Research on Key Technology of Wind Turbine Drive Train Fault Diagnosis System Based on Digital Twin

Abstract

1. Introduction

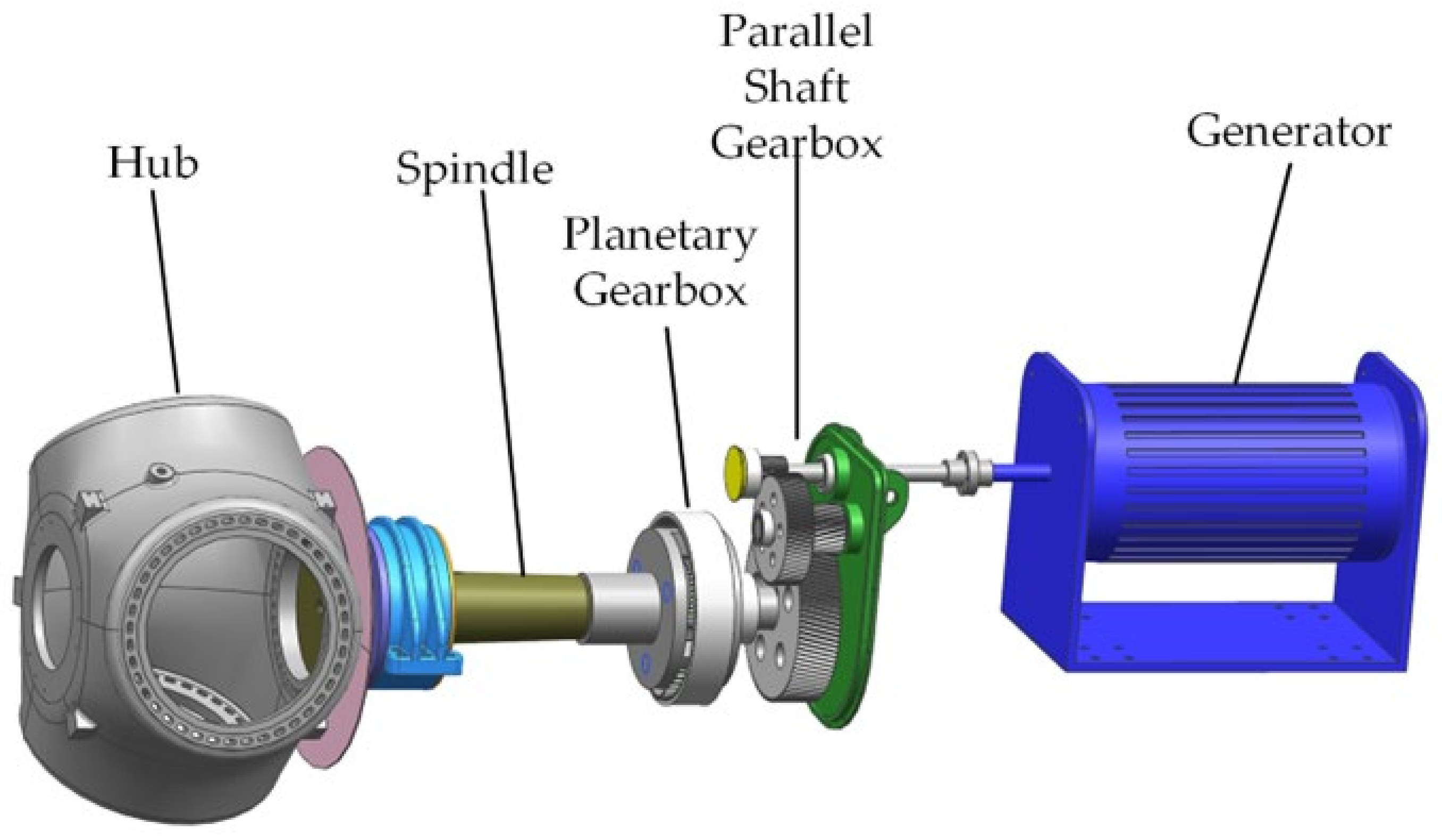

2. Composition of a Digital Twin System for Wind Turbines

3. Digital Twin Model Construction of Wind Turbine Transmission System

3.1. Lightweighting of Wind Turbine Drive Train Models

3.2. Construction of Kinematic Models for Transmission Systems

3.3. Digital Twin Model Building and Driving

4. Fault Diagnosis Method Based on Digital Twin

4.1. Implementation Method of Fault Diagnosis System Based on Digital Twin

- Step 1: The digital twin fault diagnosis system of the wind power transmission system collects the vibration signal of the wind turbine.

- Step 2: The data acquisition card is used to convert the analog signal collected by the acceleration sensor into a digital signal and transfer it to the PC.

- Step 3: The collected data are saved as a .CSV or .txt file by data acquisition software and exported to Unity3D.

- Step 4: The IVMD-PSO-LSSVM is packaged as a DLL file and integrated into the digital twin file.

- Step 5: The digital twin periodically or manually invokes vibration signals for fault diagnosis.

- Step 6: The digital twin model updates its running status according to the diagnosis results and is displayed in Unity3D.

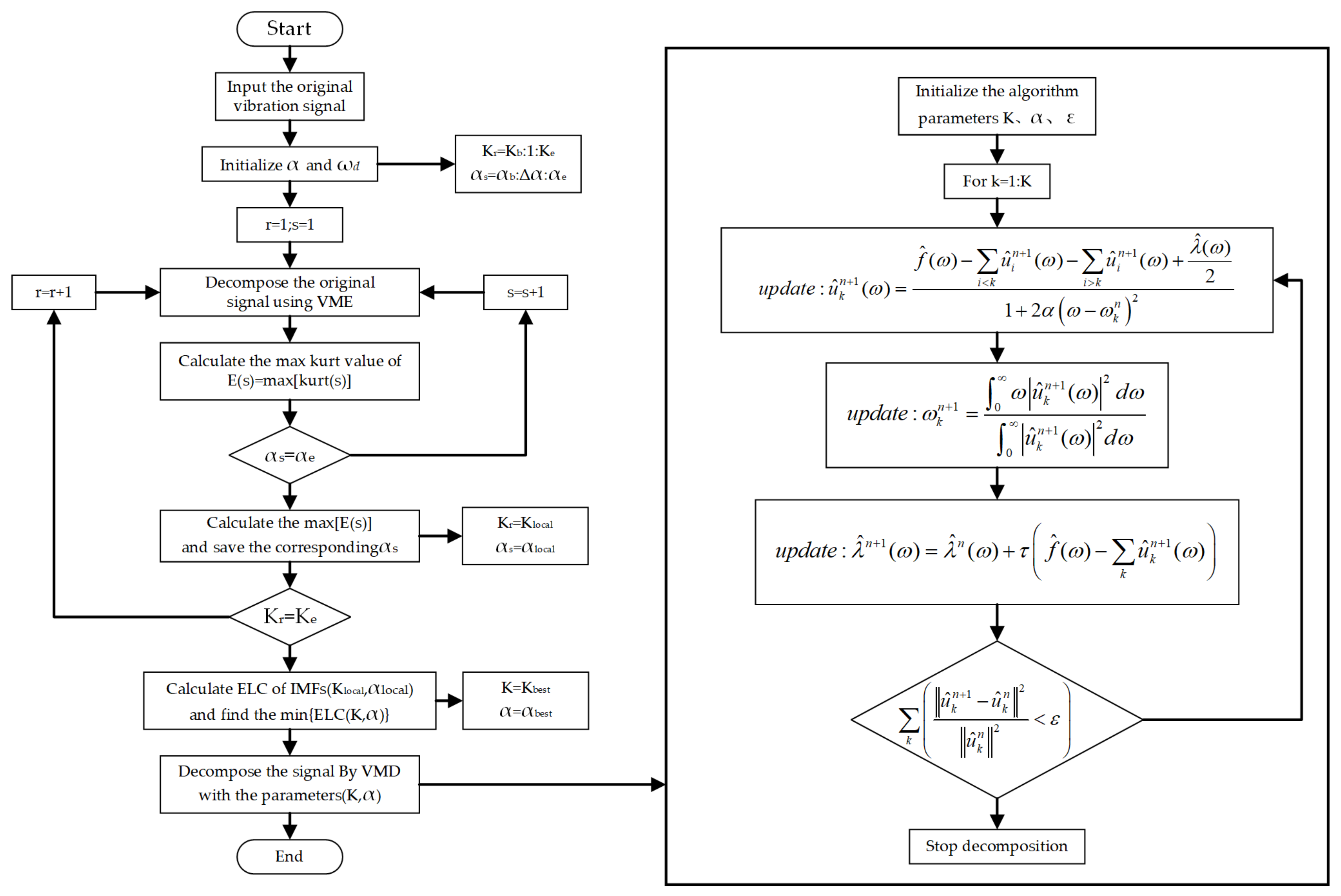

4.2. Feature Extraction Based on Improved Variational Modal Decomposition (IVMD)

4.3. Particle Swarm Optimization Algorithm Optimizing Least Squares Support Vector Machine (PSO-LSSVM)

4.4. Fault Diagnosis Model

- Step 1: The vibration signals of wind turbine bearings are collected under different fault conditions.

- Step 2: The kurtosis index and the energy loss coefficient are used to determine the optimal parameter pairs (, ) of the VMD, and then the raw vibration signal is decomposed into several IMF components.

- Step 3: Based on the minimum envelope entropy criterion, the optimal IMF component is selected for subsequent analysis.

- Step 4: Feature vectors containing rich fault information from optimal IMF components are extracted using the NCMDE algorithm.

- Step 5: The optimal combination of penalty factor c and kernel function parameters are determined for LSSVM using the PSO algorithm.

- Step 6: The extracted feature vector is randomly divided into training and test samples. The training samples are used to train the LSSVM after optimizing the parameters, and the test samples are used to test the trained LSSVM, which ultimately verifies the effectiveness and superiority of the method proposed in this paper.

5. Case Study

5.1. Experimental Verification of Fault Diagnosis Model

5.2. Implementation of Fault Diagnosis System of Wind Turbine Transmission System Based on Digital Twin

6. Discussion

7. Conclusions

- (1)

- The kinematics equations of the wind turbine drive system are integrated into the digital twin model of the wind turbine drive system so that the model can simulate the real running state of the wind turbine by using data such as speed.

- (2)

- An IVMD-PSO-LSSVM fault diagnosis method based on digital twin technology is proposed, which improves the calculation accuracy and efficiency and better embodies the real-time accuracy of fault diagnosis.

- (3)

- Unity3D, cloud server, and database were utilized to complete the construction of the digital twin scenario, which realized the fault diagnosis of the wind turbine drive train based on the digital twin, as well as the real-time mapping of the virtual module and the physical module and the reproduction of the operation status of a certain time period in the past.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Strielkowski, W.; Civín, L.; Tarkhanova, E. Renewable energy in the sustainable development of electrical power sector: A review. Energies 2021, 14, 8240. [Google Scholar] [CrossRef]

- Peng, H.; Li, S.; Shangguan, L. Analysis of wind turbine equipment failure and intelligent operation and maintenance research. Sustainability 2023, 15, 8333. [Google Scholar] [CrossRef]

- Grieves, M.; Vickers, J. Digital twin: Mitigating unpredictable, undesirable emergent behavior in complex systems. In Transdisciplinary Perspectives on Complex Systems: New Findings and Approaches; Springer: Berlin/Heidelberg, Germany, 2017; pp. 85–113. [Google Scholar]

- Lei, H.; Fanli, Z.; Wei, W. Digital twin method and application practice of spacecraft system driven by mechanism data. Digit. Twin 2024, 4, 2. [Google Scholar] [CrossRef]

- Yin, Y.; Zheng, P.; Li, C. A state-of-the-art survey on Augmented Reality-assisted Digital Twin for futuristic human-centric industry transformation. Robot. Comput.-Integr. Manuf. 2023, 81, 102515. [Google Scholar] [CrossRef]

- Wang, B.; Zhou, H.; Li, X. Human Digital Twin in the context of Industry 5.0. Robot. Comput.-Integr. Manuf. 2024, 85, 102626. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Zhang, C. Advancements and challenges of digital twins in industry. Nat. Comput. Sci. 2024, 4, 169–177. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Sun, W.; Liu, L. Fault Diagnosis of Wind Turbine Planetary Gear Based on a Digital Twin. Appl. Sci. 2023, 13, 4776. [Google Scholar] [CrossRef]

- Yan, J.; Möhrlen, C.; Göçmen, T. Uncovering wind power forecasting uncertainty sources and their propagation through the whole modelling chain. Renew. Sustain. Energy Rev. 2022, 165, 112519. [Google Scholar] [CrossRef]

- Stetco, A.; Dinmohammadi, F.; Zhao, X. Machine learning methods for wind turbine condition monitoring: A review. Renew. Energy 2019, 133, 620–635. [Google Scholar] [CrossRef]

- Liu, Z.; Sun, W.; Chang, S. Corn Harvester Bearing fault diagnosis based on ABC-VMD and optimized EfficientNet. Entropy 2023, 25, 1273. [Google Scholar] [CrossRef]

- Yu, G.; Wu, P.; Lv, Z. Few-shot fault diagnosis method of rotating machinery using novel MCGM based CNN. IEEE Trans. Ind. Inform. 2023, 19, 10944–10955. [Google Scholar] [CrossRef]

- Wang, Z.; Nie, P.; Liu, J. Bearing fault diagnosis based on a multiple-constraint modal-invariant graph convolutional fusion network. High-Speed Railw. 2024, 2, 92–100. [Google Scholar] [CrossRef]

- Daems, P.J.; Peeters, C.; Matthys, J. Fleet-wide analytics on field data targeting condition and lifetime aspects of wind turbine drivetrains. Forsch. Ingenieurwesen 2023, 87, 285–295. [Google Scholar] [CrossRef]

- Tao, F.; Xiao, B.; Qi, Q. Digital twin modeling. J. Manuf. Syst. 2022, 64, 372–389. [Google Scholar] [CrossRef]

- Garland, M.; Heckbert, P.S. Surface simplification using quadric error metrics. In Proceedings of the 24th Annual Conference on Computer Graphics and Interactive Techniques, Los Angeles, CA, USA, 3–8 August 1997; pp. 209–216. [Google Scholar]

- Chang, H.; Dong, Y.; Zhang, D. Review of Three-Dimensional Model Simplification Algorithms Based on Quadric Error Metrics and Bibliometric Analysis by Knowledge Map. Mathematics 2023, 11, 4815. [Google Scholar] [CrossRef]

- Dragomiretskiy, K.; Zosso, D. Variational mode decomposition. IEEE Trans. Signal Process. 2013, 62, 531–544. [Google Scholar] [CrossRef]

- Jiang, X.; Wang, J.; Shen, C. An adaptive and efficient variational mode decomposition and its application for bearing fault diagnosis. Struct. Health Monit. 2021, 20, 2708–2725. [Google Scholar] [CrossRef]

- Zhang, F.; Sun, W.; Wang, H. Fault diagnosis of a wind turbine gearbox based on improved variational mode algorithm and information entropy. Entropy 2021, 23, 794. [Google Scholar] [CrossRef]

- Rostaghi, M.; Azami, H. Dispersion entropy: A measure for time-series analysis. IEEE Signal Process. Lett. 2016, 23, 610–614. [Google Scholar] [CrossRef]

- Suthaharan, S.; Suthaharan, S. Support vector machine. In Machine Learning Models and Algorithms for Big Data Classification: Thinking with Examples for Effective Learning; Springer: Berlin/Heidelberg, Germany, 2016; pp. 207–235. [Google Scholar]

- Suykens, J.A.K.; Vandewalle, J. Least squares support vector machine classifiers. Neural Process. Lett. 1999, 9, 293–300. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the ICNN’95-International Conference on Neural Networks, Perth, WA, Australia, 27 November–1 December 1995; IEEE: Piscataway, NJ, USA, 1995; Volume 4, pp. 1942–1948. [Google Scholar]

- Li, H.; Fan, B.; Jia, R.; Zhai, F.; Bai, L.; Luo, X. Research on multi-domain fault diagnosis of gearbox of wind turbine based on adaptive variational mode decomposition and extreme learning machine algorithms. Energies 2020, 13, 1375. [Google Scholar] [CrossRef]

| Name | Drive Class Transmission Ratio | Number of Teeth | Module of Gear (m) | Tooth Width (b) | Helix ) | ) | Reference Radius (d) |

|---|---|---|---|---|---|---|---|

| Annular gear | First stage i = 5.04 | 101 | 10 | 225 | 0 | 20 | 1010 |

| Planet gear | 38 | 225 | 380 | ||||

| Sun gear | 25 | 225 | 250 | ||||

| Helical gear 1 | Second stage i = 3.8 | 99 | 240 | 14 | 1020.3074 | ||

| Helical gear 2 | 26 | 245 | 267.9595 | ||||

| Helical gear 3 | Third stage i = 3.505 | 74 | data | 160 | 14 | 610.1233 | |

| Helical gear 4 | 21 | 160 | 173.1431 |

| Bearing Type | Number of Scrollers | Rolling Body Diameter | Pitch Circle Diameter |

|---|---|---|---|

| ER-16K | 9 | 7.9375 | 38.5064 |

| Bearing Condition | Load (A) | Rotate Speed | Class Label |

|---|---|---|---|

| Normal | 1.2/1.5 | 1200/1500 | 1 |

| Inner ring fault | 1.2/1.5 | 1200/1500 | 2 |

| Outer ring fault | 1.2/1.5 | 1200/1500 | 3 |

| Rolling body fault | 1.2/1.5 | 1200/1500 | 4 |

| Signal Decomposition Algorithm | Classification Algorithm | Accuracy | Time |

|---|---|---|---|

| VMD | PSO-LSSVM | 95.7% | 14.4 s |

| IVMD | LSSVM | 96.6% | 16.8 s |

| IVMD | PSO-SVM | 98.3% | 26.4 s |

| IVMD | PSO-LSSVM | 99.1% | 21.2 s |

| Sensor Type | Sensitivity | Measuring Range | Frequency Range | Operating Temperature |

|---|---|---|---|---|

| RH103 | 100 mV/g | 80 g | 0.5~15,000 Hz (±3 dB) | −40~120 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, H.; Sun, W.; Bao, S.; Xiao, L.; Jiang, L. Research on Key Technology of Wind Turbine Drive Train Fault Diagnosis System Based on Digital Twin. Appl. Sci. 2024, 14, 5991. https://doi.org/10.3390/app14145991

Liu H, Sun W, Bao S, Xiao L, Jiang L. Research on Key Technology of Wind Turbine Drive Train Fault Diagnosis System Based on Digital Twin. Applied Sciences. 2024; 14(14):5991. https://doi.org/10.3390/app14145991

Chicago/Turabian StyleLiu, Han, Wenlei Sun, Shenghui Bao, Leifeng Xiao, and Lun Jiang. 2024. "Research on Key Technology of Wind Turbine Drive Train Fault Diagnosis System Based on Digital Twin" Applied Sciences 14, no. 14: 5991. https://doi.org/10.3390/app14145991

APA StyleLiu, H., Sun, W., Bao, S., Xiao, L., & Jiang, L. (2024). Research on Key Technology of Wind Turbine Drive Train Fault Diagnosis System Based on Digital Twin. Applied Sciences, 14(14), 5991. https://doi.org/10.3390/app14145991