Integration of BIM Tools for the Facility Management of Railway Bridges

Abstract

:1. Introduction

2. Materials and Methods

3. Literature Review

3.1. Inspection and Monitoring of Railway Bridges

3.2. BIM/Data Automation as an Initial Step Towards a Digital Twin

3.3. Knowledge Gap and Research Objectives

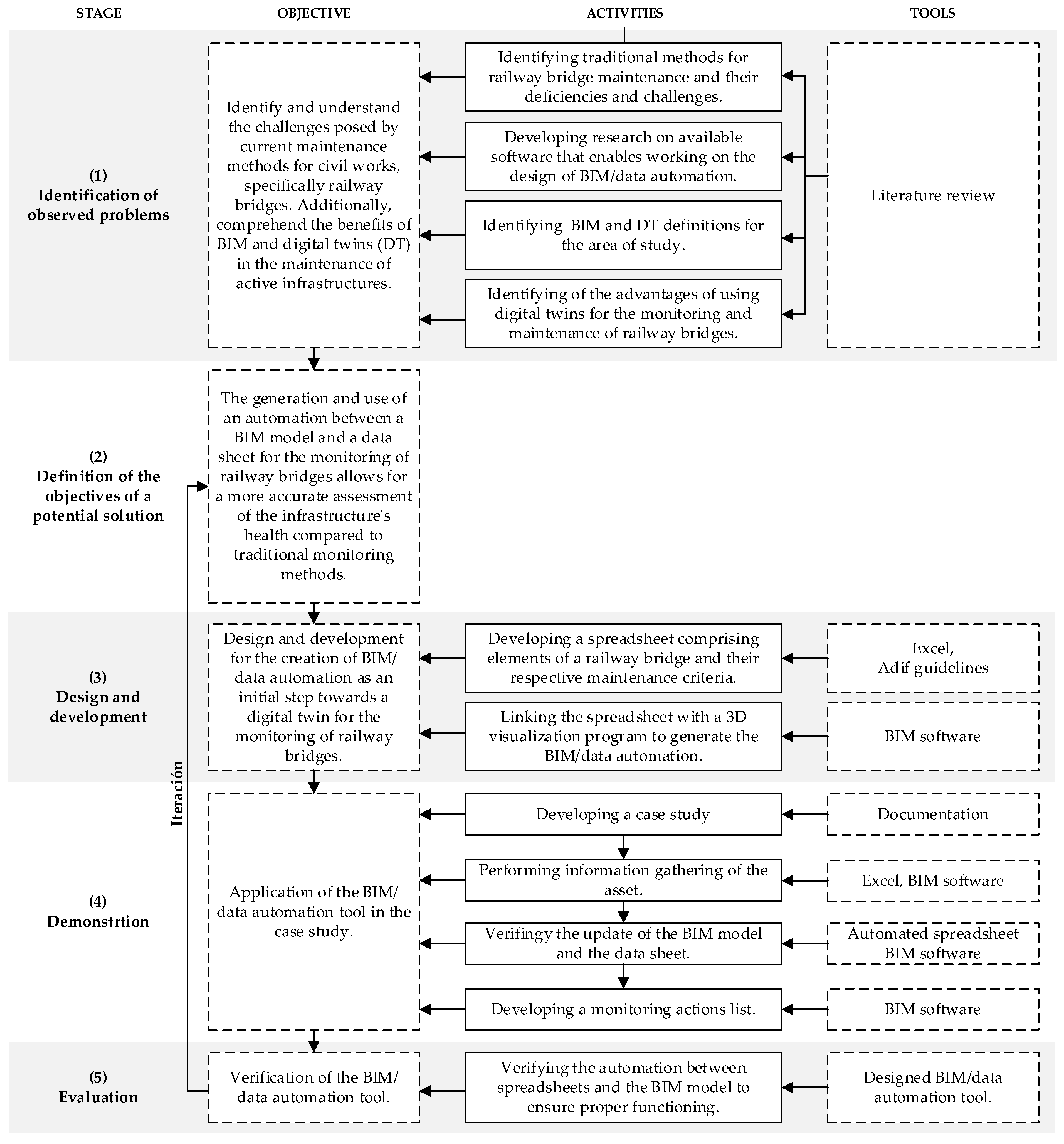

4. Development Method

5. Case Study

5.1. Knowledge Gap and Research Objectives

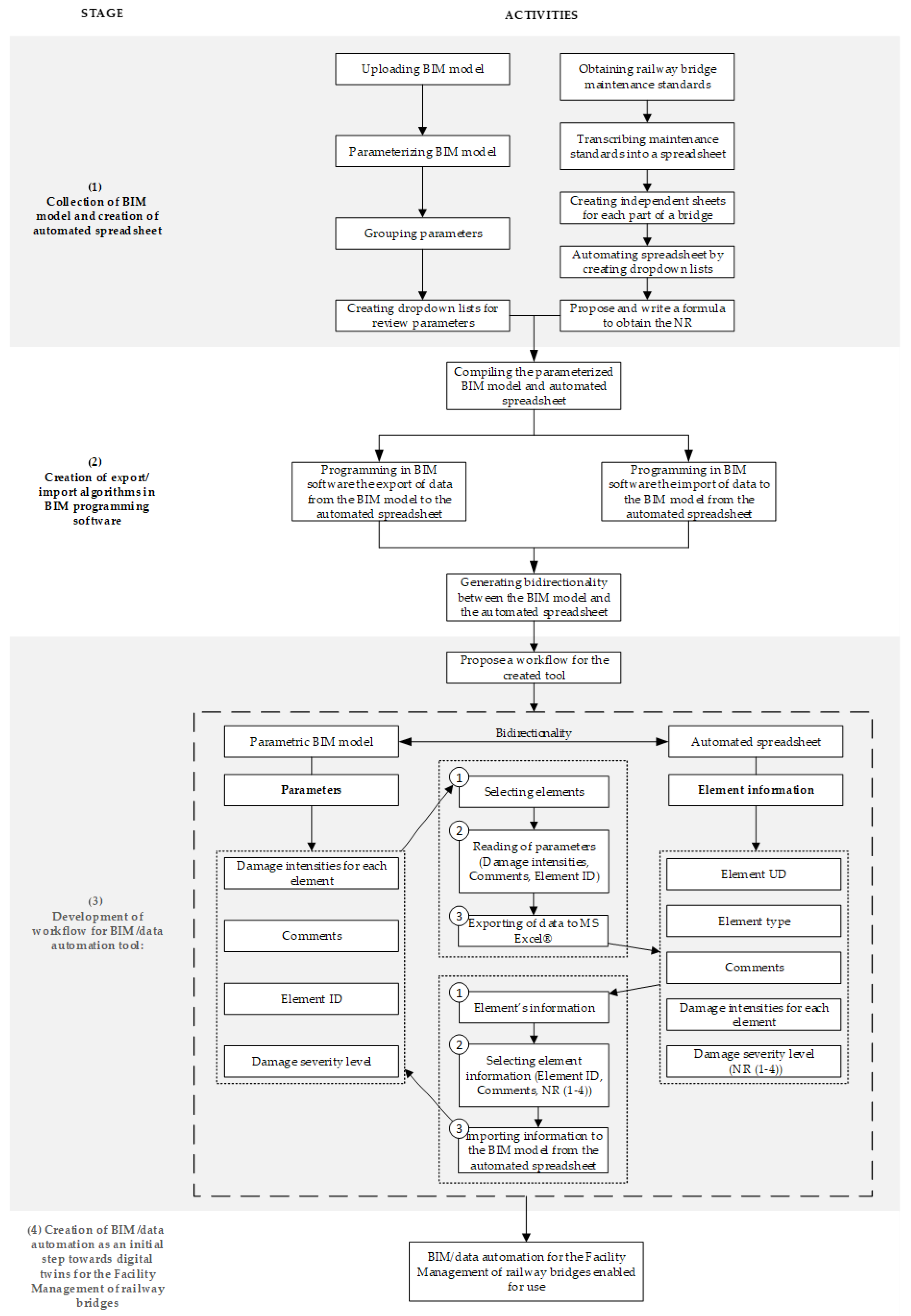

5.2. Tool’s Implementation Process

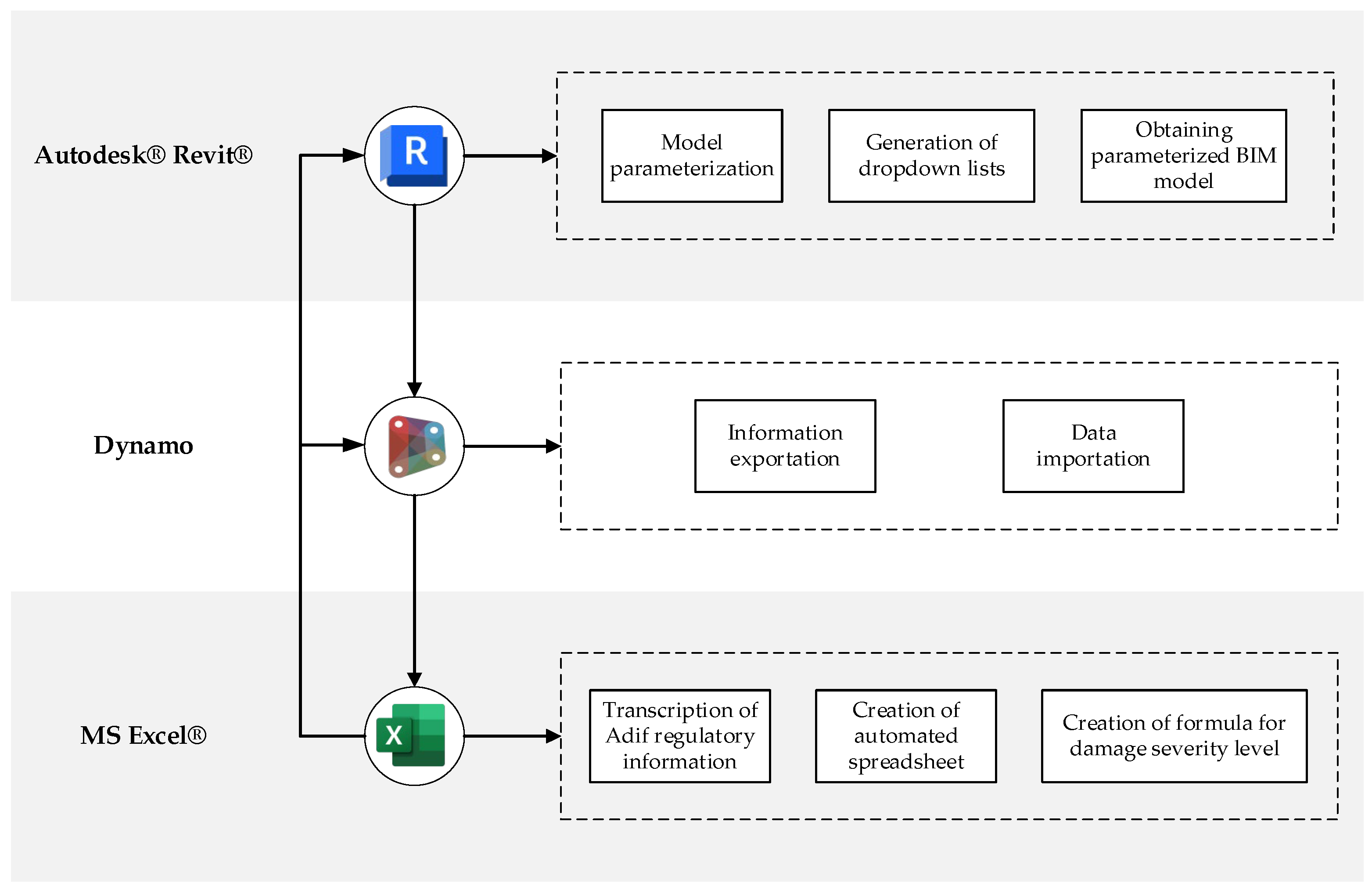

5.3. Software Used to Generate BIM/Data Automation

5.4. Creation of an Automated MS Excel® Spreadsheet

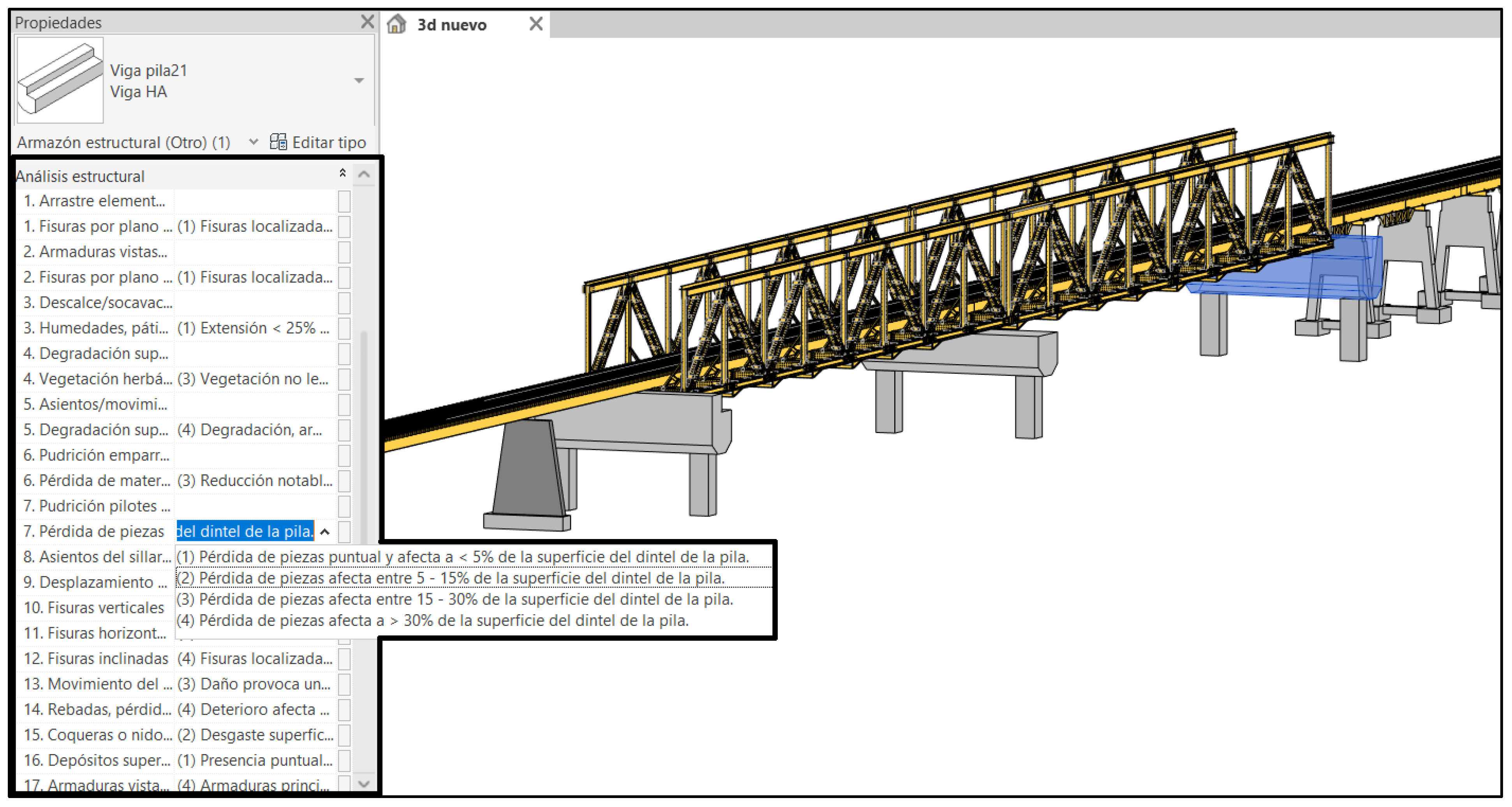

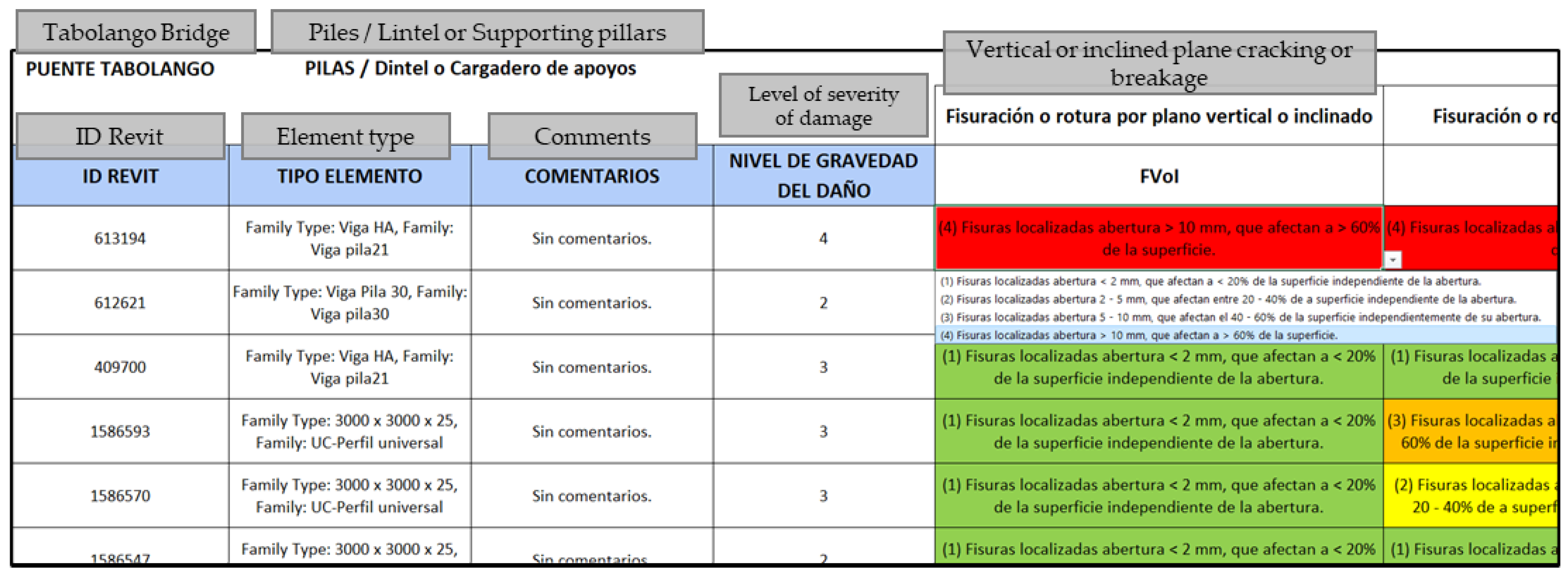

5.5. Parameterization of the BIM Model

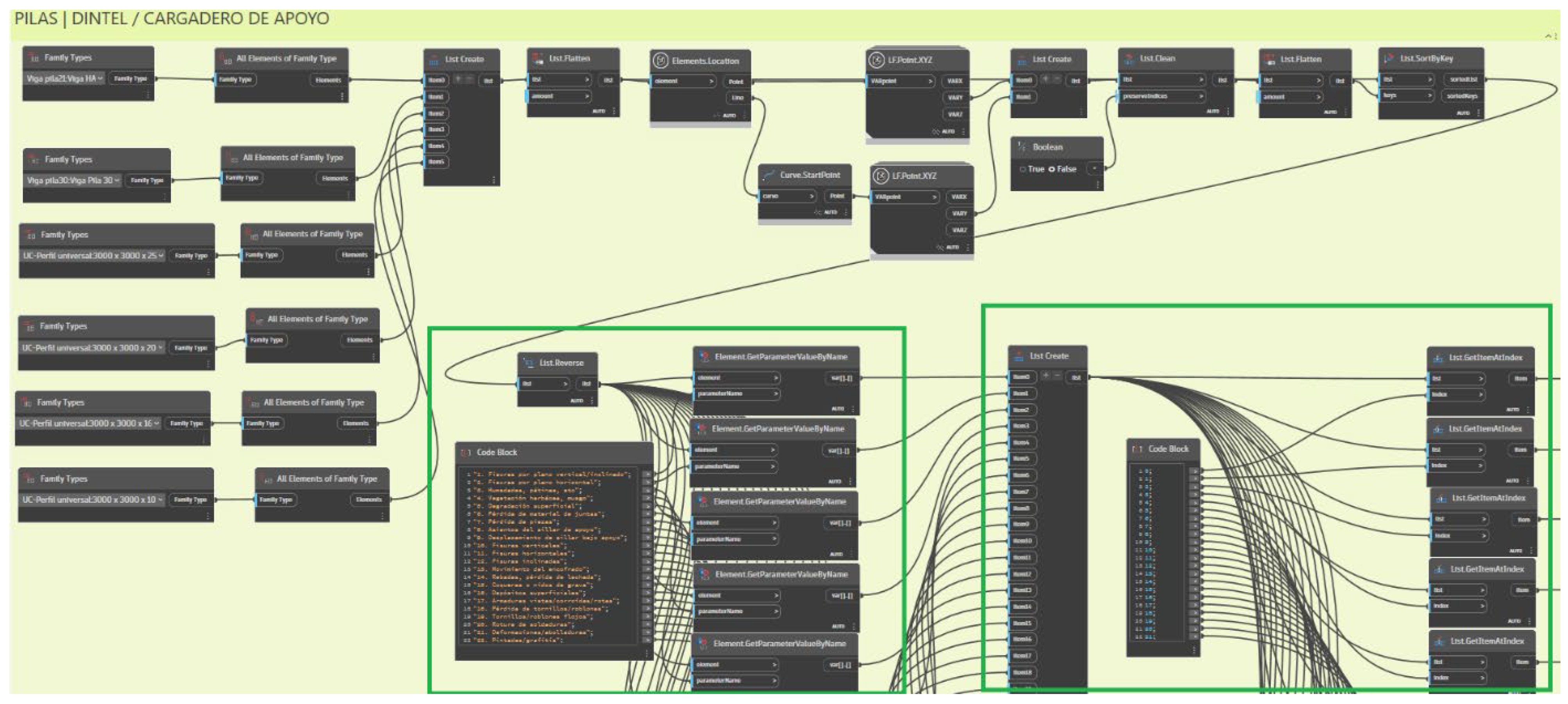

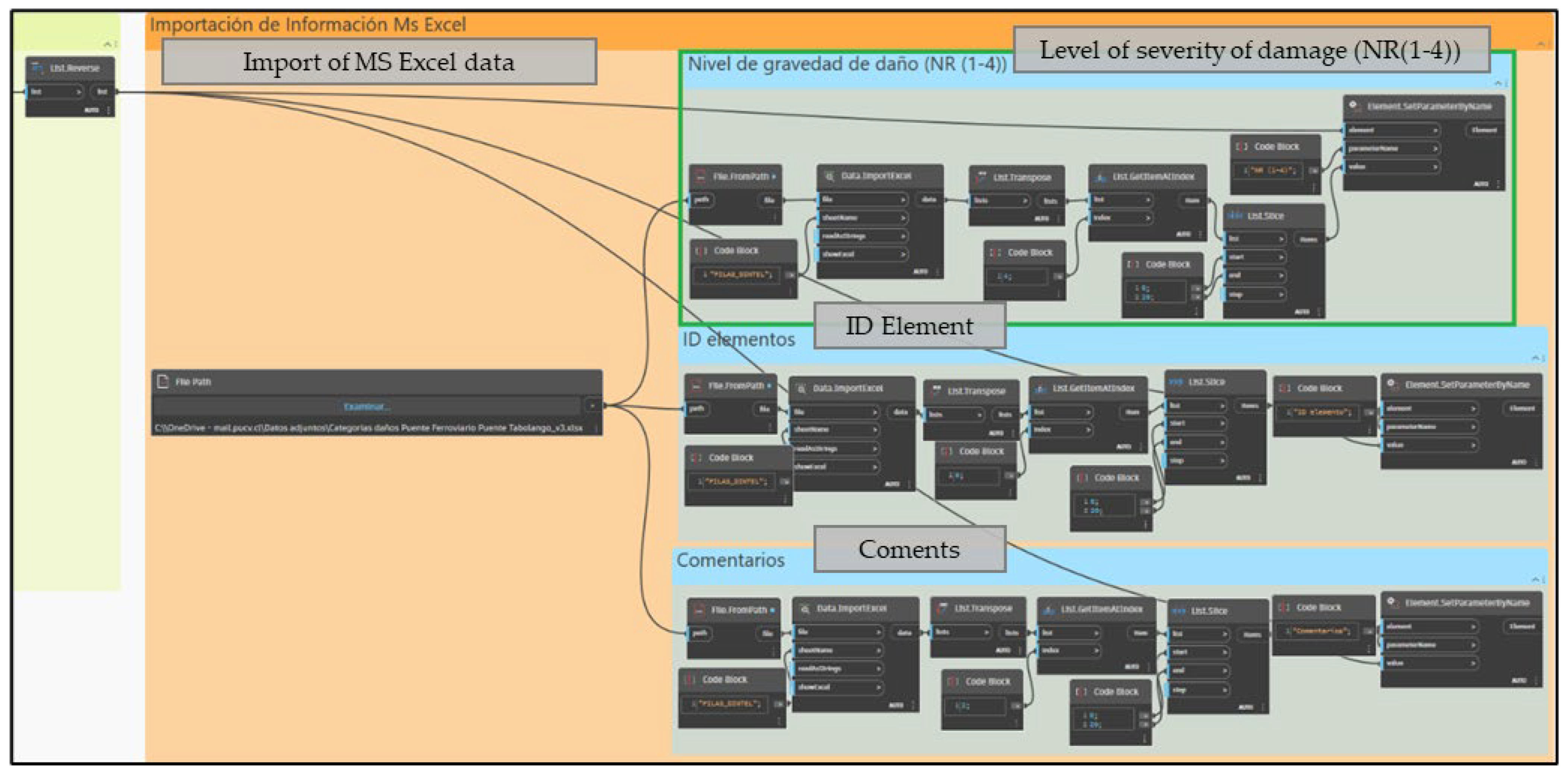

5.6. Creation of BIM/Data Automation

6. Discussion

6.1. General Discussion

- BIM/Data automation: The paper presents the integration of a parametric BIM model in Revit® with an automated spreadsheet in MS Excel® through visual programming in Dynamo. This BIM/data automation serves as an initial step towards creating a digital twin for railway bridges, significantly advancing traditional maintenance methods based on static data that are often difficult to reuse and integrate into a lifecycle management system.

- Bidirectional data exchange: The developed tool enables a bidirectional flow of information, allowing for the automatic import and export of data between the BIM model and the spreadsheet. This bidirectional exchange ensures that the structural condition of elements is accurately reflected in the BIM model based on real-time inspection data.

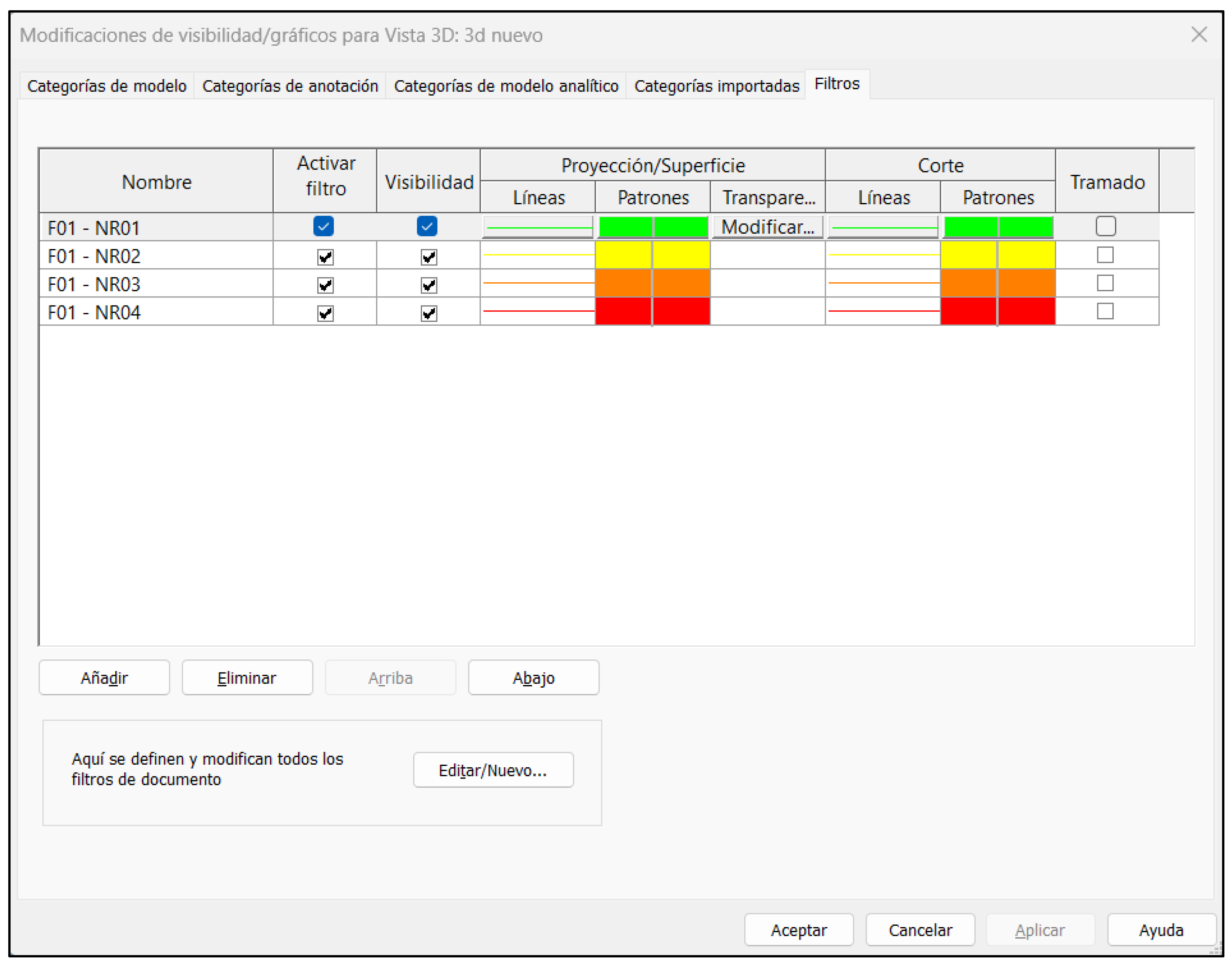

- Enhanced visual management: The automation allows the BIM model to visually reflect the condition of bridge elements by changing their colors based on the severity of the damage. This visual representation provides a clear and immediate understanding of the structural health of the bridge, facilitating more informed decision-making.

- Centralized information consolidation: By consolidating inspection data into a single, centralized source, the tool reduces the risk of information loss and improves data accessibility. This centralization streamlines the inspection process and enhances the efficiency of maintenance management.

- Preventive monitoring: The integration of the BIM model and automated spreadsheet supports a preventive approach to bridge maintenance. By providing an up-to-date digital and navigable representation of the bridge’s condition, the tool enables proactive identification and mitigation of potential issues, reducing the need for costly reactive repairs.

- Application in the case study: The methodology and tool were applied to a railway bridge in use, demonstrating the practical applicability and effectiveness of the proposed system. The case study highlights the tool’s capability to handle complex real-world scenarios and its potential for widespread adoption.

- Foundation for digital twins: The research lays the groundwork for adopting digital twins in the monitoring and maintenance of railway bridges. Digital twins offer significant advantages, such as real-time monitoring, predictive maintenance, and improved decision-making processes.

- Interoperability with related standards: The tool incorporates technical standards from Adif for defining damage categories and intensities, ensuring that the inspection criteria are aligned with established industry guidelines. This standardization enhances the reliability and accuracy of the inspection data. Additionally, using a reference standard with structured concepts enhances the scalability and interoperability of the tool, allowing for increased granularity, addition of new components, or expansion of the damage ontology.

- Customizable and scalable tool: The automated spreadsheet is designed to be generic and applicable to any railway bridge, with the flexibility to adjust element names, parameters, and sheets according to specific projects. This scalability makes the tool adaptable to various types of infrastructure.

6.2. Practical Implications

- Inspection and maintenance of railway bridges: The main application of the automation focuses on improving the processes of inspection, monitoring, and maintenance of railway bridges, particularly in inspection. By clearly visualizing the condition of each element and consolidating the information into a single source, decision-making regarding future maintenance actions is facilitated, following a preventive approach.

- Facility management: This can be particularly useful for companies and organizations responsible for the FM of railway bridges, as well as being part of an integrated management system for such assets. By having precise and updated information about the condition of the bridges, resource allocation and planning of inspection and maintenance activities can be optimized, ensuring safety and continuity of service.

- Training and education: The parametric BIM model and the visualization of the elements’ condition can be used as training and education tools for the personnel responsible for monitoring and maintaining railway bridges. This is of great value to professionals in charge of bridge inspections, as it provides an integrated platform to efficiently and accurately record and analyze data.

- Documentation and historical record: It allows maintaining a detailed historical record of all inspections, detected damages, and maintenance actions carried out on a railway bridge. This information can be valuable for audits, research, long-term analysis, etc.

6.3. Limitations

- The first limitation focuses on the damage intensities. This information available for each bridge element can be exported from Autodesk® Revit® to MS Excel®, but not the other way around. This is reflected in the proposed workflow of the tool because the spreadsheet contains all the damage intensities marked from the BIM model during the on-site visit, and the damage severity level value for each element is obtained, which is then imported into the model and changes the color of the elements. This is designed with the idea that during the on-site monitoring visit, it is more convenient to perform it with the help of software that allows the visualization of the BIM model, enabling the selection of damage intensities, rather than with the help of the automated spreadsheet on-site. However, if a change in intensity from MS Excel® is desired, it is possible to make the change and note it in the comments so that the intensity of the damage is modified in the model.

- The second limitation lies in the bidirectionality of the project, as the reciprocity of the components is only total in the pile divisions, that is, in the support lintels, shafts, and foundations, while for the beams and arches of the span and the superstructure of the non-structural elements, it is not possible to export the damage intensity parameters because these components were not parameterized. However, the comments and ID of the elements do have the desired bidirectionality, and the damage severity level can be imported for all bridge components, which explains why all elements of the model have a value in the “NR (1–4)” parameter.

- Although the automated spreadsheet is designed to be generic and applicable to any type of bridge, it is necessary to adjust the names of the elements, parameters, and sheets according to the specific case, which requires additional configuration effort.

7. Conclusions

- In this context, the BIM/data automation designed in this research, which integrates a parametrized BIM model with an automated data spreadsheet created from the Adif inspection manual, has several key functionalities.

- Clear visualization of the condition of each bridge element through automatic color changes based on the severity level of detected damages.

- Consolidation and centralized management of all information related to the bridge inspection in a single data source, significantly reducing the risk of information loss.

- Ability to export and import data bidirectionally between the BIM model and the data spreadsheet, facilitating the updating and synchronization of information.

- Historical record of all inspections, detected damages, and possible maintenance actions carried out on the railway bridge.

- Additionally, the same automated spreadsheet created in this research can be used for any railway bridge, only requiring configuration when programming in Dynamo.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Frangopol, D.M.; Beck, A.T.; Bittencourt, T.N. Maintenance, monitoring, safety, risk and resilience of bridges and bridge networks. In Proceedings of the Eighth International Conference on Bridge Maintenance, Safety and Management (IABMAS 2016), Foz do Iguaçu, Brazil, 26–30 June 2016. [Google Scholar]

- Park, G.; Lee, J.H.; Yoon, H. Semantic structure from motion for railroad bridges using deep learning. Appl. Sci. 2021, 11, 4332. [Google Scholar] [CrossRef]

- Tita, E.E.; Watanabe, G.; Shao, P.; Arii, K. Development and Application of Digital Twin–BIM Technology for Bridge Management. Appl. Sci. 2023, 13, 7435. [Google Scholar] [CrossRef]

- Azhar, A.S.; Kudus, S.A.; Jamadin, A.; Mustaffa, N.K.; Sugiura, K. Recent vibration-based structural health monitoring on steel bridges: Systematic literature review. Ain Shams Eng. J. 2024, 15, 102501. [Google Scholar] [CrossRef]

- Tung, P.-C.; Hwang, Y.-R.; Wu, M.-C. The Development of a Mobile Manipulator Imaging System for Bridge Crack Inspection. Available online: www.elsevier.com/locate/autcon (accessed on 1 December 2023).

- Costa, B.J.A.; Figueiras, J.A. Evaluation of a strain monitoring system for existing steel railway bridges. J. Constr. Steel Res. 2012, 72, 179–191. [Google Scholar] [CrossRef]

- Sutter, B.; Lelevé, A.; Pham, M.T.; Gouin, O.; Jupille, N.; Kuhn, M.; Lulé, P.; Michaud, P.; Rémy, P. A semi-autonomous mobile robot for bridge inspection. Autom. Constr. 2018, 91, 111–119. [Google Scholar] [CrossRef]

- Chan, B.; Guan, H.; Hou, L.; Jo, J.; Blumenstein, M.; Wang, J. Defining a conceptual framework for the integration of modelling and advanced imaging for improving the reliability and efficiency of bridge assessments. J. Civ. Struct. Health Monit. 2016, 6, 703–714. [Google Scholar] [CrossRef]

- Mohammadi, M.; Rashidi, M.; Yu, Y.; Samali, B. Integration of TLS-derived Bridge Information Modeling (BrIM) with a Decision Support System (DSS) for digital twinning and asset management of bridge infrastructures. Comput. Ind. 2023, 147, 103881. [Google Scholar] [CrossRef]

- Bocchini, P.; Frangopol, D.M.; Ummenhofer, T.; Zinke, T. Resilience and Sustainability of Civil Infrastructure: Toward a Unified Approach. J. Infrastruct. Syst. 2014, 20, 04014004. [Google Scholar] [CrossRef]

- Girardet, A.; Boton, C. A parametric BIM approach to foster bridge project design and analysis. Autom. Constr. 2021, 126, 103679. [Google Scholar] [CrossRef]

- Tzortzinis, G.; Ai, C.; Breña, S.F.; Gerasimidis, S. Using 3D laser scanning for estimating the capacity of corroded steel bridge girders: Experiments, computations and analytical solutions. Eng. Struct. 2022, 265, 114407. [Google Scholar] [CrossRef]

- Kaewunruen, S.; Sresakoolchai, J.; Zhou, Z. Sustainability-based lifecycle management for bridge infrastructure using 6D BIM. Sustainability 2020, 12, 2436. [Google Scholar] [CrossRef]

- Chen, S.S.; Shirolé, A.M. Integration of Information and Automation Technologies in Bridge Engineering and Management: Extending the State of the Art. Transp. Res. Rec. J. Transp. Res. Board 2006, 1976, 2–12. [Google Scholar] [CrossRef]

- NBR9452—Arquivo para Impressão. Available online: https://pdfcoffee.com/nbr9452-arquivo-para-impressao-pdf-free.html (accessed on 9 July 2024).

- DNIT Inspeções em Pontes e Viadutos de Concreto Armado e Protendido—Procedimento. Available online: https://www.gov.br/dnit/pt-br/assuntos/planejamento-e-pesquisa/ipr/coletanea-de-normas/coletanea-de-normas/procedimento-pro/DNIT_010_2004_PRO (accessed on 9 July 2024).

- Brasileira, N. ABNT NBR. 2013. Available online: www.abnt.org.br (accessed on 9 July 2024).

- Perno, M.; Hvam, L.; Haug, A. Implementation of digital twins in the process industry: A systematic literature review of enablers and barriers. Comput. Ind. 2021, 134, 103558. [Google Scholar] [CrossRef]

- Mohammadi, M.; Rashidi, M.; Mousavi, V.; Yu, Y.; Samali, B. Application of TLS Method in Digitization of Bridge Infrastructures: A Path to BrIM Development. Remote Sens. 2022, 14, 1148. [Google Scholar] [CrossRef]

- Agnisarman, S.; Lopes, S.; Madathil, K.C.; Piratla, K.; Gramopadhye, A. A survey of automation-enabled human-in-the-loop systems for infrastructure visual inspection. Autom. Constr. 2018, 97, 52–76. [Google Scholar] [CrossRef]

- Omer, M.; Margetts, L.; Mosleh, M.H.; Cunningham, L.S. Inspection of Concrete Bridge Structures: Case Study Comparing Conventional Techniques with a Virtual Reality Approach. J. Bridg. Eng. 2021, 26, 05021010. [Google Scholar] [CrossRef]

- Muñoz-La Rivera, F.; Mora-Serrano, J.; Valero, I.; Oñate, E. Methodological-Technological Framework for Construction 4.0. Arch. Comput. Methods Eng. 2021, 28, 689–711. [Google Scholar] [CrossRef]

- Cano, M.; Pastor, J.L.; Tomás, R.; Riquelme, A.; Asensio, J.L. A New Methodology for Bridge Inspections in Linear Infrastructures from Optical Images and HD Videos Obtained by UAV. Remote Sens. 2022, 14, 1244. [Google Scholar] [CrossRef]

- Venglár, M.; Lamperová, K.; Sokol, M. Performance assessment of steel truss railway bridge with curved track. Acta Polytech. 2022, 62, 558–566. [Google Scholar] [CrossRef]

- Indika, W.A.; Wijesooriya, P.; Siriwardane, S.C.; Dissanayake, P.B.R.; Wijesooriya, P. Vibration measurement-based simple technique for structural appraisal of steel bridges. In Proceedings of the 5th International Conference on Computational Methods in Structural Dynamics and Earthquake Engineering Methods in Structural Dynamics and Earthquake Engineering, Crete Island, Greece, 25–27 May 2015. [Google Scholar] [CrossRef]

- Popescu, C.; Täljsten, B.; Blanksvärd, T.; Sas, G.; Jimenez, A.; Gärdin, D.C.; Elfgren, L.; Carolin, A. Optical methods and wireless sensors for monitoring of bridges. In IABSE Symposium, Guimaraes 2019: Towards a Resilient Built Environment Risk and Asset Management—Report; International Association for Bridge and Structural Engineering (IABSE): Zurich, Switzerland, 2019; pp. 1191–1198. [Google Scholar] [CrossRef]

- Aglietti, A.; Biagini, C.; Bongini, A.; Ottobri, P. Historic bridges monitoring through sensor data management with bim methodologies. In International Archives of the Photogrammetry, Remote Sensing and Spatial Information Sciences—ISPRS Archives; International Society for Photogrammetry and Remote Sensing: Bethesda, MD, USA, 2023; pp. 33–41. [Google Scholar] [CrossRef]

- Gharehbaghi, V.R.; Noroozinejad Farsangi, E.; Noori, M.; Yang, T.Y.; Li, S.; Nguyen, A.; Málaga-Chuquitaype, C.; Gardoni, P.; Mirjalili, S. A Critical Review on Structural Health Monitoring: Definitions, Methods, and Perspectives. Arch. Comput. Methods Eng. 2022, 29, 2209–2235. [Google Scholar] [CrossRef]

- Carnevale, M.; Collina, A.; Peirlinck, T. A feasibility study of the drive-by method for damage detection in railway bridges. Appl. Sci. 2019, 9, 160. [Google Scholar] [CrossRef]

- Samadi, D.; Taghaddos, H.; Nili, M.H.; Noghabaei, M. Development of a Bridge Maintenance System Using Bridge Information Modeling. Civ. Eng. Infrastruct. J. 2021, 54, 351–364. [Google Scholar] [CrossRef]

- Thomson, I.; Angerstein, D. Historia del Ferrocarril en Chile; DIBAM, Centro de Investigaciones Diego Barros Arana: Santiago, Chile, 2000. [Google Scholar]

- Luo, X.; Haya, H.; Inaba, T.; Shiotani, T.; Nakanishi, Y. Damage evaluation of railway structures by using train-induced AE. Constr. Build. Mater. 2004, 18, 215–223. [Google Scholar] [CrossRef]

- Zhao, J.; Feng, H.; Chen, Q.; de Soto, B.G. Developing a conceptual framework for the application of digital twin technologies to revamp building operation and maintenance processes. J. Build. Eng. 2022, 49, 104028. [Google Scholar] [CrossRef]

- Lebelt, P.; Gehrke, J. Korrosionsschutztechnologie für Montageschweißstöße einer feuerverzinkten Stahlbrücke. Stahlbau 2017, 86, 191–196. [Google Scholar] [CrossRef]

- Linh, B.; Le, H. Modelling Railway Bridge Asset Management. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2013, 227, 644–656. [Google Scholar]

- Adasooriya, N.; Siriwardane, S.C. Remaining fatigue life estimation of railway bridge members subjected to time-dependent corrosion. In Proceedings of the IABSE Conference, Geneva 2015: Structural Engineering: Providing Solutions to Global Challenges—Report, Geneva, Switzerland, 23–25 September 2015; International Association for Bridge and Structural Engineering (IABSE): Zurich, Switzerland, 2015; pp. 1112–1119. [Google Scholar] [CrossRef]

- Calvert, G.; Neves, L.; Andrews, J.; Hamer, M. Multi-defect modelling of bridge deterioration using truncated inspection records. Reliab. Eng. Syst. Saf. 2020, 200, 106962. [Google Scholar] [CrossRef]

- Bujňák, J.; Gocál, J.; Hlinka, R. Assessment of Railway Steel Bridge Structures. Procedia Eng. 2016, 156, 75–82. [Google Scholar] [CrossRef]

- Akcamete, A.; Akinci, B.; Garrett, J.H. Potential Utilization of Building Information Models for Planning Maintenance Activities. 2010. Available online: https://www.researchgate.net/publication/260056325 (accessed on 9 July 2024).

- Salzano, A.; Parisi, C.M.; Acampa, G.; Nicolella, M. Existing assets maintenance management: Optimizing maintenance procedures and costs through BIM tools. Autom. Constr. 2023, 149, 104788. [Google Scholar] [CrossRef]

- Elyasi, N.; Bellini, A.; Klungseth, N.J. Digital transformation in facility management: An analysis of the challenges and benefits of implementing digital twins in the use phase of a building. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Trondheim, Norway, 11 May 2023. [Google Scholar] [CrossRef]

- Torzoni, M.; Tezzele, M.; Mariani, S.; Manzoni, A.; Willcox, K.E. A digital twin framework for civil engineering structures. Comput. Methods Appl. Mech. Eng. 2024, 418, 116584. [Google Scholar] [CrossRef]

- Liu, Q.; Gao, T. The Information Requirements for Transportation Industry’s Facilities Management Based on BIM. Open Constr. Build. Technol. J. 2017, 11, 136–141. [Google Scholar] [CrossRef]

- Aladağ, H.; Demirdöğen, G.; Demirbağ, A.T.; Işık, Z. Understanding the perception differences on BIM adoption factors across the professions of AEC industry. Ain Shams Eng. J. 2023, 14, 102545. [Google Scholar] [CrossRef]

- El-Din, M.N.; Pereira, P.F.; Martins, J.P.; Ramos, N.M.M. Digital Twins for Construction Assets Using BIM Standard Specifications. Buildings 2022, 12, 2155. [Google Scholar] [CrossRef]

- Park, C.; Pour Rahimian, F.; Dawood, N.; Pedro, A.; Dongmin, L.; Hussain, R.; Soltani, M. Digitalization in Construction Recent Trends and Advances; Taylor & Francis: London, UK, 2023; ISBN 9781003408949. [Google Scholar] [CrossRef]

- Nhamage, S.A. Development of BIM-Based Digital Twin Model for Fatigue Assessment in Metallic Railway Bridges. U.Porto J. Eng. 2023, 9, 12–23. [Google Scholar] [CrossRef]

- Kaewunruen, S.; AbdelHadi, M.; Kongpuang, M.; Pansuk, W.; Remennikov, A.M. Digital Twins for Managing Railway Bridge Maintenance, Resilience, and Climate Change Adaptation. Sensors 2022, 23, 252. [Google Scholar] [CrossRef] [PubMed]

- Costin, A.; Adibfar, A.; Hu, H.; Chen, S.S. Building Information Modeling (BIM) for transportation infrastructure—Literature review, applications, challenges, and recommendations. Autom. Constr. 2018, 94, 257–281. [Google Scholar] [CrossRef]

- VanDerHorn, E.; Mahadevan, S. Digital Twin: Generalization, characterization and implementation. Decis. Support Syst. 2021, 145, 113524. [Google Scholar] [CrossRef]

- Kang, J.-S.; Chung, K.; Hong, E.J. Multimedia knowledge-based bridge health monitoring using digital twin. Multimed. Tools Appl. 2021, 80, 34609–34624. [Google Scholar] [CrossRef]

- Bergs, T.; Gierlings, S.; Auerbach, T.; Klink, A.; Schraknepper, D.; Augspurger, T. The concept of digital twin and digital shadow in manufacturing. Procedia CIRP 2021, 101, 81–84. [Google Scholar] [CrossRef]

- Hilal, M.; Maqsood, T.; Abdekhodaee, A. A scientometric analysis of BIM studies in facilities management. Int. J. Build. Pathol. Adapt. 2019, 37, 122–139. [Google Scholar] [CrossRef]

- Rosen, R.; von Wichert, G.; Lo, G.; Bettenhausen, K.D. About the importance of autonomy and digital twins for the future of manufacturing. IFAC-PapersOnLine 2015, 48, 567–572. [Google Scholar] [CrossRef]

- Lawrence, C.; Tuunanen, T.; Myers, M.D. Extending Design Science Research Methodology for a Multicultural World. In Proceedings of the Human Benefit through the Diffusion of Information Systems Design Science Research: IFIP WG 8.2/8.6 International Working Conference, Perth, Australia, 30 March–1 April 2010. [Google Scholar]

- Peffers, K.; Tuunanen, T.; Rossi, M. The Design Science Research Process: A Model for Producing and Presenting Information Systems Research. 2006. Available online: https://www.researchgate.net/publication/238077290 (accessed on 1 December 2023).

- Aldea, L.E.; Barquín, J.A.G. Historia y futuro del mantenimiento y la vigilancia de los puentes ferroviarios. Hormig. Acero 2021, 72, 151–161. [Google Scholar] [CrossRef]

- Zhang, A.; Yang, J.; Wang, F. Application and enabling digital twin technologies in the operation and maintenance stage of the AEC industry: A literature review. J. Build. Eng. 2023, 80, 107859. [Google Scholar] [CrossRef]

- Leander, J.; Andersson, A.; Karoumi, R. Enhanced assessment of the remaining service life of a steel railway bridge. Key Eng. Mater. 2009, 413–414, 245–252. [Google Scholar] [CrossRef]

- Ko, J.M.; Ni, Y.-Q. Technology developments in structural health monitoring of large-scale bridges. Eng. Struct. 2005, 27, 1715–1725. [Google Scholar] [CrossRef]

- Luo, X.; Haya, H.; Inaba, T.; Shiotani, T.; Nakanishi, Y. Secondary AE Techniques for Non-Destructive Inspection of Railway Structures. Q. Rep. RTRI 2003, 44, 154–159. [Google Scholar] [CrossRef]

- Akintunde, E.; Azam, S.E.; Linzell, D.G. Singular value decomposition and unsupervised machine learning for virtual strain sensing: Application to an operational railway bridge. Structures 2023, 58, 105417. [Google Scholar] [CrossRef]

- Frigui, F.; Faye, J.; Martin, C.; Dalverny, O.; Peres, F.; Judenherc, S. Global methodology for damage detection and localization in civil engineering structures. Eng. Struct. 2018, 171, 686–695. [Google Scholar] [CrossRef]

- Rakoczy, A.M. Estimation of the current structural reliability level of existing railway bridges and viaducts. Roads Bridges Drogi Mosty 2021, 20, 289–309. [Google Scholar] [CrossRef]

- Kale, A.; Kassa, Y.; Ricks, B.; Gandhi, R. A Comparative Assessment of Bridge Deck Wearing Surfaces: Performance, Deterioration, and Maintenance. Appl. Sci. 2023, 13, 10883. [Google Scholar] [CrossRef]

- Seo, M.B.; Lee, D. Development of railway infrastructure bim prototype libraries. Appl. Sci. 2020, 10, 8118. [Google Scholar] [CrossRef]

- Ospina-Bohórquez, A.; López-Rebollo, J.; Muñoz-Sánchez, P.; González-Aguilera, D. A Digital Twin for Monitoring the Construction of a Wind Farm. Infrastructures 2023, 8, 10. [Google Scholar] [CrossRef]

- Negri, E.; Fumagalli, L.; Macchi, M. A Review of the Roles of Digital Twin in CPS-based Production Systems. Procedia Manuf. 2017, 11, 939–948. [Google Scholar] [CrossRef]

- Opoku, D.-G.J.; Perera, S.; Osei-Kyei, R.; Rashidi, M. Digital twin application in the construction industry: A literature review. J. Build. Eng. 2021, 40, 102726. [Google Scholar] [CrossRef]

- Huang, W.; Zhang, Y.; Zeng, W. Development and application of digital twin technology for integrated regional energy systems in smart cities. Sustain. Comput. Inform. Syst. 2022, 36, 100781. [Google Scholar] [CrossRef]

- Hosamo, H.H.; Nielsen, H.K.; Alnmr, A.N.; Svennevig, P.R.; Svidt, K. A review of the Digital Twin technology for fault detection in buildings. Front. Built Environ. 2022, 8, 1013196. [Google Scholar] [CrossRef]

- Jiang, F.; Ma, L.; Broyd, T.; Chen, K. Digital twin and its implementations in the civil engineering sector. Autom. Constr. 2021, 130, 103838. [Google Scholar] [CrossRef]

- Anales del Instituto de Ingenieros de Chile. Puente Sobre el río Aconcagua en el Ferrocarril de San Pedro al Puerto de Quintero; Anales del Instituto de Ingenieros de Chile: Santiago, Chile, 2014; p. 504. Available online: https://rchdt.uchile.cl/index.php/AICH/article/view/33763 (accessed on 1 December 2023).

- ADIF. Inspección Principal de Puentes de Ferrocarril. NAP 2-4-1.0. Norma ADIF Plataforma. Segunda Edición: Enero 2023. Available online: https://drive.google.com/drive/folders/1FMI4yRUPQMK3AFyYt_FLKVnq07RC5NUf?usp=sharing (accessed on 9 July 2024).

- Volk, R.; Stengel, J.; Schultmann, F. Building Information Modeling (BIM) for existing buildings—Literature review and future needs. Autom. Constr. 2014, 38, 109–127. [Google Scholar] [CrossRef]

- Asare, K.A.B.; Liu, R.; Anumba, C.J. Building information modelling for airport facility management: The case of a US airport. Infrastruct. Asset Manag. 2024, 11, 3–14. [Google Scholar] [CrossRef]

- Zhou, Y.; Bao, T.; Shu, X.; Li, Y.; Li, Y. BIM and ontology-based knowledge management for dam safety monitoring. Autom. Constr. 2023, 145, 104649. [Google Scholar] [CrossRef]

- Zhang, L.; Wu, X.; Ding, L.; Skibniewski, M.J.; Lu, Y. Bim-Based Risk Identification System in tunnel construction. J. Civ. Eng. Manag. 2016, 22, 529–539. [Google Scholar] [CrossRef]

- Castañeda, K.; Sánchez, O.; Herrera, R.F.; Gómez-Cabrera, A.; Mejía, G. Building Information Modeling Uses and Complementary Technologies in Road Projects: A Systematic Review. Buildings 2024, 14, 563. [Google Scholar] [CrossRef]

- Liu, Z.; Chi, Z.; Osmani, M.; Demian, P. Blockchain and building information management (Bim) for sustainable building development within the context of smart cities. Sustainability 2021, 13, 2090. [Google Scholar] [CrossRef]

- Marzouk, M.; Othman, A. Planning utility infrastructure requirements for smart cities using the integration between BIM and GIS. Sustain. Cities Soc. 2020, 57, 102120. [Google Scholar] [CrossRef]

| Damage | Category | Damage Intensity |

|---|---|---|

| Vertical cracks | 4 | (1) Localized cracks with an opening < 2 mm, affecting < 20% of the shaft height, regardless of the opening. |

| (2) Localized cracks with an opening of 2–5 mm, affecting between 20–40% of the shaft height, regardless of the opening. | ||

| (3) Localized cracks with an opening of 5–10 mm, affecting 40–60% of the shaft height, regardless of the opening. | ||

| (4) Localized cracks with an opening > 10 mm, affecting > 60% of the shaft height. | ||

| Moisture, patinas, crusts, or efflorescences | 2 | (1) Extent < 25% of the element’s surface (No other damage). |

| (2) Extent between 25–50% of the element’s surface, or there are other significant deteriorations. | ||

| (3) Extent between 50–75% of the element’s surface or associated medium-severity damage. | ||

| (4) Extent > 75% of the element’s surface, or there are other high-severity deteriorations. | ||

| Paintings/Graffiti | 1 | (1) Extent < 25% of the affected surface. |

| (2) Extent between 25–50% of the affected surface. | ||

| (3) Extent between 50–75% of the affected surface. | ||

| (4) Extent > 75% of the affected surface. | ||

| Rooted arboreal vegetation | 3 | (1) Woody vegetation in initial growth, causing no deterioration to the shaft. |

| (2) Woody vegetation causing slight deterioration. | ||

| (3) Woody vegetation causing medium deterioration. | ||

| (4) Woody vegetation causing severe deterioration. | ||

| Nesting, dirt | 2 | (1) Isolated presence of dirt or isolated deposits of small volume. |

| (2) Widespread presence of dirt on < 30% of the pile elements. | ||

| (3) Widespread presence of dirt on 30–60% of the pile elements. | ||

| (4) Widespread presence of dirt on > 60% of the pile elements. |

| Damage | Category | Damage Intensity |

|---|---|---|

| Cracks perpendicular to the main axis of the beam | 4 | (1) Cracks not associated with bending stresses, with an opening < 0.40 mm. |

| (2) Cracks not associated with bending stresses, with an opening > 0.40 mm; cracks associated with bending stresses, with an opening < 1.00 mm or affecting < 40% of the beam’s depth. | ||

| (3) Cracks associated with bending stresses, with an opening between 1.00–3.00 mm or affecting 40–60% of the beam’s depth. | ||

| (4) Cracks associated with bending stresses with an opening > 3.00 mm or affecting > 60% of the beam’s depth. | ||

| Honeycombing or gravel nests | 2 | (1) Surface wear, affecting < 25% of the beam’s surface. |

| (2) Surface wear, slight reduction in concrete cover, affecting 25–50% of the beam’s surface. | ||

| (3) Noticeable reduction in concrete cover, affecting 50–75% of the beam’s surface. | ||

| (4) Degradation, visible rebar, affecting > 75% of the beam’s surface. | ||

| Herbaceous vegetation, moss, or lichens | 2 | (1) Non-woody vegetation covering < 25% of the beam’s surface. |

| (2) Non-woody vegetation covering 25–50% of the beam’s surface. | ||

| (3) Non-woody vegetation covering 50–75% of the beam’s surface. | ||

| (4) Non-woody vegetation covering > 75% of the beam’s surface | ||

| Deformations | 4 | (1) Visible deformation, but < 0.05% of the beam’s magnitude relative to its theoretical plane. |

| (2) Visible deformation, but between 0.05 and 0.10% of the beam’s magnitude relative to its theoretical plane. | ||

| (3) Visible deformation, but between 0.10 and 0.50% of the beam’s magnitude relative to its theoretical plane. | ||

| (4) Visible deformation, but > 0.50% of the beam’s magnitude relative to its theoretical plane. | ||

| Visible/corroded/broken rebar | 4 | (1) Visible secondary rebar. |

| (2) Visible main rebar or corroded secondary rebar with losses < 50% of the beam’s reinforcement. | ||

| (3) Corroded main rebar with losses < 10% of the main reinforcement section, or secondary rebar with losses ≥ 50%. | ||

| (4) Corroded main rebar with losses ≥ 10% of the main reinforcement section. |

| Damage Severity | Description |

|---|---|

| 1 | Defects with no impact on the structural behavior of the asset, railway operations, or the durability or functionality of the asset. |

| 2 | Defects with no impact on the structural behavior of the asset or railway operations but that undermine the durability or functionality of the asset. |

| 3 | Defects indicating a pathological evolution that may affect the structural safety of the asset, the safety of the users, or railway operations. |

| 4 | Defects affecting structural safety or railway operations. Speed limitation is required to maintain safety levels. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cavieres-Lagos, S.; Muñoz La Rivera, F.; Atencio, E.; Herrera, R.F. Integration of BIM Tools for the Facility Management of Railway Bridges. Appl. Sci. 2024, 14, 6209. https://doi.org/10.3390/app14146209

Cavieres-Lagos S, Muñoz La Rivera F, Atencio E, Herrera RF. Integration of BIM Tools for the Facility Management of Railway Bridges. Applied Sciences. 2024; 14(14):6209. https://doi.org/10.3390/app14146209

Chicago/Turabian StyleCavieres-Lagos, Sebastián, Felipe Muñoz La Rivera, Edison Atencio, and Rodrigo F. Herrera. 2024. "Integration of BIM Tools for the Facility Management of Railway Bridges" Applied Sciences 14, no. 14: 6209. https://doi.org/10.3390/app14146209

APA StyleCavieres-Lagos, S., Muñoz La Rivera, F., Atencio, E., & Herrera, R. F. (2024). Integration of BIM Tools for the Facility Management of Railway Bridges. Applied Sciences, 14(14), 6209. https://doi.org/10.3390/app14146209