Research on the Capillary Filling Behavior of Liquid Solder Al-12Si under the Action of Electromagnetic Ultrasonic Wave

Abstract

:1. Introduction

2. Physical Model

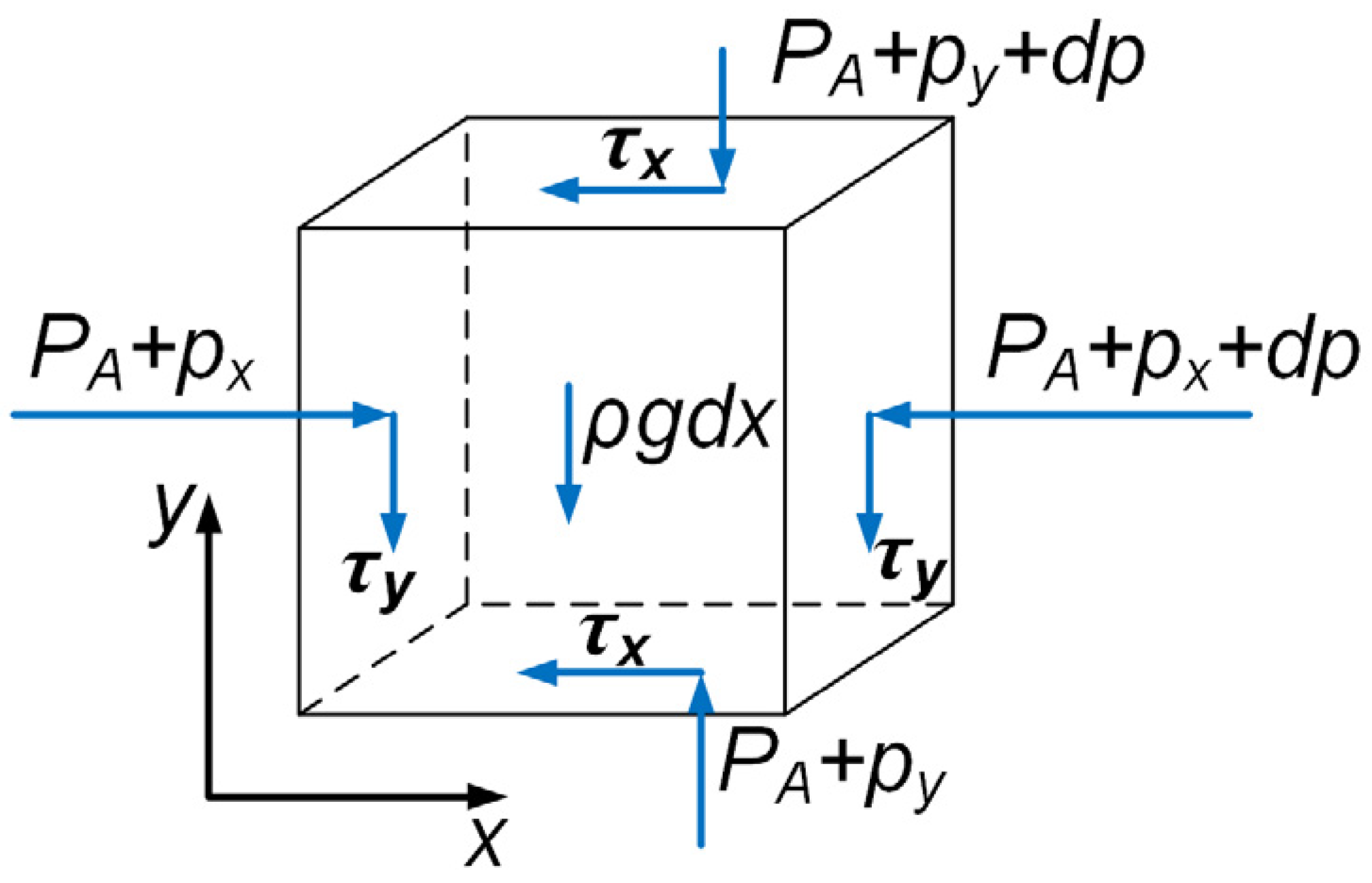

2.1. Governing Equation

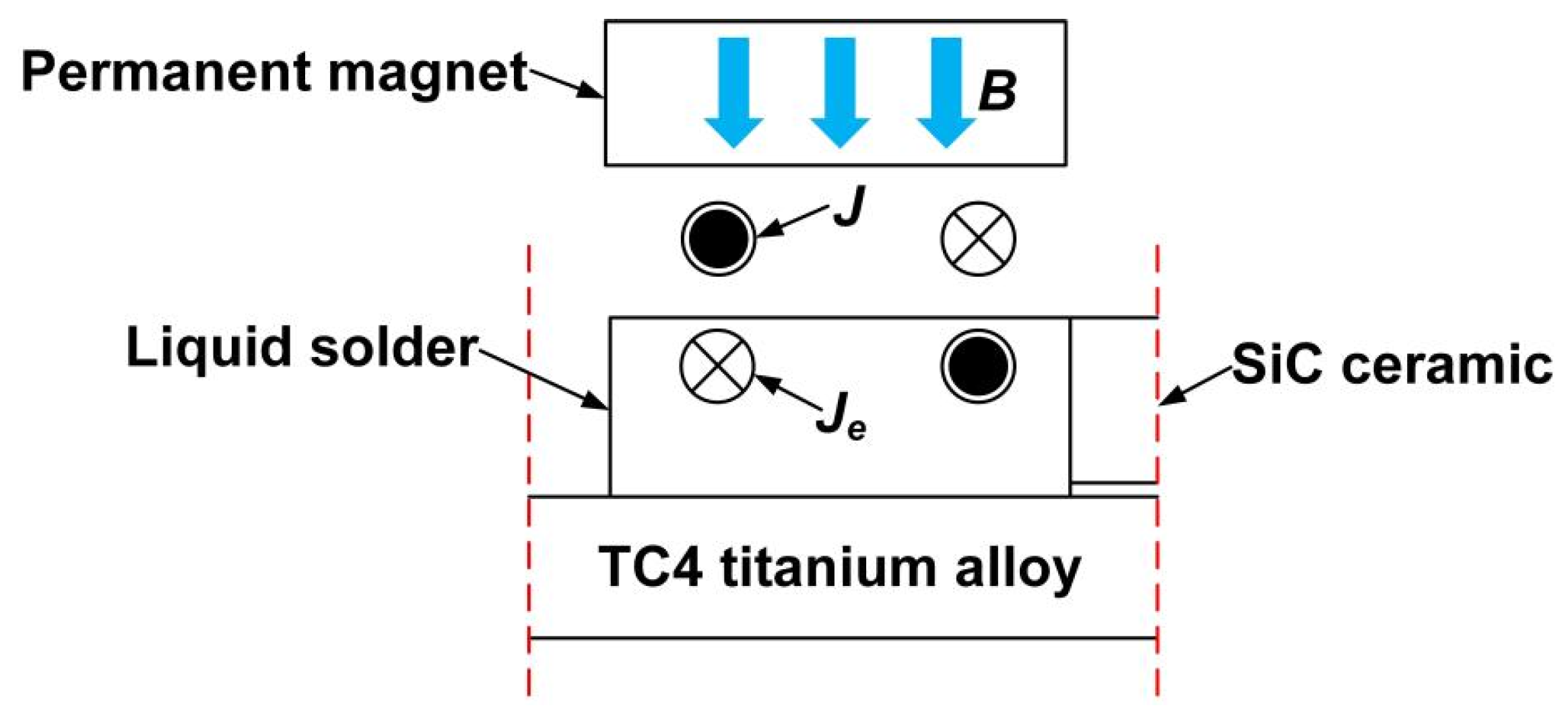

2.2. Establishment of the Model

3. Results

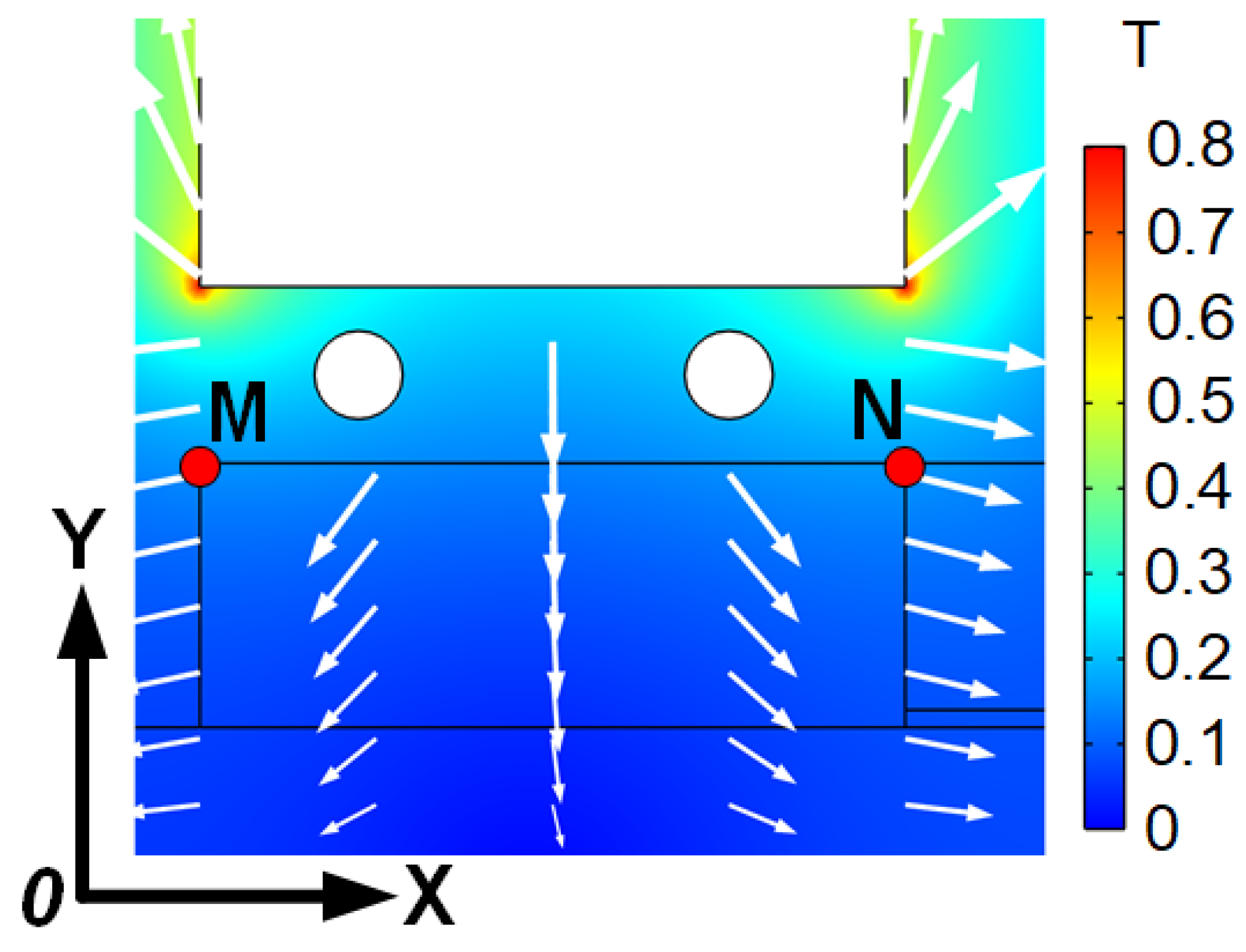

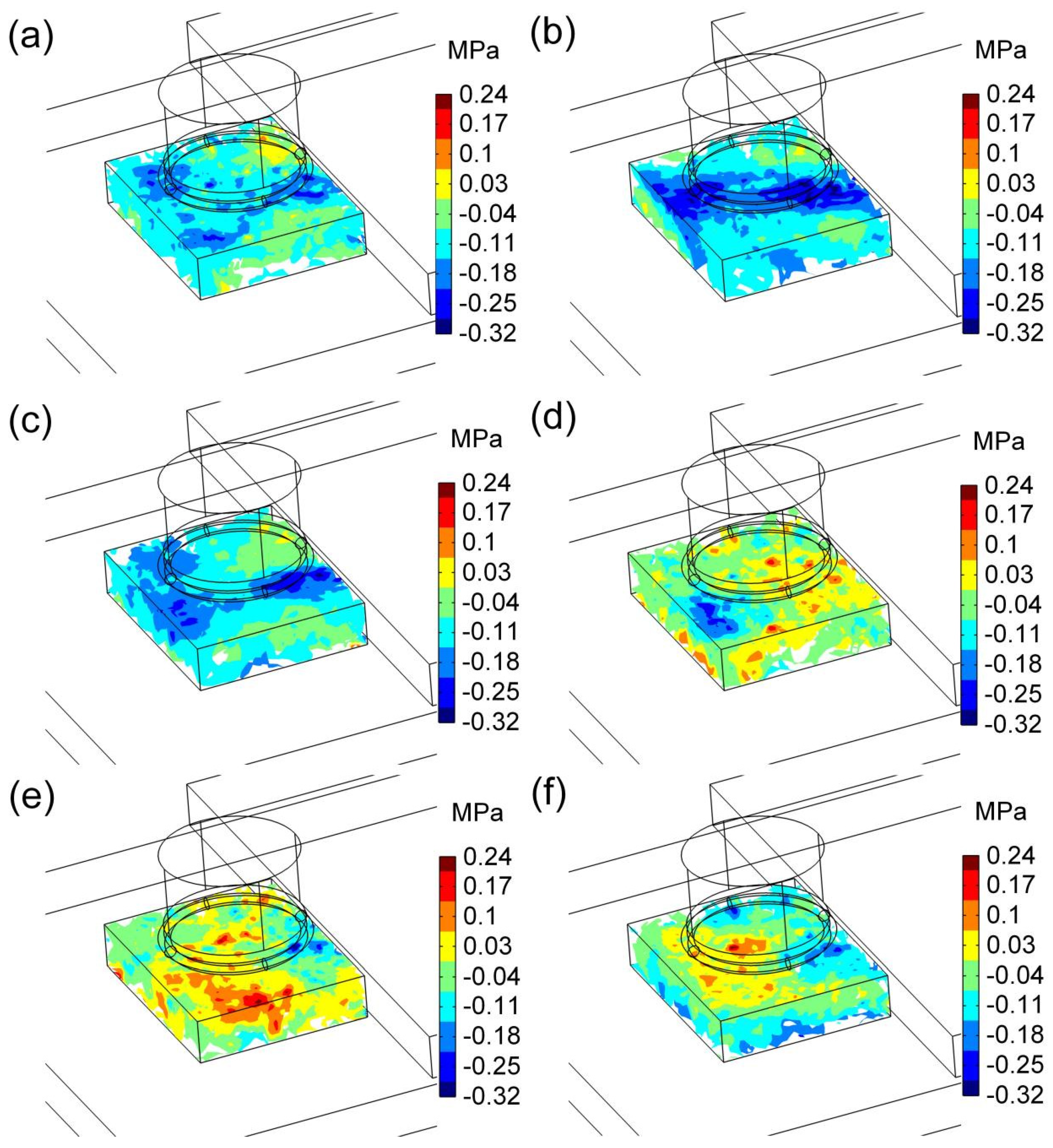

3.1. MIS and Distribution

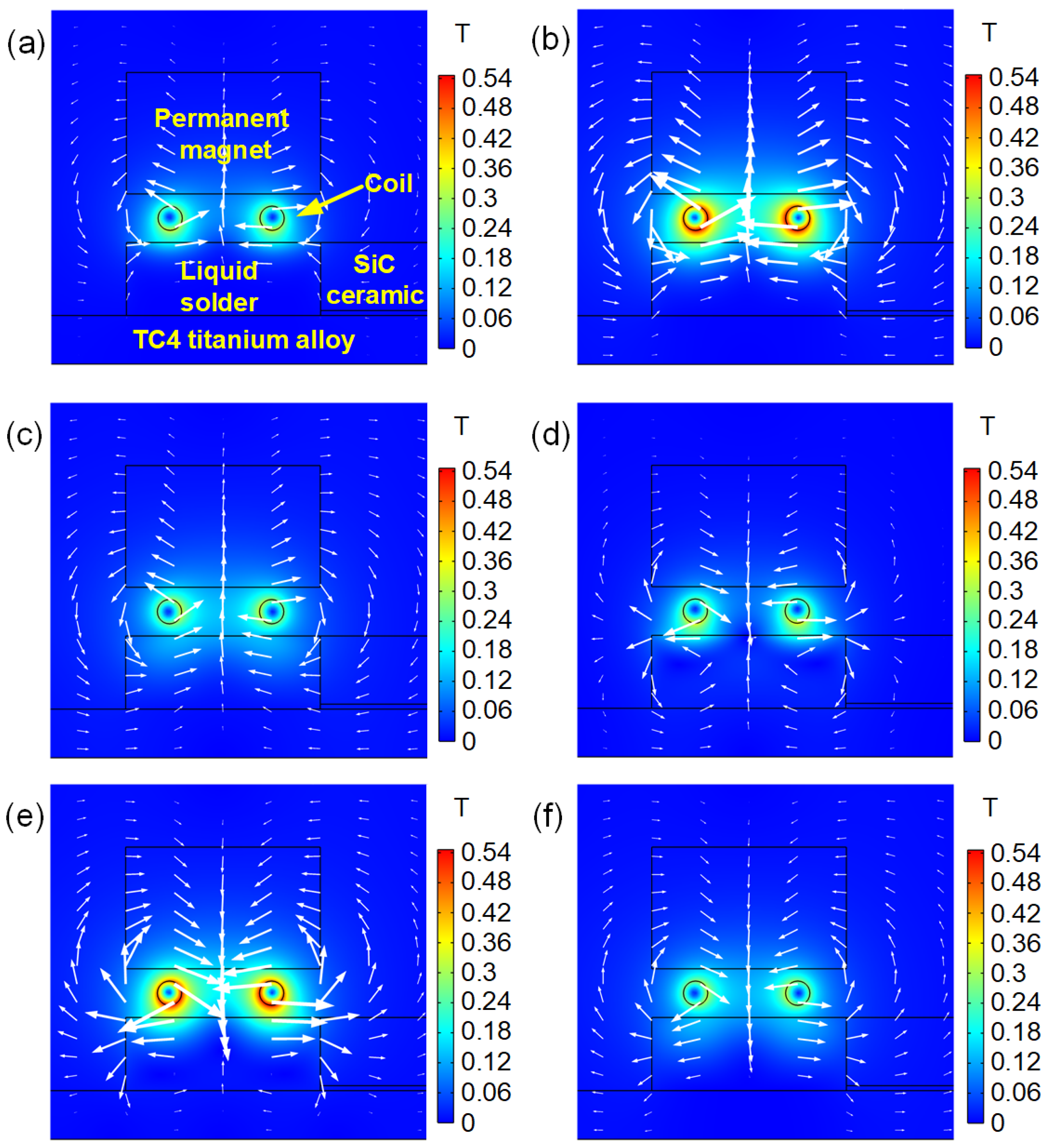

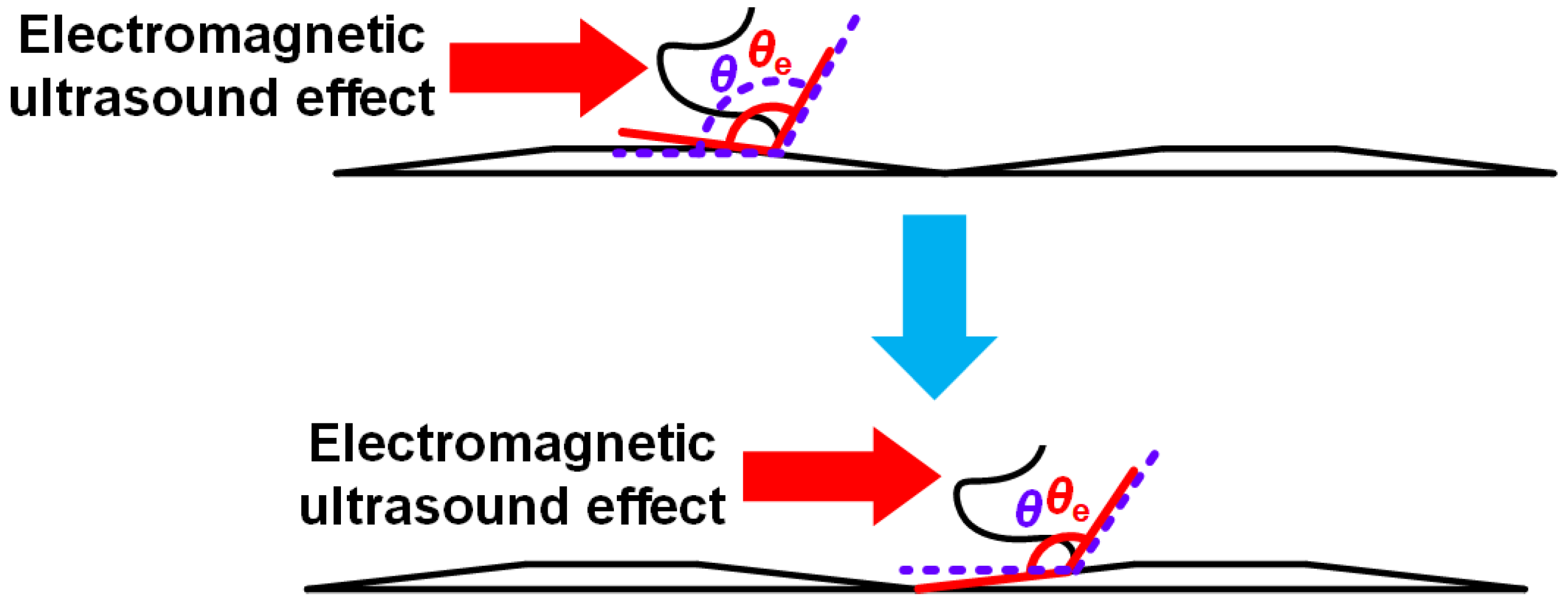

3.2. CF Process of Liquid Solder

4. Discussion

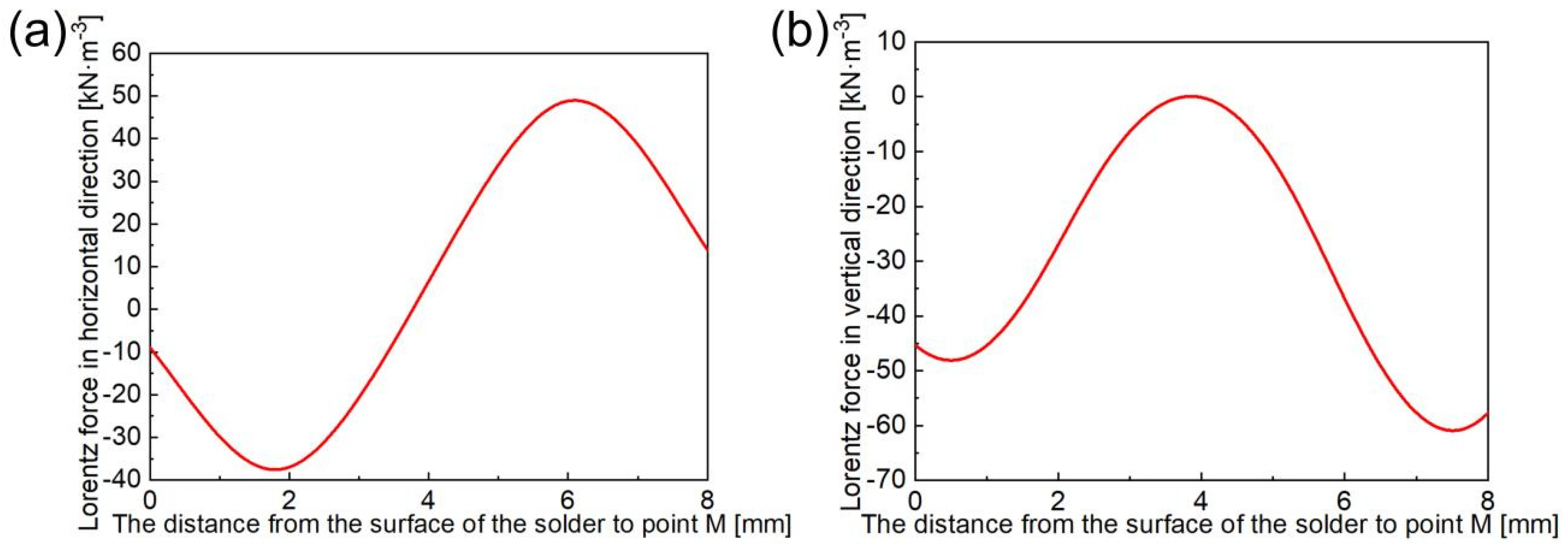

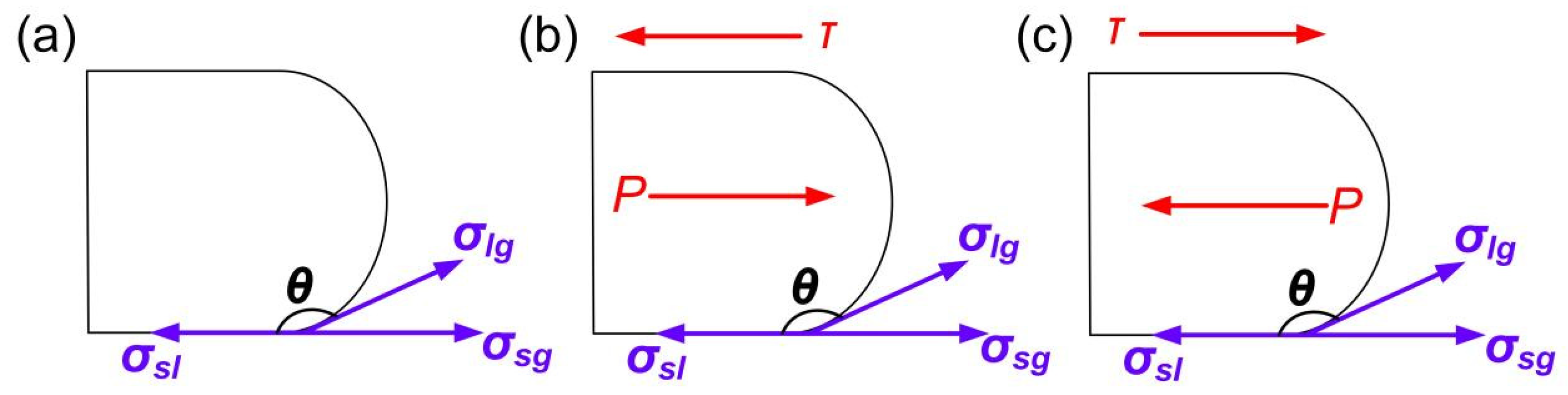

4.1. Driving Force Analysis of Liquid Solder CF Process

4.2. Interface Mechanical Analysis of Liquid Solder CF Process

4.3. Interface Mechanical Analysis of Liquid Solder CF Process

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shevchenko, V.Y.; Dolgin, A.S.; Sychov, M.M.; Makogon, A.I.; Perevislov, S.N. Ideal: A promising diamond-silicon carbide composite for enhanced ceramic armor. Ceram. Int. 2024, 50, 4264–4273. [Google Scholar] [CrossRef]

- Thakur, N.; Kumar, P.; Bharj, R.S.; Bahl, S.; Singh, O.; Sharma, P. A numerical study on high-velocity impact behaviour of ceramic composite laminates. Phys. Scr. 2023, 98, 115031. [Google Scholar] [CrossRef]

- Luo, Z.; Wang, G.; Zhao, Y.; Tan, C.; He, R. Brazing SiC ceramics and Zr with CoCrFeNiCuSn high entropy alloy. Ceram. Int. 2022, 48, 23325–23333. [Google Scholar] [CrossRef]

- Zhang, Z.; Cai, Y.; Liu, Y.; Feng, K. Study on Brazing of SiC Ceramics with Zr-Cu-Nb Filler Metal. J. Mater. Eng. Perform. 2023, 7, 1–11. [Google Scholar] [CrossRef]

- Aghdam, M.M.; Morsali, S.; Hosseini, S.; Sadighi, M. Mechanical behavior of unidirectional SiC/Ti composites subjected to off-axis loading at elevated temperatures. Mater. Sci. Eng. 2017, 688, 244–249. [Google Scholar] [CrossRef]

- Pei, Y.T.; Ocelik, V.; Hosson, J.T. SiCp/Ti6Al4V functionally graded materials produced by laser melt injection. Acta Mater. 2002, 50, 2035–2051. [Google Scholar] [CrossRef]

- Li, Z.; Shi, H.; Zhao, Y.; Gu, J.; Zhang, P.; Yu, Z.; Wang, B.; Song, N.; Sun, T. Microstructure and mechanical properties of vacuum brazed joints of TC4 waveform structure fabricated by 3D printed technology. Weld. World 2023, 67, 2049–2065. [Google Scholar] [CrossRef]

- Xie, Y.; Wang, T.; Wang, L.; Yang, Y.; Shang, X. Numerical investigation of ballistic performance of SiC/TC4/UHMWPE composite armor against 7.62 mm AP projectile. Ceram. Int. 2022, 48, 24079–24090. [Google Scholar] [CrossRef]

- Huang, C.D.; Hwang, J.R.; Huang, J.Y. Optimization of Vacuum Brazing Process Parameters in Ti-6Al-4V Alloy. Metals 2022, 12, 974. [Google Scholar] [CrossRef]

- Basude, A.; Kumar, A.; Rajasingh, G.; Mugada, K.K. Dissimilar joining of Titanium alloy to Aluminium using Al-Si based filler alloy by vacuum brazing technique. Proc. Inst. Mech. Eng. Part L 2022, 236, 1724–1737. [Google Scholar] [CrossRef]

- Ma, Q.; Pu, J.; Li, S.G.; Chen, Y.W.; He, P. Introducing a 3D-SiO2-fiber interlayer for brazing SiC with TC4 by AgCuTi. J. Adv. Join. Process. 2022, 5, 100082. [Google Scholar] [CrossRef]

- Wang, G.; Wang, Z.; Wang, W.; He, R.; Gui, K.; Tan, C.; Cao, W. Microstructure and shear strength of ZrB2-SiC/Ti6Al4V joint by TiCuZrNi with Cu foam. Ceram. Int. 2019, 45, 10223–10229. [Google Scholar] [CrossRef]

- Gao, L.; Cai, C.; Xiong, J.; Huang, J.; Zhao, X. Research on brazing joints of Cf/SiC and TC4 using AgCuTi-Al filler materials. Trans. China Weld. Inst. 2011, 32, 35–38. [Google Scholar]

- Way, M.; Willingham, J.; Goodall, R. Brazing filler metals. Int. Mater. Rev. 2020, 65, 257–285. [Google Scholar] [CrossRef]

- Xu, R.; Chen, M.; Ji, G.; Xin, L.; Wu, F. Microstructure and Mechanical Properties of Ti-Based Amorphous Solder Vacuum Brazing Joint for Stainless Steel. J. Mater. Eng. Perform. 2024, 1, 1–6. [Google Scholar] [CrossRef]

- Sypien, A. Microstructural and Mechanical Characterization of Interfacial Phenomena Occurring in Brazing Ti-6Al-4V Alloy Using TiZrCuPd Amorphous Ribbons. J. Mater. Eng. Perform. 2023, 32, 5731–5740. [Google Scholar] [CrossRef]

- Bai, G.; Liu, Z.; Lin, J.; Yu, Z.; Hu, Y.; Wen, C. Effects of the addition of lanthanum and ultrasonic stirring on the microstructure and mechanical properties of the in situ Mg2Si/Al composites. Mater. Des. 2016, 90, 424–432. [Google Scholar] [CrossRef]

- Chen, X.; Jia, Y.; Liao, Q.; Jia, W.; Le, Q.; Ning, S.; Yu, F. The simultaneous application of variable frequency ultrasonic and low frequency electromagnetic fields in semi continuous casting of AZ80 magnesium alloy. J. Alloys Compd. 2019, 774, 710–720. [Google Scholar] [CrossRef]

- Farhang, B.; Tanrikulu, A.A.; Ganesh, A.; Jain, A.; Amerinatanzi, A. Electromagnetic field-assisted laser welding of NiTi to stainless steel: Towards a lightweight, high-strength joint with preserved properties. J. Mater. Process. Technol. 2023, 314, 117888. [Google Scholar] [CrossRef]

- Bachmann, M.; Avilov, V.; Gumenyuk, A.; Rethmeier, M. Numerical assessment and experimental verification of the influence of the Hartmann effect in laser beam welding processes by steady magnetic fields. Int. J. Therm. Sci. 2016, 101, 24–34. [Google Scholar] [CrossRef]

- Zhang, M.; Ma, Z.; Geng, D.; Xia, F.; Yu, X. Capillary filling ability of Sn-Zn solder on SiC ceramic surface under electromagnetic ultrasonic action. J. Mater. Res. Technol. 2023, 23, 2836–2851. [Google Scholar] [CrossRef]

- Cifuentes, G.; Manríquez, J.; Sepulveda, G. Fluid dynamics and simulation study of particles inside of a hydrocyclone using comsol. Chem. Eng. Trans. 2017, 57, 1291–1296. [Google Scholar]

- Kumar, R.; Jha, P.K. Effect of electromagnetic stirring on the transient flow, solidification and inclusion movements in the continuous casting slab mold. Int. J. Numer. Methods Heat Fluid Flow 2023, 33, 3716–3733. [Google Scholar] [CrossRef]

- Yue, P.; Xiao, J.; Xu, K.; Li, M.; Jiang, F.; Lu, Y.; Peng, D. Mathematical model and analysis method for flowfield separation and transition. Phys. Fluids 2021, 33, 044116–044132. [Google Scholar] [CrossRef]

- Zhou, B.; Zeng, Z.; Cai, Y.; Feng, K. FEM Simulation and Verification of Brazing SiC Ceramic with Novel Zr-Cu Filler Metal. Materials 2019, 12, 3380. [Google Scholar] [CrossRef] [PubMed]

- Song, S.; Gao, Z.; Lu, B.; Bao, C.; Zheng, B.; Wang, L. Performance optimization of complicated structural SiC/Si composite ceramics prepared by selective laser sintering. Ceram. Int. 2020, 46, 568–575. [Google Scholar] [CrossRef]

- Li, H.; Hou, H.; Sun, Z. Relationship Between Effect of Hydrogen on Physical and Mechanical Properties and Its Machinability for TC4 Titanium Alloy. Aeronaut. Manuf. Technol. 2008, 20, 80–83. [Google Scholar]

- Ankudinov, V.; Gordeev, G.A.; Kharanzhevskiy, E.V.; Krivilyov, M.D. Numerical Simulation of Thermal Conductivity of Stainless Steel and Al-12Si Powders for Additive Manufacturing. J. Heat Transf. 2022, 144, 052201–052209. [Google Scholar] [CrossRef]

- Li, P.; Guo, J.; Jia, J.; Li, Q.; Ri, K. Physical Properties and Solidification Structure of Al-Si Eutectic Alloy Melt with Cerium Modification. J. Rare Earths 1996, 2, 140–144. [Google Scholar]

- Wang, W.; Zhang, Y.; Yue, C.; Kong, X.; Hao, Z.; Wang, T.; Li, T. Processing defect, microstructure evolution and mechanical properties of laser powder bed fusion Al-12Si alloys. J. Mater. Res. Technol. 2023, 26, 681–696. [Google Scholar] [CrossRef]

- Wang, Q.; He, J.; Kawai, S.; Iwai, K.; Asai, S. Effect of magneto-acoustic waves on solidification structures of metal. Acta Metall. Sin. 2002, 9, 961–965. [Google Scholar]

- Xu, H.; Han, Q.; Meek, T.T. Effects of ultrasonic vibration on degassing of aluminum alloys. Mater. Sci. Eng. 2008, 473, 96–104. [Google Scholar] [CrossRef]

- Li, Y.; Wu, C.; Chen, M. Numerical analysis of the heat-pressure characteristics in ultrasonic vibration assisted plasma arc. J. Appl. Phys. 2020, 128, 114903. [Google Scholar] [CrossRef]

- Elsayed, D.; Afza, S.; Wedad, R.A.; Hasson, S. Simulation of electric field response of horizontal circular electric half wave dipole antenna for seabed logging. Alex. Eng. J. 2023, 66, 421–431. [Google Scholar]

- Marting, L.H.; Karatsu, K.; Endo, A.; Baselmans, J.A.; Laguna, A.P. Directional Filter Design and Simulation for Superconducting On-Chip Filter-Banks. J. Low Temp. Phys. 2024, 5, 1–10. [Google Scholar] [CrossRef]

- Yao, M.; Xue, J.; Huang, H.; Su, F.; Zhang, A.; Gong, J.; Yu, X.; Yang, J. Study on the effect of ultrasonic treatment for fabricating nodular cast iron with improved mechanical properties. J. Mater. Res. Technol. 2024, 29, 5295–5303. [Google Scholar] [CrossRef]

- Meliani, M.; Nikolić, V. Mixed approximation of nonlinear acoustic equations: Well-posedness and a priori error analysis. Appl. Numer. Math. 2024, 198, 94–111. [Google Scholar] [CrossRef]

- Butt, H.J.; Liu, J.; Koynov, K.; Straub, B.; Hinduja, C.; Roismann, I.; Berger, R.; Li, X.M.; Vollmer, D.; Steffen, W.; et al. Contact angle hysteresis. Curr. Opin. Colloid Interface Sci. 2022, 59, 101574–101610. [Google Scholar] [CrossRef]

- Moustavi, S.M.; Jarrahbashi, D.; Jik, L.B.; Karimi, N.K.; Faroughi, S.A. Impact of hybrid surfaces on the droplet breakup dynamics in microgravity slug flow: A dynamic contact angle analysis. Phys. Fluids 2023, 35, 072003–072010. [Google Scholar] [CrossRef]

- Vukovic, T.; Rostad, J.; Farooq, U.; Torsaeter, O.; Net, A. Systematic Study of Wettability Alteration of Glass Surfaces by Dichlorooctamethyltetrasiloxane Silanization—A Guide for Contact Angle Modification. ACS Omega 2023, 40, 36662–36676. [Google Scholar] [CrossRef]

- Vigdorowitsch, M.; Tsygankova, L.E.; Ostrikov, V.V.; Rodionova, L.D. Beyond the Wenzel and Cassie-Baxter world: Mathematical insight into contact angles. Math. Methods Appl. Sci. 2022, 45, 11479–11497. [Google Scholar] [CrossRef]

- Wang, J.; Wu, Y.; Cao, Y.; Li, G.; Liao, Y. Influence of surface roughness on contact angle hysteresis and spreading work. Colloid Polym. Sci. 2020, 298, 1107–1112. [Google Scholar] [CrossRef]

- Jiang, Y.; Xu, Z.; Li, B.; Li, J.; Guan, D. Soft Wetting: Droplet Receding Contact Angles on Soft Superhydrophobic Surfaces. Langmuir 2023, 43, 15401–15408. [Google Scholar] [CrossRef] [PubMed]

| Substrate | Elastic Modulus (GPa) | Poisson Ratio | Density (g/cm3) |

|---|---|---|---|

| SiC | 450 | 0.142 | 3.1 |

| TC4 | 110 | 0.31 | 4.44 |

| Solder | Melting (°C) | Viscosity (mPa·s) | Density (g/cm3) |

|---|---|---|---|

| Al-12Si | 577 | 0.88 (700 °C) | 2.654 |

| Parameter Name | Value |

|---|---|

| Peak current | 50 A |

| Current frequency | 20 kHz |

| Number of coils | 30 |

| Static MF | 1 T |

| Micro-Point | Sound Pressure Amplitude (MPa) | Sound Pressure Frequency (kHz) | Initial Phase (μs) | Half-Wave Offset (MPa) |

|---|---|---|---|---|

| F | 0.121 | 20 | 13.501 | 0.092 |

| G | 0.07 | 20 | 13.025 | 0.031 |

| H | 0.039 | 20 | 13.115 | 0.018 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, G.; Gao, Q.; Zhang, M.; Yu, H. Research on the Capillary Filling Behavior of Liquid Solder Al-12Si under the Action of Electromagnetic Ultrasonic Wave. Appl. Sci. 2024, 14, 4557. https://doi.org/10.3390/app14114557

Chen G, Gao Q, Zhang M, Yu H. Research on the Capillary Filling Behavior of Liquid Solder Al-12Si under the Action of Electromagnetic Ultrasonic Wave. Applied Sciences. 2024; 14(11):4557. https://doi.org/10.3390/app14114557

Chicago/Turabian StyleChen, Guijuan, Qianqian Gao, Mingxuan Zhang, and Haonan Yu. 2024. "Research on the Capillary Filling Behavior of Liquid Solder Al-12Si under the Action of Electromagnetic Ultrasonic Wave" Applied Sciences 14, no. 11: 4557. https://doi.org/10.3390/app14114557

APA StyleChen, G., Gao, Q., Zhang, M., & Yu, H. (2024). Research on the Capillary Filling Behavior of Liquid Solder Al-12Si under the Action of Electromagnetic Ultrasonic Wave. Applied Sciences, 14(11), 4557. https://doi.org/10.3390/app14114557