Advances in Solutions to Improve the Energy Performance of Agricultural Greenhouses: A Comprehensive Review

Abstract

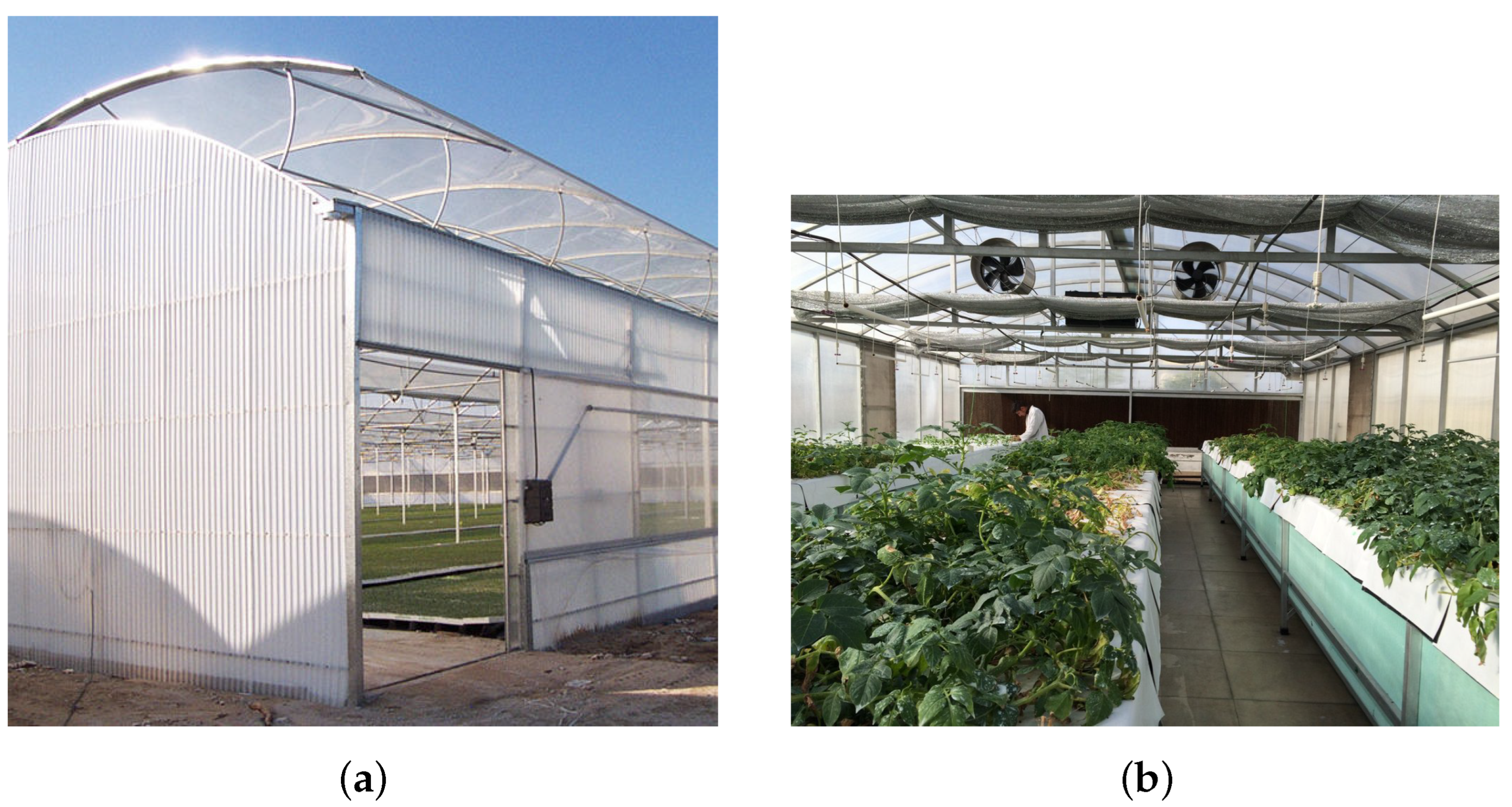

1. Introduction

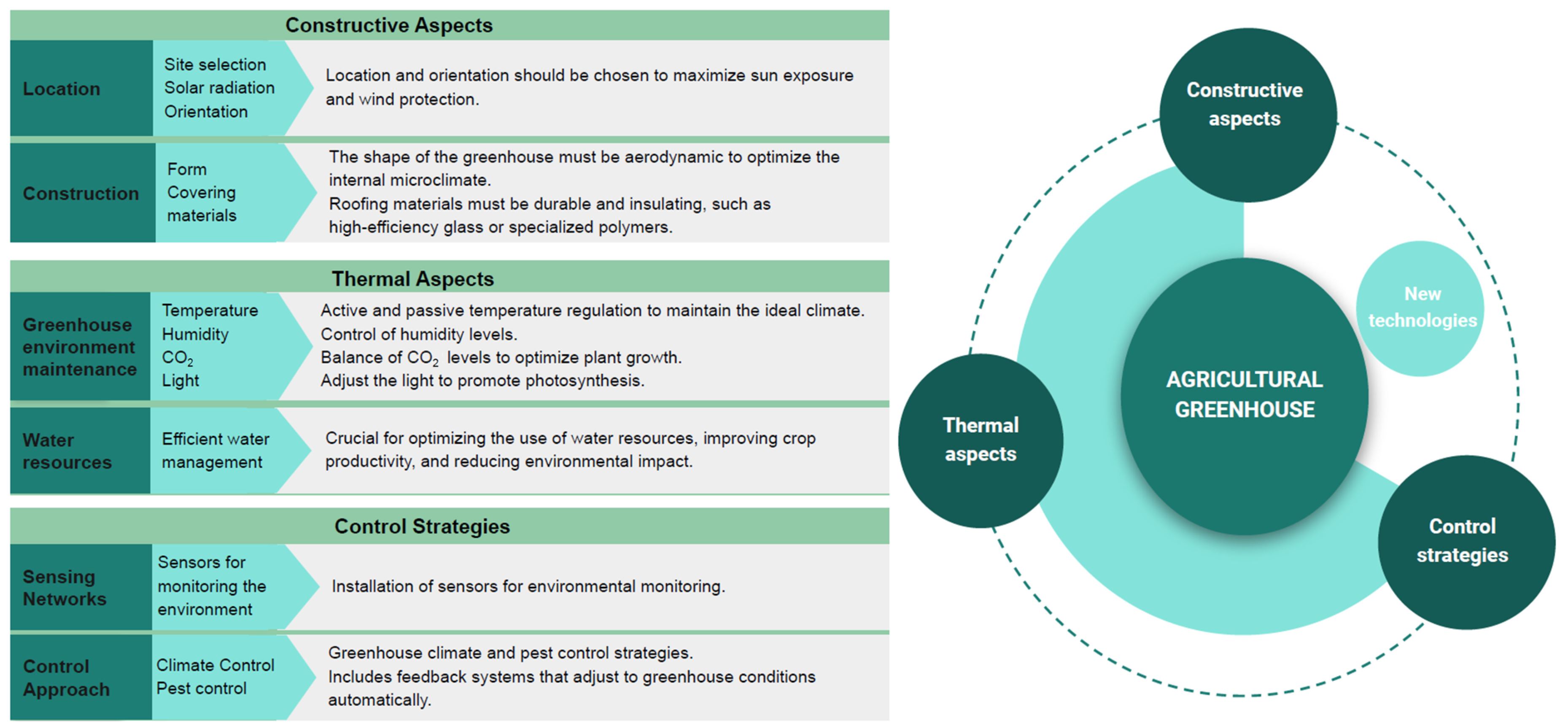

2. Construction Aspects for Energy Performance Improvement

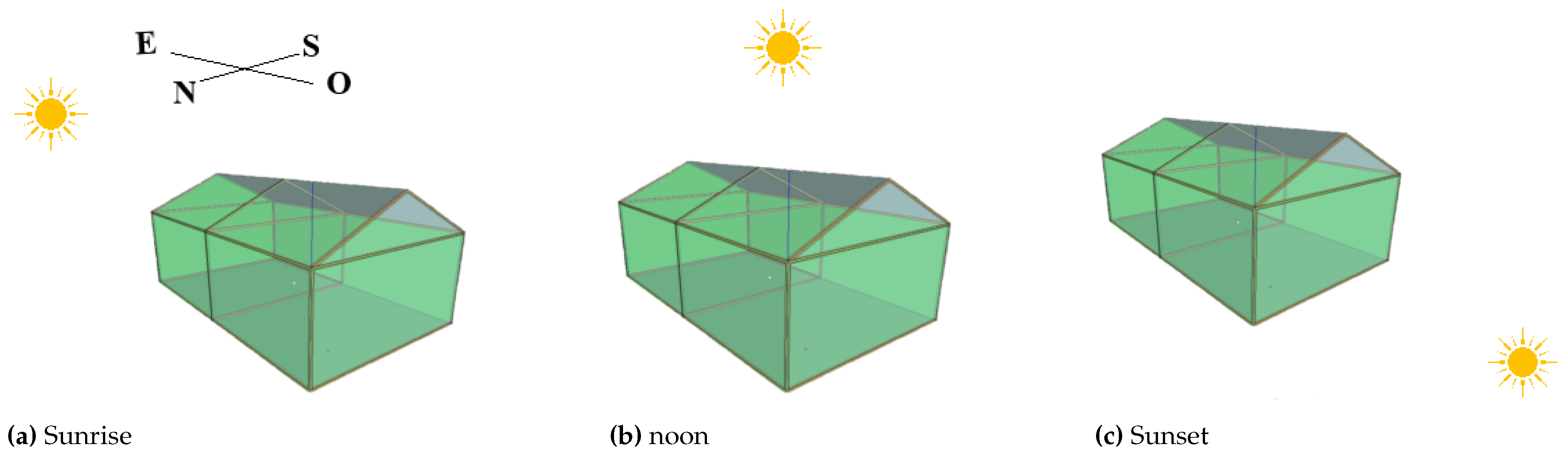

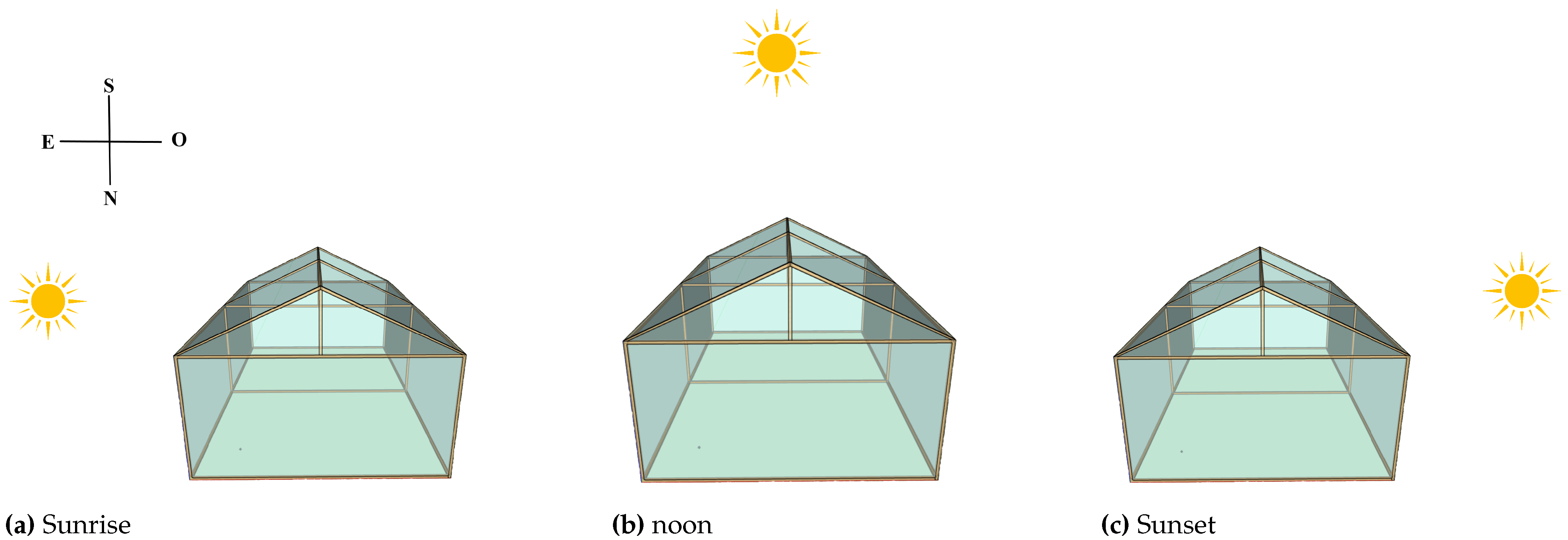

2.1. Location and Orientation

2.1.1. Choosing the Location and Orientation of Greenhouses

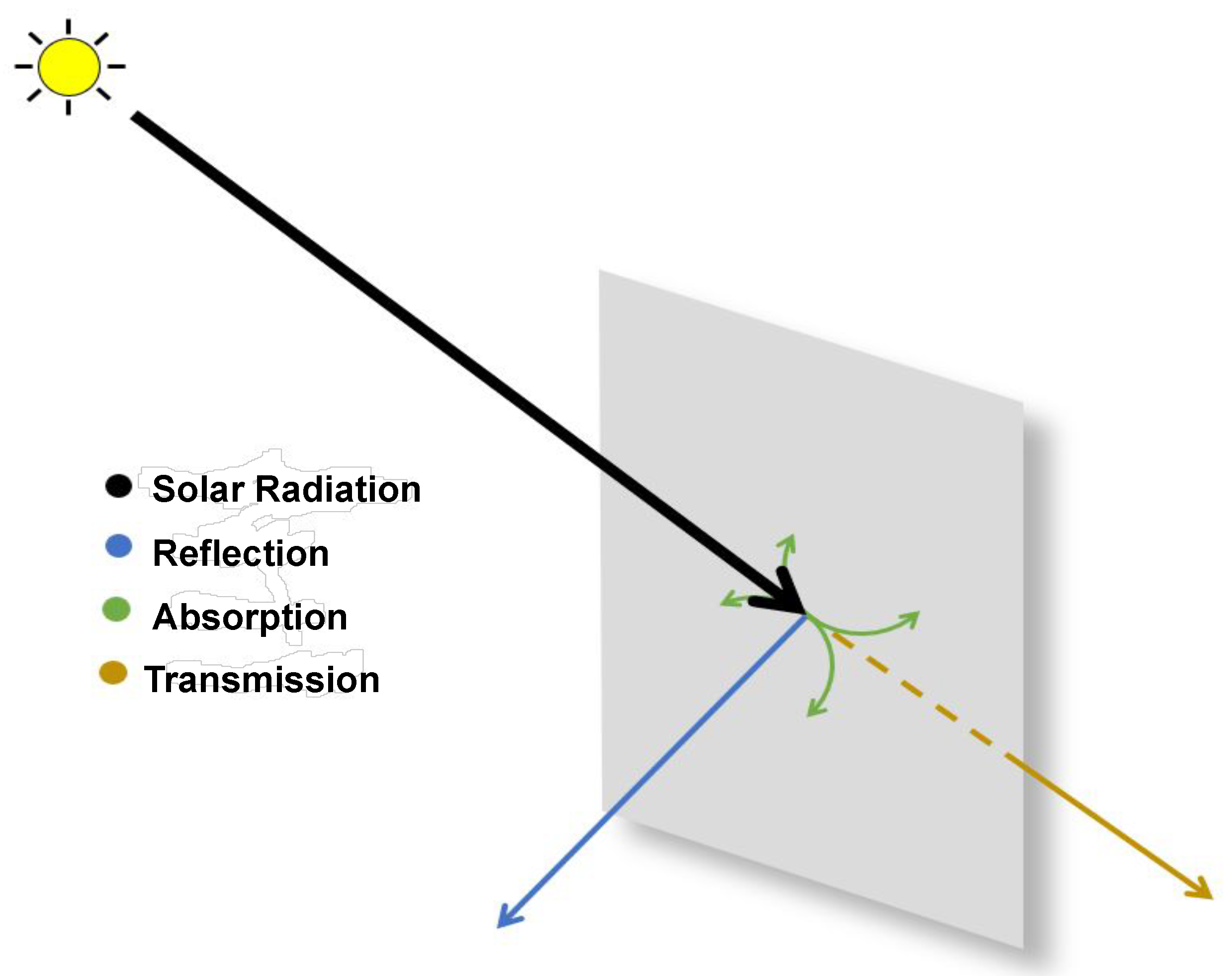

2.1.2. Influence of Solar Radiation on Greenhouses

2.2. Greenhouse Construction

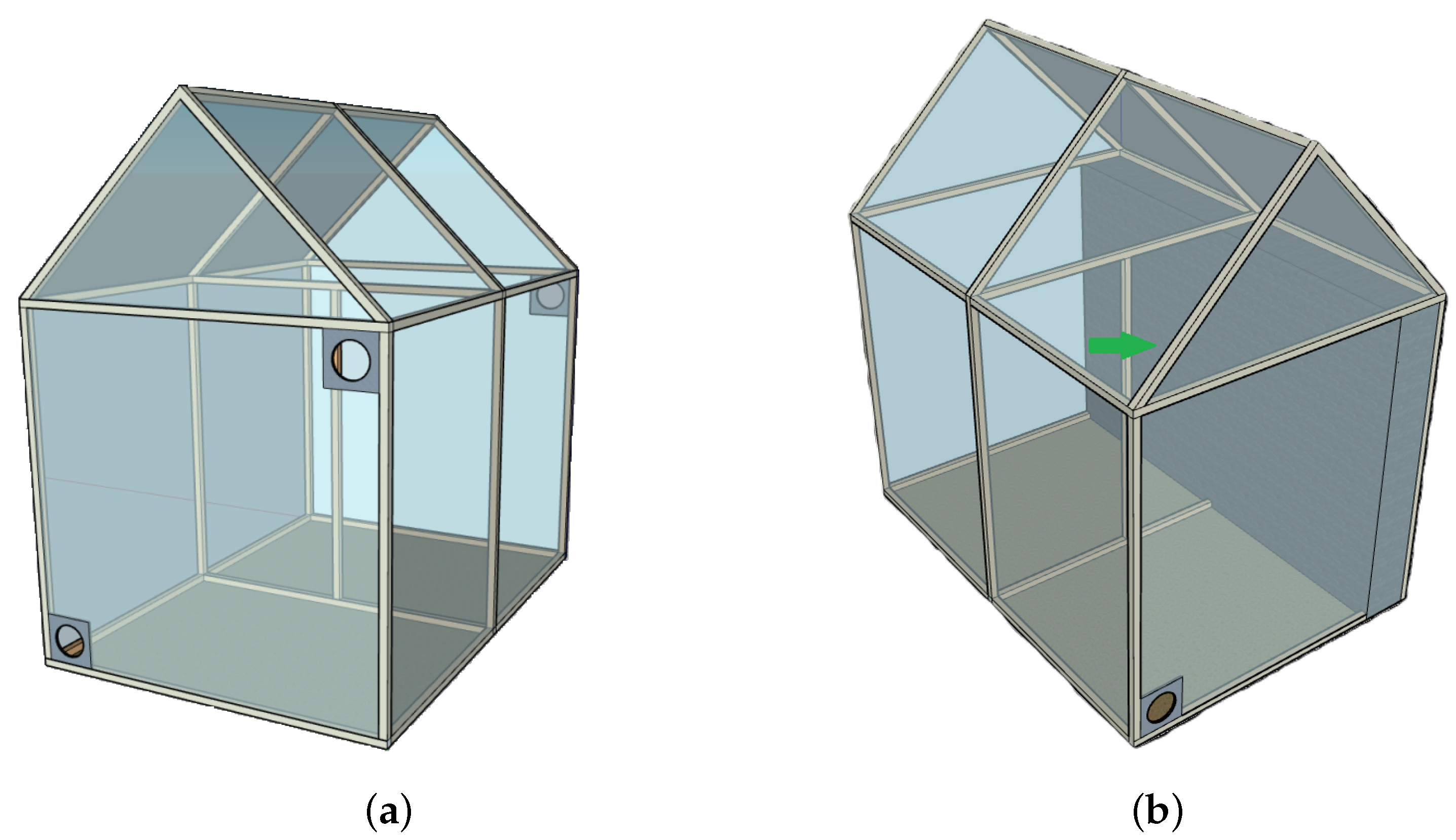

2.2.1. Greenhouse Shapes and Their Impacts

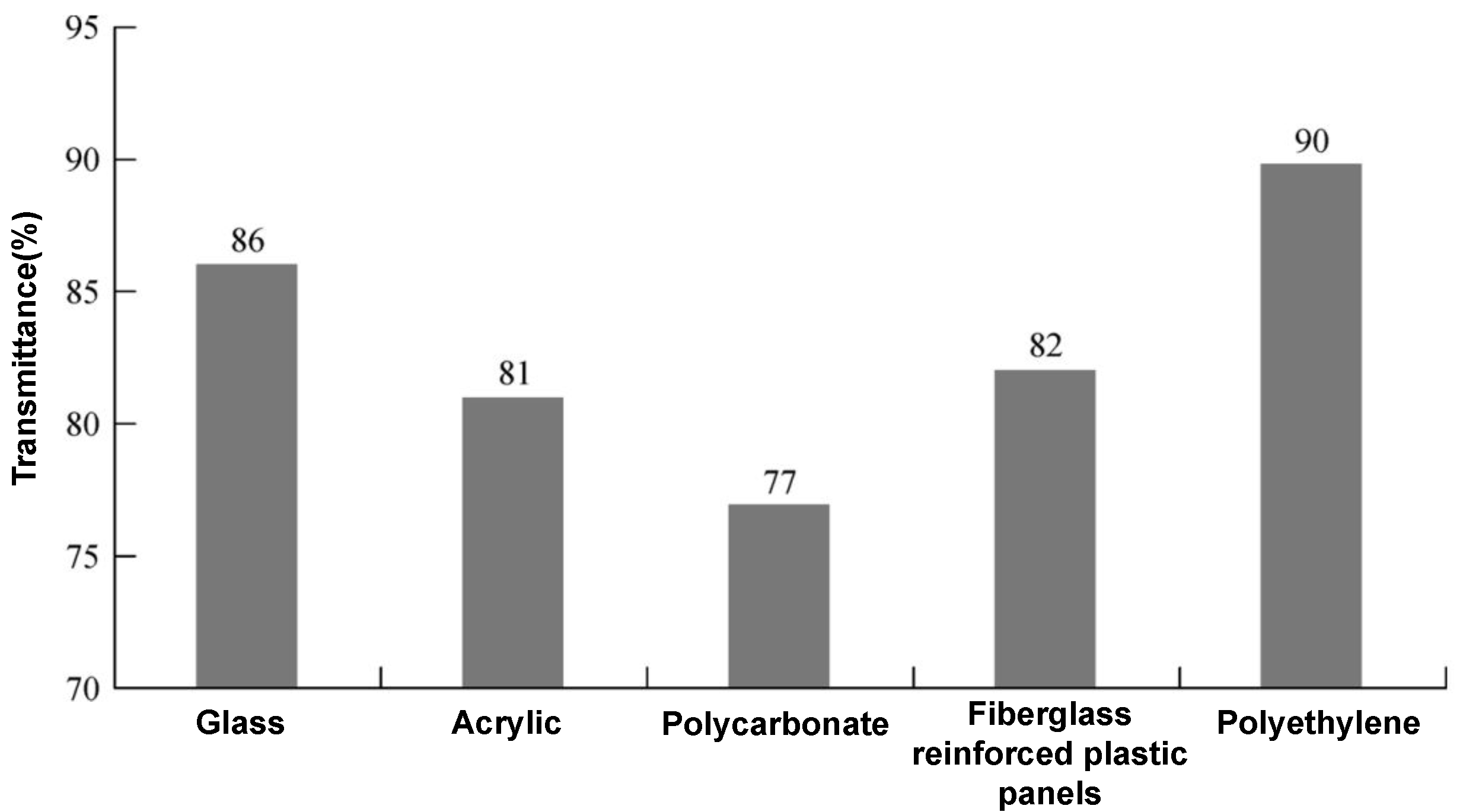

2.2.2. Covering and Insulation Material for Greenhouses

3. Thermal Aspects for Improving Energy Performance

3.1. Maintenance of the Greenhouse Environment

3.1.1. Temperature Maintenance

3.1.2. Humidity Maintenance

3.1.3. Passive Heating and Cooling Systems

3.1.4. Active Heating and Cooling Systems

3.1.5. Maintenance of Carbon Dioxide and Light

3.2. Water Resources in Greenhouses

4. Control Strategies in Greenhouses

4.1. Sensors Used in Greenhouses

- Temperature Sensors: Monitor air and soil temperatures inside the greenhouse, allowing automatic adjustments to maintain optimal conditions for plant growth [232].

- Humidity Sensors: Measure relative air humidity and soil moisture, helping to ensure that plants receive the appropriate amount of water [233].

- Light Sensors: Monitor the intensity and duration of light received by plants, helping to control artificial lighting to optimize photosynthesis [234].

- sensors: Measure carbon dioxide levels in the environment, which is crucial for photosynthesis and plant growth [235].

- pH and EC (Electrical Conductivity) sensors: Monitor the pH and electrical conductivity of the nutrient solution, ensuring that plants receive nutrients appropriately [236].

- Wind and Precipitation Sensors: Used mainly in greenhouses with natural ventilation, they help adjust ventilation openings based on external conditions [237].

- Pest Presence Sensors: Detect the presence of pests and diseases, allowing quick and effective intervention [238].

4.2. Actuators Used in Greenhouses

- Automated Irrigation Systems: Control the quantity and frequency of irrigation based on soil moisture data [239].

- Fans and Ventilation Systems: Regulate air circulation and ventilation within the greenhouse to maintain adequate temperature and humidity [240].

- Heaters: Maintain the ideal temperature in cold climates, activating automatically when the temperature drops below a certain level [241].

- Shading Systems: Control the amount of sunlight that enters the greenhouse, protecting plants from excess light and heat [242].

- Grow Lamps: Provide supplemental lighting, especially during periods of low natural light, to ensure plants receive enough light for photosynthesis [243].

- dosers: Adjust carbon dioxide levels in the environment to optimize plant growth [244].

- Automatic Ventanas and Blinds: Automatically adjust to control ventilation and sunlight based on sensor data [235].

5. New Technologies in Greenhouses

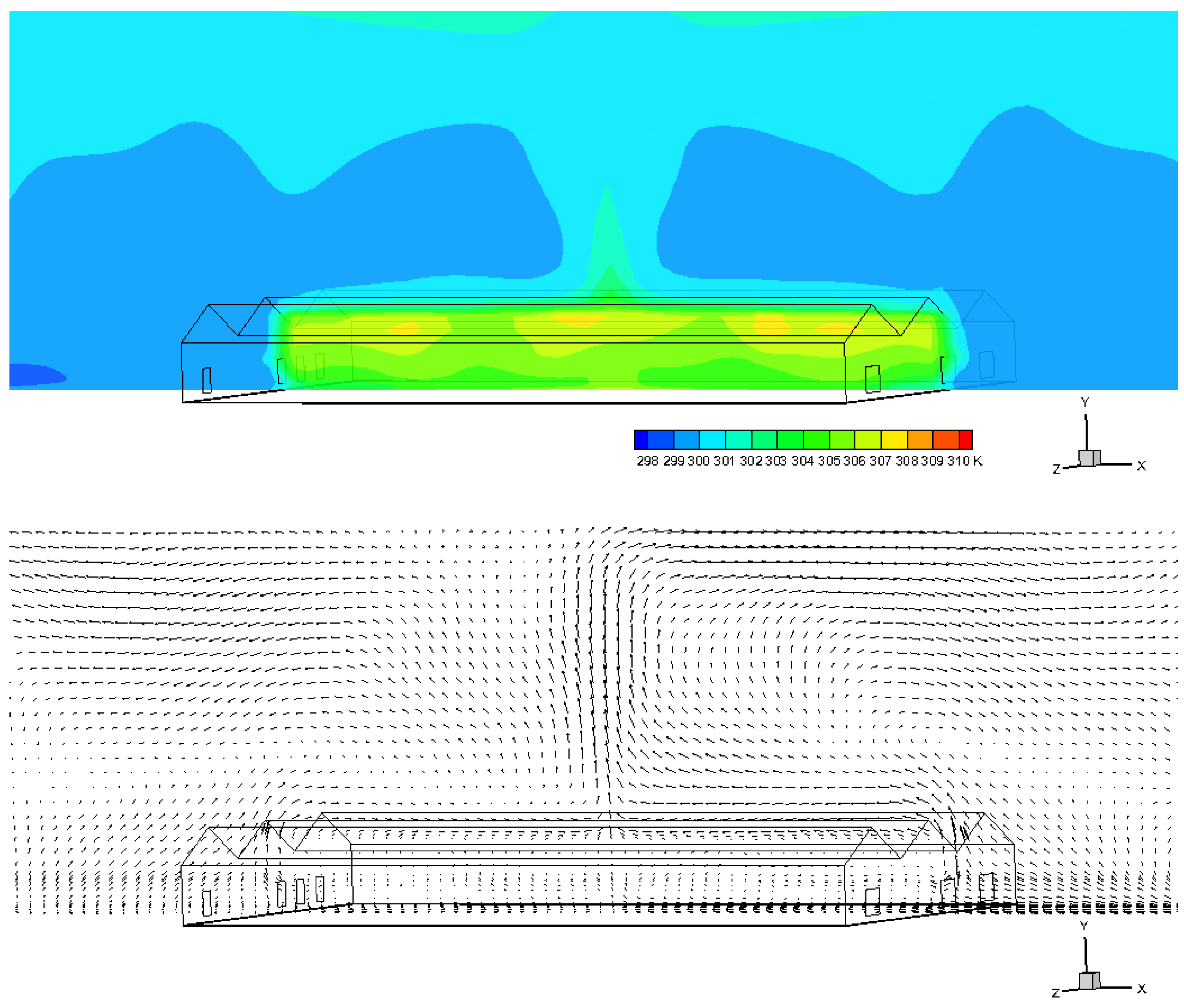

5.1. Computational Modeling and Simulation

5.1.1. Benefits of Computational Modeling and Simulation in Greenhouses

- Optimizing Energy Efficiency: Optimizes energy consumption in greenhouses, resulting in a more sustainable and economical operation. It predicts the thermal behavior of the greenhouse and allows adjustments that reduce energy use [43].

- Improved Microclimatic Control: Allows you to accurately predict and control microclimatic conditions inside the greenhouse, including temperature, humidity and concentration, which improves plant growth and health [258].

- Development of Accurate Models: Computational modeling allows for the creation of detailed models that consider several factors, such as solar radiation, airflow and evapotranspiration, providing an accurate prediction of the greenhouse’s internal environment [194].

- Greenhouse Planning and Design: Computer simulation helps in the planning and design of greenhouses, allowing the evaluation of different configurations and materials to optimize energy performance and growing conditions [45].

5.1.2. Challenges and Considerations in Greenhouses

- Complexity and Initial Cost: Implementing computational modeling systems can be complex and expensive, requiring advanced hardware and software, as well as qualified professionals to configure and operate the models [263].

- Maintenance and Update: Computer models and simulation systems require regular maintenance and technology updates to ensure ongoing accuracy and efficiency. This includes sensor calibration and algorithm updating [254].

- Qualification and Training: Operators and managers need to be trained to understand and effectively use modeling and simulation technologies. Lack of training can lead to underutilization of these advanced tools [264].

- Data Integration: Collecting and integrating accurate, real-time data from sensors and other devices is crucial to the effectiveness of models. Any discrepancies in the data can affect the accuracy of simulations and subsequent decisions [265].

5.2. Automation of Greenhouse

- Increased Productivity: Controlled conditions allow for faster cultivation cycles and higher yields [266].

- Efficient Use of Resources: Reduced waste of water and nutrients, in addition to lower energy consumption [279].

- Sustainability: Lower environmental impact due to efficient use of resources and reduced need for pesticides [285].

- Quality and Consistency: Producing high-quality food with less variability [266].

- Initial Cost: Implementing automated systems can be expensive, but the long-term benefits often justify the investment [294].

- Maintenance and Updates: Automated systems require regular maintenance and technological updates to remain efficient [225].

- Training: Operators and managers need to be trained to use and maintain automation technologies effectively [287].

6. Building More Efficient Greenhouses in Diverse Climates

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| MDPI | Multidisciplinary Digital Publishing Institute |

| DOAJ | Directory of open access journals |

| TLA | Three letter acronym |

| LD | Linear dichroism |

| UN | United Nations |

| EAHE | Earth-Air Heat |

| MCDA | Multi-criteria Decision Analysis |

| GIS | Geographic Information Systems |

| DEM | Digital Elevation Data Modeling |

| F-DEMATEL | FUZZY-DEcision-MAking Trial and Evaluation Laboratory |

| PV | Photovoltaic |

| AHP | Analytical Hierarchy Process |

| BES | Building Energy Simulation |

| OSCs | Organic Solar Cells |

| CPV/T | Photovoltaic/Thermal concentrator |

| TES | Thermal Energy Storage |

| PE | Polyethylene |

| EVA | EthylVinylAcetate |

| PC | Polycarbonate |

| UV | Ultra Violet |

| PCMs | Phase Transition Materials |

| PAR | Photosynthetic Active Radiation |

| CBD | Completely Randomized Design |

| EU | European Union |

| MHPAs | Micro Heat Pipe Arrays |

| CFD | Computational Fluid Dynamic |

| CMV | Controlled Mechanical Ventilation |

| DSSC | Dye Sensitized Solar Cell |

| OPV | Organic PhotoVoltaic |

| ACH | Air Changes Per Hour |

| FEM | Finite Element Method |

| FVM | Finite Volume Method |

| 3D | Three Dimensional |

| ANFIS | Adaptive Neuro-Fuzzy Inference System |

| LSIS | Laser Spray Irrigation System |

| UNMR | One-sided Nuclear Magnetic Resonance |

| PPFD | Photosynthetic Photon Flux Density |

| FAM | Fuzzy Associative Memory |

| ANN | Artificial Neural Networks |

| UAVs | Drones and Unmanned Aerial Vehicles |

| RCNN | Regional Convolutional Neural Networks |

| WSN | Wireless Sensor Networks |

References

- UNICEF. Trends in Maternal Mortality 2000 to 2017 Estimates by WHO, UNICEF, UNFPA, World Bank Group and the United Nations Population Division; World Health Organization: Geneva, Switzerland, 2019. [Google Scholar]

- Vollset, S.E.; Goren, E.; Yuan, C.W.; Cao, J.; Smith, A.E.; Hsiao, T.; Bisignano, C.; Azhar, G.S.; Castro, E.; Chalek, J.; et al. Fertility, mortality, migration, and population scenarios for 195 countries and territories from 2017 to 2100: A forecasting analysis for the Global Burden of Disease Study. Lancet 2020, 396, 1285–1306. [Google Scholar] [CrossRef] [PubMed]

- Gourdo, L.; Fatnassi, H.; Bouharroud, R.; Ezzaeri, K.; Bazgaou, A.; Wifaya, A.; Demrati, H.; Bekkaoui, A.; Aharoune, A.; Poncet, C.; et al. Heating Canarian greenhouse with a passive solar water–sleeve system: Effect on microclimate and tomato crop yield. Sol. Energy 2019, 188, 1349–1359. [Google Scholar] [CrossRef]

- Banakar, A.; Montazeri, M.; Ghobadian, B.; Pasdarshahri, H.; Kamrani, F. Energy analysis and assessing heating and cooling demands of closed greenhouse in Iran. Therm. Sci. Eng. Prog. 2021, 25, 101042. [Google Scholar] [CrossRef]

- Neugebauer, M.; Hałacz, J.; Olkowski, T. A compost heating solution for a greenhouse in north-eastern Poland in fall. J. Clean. Prod. 2021, 279, 123613. [Google Scholar] [CrossRef]

- Yano, A.; Cossu, M. Energy sustainable greenhouse crop cultivation using photovoltaic technologies. Renew. Sustain. Energy Rev. 2019, 109, 116–137. [Google Scholar] [CrossRef]

- Sahdev, R.K.; Kumar, M.; Dhingra, A.K. A comprehensive review of greenhouse shapes and its applications. Front. Energy 2019, 13, 427–438. [Google Scholar] [CrossRef]

- Dhiman, M.; Sethi, V.P.; Singh, B.; Sharma, A. CFD analysis of greenhouse heating using flue gas and hot water heat sink pipe networks. Comput. Electron. Agric. 2019, 163, 104853. [Google Scholar] [CrossRef]

- Xu, W.; Guo, H.; Ma, C. An active solar water wall for passive solar greenhouse heating. Appl. Energy 2022, 308, 118270. [Google Scholar] [CrossRef]

- Hamdane, S.; Pires, L.C.C.; Silva, P.D.; Gaspar, P.D. Evaluating the thermal performance and environmental impact of agricultural greenhouses using earth-to-air heat exchanger: An experimental study. Appl. Sci. 2023, 13, 1119. [Google Scholar] [CrossRef]

- Al-Helal, I.; Alsadon, A.; Marey, S.; Ibrahim, A.; Shady, M.; Abdel-Ghany, A. Geothermal energy potential for cooling/heating greenhouses in hot arid regions. Atmosphere 2022, 13, 105. [Google Scholar] [CrossRef]

- Al-Helal, I.; Picuno, P.; Alsadon, A.A.; Ibrahim, A.; Shady, M.; Abdel-Ghany, A.M. Effect of shape, orientation and aging of a plastic greenhouse cover on the degradation rate of the optical properties in arid climates. Appl. Sci. 2022, 12, 2709. [Google Scholar] [CrossRef]

- Chen, C.; Li, Y.; Li, N.; Wei, S.; Yang, F.; Ling, H.; Yu, N.; Han, F. A computational model to determine the optimal orientation for solar greenhouses located at different latitudes in China. Sol. Energy 2018, 165, 19–26. [Google Scholar] [CrossRef]

- Dragicevic, S. Determining the optimum orientation of a greenhouse on the basis of the total solar radiation availability. Therm. Sci. 2011, 15, 215–221. [Google Scholar] [CrossRef]

- Pieters, J.G.; Deltour, J.M. Modelling solar energy input in greenhouses. Sol. Energy 1999, 67, 119–130. [Google Scholar] [CrossRef]

- Cossu, M.; Murgia, L.; Ledda, L.; Deligios, P.A.; Sirigu, A.; Chessa, F.; Pazzona, A. Solar radiation distribution inside a greenhouse with south-oriented photovoltaic roofs and effects on crop productivity. Appl. Energy 2014, 133, 89–100. [Google Scholar] [CrossRef]

- Aguilar, M.A.; Bianconi, F.; Aguilar, F.J.; Fernández, I. Object-based greenhouse classification from GeoEye-1 and WorldView-2 stereo imagery. Remote Sens. 2014, 6, 3554–3582. [Google Scholar] [CrossRef]

- Dar, I.A.; Sankar, K.; Dar, M.A. Remote sensing technology and geographic information system modeling: An integrated approach towards the mapping of groundwater potential zones in Hardrock terrain, Mamundiyar basin. J. Hydrol. 2010, 394, 285–295. [Google Scholar] [CrossRef]

- Graeff, C.; Loui, M.C. Ethical implications of technical limitations in GIS. IEEE Technol. Soc. Mag. 2008, 27, 27–36. [Google Scholar] [CrossRef]

- Zambon, K.L.; Carneiro, A.A.F.M.; Silva, A.N.R.; Negri, J.C. Multicriteria Decision Analysis for Site Selection of Thermoelectric Power Plants Using GIS. Pesqui. Oper. 2005, 25, 183–199. [Google Scholar] [CrossRef]

- Martinez, C.; Hancock, G.R.; Kalma, J.D.; Wells, T.; Boland, L. An assessment of digital elevation models and their ability to capture geomorphic and hydrologic properties at the catchment scale. Int. J. Remote Sens. 2010, 31, 6239–6257. [Google Scholar] [CrossRef]

- Ajayi, O.G.; Salubi, A.A.; Angbas, A.F.; Odigure, M.G. Generation of accurate digital elevation models from UAV acquired low percentage overlapping images. Int. J. Remote Sens. 2017, 38, 3113–3134. [Google Scholar] [CrossRef]

- Liu, Y.; Li, D.; Wan, S.; Wang, F.; Dou, W.; Xu, X.; Li, S.; Ma, R.; Qi, L. A long short-term memory-based model for greenhouse climate prediction. Int. J. Intell. Syst. 2022, 37, 135–151. [Google Scholar] [CrossRef]

- Kearney, M.R.; Shamakhy, A.; Tingley, R.; Karoly, D.J.; Hoffmann, A.A.; Briggs, P.R.; Porter, W.P. Microclimate modelling at macro scales: A test of a general microclimate model integrated with gridded continental-scale soil and weather data. Methods Ecol. Evol. 2014, 5, 273–286. [Google Scholar] [CrossRef]

- Esmaeli, H.; Roshandel, R. Optimal design for solar greenhouses based on climate conditions. Renew. Energy 2020, 145, 1255–1265. [Google Scholar] [CrossRef]

- Mohammadi, B.; Ranjbar, S.F.; Ajabshirchi, Y. Application of dynamic model to predict some inside environment variables in a semi-solar greenhouse. Inf. Process. Agric. 2018, 5, 279–288. [Google Scholar] [CrossRef]

- El-Maghlany, W.M.; Teamah, M.A.; Tanaka, H. Optimum design and orientation of the greenhouses for maximum capture of solar energy in North Tropical Region. Energy Convers. Manag. 2015, 105, 1096–1104. [Google Scholar] [CrossRef]

- Chen, J.; Ma, Y.; Pang, Z. A mathematical model of global solar radiation to select the optimal shape and orientation of the greenhouses in southern China. Sol. Energy 2020, 205, 380–389. [Google Scholar] [CrossRef]

- Badji, A.; Benseddik, A.; Bensaha, H.; Boukhelifa, A.; Hasrane, I. Design, technology, and management of greenhouse: A review. J. Clean. Prod. 2022, 373, 133753. [Google Scholar] [CrossRef]

- Stanciu, C.; Stanciu, D.; Dobrovicescu, A. Effect of greenhouse orientation with respect to EW axis on its required heating and cooling loads. Energy Procedia 2016, 85, 498–504. [Google Scholar] [CrossRef]

- Aissa, M.; Bezari, S. The orientation effect of the agricultural tunnel greenhouse on aerodynamic and energy properties. In Proceedings of the 2018 5th International Symposium on Environment-Friendly Energies and Applications (EFEA), Rome, Italy, 24–26 September 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–4. [Google Scholar]

- Mercan, Y.; Sezgin, F. The Use Of Multi-Criteria Decision Analysis (MCDA) And Geographic Information System (GIS) In Selection Of Greenhouse Site Location: The Case Of Aydin Region In Türkiye. Adnan Menderes Univ. Ziraat Fak. Derg. 2023, 20, 149–158. [Google Scholar] [CrossRef]

- Vanthoor, B.; Stanghellini, C.; Van Henten, E.J.; de Visser, P. The effect of outdoor climate conditions on passive greenhouse design. Acta Hortic. 2009, 807, 61–66. [Google Scholar] [CrossRef]

- Jeong, J.S.; Ramírez-Gómez, Á. Optimizing the location of a biomass plant with a fuzzy-DEcision-MAking Trial and Evaluation Laboratory (F-DEMATEL) and multi-criteria spatial decision assessment for renewable energy management and long-term sustainability. J. Clean. Prod. 2018, 182, 509–520. [Google Scholar] [CrossRef]

- Feyzi, S.; Khanmohammadi, M.; Abedinzadeh, N.; Aalipour, M. Multi-criteria decision analysis FANP based on GIS for siting municipal solid waste incineration power plant in the north of Iran. Sustain. Cities Soc. 2019, 47, 101513. [Google Scholar] [CrossRef]

- Geetha, S.; Narayanamoorthy, S.; Kang, D.; Baleanu, D. An adoptive renewable energy resource selection using Hesitant Pythagorean Fuzzy DEMATEL and VIKOR methods. J. Intell. Fuzzy Syst. 2022, 43, 4285–4302. [Google Scholar] [CrossRef]

- Castilla, N. Greenhouse Technology and Management; CABI: Wallingford, UK, 2013. [Google Scholar]

- Odesola, I.F.; Ezekwem, C. The effect of shape and orientation on a greenhouse: A review. AFRREV STECH: Int. J. Sci. Technol. 2012, 1, 122–130. [Google Scholar]

- Gupta, R.; Tiwari, G.N.; Kumar, A.; Gupta, Y. Calculation of total solar fraction for different orientation of greenhouse using 3D-shadow analysis in Auto-CAD. Energy Build. 2012, 47, 27–34. [Google Scholar] [CrossRef]

- Ahamed, M.S.; Guo, H.; Tanino, K. Energy saving techniques for reducing the heating cost of conventional greenhouses. Biosyst. Eng. 2019, 178, 9–33. [Google Scholar] [CrossRef]

- Saltuk, B.; Artun, O. Multi-criteria decision system for greenhouse site selection in Lower Euphrates Basin using geographic information systems (GIS). Afr. J. Agric. Res. 2018, 13, 2716–2724. [Google Scholar]

- Hernandez, C.; del Sagrado, J.; Rodriguez, F.; Moreno, J.C.; Sánchez, J.A. Modeling of energy demand of a high-tech greenhouse in warm climate based on bayesian networks. Math. Probl. Eng. 2015, 2015, 1–10. [Google Scholar] [CrossRef]

- Rasheed, A.; Lee, J.W.; Lee, H.W. Development and optimization of a building energy simulation model to study the effect of greenhouse design parameters. Energies 2018, 11, 2001. [Google Scholar] [CrossRef]

- Ravishankar, E.; Booth, R.E.; Saravitz, C.; Sederoff, H.; Ade, H.W.; O’Connor, B.T. Achieving net zero energy greenhouses by integrating semitransparent organic solar cells. Joule 2020, 4, 490–506. [Google Scholar] [CrossRef]

- Lebre, B.; Silva, P.D.; Pires, L.C.; Gaspar, P.D. Computational Modeling of the Thermal Behavior of a Greenhouse. Appl. Sci. 2021, 11, 11816. [Google Scholar] [CrossRef]

- Yang, F.; Fan, Y.; Wu, X.; Cheng, Y.; Liu, Q.; Feng, L.; Chen, J.; Wang, Z.; Wang, X.; Yong, T.; et al. Auxin-to-gibberellin ratio as a signal for light intensity and quality in regulating soybean growth and matter partitioning. Front. Plant Sci. 2018, 9, 56. [Google Scholar] [CrossRef] [PubMed]

- Feng, L.; Raza, M.A.; Li, Z.; Chen, Y.; Khalid, M.H.B.; Du, J.; Liu, W.; Wu, X.; Song, C.; Yu, L.; et al. The influence of light intensity and leaf movement on photosynthesis characteristics and carbon balance of soybean. Front. Plant Sci. 2019, 9, 1952. [Google Scholar] [CrossRef] [PubMed]

- Teixeira-Gandra, C.F.A.; Damé, R.C.F.; Simonete, M.A. Predição da precipitação a partir das coordenadas geográficas no Estado do Rio Grande do Sul. Rev. Bras. Geogr. Fis. 2015, 8, 848–856. [Google Scholar] [CrossRef]

- Häder, D.P.; Cabrol, N.A. Monitoring of solar irradiance in the high Andes. Photochem. Photobiol. 2020, 96, 1133–1139. [Google Scholar] [CrossRef] [PubMed]

- Huang, L.; Deng, L.; Li, A.; Gao, R.; Zhang, L.; Lei, W. Analytical model for solar radiation transmitting the curved transparent surface of solar greenhouse. J. Build. Eng. 2020, 32, 101785. [Google Scholar] [CrossRef]

- Moshari, A.; Aslani, A.; Entezari, A.; Ghanbari, K. Performance assessment of the integration of semitransparent solar cells with different geometry of greenhouses under different climate regions. Environ. Sci. Pollut. Res. 2023, 30, 62281–62294. [Google Scholar] [CrossRef]

- Maraveas, C.; Karavas, C.S.; Loukatos, D.; Bartzanas, T.; Arvanitis, K.G.; Symeonaki, E. Agricultural greenhouses: Resource management technologies and perspectives for zero greenhouse gas emissions. Agriculture 2023, 13, 1464. [Google Scholar] [CrossRef]

- Zhang, X.; Lv, J.; Xie, J.; Yu, J.; Zhang, J.; Tang, C.; Li, J.; He, Z.; Wang, C. Solar radiation allocation and spatial distribution in Chinese solar greenhouses: Model development and application. Energies 2020, 13, 1108. [Google Scholar] [CrossRef]

- Soares, G.F.W.; Vieira, L.S.R.; Galdino, M.A.E.; de Almeida Oliveiri, M.M.; de Paula Borges, E.L.; de Carvalho, C.M.; Lima, A.A.N. Comparação de custos entre sistemas fotovoltaicos individuais e minicentrais fotovoltaicas para eletrificação rural. In Proceedings of the Congresso Brasileiro de Energia Solar-CBENS, Fortaleza, Brazil, 3–6 November 2010; pp. 1–6. [Google Scholar]

- Polman, A.; Knight, M.; Garnett, E.C.; Ehrler, B.; Sinke, W.C. Photovoltaic materials: Present efficiencies and future challenges. Science 2016, 352, aad4424. [Google Scholar] [CrossRef] [PubMed]

- Furini, P.H.; Makiyama, M.K.; Orso, K.D.F.; Casonatto, D.C. Efeitos do sombreamento em módulos fotovoltaicos half-cell de 144 células. Anais Eng. Mec. 2022, 6, 163–184. [Google Scholar]

- Simões, M.C.S.; Brito, N.S.D.; da Silva, C.A. Análise dos Impactos da Conexão de Usinas Fotovoltaicas na Estabilidade de Tensão do Sistema Elétrico. Simpósio Bras. Sist. Elétr. SBSE 2020, 1, 1. [Google Scholar]

- Sonneveld, P.J.; Swinkels, G.L.A.M.; Van Tuijl, B.A.J.; Janssen, H.J.J.; Campen, J.; Bot, G.P.A. Performance of a concentrated photovoltaic energy system with static linear Fresnel lenses. Sol. Energy 2011, 85, 432–442. [Google Scholar] [CrossRef]

- Wu, G.; Yang, Q.; Zhang, Y.; Fang, H.; Feng, C.; Zheng, H. Energy and optical analysis of photovoltaic thermal integrated with rotary linear curved Fresnel lens inside a Chinese solar greenhouse. Energy 2020, 197, 117215. [Google Scholar] [CrossRef]

- Li, Z.; Ma, X.; Zhao, Y.; Zheng, H. Study on the performance of a curved Fresnel solar concentrated system with seasonal underground heat storage for the greenhouse application. J. Sol. Energy Eng. 2019, 141, 011004. [Google Scholar] [CrossRef]

- Tripanagnostopoulos, Y.; Siabekou, C.; Tonui, J.K. The Fresnel lens concept for solar control of buildings. Sol. Energy 2007, 81, 661–675. [Google Scholar] [CrossRef]

- Tripanagnostopoulos, Y.; Souliotis, M.; Tonui, J.K.; Kavga, A. Irradiation aspects for energy balance in greenhouses. In Proceedings of the International Conference on Sustainable Greenhouse Systems-Greensys2004, Leuven, Belgium, 12–16 September 2004; ISHS: Leuven, Belgium, 2004; pp. 733–740. [Google Scholar]

- Miller, D.C.; Kurtz, S.R. Durability of Fresnel lenses: A review specific to the concentrating photovoltaic application. Sol. Energy Mater. Sol. Cells 2011, 95, 2037–2068. [Google Scholar] [CrossRef]

- Gorjian, S.; Calise, F.; Kant, K.; Ahamed, M.S.; Copertaro, B.; Najafi, G.; Zhang, X.; Aghaei, M.; Shamshiri, R.R. A review on opportunities for implementation of solar energy technologies in agricultural greenhouses. J. Clean. Prod. 2021, 285, 124807. [Google Scholar] [CrossRef]

- Ghani, S.; Bakochristou, F.; ElBialy, E.M.A.A.; Gamaledin, S.M.A.; Rashwan, M.M.; Abdelhalim, A.M.; Ismail, S.M. Design challenges of agricultural greenhouses in hot and arid environments: A review. Eng. Agric. Environ. Food 2019, 12, 48–70. [Google Scholar] [CrossRef]

- Mazzeo, D.; Baglivo, C.; Panico, S.; Congedo, P.M. Solar greenhouses: Climates, glass selection, and plant well-being. Sol. Energy 2021, 230, 222–241. [Google Scholar] [CrossRef]

- Singh, R.D.; Tiwari, G.N. Energy conservation in the greenhouse system: A steady state analysis. Energy 2010, 35, 2367–2373. [Google Scholar] [CrossRef]

- Pakari, A.; Ghani, S. Evaluation of a novel greenhouse design for reduced cooling loads during the hot season in subtropical regions. Sol. Energy 2019, 181, 234–242. [Google Scholar] [CrossRef]

- Sethi, V.P. On the selection of shape and orientation of a greenhouse: Thermal modeling and experimental validation. Sol. Energy 2009, 83, 21–38. [Google Scholar] [CrossRef]

- Claudino, P. Experimental and Modelling Study of a Geodesic Dome Solar Greenhouse System in Ottawa. Ph.D. Thesis, Carleton University, Ottawa, ON, Canada, 2016. [Google Scholar]

- Cossu, M.; Cossu, A.; Deligios, P.A.; Ledda, L.; Li, Z.; Fatnassi, H.; Poncet, C.; Yano, A. Assessment and comparison of the solar radiation distribution inside the main commercial photovoltaic greenhouse types in Europe. Renew. Sustain. Energy Rev. 2018, 94, 822–834. [Google Scholar] [CrossRef]

- Mellalou, A.; Mouaky, A.; Bacaoui, A.; Outzourhit, A. A comparative study of greenhouse shapes and orientations under the climatic conditions of Marrakech, Morocco. Int. J. Environ. Sci. Technol. 2021, 18, 6045–6056. [Google Scholar] [CrossRef]

- Akrami, M.; Javadi, A.A.; Hassanein, M.J.; Farmani, R.; Dibaj, M.; Tabor, G.R.; Negm, A. Study of the effects of vent configuration on mono-span greenhouse ventilation using computational fluid dynamics. Sustainability 2020, 12, 986. [Google Scholar] [CrossRef]

- Liu, J.; Wu, X.; Sun, F.; Wang, B. Development and Application of a Crossed Multi-Arch Greenhouse in Tropical China. Agriculture 2022, 12, 2164. [Google Scholar] [CrossRef]

- Serale, G.; Gnoli, L.; Giraudo, E.; Fabrizio, E. A supervisory control strategy for improving energy efficiency of artificial lighting systems in greenhouses. Energies 2021, 14, 202. [Google Scholar] [CrossRef]

- Fan, Z.; Li, Y.; Jiang, L.; Wang, L.; Li, T.; Liu, X. Analysis of the Effect of Exhaust Configuration and Shape Parameters of Ventilation Windows on Microclimate in Round Arch Solar Greenhouse. Sustainability 2023, 15, 6432. [Google Scholar] [CrossRef]

- Li, H.; Li, Y.; Yue, X.; Liu, X.; Tian, S.; Li, T. Evaluation of airflow pattern and thermal behavior of the arched greenhouses with designed roof ventilation scenarios using CFD simulation. PLoS ONE 2020, 15, e0239851. [Google Scholar] [CrossRef] [PubMed]

- Goswami, D.Y.; Lavania, A.; Shahbazi, S.; Masood, M. Analysis of a geodesic dome solar fruit dryer. Dry. Technol. 1991, 9, 677–691. [Google Scholar] [CrossRef]

- Boulard, T.; Wang, S. Experimental and numerical studies on the heterogeneity of crop transpiration in a plastic tunnel. Comput. Electron. Agric. 2002, 34, 173–190. [Google Scholar] [CrossRef]

- Condori, M.; Echazu, R.; Saravia, L. Solar drying of sweet pepper and garlic using the tunnel greenhouse drier. Renew. Energy 2001, 22, 447–460. [Google Scholar] [CrossRef]

- Marucci, A.; Zambon, I.; Colantoni, A.; Monarca, D. A combination of agricultural and energy purposes: Evaluation of a prototype of photovoltaic greenhouse tunnel. Renew. Sustain. Energy Rev. 2018, 82, 1178–1186. [Google Scholar] [CrossRef]

- Ahamed, M.S.; Guo, H.; Tanino, K. Energy-efficient design of greenhouse for Canadian Prairies using a heating simulation model. Int. J. Energy Res. 2018, 42, 2263–2272. [Google Scholar] [CrossRef]

- Bibi-Triki, N.; Bendimerad, S.; Chermiti, A.; Mahdjoub, T.; Draoui, B.; Abène, A. Modeling, characterization and analysis of the dynamic behavior of heat transfers through polyethylene and glass walls of greenhouses. Phys. Procedia 2011, 21, 67–74. [Google Scholar] [CrossRef]

- Robles Algarín, C.; Callejas Cabarcas, J.; Polo Llanos, A. Low-cost fuzzy logic control for greenhouse environments with web monitoring. Electronics 2017, 6, 71. [Google Scholar] [CrossRef]

- Choab, N.; Allouhi, A.; El Maakoul, A.; Kousksou, T.; Saadeddine, S.; Jamil, A. Effect of greenhouse design parameters on the heating and cooling requirement of greenhouses in Moroccan climatic conditions. IEEE Access 2020, 9, 2986–3003. [Google Scholar] [CrossRef]

- Karambasti, B.M.; Naghashzadegan, M.; Ghodrat, M.; Ghorbani, G.; Simorangkir, R.B.V.B.; Lalbakhsh, A. Optimal solar greenhouses design using multiobjective genetic algorithm. IEEE Access 2022, 10, 73728–73742. [Google Scholar] [CrossRef]

- Mobtaker, H.G.; Ajabshirchi, Y.; Ranjbar, S.F.; Matloobi, M. Solar energy conservation in greenhouse: Thermal analysis and experimental validation. Renew. Energy 2016, 96, 509–519. [Google Scholar] [CrossRef]

- Mobtaker, H.G.; Ajabshirchi, Y.; Ranjbar, S.F.; Matloobi, M. Simulation of thermal performance of solar greenhouse in north-west of Iran: An experimental validation. Renew. Energy 2019, 135, 88–97. [Google Scholar] [CrossRef]

- Lamnatou, C.; Chemisana, D. Solar radiation manipulations and their role in greenhouse claddings: Fresnel lenses, NIR-and UV-blocking materials. Renew. Sustain. Energy Rev. 2013, 18, 271–287. [Google Scholar] [CrossRef]

- Maraveas, C.; Kotzabasaki, M.I.; Bayer, I.S.; Bartzanas, T. Sustainable Greenhouse Covering Materials with Nano-and Micro-Particle Additives for Enhanced Radiometric and Thermal Properties and Performance. AgriEngineering 2023, 5, 1347–1377. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, Z.; Cao, C.; Gao, Y. Near-Infrared Reflective Greenhouse Covering: A Novel Strategy for Electricity-Free Cooling. ACS Agric. Sci. Technol. 2024, in press. [CrossRef]

- Baeza, E.; López, J.C. Light transmission through greenhouse covers. In Proceedings of the VII International Symposium on Light in Horticultural Systems, Wageningen, The Netherlands, 15–19 October 2012; ISHS: Leuven, Belgium, 2012; pp. 425–440. [Google Scholar]

- Feng, C.; Yuan, G.; Wang, R.; Chen, X.; Ma, F.; Yang, H.; Li, X. Performance study on a novel greenhouse cover structure with beam split and heat control function. Energy Convers. Manag. 2024, 301, 118077. [Google Scholar] [CrossRef]

- Katsoulas, N.; Bari, A.; Papaioannou, C. Plant responses to UV blocking greenhouse covering materials: A review. Agronomy 2020, 10, 1021. [Google Scholar] [CrossRef]

- Maraveas, C. Environmental sustainability of greenhouse covering materials. Sustainability 2019, 11, 6129. [Google Scholar] [CrossRef]

- Xu, H.; Ding, J.; Li, T.; Mu, C.; Gu, X.; Wang, R. A study on optimum insulation thickness in walls of Chinese solar greenhouse for energy saving. Agronomy 2022, 12, 1104. [Google Scholar] [CrossRef]

- Dong, Y.; Kong, J.; Mousavi, S.; Rismanchi, B.; Yap, P.S. Wall insulation materials in different climate zones: A review on challenges and opportunities of available alternatives. Thermo 2023, 3, 38–65. [Google Scholar] [CrossRef]

- Swinkels, G.L.A.M.; Sonneveld, P.J.; Bot, G.P.A. SE—Structures and environment: Improvement of greenhouse insulation with restricted transmission loss through zigzag covering material. J. Agric. Eng. Res. 2001, 79, 91–97. [Google Scholar] [CrossRef]

- Du, W.-C.; Xie, J.; Xia, L.; Liu, Y.-J.; Yang, H.-W.; Zhang, Y. Study of new solar film based on near-infrared shielding. J. Photochem. Photobiol. A Chem. 2021, 418, 113410. [Google Scholar] [CrossRef]

- Briassoulis, D.; Waaijenberg, D.; Gratraud, J.; Von Eslner, B. Mechanical properties of covering materials for greenhouses: Part 1, general overview. J. Agric. Eng. Res. 1997, 67, 81–96. [Google Scholar] [CrossRef]

- Waaijenberg, D. Design, construction and maintenance of greenhouse structures. In Proceedings of the International Symposium on Greenhouses, Environmental Controls and In-house Mechanization for Crop Production in the Tropics, Leiden, The Netherlands, 6–10 September 2004; ISHS: Leuven, Belgium, 2004; pp. 31–42. [Google Scholar]

- Al-Mahdouri, A.; Baneshi, M.; Gonome, H.; Okajima, J.; Maruyama, S. Evaluation of optical properties and thermal performances of different greenhouse covering materials. Sol. Energy 2013, 96, 21–32. [Google Scholar] [CrossRef]

- Zhang, Y.; Gauthier, L.; de Halleux, D.; Dansereau, B.; Gosselin, A. Effect of covering materials on energy consumption and greenhouse microclimate. Agric. For. Meteorol. 1996, 82, 227–244. [Google Scholar] [CrossRef]

- Paneri, A.; Wong, I.L.; Burek, S. Transparent insulation materials: An overview on past, present and future developments. Sol. Energy 2019, 184, 59–83. [Google Scholar] [CrossRef]

- Wang, H.; Li, J.; Cheng, M.; Zhang, F.; Wang, X.; Fan, J.; Wu, L.; Fang, D.; Zou, H.; Xiang, Y. Optimal drip fertigation management improves yield, quality, water and nitrogen use efficiency of greenhouse cucumber. Sci. Hortic. 2019, 243, 357–366. [Google Scholar] [CrossRef]

- Jha, M.K.; Paikra, S.S.; Sahu, M.R. Protected Cultivation of Horticulture Crops; Educreation Publishing: Bilaspur, India, 2019. [Google Scholar]

- Li, Y.; Sun, D.; Xia, T.; Varbanov, P.S.; Liu, X.; Li, T. Performance of a novel internal insulation in Chinese solar greenhouse for the cleaner and energy-saving production in high latitudes and cold regions. J. Clean. Prod. 2023, 412, 137442. [Google Scholar] [CrossRef]

- Mavroeidis, A.; Bilalis, D.; Tataridas, A.; Roussis, I.; Kakabouki, I.; Folina, A.; Papastyliannou, P.; Stefanopoulos, A. Do Greenhouse Cover Materials Affect Cannabis Performance? Bull. Univ. Agric. Sci. Vet. Med. Cluj-Napoca Hortic. 2021, 78, 117–122. [Google Scholar] [CrossRef]

- Papadakis, G.; Briassoulis, D.; Mugnozza, G.S.; Vox, G.; Feuilloley, P.; Stoffers, J.A. Review Paper (SE—Structures and Environment): Radiometric and thermal properties of, and testing methods for, greenhouse covering materials. J. Agric. Eng. Res. 2000, 77, 7–38. [Google Scholar] [CrossRef]

- Kim, H.-K.; Kang, G.-C.; Moon, J.-P.; Lee, T.-S.; Oh, S.-S. Estimation of thermal performance and heat loss in plastic greenhouses with and without thermal curtains. Energies 2018, 11, 578. [Google Scholar] [CrossRef]

- Kavga, A.; Souliotis, M.; Koumoulos, E.P.; Fokaides, P.A.; Charitidis, C.A. Environmental and nanomechanical testing of an alternative polymer nanocomposite greenhouse covering material. Sol. Energy 2018, 159, 1–9. [Google Scholar] [CrossRef]

- Stirbet, A.; Lazár, D.; Guo, Y.; Govindjee, G. Photosynthesis: Basics, history and modelling. Ann. Bot. 2020, 126, 511–537. [Google Scholar] [CrossRef] [PubMed]

- Techawongstien, S. Factors affecting plant growth and development. Khon Kaen J. Sci. Technol. 2016, 24, 45–67. [Google Scholar]

- Hatfield, J.L.; Prueger, J.H. Temperature extremes: Effect on plant growth and development. Weather Clim. Extrem. 2015, 10, 4–10. [Google Scholar] [CrossRef]

- Salazar, R.; Rojano, A.; López, I.; Schmidt, U. A Model for the Combine Description of the Temperature and Relative Humidity Regime in the Greenhouse. In Proceedings of the 2010 Ninth Mexican International Conference on Artificial Intelligence, Pachuca, Mexico, 8–13 November 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 113–117. [Google Scholar]

- Körner, O.; Challa, H. Process-based humidity control regime for greenhouse crops. Comput. Electron. Agric. 2003, 39, 173–192. [Google Scholar] [CrossRef]

- Kramer, P.J.; Boyer, J.S. Water Relations of Plants and Soils; Academic Press: San Diego, CA, USA, 1995. [Google Scholar]

- Jones, H.G. Plants and Microclimate: A Quantitative Approach to Environmental Plant Physiology, 3rd ed.; Cambridge University Press: Cambridge, UK, 2013. [Google Scholar]

- Taiz, L.; Zeiger, E.; Møller, I.M.; Murphy, A. Plant Physiology and Development, 6th ed.; Sinauer Associates Incorporated: Sunderland, MA, USA, 2015. [Google Scholar]

- Monteith, J.; Unsworth, M. Principles of Environmental Physics: Plants, Animals, and the Atmosphere, 4th ed.; Academic Press: Cambridge, MA, USA, 2013. [Google Scholar]

- Danneberger, T.K. Effects of humidity on plant growth. In Plant-Environment Interactions; CRC Press: Boca Raton, FL, USA, 2000; pp. 361–378. [Google Scholar]

- Soussi, M.; Chaibi, M.T.; Buchholz, M.; Saghrouni, Z. Comprehensive review on climate control and cooling systems in greenhouses under hot and arid conditions. Agronomy 2022, 12, 626. [Google Scholar] [CrossRef]

- Liu, X.; Li, H.; Li, Y.; Yue, X.; Tian, S.; Li, T. Effect of internal surface structure of the north wall on Chinese solar greenhouse thermal microclimate based on computational fluid dynamics. PLoS ONE 2020, 15, e0231316. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Yue, X.; Zhao, L.; Xu, H.; Liu, X.; Li, T. Effect of north wall internal surface structure on heat storage-release performance and thermal environment of Chinese solar greenhouse. J. Build. Phys. 2022, 45, 507–527. [Google Scholar] [CrossRef]

- Zhang, X.; Lv, J.; Dawuda, M.M.; Xie, J.; Yu, J.; Gan, Y.; Zhang, J.; Tang, Z.; Li, J. Innovative passive heat-storage walls improve thermal performance and energy efficiency in Chinese solar greenhouses for non-arable lands. Sol. Energy 2019, 190, 561–575. [Google Scholar] [CrossRef]

- Chen, C.; Ling, H.; Zhai, Z.J.; Li, Y.; Yang, F.; Han, F.; Wei, S. Thermal performance of an active-passive ventilation wall with phase change material in solar greenhouses. Appl. Energy 2018, 216, 602–612. [Google Scholar] [CrossRef]

- Santolini, E.; Pulvirenti, B.; Guidorzi, P.; Bovo, M.; Torreggiani, D.; Tassinari, P. Analysis of the effects of shading screens on the microclimate of greenhouses and glass facade buildings. Build. Environ. 2022, 211, 108691. [Google Scholar] [CrossRef]

- Xia, T.; Li, Y.; Sun, Z.; Wan, X.; Sun, D.; Wang, L.; Liu, X.; Li, T. Performance study of an active solar water curtain heating system for Chinese solar greenhouse heating in high latitudes regions. Appl. Energy 2023, 332, 120548. [Google Scholar] [CrossRef]

- Downs, R.J. Environment and the Experimental Control of Plant Growth; Elsevier: Amsterdam, The Netherlands, 2012; Volume 6. [Google Scholar]

- Ferrante, A.; Mariani, L. Agronomic management for enhancing plant tolerance to abiotic stresses: High and low values of temperature, light intensity, and relative humidity. Horticulturae 2018, 4, 21. [Google Scholar] [CrossRef]

- Amoatey, P.; Al-Jabri, K.; Al-Saadi, S. Influence of phase change materials on thermal comfort, greenhouse gas emissions, and potential indoor air quality issues across different climatic regions: A critical review. Int. J. Energy Res. 2022, 46, 22386–22420. [Google Scholar] [CrossRef]

- Roslan, N.; Ya’acob, M.E.; Radzi, M.A.M.; Hashimoto, Y.; Jamaludin, D.; Chen, G. Dye Sensitized Solar Cell (DSSC) greenhouse shading: New insights for solar radiation manipulation. Renew. Sustain. Energy Rev. 2018, 92, 171–186. [Google Scholar] [CrossRef]

- Maraveas, C.; Loukatos, D.; Bartzanas, T.; Arvanitis, K.G.; Uijterwaal, J.F. Smart and solar greenhouse covers: Recent developments and future perspectives. Front. Energy Res. 2021, 9, 783587. [Google Scholar] [CrossRef]

- López-Díaz, G.; Carreño-Ortega, A.; Fatnassi, H.; Poncet, C.; Díaz-Pérez, M. The effect of different levels of shading in a photovoltaic greenhouse with a north–south orientation. Appl. Sci. 2020, 10, 882. [Google Scholar] [CrossRef]

- Moretti, S.; Marucci, A. A photovoltaic greenhouse with variable shading for the optimization of agricultural and energy production. Energies 2019, 12, 2589. [Google Scholar] [CrossRef]

- La Notte, L.; Giordano, L.; Calabrò, E.; Bedini, R.; Colla, G.; Puglisi, G.; Reale, A. Hybrid and organic photovoltaics for greenhouse applications. Appl. Energy 2020, 278, 115582. [Google Scholar] [CrossRef]

- Abdel-Ghany, A.M.; Picuno, P.; Al-Helal, I.; Alsadon, A.; Ibrahim, A.; Shady, M. Radiometric characterization, solar and thermal radiation in a greenhouse as affected by shading configuration in an arid climate. Energies 2015, 8, 13928–13937. [Google Scholar] [CrossRef]

- Aberkani, K.; Hao, X.; de Halleux, D.; Dorais, M.; Vineberg, S.; Gosselin, A. Effects of shading using a retractable liquid foam technology on greenhouse and plant microclimates. HortTechnology 2010, 20, 283–291. [Google Scholar] [CrossRef]

- Blanchard, M.G.; Runkle, E.S. Influence of NIR-reflecting shading paint on greenhouse environment, plant temperature, and growth and flowering of bedding plants. Trans. ASABE 2010, 53, 939–944. [Google Scholar] [CrossRef]

- Xu, Y.; Lyu, X.; Song, H.; Lin, B.; Wei, M.; Yin, Y.; Wang, S. Large-span M-shaped greenhouse with superior wind resistance and ventilation performance. J. Wind Eng. Ind. Aerodyn. 2023, 238, 105410. [Google Scholar] [CrossRef]

- Van den Bulck, N.; Coomans, M.; Wittemans, L.; Hanssens, J.; Steppe, K. Monitoring and energetic performance analysis of an innovative ventilation concept in a Belgian greenhouse. Energy Build. 2013, 57, 51–57. [Google Scholar] [CrossRef]

- Ghoulem, M.; El Moueddeb, K.; Nehdi, E.; Boukhanouf, R.; Calautit, J.K. Greenhouse design and cooling technologies for sustainable food cultivation in hot climates: Review of current practice and future status. Biosyst. Eng. 2019, 183, 121–150. [Google Scholar] [CrossRef]

- Akrami, M.; Salah, A.H.; Javadi, A.A.; Fath, H.E.S.; Hassanein, M.J.; Farmani, R.; Dibaj, M.; Negm, A. Towards a sustainable greenhouse: Review of trends and emerging practices in analysing greenhouse ventilation requirements to sustain maximum agricultural yield. Sustainability 2020, 12, 2794. [Google Scholar] [CrossRef]

- Ponce, P.; Molina, A.; Cepeda, P.; Lugo, E.; MacCleery, B. Greenhouse Design and Control; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Zhang, J.; Zhao, S.; Dai, A.; Wang, P.; Liu, Z.; Liang, B.; Ding, T. Greenhouse Natural Ventilation Models: How Do We Develop with Chinese Greenhouses? Agronomy 2022, 12, 1995. [Google Scholar] [CrossRef]

- Li, H.; Li, A.; Hou, Y.; Zhang, C.; Guo, J.; Li, J.; Ma, Y.; Wang, T.; Yin, Y. Analysis of Heat and Humidity in Single-Slope Greenhouses with Natural Ventilation. Buildings 2023, 13, 606. [Google Scholar] [CrossRef]

- Asthor. Greenhouse—ASTHOR—Agricultural/Commercial/Production. Available online: https://www.agriexpo.online/prod/asthor/product-175975-126081.html (accessed on 29 January 2024).

- Choi, Y.; Kang, N.; Park, K.; Chun, H.; Cho, M.; Lee, S.; Um, Y. Effect of greenhouse orientation on the environment of greenhouse and the growth and yield of tomato and oriental melon. Korean J. Hortic. Sci. Technol. 2008, 26, 380–386. [Google Scholar]

- Boulard, T.; Meneses, J.F.; Mermier, M.; Papadakis, G. The mechanisms involved in the natural ventilation of greenhouses. Agric. For. Meteorol. 1996, 79, 61–77. [Google Scholar] [CrossRef]

- Majdoubi, H.; Boulard, T.; Hanafi, A.; Bekkaoui, A.; Fatnassi, H.; Demrati, H.; Nya, M.; Bouirden, L. Natural ventilation performance of a large greenhouse equipped with insect screens. Trans. ASABE 2007, 50, 641–650. [Google Scholar] [CrossRef]

- Bournet, P.E.; Boulard, T. Effect of ventilator configuration on the distributed climate of greenhouses: A review of experimental and CFD studies. Comput. Electron. Agric. 2010, 74, 195–217. [Google Scholar] [CrossRef]

- Ali, A.; Iqbal, T.; Cheema, M.J.M.; Afzal, A.; Yasin, M.; Haq, Z.U.; Malik, A.M.; Khan, K.S. Development of a Low-Cost Biomass Furnace for Greenhouse Heating. Sustainability 2021, 13, 5152. [Google Scholar] [CrossRef]

- Roy, Y.; Lefsrud, M.; Orsat, V.; Filion, F.; Bouchard, J.; Nguyen, Q.; Dion, L.M.; Glover, A.; Madadian, E.; Lee, C.P. Biomass combustion for greenhouse carbon dioxide enrichment. Biomass Bioenergy 2014, 66, 186–196. [Google Scholar] [CrossRef]

- Van Henten, E.J. Automation and robotics in greenhouses. In Achieving Sustainable Greenhouse Cultivation; Burleigh Dodds Science Publishing: Cambridge, UK, 2019; pp. 359–378. [Google Scholar]

- Attar, I.; Farhat, A. Efficiency evaluation of a solar water heating system applied to the greenhouse climate. Sol. Energy 2015, 119, 212–224. [Google Scholar] [CrossRef]

- Bonuso, S.; Panico, S.; Baglivo, C.; Mazzeo, D.; Matera, N.; Congedo, P.M.; Oliveti, G. Dynamic analysis of the natural and mechanical ventilation of a solar greenhouse by coupling controlled mechanical ventilation (CMV) with an earth-to-air heat exchanger (EAHX). Energies 2020, 13, 3676. [Google Scholar] [CrossRef]

- Cherrad, I.; Dokkar, B.; Khenfer, N.; Benoumhani, S.; Benzid, M.C. Cooling improvement of an agricultural greenhouse using geothermal energy in a desert climate. Int. J. Energy Environ. Eng. 2023, 14, 211–228. [Google Scholar] [CrossRef]

- Agris, A.; Arnis, H.I.; Semjons, I.; Aivars, J.; Ugis, G.; Adolfs, R. Development of technological process solutions in modular system of solar electricity and heat supply for greenhouses. In Proceedings of the 22nd International Scientific Conference “Engineering for Rural Development”, Jelgava, Latvia, 24–26 May 2023; pp. 636–643. [Google Scholar]

- Kant, K.; Biwole, P.; Shamseddine, I.; Tlaiji, G.; Pennec, F. Advances in solar greenhouse systems for cultivation of agricultural products. In Solar Energy Advancements in Agriculture and Food Production Systems; Elsevier: Amsterdam, The Netherlands, 2022; pp. 77–111. [Google Scholar]

- Misra, D.; Ghosh, S. Evaporative cooling technologies for greenhouses: A comprehensive review. Agric. Eng. Int. CIGR J. 2018, 20, 1–15. [Google Scholar]

- Sethi, V.P.; Sharma, S.K. Survey of cooling technologies for worldwide agricultural greenhouse applications. Sol. Energy 2007, 81, 1447–1459. [Google Scholar] [CrossRef]

- Aljubury, I.M.A.; Ridha, H.D. Enhancement of evaporative cooling system in a greenhouse using geothermal energy. Renew. Energy 2017, 111, 321–331. [Google Scholar] [CrossRef]

- Liu, C.-H.; Ay, C.; Tsai, C.-Y.; Lee, M.-T. The application of passive radiative cooling in greenhouses. Sustainability 2019, 11, 6703. [Google Scholar] [CrossRef]

- Campiotti, C.A.; Morosinotto, G.; Puglisi, G.; Schettini, E.; Vox, G. Performance evaluation of a solar cooling plant applied for greenhouse thermal control. Agric. Agric. Sci. Procedia 2016, 8, 664–669. [Google Scholar] [CrossRef]

- Hughes, B.R.; Chaudhry, H.N.; Ghani, S.A. A review of sustainable cooling technologies in buildings. Renew. Sustain. Energy Rev. 2011, 15, 3112–3120. [Google Scholar] [CrossRef]

- Rhee, K.N.; Olesen, B.W.; Kim, K.W. Ten questions about radiant heating and cooling systems. Build. Environ. 2017, 112, 367–381. [Google Scholar] [CrossRef]

- Andresen, M.; Liserre, M. Impact of active thermal management on power electronics design. Microelectron. Reliab. 2014, 54, 1935–1939. [Google Scholar] [CrossRef]

- Miner, A.; Ghoshal, U. Limits of heat removal in microelectronic systems. IEEE Trans. Components Packag. Technol. 2006, 29, 743–749. [Google Scholar] [CrossRef]

- Paris, B.; Vandorou, F.; Balafoutis, A.T.; Vaiopoulos, K.; Kyriakarakos, G.; Manolakos, D.; Papadakis, G. Energy use in greenhouses in the EU: A review recommending energy efficiency measures and renewable energy sources adoption. Appl. Sci. 2022, 12, 5150. [Google Scholar] [CrossRef]

- Ferraro, V.; Bevilacqua, P.; Bruno, R.; Arcuri, N. Energy savings in greenhouses through the use of heat recovery systems. Tec. Ital.-Ital. J. Eng. Sci. 2019, 63, 467–473. [Google Scholar] [CrossRef]

- Tawalbeh, M.; Aljaghoub, H.; Alami, A.H.; Olabi, A.G. Selection criteria of cooling technologies for sustainable greenhouses: A comprehensive review. Therm. Sci. Eng. Prog. 2023, 38, 101666. [Google Scholar] [CrossRef]

- Guan, Y.; Meng, Q.; Ji, T.; Hu, W.; Li, W.; Liu, T. Experimental study of the thermal characteristics of a heat storage wall with micro-heat pipe array (MHPA) and PCM in solar greenhouse. Energy 2023, 264, 126183. [Google Scholar] [CrossRef]

- Sokolov, S.V. Optimization of greenhouse microclimate parameters considering the impact of CO2 and light. Eng. Sci. 2023, 10, G14–G21. [Google Scholar] [CrossRef]

- Katzin, D.; Marcelis, L.F.M.; van Mourik, S. Energy savings in greenhouses by transition from high-pressure sodium to LED lighting. Appl. Energy 2021, 281, 116019. [Google Scholar] [CrossRef]

- Paradiso, R.; Proietti, S. Light-quality manipulation to control plant growth and photomorphogenesis in greenhouse horticulture: The state of the art and the opportunities of modern LED systems. J. Plant Growth Regul. 2022, 41, 742–780. [Google Scholar] [CrossRef]

- Shen, L.; Lou, R.; Park, Y.; Guo, Y.; Stallknecht, E.J.; Xiao, Y.; Rieder, D.; Yang, R.; Runkle, E.S.; Yin, X. Increasing greenhouse production by spectral-shifting and unidirectional light-extracting photonics. Nat. Food 2021, 2, 434–441. [Google Scholar] [CrossRef]

- Bersani, C.; Ruggiero, C.; Sacile, R.; Soussi, A.; Zero, E. Internet of Things Approaches for Monitoring and Control of Smart Greenhouses in Industry 4.0. Energies 2022, 15, 3834. [Google Scholar] [CrossRef]

- Li, Y.; Ding, Y.; Li, D.; Miao, Z. Automatic carbon dioxide enrichment strategies in the greenhouse: A review. Biosyst. Eng. 2018, 171, 101–119. [Google Scholar] [CrossRef]

- Han, X.; Sun, Y.; Chen, J.; Wang, Z.; Qi, H.; Liu, Y.; Liu, Y. Effects of CO2 Enrichment on Carbon Assimilation, Yield and Quality of Oriental Melon Cultivated in a Solar Greenhouse. Horticulturae 2023, 9, 561. [Google Scholar] [CrossRef]

- Van Tuyll, A.; Graamans, L.; Boedijn, A. Carbon Dioxide Enrichment in a Decarbonised Future; Stichting Wageningen Research, Wageningen Plant Research, Business Unit: Wageningen, The Netherlands, 2022. [Google Scholar]

- Dion, L.M.; Lefsrud, M.; Orsat, V.; Cimon, C. Biomass gasification and syngas combustion for greenhouse CO2 enrichment. Bioresources 2013, 8, 1520–1538. [Google Scholar] [CrossRef]

- Kuroyanagi, T.; Yasuba, K.; Higashide, T.; Iwasaki, Y.; Takaichi, M. Efficiency of carbon dioxide enrichment in an unventilated greenhouse. Biosyst. Eng. 2014, 119, 58–68. [Google Scholar] [CrossRef]

- Wang, A.; Lv, J.; Wang, J.; Shi, K. CO2 enrichment in greenhouse production: Towards a sustainable approach. Front. Plant Sci. 2022, 13, 1029901. [Google Scholar] [CrossRef] [PubMed]

- Yang, S.-H.; Lee, C.G.; Ashtiani-Araghi, A.; Kim, J.Y.; Rhee, J.Y. Development and evaluation of combustion-type CO2 enrichment system connected to heat pump for greenhouses. Eng. Agric. Environ. Food 2014, 7, 28–33. [Google Scholar] [CrossRef]

- Kochhar, A.; Kumar, N. Wireless sensor networks for greenhouses: An end-to-end review. Comput. Electron. Agric. 2019, 163, 104877. [Google Scholar] [CrossRef]

- Bai, X.; Wang, Z.; Zou, L.; Alsaadi, F.E. Collaborative fusion estimation over wireless sensor networks for monitoring CO2 concentration in a greenhouse. Inf. Fusion 2018, 42, 119–126. [Google Scholar] [CrossRef]

- Ting, L.; Man, Z.; Yuhan, J.; Sha, S.; Yiqiong, J.; Minzan, L. Management of CO2 in a tomato greenhouse using WSN and BPNN techniques. Int. J. Agric. Biol. Eng. 2015, 8, 43–51. [Google Scholar]

- Mekki, M.; Abdallah, O. Development of a Wireless Sensors Network for Greenhouse Monitoring and Control. Indones. J. Electr. Eng. Inform. (IJEEI) 2017, 5, 270–274. [Google Scholar]

- Saínchez-Molina, J.A.; Reinoso, J.V.; Acieín, F.G.; Rodríquez, F.; Loípez, J.C. Development of a biomass-based system for nocturnal temperature and diurnal CO2 concentration control in greenhouses. Biomass Bioenergy 2014, 67, 60–71. [Google Scholar] [CrossRef]

- Ohyama, K.; Kozai, T.; Ishigami, Y.; Ohno, Y.; Toida, H.; Ochi, Y. A CO2 control system for a greenhouse with a high ventilation rate. In Proceedings of the International Conference on Sustainable Greenhouse Systems-Greensys2004, Leuven, Belgium, 26–29 September 2004; Volume 691, pp. 649–654. [Google Scholar]

- Berkovich, Y.A.; Konovalova, I.O.; Smolyanina, S.O.; Erokhin, A.N.; Avercheva, O.V.; Bassarskaya, E.M.; Kochetova, G.V.; Zhigalova, T.V.; Yakovleva, O.S.; Tarakanov, I.G. LED crop illumination inside space greenhouses. Reach 2017, 6, 11–24. [Google Scholar] [CrossRef]

- Cossu, M.; Yano, A.; Solinas, S.; Deligios, P.A.; Tiloca, M.T.; Cossu, A.; Ledda, L. Agricultural sustainability estimation of the European photovoltaic greenhouses. Eur. J. Agron. 2020, 118, 126074. [Google Scholar] [CrossRef]

- Afzali, S.; Mosharafian, S.; van Iersel, M.W.; Mohammadpour Velni, J. Development and implementation of an IoT-enabled optimal and predictive lighting control strategy in greenhouses. Plants 2021, 10, 2652. [Google Scholar] [CrossRef]

- Baglivo, C.; Mazzeo, D.; Panico, S.; Bonuso, S.; Matera, N.; Congedo, P.M.; Oliveti, G. Complete greenhouse dynamic simulation tool to assess the crop thermal well-being and energy needs. Appl. Therm. Eng. 2020, 179, 115698. [Google Scholar] [CrossRef]

- Gorjian, S.; Ebadi, H.; Najafi, G.; Chandel, S.S.; Yildizhan, H. Recent advances in net-zero energy greenhouses and adapted thermal energy storage systems. Sustain. Energy Technol. Assess. 2021, 43, 100940. [Google Scholar] [CrossRef]

- Amara, H.B.; Bouadila, S.; Guizani, A.; Fatnassi, H. Study of structural characteristics of wind-speed natural ventilation on single span greenhouse. In Proceedings of the 2020 11th International Renewable Energy Congress (IREC), Nabeul, Tunisia, 24–26 March 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1–6. [Google Scholar]

- Peretz, M.F.; Geoola, F.; Yehia, I.; Ozer, S.; Levi, A.; Magadley, E.; Brikman, R.; Rosenfeld, L.; Levy, A.; Kacira, M.; et al. Testing organic photovoltaic modules for application as greenhouse cover or shading element. Biosyst. Eng. 2019, 184, 24–36. [Google Scholar] [CrossRef]

- Amara, H.B.; Bouadila, S.; Fatnassi, H.; Arici, M.; Guizani, A.A. Climate assessment of greenhouse equipped with south-oriented PV roofs: An experimental and computational fluid dynamics study. Sustain. Energy Technol. Assess. 2021, 45, 101100. [Google Scholar]

- Nikolaou, G.; Neocleous, D.; Katsoulas, N.; Kittas, C. Irrigation of greenhouse crops. Horticulturae 2019, 5, 7. [Google Scholar] [CrossRef]

- Marcelis, L.F.M.; Costa, J.M.; Heuvelink, E. Achieving sustainable greenhouse production: Present status, recent advances and future developments. In Achieving Sustainable Greenhouse Cultivation; Burleigh Dodds Science Publishing: Cambridge, UK, 2019; pp. 1–14. [Google Scholar]

- Lambers, H.; Oliveira, R.S. Plant water relations. In Plant Physiological Ecology; Springer: Cham, Switzerland, 2019; pp. 187–263. [Google Scholar]

- Landis, T.D. Water Quality and Irrigation. In Nursery Manual for Native Plants: A Guide for Tribal Nurseries; US Department of Agriculture, Forest Service: Washington, DC, USA, 2009; No. 730; p. 177. [Google Scholar]

- Rodríguez, F.; Berenguel, M.; Guzmán, J.L.; Ramírez-Arias, A. Modeling and Control of Greenhouse Crop Growth; Springer: Cham, Switzerland, 2015. [Google Scholar]

- Incrocci, L.; Thompson, R.B.; Fernandez-Fernandez, M.D.; De Pascale, S.; Pardossi, A.; Stanghellini, C.; Rouphael, Y.; Gallardo, M. Irrigation management of European greenhouse vegetable crops. Agric. Water Manag. 2020, 242, 106393. [Google Scholar] [CrossRef]

- Murthy, B.Y.S.S.; Reddy, C.B.K.; Jilani, S.; Sindhwani, M. Smart Irrigation System. In Proceedings of the 2022 1st International Conference on Sustainable Technology for Power and Energy Systems (STPES), Coimbatore, India, 24–25 March 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–4. [Google Scholar]

- Setiowati, S.; Wardhani, R.N.; Azzam, A.; Rahmadhitya, A.A.; Adillah, R.F. Sprinkler Irrigation System for Pakcoy Cultivation Based on Mamdani Fuzzy Logic and LoRa Communication. In Proceedings of the 2023 6th International Conference of Computer and Informatics Engineering (IC2IE), Yogyakarta, Indonesia, 10–11 October 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 81–86. [Google Scholar]

- Kumar, A.; Burdak, B.; Thakur, H.; Harshavardhan, S.; Rao, S.N.; Mrudula, P.; Aibel, H.P. A review on role of micro irrigation for modern agriculture. Pharma J. 2023, 12, 2585–2589. [Google Scholar]

- Martin-Gorriz, B.; Maestre-Valero, J.F.; Gallego-Elvira, B.; Marín-Membrive, P.; Terrero, P.; Martínez-Alvarez, V. Recycling drainage effluents using reverse osmosis powered by photovoltaic solar energy in hydroponic tomato production: Environmental footprint analysis. J. Environ. Manag. 2021, 297, 113326. [Google Scholar] [CrossRef]

- Jensen, M.H. Hydroponics worldwide. In Proceedings of the International Symposium on Growing Media and Hydroponics, Windsor, ON, Canada, 19–26 May 1997; Volume 481, pp. 719–730. [Google Scholar]

- Velazquez-Gonzalez, R.S.; Garcia-Garcia, A.L.; Ventura-Zapata, E.; Barceinas-Sanchez, J.D.O.; Sosa-Savedra, J.C. A review on hydroponics and the technologies associated for medium-and small-scale operations. Agriculture 2022, 12, 646. [Google Scholar] [CrossRef]

- Katsoulas, N.; Baille, A.; Kittas, C. Effect of misting on transpiration and conductances of a greenhouse rose canopy. Agric. For. Meteorol. 2001, 106, 233–247. [Google Scholar] [CrossRef]

- Grange, R.I.; Hand, D.W. A review of the effects of atmospheric humidity on the growth of horticultural crops. J. Hortic. Sci. 1987, 62, 125–134. [Google Scholar] [CrossRef]

- Raudales, R.E.; Fisher, P.R.; Hall, C.R. The cost of irrigation sources and water treatment in greenhouse production. Irrig. Sci. 2017, 35, 43–54. [Google Scholar] [CrossRef]

- Li, B.; Shi, B.; Yao, Z.; Shukla, M.K.; Du, T. Energy partitioning and microclimate of solar greenhouse under drip and furrow irrigation systems. Agric. Water Manag. 2020, 234, 106096. [Google Scholar] [CrossRef]

- Singh, A. Soil salinization management for sustainable development: A review. J. Environ. Manag. 2021, 277, 111383. [Google Scholar] [CrossRef]

- García-Sánchez, F.; Sánchez-Martínez, M.; Marín-Sánchez, A. Performance of a subsurface drip irrigation system in a Mediterranean horticultural crop. Agric. Water Manag. 2018, 204, 200–211. [Google Scholar]

- Durai, C.R.B.; Vipulan, B.; Khan, T.A.; Prakash, T.S.R. Solar powered automatic irrigation system. In Proceedings of the 2018 International Conference on Power, Energy, Control and Transmission Systems (ICPECTS), Chennai, India, 22–23 February 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 139–142. [Google Scholar]

- Zhang, M.Z.; Niu, W.Q.; Bai, Q.J.; Li, Y.; Wang, J.W.; Wang, Z.Q.; Zhang, Z.X. Improvement of quality and yield of greenhouse tomato (Solanum lycopersicum L.) plants by micro-sprinkler irrigation under plastic film. Appl. Ecol. Environ. Res. 2020, 18, 5. [Google Scholar] [CrossRef]

- Bronson, K.F.; Hunsaker, D.J.; Williams, C.F.; Thorp, K.R.; Rockholt, S.M.; Del Grosso, S.J.; Venterea, R.T.; Barnes, E.M. Nitrogen management affects nitrous oxide emissions under varying cotton irrigation systems in the Desert Southwest, USA. J. Environ. Qual. 2018, 47, 70–78. [Google Scholar] [CrossRef] [PubMed]

- Gultekin, R.; Avag, K.; Görgişen, C.; Öztürk, Ö.; Yeter, T.; Alsan, P.B. Effect of deficit irrigation practices on greenhouse gas emissions in drip irrigation. Sci. Hortic. 2023, 310, 111757. [Google Scholar] [CrossRef]

- Lucero-Vega, G.; Troyo-Dieguez, E.; Murillo-Amador, B.; Nieto-Garibay, A.; Ruíz-Espinoza, F.H.; Beltrán-Morañes, F.A.; Zamora-Salgado, S. Design of an underground irrigation system to decrease soil evaporation, as compared with two conventional methods. Agrociencia 2017, 51, 487–505. [Google Scholar]

- Dik, D.; Polyakova, E.; Chelovechkova, A.; Moskvin, V.; Nikiforova, T. The System of Environment Control of Botanic Garden Greenhouses. In Proceedings of the 2018 International Multi-Conference on Industrial Engineering and Modern Technologies (FarEastCon), Vladivostok, Russia, 2–4 October 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–7. [Google Scholar]

- Yang, L.; Wu, Y.; Lu, C.; Yan, S.; Liu, H.; Luo, Y. Design and Optimization of Intelligent Greenhouse Automatic Control System. In Proceedings of the 2023 5th International Conference on Intelligent Control, Measurement and Signal Processing (ICMSP), Hangzhou, China, 26–28 April 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 316–319. [Google Scholar]

- Zhang, S.; Guo, Y.; Zhao, H.; Wang, Y.; Chow, D.; Fang, Y. Methodologies of control strategies for improving energy efficiency in agricultural greenhouses. J. Clean. Prod. 2020, 274, 122695. [Google Scholar] [CrossRef]

- Bagagiolo, G.; Matranga, G.; Cavallo, E.; Pampuro, N. Greenhouse Robots: Ultimate Solutions to Improve Automation in Protected Cropping Systems—A Review. Sustainability 2022, 14, 6436. [Google Scholar] [CrossRef]

- Van Mourik, S.; van der Tol, R.; Linker, R.; Reyes-Lastiri, D.; Kootstra, G.; Koerkamp, P.G.; van Henten, E.J. Introductory overview: Systems and control methods for operational management support in agricultural production systems. Environ. Model. Softw. 2021, 139, 105031. [Google Scholar] [CrossRef]

- Rayhana, R.; Xiao, G.; Liu, Z. Internet of things empowered smart greenhouse farming. IEEE J. Radio Freq. Identif. 2020, 4, 195–211. [Google Scholar] [CrossRef]

- Abbassy, M.M.; Ead, W.M. Intelligent greenhouse management system. In Proceedings of the 2020 6th International Conference on Advanced Computing and Communication Systems (ICACCS), Coimbatore, India, 6–7 March 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 1317–1321. [Google Scholar]

- Iddio, E.; Wang, L.; Thomas, Y.; McMorrow, G.; Denzer, A. Energy efficient operation and modeling for greenhouses: A literature review. Renew. Sustain. Energy Rev. 2020, 117, 109480. [Google Scholar] [CrossRef]

- Sumalan, R.L.; Stroia, N.; Moga, D.; Muresan, V.; Lodin, A.; Vintila, T.; Popescu, C.A. A Cost-effective embedded platform for greenhouse environment control and remote monitoring. Agronomy 2020, 10, 936. [Google Scholar] [CrossRef]

- Li, H.; Guo, Y.; Zhao, H.; Wang, Y.; Chow, D. Towards automated greenhouse: A state of the art review on greenhouse monitoring methods and technologies based on internet of things. Comput. Electron. Agric. 2021, 191, 106558. [Google Scholar] [CrossRef]

- Lee, S.; Lee, I.; Yeo, U.; Kim, R.; Kim, J. Optimal sensor placement for monitoring and controlling greenhouse internal environments. Biosyst. Eng. 2019, 188, 190–206. [Google Scholar] [CrossRef]

- Tekcin, M.; Tuzer Hamzaoglu, D.R.; Kursun, S. Flexible humidity sensor for smart agricultural applications. Flex. Print. Electron. 2023, 8, 035003. [Google Scholar] [CrossRef]

- Gupta, G.S.; Quan, V.M. Multi-sensor integrated system for wireless monitoring of greenhouse environment. In Proceedings of the 2018 IEEE Sensors Applications Symposium (SAS), Seoul, Republic of Korea, 12–14 March 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Ajani, O.S.; Usigbe, J.; Aboyeji, E.; Uyeh, D.D.; Ha, Y.; Park, T.; Mallipeddi, R. Greenhouse Micro-Climate Prediction Based on Fixed Sensor Placements: A Machine Learning Approach. Mathematics 2023, 11, 3052. [Google Scholar] [CrossRef]

- Fletcher, R.; Fisher, D. A Miniature Sensor for Measuring Reflectance, Relative Humidity, and Temperature: A Greenhouse Example. Agric. Sci. 2018, 9, 1516–1527. [Google Scholar] [CrossRef]

- Shen, D.; Xiao, M.; Xiao, Y.; Zou, G.; Hu, L.; Zhao, B.; Liu, L.; Duley, W.W.; Zhou, Y. Self-Powered, Rapid-Response, and Highly Flexible Humidity Sensors Based on Moisture-Dependent Voltage Generation. ACS Appl. Mater. Interfaces 2019, 11, 14249–14255. [Google Scholar] [CrossRef] [PubMed]

- Lan, L.; Le, X.; Dong, H.; Xie, J.; Ying, Y.; Ping, J. One-step and large-scale fabrication of flexible and wearable humidity sensor based on laser-induced graphene for real-time tracking of plant transpiration at bio-interface. Biosens. Bioelectron. 2020, 165, 112360. [Google Scholar] [CrossRef] [PubMed]

- Danita, M.; Mathew, B.; Shereen, N.; Sharon, N.; Paul, J. IoT Based Automated Greenhouse Monitoring System. In Proceedings of the 2018 Second International Conference on Intelligent Computing and Control Systems (ICICCS), Madurai, India, 14–15 June 2018; pp. 1933–1937. [Google Scholar] [CrossRef]

- Zarnescu, A.; Ungurelu, R.; Vărzaru, G. Controlling the Temperature and Humidity in a Greenhouse. In Proceedings of the 2019 IEEE 25th International Symposium for Design and Technology in Electronic Packaging (SIITME), Cluj-Napoca, Romania, 23–26 October 2019; pp. 168–171. [Google Scholar] [CrossRef]

- Meili, L.; Yankang, B. Embedded Automatic Control System for Temperature, Humidity and Light Intensity in Agricultural Greenhouses. In Proceedings of the 2nd International Symposium on Computer Science and Intelligent Control, Stockholm, Sweden, 21–23 September 2018. [Google Scholar] [CrossRef]

- Valdivia, C.H.G.; Escobedo, J.L.C.; Durán-Muñoz, H.; Berumen, J.; Ortiz, A.A.; Guirette, O.A.; Arroyo, A.; Brizuela, J.; Gómez, F.A.; Blanco-Ortega, A.; et al. Implementation of Virtual Sensors for Monitoring Temperature in Greenhouses Using CFD and Control. Sensors 2018, 19, 60. [Google Scholar] [CrossRef] [PubMed]

- Wardani, I.K.; Ichniarsyah, A.; Telaumbanua, M.; Priyonggo, B.; Fil’aini, R.; Mufidah, Z.; Dewangga, D.A. The feasibility study: Accuracy and precision of DHT 22 in measuring the temperature and humidity in the greenhouse. IOP Conf. Ser. Earth Environ. Sci. 2023, 1230, 012146. [Google Scholar] [CrossRef]

- Bhujel, A.; Basak, J.; Khan, F.; Arulmozhi, E.; Jaihuni, M.; Sihalath, T.; Lee, D.; Park, J.; Kim, H. Sensor Systems for Greenhouse Microclimate Monitoring and Control: A Review. J. Biosyst. Eng. 2020, 45, 341–361. [Google Scholar] [CrossRef]

- Guzman, B.G.; Talavante, J.; Frometa, D.F.; Mir, M.S.; Giustiniano, D.; Obraczka, K.; Loik, M.E.; Childress, S.; Wong, D.G. Toward Sustainable Greenhouses Using Battery-Free LiFi-Enabled Internet of Things. IEEE Commun. Mag. 2023, 61, 129–135. [Google Scholar] [CrossRef]

- Hamad, I.H.; Chouchaine, A.; Bouzaouache, H. On modeling greenhouse air-temperature: An experimental validation. In Proceedings of the 2021 18th International Multi-Conference on Systems, Signals & Devices (SSD), Monastir, Tunisia, 23–26 March 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 353–358. [Google Scholar]

- Pierart, F.G.; Sanhueza, D.A.V.; Riquelme, S. Greenhouse Parametric Computational Fluid Dynamic model. In Proceedings of the 2022 IEEE International Conference on Automation/XXV Congress of the Chilean Association of Automatic Control (ICA-ACCA), Valparaíso, Chile, 7–9 December 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–6. [Google Scholar]

- Ghani, S.; El-Bialy, E.M.A.A.; Bakochristou, F.; Rashwan, M.M.; Abdelhalim, A.M.; Ismail, S.M.; Ben, P. Experimental and numerical investigation of the thermal performance of evaporative cooled greenhouses in hot and arid climates. Sci. Technol. Built Environ. 2020, 26, 141–160. [Google Scholar] [CrossRef]

- Choab, N.; Allouhi, A.; El Maakoul, A.; Kousksou, T.; Saadeddine, S.; Jamil, A. Review on greenhouse microclimate and application: Design parameters, thermal modeling and simulation, climate controlling technologies. Sol. Energy 2019, 191, 109–137. [Google Scholar] [CrossRef]

- Miyoshi, T.; Kondo, K.; Terasaki, K. Big ensemble data assimilation in numerical weather prediction. Computer 2015, 48, 15–21. [Google Scholar] [CrossRef]

- Aaslyng, J.M.; Ehler, N.; Jakobsen, L. Climate control software integration with a greenhouse environmental control computer. Environ. Model. Softw. 2005, 20, 521–527. [Google Scholar] [CrossRef]

- Du, J.; Bansal, P.; Huang, B. Simulation model of a greenhouse with a heat-pipe heating system. Appl. Energy 2012, 93, 268–276. [Google Scholar] [CrossRef]

- Fitz-Rodríguez, E.; Kubota, C.; Giacomelli, G.A.; Tignor, M.E.; Wilson, S.B.; McMahon, M. Dynamic modeling and simulation of greenhouse environments under several scenarios: A web-based application. Comput. Electron. Agric. 2010, 70, 105–116. [Google Scholar] [CrossRef]

- Ma, D.; Carpenter, N.; Maki, H.; Rehman, T.U.; Tuinstra, M.R.; Jin, J. Greenhouse environment modeling and simulation for microclimate control. Comput. Electron. Agric. 2019, 162, 134–142. [Google Scholar] [CrossRef]

- Nguyen, N.M.; Tran, H.T.; Duong, M.V.; Bui, H.; Tran, K. Differentiable Physics-based Greenhouse Simulation. arXiv 2022, arXiv:2211.11502. [Google Scholar]

- Molina-Aiz, F.D.; Fatnassi, H.; Boulard, T.; Roy, J.C.; Valera, D.L. Comparison of finite element and finite volume methods for simulation of natural ventilation in greenhouses. Comput. Electron. Agric. 2010, 72, 69–86. [Google Scholar] [CrossRef]

- Kim, R.; Kim, J.; Lee, I.; Yeo, U.; Lee, S.; Decano-Valentin, C. Development of three-dimensional visualisation technology of the aerodynamic environment in a greenhouse using CFD and VR technology, part 1: Development of VR a database using CFD. Biosyst. Eng. 2021, 207, 12–32. [Google Scholar] [CrossRef]

- Boulard, T.; Roy, J.; Pouillard, J.B.; Fatnassi, H.; Grisey, A. Modelling of micrometeorology, canopy transpiration and photosynthesis in a closed greenhouse using computational fluid dynamics. Biosyst. Eng. 2017, 158, 110–133. [Google Scholar] [CrossRef]

- Taki, M.; Ajabshirchi, Y.; Ranjbar, S.; Rohani, A.; Matloobi, M. Modeling and experimental validation of heat transfer and energy consumption in an innovative greenhouse structure. Inf. Process. Agric. 2016, 3, 157–174. [Google Scholar] [CrossRef]

- Gao, Y.; Dong, J.; Isabella, O.; Santbergen, R.; Tan, H.; Zeman, M.; Zhang, G. Modeling and analyses of energy performances of photovoltaic greenhouses with sun-tracking functionality. Appl. Energy 2019, 233, 424–442. [Google Scholar] [CrossRef]

- Lachouri, C.E.; Mansouri, K.; Lafifi, M.M. Greenhouse Climate Modeling Using Fuzzy Neural Network Machine Learning Technique. Rev. Intell. Artif. 2022, 36, 925. [Google Scholar] [CrossRef]

- Li, K.; Xue, W.; Mao, H.; Chen, X.; Jiang, H.; Tan, G. Optimizing the 3D Distributed Climate inside Greenhouses Using Multi-Objective Optimization Algorithms and Computer Fluid Dynamics. Energies 2019, 12, 2873. [Google Scholar] [CrossRef]

- Chen, J.; Xu, F.; Tan, D.; Shen, Z.; Zhang, L.; Ai, Q. A control method for agricultural greenhouses heating based on computational fluid dynamics and energy prediction model. Appl. Energy 2015, 141, 106–118. [Google Scholar] [CrossRef]

- Rezvani, S.M.-E.; Shamshiri, R.; Hameed, I.; Abyane, H.Z.; Godarzi, M.; Momeni, D.; Balasundram, S.K. Greenhouse Crop Simulation Models and Microclimate Control Systems, A Review; IntechOpen: Rijeka, Croatia, 2021. [Google Scholar] [CrossRef]

- Weng, Y.; Wang, X.; Hua, J.; Wang, H.; Kang, M. Greenhouse Environment Control based on Computational Experiments. In Proceedings of the 2020 4th High Performance Computing and Cluster Technologies Conference & 2020 3rd International Conference on Big Data and Artificial Intelligence, Qingdao, China, 3–6 July 2020. [Google Scholar] [CrossRef]

- Maraveas, C. Incorporating artificial intelligence technology in smart greenhouses: Current State of the Art. Appl. Sci. 2022, 13, 14. [Google Scholar] [CrossRef]

- Kim, W.S.; Lee, W.S.; Kim, Y.J. A review of the applications of the internet of things (IoT) for agricultural automation. J. Biosyst. Eng. 2020, 45, 385–400. [Google Scholar] [CrossRef]

- Luna, D.F.O.; Ruiz, P.A.M. Automation and control of greenhouse implemented technologies: A review. Visión Electrónica 2019, 2, 381–394. [Google Scholar] [CrossRef]

- Gullino, M.L.; Albajes, R.; Nicot, P.C. Integrated Pest and Disease Management in Greenhouse Crops; Springer: Cham, Switzerland, 2020; Volume 9. [Google Scholar]

- Ullah, I.; Fayaz, M.; Aman, M.; Kim, D. Toward Autonomous Farming—A Novel Scheme Based on Learning to Prediction and Optimization for Smart Greenhouse Environment Control. IEEE Internet Things J. 2022, 9, 25300–25323. [Google Scholar] [CrossRef]

- Moradi, P.; Sadighi, H.; Chizari, M.; Sharifikia, M. Identification of Strategies for Application of Pro-Environmental Technologies to Produce Greenhouse Vegetables. J. Agric. Sci. Technol. 2020, 22, 653–666. [Google Scholar]

- Salimi, M.; Pourdarbani, R.; Nouri, B.A. Factors affecting the adoption of agricultural automation using Davis’s acceptance model (case study: Ardabil). Acta Technol. Agric. 2020, 23, 30–39. [Google Scholar] [CrossRef]

- Van Henten, E.J.; Hemming, J.; Van Tuijl, B.A.J.; Kornet, J.G.; Meuleman, J.; Bontsema, J.; Van Os, E.A. An autonomous robot for harvesting cucumbers in greenhouses. Auton. Robots 2002, 13, 241–258. [Google Scholar] [CrossRef]

- Komarchuk, D.S.; Gunchenko, Y.A.; Pasichnyk, N.A.; Opryshko, O.A.; Shvorov, S.A.; Reshetiuk, V. Use of Drones in Industrial Greenhouses. In Proceedings of the 2021 IEEE 6th International Conference on Actual Problems of Unmanned Aerial Vehicles Development (APUAVD), Kyiv, Ukraine, 21–23 September 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 184–187. [Google Scholar]

- Aslan, M.F.; Durdu, A.; Sabanci, K.; Ropelewska, E.; Gültekin, S.S. A comprehensive survey of the recent studies with UAV for precision agriculture in open fields and greenhouses. Appl. Sci. 2022, 12, 1047. [Google Scholar] [CrossRef]

- Sivagami, A.; Kandavalli, M.A.; Yakkala, B. Design and Evaluation of an Automated Monitoring and Control System for Greenhouse Crop Production. Next-Gener. Greenh. Food Secur. 2021, 1, 149–167. [Google Scholar] [CrossRef]

- Ramasamy, P.; Pandian, N.; Mayathevar, K.; Ravindran, R.; Kandula, S.R.; Devadoss, S.; Kuppusamy, S. Design of Arduino UNO based smart irrigation system for real time applications. Int. J. Reconfigurable Embed. Syst. (IJRES) 2024, 13, 105–110. [Google Scholar] [CrossRef]

- Salman, M.; Mahdi, M.M.; Ahmed, M.K. Optimization of solar powered air conditioning system using alternating Peltier power supply. Bull. Electr. Eng. Inform. 2024, 13, 20–30. [Google Scholar] [CrossRef]

- Prabha, C.; Pathak, A. Enabling Technologies in Smart Agriculture: A Way Forward Towards Future Fields. In Proceedings of the 2023 International Conference on Advancement in Computation & Computer Technologies (InCACCT), Gharuan, India, 5–6 May 2023; pp. 821–826. [Google Scholar] [CrossRef]

- Lin, T.; Wang, H.; Li, Z.; Zhu, J. A Novel Design of a Unilateral Nuclear Magnetic Resonance Sensor for Soil Moisture Detection Based on a Simplified Analytical Model. IEEE Trans. Geosci. Remote Sens. 2024, 62, 1–11. [Google Scholar] [CrossRef]

- Chakraborty, A.; Islam, M.; Dhar, A.; Hossain, M.S. IoT Based Greenhouse Environment Monitoring and Smart Irrigation System for Precision Farming Technology. In Proceedings of the 2022 International Conference on Innovations in Science, Engineering and Technology (ICISET), Istanbul, Turkeym, 23–25 November 2022; pp. 123–128. [Google Scholar] [CrossRef]

- Biradar, K.; Meng, Q. Nutrient Solution Application of a Calcium-mobilizing Biostimulant Mitigates Tipburn without Decreasing Biomass of Greenhouse Hydroponic Lettuce. HortScience 2024, 59, 92–98. [Google Scholar] [CrossRef]

- Omara, A. Improving Water Use Efficiency of Maize Under A Laser Spray Irrigation System. Alex. J. Soil Water Sci. 2024, 8, 1–22. [Google Scholar] [CrossRef]

- Mohagheghi, A.; Moallem, M. Measuring Photosynthetic Photon Flux Density in the Blue and Red Spectrum for Horticultural Lighting Using Machine Learning Methods. IEEE Trans. Instrum. Meas. 2024, 73, 1–10. [Google Scholar] [CrossRef]

- Emmi, L.; Fernández, R.; Guerrero, J.M. Editorial: Robotics for smart farms. Front. Robot. AI 2023, 9, 123–134. [Google Scholar] [CrossRef]

- Mujtahidin, M.H.; Shah, A.F.M.; Jais, A.S.A.; Annuar, K.A.M.; Sapiee, M.R. Design and development of control and monitoring hydroponic system. Int. J. Reconfigurable Embed. Syst. (IJRES) 2024, 13, 41–51. [Google Scholar] [CrossRef]

- Shamshiri, R.; Hameed, I.; Thorp, K.; Balasundram, S.K.; Shafian, S.; Fatemieh, M.; Sultan, M.; Mahns, B.; Samiei, S. Greenhouse Automation Using Wireless Sensors and IoT Instruments Integrated with Artificial Intelligence; IntechOpen: Rijeka, Croatia, 2021. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, M.; Liu, B.; Zou, C.; Sun, Y.; Wu, G.; Zhang, Q.; Jin, G.; Jin, Z.; Chadwick, D.; et al. Integrated systematic approach increase greenhouse tomato yield and reduce environmental losses. J. Environ. Manag. 2020, 266, 110569. [Google Scholar] [CrossRef]

- Lin, Y.-B.; Liu, C.-Y.; Chen, W.-L.; Chang, C.-H.; Ng, F.-L.; Yang, K.; Hsung, J. IoT-Based Strawberry Disease Detection With Wall-Mounted Monitoring Cameras. IEEE Internet Things J. 2024, 11, 1439–1451. [Google Scholar] [CrossRef]

- Castañeda-Miranda, A.; Castaño-Meneses, V.M. Smart frost measurement for anti-disaster intelligent control in greenhouses via embedding IoT and hybrid AI methods. Measurement 2020, 164, 108043. [Google Scholar] [CrossRef]

- Simon, J.; Petkovič, I.; Petkovic, D.; Petkovics, Á. Navigation and Applicability of Hexa Rotor Drones in Greenhouse Environment. Teh. Vjesn.-Tech. Gaz. 2018, 25, 249–255. [Google Scholar] [CrossRef]

- Cuce, E.; Harjunowibowo, D.; Cuce, P.M. Renewable and sustainable energy saving strategies for greenhouse systems: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 64, 34–59. [Google Scholar] [CrossRef]

- Dalai, R.; Senapati, K.K. An Intelligent Vision based Pest Detection System Using RCNN based Deep Learning Mechanism. In Proceedings of the 2019 International Conference on Recent Advances in Energy-efficient Computing and Communication (ICRAECC), Nagercoil, India, 7–8 March 2019; pp. 1–4. [Google Scholar] [CrossRef]

- Skripko, L.P.; Skripko, A. Automated Control Systems in Greenhouses. Herald Dagestan State Tech. Univ. Tech. Sci. 2023, 50, 150–155. [Google Scholar] [CrossRef]

- Yan, S.-R.; Fazilati, M.; Samani, N.; Ghasemi, H.; Toghraie, D.; Nguyen, Q.; Karimipour, A. Energy efficiency optimization of the waste heat recovery system with embedded phase change materials in greenhouses: A thermo-economic-environmental study. J. Energy Storage 2020, 30, 101445. [Google Scholar] [CrossRef]

| Study Title | Purpose of the Study | Methodology Used | Main Results |

|---|---|---|---|

| A computational model to determine the optimal orientation for solar greenhouses located at different latitudes in China [13] | Determine the optimal orientation of solar greenhouses at different latitudes in China. | Computational model based on the law of solar trajectory and thermal balance theory using the EnergyPlus software. | This paper proposed a calculation model to determine the optimal orientation of greenhouses to maximize solar energy harvesting at different latitudes in China. Validation has shown that the method can predict optimal orientations that result in significant energy savings for heating greenhouses, especially in northern China. |

| Development and optimization of a building energy simulation model to study the effect of greenhouse design parameters [43] | Evaluate the effect of greenhouse design parameters on energy conservation. | Building Energy Simulation (BES) using TRNSYS. | The east–west orientation, a Gothic-shaped roof, and the double-glazed PMMA (Polymethyl Methacrylate) roofing are the most effective design parameters for energy conservation in a greenhouse. In addition, natural ventilation has been shown to be effective in reducing the internal temperature of the greenhouse, which decreases the energy demand needed for cooling. |