Predicting Blast-Induced Damage and Dynamic Response of Drill-and-Blast Tunnel Using Three-Dimensional Finite Element Analysis

Abstract

1. Introduction

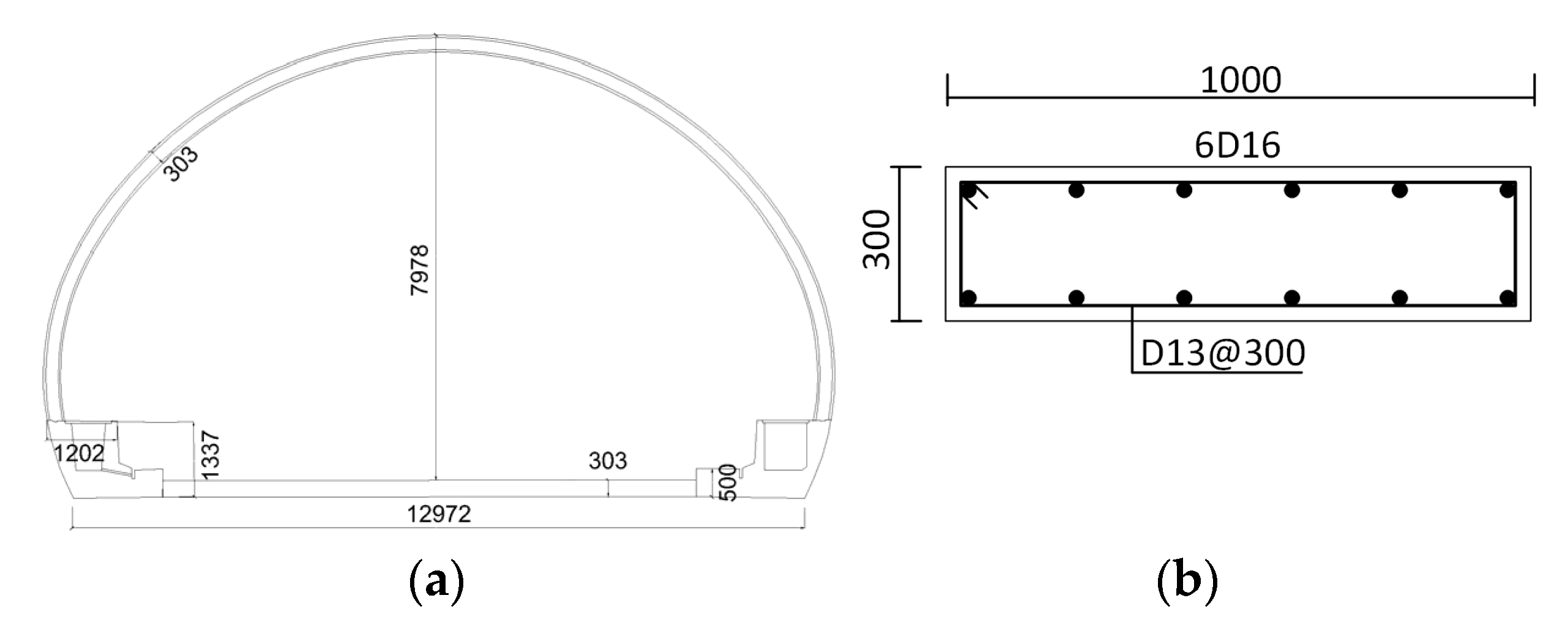

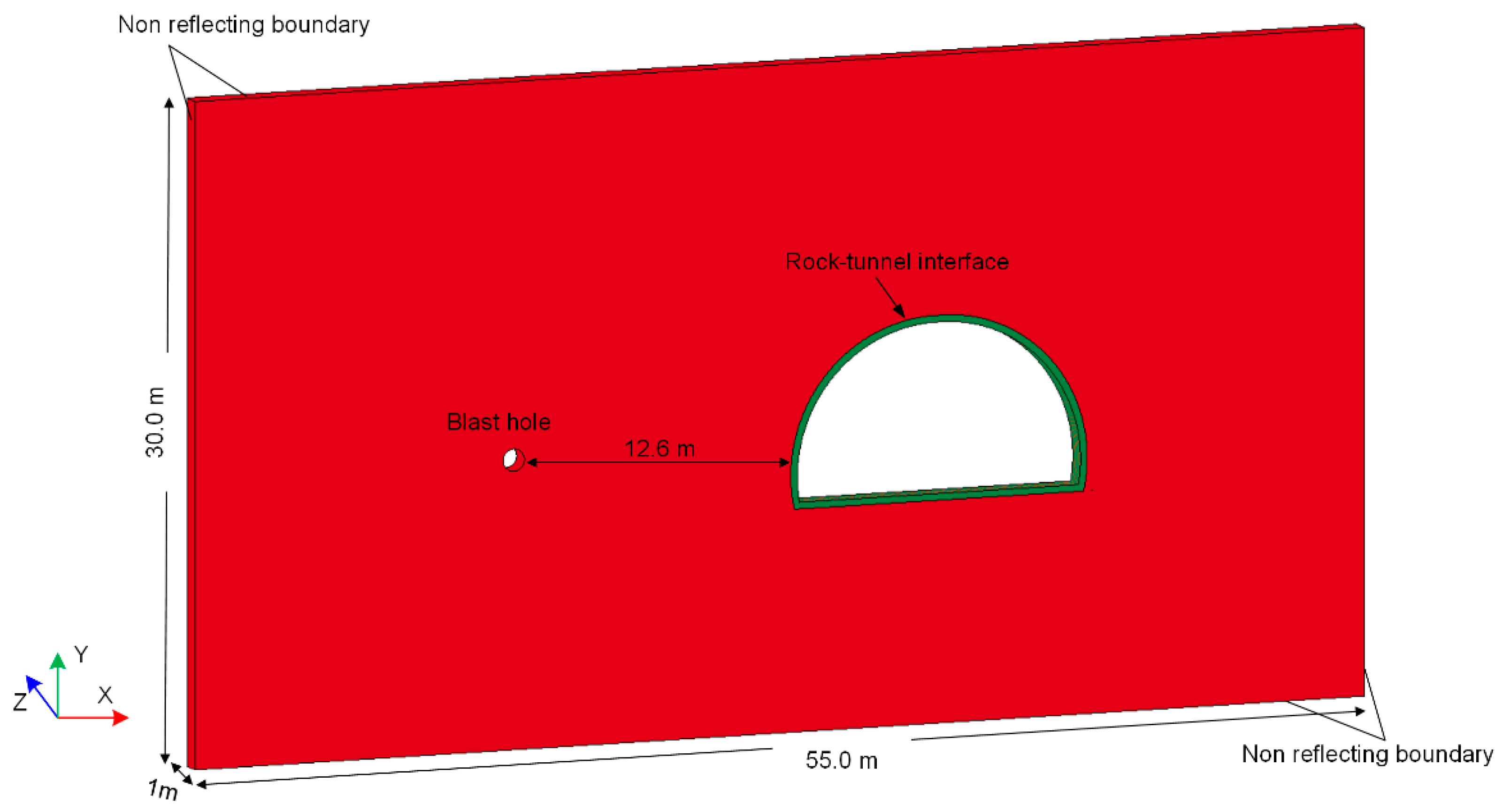

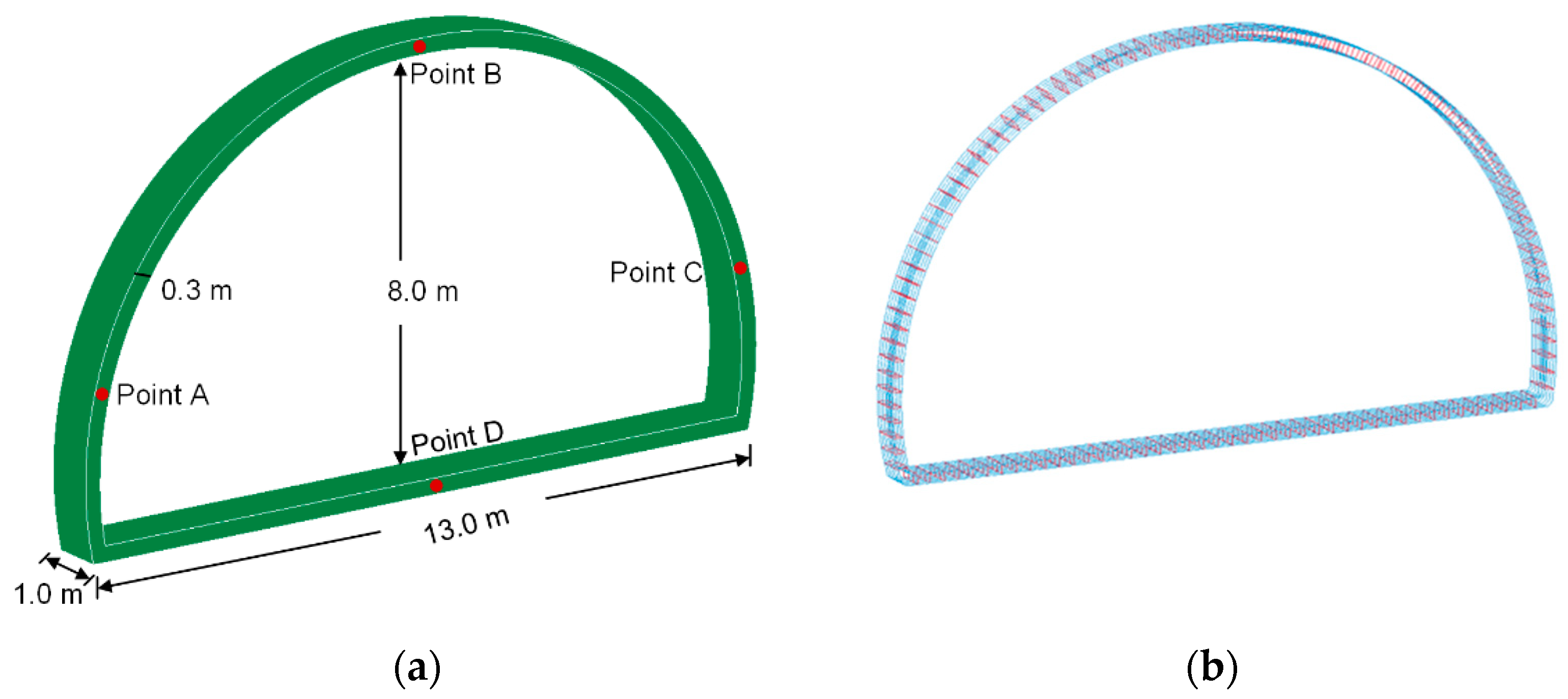

2. Numerical Model

2.1. Material Model

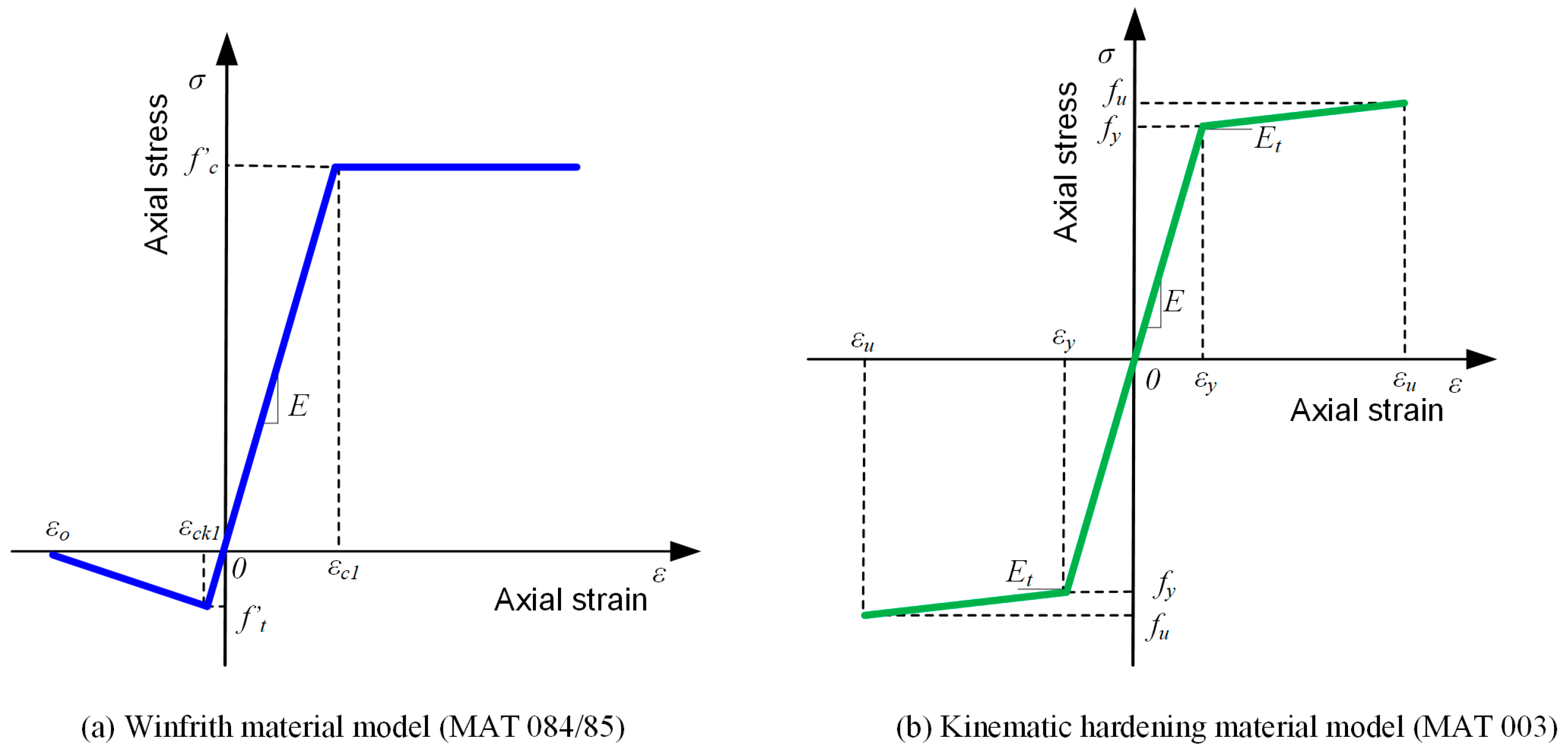

2.1.1. Concrete

2.1.2. Steel Rebar

2.1.3. Rock

2.2. Contact and Boundary Condition

2.3. Equivalent Blast Loading

2.4. Mesh Sensitivity Analysis

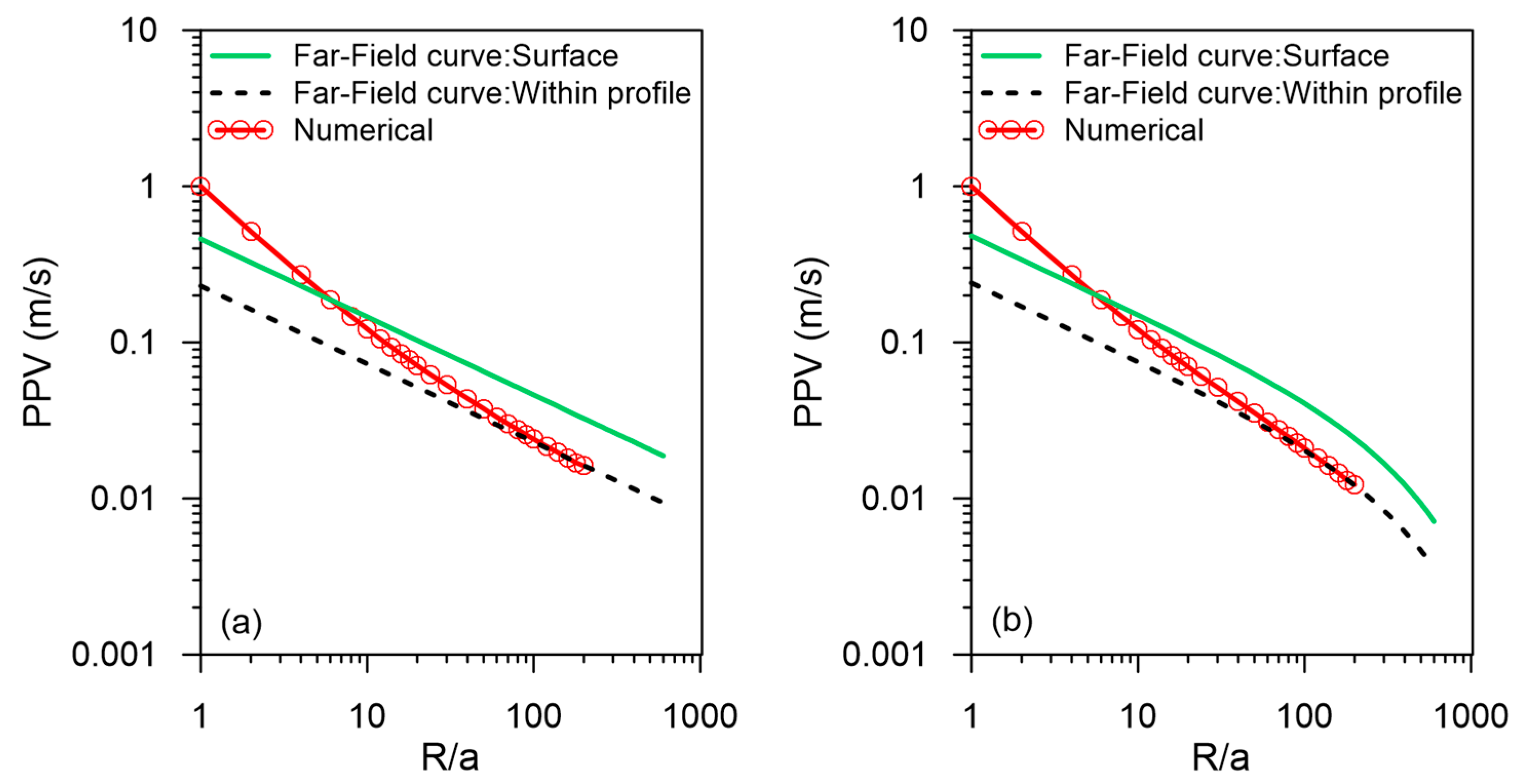

2.5. Numerical Model Verification with Far-Field Theoretical Solution

3. Results and Discussion

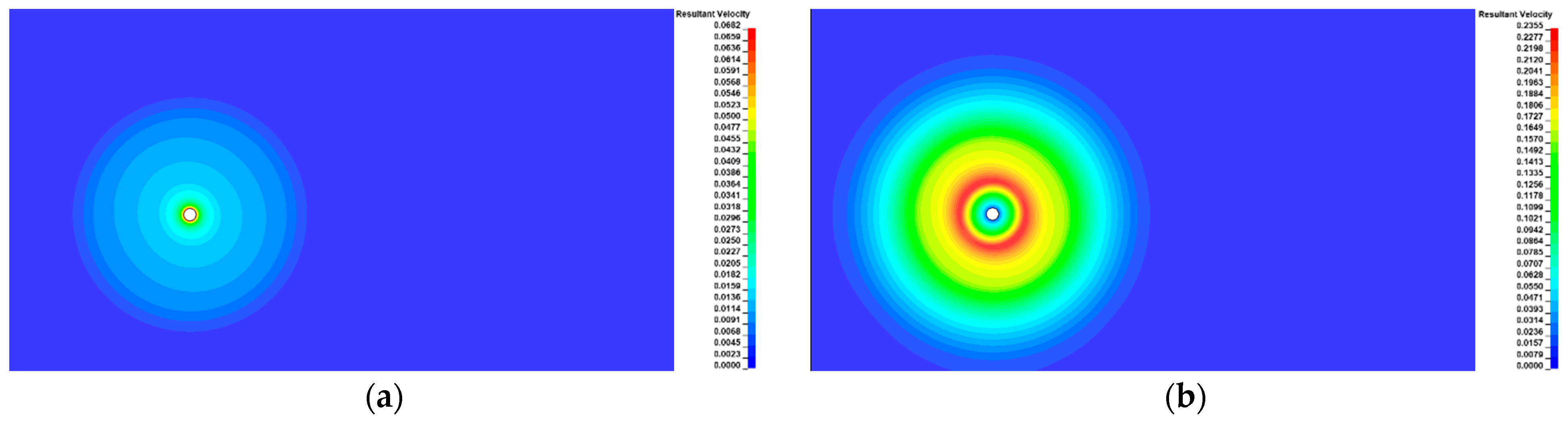

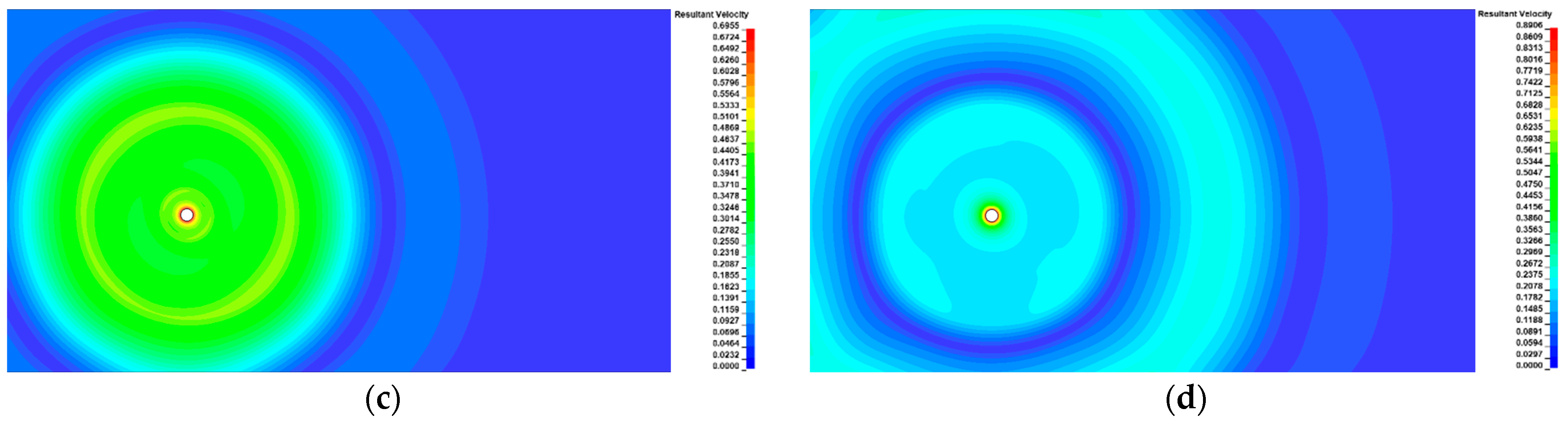

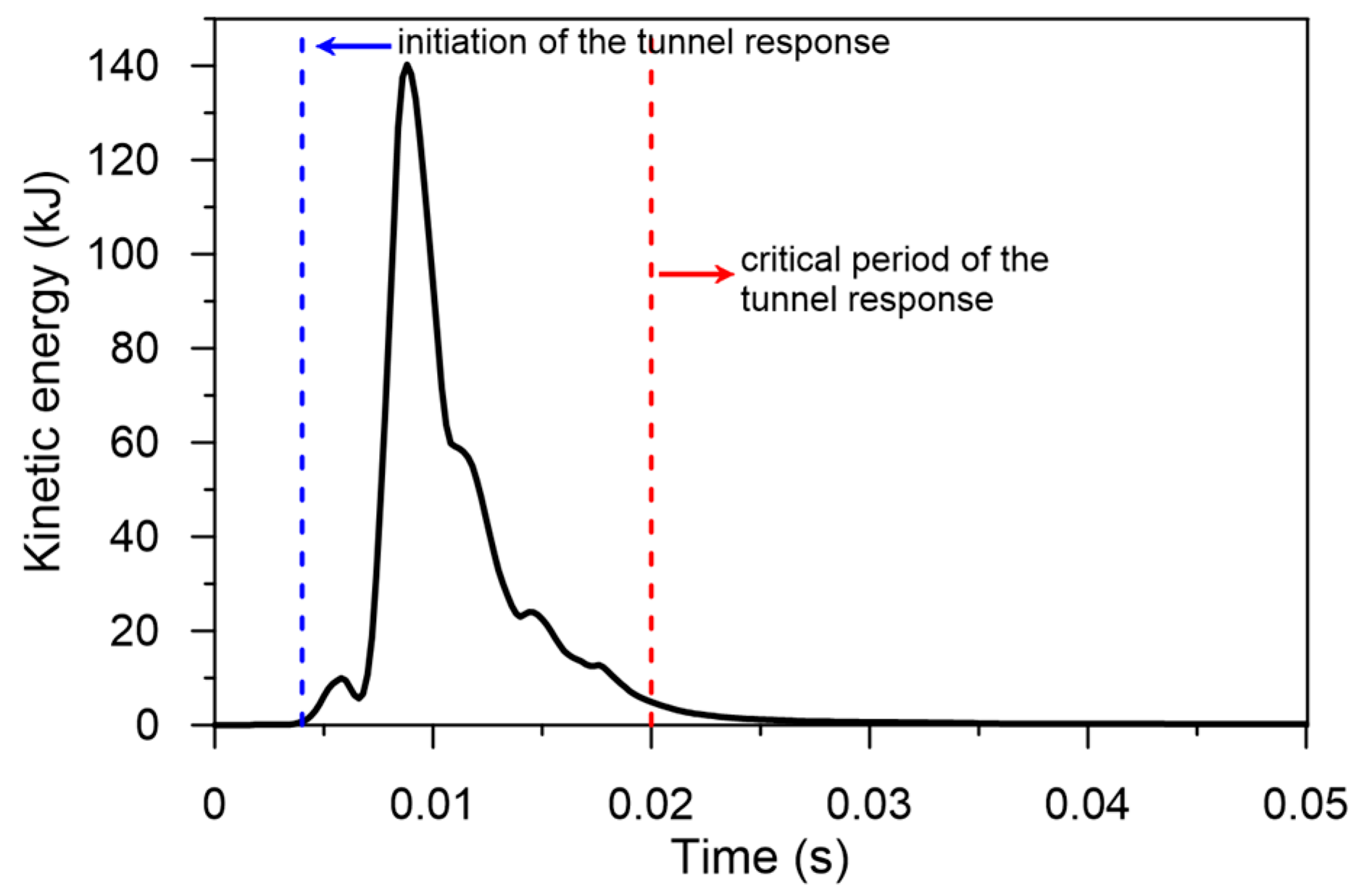

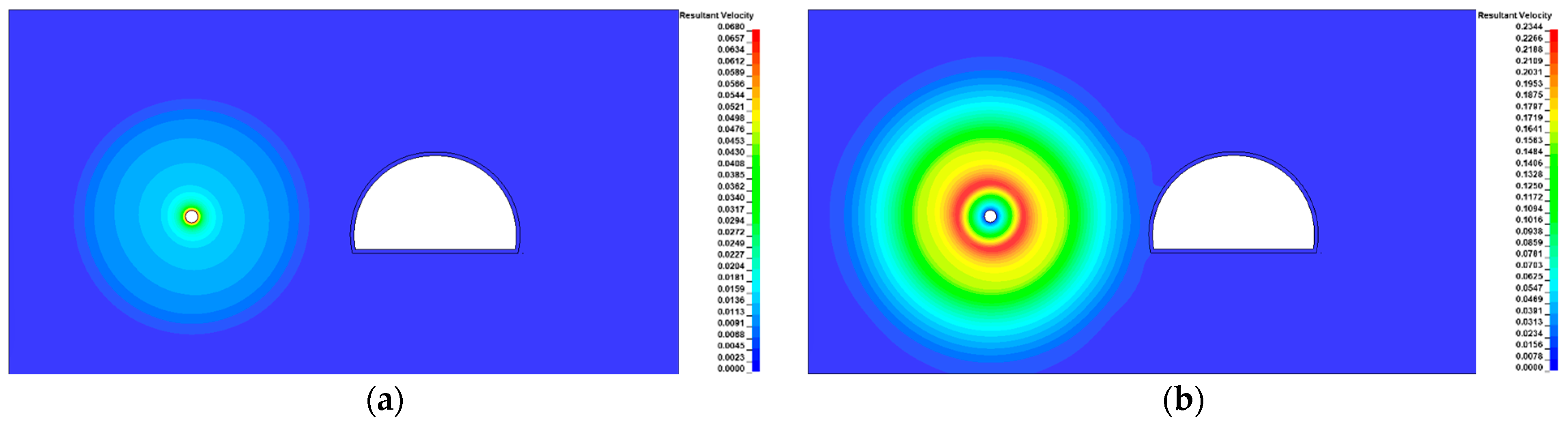

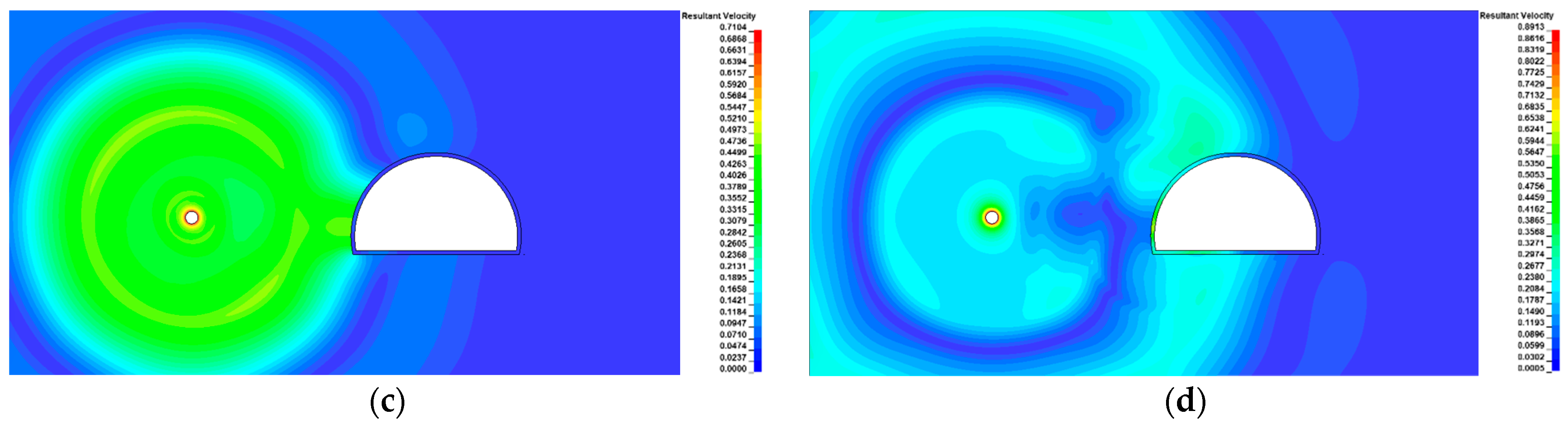

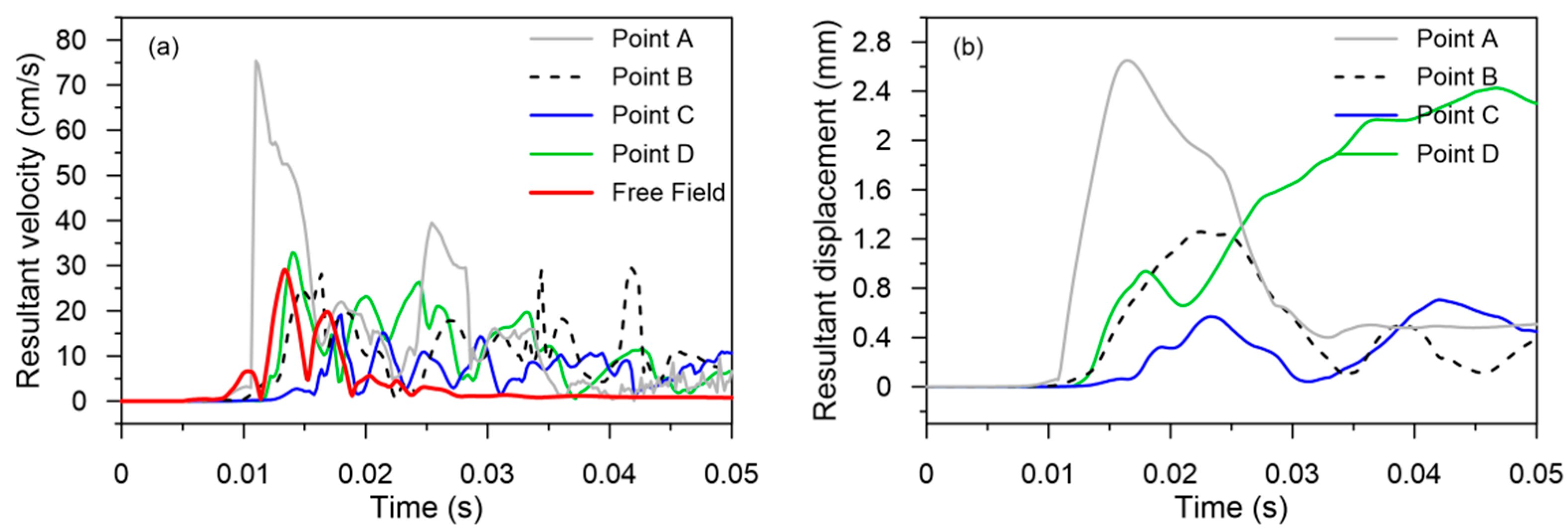

3.1. Wave Propagation and Structural Response

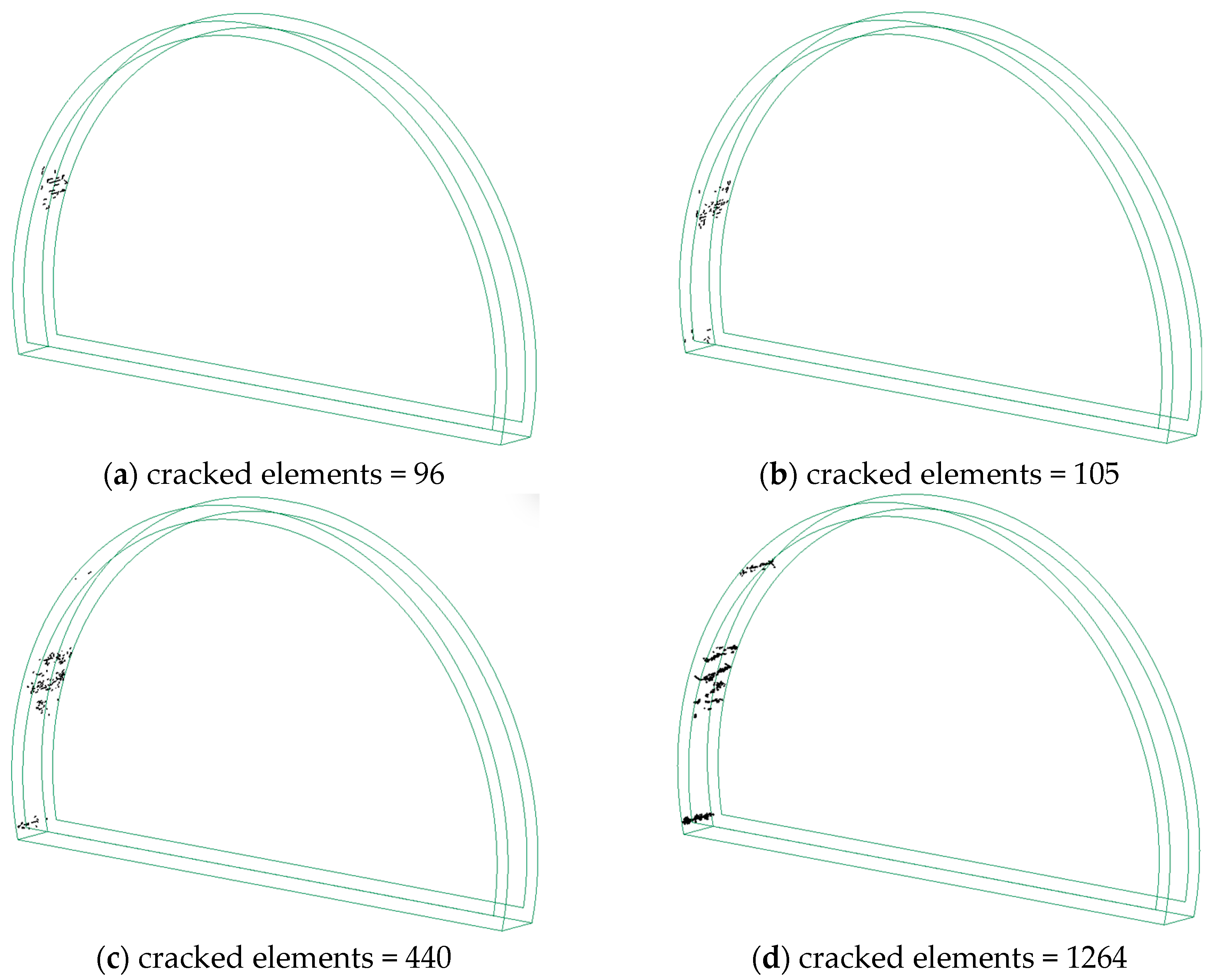

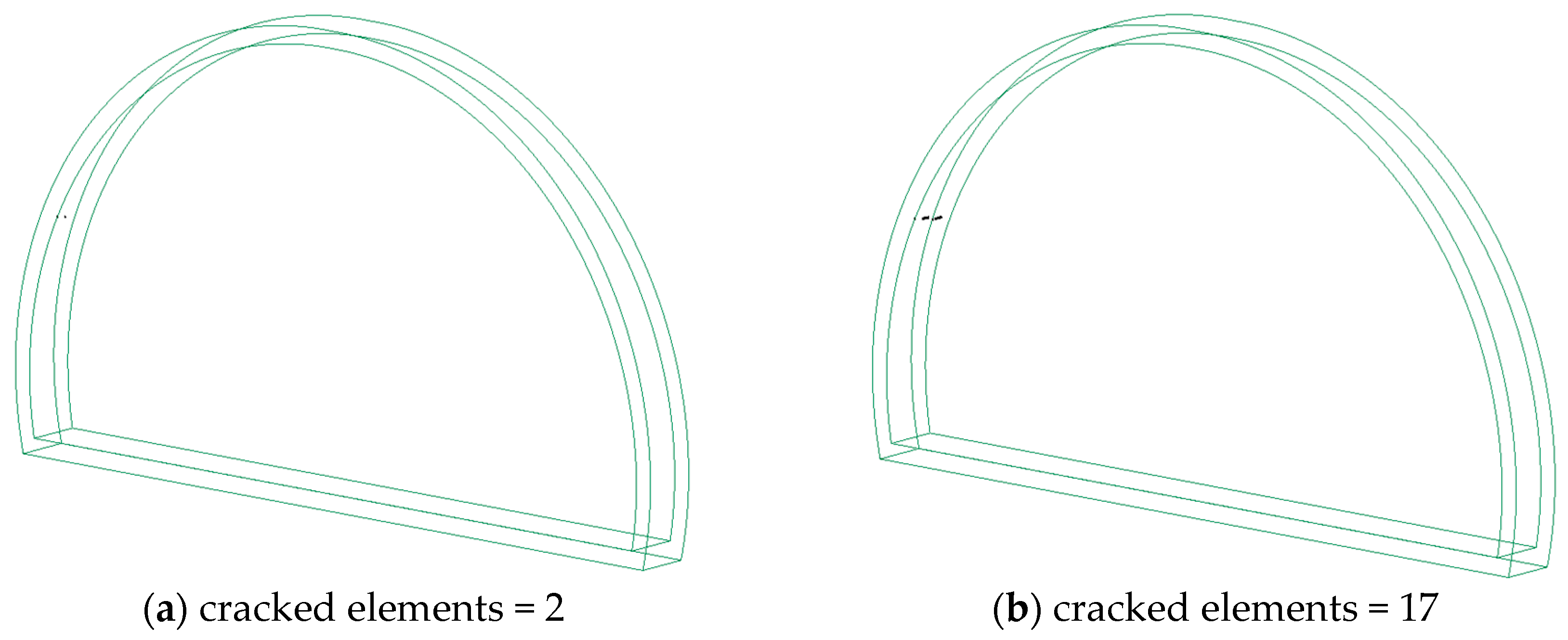

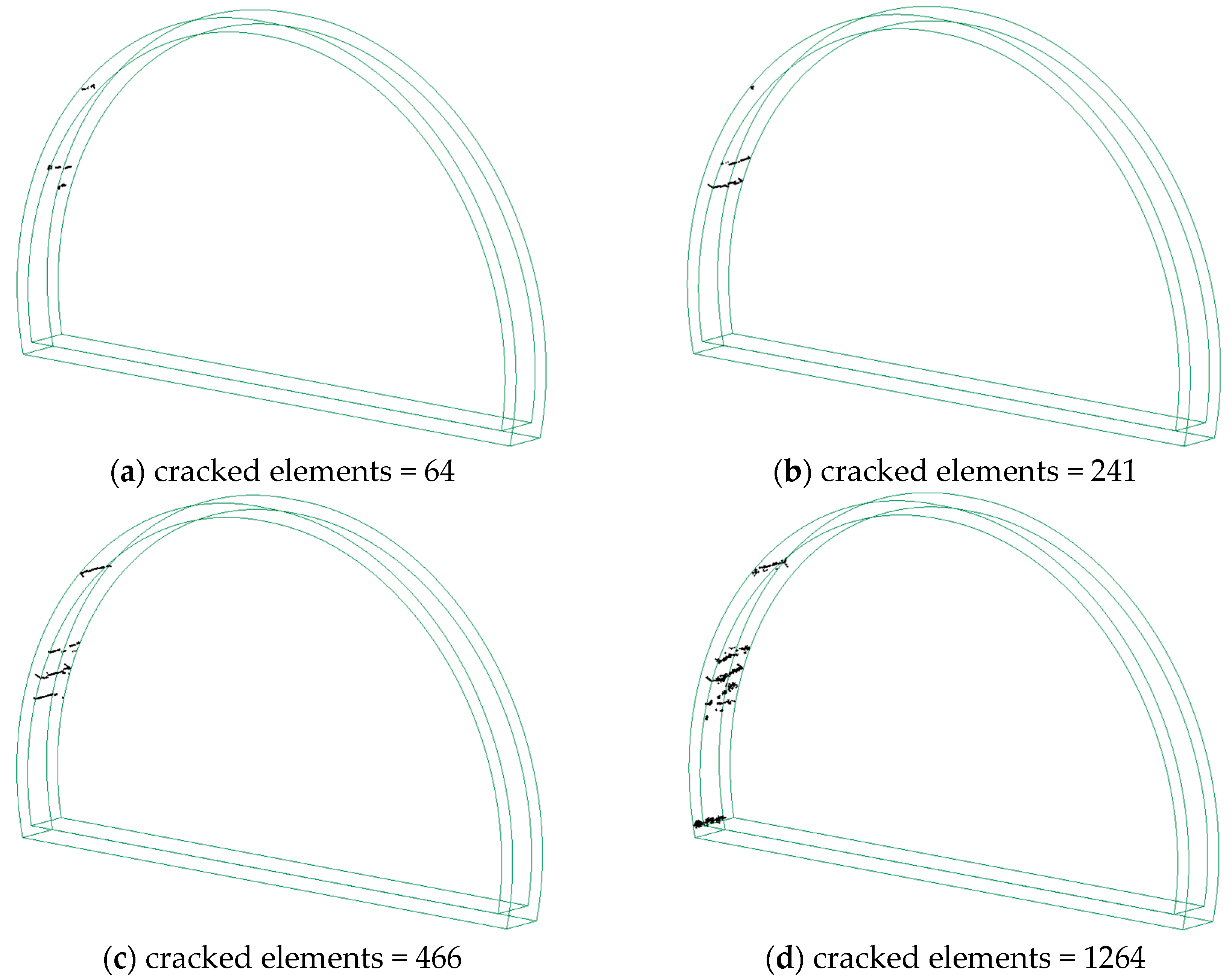

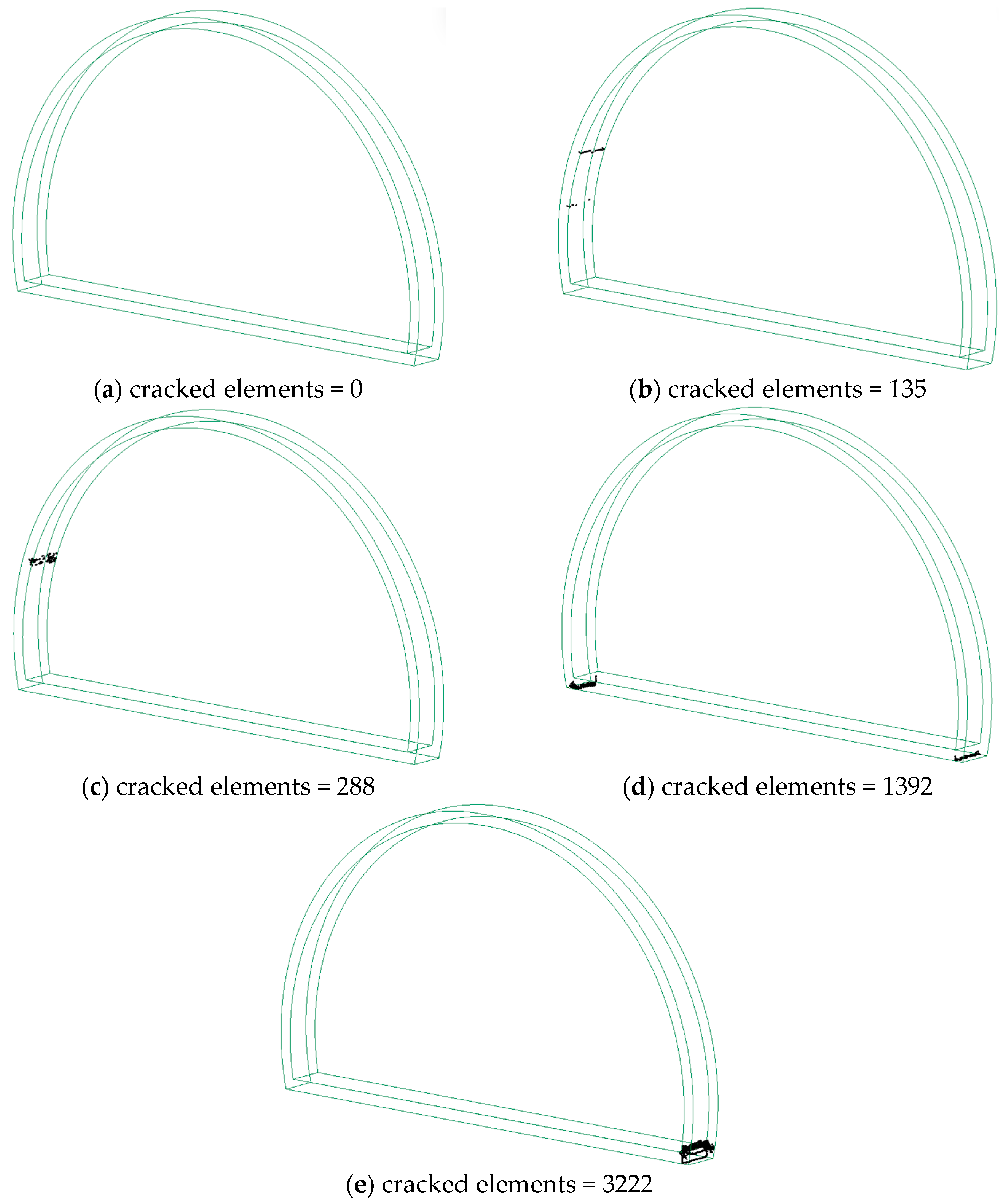

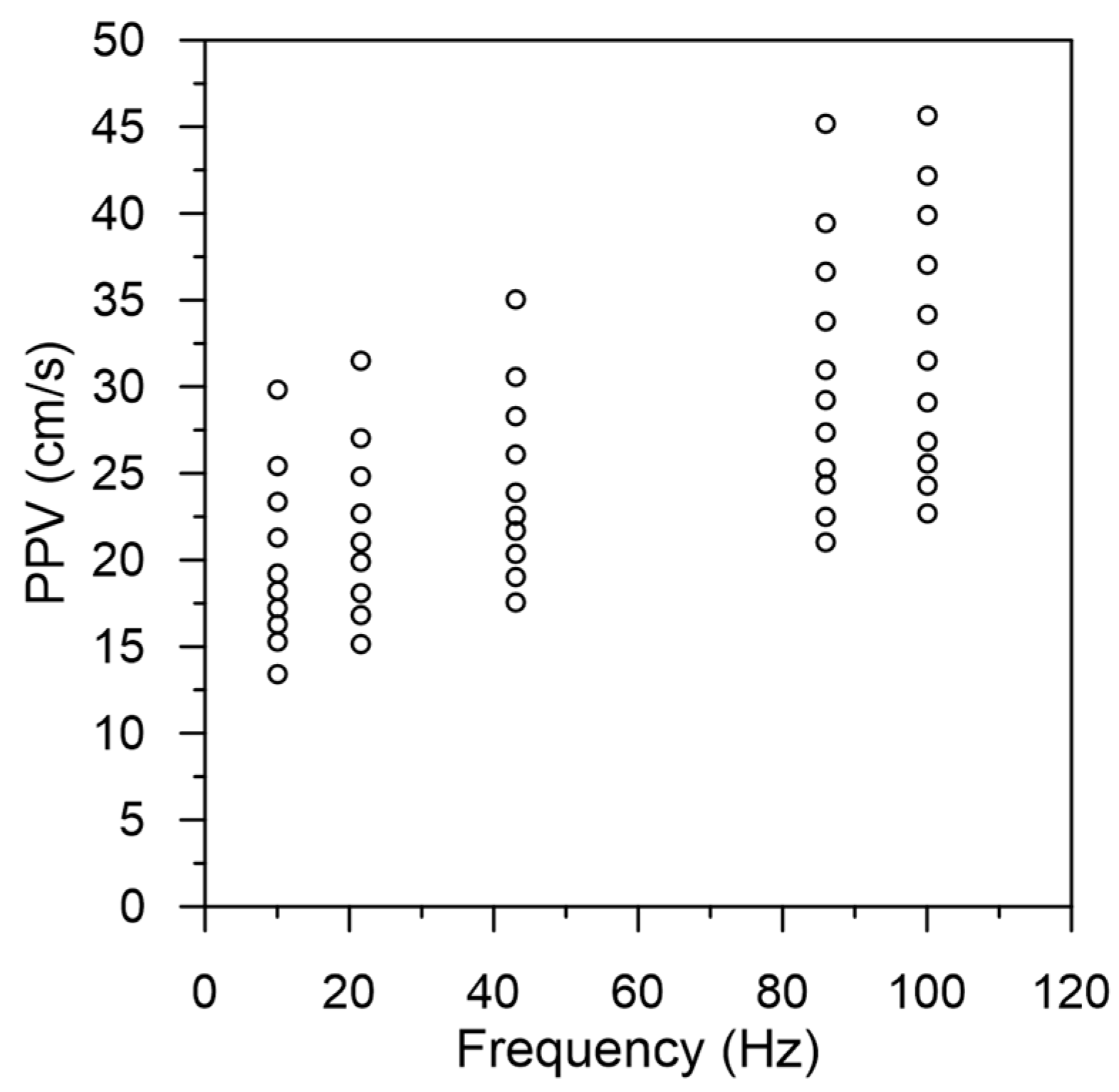

3.2. Damage Assessment

4. Conclusions

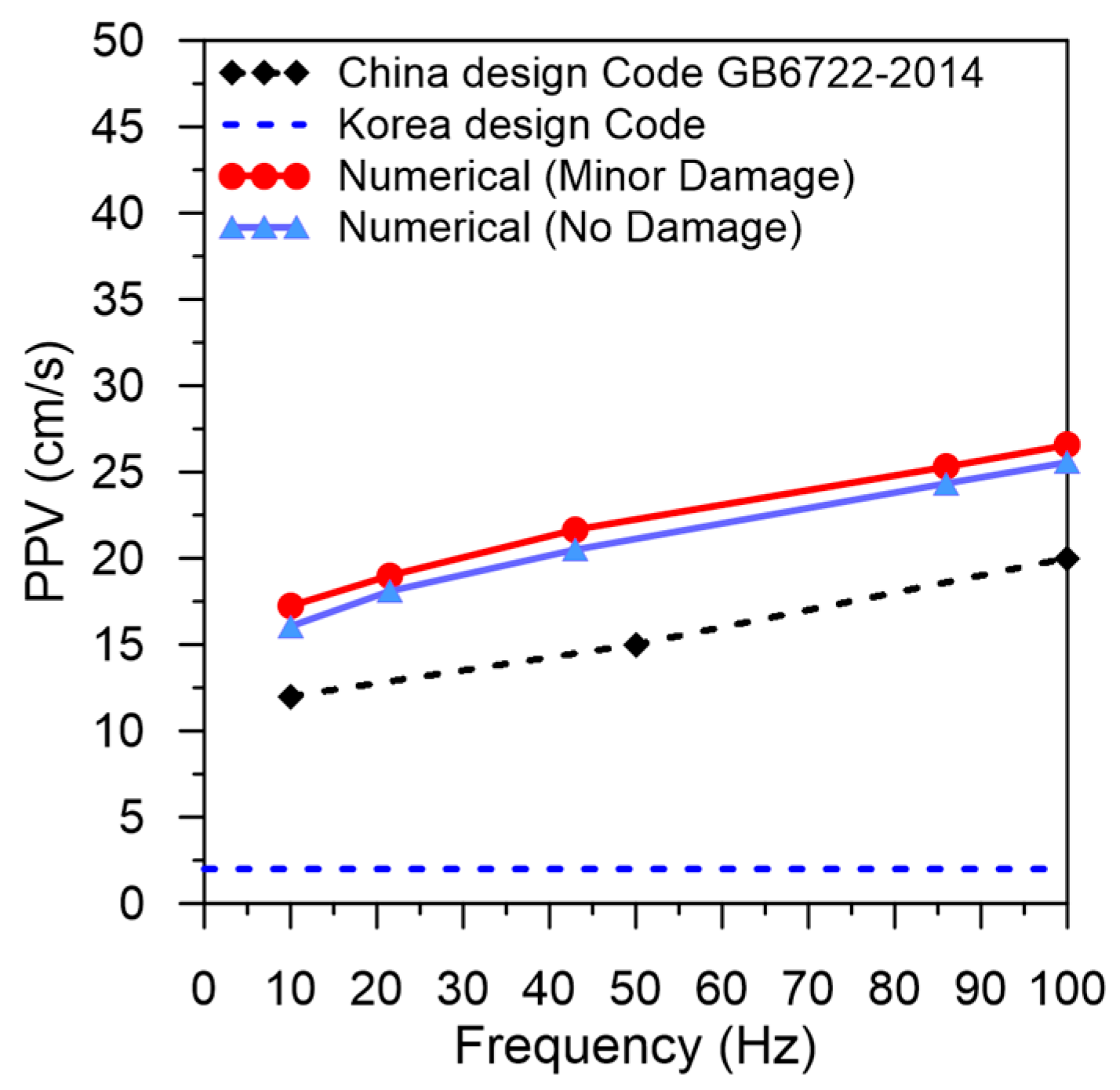

- With the constant distance from the blast hole, PPV increased with the increasing amplitude. With the constant predicted PPV, decreasing frequency content of the blasting load increased damage to the tunnel.

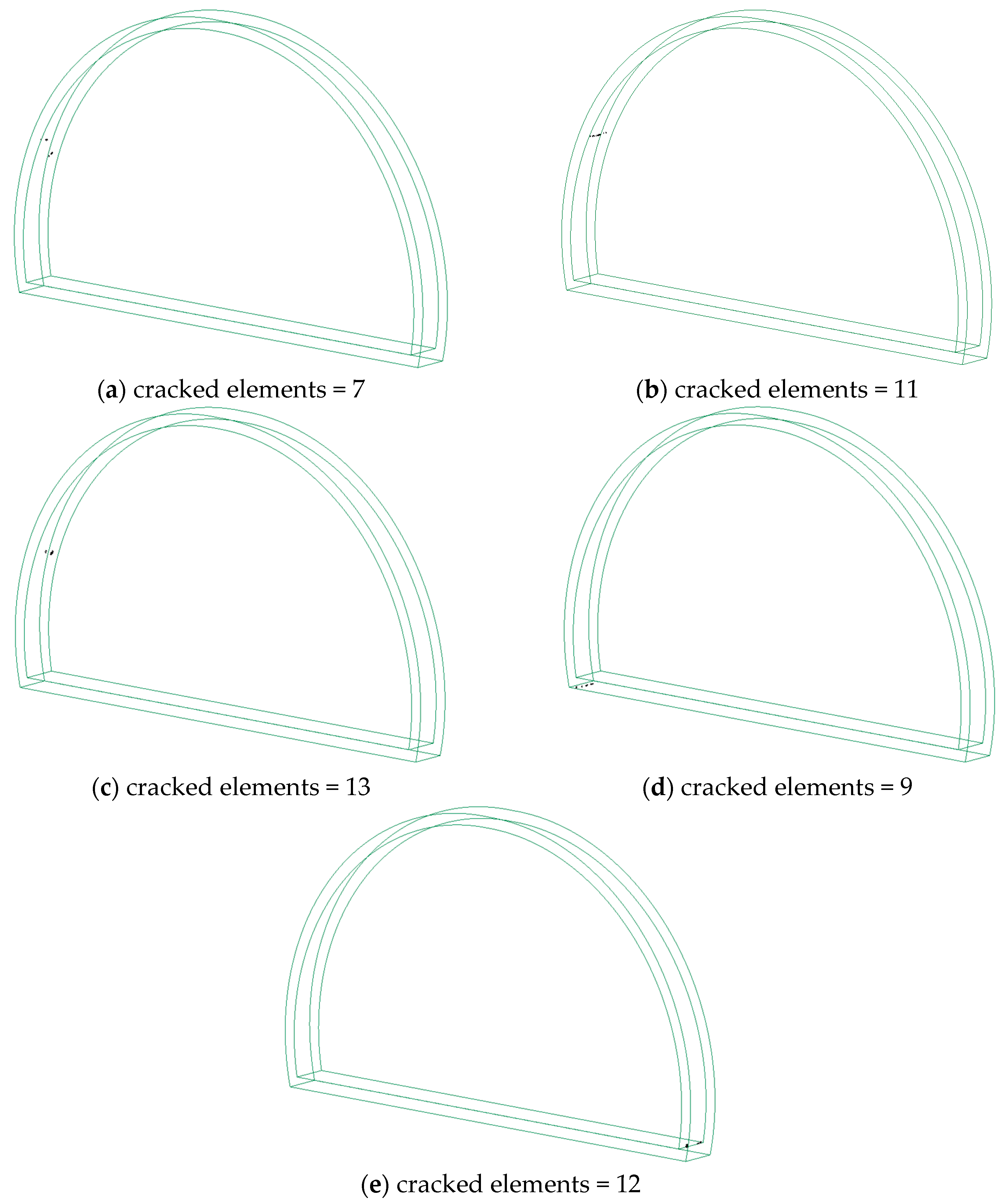

- The concrete lining cracking was mainly seen on the left side of the wall for high-frequency loading, while low-frequency loading created damage to the floor and the toe of the tunnel. The tunnel exhibited a much greater extent of tensile damage than compression damage.

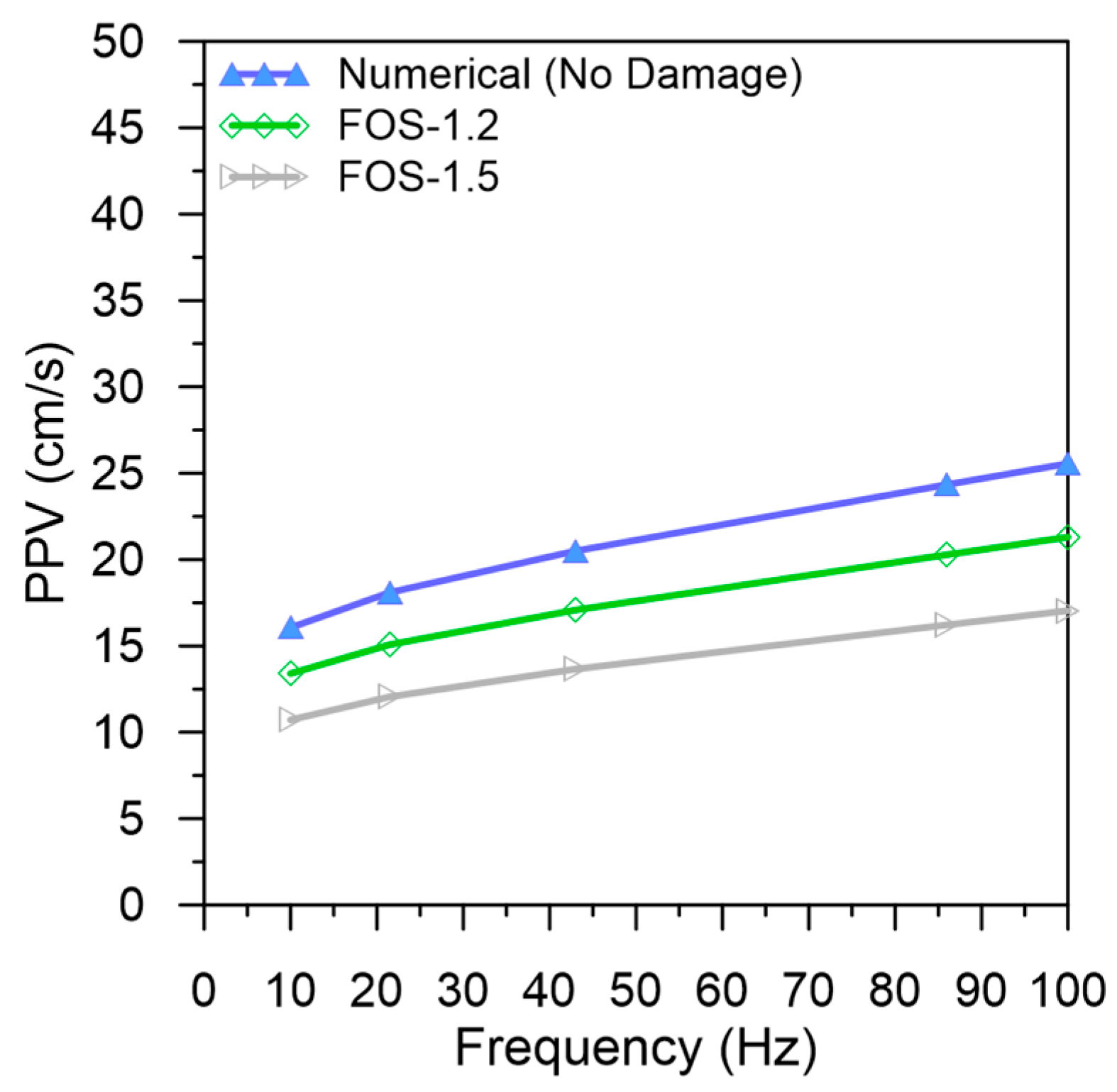

- The PPVs for No Damage and Minor Damage states were predicted.

- The damage prediction based on PPV combined with frequency was proposed, and their relationship with tunnel damage status from numerical simulation was established.

- The assessment of tunnel damage based on proposed damage criteria with additional equations for a factor of safety might be broadly adopted by engineers to ensure an accurate design of the underground horseshoe-shaped drill-and-blast tunnel subjected to blast loads.

- This study can be extended further by considering different types of site conditions with different tunnel types, lining thickness, and material properties.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sharafat, A.; Tanoli, W.A.; Raptis, G.; Seo, J.W. Controlled Blasting in Underground Construction: A Case Study of a Tunnel Plug Demolition in the Neelum Jhelum Hydroelectric Project. Tunn. Undergr. Space Technol. 2019, 93, 103098. [Google Scholar] [CrossRef]

- Ainalis, D.; Kaufmann, O.; Tshibangu, J.-P.; Verlinden, O.; Kouroussis, G. Modelling the Source of Blasting for the Numerical Simulation of Blast-Induced Ground Vibrations: A Review. Rock Mech. Rock Eng. 2017, 50, 171–193. [Google Scholar] [CrossRef]

- Liang, Q.; Li, J.; Li, D.; Ou, E. Effect of Blast-Induced Vibration from New Railway Tunnel on Existing Adjacent Railway Tunnel in Xinjiang, China. Rock Mech. Rock Eng. 2013, 46, 19–39. [Google Scholar] [CrossRef]

- Cheng, R.; Chen, W.; Hao, H.; Li, J. Effect of Internal Explosion on Tunnel Secondary and Adjacent Structures: A Review. Tunn. Undergr. Space Technol. 2022, 126, 104536. [Google Scholar] [CrossRef]

- Shin, J.-H.; Moon, H.-G.; Chae, S.-E. Effect of Blast-Induced Vibration on Existing Tunnels in Soft Rocks. Tunn. Undergr. Space Technol. 2011, 26, 51–61. [Google Scholar] [CrossRef]

- Gb6722-2014; Safety Regulations for Blasting. China Water Power Press: Beijing, China, 2014.

- Zhou, Q.; He, H.; Liu, S.; Wang, P.; Zhou, Y.; Zhou, J.; Fan, H.; Jin, F. Evaluation of Blast-Resistant Ability of Shallow-Buried Reinforced Concrete Urban Utility Tunnel. Eng. Fail. Anal. 2021, 119, 105003. [Google Scholar] [CrossRef]

- Meng, F.; Jin, F.; Kong, X.; Zhou, J.; Guan, L.; Xu, Y.; Wang, W.; Zhou, Y.; Chen, H.; Geng, H. Field Test and Theoretical Analysis of a Large Underground Arch Structure Subjected to Buried Explosion. Structures 2023, 57, 105141. [Google Scholar] [CrossRef]

- Pan, Y.; Zong, Z.; Li, J.; Qian, H.; Wu, C. Investigating the Dynamic Response of a Double-Box Utility Tunnel Buried in Calcareous Sand against Ground Surface Explosion. Tunn. Undergr. Space Technol. 2024, 146, 105636. [Google Scholar] [CrossRef]

- Zhou, L.; Li, X.; Yan, Q.; Li, S.; Chang, S.; Ren, P. Test and Damage Assessment of Shallow Buried Rc Tunnel under Explosion. Undergr. Space 2024, 14, 118–137. [Google Scholar] [CrossRef]

- Qing, H.; Guangkun, L.; Wei, W.; Congkun, Z.; Xiaodong, S. Failure Mode and Damage Assessment of Underground Reinforced Concrete Arched Structure under Side Top Explosion. Structures 2024, 59, 105801. [Google Scholar] [CrossRef]

- Zhao, D.; Huang, Y.; Chen, X.; Han, K.; Chen, C.; Zhao, X.; Chen, W. Numerical Investigations on Dynamic Responses of Subway Segmental Tunnel Lining Structures under Internal Blasts. Tunn. Undergr. Space Technol. 2023, 135, 105058. [Google Scholar] [CrossRef]

- Xia, X.; Li, H.; Li, J.; Liu, B.; Yu, C. A Case Study on Rock Damage Prediction and Control Method for Underground Tunnels Subjected to Adjacent Excavation Blasting. Tunn. Undergr. Space Technol. 2013, 35, 1–7. [Google Scholar] [CrossRef]

- Liu, Z.; Jiang, N.; Sun, J.; Xia, Y.; Lyu, G. Influence of Tunnel Blasting Construction on Adjacent Highway Tunnel: A Case Study in Wuhan, China. Int. J. Prot. Struct. 2020, 11, 283–303. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhou, C.; Remennikov, A.; Wu, T.; Lu, S.; Xia, Y. Dynamic Response and Safety Control of Civil Air Defense Tunnel under Excavation Blasting of Subway Tunnel. Tunn. Undergr. Space Technol. 2021, 112, 103879. [Google Scholar] [CrossRef]

- Yang, F.; Jiang, N.; Zhou, C.; Lyu, G.; Yao, Y. Dynamic Response and Safety Control of Civil Air Defense Tunnel Group during the Whole Process of Underpass Tunnel Blasting Excavation. Int. J. Prot. Struct. 2023, 14, 483–508. [Google Scholar] [CrossRef]

- Mussa, M.H.; Mutalib, A.A.; Hamid, R.; Naidu, S.R.; Radzi, N.A.M.; Abedini, M. Assessment of Damage to an Underground Box Tunnel by a Surface Explosion. Tunn. Undergr. Space Technol. 2017, 66, 64–76. [Google Scholar] [CrossRef]

- Koneshwaran, S.; Thambiratnam, D.P.; Gallage, C. Blast Response and Failure Analysis of a Segmented Buried Tunnel. Struct. Eng. Int. 2015, 25, 419–431. [Google Scholar] [CrossRef]

- Rashiddel, A.; Kharghani, M.; Dias, D.; Hajihassani, M. Numerical Study of the Segmental Tunnel Lining Behavior under a Surface Explosion–Impact of the Longitudinal Joints Shape. Comput. Geotech. 2020, 128, 103822. [Google Scholar] [CrossRef]

- Yang, G.; Wang, G.; Lu, W.; Yan, P.; Chen, M. Damage Assessment and Mitigation Measures of Underwater Tunnel Subjected to Blast Loads. Tunn. Undergr. Space Technol. 2019, 94, 103131. [Google Scholar] [CrossRef]

- Jiang, N.; Zhou, C. Blasting Vibration Safety Criterion for a Tunnel Liner Structure. Tunn. Undergr. Space Technol. 2012, 32, 52–57. [Google Scholar] [CrossRef]

- Xiong, L.; Jiang, N.; Zhou, C.; Li, H. Dynamic Response Characteristics of Adjacent Tunnel Lining under Blasting Impact in Subway Connecting Passage. Int. J. Prot. Struct. 2023, 14, 87–106. [Google Scholar] [CrossRef]

- Xia, J.; Wang, B.; Guo, X.; Xie, Z. Vibration Response and Safety Control for Blasting Vibration of the Existing Tunnel with Defects. Undergr. Space 2024, 15, 76–89. [Google Scholar] [CrossRef]

- Chopra, A. Structural Dynamics: Theory and Applications to Earthquake Engineering, 2nd ed.; Prentice Hall: Bergen County, NJ, USA, 2001. [Google Scholar]

- Nguyen, V.-Q.; Nizamani, Z.A.; Park, D.; Kwon, O.-S. Numerical Simulation of Damage Evolution of Daikai Station during the 1995 Kobe Earthquake. Eng. Struct. 2020, 206, 110180. [Google Scholar] [CrossRef]

- Ahn, J.K.; Park, D. Prediction of near-Field Wave Attenuation Due to a Spherical Blast Source. Rock Mech. Rock Eng. 2017, 50, 3085–3099. [Google Scholar] [CrossRef]

- Schwer, L. An Introduction to the Winfrith Concrete Model; Schwer Engineering & Consulting Services: Windsor, CA, USA, 2010; pp. 1–28. [Google Scholar]

- Ye, X.; Zhao, C.; He, K.; Zhou, L.; Li, X.; Wang, J. Blast Behaviors of Precast Concrete Sandwich Eps Panels: Fem and Theoretical Analysis. Eng. Struct. 2021, 226, 111345. [Google Scholar] [CrossRef]

- Nguyen, V.-Q.; Lee, Y.-G.; Park, D. Seismic Damage Evaluation of Double-Box Metro Tunnel Accounting for Soil Stiffness Using Three-Dimensional Finite Element Analysis. Structures 2023, 50, 1584–1597. [Google Scholar] [CrossRef]

- LSTC. LS-DYNA Keyword User’s Manual Version 971; LSTC: Livermore, CA, USA, 2007. [Google Scholar]

- Thai, D.-K.; Nguyen, D.-L.; Pham, T.-H.; Doan, Q.H. Prediction of Residual Strength of Frc Columns under Blast Loading Using the Fem Method and Regression Approach. Constr. Build. Mater. 2021, 276, 122253. [Google Scholar] [CrossRef]

- Jones, N. Structural Impact; Cambridge University Press: Cambridge, UK, 2011. [Google Scholar]

- Torano, J.; Rodríguez, R.; Diego, I.; Rivas, J.M.; Casal, M.D. Fem Models Including Randomness and Its Application to the Blasting Vibrations Prediction. Comput. Geotech. 2006, 33, 15–28. [Google Scholar] [CrossRef]

- Lu, W.; Yang, J.; Chen, M.; Zhou, C. An Equivalent Method for Blasting Vibration Simulation. Simul. Model. Pract. Theory 2011, 19, 2050–2062. [Google Scholar] [CrossRef]

- Fan, S.C.; Jiao, Y.Y.; Zhao, J. On Modelling of Incident Boundary for Wave Propagation in Jointed Rock Masses Using Discrete Element Method. Comput. Geotech. 2004, 31, 57–66. [Google Scholar] [CrossRef]

- ISO 4866:2010; Mechanical Vibration and Shock, Vibration of Fixed Structures, Guidelines for the Measurement of Vibrations and Evaluation of Their Effects on Structures. International Organisation for Standardisation ISO: Geneva, Switzerland, 2010.

- Blair, D.P. Acoustic Pulse Transmission in Half-Spaces and Finite-Length Cylindrical Rods. Geophysics 1985, 50, 1676–1683. [Google Scholar] [CrossRef]

- Qian, H.; Zong, Z.; Wu, C.; Li, J.; Gan, L. Numerical Study on the Behavior of Utility Tunnel Subjected to Ground Surface Explosion. Thin-Walled Struct. 2021, 161, 107422. [Google Scholar] [CrossRef]

- Dowding, C.H. Construction Vibrations; Prentice Hall Inc.: Englewood Cliffs, NJ, USA, 1996. [Google Scholar]

- Kim, D.-S.; Lee, J.-S. Propagation and Attenuation Characteristics of Various Ground Vibrations. Soil Dyn. Earthq. Eng. 2000, 19, 115–126. [Google Scholar] [CrossRef]

- Nelson, J.T.; Saurenman, H.J.; Wilson, I. State-of-the-Art Review: Prediction and Control of Groundborne Noise and Vibration from Rail Transit Trains; U.S. Department of Transportation; Urban Mass Transportation Administration: Washington, DC, USA, 1983. [Google Scholar]

| Material | Material Model | Parameter | Value |

|---|---|---|---|

| Concrete | Winfrith_Concrete | Mass density (kg/m3) | 2500 |

| Elastic modulus, E (GPa) | 24.8 | ||

| Poisson’s ratio | 0.17 | ||

| Uniaxial compressive strength, f’c (MPa) | 27.5 | ||

| Uniaxial tensile strength, f’t (MPa) | 3.2 | ||

| Axial strain at compressive strength, εc1 (%) | 0.22 | ||

| Axial strain at tensile strength, εck1 (%) | 0.03 | ||

| Ultimate strain value, εo (%) | 0.14 |

| Material | Material Model | Parameter | Value |

|---|---|---|---|

| Steel rebar | Plastic_Kinematic | Mass density (kg/m3) | 7800 |

| Elastic modulus, E (GPa) | 200 | ||

| Tangent modulus, Et (GPa) | 0.4 | ||

| Poisson’s ratio | 0.3 | ||

| Yield strength, fy (MPa) | 413 | ||

| Yield strain, εy (%) | 0.20 | ||

| Ultimate strength, fu (MPa) | 620 | ||

| Ultimate strain, εu (%) | 20 |

| Material | Material Model | Parameter | Value |

|---|---|---|---|

| Rock | Elastic | Mass density (kg/m3) | 2500 |

| Elastic modulus, E (GPa) | 33.3 | ||

| Poisson’s ratio | 0.25 | ||

| P-wave velocity, Vp | 4000 | ||

| S-wave velocity, Vs | 2309 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rehman, J.U.; Park, D.; Ahn, J.-K. Predicting Blast-Induced Damage and Dynamic Response of Drill-and-Blast Tunnel Using Three-Dimensional Finite Element Analysis. Appl. Sci. 2024, 14, 6152. https://doi.org/10.3390/app14146152

Rehman JU, Park D, Ahn J-K. Predicting Blast-Induced Damage and Dynamic Response of Drill-and-Blast Tunnel Using Three-Dimensional Finite Element Analysis. Applied Sciences. 2024; 14(14):6152. https://doi.org/10.3390/app14146152

Chicago/Turabian StyleRehman, Jawad Ur, Duhee Park, and Jae-Kwang Ahn. 2024. "Predicting Blast-Induced Damage and Dynamic Response of Drill-and-Blast Tunnel Using Three-Dimensional Finite Element Analysis" Applied Sciences 14, no. 14: 6152. https://doi.org/10.3390/app14146152

APA StyleRehman, J. U., Park, D., & Ahn, J.-K. (2024). Predicting Blast-Induced Damage and Dynamic Response of Drill-and-Blast Tunnel Using Three-Dimensional Finite Element Analysis. Applied Sciences, 14(14), 6152. https://doi.org/10.3390/app14146152