Laser Processing of Intraocular Lenses

Abstract

:1. Introduction

2. Materials and Methods

2.1. IOLs

2.2. IOL Characterization

2.3. Femtosecond Laser Micromachining Setup

2.4. Nanosecond Laser Setup

2.5. CW Diode Laser Micromachining Setup

3. Results

3.1. Optical Properties

3.2. Fabrication and Characterization of Femtosecond Laser-Induced Micro-Patterns

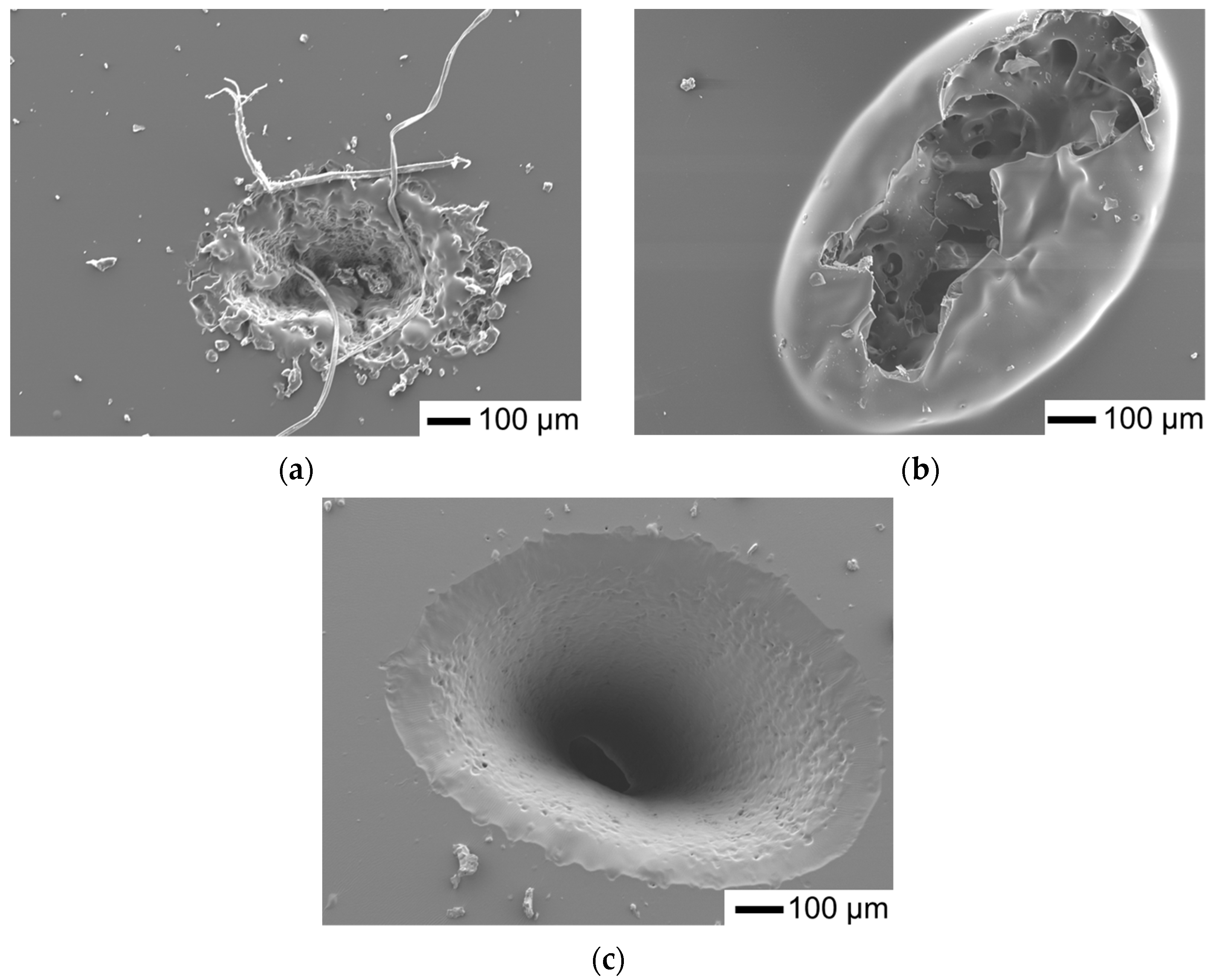

3.3. Nanosecond Laser Ablation of Acrylic IOLs

3.4. CW Diode Laser Patterns

3.5. Characterization of Structural Modification and Chemical Composition

4. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bloemendal, H.; De Jong, W.; Jaenicke, R.; Lubsen, N.H.; Slingsby, C.; Tardieu, A. Ageing and Vision: Structure, Stability and Function of Lens Crystallins. Prog. Biophys. Mol. Biol. 2004, 86, 407–485. [Google Scholar] [CrossRef] [PubMed]

- Vacalebre, M.; Frison, R.; Corsaro, C.; Neri, F.; Santoro, A.; Conoci, S.; Anastasi, E.; Curatolo, M.C.; Fazio, E. Current State of the Art and Next Generation of Materials for a Customized IntraOcular Lens According to a Patient-Specific Eye Power. Polymers 2023, 15, 1590. [Google Scholar] [CrossRef] [PubMed]

- Luo, C.; Wang, H.; Chen, X.; Xu, J.; Yin, H.; Yao, K. Recent Advances of Intraocular Lens Materials and Surface Modification in Cataract Surgery. Front. Bioeng. Biotechnol. 2022, 10, 913383. [Google Scholar] [CrossRef] [PubMed]

- Han, Y.; Tang, J.; Xia, J.; Wang, R.; Qin, C.; Liu, S.; Zhao, X.; Chen, H.; Lin, Q. Anti-Adhesive and Antiproliferative Synergistic Surface Modification of Intraocular Lens for Reduced Posterior Capsular Opacification. Int. J. Nanomed. 2019, 14, 9047–9061. [Google Scholar] [CrossRef]

- Bozukova, D.; Pagnoulle, C.; De Pauw-Gillet, M.-C.; Desbief, S.; Lazzaroni, R.; Ruth, N.; Jérôme, R.; Jérôme, C. Improved Performances of Intraocular Lenses by Poly(Ethylene Glycol) Chemical Coatings. Biomacromolecules 2007, 8, 2379–2387. [Google Scholar] [CrossRef] [PubMed]

- Wilkins, M.R.; Allan, B.; Rubin, G. Moorfields IOL Study Group Spectacle Use after Routine Cataract Surgery. Br. J. Ophthalmol. 2009, 93, 1307–1312. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.Y.; Stem, M.S.; Oren, G.; Shtein, R.; Lichter, P.R. Patient-Centered and Visual Quality Outcomes of Premium Cataract Surgery: A Systematic Review. Eur. J. Ophthalmol. 2017, 27, 387–401. [Google Scholar] [CrossRef] [PubMed]

- Ruhswurm, I.; Scholz, U.; Zehetmayer, M.; Hanselmayer, G.; Vass, C.; Skorpik, C. Astigmatism Correction with a Foldable Toric Intraocular Lens in Cataract Patients. J. Cataract. Refract. Surg. 2000, 26, 1022–1027. [Google Scholar] [CrossRef] [PubMed]

- Alio, J.L.; Plaza-Puche, A.B.; Férnandez-Buenaga, R.; Pikkel, J.; Maldonado, M. Multifocal Intraocular Lenses: An Overview. Surv. Ophthalmol. 2017, 62, 611–634. [Google Scholar] [CrossRef]

- Aslam, T.M.; Devlin, H.; Dhillon, B. Use of Nd:YAG Laser Capsulotomy. Surv. Ophthalmol. 2003, 48, 594–612. [Google Scholar] [CrossRef]

- Schriefl, S.M.; Menapace, R.; Stifter, E.; Zaruba, D.; Leydolt, C. Posterior Capsule Opacification and Neodymium:YAG Laser Capsulotomy Rates with 2 Microincision Intraocular Lenses: Four-Year Results. J. Cataract. Refract. Surg. 2015, 41, 956–963. [Google Scholar] [CrossRef] [PubMed]

- Seo, Y.; Kim, S.; Lee, H.S.; Park, J.; Lee, K.; Jun, I.; Seo, H.; Kim, Y.J.; Yoo, Y.; Choi, B.C.; et al. Femtosecond Laser Induced Nano-Textured Micropatterning to Regulate Cell Functions on Implanted Biomaterials. Acta Biomater. 2020, 116, 138–148. [Google Scholar] [CrossRef] [PubMed]

- Madrid-Costa, D.; Pérez-Vives, C.; Ruiz-Alcocer, J.; Albarrán-Diego, C.; Montés-Micó, R. Visual Simulation through Different Intraocular Lenses in Patients with Previous Myopic Corneal Ablation Using Adaptive Optics: Effect of Tilt and Decentration. J. Cataract. Refract. Surg. 2012, 38, 774–786. [Google Scholar] [CrossRef] [PubMed]

- Kalli, K.; Riziotis, C.; Posporis, A.; Markos, C.; Koutsides, C.; Ambran, S.; Webb, A.S.; Holmes, C.; Gates, J.C.; Sahu, J.K.; et al. Flat Fibre and Femtosecond Laser Technology as a Novel Photonic Integration Platform for Optofluidic Based Biosensing Devices and Lab-on-Chip Applications: Current Results and Future Perspectives. Sens. Actuators B Chem. 2015, 209, 1030–1040. [Google Scholar] [CrossRef]

- Athanasekos, L.; Vasileiadis, M.; El Sachat, A.; Vainos, N.A.; Riziotis, C. ArF Excimer Laser Microprocessing of Polymer Optical Fibers for Photonic Sensor Applications. J. Opt. 2015, 17, 015402. [Google Scholar] [CrossRef]

- Koo, J.-S.; Smith, P.G.R.; Williams, R.B.; Riziotis, C.; Grossel, M.C. UV Written Waveguides Using Crosslinkable PMMA-Based Copolymers. Opt. Mater. 2003, 23, 583–592. [Google Scholar] [CrossRef]

- Sinani, A.; Karachousos-Spiliotakopoulos, K.; Tangoulis, V.; Manouras, T.; Angelakos, E.; Riziotis, C. Sub-Diffraction Limited Direct Diode Laser Patterning of Methacrylic Polymer Thin Films Doped with Silver Nanoparticles. In Proceedings of the Laser-based Micro- and Nanoprocessing XVIII, San Francisco, CA, USA, 29 January–1 February 2024; Kling, R., Pfleging, W., Sugioka, K., Eds.; SPIE: San Francisco, CA, USA, 2024; p. 44. [Google Scholar]

- Phillips, K.C.; Gandhi, H.H.; Mazur, E.; Sundaram, S.K. Ultrafast Laser Processing of Materials: A Review. Adv. Opt. Photon. 2015, 7, 684. [Google Scholar] [CrossRef]

- Rauh, S.; Wöbbeking, K.; Li, M.; Schade, W.; Hübner, E.G. From Femtosecond to Nanosecond Laser Microstructuring of Conical Aluminum Surfaces by Reactive Gas Assisted Laser Ablation. ChemPhysChem 2020, 21, 1644–1652. [Google Scholar] [CrossRef]

- Krüger, J.; Martin, S.; Mädebach, H.; Urech, L.; Lippert, T.; Wokaun, A.; Kautek, W. Femto- and Nanosecond Laser Treatment of Doped Polymethylmethacrylate. Appl. Surf. Sci. 2005, 247, 406–411. [Google Scholar] [CrossRef]

- Kanidi, M.; Papadimitropoulou, A.; Charalampous, C.; Chakim, Z.; Tsekenis, G.; Sinani, A.; Riziotis, C.; Kandyla, M. Regulating MDA-MB-231 Breast Cancer Cell Adhesion on Laser-Patterned Surfaces with Micro- and Nanotopography. Biointerphases 2022, 17, 021002. [Google Scholar] [CrossRef]

- Serafetinides, A.A.; Makropoulou, M.; Fabrikesi, E.; Spyratou, E.; Bacharis, C.; Thomson, R.R.; Kar, A.K. Ultrashort Laser Ablation of PMMA and Intraocular Lenses. Appl. Phys. A 2008, 93, 111–116. [Google Scholar] [CrossRef]

- Sola, D.; Cases, R. High-Repetition-Rate Femtosecond Laser Processing of Acrylic Intra-Ocular Lenses. Polymers 2020, 12, 242. [Google Scholar] [CrossRef] [PubMed]

- Sola, D.; Aldana, J.R.V.D.; Artal, P. The Role of Thermal Accumulation on the Fabrication of Diffraction Gratings in Ophthalmic PHEMA by Ultrashort Laser Direct Writing. Polymers 2020, 12, 2965. [Google Scholar] [CrossRef] [PubMed]

- De Marco, C.; Eaton, S.M.; Suriano, R.; Turri, S.; Levi, M.; Ramponi, R.; Cerullo, G.; Osellame, R. Surface Properties of Femtosecond Laser Ablated PMMA. ACS Appl. Mater. Interfaces 2010, 2, 2377–2384. [Google Scholar] [CrossRef] [PubMed]

- Baset, F.; Villafranca, A.; Guay, J.-M.; Bhardwaj, R. Femtosecond Laser Induced Porosity in Poly-Methyl Methacrylate. Appl. Surf. Sci. 2013, 282, 729–734. [Google Scholar] [CrossRef]

- Eaton, S.M.; Zhang, H.; Herman, P.R.; Yoshino, F.; Shah, L.; Bovatsek, J.; Arai, A.Y. Heat Accumulation Effects in Femtosecond Laser-Written Waveguides with Variable Repetition Rate. Opt. Express 2005, 13, 4708. [Google Scholar] [CrossRef] [PubMed]

- Della Valle, G.; Osellame, R.; Laporta, P. Micromachining of Photonic Devices by Femtosecond Laser Pulses. J. Opt. A Pure Appl. Opt. 2009, 11, 013001. [Google Scholar] [CrossRef]

- Agari, Y.; Ueda, A.; Omura, Y.; Nagai, S. Thermal Diffusivity and Conductivity of PMMA/PC Blends. Polymer 1997, 38, 801–807. [Google Scholar] [CrossRef]

- Day, D.; Gu, M. Microchannel Fabrication in PMMA Based on Localized Heating by Nanojoule High Repetition Rate Femtosecond Pulses. Opt. Express 2005, 13, 5939. [Google Scholar] [CrossRef]

- Hofmeister, A.; Whittington, A. Thermal Diffusivity and Conductivity of Glasses and Melts. In Encyclopedia of Glass Science, Technology, History, and Culture; Richet, P., Conradt, R., Takada, A., Dyon, J., Eds.; Wiley: Hoboken, NJ, USA, 2021; pp. 487–500. ISBN 978-1-118-79942-0. [Google Scholar]

- Kanidi, M.; Dagkli, A.; Kelaidis, N.; Palles, D.; Aminalragia-Giamini, S.; Marquez-Velasco, J.; Colli, A.; Dimoulas, A.; Lidorikis, E.; Kandyla, M.; et al. Surface-Enhanced Raman Spectroscopy of Graphene Integrated in Plasmonic Silicon Platforms with Three-Dimensional Nanotopography. J. Phys. Chem. C 2019, 123, 3076–3087. [Google Scholar] [CrossRef]

- Kotsifaki, D.G.; Kandyla, M.; Lagoudakis, P.G. Near-Field Enhanced Optical Tweezers Utilizing Femtosecond-Laser Nanostructured Substrates. Appl. Phys. Lett. 2015, 107, 211111. [Google Scholar] [CrossRef]

- Willis, H.A.; Zichy, V.J.I.; Hendra, P.J. The Laser-Raman and Infra-Red Spectra of Poly(Methyl Methacrylate). Polymer 1969, 10, 737–746. [Google Scholar] [CrossRef]

- Dybal, J.; Krimm, S. Normal-Mode Analysis of Infrared and Raman Spectra of Crystalline Isotactic Poly(Methyl Methacrylate). Macromolecules 1990, 23, 1301–1308. [Google Scholar] [CrossRef]

- Chaurasia, S.; Rao, U.; Mishra, A.K.; Sijoy, C.D.; Mishra, V. Raman Spectroscopy of Poly (Methyl Methacrylate) under Laser Shock and Static Compression. J. Raman Spectrosc. 2020, 51, 860–870. [Google Scholar] [CrossRef]

- Jung, G.B.; Jin, K.-H.; Park, H.-K. Physicochemical and Surface Properties of Acrylic Intraocular Lenses and Their Clinical Significance. J. Pharm. Investig. 2017, 47, 453–460. [Google Scholar] [CrossRef]

- Rusciano, G.; Capaccio, A.; Pesce, G.; Sasso, A. Experimental Study of the Mechanisms Leading to the Formation of Glistenings in Intraocular Lenses by Raman Spectroscopy. Biomed. Opt. Express 2019, 10, 1870. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.H.; Lin, S.H.; Yu, N.T. Resonance Raman Enhancement of Phenyl Ring Vibrational Modes in Phenyl Iron Complex of Myoglobin. Biophys. J. 1990, 57, 851–856. [Google Scholar] [CrossRef]

- Jia, W.; Luo, Y.; Yu, J.; Liu, B.; Hu, M.; Chai, L.; Wang, C. Effects of High-Repetition-Rate Femtosecond Laser Micromachining on the Physical and Chemical Properties of Polylactide (PLA). Opt. Express 2015, 23, 26932. [Google Scholar] [CrossRef]

- Sola, D.; Milles, S.; Lasagni, A.F. Direct Laser Interference Patterning of Diffraction Gratings in Safrofilcon-A Hydrogel: Fabrication and Hydration Assessment. Polymers 2021, 13, 679. [Google Scholar] [CrossRef]

- Ding, L.; Cancado, L.G.; Novotny, L.; Knox, W.H.; Anderson, N.; Jani, D.; Linhardt, J.; Blackwell, R.I.; Künzler, J.F. Micro-Raman Spectroscopy of Refractive Index Microstructures in Silicone-Based Hydrogel Polymers Created by High-Repetition-Rate Femtosecond Laser Micromachining. J. Opt. Soc. Am. B 2009, 26, 595. [Google Scholar] [CrossRef]

- Ferrari, A.C.; Robertson, J. Interpretation of Raman Spectra of Disordered and Amorphous Carbon. Phys. Rev. B 2000, 61, 14095–14107. [Google Scholar] [CrossRef]

- Ouyang, Z.; Long, J.; Wu, J.; Lin, J.; Xie, X.; Tan, G.; Yi, X. Preparation of High-Quality Three-Dimensional Microstructures on Polymethyl Methacrylate Surfaces by Femtosecond Laser Micromachining and Thermal-Induced Micro-Leveling. Opt. Laser Technol. 2022, 145, 107499. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sinani, A.; Palles, D.; Bacharis, C.; Mouzakis, D.; Kandyla, M.; Riziotis, C. Laser Processing of Intraocular Lenses. Appl. Sci. 2024, 14, 6071. https://doi.org/10.3390/app14146071

Sinani A, Palles D, Bacharis C, Mouzakis D, Kandyla M, Riziotis C. Laser Processing of Intraocular Lenses. Applied Sciences. 2024; 14(14):6071. https://doi.org/10.3390/app14146071

Chicago/Turabian StyleSinani, Alexandra, Dimitrios Palles, Constantinos Bacharis, Dionysios Mouzakis, Maria Kandyla, and Christos Riziotis. 2024. "Laser Processing of Intraocular Lenses" Applied Sciences 14, no. 14: 6071. https://doi.org/10.3390/app14146071

APA StyleSinani, A., Palles, D., Bacharis, C., Mouzakis, D., Kandyla, M., & Riziotis, C. (2024). Laser Processing of Intraocular Lenses. Applied Sciences, 14(14), 6071. https://doi.org/10.3390/app14146071