture characteristics and comparison with KGD and PKN models. J. Pet. Explor. Prod. Technol. 2023, 13, 185–201. [Google Scholar] [CrossRef]

- Huang, L.; Liu, J.; Zhang, F.; Dontsov, E.; Damjanac, B. Exploring the influence of rock inherent heterogeneity and grain size on hydraulic fracturing using discrete element modeling. Int. J. Solids Struct. 2019, 176–177, 207–220. [Google Scholar] [CrossRef]

- Huang, L.; Liu, J.; Zhang, F.; Fu, H.; Zhu, H.; Damjanac, B. 3D lattice modeling of hydraulic fracture initiation and near-wellbore propagation for different perforation models. J. Pet. Sci. Eng. 2020, 191, 107169. [Google Scholar] [CrossRef]

- Zhu, X.; Feng, C.; Cheng, P.; Wang, X.; Li, S. A novel three-dimensional hydraulic fracturing model based on continuum–discontinuum element method. Comput. Methods Appl. Mech. Eng. 2021, 383, 113887. [Google Scholar] [CrossRef]

- Wu, M.; Jiang, C.; Song, R.; Liu, J.; Li, M.; Liu, B.; Shi, D.; Zhu, Z.; Deng, B. Comparative study on hydraulic fracturing using different discrete fracture network modeling: Insight from homogeneous to heterogeneity reservoirs. Eng. Fract. Mech. 2023, 284, 109274. [Google Scholar] [CrossRef]

- Huang, L.; Dontsov, E.; Fu, H.; Lei, Y.; Weng, D.; Zhang, F. Hydraulic fracture height growth in layered rocks: Perspective from DEM simulation of different propagation regimes. Int. J. Solids Struct. 2022, 238, 111395. [Google Scholar] [CrossRef]

- Huang, L.; Tan, J.; Fu, H.; Liu, J.; Chen, X.; Liao, X.; Wang, X.; Wang, C. The non-plane initiation and propagation mechanism of multiple hydraulic fractures in tight reservoirs considering stress shadow effects. Eng. Fract. Mech. 2023, 292, 109570. [Google Scholar] [CrossRef]

- Wu, M.; Zhang, D.M.; Wang, W.S.; Li, M.H.; Liu, S.M.; Lu, J.; Gao, H. Numerical simulation of hydraulic fracturing based on two-dimensional surface fracture morphology reconstruction and combined finite-discrete element method. J. Nat. Gas Sci. Eng. 2020, 82, 103479. [Google Scholar] [CrossRef]

- Wu, M.; Wang, W.; Zhang, D.; Deng, B.; Liu, S.; Lu, J.; Luo, Y.; Zhao, W. The pixel crack reconstruction method: From fracture image to crack geological model for fracture evolution simulation. Constr. Build. Mater. 2020, 273, 121733. [Google Scholar] [CrossRef]

- Wu, M.; Wang, W.; Song, Z.; Liu, B.; Feng, C. Exploring the influence of heterogeneity on hydraulic fracturing based on the combined finite–discrete method. Eng. Fract. Mech. 2021, 252, 107835. [Google Scholar] [CrossRef]

- Liu, Q.; Sun, L.; Liu, P.; Chen, L. Modeling Simultaneous Multiple Fracturing Using the Combined Finite-Discrete Element Method. Geofluids 2018, 2018, 4252904. [Google Scholar] [CrossRef]

- Rougier, E.; Munjiza, A.; Lei, Z.; Chau, V.T.; Knight, E.E.; Hunter, A.; Srinivasan, G. The combined plastic and discrete fracture deformation framework for FDEM. Int. J. Numer. Methods Eng. 2019, 121, 1020–1035. [Google Scholar] [CrossRef]

- Yan, C.; Jiao, Y.-Y.; Zheng, H. A fully coupled three-dimensional hydro-mechanical finite discrete element approach with real porous seepage for simulating 3D hydraulic fracturing. Comput. Geotech. 2018, 96, 73–89. [Google Scholar] [CrossRef]

- Wu, Z.; Sun, H.; Wong, L.N.Y. A Cohesive Element-Based Numerical Manifold Method for Hydraulic Fracturing Modelling with Voronoi Grains. Rock Mech. Rock Eng. 2019, 52, 2335–2359. [Google Scholar] [CrossRef]

- Wu, M.; Gao, K.; Liu, J.; Song, Z.; Huang, X. Influence of rock heterogeneity on hydraulic fracturing: A parametric study using the combined finite-discrete element method. Int. J. Solids Struct. 2022, 234–235, 111293. [Google Scholar] [CrossRef]

- Wu, Z.; Xu, X.; Liu, Q.; Yang, Y. A zero-thickness cohesive element-based numerical manifold method for rock mechanical behavior with micro-Voronoi grains. Eng. Anal. Bound. Elem. 2018, 96, 94–108. [Google Scholar] [CrossRef]

- Sharafisafa, M.; Aliabadian, Z.; Sato, A.; Shen, L. Combined finite-discrete element modelling of hydraulic fracturing in reservoirs with filled joints. Geoenergy Sci. Eng. 2023, 228, 212025. [Google Scholar] [CrossRef]

- Shi, F.; Wang, D.; Li, H. An XFEM-based approach for 3D hydraulic fracturing simulation considering crack front segmentation. J. Pet. Sci. Eng. 2022, 214, 110518. [Google Scholar] [CrossRef]

- Cramer, D.; Friehauf, K.; Roberts, G.; Whittaker, J. Integrating DAS, Treatment Pressure Analysis and Video-Based Perforation Imaging to Evaluate Limited Entry Treatment Effectiveness. In Proceedings of the SPE Hydraulic Fracturing Technology Conference and Exhibition, The Woodlands, TX, USA, 5–7 February 2019; p. D031S007R001. [Google Scholar]

- Chen, H.; Meng, X.; Niu, F.; Tang, Y.; Yin, C.; Wu, F. Microseismic Monitoring of Stimulating Shale Gas Reservoir in SW China: 2. Spatial Clustering Controlled by the Preexisting Faults and Fractures. J. Geophys. Res. Solid Earth 2018, 123, 1659–1672. [Google Scholar] [CrossRef]

- Ou, C.; Liang, C.; Li, Z.; Luo, L.; Yang, X. 3D visualization of hydraulic fractures using micro-seismic monitoring: Methodology and application. Petroleum 2022, 8, 92–101. [Google Scholar] [CrossRef]

- Lu, Z.; Jia, Y.; Cheng, L.; Pan, Z.; Xu, L.; He, P.; Guo, X.; Ouyang, L. Microseismic Monitoring of Hydraulic Fracture Propagation and Seismic Risks in Shale Reservoir with a Steep Dip Angle. Nat. Resour. Res. 2022, 31, 2973–2993. [Google Scholar]

- Shang, X.; Long, S.; Duan, T. Fracture system in shale gas reservoir: Prospect of characterization and modeling techniques. J. Nat. Gas Geosci. 2021, 6, 157–172. [Google Scholar] [CrossRef]

- Li, Y.; Cheng, C.H.; Toksöz, M.N. Seismic monitoring of the growth of a hydraulic fracture zone at Fenton Hill, New Mexico. Geophysics 1998, 63, 120–131. [Google Scholar] [CrossRef]

- Dahi Taleghani, A.; Gonzalez-Chavez, M.; Yu, H.; Asala, H. Numerical simulation of hydraulic fracture propagation in naturally fractured formations using the cohesive zone model. J. Pet. Sci. Eng. 2018, 165, 42–57. [Google Scholar] [CrossRef]

- Wang, H. Hydraulic fracture propagation in naturally fractured reservoirs: Complex fracture or fracture networks. J. Nat. Gas Sci. Eng. 2019, 68, 102911. [Google Scholar] [CrossRef]

| Input Parameters | Value |

|---|---|

| Young’s modulus (GPa) | 40 |

| Poisson’s ratio | 0.22 |

| Permeability coefficient (m/s) | 1 × 10−7 |

| Porosity | 0.04 |

| Tensile strength of natural fractures (MPa) | 2 |

| Critical damage displacement of natural fractures (m) | 0.0001 |

| Tensile strength of matrix interfaces (MPa) | 6 |

| Critical damage displacement of matrix interfaces (m) | 0.001 |

| Injection rate (m3/min) | 19–20 |

| Fracturing fluid viscosity (mPa·s) | 1 |

| Pipe roughness (mm) | 0.015 × 10−3 |

| Perforation diameter (m) | 0.01 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Wu, M.; Huang, H.; Guo, Y.; Wang, Y.; Gui, J.; Lu, J. A Study on Three-Dimensional Multi-Cluster Fracturing Simulation under the Influence of Natural Fractures. Appl. Sci. 2024, 14, 6342. https://doi.org/10.3390/app14146342

Li Y, Wu M, Huang H, Guo Y, Wang Y, Gui J, Lu J. A Study on Three-Dimensional Multi-Cluster Fracturing Simulation under the Influence of Natural Fractures. Applied Sciences. 2024; 14(14):6342. https://doi.org/10.3390/app14146342

Chicago/Turabian StyleLi, Yuegang, Mingyang Wu, Haoyong Huang, Yintong Guo, Yujie Wang, Junchuan Gui, and Jun Lu. 2024. "A Study on Three-Dimensional Multi-Cluster Fracturing Simulation under the Influence of Natural Fractures" Applied Sciences 14, no. 14: 6342. https://doi.org/10.3390/app14146342

APA StyleLi, Y., Wu, M., Huang, H., Guo, Y., Wang, Y., Gui, J., & Lu, J. (2024). A Study on Three-Dimensional Multi-Cluster Fracturing Simulation under the Influence of Natural Fractures. Applied Sciences, 14(14), 6342. https://doi.org/10.3390/app14146342