Optimizing Masonry Mortar: Experimental Insights into Physico-Mechanical Properties Using Recycled Aggregates and Natural Fibers

Abstract

1. Introduction

Literature Review on Mortars with Natural Fibers: Coconut, Abaca and Toquilla

2. Materials and Methods

2.1. Materials

2.1.1. Cement

2.1.2. Water

2.1.3. Aggregates

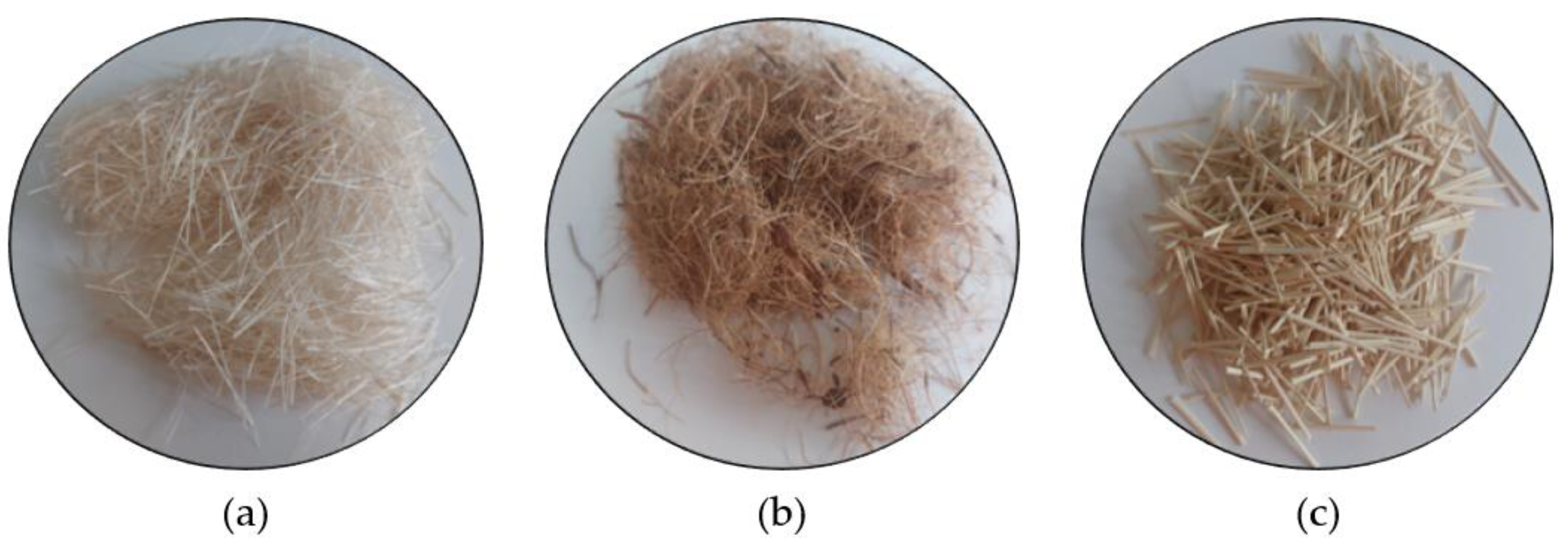

2.1.4. Natural Fibers

2.2. Production Process

2.3. Experimental Programme

- Bulk density of mortars according to UNE-EN 1015-10 [77]. To determine this value, the average of three measurements taken on samples of dimension 4 × 4 × 16 cm3 is used. The bulk density is obtained by dividing the mass of the specimen previously dried in an oven for 24 h (65 ± 5 °C) by the apparent volume of the hardened mortar sample.

- Mortar thermal conductivity was determined according to the UNE-EN ISO 8990:1997 standard [78]. For this purpose, a mini thermal hot-box equipped with thermocouples and a datalogger for accumulating temperature data was used. A total of three samples were tested for each type of mortar, with dimensions of 24 × 24 × 3 cm3. The measurements were taken 24 h after the start of the test to obtain a stationary heat flux.

- Water absorption coefficient by capillarity according to UNE-EN 1015-18 [79]. In this way, six half-samples are obtained from 4 × 4 × 16 cm3 samples so that the fractured face with the open matrix is the one in contact with the water. Thus, these half-samples, previously dried for 24 h in an oven (65 ± 5 °C), are immersed vertically in water to a depth of 10 ± 1 mm. The capillary absorption coefficient is determined with the help of Equation (1):

- Open porosity determined according to UNE-EN 1396 [80]. It is defined as the ratio between the accessible pore volume and mortar apparent volume. To determine this index, a total of three samples of each type were used and Equation (2):

- Mortar shrinkage over time according to the recommendations of the UNE 80-112-89 standard [81]. For this test, three samples of each type of mortar of dimension 2.5 × 2.5 × 28.7 cm3 were used. This test allows the determination of the dimensional stability of the mortars over time and is expressed as the longitudinal variation in mm/m experienced by the samples over 120 days.

- Mortar bonding strength according to UNE-EN 1015-12 [82]. For this purpose, a layer of each mortar type of approximately one centimeter thickness is applied to a previously moistened ceramic block. The ceramic piece is moistened immersed in water for 24 h, in such a way that the suction of the water from the mortar mixing by the ceramic piece is avoided. Subsequently, with the help of adhesion equipment, metal discs with a diameter of 50 mm are glued with epoxy resin on the hardened sample. The tensile test determines the adhesion strength between the mortar and the application surface. A total of five samples were tested for each mortar type.

- Mortar surface hardness, determined by using a Shore D durometer (Smooth-On, Inc., Macungie, PA, USA), following the recommendations of UNE-EN-ISO 868 standard [83]. A total of three 4 × 4 × 16 cm3 samples were analyzed for each dosage, taking five measurements on the two plane-parallel faces that were in contact with the mold and separating each measurement by a minimum distance of 2 cm from each other.

- Mechanical resistance to bending and compression in standardized samples of 4 × 4 × 16 cm3 according to UNE-EN 196-1 [74]. The flexural strength test consists of a three-point breakage test, where the vertical load is applied perpendicular to the longitudinal axis of the sample and at the center of the span. Subsequently, each of the two pieces generated in this bending test is subjected to a compression breaking test using a uniform load on a surface of 4 × 4 cm2. For this test, an IBERTEST hydraulic press model AUTETEST 200-10SW has been used (Madrid, Spain).

- Interior microstructure analysis of the different mortars developed in the research using scanning electron microscopy (SEM). A Jeol JSM-820 (Mitaka, Tokyo) operating at 20 kV and equipped with Oxford EDX analysis was used to carry out this analysis. The test samples were extracted from the inner matrix of the 4 × 4 × 16 cm3 mortar samples. Additionally, to ensure a good surface conductivity of electrons, the test samples were coated with a thin gold foil using a Cressington 108 model metallizer (Watford, UK).

3. Results

3.1. Physical Properties

3.2. Mechanical Properties

3.3. Critical Discussion of the Potential Application of the Developed Mortars

4. Conclusions

- Mortars made with RCA have a lower bulk density than those made with natural aggregate. This decrease in density of close to 10% is even greater for those samples made with natural fibers. Thus, this lower density and the incorporation of fibers of vegetable origin have a positive effect on the thermal conductivity of the mortars. For the best case, with the incorporation of toquilla straw fibers, the RCA–1:3–1.5%(T) dosage obtained a thermal conductivity 37% lower than that of the reference mortar (NA–1:3).

- Capillary water absorption was much higher in those mortars made with RCA due to the nature of these sands. However, the incorporation of natural fibers managed to reduce the capillary water absorption, although without reaching the values obtained for the traditional mortar made with natural sand.

- The incorporation of natural fibers reduces shrinkage during the drying of mortars made with RCA, thus approaching the behavior experienced by traditional mortars. It has been observed that the mortars made with abaca fiber showed greater dimensional stability.

- Surface hardness was not affected by the type of aggregate used in the manufacture of the mortars, although it was slightly reduced by the incorporation of natural fibers.

- The production of mortars with RCA has a negative impact on bond strength. Thus, the adhesion of traditional mortar is superior to mortar with RCA and, in turn, the incorporation of natural fibers has an impact on the decrease in this mechanical property. Mortars with higher cement content showed higher bond strength.

- Flexural strength of mortars made with recycled aggregate is lower than that of traditional mortar and is reduced as the cement content in the mix decreases. Despite this, the incorporation of natural fibers has a positive impact on the improvement of the flexural strength of mortars made with RCA, with coconut and abaca fibers showing the best performance.

- The incorporation of fibers did not significantly improve the compressive strength of the mortars, the type of aggregate being the determining factor for this property. Thus, the traditional mortars showed a higher compressive strength than their counterparts made with RCA.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bhavsar, V.; Sridharan, S.R.; Sudarsan, J.S. Barriers to circular economy practices during construction and demolition waste management in an emerging economy. Resour. Conserv. Recycl. Adv. 2023, 20, 200198. [Google Scholar] [CrossRef]

- Singh, A.K.; Kumar, V.R.P.; Dehdasht, G.; Mohandes, S.R.; Manu, P.; Rahimian, F.P. Investigating the barriers to the adoption of blockchain technology in sustainable construction projects. J. Clean. Prod. 2023, 403, 136840. [Google Scholar] [CrossRef]

- Aslam, M.S.; Huang, B.; Cui, L. Review of construction and demolition waste management in China and USA. J. Environ. Manag. 2020, 264, 110445. [Google Scholar] [CrossRef] [PubMed]

- Aylap, G.G.; Anaç, M. A comprehensive analysis of the barriers to effective construction and demolition waste management: A bibliometric approach. Clean. Waste Syst. 2024, 8, 100141. [Google Scholar] [CrossRef]

- Zhang, K.; Qing, Y.; Umer, Q.; Asmi, F. How construction and demolition waste management has addressed sustainable development goals: Exploring academic and industrial trends. J. Environ. Manag. 2023, 345, 118823. [Google Scholar] [CrossRef] [PubMed]

- Jain, S.; Singhal, S.; Pandey, S. Environmental life cycle assessment of construction and demolition waste recycling: A case of urban India. Resour. Conserv. Recycl. 2020, 155, 104642. [Google Scholar] [CrossRef]

- Caro, D.; Lodato, C.; Damgaard, A.; Cristóbal, J.; Foster, G.; Flachenecker, F.; Tonini, D. Environmental and socio-economic effects of construction and demolition waste recycling in the European Union. Sci. Total Environ. 2024, 908, 168295. [Google Scholar] [CrossRef] [PubMed]

- Xuan, D.; Sun Poon, C.; Zheng, W. Management and sustainable utilization of processing wastes from ready-mixed concrete plants in construction: A review. Resour. Conserv. Recycl. 2018, 136, 238–247. [Google Scholar] [CrossRef]

- Sobotka, A.; Sagan, J. Decision support system in management of concrete demolition waste. Autom. Constr. 2021, 128, 103734. [Google Scholar] [CrossRef]

- Khelafi, A.; Kaid, N.; Soltani, R.; Elddine, D. Elaboration of recycled concrete sand aggregates-based mortars: An alternative recycling process. Constr. Build. Mater. 2023, 398, 132333. [Google Scholar] [CrossRef]

- Liu, H.; Liu, X.; Wang, X.; Zhu, P.; Yang, L.; Yan, X. The impact of original aggregate and attached mortar types of recycled aggregates on the sulfuric acid resistance of geopolymer recycled concrete. J. Build. Eng. 2024, 82, 108273. [Google Scholar] [CrossRef]

- Muhammad, F.; Harun, M.; Ahmed, A.; Kabir, N.; Khalid, H.R.; Hanif, A. Influence of bonded mortar on recycled aggregate concrete properties: A review. Constr. Demolition Mater. 2024, 432, 136564. [Google Scholar] [CrossRef]

- Saiz, P.; González, M.; Fernández, F.; Rodríguez, A. Comparative study of three types of fine recycled aggregates from construction and demolition waste (CDW), and their use in masonry mortar fabrication. J. Clean. Prod. 2016, 118, 162–169. [Google Scholar] [CrossRef]

- Ferrández, D.; Saiz, P.; Zaragoza-Benzal, A.; Zúñiga-Vicente, J.A. Towards a more sustainable environmentally production system for the treatment of recycled aggregates in the construction industry: An experimental study Author links open overlay panel. Heliyon 2023, 9, e16641. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Wang, C.; Ma, Z. Drying shrinkage, mechanical and transport properties of sustainable mortar with both recycled aggregate and powder from concrete waste. J. Build. Eng. 2022, 49, 104048. [Google Scholar] [CrossRef]

- Khan, F.; Hossain, N.; Hasan, F.; Maksudur, S.M.; Khan, S.; Saifullah, A.Z.A.; Asaduzzaman, M. Advances of natural fiber composites in diverse engineering applications—A review. Appl. Eng. Sci. 2024, 18, 100184. [Google Scholar] [CrossRef]

- Saini, K.; Matsagar, V.A.; Kodur, V.R. Recent advances in the use of natural fibers in civil engineering structures. Constr. Build. Mater. 2024, 411, 134364. [Google Scholar] [CrossRef]

- Navaratnam, S.; Selvaranjan, K.; Jayasooriya, D.; Rajeev, P.; Sanjayan, J. Applications of natural and synthetic fiber reinforced polymer in infrastructure: A suitability assessment. J. Build. Eng. 2023, 66, 105835. [Google Scholar] [CrossRef]

- Rajeshkumar, L.; Kumar, P.S.; Boonyasopon, P. Flame retardance behaviour and degradation of plant-based natural fiber composites—A comprehensive review. Constr. Build. Mater. 2024, 432, 136552. [Google Scholar] [CrossRef]

- Elfaleh, I.; Abbassi, F.; Habibi, M.; Ahmad, F.; Guedry, M.; Nasri, M.; Garnier, C. A comprehensive review of natural fibers and their composites: An eco-friendly alternative to conventional materials. Results Eng. 2023, 19, 101271. [Google Scholar] [CrossRef]

- Laverde, V.; Marin, A.; Benjumea, J.M.; Rincón, M. Use of vegetable fibers as reinforcements in cement-matrix composite materials: A review. Constr. Build. Mater. 2022, 340, 127729. [Google Scholar] [CrossRef]

- Sathiparan, N.; Anburuvel, A.; Muralitharan, M.; Kothalawala, D.A.I. Sustainable use of coco pith in cement-sand mortar for masonry block production: Mechanical characteristics, durability and environmental benefit. J. Clenaer Prod. 2022, 360, 132243. [Google Scholar] [CrossRef]

- Thanushan, K.; Yogananth, Y.; Sangeeth, P.; Gracian, J.; Sathiparan, N. Strength and Durability Characteristics of Coconut Fibre Reinforced Earth Cement Blocks. J. Nat. Fibers 2021, 18, 773–778. [Google Scholar] [CrossRef]

- Muñoz Pérez, S.P.; Villena Zapata, L.I.; Tesen Muñoz, F.L.; Coronel Sanchez, Y.C.; Garcia, J.; Ramos, C.E.R. Influence of coconut fiber on mortar properties in masonry walls. Electron. J. Struct. Eng. 2023, 23, 52–58. [Google Scholar] [CrossRef]

- Tang, Z.; Li, Z.; Hua, J.; Lu, S.; Chi, L. Enhancing the damping properties of cement mortar by pretreating coconut fibers for weakened interfaces. J. Clean. Prod. 2022, 379, 134662. [Google Scholar] [CrossRef]

- Sathiparan, N.; Nishanthana, M.; Pavithra, B.H.M. Performance of coconut coir reinforced hydraulic cement mortar for surface plastering application. Constr. Build. Mater. 2017, 142, 23–30. [Google Scholar] [CrossRef]

- Hwang, C.L.; Tran, V.A.; Hong, J.W.; Hsieh, Y.C. Effects of short coconut fiber on the mechanical properties, plastic cracking behavior, and impact resistance of cementitious composites. Constr. Build. Mater. 2016, 127, 984–992. [Google Scholar] [CrossRef]

- Bui, H.; Boutouil, M.; Sebaibi, N.; Levacher, D. Hydration characteristics of coconut fibre-reinforced mortars containing CSA and Portland cement. J. Mater. Cycles Waste Manag. 2022, 24, 1295–1303. [Google Scholar] [CrossRef]

- Bui, H.; Levacher, D.; Boutouil, M.; Sebaibi, N. Effects of Wetting and Drying Cycles on Microstructure Change and Mechanical Properties of Coconut Fibre-Reinforced Mortar. J. Compos. Sci. 2022, 6, 102. [Google Scholar] [CrossRef]

- Kesikidou, F.; Stefanidou, M. Natural fiber-reinforced mortars. J. Build. Eng. 2019, 25, 100786. [Google Scholar] [CrossRef]

- Quiñones-Bolaños, E.; Gómez-Oviedo, M.; Mouthon-Bello, J.; Sierra-Vitola, L.; Berardi, U.; Bustillo, C. Potential use of coconut fibre modified mortars to enhance thermal comfort in low-income housing. J. Environ. Manag. 2021, 277, 111503. [Google Scholar] [CrossRef]

- Syamala, L.M.; Vishnudas, S.; Anil, K.R. Effect of Coir Fiber Reinforcement on Flexural and Compressive Strengths of Masonry Mortar. J. Mater. Civ. Eng. 2023, 35, 04023457. [Google Scholar] [CrossRef]

- Nawad, M.S.; Zeeshan, M.; Zaid, O.; Kahla, N.B.; Sun, Y.; Anwar, N.; Ajwad, A. A study on improving the performance of cement-based mortar with silica fume, metakaolin, and coconut fibers. Case Stud. Constr. Mater. 2023, 19, e02480. [Google Scholar] [CrossRef]

- Alcivar-Bastidas, S.; Petroche, D.M.; Martínez-Echevarria, M.J. The effect of different treatments on abaca fibers used in cementitious composites. J. Nat. Fibers 2023, 20, 2177235. [Google Scholar] [CrossRef]

- Alcivar-Bastidas, S.; Petroche, D.M.; Cornejo, M.H.; Martinez-Echevarria, M.J. Effect of aging process on mechanical performance of reinforced mortar with NaOH abaca fibers. Case Stud. Constr. Mater. 2024, 20, e03122. [Google Scholar] [CrossRef]

- Lee, G.W.; Choi, Y.C. Effect of abaca natural fiber on the setting behavior and autogenous shrinkage of cement composite. J. Build. Eng. 2022, 56, 104719. [Google Scholar] [CrossRef]

- Suhelmidawati, E.; Adibroto, F.; Suhendrik, H.; Numada, M.; Kimiro, M. Experimental Test of Masonry Wallets Retrofitted by Abaca Fiber Reinforced Mortar. Int. J. Adv. Sci. Eng. Inf. Technol. 2019, 9, 929. [Google Scholar] [CrossRef]

- Garzón, L.; López, L.M.; Seminario, J.F.; Zuluaga, R.; Betancourt, S.; Gañán, P.; Cruz, L.J. A new natural fiber: Toquilla straw a potential reinforcement in thermoplastic polymer composites. In Proceedings of the 5th International Conference on Advanced Materials and Systems, Bucharest, Romania, 23–25 October 2014; pp. 49–54. [Google Scholar]

- Skinner, C.; Baker, P.; Tomkinson, J.; Richards, D.; Charlton, A. Pressurised disc refining of wheat straw as a pre-treatment approach for agricultural residues: A preliminary assessment of energy consumption and fibre composition. Bioresour. Technol. 2020, 204, 122976. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Liu, X.; Wang, S.; Zhou, S.; Zang, T.; Dai, L.; Ai, S. Hydrophobic kenaf straw core for biomass-based cement mortar with excellent mechanical properties. Mater. Chem. Phys. 2021, 267, 124594. [Google Scholar] [CrossRef]

- Basta, A.H.; Lotfy, V.F.; Shafik, E.S. Synergistic valorization of rice straw and red brick demolition in development performance of lightweight cement mortars. J. Build. Eng. 2024, 92, 109769. [Google Scholar] [CrossRef]

- Yu, X.; Li, G.; Zhao, H.; Ma, Y.; Li, Q.; Chen, Y.; Li, W. Influence of chemically-modified cotton straw fibers on the properties of asphalt mortar. Case Stud. Constr. Mater. 2023, 18, e01787. [Google Scholar] [CrossRef]

- Awoyera, P.O.; Akinrinade, A.D.; de Sousa Galdino, A.G.; Althoey, F.; Serkan Kirgiz, M.; Tayeh, B.A. Thermal insulation and mechanical characteristics of cement mortar reinforced with mineral wool and rice straw fibers. J. Build. Eng. 2022, 53, 104568. [Google Scholar] [CrossRef]

- Santo de Lima, T.E.; Natalli, J.F.; Marvila, M.T.; Candido, V.S.; da Silva, A.C.R.; de Azevedo, A.R.G. Potentiality of using guarumã natural fiber (Ischinosiphon koern) in sustainable coating mortars. J. Mater. Res. Technol. 2024, 30, 1301–1309. [Google Scholar] [CrossRef]

- de Lima, T.E.; de Azevedo, A.R.; Marvila, M.T.; Candido, V.S.; Fediuk, R.; Monteiro, S.N. Potential of using amazon natural fibers to reinforce cementitious composites: A review. Polymers 2022, 14, 647. [Google Scholar] [CrossRef]

- Lilargem Rocha, D.; Tambara Júnior, L.U.D.; Marvila, M.T.; Pereira, E.C.; Souza, D.; de Azevedo, A.R.G. A review of the use of natural fibers in cement composites: Concepts, applications and Brazilian history. Polymers 2022, 14, 2043. [Google Scholar] [CrossRef]

- Hamada, H.M.; Shi, J.; Al Jawahery, M.S.; Majdi, A.; Yousif, S.T.; Kaplan, G. Application of natural fibres in cement concrete: A critical review. Mater. Today Commun. 2023, 35, 105833. [Google Scholar] [CrossRef]

- Ferreira de Lima, C.P.; Chagas Cordeiro, G. Evaluation of corn straw ash as supplementary cementitious material: Effect of acid leaching on its pozzolanic activity. Cement 2021, 4, 100007. [Google Scholar] [CrossRef]

- Aliu, A.O.; Olalusi, O.B.; Aworera, P.O.; Kiliswa, M. Evaluation of pozzolanic reactivity of maize straw ash as a binder supplement in concrete. Case Stud. Constr. Mater. 2023, 18, e01790. [Google Scholar] [CrossRef]

- United Nations. 17 Goals to Transform Our World. Available online: https://www.un.org/sustainabledevelopment/es/ (accessed on 8 June 2024).

- Amin, M.N.; Ahmad, W.; Khan, K.; Ahmad, A. A Comprehensive Review of Types, Properties, Treatment Methods and Application of Plant Fibers in Construction and Building Materials. Materials 2022, 15, 4362. [Google Scholar] [CrossRef]

- Harasymiuk, J.; Szafranko, E. On the application of sustainable building materials in geodesy and civil engineering. Mater. Today Proc. 2022, 57, 701–704. [Google Scholar] [CrossRef]

- Real Decreto 256/2016. Instrucción Para la Recepción de Cemento (RC-16). Available online: https://www.boe.es/eli/es/rd/2016/06/10/256/con (accessed on 8 June 2024).

- Arroyo Portero, J.C.; Morán Cabré, F.; García Messeguer, A. Homigón Armado, 16th ed.; Cinter Divulgación Técnica, S.L.: Madrid, Spain, 2018; ISBN 9788493930578. [Google Scholar]

- Morón, A.; Ferrández, D.; Saiz, P.; Morón, C. Experimental Study with Cement Mortars Made with Recycled Concrete Aggregate and Reinforced with Aramid Fibers. Appl. Sci. 2021, 11, 7791. [Google Scholar] [CrossRef]

- Piña, C.; del Río, M.; Viñas, C.; Vidales, A.; Kosior-Kaberuk, M. Analysis of the mechanical behaviour of the cement mortars with additives of mineral wool fibres from recycling of CDW. Constr. Build. Mater. 2019, 210, 56–62. [Google Scholar] [CrossRef]

- Council Directive 98/83/EC of 3 November 1998 on the Quality of Water Intended for Human Consumption; EU: Brussels, Belgium, 1998.

- Canal de Isabel, II. Calidad del Agua. Available online: www.canaldeisabelsegunda.es/calidad-del-agua (accessed on 9 June 2024).

- UNE–EN 933-1:2012; Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method. UNE: Madrid, Spain, 2012.

- UNE-EN 13139/AC:2004; Aggregates for Mortar. UNE: Madrid, Spain, 2004.

- UNE 146404:2018; Aggregates for Concrete. Determination of the Coefficient of Friability of the Sands. UNE: Madrid, Spain, 2018.

- UNE-EN 1097-3:1999; Tests for Mechanical and Physical Properties of Aggregates—Part 3: Determination of Loose Bulk Density and Voids. UNE: Madrid, Spain, 1999.

- UNE-EN 1097-6:2014; Tests for Mechanical and Physical Properties of Aggregates—Part 6: Determination of Particle Density and Water Absorption. UNE: Madrid, Spain, 2014.

- Saiz Martínez, P. Utilización de Arenas Procedentes de Residuos de Construcción y Demolición, RCD, en la Fabricación de Morteros de Albañilería. Ph.D. Thesis, Universidad Politécnica de Madrid, Madrid, Spain, 2015. [Google Scholar] [CrossRef]

- Morón, A.; Ferrández, D.; Saiz, P.; Atanes-Sánchez, E.; Morón, C. Study of the properties of lime and cement mortars made from recycled ceramic aggregate and reinforced with fibers. J. Build. Eng. 2021, 35, 102097. [Google Scholar] [CrossRef]

- Li, H.; Liu, J.; Xiao, J.; Zhong, P. A method to determine water absorption of recycled fine aggregate in paste for design and quality control of fresh mortar. Constr. Build. Mater. 2019, 197, 30–41. [Google Scholar] [CrossRef]

- UNE-EN 933-2:2022; Tests for Geometrical Properties of Aggregates—Part 2: Determination of Particle Size Distribution—Test Sieves, Nominal Size of Apertures. UNE: Madrid, Spain, 2022.

- NBE FL-90. Norma Básica de Edificación. Muros Resistentes de Fábrica de Ladrillo; BOE–Agencia Estatal Boletín Oficial del Estado: Madrid, Spain, 1991.

- Ulsen, C.; Kahn, H.; Hawlitschek, G.; Masini, E.A.; Angulo, S.C.; John, V.M. Production of recycled sand from construction and demolition waste. Constr. Build. Mater. 2013, 40, 1168–1173. [Google Scholar] [CrossRef]

- Andersen, R.; Stokbro Ravn, A.; Walbech Ryberg, M. Environmental benefits of applying selective demolition to buildings: A case study of the reuse of façade steel cladding. Resour. Conserv. Recycl. 2022, 184, 106430. [Google Scholar] [CrossRef]

- Juradin, S.; Boko, I.; Netinger, I.; Jozić, D.; Mrakovčić, S. Influence of different treatment and amount of Spanish broom and hemp fibres on the mechanical properties of reinforced cement mortars. Constr. Build. Mater. 2021, 273, 121702. [Google Scholar] [CrossRef]

- Jiang, D.; An, P.; Cui, S.; Xu, F.; Tuo, T.; Zhang, J.; Jiang, H. Effect of leaf fiber modification methods on mechanical and heat-insulating properties of leaf fiber cement-based composite materials. J. Build. Eng. 2018, 19, 573–583. [Google Scholar] [CrossRef]

- Cai, M.; Takgi, H.; Nakagaito, A.N.; Li, Y.; Waterhouse, G.I.N. Effect of alkali treatment on interfacial bonding in abaca fiber-reinforced composites. Compos. Part A Appl. Sci. Manuf. 2016, 90, 589–597. [Google Scholar] [CrossRef]

- UNE-EN 196-1:2018; Methods of Testing Cement—Part 1: Determination of Strength. UNE: Madrid, Spain, 2018.

- UNE-EN 1015-3:1999; Methods of Test for Mortar for Masonry. Part 3: Determination of Consistence of Fresh Mortar (by Flow Table). UNE: Madrid, Spain, 1999.

- Marvila, M.; de Matos, P.; Rodríguez, E.; Monteiro, S.N.; de Azevedo, A.R.G. Recycled Aggregate: A Viable Solution for Sustainable Concrete Production. Materials 2022, 15, 5276. [Google Scholar] [CrossRef]

- UNE-EN 1015-10:2000/A1:2007; Methods of Test for Mortar for Masonry—Part 10: Determination of Dry Bulk Density of Hardened Mortar. UNE: Madrid, Spain, 2007.

- UNE-EN ISO 8990:1997; Thermal Insulation. Determination of Steady-State Thermal Transmission Properties. Calibrated and Guarded Hot-Box. UNE: Madrid, Spain, 1997.

- UNE-EN 1015-18:2003; Methods of Test for Mortar for Masonry—Part 18: Determination of Water Absorption Coefficient due to Capillary Action of Hardened Mortar. UNE: Madrid, Spain, 2003.

- UNE-EN 1936:2007; Natural Stone Test Methods—Determination of Real Density and Apparent Density, and of Total and Open Porosity. UNE: Madrid, Spain, 2007.

- UNE 80-112-89; Test methods for Cements. Physical Tests: Determination of Drying Shrinkage and Swelling in Water. UNE: Madrid, Spain, 1989.

- UNE-EN 1015-12:2016; Methods of Test for Mortar for Masonry—Part 12: Determination of Adhesive Strength of Hardened Rendering and Plastering Mortars on Substrates. UNE: Madrid, Spain, 2016.

- UNE-EN ISO 868:2003; Plastics and Ebonite—Determination of Indentation Hardness by Means of a Durometer (Shore Hardness) (ISO 868:2003). UNE: Madrid, Spain, 2003.

- Lamichhane, N.; Lamichhane, A.; Gyawali, T.R. Enhancing mechanical properties of mortar with short and thin banana fibers: A sustainable alternative to synthetic fibers. Heliyon 2024, 10, e30652. [Google Scholar] [CrossRef] [PubMed]

- Francioso, V.; Moro, C.; Velay-Lizancos, M. Effect of recycled concrete aggregate (RCA) on mortar’s thermal conductivity susceptibility to variations of moisture content and ambient temperature. J. Clean. Prod. 2021, 43, 103208. [Google Scholar] [CrossRef]

- Benmansour, N.; Agoudjil, B.; Gherabli, A.; Kareche, A.; Boudenne, A. Thermal and mechanical performance of natural mortar reinforced with date palm fibers for use as insulating materials in building. Energy Build. 2014, 81, 98–104. [Google Scholar] [CrossRef]

- Yedra, E.; Ferrández, D.; Morón, C.; Saiz, P. New test methods to determine water absorption by capillarity. Experimental study in masonry mortars. Constr. Build. Mater. 2022, 319, 125988. [Google Scholar] [CrossRef]

- García Morales, S. Metodología de Diagnóstico de Humedades de Capilaridad Ascendente y Condensación Higroscópica, en Edificios Históricos. Ph.D. Thesis, Technical University of Madrid, Madrid, Spain, 1995. [Google Scholar] [CrossRef]

- Miah, M.J.; Ali, M.K.; Paul, S.C.; John Babafemi, A.; Kong, S.Y.; Šavija, B. Effect of Recycled Iron Powder as Fine Aggregate on the Mechanical, Durability, and High Temperature Behavior of Mortars. Materials 2020, 13, 1168. [Google Scholar] [CrossRef]

- Mesbah, H.A.; Buyle-Bodin, F. Efficiency of polypropylene and metallic fibres on control of shrinkage and cracking of recycled aggregate mortars. Constr. Build. Mater. 1999, 13, 439–447. [Google Scholar] [CrossRef]

- Miah, M.J.; Chandra Paul, S.; John Babafemi, A. Mechanical strength, shrinkage, and porosity of mortar reinforced with areca nut husk fibers. Constr. Build. Mater. 2023, 363, 129688. [Google Scholar] [CrossRef]

- García López de la Osa, G. Análisis de la Adherencia Entre Morteros y Piezas Cerámicas. Ph.D. Thesis, Univeresidad Politécnica de Madrid, Madrid, Spain, 2020. [Google Scholar] [CrossRef]

- Samiei, R.R.; Daniotti, B.; Pelosato, R.; Dotelli, G. Properties of cement–lime mortars vs. cement mortars containing recycled concrete aggregates. Constr. Build. Mater. 2015, 84, 84–94. [Google Scholar] [CrossRef]

- Bedoya, M.A.; Tobón, J.I. Incidence of recycled aggregates and ternary cements on the compressive strength and durability of ecological mortars. Case Stud. Constr. Mater. 2022, 17, e01192. [Google Scholar] [CrossRef]

- Chandrasekaran, R.G.; Ramakishna, G. Experimental investigation on mechanical properties of economical local natural fibre reinforced cement mortar. Mater. Today Proc. 2021, 46, 7633–7638. [Google Scholar] [CrossRef]

- Martínez, I.; Etxeberria, M.; Pavón, E.; Díaz, N. A comparative analysis of the properties of recycled and natural aggregate in masonry mortars. Constr. Build. Mater. 2013, 49, 384–392. [Google Scholar] [CrossRef]

- Mohammad Moayedian, S.; Hejazi, M. Estimating the modulus of elasticity and the compressive strength of brick, mortar and masonry at different scales. Structures 2024, 61, 103116. [Google Scholar] [CrossRef]

- Sánchez-Roldán, Z.; Martín-Morales, M.; Valverde-Espinosa, I.; Zamorano, M. Technical feasibility of using recycled aggregates to produce eco-friendly urban furniture. Constr. Build. Mater. 2020, 250, 118890. [Google Scholar] [CrossRef]

- Wang, B.; Yan, L.; Fu, Q.; Kasal, B. A Comprehensive Review on Recycled Aggregate and Recycled Aggregate Concrete. Resour. Conserv. Recycl. 2021, 171, 105565. [Google Scholar] [CrossRef]

- Tolêdo Filho, R.D.; Scrivener, K.; Engrand, G.L.; Ghavami, K. Durability of alkali-sensitive sisal and coconut fibres in cement mortar composites. Cem. Concr. Compos. 2000, 22, 127–143. [Google Scholar] [CrossRef]

- Zaragoza-Benzal, A.; Ferrández, D.; Santos, P.; Morón, C. Recovery of End-of-Life Tyres and Mineral Wool Waste: A Case Study with Gypsum Composite Materials Applying Circular Economy Criteria. Materials 2023, 16, 243. [Google Scholar] [CrossRef] [PubMed]

- Paula Junior, A.C.; Jacinto, C.; Oliveira, T.M.; Polisseni, A.E.; Brum, F.M.; Teixeira, E.R.; Mateus, R. Characterisation and Life Cycle Assessment of Pervious Concrete with Recycled Concrete Aggregates. Crystals 2021, 11, 209. [Google Scholar] [CrossRef]

- Agung Wibowo, M.; Nur Sholeh, E.M.; Seti Adji, H. Supply Chain Management Strategy for Recycled Materials to Support Sustainable Construction. Procedia Eng. 2017, 171, 185–190. [Google Scholar] [CrossRef]

- Villoria, P.; Del Río, M.; San-Antonio, A.; Porrás-Amores, C. Best practice measures assessment for construction and demolition waste management in building constructions. Resour. Conserv. Recycl. 2013, 75, 52–62. [Google Scholar] [CrossRef]

| Ref. | Fiber Addition | Fiber Length [mm] | Main Results |

|---|---|---|---|

| [22] | 0, 4, 6, and 8% by weight of cement | 16.7 | In all cases the flexural strength was increased, however, for the compressive strength a decrease was observed from 4% added fiber. Capillary water absorption in the mortars is increased. Energy consumption and CO2 emissions during production decreased by more than 11% compared to the control mortar without coconut fiber. |

| [23] | 0, 0.2, 0.4, and 0.6% mass fractions of cement and soil mix | 24.0 | The coconut fiber reinforcement increased mortar blocks’ residual strength under compression, as well as their ductility and energy absorption. In addition, a significant improvement in mortar durability against freeze–thaw and moisture–dryness cycles was obtained. |

| [24] | 0.5, 1.0, 1.5, and 2.0% relative to the weight of cement | 30.0 | Properties of cement mortars with coconut fiber in masonry walls were evaluated. The best results were obtained for addition of 0.5% fiber, significantly improving flexural strength and slightly increasing diagonal compression in walls. |

| [25] | 0, 0.25, 0.5, 0.75, 1.0, 1.25 and 1.5% by volume | Less than 3.0 | As the interface between added fibers and mortar matrix weakened, there was an improvement in the mortars’ cushioning properties. However, there was a compressive strength loss and an increase in porosity. |

| [26] | 0.125, 0.25, 0.5 and 0.75 by weight of mortar mix | 24.0 | While there was no significant improvement in flexural and compressive mechanical strengths, post-cracking properties such as ductility, residual strength and toughness increased with a higher fraction of coconut fiber in the mortar matrix. |

| [27] | 0, 1, 2.5, and 4% by volume | 17.0 | Coconut fiber addition positively influenced the first crack deflection, improving the toughness indices, plastic cracking and impact strength of the produced cementitious mortars. |

| [28] | 0, 1, 2 and 3% by volume of mortar | 10.0–20.0 | The best results were obtained with additions of coconut fiber at 2% by volume of mortar, significantly increasing flexural strength compared to the reference, improving toughness, and preventing cracking. |

| [29] | 0, 1, 2 and 3% by volume of mortar | 16.0–18.0 | The mortars were subjected to moisture–dryness cycles and an increase in wetting was observed in coconut fiber samples. Natural degradation of the fibers in the mortar matrix occurred, which decreased the mechanical strengths. |

| [30] | 1.5% by volume of mortar | 15.0 | Higher flexural strengths, increased fracture energy and increased capillary water absorption were obtained compared to traditional mortar. |

| [31] | 0, 5, 10, 15, and 20% by weight of cement | 60.0 | The potential use of coconut fiber reinforced mortars as a façade cladding material was analyzed. It was found that these mortars with plant fibers could reduce dwelling interior temperatures by 0.5–1.5 °C. |

| [32] | 0.25 and 0.5% by weight of cement | More than 10 | The coconut fiber reinforced mortars significantly improved flexural and compressive mechanical strengths, satisfying the criteria for application as mortar in masonry walls according to Colombian standards. |

| [33] | 0, 3, 6, 9, 12, and 15% by weight of cement | 10.0–30.0 | Composite with a combination of 10% silica fume, 10% metakaolin and 6% coconut fibers showed superior mechanical and physical properties to the reference mortar, with a compact microstructure, making it a sustainable and environmentally friendly alternative. |

| Ref. | Fiber Addition | Fiber Length [mm] | Main Results |

|---|---|---|---|

| [34] | 0.2, 0.3 and 0.4% over the total solid weight | 20.0, 25.0, 30.0 and 35.0 | The best results were obtained in mortars made with treated fibers with a 3% NaOH solution, with a length of 30 mm and incorporated at 0.2% of the mortar weight. With this composition, it was possible to improve the mechanical resistance to bending and compression, with a good fiber integration in the matrix. |

| [35] | 0.2% over the total solid weight | 30.0 | Flexural strength was improved by 20%, compressive strength by 28% and tensile strength by 26% compared to the reference mortars. In addition, the abaca fiber mortars improved their dimensional stability by reducing shrinkage. |

| [36] | 0, 0.25, 0.5, 1 and 2% of the weight of cement | 4.5 | The good hygroscopic properties of abaca fibers reduce the autogenous shrinkage of mortars, improving their mechanical performance and mitigating cracking risk. In addition, the presence of these fibers delays mortar setting time. |

| [37] | 1% over the total solid weight | 10.0, 30.0, 80.0, 100.0 and 300.0 | Abaca fibers showed great potential for application in rehabilitation mortars for masonry houses. The optimum fiber length for improving flexural strength and wall ductility was found to be 80 mm. |

| CaO | SiO2 | SO3 | Al2O3 | Fe2O3 | K2O | TiO2 | MgO | SrO | BaO | MnO | P2O5 | I. Loss |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 67.11 | 16.98 | 4.56 | 4.38 | 3.56 | 0.71 | 0.23 | 0.25 | 0.09 | 0.07 | 0.09 | 0.04 | 1.93 |

| Properties | NA | RCA | Normative |

|---|---|---|---|

| Fine Content (%) | 1.23 ± 0.06 | 3.87 ± 0.10 | UNE–EN 933-1 [59] |

| Particle Form | Not relevant | Not relevant | UNE–EN 13139 [60] |

| Fineness Modulus (%) | 2.56 ± 0.14 | 4.11 ± 0.08 | UNE–EN 13139 [60] |

| Friability Coefficient (%) | 14.11 ± 0.25 | 24.15 ± 0.23 | UNE–EN 146404 [61] |

| Bulk Density (kg/m3) | 1560 ± 17 | 1387 ± 14 | UNE–EN 1097-3 [62] |

| Dry Density (kg/m3) | 2569 ± 3 | 2398 ± 16 | UNE–EN 1097-6 [63] |

| Water Absorption (%) | 0.54 ± 0.04 | 5.87 ± 0.09 | UNE–EN 1097-6 [63] |

| Aggregate | Al2O3 | CaO | Fe2O3 | K2O | MgO | SiO2 | MnO | TiO2 | SO3 | P2O5 | NaO2 | I. Loss |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RCA | 10.81 | 12.03 | 1.56 | 2.41 | 0.98 | 57.92 | 0.43 | 0.65 | 1.03 | 0.09 | 0.41 | 11.68 |

| Fiber | Bulk Density (kg/m3) | Young’s Modulus (GPa) | Diameter (mm) |

|---|---|---|---|

| Abaca | 1230 ± 8 | 22.7 ± 1.3 | 0.1–0.4 |

| Coconut | 1340 ± 15 | 16.4 ± 0.9 | 0.1–1.2 |

| Toquilla straw | 670 ± 12 | 11.5 ± 0.7 | 0.7–1.1 |

| Type | Cement [g] | Sand [g] | Water [g] | Water/Cement Ratio | Natural Fiber Reinforcement [g] | ||

|---|---|---|---|---|---|---|---|

| Abaca | Coconut | Toquilla Straw | |||||

| NA–1:3 | 450.0 | 1350 | 234.0 | 0.52 | — | — | — |

| RCA–1:3 | 450.0 | 1350 | 328.5 | 0.73 | — | — | — |

| RCA–1:3–1.5%(A) | 450.0 | 1350 | 328.5 | 0.73 | 6.75 | — | — |

| RCA–1:3–1.5%(C) | 450.0 | 1350 | 328.5 | 0.73 | — | 6.75 | — |

| RCA–1:3–1.5%(T) | 450.0 | 1350 | 328.5 | 0.73 | — | — | 6.75 |

| NA–1:4 | 337.5 | 1350 | 183.0 | 0.54 | — | — | — |

| RCA–1:4 | 337.5 | 1350 | 283.5 | 0.84 | — | — | — |

| RCA–1:4–1.5%(A) | 337.5 | 1350 | 283.5 | 0.84 | 6.75 | — | — |

| RCA–1:4–1.5%(C) | 337.5 | 1350 | 283.5 | 0.84 | — | 6.75 | — |

| RCA–1:4–1.5%(T) | 337.5 | 1350 | 283.5 | 0.84 | — | — | 6.75 |

| Sample | Capillarity Water Absorption (kg/m2·min0.5) | Open Porosity (%) | Sample | Capillarity Water Absorption (kg/m2·min0.5) | Open Porosity (%) |

|---|---|---|---|---|---|

| NA–1:3 | 0.41 ± 0.03 | 67.3 ± 0.9 | NA–1:4 | 0.39 ± 0.01 | 70.1 ± 0.3 |

| RCA–1:3 | 0.63 ± 0.01 | 82.4 ± 1.2 | RCA–1:4 | 0.57 ± 0.03 | 83.3 ± 0.3 |

| RCA–1:3–1.5%(A) | 0.50 ± 0.03 | 76.5 ± 0.7 | RCA–1:4–1.5%(A) | 0.44 ± 0.01 | 76.4 ± 1.3 |

| RCA–1:3–1.5%(C) | 0.55 ± 0.02 | 77.1 ± 0.9 | RCA–1:4–1.5%(C) | 0.46 ± 0.03 | 78.8 ± 0.5 |

| RCA–1:3–1.5%(T) | 0.57 ± 0.02 | 76.8 ± 0.4 | RCA–1:4–1.5%(T) | 0.50 ± 0.02 | 78.5 ± 0.5 |

| Sample | Superficial Hardness (Shore D Units) | Bonding Strength (MPa) | Sample | Superficial Hardness (Shore D Units) | Bonding Strength (MPa) |

|---|---|---|---|---|---|

| NA–1:3 | 84.1 ± 0.7 | 0.53 ± 0.05 | NA–1:4 | 83.7 ± 0.6 | 0.42 ± 0.02 |

| RCA–1:3 | 83.8 ± 0.4 | 0.41 ± 0.02 | RCA–1:4 | 83.9 ± 0.5 | 0.35 ± 0.01 |

| RCA–1:3–1.5%(A) | 78.9 ± 0.4 | 0.35 ± 0.04 | RCA–1:4–1.5%(A) | 79.2 ± 0.8 | 0.29 ± 0.03 |

| RCA–1:3–1.5%(C) | 78.1 ± 1.1 | 0.38 ± 0.01 | RCA–1:4–1.5%(C) | 78.5 ± 0.7 | 0.30 ± 0.03 |

| RCA–1:3–1.5%(T) | 79.3 ± 0.6 | 0.30 ± 0.02 | RCA–1:4–1.5%(T) | 78.1 ± 0.4 | 0.26 ± 0.02 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferrández, D.; Zaragoza-Benzal, A.; Pastor Lamberto, R.; Santos, P.; Michalak, J. Optimizing Masonry Mortar: Experimental Insights into Physico-Mechanical Properties Using Recycled Aggregates and Natural Fibers. Appl. Sci. 2024, 14, 6226. https://doi.org/10.3390/app14146226

Ferrández D, Zaragoza-Benzal A, Pastor Lamberto R, Santos P, Michalak J. Optimizing Masonry Mortar: Experimental Insights into Physico-Mechanical Properties Using Recycled Aggregates and Natural Fibers. Applied Sciences. 2024; 14(14):6226. https://doi.org/10.3390/app14146226

Chicago/Turabian StyleFerrández, Daniel, Alicia Zaragoza-Benzal, Rocío Pastor Lamberto, Paulo Santos, and Jacek Michalak. 2024. "Optimizing Masonry Mortar: Experimental Insights into Physico-Mechanical Properties Using Recycled Aggregates and Natural Fibers" Applied Sciences 14, no. 14: 6226. https://doi.org/10.3390/app14146226

APA StyleFerrández, D., Zaragoza-Benzal, A., Pastor Lamberto, R., Santos, P., & Michalak, J. (2024). Optimizing Masonry Mortar: Experimental Insights into Physico-Mechanical Properties Using Recycled Aggregates and Natural Fibers. Applied Sciences, 14(14), 6226. https://doi.org/10.3390/app14146226