Examining the Progress in Additive Manufacturing in Supporting Lean, Green and Sustainable Manufacturing: A Systematic Review

Abstract

1. Introduction

- (1)

- How should the impact of AM be conceptualized in LM and GM?

- (2)

- What is the effect of AM, LM and GM on sustainable performance?

- (3)

- What are the existing gaps and potential directions for future research at the AM and lean–green manufacturing interface?

2. Methodology

3. Literature Review

3.1. Lean Manufacturing

3.2. Green Manufacturing

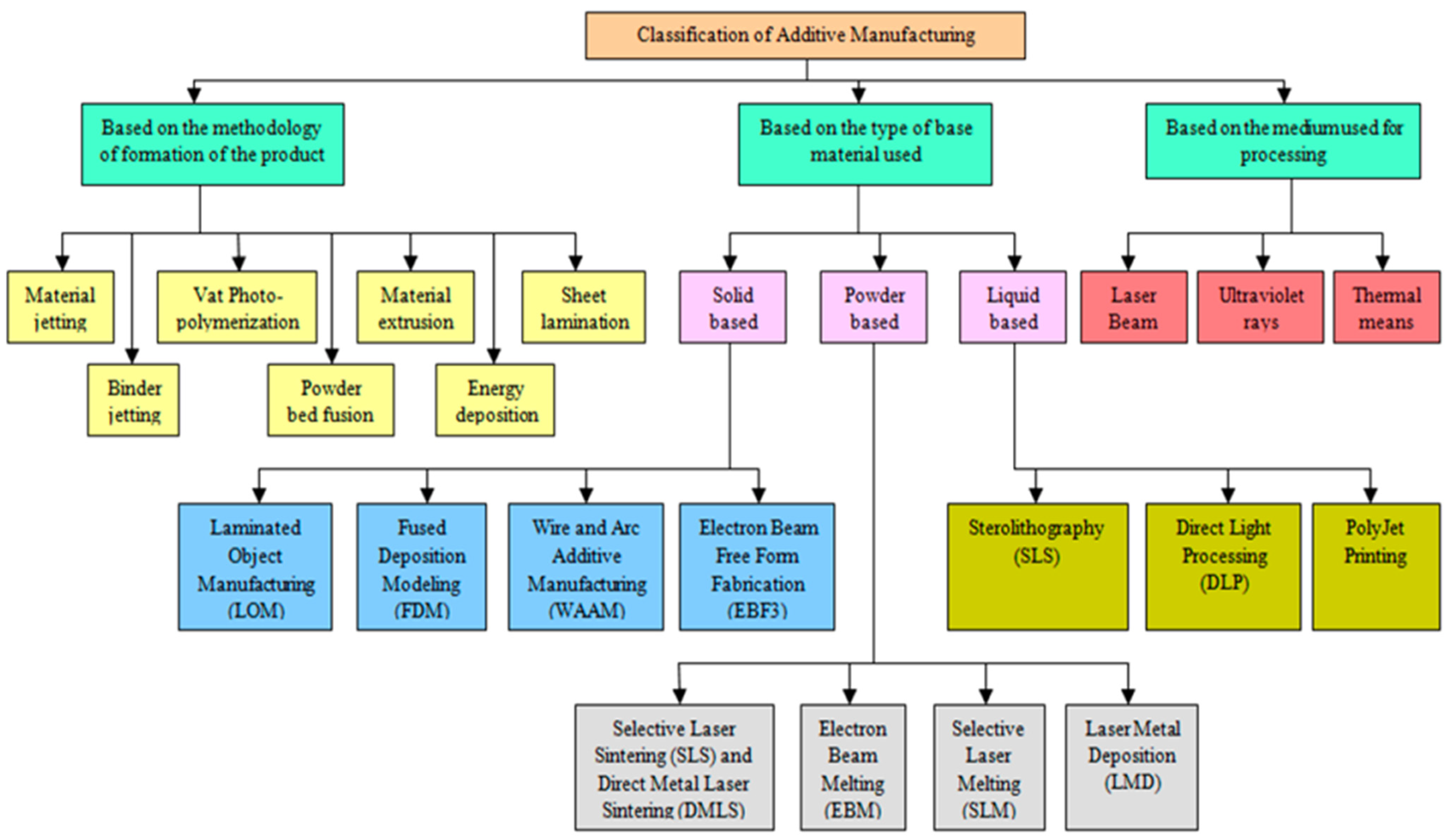

3.3. Additive Manufacturing

3.4. Additive Manufacturing and Green Manufacturing

3.5. Additive Manufacturing and Lean Manufacturing

3.6. Impact of Additive Manufacturing on Environmental Performance

3.7. An Overview of the Impact of AM, Lean and Green Manufacturing Studies Conducted for Manufacturing Organizations

4. Results and Discussion

4.1. Role of AM in Reducing Green Wastes

4.2. Quantitative Analysis of the Impact of AM, Lean and Green Manufacturing

5. Conclusions, Recommendations and Future Works

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R.; Rab, S. Role of additive manufacturing applications towards environmental sustainability. Adv. Ind. Eng. Polym. Res. 2021, 4, 312–322. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive manufacturing and sustainability: An exploratory study of the advantages and challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Ghobadian, A.; Talavera, I.; Bhattacharya, A.; Kumar, V.; Garza-Reyes, J.A.; O’regan, N. Examining legitimatisation of additive manufacturing in the interplay between innovation, lean manufacturing and sustainability. Int. J. Prod. Econ. 2020, 219, 457–468. [Google Scholar] [CrossRef]

- Jum’a, L.; Zimon, D.; Ikram, M.; Madzík, P. Towards a sustainability paradigm; the nexus between lean green practices, sustainability-oriented innovation and Triple Bottom Line. Int. J. Prod. Econ. 2022, 245, 108393. [Google Scholar] [CrossRef]

- Oyesola, M.O.; Mpofu, K.; Mathe, N.; Daniyan, I.A. Development of an integrated design methodology model for quality and throughput of additive manufacturing processes. Procedia CIRP 2019, 84, 688–693. [Google Scholar] [CrossRef]

- Oyesola, M.O.; Mpofu, K.; Mathe, N.; Fatoba, S.; Hoosain, S.; Daniyan, I.A. Optimization of selective laser melting process parameters for surface quality performance of the fabricated Ti6Al4V. Int. J. Adv. Manuf. Technol. 2021, 114, 1585–1599. [Google Scholar] [CrossRef]

- Office of Energy Efficiency & Renewable Energy, What Is Additive Manufacturing? 2017. Available online: https://www.energy.gov/eere/articles/what-additive-manufacturing (accessed on 9 June 2024).

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Melton, T. The benefits of lean manufacturing: What lean thinking has to offer the process industries. Chem. Eng. Res. Des. 2005, 83, 662–673. [Google Scholar] [CrossRef]

- Liker, J.K.; Morgan, J.M. The Toyota way in services: The case of lean product development. Acad. Manag. Perspect. 2006, 20, 5–20. [Google Scholar] [CrossRef]

- Charron, R.; Harrington, H.J.; Voehl, F.; Wiggin, H. The Lean Management Systems Handbook; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Adeodu, A.O.; Maladzhi, R.; Kana-kana Katumba, M.G.; Daniyan, I.A. Development of an improvement framework for warehouse processes using lean Six Sigma (DMAIC) approach. a case of third party logistics (3PL) services. Heliyon 2023, 9, e14915. [Google Scholar] [CrossRef]

- Alves, A.C.; Dinis-Carvalho, J.; Sousa, R.M. Lean production as promoter of thinkers to achieve companies’ agility. Learn. Organ. 2012, 19, 219–237. [Google Scholar] [CrossRef]

- Black, J.; Black, J.R. Lean Production: Implementing a World-Class System; Industrial Press Inc.: New York, NY, USA, 2008. [Google Scholar]

- Muvunzi, R.; Maware, C.; Chinguwa, S.; Caspa, M. Application of lean value stream mapping to reduce waste and improve productivity: A case of tile manufacturing company in Zimbabwe. Int. J. Appl. Innovat. Eng. Manag. 2013, 2, 214–219. [Google Scholar]

- Ikumapayi, O.; Akinlabi, E.; Mwema, F.; Ogbonna, O. Six sigma versus lean manufacturing—An overview. Mater. Today Proc. 2020, 26, 3275–3281. [Google Scholar] [CrossRef]

- Tohidi, H.; Khedriliraviasl, K. Six sigma methodology and its relationship with lean manufacturing system. Adv. Environ. Biol. 2012, 6, 895–906. [Google Scholar]

- Sutrisno, A.; Vanany, I.; Gunawan, I.; Asjad, M. Lean waste classification model to support the sustainable operational practice. IOP Conf. Ser. Mater. Sci. Eng. 2018, 337, 012067. [Google Scholar] [CrossRef]

- Vinodh, S.; Arvind, K.; Somanaathan, M. Tools and techniques for enabling sustainability through lean initiatives. Clean Technol. Environ. Policy 2011, 13, 469–479. [Google Scholar] [CrossRef]

- King, A.A.; Lenox, M.J. Lean and green? An empirical examination of the relationship between lean production and environmental performance. Prod. Oper. Manag. 2001, 10, 244–256. [Google Scholar] [CrossRef]

- Resta, B.; Dotti, S.; Gaiardelli, P.; Boffelli, A. Lean manufacturing and sustainability: An integrated view. In IFIP International Conference on Advances in Production Management Systems; Springer: Berlin/Heidelberg, Germany, 2016; pp. 659–666. [Google Scholar]

- Machingura, T.; Adetunji, O.; Maware, C. A hierarchical complementary Lean-Green model and its impact on operational performance of manufacturing organisations. Int. J. Qual. Reliab. Manag. 2024, 41, 425–446. [Google Scholar] [CrossRef]

- Afum, E.; Agyabeng-Mensah, Y.; Sun, Z.; Frimpong, B.; Kusi, L.Y.; Acquah, I.S.K. Exploring the link between green manufacturing, operational competitiveness, firm reputation and sustainable performance dimensions: A mediated approach. J. Manuf. Technol. Manag. 2020, 31, 1417–1438. [Google Scholar] [CrossRef]

- Wiese, A.; Luke, R.; Heyns, G.J.; Pisa, N.M. The integration of lean, green and best practice business principles. J. Transp. Supply Chain. Manag. 2015, 9, 1–10. [Google Scholar] [CrossRef]

- Rehman, M.A.A.; Shrivastava, R.; Shrivastava, R.L. Validating green manufacturing (GM) framework for sustainable development in an Indian steel industry. Univers. J. Mech. Eng. 2013, 1, 49–61. [Google Scholar] [CrossRef]

- Acharya, S.; Vadher, J.; Acharya, G. 232 A review on evaluating green manufacturing for sustainable development in foundry industries. Int. J. Emerg. Technol. Adv. Eng. 2014, 4, 232. [Google Scholar]

- Hines, P.; Holweg, M.; Rich, N. Learning to evolve: A review of contemporary lean thinking. Int. J. Oper. Prod. Manag. 2004, 24, 994–1011. [Google Scholar] [CrossRef]

- Chugani, N.; Kumar, V.; Garza-Reyes, J.A.; Rocha-Lona, L.; Upadhyay, A. Investigating the green impact of Lean, Six Sigma and Lean Six Sigma: A systematic literature review. Int. J. Lean Six Sigma 2017, 8, 7–32. [Google Scholar] [CrossRef]

- Viles, E.; Santos, J.; Muñoz-Villamizar, A.; Grau, P.; Fernández-Arévalo, T. Lean–green improvement opportunities for sustainable manufacturing using water telemetry in agri-food industry. Sustainability 2021, 13, 2240. [Google Scholar] [CrossRef]

- Fercoq, A.; Lamouri, S.; Carbone, V. Lean/Green integration focused on waste reduction techniques. J. Clean. Prod. 2016, 137, 567–578. [Google Scholar] [CrossRef]

- The World Economic Forum Report. The Future of Additive Manufacturing. 2019. Available online: https://www.weforum.org/projects/the-future-of-additive-manufacturing (accessed on 6 August 2023).

- Oyesola, M.O.; Mpofu, K.; Daniyan, I.A.; Mathe, N. Design and simulation of a bearing housing aerospace component from titanium alloy (Ti6Al4V) for additive manufacturing. Acta Polytech. 2022, 62, 639–653. [Google Scholar] [CrossRef]

- Oladapo, B.I.; Daniyan, I.A.; Ikumapayi, O.M.; Malachi, O.B.; Malachi, I.O. Microanalysis of hybrid characterization of PLA/cHA polymer scaffolds for bone regeneration. J. Polym. Test. 2020, 83, 106341. [Google Scholar] [CrossRef]

- EU Parliament Report. Reducing Carbon Emissions: EU Targets and Policies. 2023. Available online: https://www.europarl.europa.eu/news/en/headlines/society/20180208STO97442/cutting-eu-greenhouse-gas-emissions-national-targets-for-2030?&at_campaign=20234-Green&at_medium=Google_Ads&at_platform=Search&at_creation=RSA&at_goal=TR_G&at_audience=greenhouse%20emissions&at_topic=Greenhouse&at_location=GR&gclid=Cj0KCQjw756lBhDMARIsAEI0Agmtfvn82PqKCSIzQfNERHfW6xNqYUcbAcppJ-gu4FjthrsvPQrzmnAaAkygEALw_wcB (accessed on 7 July 2023).

- Soubihia, D.F.; Jabbour, C.J.C.; De Sousa Jabbour, A.B.L. Green manufacturing: Relationship between adoption of green operational practices and green performance of Brazilian ISO 9001-certified firms. Int. J. Precis. Eng. Manuf. Green Technol. 2015, 2, 95–98. [Google Scholar] [CrossRef]

- Green, K.W.; Zelbst, P.J.; Meacham, J.; Bhadauria, V.S. Green supply chain management practices: Impact on performance. Supply Chain. Manag. Int. J. 2012, 17, 290–305. [Google Scholar] [CrossRef]

- Sezen, B.; Cankaya, S.Y. Effects of green manufacturing and eco-innovation on sustainability performance. Procedia-Soc. Behav. Sci. 2013, 99, 154–163. [Google Scholar] [CrossRef]

- Yu, W.; Chavez, R.; Feng, M.; Wiengarten, F. Integrated green supply chain management and operational performance. Supply Chain. Manag. Int. J. 2014, 19, 683–696. [Google Scholar] [CrossRef]

- ASTM. 2012. Available online: http://www.astm.org/Committee/F42.htm (accessed on 7 April 2023).

- Alghamdi, S.; John, S.; Roy Choudhury, N.; Dutta, N.K. Additive manufacturing of polymer materials: Progress, promise and challenges. Polymers 2021, 13, 753. [Google Scholar] [CrossRef] [PubMed]

- Sanchez, F.A.C.; Boudaoud, H.; Camargo, M.; Pearce, J.M. Plastic recycling in additive manufacturing: A systematic literature review and opportunities for the circular economy. J. Clean. Prod. 2020, 264, 121602. [Google Scholar] [CrossRef]

- Hettiarachchi, B.D.; Brandenburg, M.; Seuring, S. Connecting additive manufacturing to circular economy implementation strategies: Links, contingencies and causal loops. Int. J. Prod. Econ. 2022, 246, 108414. [Google Scholar] [CrossRef]

- Puppi, D.; Chiellini, F. Biodegradable polymers for biomedical additive manufacturing. Appl. Mater. Today 2020, 20, 100700. [Google Scholar] [CrossRef]

- Pakkanen, J.; Manfredi, D.; Minetola, P.; Iuliano, L. About the use of recycled or biodegradable filaments for sustainability of 3D printing: State of the art and research opportunities. Smart Innov. Syst. Technol. 2017, 68, 776–785. [Google Scholar] [CrossRef]

- Guerra, A.; Roca, A.; De Ciurana, J. A novel 3D additive manufacturing machine to biodegradable stents. Procedia Mauf. 2017, 13, 718–723. [Google Scholar] [CrossRef]

- Jiang, D.; Ning, F.; Wang, Y. Additive manufacturing of biodegradable iron-based particle reinforced polylactic acid composite scaffolds for tissue engineering. J. Mater. Process. Technol. 2021, 289, 116952. [Google Scholar] [CrossRef]

- Mangat, A.S.; Singh, S.; Gupta, M.; Sharma, R. Experimental investigations on natural fiber embedded additive manufacturing-based biodegradable structures for biomedical applications. Rapid Prototyp. J. 2018, 24, 1221–1234. [Google Scholar] [CrossRef]

- Peng, T.; Kellens, K.; Tang, R.; Chen, C.; Chen, G. Sustainability of additive manufacturing: An overview on its energy demand and environmental impact. Addit. Manuf. 2018, 21, 694–704. [Google Scholar] [CrossRef]

- Böckin, D.; Tillman, A.-M. Environmental assessment of additive manufacturing in the automotive industry. J. Clean. Prod. 2019, 226, 977–987. [Google Scholar] [CrossRef]

- Shi, Y.; Yang, S.; Zhou, K.; Yan, C. Four-Dimensional (4D) Printing. Front. Mater. 2021, 8, 757479. [Google Scholar] [CrossRef]

- Hossain, M.S.; Gonzalez, J.A.; Hernandez, R.M.; Shuvo, M.A.I.; Mireles, J.; Choudhuri, A.; Lin, Y.; Wicker, R.B. Fabrication of smart parts using powder bed fusion additive manufacturing technology. Addit. Manuf. 2016, 10, 58–66. [Google Scholar] [CrossRef]

- Rahito, D.A.W.; Azman, A.H. Additive manufacturing for repair and restoration in remanufacturing: An overview from object design and systems perspectives. Processes 2019, 7, 802. [Google Scholar] [CrossRef]

- Leino, M.; Pekkarinen, J.; Soukka, R. The role of laser additive manufacturing methods of metals in repair, refurbishment and remanufacturing—Enabling circular economy. Physics Procedia 2016, 83, 752–760. [Google Scholar] [CrossRef]

- Shrivastava, A.; Kumar, S.; Rao, S.; Nagesha, B.K.; Barad, S.; Suresh, T.N. Remanufacturing of nickel-based aero-engine components using metal additive manufacturing technology. Mater. Today Proc. 2021, 45, 4893–4897. [Google Scholar] [CrossRef]

- Saboori, A.; Aversa, A.; Marchese, G.; Biamino, S.; Lombardi, M.; Fino, P. Application of directed energy deposition-based additive manufacturing in repair. Appl. Sci. 2019, 9, 3316. [Google Scholar] [CrossRef]

- Shanmugam, V.; Rajendran, D.J.J.; Babu, K.; Rajendran, S.; Veerasimman, A.; Marimuthu, U.; Singh, S.; Das, O.; Neisiany, R.E.; Hedenqvist, M.S.; et al. The mechanical testing and performance analysis of polymer-fibre composites prepared through the additive manufacturing. Polym. Test. 2021, 93, 106925. [Google Scholar] [CrossRef]

- Rahimizadeh, A.; Kalman, J.; Fayazbakhsh, K.; Lessard, L. Recycling of fiberglass wind turbine blades into reinforced filaments for use in Additive Manufacturing. Compos. Part. B Eng. 2019, 175, 107101. [Google Scholar] [CrossRef]

- Daniyan, I.A.; Mpofu, K.; Daniyan, O.L.; Fameso, F.; Oyesola, M. Computer aided simulation and performance evaluation of additive manufacturing technology for component parts manufacturing. Int. J. Adv. Manuf. Technol. 2020, 107, 4517–4530. [Google Scholar] [CrossRef]

- Daniyan, I.A.; Balogun, V.; Mpofu, K.; Omigbodun, F.T. An interactive approach towards the development of an additive manufacturing technology for railcar manufacturing. Int. J. Interact. Des. Manuf. 2020, 14, 651–666. [Google Scholar] [CrossRef]

- Daniyan, I.A.; Mpofu, K.; Oyesola, M.; Daniyan, O.L. Process optimization of additive manufacturing technology: A case evaluation for the manufactured railcar accessory. Procedia CIRP 2021, 95, 89–96. [Google Scholar] [CrossRef]

- Muvunzi, R.; Mpofu, K.; Daniyan, I.A.; Fameso, F. Analysis of potential materials for local production of a rail car component using additive manufacturing. Heliyon 2022, 8, e09405. [Google Scholar] [CrossRef] [PubMed]

- Muvunzi, R.; Khumbulani, K.; Khodja, M.; Daniyan, I.A. A framework for additive manufacturing technology selection: A case for the rail industry. Int. J. Manuf. Mater. Mech. Eng. 2022, 12, 1–21. [Google Scholar] [CrossRef]

- Niaki, M.K.; Torabi, S.A.; Nonino, F. Why manufacturers adopt additive manufacturing technologies: The role of sustainability. J. Clean. Prod. 2019, 222, 381–392. [Google Scholar] [CrossRef]

- Mani, M.; Lyons, K.W.; Gupta, S.K. Sustainability characterization for additive manufacturing. J. Res. Natl Inst Stand Technol. 2014, 119, 419–428. [Google Scholar] [CrossRef]

- Frăţilă, D.; Rotaru, H. Additive manufacturing–a sustainable manufacturing route. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2017; Volume 94, p. 03004. [Google Scholar]

- Kellens, K.; Baumers, M.; Gutowski, T.G.; Flanagan, W.; Lifset, R.; Duflou, J.R. Environmental dimensions of additive manufacturing: Mapping application domains and their environmental implications. J. Ind. Ecol. 2017, 21, S49–S68. [Google Scholar] [CrossRef]

- Kellens, K.; Mertens, R.; Paraskevas, D.; Dewulf, W.; Duflou, J.R. Environmental impact of additive manufacturing processes: Does AM contribute to a more sustainable way of part manufacturing? Procedia CIRP 2017, 61, 582–587. [Google Scholar] [CrossRef]

- Huang, Y.; Leu, M.C.; Mazumder, J.; Donmez, A. Additive manufacturing: Current state, future potential, gaps and needs, and recommendations. J. Manuf. Sci. Eng. 2015, 137, 014001. [Google Scholar] [CrossRef]

- Najmon, J.C.; Raeisi, S.; Tovar, A. Review of additive manufacturing technologies and applications in the aerospace industry. Addit. Manuf. Aerosp. Ind. 2019, 2019, 7–31. [Google Scholar]

- Ingarao, G.; Priarone, P.C.; Deng, Y.; Paraskevas, D. Environmental modelling of aluminium based components manufacturing routes: Additive manufacturing versus machining versus forming. J. Clean. Prod. 2018, 176, 261–275. [Google Scholar] [CrossRef]

- Yang, S.; Min, W.; Ghibaudo, J.; Zhao, Y.F. Understanding the sustainability potential of part consolidation design supported by additive manufacturing. J. Clean. Prod. 2019, 232, 722–738. [Google Scholar] [CrossRef]

- Yang, S.; Santoro, F.; Sulthan, M.A.; Zhao, Y.F. A numerical-based part consolidation candidate detection approach with modularization considerations. Res. Eng. Des. 2019, 30, 63–83. [Google Scholar] [CrossRef]

- Tang, Y.; Mak, K.; Zhao, Y.F. A framework to reduce product environmental impact through design optimization for additive manufacturing. J. Clean. Prod. 2016, 137, 1560–1572. [Google Scholar] [CrossRef]

- Nagarajan, H.P.N.; Haapala, K.R. Characterizing the influence of resource-energy-exergy factors on the environmental performance of additive manufacturing systems. J. Manuf. Syst. 2018, 48, 87–96. [Google Scholar] [CrossRef]

- Ching, N.T.; Ghobakhloo, M.; Iranmanesh, M.; Maroufkhani, P.; Asadi, S. Industry 4.0 applications for sustainable manufacturing: A systematic literature review and a roadmap to sustainable development. J. Clean. Prod. 2021, 334, 130133. [Google Scholar] [CrossRef]

- Chandra, M.; Shahab, F.; Vimal, K.E.K.; Rajak, S. Selection for additive manufacturing using hybrid MCDM technique considering sustainable concepts. Rapid Prototyp. J. 2022, 28, 1297–1311. [Google Scholar] [CrossRef]

- Huang, S.H.; Liu, P.; Mokasdar, A.; Hou, L. Additive manufacturing and its societal impact: A literature review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Naghshineh, B.; Ribeiro, A.; Jacinto, C.; Carvalho, H. Social impacts of additive manufacturing: A stakeholder-driven framework. Technol. Forecast. Soc. Chang. 2021, 164, 120368. [Google Scholar] [CrossRef]

- Priarone, P.C.; Pagone, E.; Martina, F.; Catalano, A.R.; Settineri, L. Multi-criteria environmental and economic impact assessment of wire arc additive manufacturing. CIRP Ann. 2020, 69, 37–40. [Google Scholar] [CrossRef]

- Touriki, F.E.; Benkhati, I.; Kamble, S.S.; Belhadi, A. An integrated smart, green, resilient, and lean manufacturing framework: A literature review and future research directions. J. Clean. Prod. 2021, 319, 128691. [Google Scholar] [CrossRef]

- Belhadi, A.; Kamble, S.S.; Zkik, K.; Cherrafi, A.; Touriki, F.E. The integrated effect of Big Data Analytics, Lean Six Sigma and Green Manufacturing on the environmental performance of manufacturing companies: The case of North Africa. J. Clean. Prod. 2020, 252, 119903. [Google Scholar] [CrossRef]

- Agnusdei, G.P.; Coluccia, B. Sustainable agrifood supply chains: Bibliometric, network and content analyses. Sci. Total Environ. 2022, 84, 153704. [Google Scholar] [CrossRef] [PubMed]

- Ghobakhloo, M.; Fathi, M. Industry 4.0 and opportunities for energy sustainability. J. Clean. Prod. 2021, 295, 126427. [Google Scholar] [CrossRef]

- Kumar, A.; Chhabra, D. Adopting additive manufacturing as a cleaner fabrication framework for topologically optimized orthotic devices: Implications over sustainable rehabilitation. Clean. Eng. Technol. 2022, 10, 100559. [Google Scholar] [CrossRef]

- Liu, J.; Nguyen-Van, V.; Panda, B.; Fox, K.; du Plessis, A.; Tran, P. Additive manufacturing of sustainable construction materials and form-finding structures: A review on recent progresses. 3D Print. Addit. Manuf. 2022, 9, 12–34. [Google Scholar] [CrossRef] [PubMed]

- Majeed, A.; Zhang, Y.; Ren, S.; Lv, J.; Peng, T.; Waqar, S.; Yin, E. A big data-driven framework for sustainable and smart additive manufacturing. Robot. Comput. Integr. Manuf. 2021, 67, 102026. [Google Scholar] [CrossRef]

- Shuaib, M.; Haleem, A.; Kumar, S.; Javaid, M. Impact of 3D printing on the environment: A literature based study. Sustain. Oper. Comput. 2021, 2, 57–63. [Google Scholar] [CrossRef]

- Colorado, H.A.; Velásquez, E.I.G.; Monteiro, S.N. Sustainability of additive manufacturing: The circular economy of materials and environmental perspectives. J. Mater. Res. Technol. 2020, 9, 8221–8234. [Google Scholar] [CrossRef]

- Zhao, P.; Rao, C.; Gu, F.; Sharmin, N.; Fu, J. Close-looped recycling of polylactic acid used in 3D printing: An experimental investigation and life cycle assessment. J. Clean. Prod. 2018, 197, 1046–1055. [Google Scholar] [CrossRef]

- Jiang, J.; Xu, X.; Stringer, J. Support structures for additive manufacturing: A review. J. Manuf. Mater. Process 2018, 2, 64. [Google Scholar] [CrossRef]

- Jiang, J.; Ma, Y. Path planning strategies to optimize accuracy, quality, build time and material use in additive manufacturing: A review. Micromachines 2020, 11, 633. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Ganewatta, M.S.; Tang, C. Sustainable polymers from biomass: Bridging chemistry with materials and processing. Progress Polym. Sci. 2020, 101, 101197. [Google Scholar] [CrossRef]

- Pellis, A.; Malinconico, M.; Guarneri, A.; Gardossi, L. Renewable polymers and plastics: Performance beyond the green. New Biotechnol. 2021, 60, 146–158. [Google Scholar] [CrossRef] [PubMed]

- Aldhafeeri, T.; Alotaibi, M.; Barry, C.F. Impact of melt processing conditions on the degradation of polylactic acid. Polymers 2022, 14, 2790. [Google Scholar] [CrossRef] [PubMed]

- Baumers, M.; Tuck, C.; Bourell, D.L.; Sreenivasan, R.; Hague, R. Sustainability of additive manufacturing: Measuring the energy consumption of the laser sintering process. Proc. Inst. Mech. Eng. Part. B J. Eng. Manuf. 2011, 225, 2228–2239. [Google Scholar] [CrossRef]

- Azimi, P.; Zhao, D.; Pouzet, C.; Crain, N.E.; Stephens, B. Emissions of ultrafine particles and volatile organic compounds from commercially available desktop three-dimensional printers with multiple filaments. Environ. Sci. Technol. 2016, 50, 1260–1268. [Google Scholar] [CrossRef] [PubMed]

- Huang, R.; Riddle, M.; Graziano, D.; Warren, J.; Das, S.; Nimbalkar, S.; Cresko, J.; Masanet, E. Energy and emissions saving potential of additive manufacturing: The case of lightweight aircraft components. J. Clean. Prod. 2016, 135, 1559–1570. [Google Scholar] [CrossRef]

- Tao, Y.; Wang, H.; Li, Z.; Li, P.; Shi, S.Q. Development and application of wood flour-filled polylactic acid composite filament for 3D printing. Materials 2017, 10, 339. [Google Scholar] [CrossRef]

- Morrow, W.R.; Qi, H.; Kim, I.; Mazumder, J.; Skerlos, S.J. Environmental aspects of laser-based and conventional tool and die manufacturing. J. Clean. Prod. 2007, 15, 932–943. [Google Scholar] [CrossRef]

- Qin, Y.; Wen, P.; Guo, H.; Xia, D.; Zheng, Y.; Jauer, L.; Poprawe, R.; Voshage, M.; Schleifenbaum, J.H. Additive manufacturing of biodegradable metals: Current research status and future perspectives. Acta Biomater. 2019, 98, 3–22. [Google Scholar] [CrossRef] [PubMed]

- Wilson, J.M.; Piya, C.; Shin, Y.C.; Zhao, F.; Ramani, K. Remanufacturing of turbine blades by laser direct deposition with its energy and environmental impact analysis. J. Clean. Prod. 2014, 80, 170–178. [Google Scholar] [CrossRef]

- Phuluwa, H.S.; Daniyan, I.A.; Mpofu, K. Development of a sustainable decision framework for the implementation of end-of-life (EoL) options for the railcar industry. Environ. Dev. Sustain. 2021, 23, 9433–9453. [Google Scholar] [CrossRef]

- Gaikwad, V.; Ghose, A.; Cholake, S.; Rawal, A.; Iwato, M.; Sahajwalla, V. Transformation of E-Waste Plastics into Sustainable Filaments for 3D Printing. ACS Sustain. Chem. Eng. 2018, 6, 14432–14440. [Google Scholar] [CrossRef]

- Lopez Taborda, L.L.; Maury, H.; Pacheco, J. Design for additive manufacturing: A comprehensive review of the tendencies and limitations of methodologies. Prototyp. J. 2021, 27, 918–966. [Google Scholar] [CrossRef]

- Orme, M.E.; Gschweitl, M.; Ferrari, M.; Vernon, R.; Madera, I.J.; Yancey, R.; Mouriaux, F. Additive manufacturing of lightweight, optimized, metallic components suitable for space flight. J. Spacecr. Rocket. 2017, 54, 1050–1059. [Google Scholar] [CrossRef]

- Ganesh Sarvankar, S.; Yewale, S.N. Additive Manufacturing in Automobile Industry. Int. J. Res. Aeronaut. Mech. Eng. 2019, 7, 1–10. [Google Scholar]

- Knofius, N.; van der Heijden, M.C.; Zijm, W.H.M. Consolidating spare parts for asset maintenance with additive manufacturing. Int. J. Prod. Econ. 2019, 208, 269–280. [Google Scholar] [CrossRef]

- Hettesheimer, T.; Hirzel, S.; Roß, H.B. Energy savings through additive manufacturing: An analysis of selective laser sintering for automotive and aircraft components. Energy Effic. 2018, 11, 1227–1245. [Google Scholar] [CrossRef]

- Taddese, G.; Durieux, S.; Duc, E. Sustainability performance indicators for additive manufacturing: A literature review based on product life cycle studies. Int. J. Adv. Manuf. Technol. 2020, 107, 3109–3134. [Google Scholar] [CrossRef]

- Yusuf, S.M.; Cutler, S.; Gao, N. Review: The impact of metal additive on the aerospace industry. Metals 2019, 9, 1–35. [Google Scholar] [CrossRef]

- Jamwal, A.; Agrawal, R.; Sharma, M.; Giallanza, A. Industry 4.0 technologies for manufacturing sustainability: A systematic review and future research directions. Appl. Sci. 2021, 11, 5725. [Google Scholar] [CrossRef]

- Hu, P.; He, B.; Ying, L. Numerical investigation on cooling performance of hot stamping tool with various channel designs. Appl. Therm. Eng. 2016, 96, 338–351. [Google Scholar] [CrossRef]

- Muvunzi, R.; Hagedorn-Hansen, D.; Matope, S.; Madyibi, X.; Swart, C.B.; Nagel, M. Industry case study: Process chain for manufacturing of a large hybrid hot stamping tool with conformal cooling channels. Int. J. Adv. Manuf. Technol. 2020, 110, 1723–1730. [Google Scholar] [CrossRef]

- Muvunzi, R.; Mpofu, K.; Daniyan, I.A. An evaluation model for selecting part candidates for additive manufacturing in the transport sector. Met. J. 2021, 11, 765. [Google Scholar] [CrossRef]

- Knofius, N.; Heijden, M.V.D. Selecting parts for additive manufacturing in service logistics. J. Manuf. Technol. Manag. 2016, 27, 915–931. [Google Scholar] [CrossRef]

- Gonzalez-Varoa, J.M.; Poza, D.; Acebes, F.; Pajares, J.; Lopez-Paredes, A. New Business Models for Sustainable Spare Parts Logistics: A Case Study. Sustainability 2020, 12, 3071. [Google Scholar] [CrossRef]

- Attaran, M. Additive Manufacturing: The most promising technology to alter the supply chain and logistics. J. Serv. Sci. Manag. 2017, 10, 189–206. [Google Scholar] [CrossRef]

- Dey, P.K.; Malesios, C.; De, D.; Chowdhury, S.; Abdelaziz, F.B. The impact of lean management practices and sustainably-oriented innovation on sustainability performance of small and medium-sized enterprises: Empirical evidence from the UK. Br. J. Manag. 2020, 31, 141–161. [Google Scholar] [CrossRef]

- Singh, J.; Singh, H.; Kumar, A. Impact of lean practices on organizational sustainability through green supply chain management–an empirical investigation. Int. J. Lean Six Sigma 2020, 11, 1035–1068. [Google Scholar] [CrossRef]

- Ghaithan, A.M.; Alshammakhi, Y.; Mohammed, A.; Mazher, K.M. Integrated impact of circular economy, industry 4.0, and lean manufacturing on sustainability performance of manufacturing firms. Int. J. Environ. Res. Public Health 2023, 20, 5119. [Google Scholar] [CrossRef] [PubMed]

- Wu, L.; Subramanian, N.; Abdulrahman, M.D.; Liu, C.; Lai, K.H.; Pawar, K.S. The impact of integrated practices of lean, green, and social management systems on firm sustainability performance—Evidence from Chinese fashion auto-parts suppliers. Sustainability 2015, 7, 3838–3858. [Google Scholar] [CrossRef]

- Garza-Reyes, J.A.; Kumar, V.; Chaikittisilp, S.; Tan, K.H. The effect of lean methods and tools on the environmental performance of manufacturing organisations. Int. J. Prod. Econ. 2018, 200, 170–180. [Google Scholar] [CrossRef]

- Nawanir, G.; Lim, K.T.; Lee, K.L.; Moshood, T.D.; Ahmad, A.N.A. Less for more: The structural effects of lean manufacturing practices on sustainability of manufacturing SMEs in Malaysia. Int. J. Supply Chain. Manag. 2020, 2, 961–975. [Google Scholar]

- Rusinko, C. Green manufacturing: An evaluation of environmentally sustainable manufacturing practices and their impact on competitive outcomes. IEEE Trans. Eng. Manag. 2007, 54, 445–454. [Google Scholar] [CrossRef]

- Famiyeh, S.; Kwarteng, A.; Asante-Darko, D.; Dadzie, S.A. Green supply chain management initiatives and operational competitive performance. Benchmarking Int. J. 2018, 25, 607–631. [Google Scholar] [CrossRef]

- Mafini, C.; Loury-Okoumba, W.V. Extending green supply chain management activities to manufacturing small and medium enterprises in a developing economy. S. Afr. J. Econ. Manag. Sci. 2018, 21, a1996. [Google Scholar] [CrossRef]

- Eshikumo, S.M.; Odock, S.O. Green manufacturing and operational performance of a firm: Case of cement manufacturing in Kenya. Int. J. Bus. Soc. Sci. 2017, 8, 106–120. [Google Scholar]

- Ivan, S.; Yin, Y. Additive manufacturing impact for supply chain—Two cases. In Proceedings of the 2017 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM), Singapore, 10–13 December 2017; pp. 450–454. [Google Scholar]

- Thomas, D.S.; Gilbert, S.W. Costs and cost effectiveness of additive manufacturing. NIST Spec. Publ. 2014, 1176, 12. [Google Scholar]

- Sahu, M.; Hajra, S.; Kim, H.G.; Rubahn, H.G.; Mishra, Y.K.; Kim, H.J. Additive manufacturing-based recycling of laboratory waste into energy harvesting device for self-powered applications. Nano Energy 2021, 88, 106255. [Google Scholar] [CrossRef]

- Priarone, P.C.; Lunetto, V.; Atzeni, E.; Salmi, A. Laser powder bed fusion (L-PBF) additive manufacturing: On the correlation between design choices and process sustainability. Procedia CIRP 2018, 78, 85–90. [Google Scholar] [CrossRef]

- Mami, F.; Reveret, J.P.; Fallaha, S.; Margni, M. Evaluating eco-efficiency of 3D printing in the aeronautic industry. J. Ind. Ecol. 2017, 21, S37–S48. [Google Scholar] [CrossRef]

- DeBoer, B.; Nguyen, N.; Diba, F.; Hosseini, A. Additive, subtractive, and formative manufacturing of metal components: A life cycle assessment comparison. Int. J. Adv. Manuf. Technol. 2021, 115, 413–432. [Google Scholar] [CrossRef]

- Reis, R.C.; Kokare, S.; Oliveira, J.P.; Matias, J.C.O.; Godina, R. Life cycle assessment of metal products: A comparison between wire arc additive manufacturing and CNC milling. Adv. Ind. Manuf. Eng. 2023, 6, 100117. [Google Scholar] [CrossRef]

- Yang, S.; Talekar, T.; Sulthan, M.A.; Zhao, Y.F. A generic sustainability assessment model towards consolidated parts fabricated by additive manufacturing process. Procedia Manuf. 2017, 10, 831–844. [Google Scholar] [CrossRef]

- Bennett, J.; Garcia, D.; Kendrick, M.; Hartman, T.; Hyatt, G.; Ehmann, K.; You, F.; Cao, J. Repairing automotive dies with directed energy deposition: Industrial application and life cycle analysis. J. Manuf. Sci. Eng. Trans. ASME 2019, 141, 021019. [Google Scholar] [CrossRef]

- Priarone, P.C.; Campatelli, G.; Catalano, A.R.; Baffa, F. Life-cycle energy and carbon saving potential of wire arc additive manufacturing for the repair of mold inserts. CIRP J. Manuf. Sci. Technol. 2021, 35, 943–958. [Google Scholar] [CrossRef]

- Ma, K.; Smith, T.; Lavernia, E.J.; Schoenung, J.M. Environmental sustainability of laser metal deposition: The role of feedstock powder and feedstock utilization factor. Procedia Manuf. 2017, 7, 198–204. [Google Scholar] [CrossRef]

- Faludi, J.; Baumers, M.; Maskery, I.; Hague, R. Environmental impacts of selective laser melting: Do printer, powder, or power dominate? J. Ind. Ecol. 2017, 21, S144–S156. [Google Scholar] [CrossRef]

- Daraban, A.E.O.; Negrea, C.; Artimon, F.G.P.; Angelescu, D.; Popan, G.; Gheorghr, S.I.; Gheorghe, M. A deep look at metal additive manufacturing recycling and use tools for sustainability performance. Sustainability 2019, 11, 5494. [Google Scholar] [CrossRef]

- Walachowicz, F.; Bernsdorf, I.; Papenfuss, U.; Zeller, C.; Graichen, A.; Avrotsky, V.; Rajvanshi, N. Comparative energy, resource and recycling lifecycle analysis of the industrial repair process of gas turbine burners using conventional machining and additive manufacturing. J. Ind. Ecol. 2017, 21, 203–215. [Google Scholar] [CrossRef]

- Armao, F.; Byall, L.; Kotecki, D.; Miller, D. Gas Metal arc Welding: Product and Procedure Selection. 2023. Available online: https://www.lincolnelectric.com/assets/global/Products/Consumable_MIGGMAWWires-SuperArc-SuperArcL-56/c4200.pdf (accessed on 10 June 2024).

- Kokare, S.; Oliveira, J.P.; Godina, R.A. LCA and LCC analysis of pure subtractive manufacturing, wire arc additive manufacturing, and selective laser melting approaches. J. Manuf. Process 2023, 101, 67–85. [Google Scholar] [CrossRef]

- Durach, C.F.; Kurpjuweit, S.; Wagner, S.M. The impact of additive manufacturing on supply chains. Int. J. Phys. Distrib. Logist. Manag. 2017, 47, 954–971. [Google Scholar] [CrossRef]

- Yan, X.; Gu, P.E.N.G. A review of rapid prototyping technologies and systems. Comput. Aided Des. 1996, 28, 307–318. [Google Scholar] [CrossRef]

- Luo, Y.; Ji, M.; Leu, M.C.; Caudill, R. Environmental performance analysis of solid freedom fabrication processes. In Proceedings of the 1999 IEEE International Symposium on Electronics and the Environment, Danvers, MA, USA, 13 May 1999; pp. 1–6. [Google Scholar]

- Paris, H.; Mokhtarian, H.; Coatanea, E.; Museau, M.; Ituarte, I.F. Comparative environmental impacts of additive and subtractive manufacturing technologies. CIRP Ann. 2016, 65, 29–32. [Google Scholar] [CrossRef]

- Karafa, M.; Schuting, M.; Kemnitzer, J.; Westermann, H.H.; Steinhilper, R. Comparative lifecycle assessment of conventional and additive manufacturing in mold core making for CFRP production. Procedia Manuf. 2017, 8, 223–230. [Google Scholar] [CrossRef]

- Mahamood, R.M.; Jen, T.C.; Akinlabi, S.A.; Hassan, S.; Abdulrahman, K.O.; Akinlabi, E.T. Role of additive manufacturing in the era of Industry 4.0. In Additive Manufacturing; Woodhead Publishing: Sawston, UK, 2021; pp. 107–126. [Google Scholar]

- Machado, C.G.; Despeisse, M.; Winroth, M.; da Silva, E.H.D.R. Additive manufacturing from the sustainability perspective: Proposal for a self-assessment tool. Procedia CIRP 2019, 81, 482–487. [Google Scholar] [CrossRef]

- Felice, G.; Lamperti, F.; Piscitello, L. The employment implications of additive manufacturing. Ind. Innov. 2022, 29, 333–366. [Google Scholar] [CrossRef]

- Kianian, B.; Tavassoli, S.; Larsson, T.C. The role of additive manufacturing technology in job creation: An exploratory case study of suppliers of additive manufacturing in Sweden. Procedia CIRP 2015, 26, 93–98. [Google Scholar] [CrossRef]

- Junk, S.; Rothe, N. Lightweight design of automotive components using generative design with fiber-reinforced additive manufacturing. Procedia CIRP 2022, 109, 119–124. [Google Scholar] [CrossRef]

- Kellens, K.; Renaldi, R.; Dewulf, W.; Kruth, J.P.; Duflou, J.R. Environmental impact modelling of selective laser sintering processes. Rapid Prototyp. J. 2014, 20, 459–470. [Google Scholar] [CrossRef]

- Leong, W.D.; Teng, S.Y.; How, B.S.; Ngan, S.L.; Rahman, A.A.; Tan, C.P.; Ponnambalam, S.G.; Lam, H.L. Enhancing the adaptability: Lean and green strategy towards the Industry Revolution 4.0. J. Clean. Prod. 2020, 273, 122870. [Google Scholar] [CrossRef]

- Meena, V.K.; Kalra, P.; Sinha, R.K. Additive manufacturing parameters optimization of Ti6AL4V eli for medical implants. Surf. Rev. Lett. 2022, 29, 2250040. [Google Scholar] [CrossRef]

- Thomas, D. Costs, benefits, and adoption of additive manufacturing: A supply chain perspective. Int. J. Adv. Manuf. Technol. 2016, 85, 1857–1876. [Google Scholar] [CrossRef]

- Zhang, Y.; Jedeck, S.; Yang, L.; Bai, L. Modeling and analysis of the on-demand spare parts supply using additive manufacturing. Rapid Prototyp. J. 2018, 25, 473–487. [Google Scholar] [CrossRef]

| Search Aids | LM | GM | AM |

|---|---|---|---|

| Synonyms | Lean manufacturing Lean production Toyota production system (TPS) | Green manufacturing Environmental manufacturing Eco/ecological manufacturing Clean manufacturing Low-carbon manufacturing | Additive fabrication Direct digital manufacturing Freeform fabrication Solid freeform fabrication |

| Keywords | Just in Time Kaizen Kanban Jidoka Total Quality Management (TQM) 5 Why’s Single Minute Exchange of Dies (SMED) 5S Visual Control Cellular manufacturing Total Preventive Maintenance (TPM) Value Stream Mapping (VSM) Poka yoke Takt time Heijunka Gemba Andon | Design for environment (DFE) Reduce, recycle and reuse (3R) Total-quality environmental management (TEQM) Life cycle assessment (LCA) Environmental emission control (EEC) Environmental management system (EMS) Green supply chain management (GSCM) Green purchasing Green procurement Green packaging | 3D printing Rapid prototyping |

| Author | Focus | Description | Impact of AM on Lean/Green Manufacturing | How the AM, LM and GM Impact Sustainable Manufacturing |

|---|---|---|---|---|

| Ford and Despeisse [2] | Raw materials and product development | An investigation of the deployment of AM from a life cycle assessment to enable sustainability benefits. | An increase in the efficiency of raw materials. Since additive manufacturing calls for many kinds of material inputs, beneficiation of materials with less toxic effects, waste, non-value-added activities and byproducts being removed from the waste stream, and less intense energy utilization. | The ability of the resulting geometry to meet performance requirements, dematerialization of products, streamlined assemblies, goods, and parts, modular design’s flexibility to be upgraded, and democratized method of design. |

| Tang et al. [73] | Energy conservation | Design of a life cycle assessment framework that incorporates the design stage to reduce the environmental effect of the binder jetting AM process. | The binder jetting process produced an optimal part that used a significantly reduced energy and produced lower amounts of carbon dioxide compared to the CNC milling machine. | The sustainability in manufacturing arises from the fact that energy and resources conservation can be addressed from the design stage to reduce the impact of the manufacturing process on the environment. |

| Ching et al. [75] | Energy, materials and cost conservation | A thorough examination of the literature to identify the sustainability functions that Industry 4.0 uses to support sustainable production. | The environmental aspect of manufacturing sustainability benefited from Industry 4.0 by the reduction in waste across the value chain and reduced the quantity of material and energy resources utilized. | Reduced manufacturing costs also result in more customer-focused production and higher manufacturing profit margins, both of which support the growth of networks that generate economic sustainable value. |

| Böckin, and Tillman [49] | Energy efficiency through weight reduction | Environmental assessment of additive manufacturing in the automotive industry. | In the aerospace and automotive industry, lightweight parts produced with AM help to reduce weight, thereby increasing the fuel efficiency. | The design of lightweight parts which consume less material makes the AM process sustainable. The quest for lightweight parts that consume less material will also result in less energy consumption and less GHG emissions. |

| Chandra et al. [76] | Product quality and environmental performance | Utilization of the complex proportional assessment (COPRAS) and stepwise weight assessment ratio analysis (SWARA) multicriteria decision making process to select the most sustainable AM process. | AM improves product quality, product ecological performance, market stability and reduces production cost | The sustainability of AM is largely affected by variables like energy consumption and environmentally friendly, waste-free manufacture. |

| Frăţilă and Rotaru [65] | Efficient resources utilization and improved waste management. | The design of a predictive assessment technique to assess the environmental effects for two AM technologies (fused deposition modeling (FDM) and selective laser sintering (SLS)) and computer numerical control (CNC) milling and taking into account the energy, fluids and materials required during a product’s manufacturing process, as well as waste materials and recycled components. | Reduced production cost, energy and raw material use and improved waste management. | Improved worker safety and health, efficient material and energy use, industrial waste management, low manufacturing costs, avoidance of toxic emissions and materials. |

| Ghobadian et al. [3] | Environment and resources conservation | An analysis of the potential of additive manufacturing to support LM, thus enhancing sustainability and innovation for organizations. | AM decreases physical environmental degradation, lead time, cost, waste and increases product’s quality. | AM lowers fuel usage, increases product durability, productivity, and create new employment opportunities. |

| Huang et al. [77] | Lean supply chain | An analysis of the effects of AM on society from a technological view. | A decrease in the need for packaging, waste shipping, and storage, and increase the effectiveness of a lean supply chain. | AM improves the wellbeing and health of people through creating specialized surgical implants and assistive devices that are tailored to each patient’s needs. |

| Kellens et al. [67] | Effective energy and raw material utilization | A summary of the life cycle inventory data and a comparison of the environmental effects of several AM technologies. | A reduction in energy and raw material usage. | AM results in fuel usage reduction, electric power savings, as well as weight reduction. |

| Naghshineh et al. [78] | Effective energy and raw material utilization, socio-economic benefits and localization | Analyzing the social effects of AM technology that have an effect on the industry stakeholders involved in various product life cycles. | AM lowers the amount of energy and raw materials used in manufacturing and encourages recycling and reuse. | AM help to maintain their cultural heritage since the community can manufacture the components and goods they require, and there will be less outside influence on their native cultures. Additionally, AM improves access to employment, income, skills, and disaster mitigation with the ability to produce goods, commodities, and replacements quickly. |

| Priarone et al. [79] | Effective energy and raw material utilization, as well as environmental conservation | An assessment of the energy use and CO2 emission between the traditional machining and wire arc additive manufacturing techniques. | Reduction in the usage of raw materials. | When the wire arc additive manufacturing based strategy is employed, there has been a notable decrease in resource/energy consumption and CO2 emissions. |

| Touriki et al. [80] | Waste elimination, efficient resources usage and recovery options | Developed a framework for integrating smart, green and lean manufacturing. | AM allows for elimination of waste, Efficient usage of resources, the possibilities of repair, refurbishment, remanufacturing actions, and recycling of products. | Improved environmental performance and increased resource efficiency. |

| Niaki et al. [63] | Efficient design, product development and resource conservation | Identified the concepts behind the application of AM in different industries and ranked them. | The design freedom offered by AM allows for lightweight designs which lead to reduced energy, tool less manufacturing and resource efficient production. | Time- and cost-saving, particularly product development. |

| Belhadi et al. [81] | Energy, waste and lifecycle management, | Used structural equation modelling to establish the linkage between big data analytics, lean six sigma and green manufacturing. | Application of AM in manufacturing results in improved energy efficiency, lifecycle management, waste elimination and reconfigurable manufacturing. | Waste elimination, increased savings, reduced environmental impact. |

| Agnusdei et al. [82] | Product and process sustainability | Conducted a systematic review on the role of AM in sustainability. Used statistical tools to identify the most ranked articles and key words on the sustainability of AM. | On demand manufacturing, cost effectiveness, high-performance designs for improved quality, reduced energy consumption and reduction in waste. | Elimination of waste, reduced production costs and improved environmental performance. |

| Ghobakhloo and Fathi [83] | Energy reduction and improved economic performance | Examining the impact of Industry 4.0 towards energy sustainability. | The application of AM has the potential to reduce energy consumption by 20%. | Reduces energy cost, will lead to improved economic performance. |

| Belhadi et al. [81] | Improved value chain and sustainability | The relationship between industry 4.0 methods such as AM and sustainable performance. | AM reduces raw material consumption, time to market, production cost, minimizes the logistic processes, reduces waste, can reduce logistics and transportation energy. | Improved economic, social and environmental performance. |

| Kumar and Chhabra [84] | Innovative design | Developed an AM framework for automatic design of orthotic devices using topology optimization. The framework can be used to design and manufacture orthotic devices which are lightweight and optimally designed. | AM allows for design optimization of orthotic devices to improve functionally while reducing weight and material consumption. | Improved quality of life of patients with orthotic patients through customized rehabilitation. Costs savings and improved innovation in the manufacture of orthotic devices. |

| Liu et al. [85] | Material sustainability | Presents a review on sustainable materials which can be used for additive manufacturing in the construction sector. The review ended by presenting the research gaps in AM using sustainable materials. | The application of AM reduces material consumption, waste and time in construction. | AM allows for the use of sustainable materials which are environmentally friendly. It also reduces the materials used in construction. |

| Majeed et al. [86] | AM sustainability and product life cycle | Developed a framework of big data analytics in smart sustainable additive manufacturing. The framework was produced by combining data analytics, additive manufacturing and sustainable smart manufacturing technologies. it is useful at the beginning of life (BOL) stage of the product life cycle. | Improved quality, reduced lead time and increased operational efficiency in the production of AM parts. | Improved energy efficiency, cost savings and improved decision making at the beginning of life stage. |

| Green Waste | Contribution/Impact of AM | Reference |

|---|---|---|

| Excessive water usage | The concept of green packaging through AM can lead to a 90% reduction in the amount of water required for production. | The report of the World Economic Forum [31]. |

| Greenhouse gases | Reduces the CO2 emissions due to the methods used and reduced transportation. | Javaid et al. [1], Yang et al. [71] |

| Excessive power usage | Reduction in the consumption of electricity. | Bockin and Tillman [49], Ingarao et al. [70], Yang et al. [71], Nagarajan and Haapala [74], Ghobakhloo and Fathi [83]. |

| Pollution | Pollution is reduced through the use of biodegradable, organic, non-toxic substances. | Javaid et al. [1]. |

| Excessive resource usage | Less resource usage as the exact amount is used. | Javaid et al. [1], Ingarao et al. [70] |

| Environmental impacts | AM has the potential to reduce environmental impacts such as abiotic depletion, acidification, global warming, eutrophication, terrestrial, marine and aquatic ecotoxicity | Shuaib et al. [87] |

| Poor health and safety | AM increases the automation levels, making the process safe and saving lives. | Javaid et al. [1]. |

| Rubbish | Reduces the amount of rubbish as the thermoplastic and other materials can be recycled and reused. | Javaid et al. [1], Yang et al. [71], Colorado et al. [88]. |

| Concept | Impact of AM in Green Manufacturing | Reference |

|---|---|---|

| Use of biodegradable materials. | Products manufactured with AM using biodegradable raw materials can decompose naturally without negatively impacting the environment. | Pakkanen et al. [44], Qin et al. [100]. |

| Remanufacturing. | AM allows for remanufacturing of worn-out metal-based parts so that they are restored to their original state, thus reducing the environmental burden associated with manufacturing new parts. | Wilson et al. [101], Rahito and Azman [52], Phuluwa et al. [102]. |

| Recycling of polymer-based products. | AM allows for the recycling of polymer-based products, thus reducing the quantity of plastic waste in landfills and the environment. | Pakkanen et al. [44], Gaikwad et al. [103]. |

| Reduction in waste through optimized designs that use less material. | The design freedom offered by AM allows for part designs that use lesser material when compared to conventional manufacturing technologies. | Lopez Taborda et al. [104] |

| Producing lightweight parts with less environmental impact. | AM allows for the manufacture of high-performance designs that result in reduced carbon emissions. | Orme et al. [105], Ganesh Sarvankar and Yewale [106] |

| Elimination of assemblies through consolidation of parts. This reduces the environmental impact associated with producing fasteners. | AM allows for the manufacture of parts that are already assembled, thus reducing the number of sub-assemblies. | Yang et al. [71], Knofius et al. [107]. |

| Energy-efficient products with improved functionality. | AM allows for the manufacture of high-performance products that use less energy. | Hettesheimer et al. [108] |

| Producing parts from digital models, thus eliminating production tools. This reduces the environmental impact of manufacturing tools. | AM eliminates the use of tools by producing parts directly from CAD design models. | Javaid et al. [1], Taddese et al. [109] |

| Eliminating the environmental burden associated with transportation of parts by producing parts on demand and on site. | Producing parts on site and on demand eliminates the need for outsourcing and transportation. | Javaid et al. [1] |

| Concept | Role of AM in Lean Manufacturing | Reference |

|---|---|---|

| Improved operational efficiency by using a shorter process chain. | AM shortens the process steps to manufacture products since parts are produced directly from digital models. | Yusuf et al. [110] Jamwal et al. [111] |

| Reduced rejects by eliminating errors associated with using conventional manufacturing technologies. | Human errors are reduced by employing digital manufacturing. | Javaid et al. [1] |

| Reduced rejects through the usage of tools and equipment with improved performance. | AM allows for the manufacture of intelligent products with embedded sensors. This results in improved quality control. | Hossain et al. [51] |

| Improved manufacturing efficiency through AM-based tools and molds with specialized features. | AM allows for the manufacture of high-performance tools with improved features such as conformal cooling systems in injection molding tools. This results in improved quality and reduced lead time. | Hu et al. [112], Muvunzi et al. [113,114]. |

| Elimination of physical inventory through the usage of digital inventory. | Inventory can be stored in the form of CAD designs as opposed to the storage of physical inventory, which ties up capital and storage space. | Knofius and Heijden [115]. |

| Reduced waiting time for spare parts by producing them locally, on demand and on site. | Parts can be produced at the point of need. This eliminates the waiting time associated with outsourcing spare parts. Reduced transportation through localized manufacturing. | Gonzalez-Varoa et al. [116], Attaran [117] |

| Eliminating overproduction by producing customized parts. | AM allows for the manufacture of customized products. | Javaid et al. [1] |

| References | Economic Performance | Social Performance | Environmental Performance |

|---|---|---|---|

| Lean Manufacturing | |||

| Dey et al. [118], Singh et al. [119] | Cost reduction, productivity, sales and business growth. | Improved safety, working conditions, labor relations, morale and work pressure. | Waste reduction, pollution reduction, recycling. |

| Singh et al. [119], Ghaithan et al. [120] | Cost reduction, improves profit, improves efficiency. | Improved safety, working conditions, labor relations, morale and work pressure. | Decreased waste (solid, liquid and gases), reduced consumption of toxic material and energy usage. |

| Ghaithan et al. [120], Wu et al. [121] | Cost reduction, improved profits. | Improved social awards and social presence. | Decreased waste (solid, liquid and gases), reduced consumption of toxic material and energy usage. |

| Ghaithan et al. [120], Garza-Reyes et al. [122] | Cost reduction, improved profits. | Potential for job creation. | Reduced material use, pollutant emission, energy consumption and non-product output. |

| Wu et al. [121] | Improved return on sales (ROS), return on assets (ROA) and reduced costs. | Potential for job creation. | Reduced waste (air, wastewater and solid), reduced use of harmful material and energy consumption. |

| Vinodh et al. [19] | Reduction in the cost of production. | Potential for job creation. | Reduced waste (air, wastewater and solid), energy use and raw material use. |

| Nawanir et al. [123]. | Improved market share, product quality, flexibility, profitability and order delivery, reduced waste treatment fees, costs and environmental accident fees. | Enhanced safety and health, improved relationship with stakeholders and community, improved quality of living of the surrounding community and the working conditions. | Reduced waste (air, wastewater and solid), decreased energy consumption, improved compliance with the environmental standards and reduced material usage. |

| Green Manufacturing | |||

| References | Economic Performance | Social Performance | Environmental Performance |

| Afum et al. [23] | The adoption of GM is positively related to increase in profits, sales, return on investment (ROI), return on equity and return on asset. | GM implementation led to improvements in quality of nearby community, safety and health of workers, job satisfaction, and stakeholder and community relationships. | GM implementation led to a decrease in the consumption of hazardous materials, environmental accidents, environmental impacts and increased compliances to the environmental standards. |

| Rusinko [124] | GM reduces the usage of resources and recycles waste, leading to the reduction in manufacturing cost. | The reduction in waste and pollution lead to improved community and workers’ health and safety. | Recycling of waste reduces resource consumption. |

| Sezen and Cankaya [38] | Improvement in the manufacturing time and cost effectiveness. | Green manufacturing led to increased occupational health and safety. | GM reduce environmental waste and environmental impact. |

| Famiyeh et al. [125] | Improved quality, delivery, flexibility, and reduction in cost are obtained as a result of implementing GM. | Improvement in environmental performance led to increase safety and health, reduction in community complaints. | Enhanced overall environmental performance is attained when organizations perform in a green way. |

| Mafini and Loury-Okoumba [126] | Results attained include improved delivery, quality, product line, capacity utilization and decreased inventory. | Decrease in scrap rate will contribute to decrease in solid waste, therefore, leading to decreased complaints from nearby customers. | Decrease in scrap rate was attained. |

| Yu et al. [38] | Improvements in flexibility, cost, quality and delivery was realized through GSCM adoption. | Potential for job creation. | Reduction in emissions, wastewater, hazardous material consumption and solid waste. |

| Eshikumo and Odock [127] | Organizations that adopt GM practices such as recycling reduced their production costs. Cost reduction and increase in ROI were attained through GM implementation. | The reduction in negative environmental impacts increases the safety and health of workers. | Adoption of recycling, emission reduction and energy reduction practices reduce the negative environmental impacts. GM led to the reduction in environmental impact, material used, energy usage during transportation. |

| Ivan et al. [128], Pakkanen et al. [44] | Eliminating of overproduction by producing parts on demand. | Potential for job creation. | AM can process biodegradable materials which decompose without negatively impacting the environment. |

| Thomas et al. [129], Rahimizadeh et al. [57] | Reducing supply chain costs. | Potential for job creation. | Polymer materials used in AM can be recycled. This reduced the quantity of polymer waste in the environment. |

| Knofius and Heijden [115] Sahu et al. [130] | Reduced transportation through localized manufacturing. | Potential for job creation. | AM can help to reduce E-waste by transforming it to sustainable filaments. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maware, C.; Muvunzi, R.; Machingura, T.; Daniyan, I. Examining the Progress in Additive Manufacturing in Supporting Lean, Green and Sustainable Manufacturing: A Systematic Review. Appl. Sci. 2024, 14, 6041. https://doi.org/10.3390/app14146041

Maware C, Muvunzi R, Machingura T, Daniyan I. Examining the Progress in Additive Manufacturing in Supporting Lean, Green and Sustainable Manufacturing: A Systematic Review. Applied Sciences. 2024; 14(14):6041. https://doi.org/10.3390/app14146041

Chicago/Turabian StyleMaware, Catherine, Rumbidzai Muvunzi, Tinotenda Machingura, and Ilesanmi Daniyan. 2024. "Examining the Progress in Additive Manufacturing in Supporting Lean, Green and Sustainable Manufacturing: A Systematic Review" Applied Sciences 14, no. 14: 6041. https://doi.org/10.3390/app14146041

APA StyleMaware, C., Muvunzi, R., Machingura, T., & Daniyan, I. (2024). Examining the Progress in Additive Manufacturing in Supporting Lean, Green and Sustainable Manufacturing: A Systematic Review. Applied Sciences, 14(14), 6041. https://doi.org/10.3390/app14146041