Abstract

The paper analyzes the prospects of using a heat-accumulating material consisting of metallized polyethylene granules. X-ray diffraction analysis has been used to study the influence of the number of heating and cooling cycles of the heat-accumulating material on the change in the degree of crystallinity of polyethylene. It was shown that the proposed heat-accumulating material showed a low resistance and a significant decrease in the degree of crystallinity of polyethylene under the experimental conditions. The crystal structure of polyethylene did not change during cyclic heating and cooling. Grounded on the obtained experimental results, it was determined that a high degree of polyethylene crystallinity is being kept for 200–300 heating-cooling cycles.

1. Introduction

The shortage of traditional energy sources as well as restrictions on their use in order to protect the environment have already become the present-day reality. This necessitates an increase in the share of renewable energy sources in the general energy balance of many countries. Renewable energy sources can offer actual practical solutions to solve a number of problems. However, they have a number of significant disadvantages. One such drawback is the impossibility of coordinating energy consumption and production schedules, which prevents their rapid implementation in the energy supply structure. This makes it necessary to look for additional technological and arrangement solutions that allow using the renewable energy sources effectively.

Technologies for thermal energy accumulation and storage using phase transition materials make it possible to effectively distribute heat consumption over time, which is necessary to solve the main problem of renewable energy (solar, wind), namely the discrepancy between the demand and supply of available energy. In addition to renewable energy, such technologies can also be used in other industries, such as energy efficient construction, waste heat recovery systems, heat pumps and temperature management of lithium-ion batteries [1,2,3]. Systems using phase transition materials will store and release heat energy as a result of the phase transition of melting and crystallization of the material with a high latent heat capacity.

There are a number of known materials that can be used to accumulate heat during a phase transition. It was proposed to use sugar alcohols as a phase transition material [4,5]. In [5], the cyclic stability of alcohols was assessed and it was shown that the heat of the phase transition decreased during successive cycles of melting and crystallization, and it also depended on the degree of overheating of the alcohol above the melting point. It is also proposed to use multicomponent systems that have an increased thermal conductivity and heat capacity compared to individual substances. Moreover, such multicomponent systems can be obtained not only via simple mixing [6]. Better results can be achieved using, for example, surface polymerization methods [7]. An example of obtaining such phase transition material based on poly(methyl methacrylate)/expanded graphite/n-octanoic acid is given in [8]. From our point of view, the use of highly crystalline polymers, in particular polyethylene, as phase transition materials is promising [9]. A considerable interest in highly crystalline polymers as a basis for creating heat storage systems is also due to the possibility of using secondary raw materials, which will enhance the positive impact of such heat storage systems on the environmental aspects of their implementation. Highly crystalline polyethylene terephthalate and polypropylene can be pointed out among the recycled polymers, which, together with polyethylene, polyvinyl chloride, and polystyrene derivatives, make up the bulk of polymers used in everyday life and subsequently pollute the environment [10,11,12,13].

As we can see, the vast majority of materials used for heat storage have low thermal conductivity, which significantly limits the implementation and development of technologies based on them [14,15,16]. Numerous studies are being conducted to improve the efficiency of using phase transition materials in heat storage systems. The main attention is focused on the design features of heat exchange surfaces, as well as on increasing the thermal conductivity of the phase transition material. In [17], two approaches are simultaneously used: adding longitudinal fins to heat transfer surfaces and using Al2O3 nanoparticles to increase the efficiency of heat transfer. It is shown that the proposed solutions improve the thermophysical properties of the phase transition material and reduce its melting time. The influence of the number of fins and the thickness and nature of the heat transfer surface material on the melting process was studied and modeled for a composite phase transition material consisting of polyethylene wax with expanded graphite particles [18]. Based on the results obtained, the authors state that an increase in the number and thickness of fins allows reducing the time of melting and crystallization. The use of materials with high thermal conductivity, low density, and low specific heat capacity for fins provides a higher heat storage capacity and a reduced melting time. The effect of fin geometry on the solid–liquid phase transition when using heat pipes for heat transfer enhancement was also studied [19]. Similar studies using fins and metal foam to improve heat transfer efficiency were also conducted in subsequent works [20,21,22,23,24].

Thus, it can be concluded that the main research on the development of heat storage systems using phase transition materials is focused on increasing the efficiency of heat transfer surfaces and is aimed, to a lesser extent, at developing new phase transition materials. The main attention of researchers in this area is focused on modifying the existing materials to improve their thermophysical properties and, as a rule, involves the use of nanosized fillers [25,26,27].

We have proposed a different approach to increase the thermal conductivity of the phase transition material: 1. to use granules of a highly crystalline organic polymer as a phase transition material, and 2. To form a continuous metal (copper) coating on the surface of polymer granules. Such a solution, in our opinion, will make it possible to avoid the complex design of heat transfer surfaces, which will result in their reduced metal capacity, weight, and cost. The use of high-tonnage industrial crystalline polymer (polyethylene) as a phase transition material may also be promising [9,28].

Another advantage of using polyethylene is its high degree of crystallinity, which can reach 95%. Polyethylene is a polymer that crystallizes with the formation of an orthorhombic unit cell consisting of parallel methylene groups that are entirely in trans conformations. The dimensions of polyethylene unit cell: a = 7.406 Å; b = 4.939 Å; c = 2.547 Å [29].

It should be kept in mind that if we are talking about crystalline polymers, we must understand that they are only partially crystalline in structure and consist of crystalline and amorphous regions. The crystalline regions in such polymers are characterized by an ordered arrangement of macromolecules, while amorphous regions consist of randomly distributed macromolecules. This structural feature of crystalline polymers significantly complicates their study, in particular, by X-ray diffraction analysis. The obtained X-ray diffraction results include peaks from the crystalline regions and halos from the amorphous phase, which are superimposed. In addition, the diffraction curves of crystalline polymers depend on the ratio between the crystalline and amorphous phases in the bulk of the solid polymer. Thus, wide-angle X-ray diffraction can be used to study the crystal structure of a polymer. The position of peaks of the crystalline phase as well as their height, width, and shape provide information about the unit cell parameters, crystallite size, degree of crystallinity, and other characteristics [30].

Wide-angle X-ray diffraction can be used to study both the structure of crystalline polymers and the changes in this structure under the influence of various external factors. The main task is to choose the best optimization method, which will allow decomposing the obtained experimental curve into crystalline peaks and an amorphous component.

The analysis of the wide-angle X-ray diffraction curves of crystalline polymers involves the correct decomposition of these curves into crystalline peaks and amorphous components. Such reliable and unambiguous decomposition is a critical step for calculating the crystallinity of polymers [30,31].

This article is devoted to the study of changes in the crystallinity of the initial metallized polyethylene as a result of repeated cyclic heating and cooling. The main goal of this research was to study the crystallization behavior of the polyethylene matrix. To characterize the change in crystal structure, X-ray diffraction was used and the change in crystallinity and crystal size was discussed.

2. Materials and Methods

Liten PL-10 (Unipetrol) granulated polyethylene was used in the research. The granules of the initial polyethylene were metallized using a developed technology, which included the activation of the surface of the granules as a result of their processing in a ball mill with finely dispersed zinc [32]. Such processing allows obtaining a catalytically active surface of the granules, which is used in the next stage of chemical metallization. The process of activating polyethylene granules was carried out in a laboratory mill with a volume of 4 L with ceramic cylindrical grinding bodies, at a rotation speed of 125 rpm. The following components were loaded into the mill: polymer—300 g, finely dispersed zinc—30 g, and grinding bodies—1.5 kg; the duration of processing was 1 h. The presence of zinc particles on the surface of the polyethylene granules ensures the start of the copper ion reduction in a stabilized electroless copper plating solution. The further reduction of copper ions by formaldehyde is an autocatalytic process and occurs on the formed copper surface. This ensures the formation of a copper coating on the surface of the polyethylene granule, the thickness of which can be adjusted by the parameters of the metallization process (concentration of the components of electroless copper plating solution, duration of metallization, the number of repeated metallizations) [33,34,35]. The composition of the electroless copper plating solution is as follows (mmol/L): CuSO4∙5H2O—60, EDTA-Na2 (C10H14N2Na2O8∙2H2O)—67, NaOH—375, stabilized formalin—365. The necessary content of copper on polyethylene granules was provided by repeated metallization.

Obtaining images of coppered polyethylene granules was carried out using a Vision Lynx EVO504 microscope (Vision Engineering Ltd., Woking, UK). SEM images and energy dispersive studies of the surface of copper granules were performed applying a Zeiss EVO-40XVP microscope (ZEISS, Jena, Germany).

The obtained copper-coated polyethylene granules were used as a heat-accumulating material, in which the presence of copper having a high thermal conductivity will provide better heat supply and removal in the bulk material. Another advantage of using copper-coated granules is obtaining a material in which copper is evenly distributed throughout the entire bulk of the material. Moreover, no additional processing procedures (mixing) are required for such uniform distribution of copper in the bulk of the heat-accumulating material. The formation of the heat-accumulating material structure will occur during the first melting of the material, accompanied by the destruction of the metal shell and the formation of individual copper particles of different sizes. Due to the high viscosity of polymer melts and the absence of convective flows of the substance, sedimentation of copper particles will occur very slowly. This will ensure the formation of the structure with a large number of thermally conductive copper particles, which are separated by the polymer material. For the research, heat-accumulating material was used in the form of a square plate 2 mm thick with a lateral length of 10 mm, obtained by preliminary hot pressing of metallized polyethylene granules (copper content—10 wt.%).

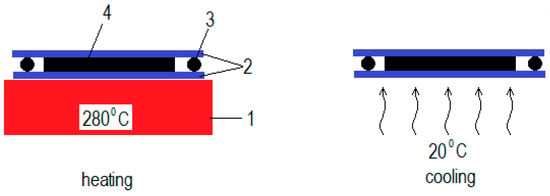

In order to study the effect of the cyclical use of the heat-accumulating material on the crystal structure of the heat-accumulating material, an experiment was developed that involved heating and cooling of the heat-accumulating material. The material was heated on a solid metal plate heated to 280 °C, followed by the air convection cooling. The duration of heating was 10 min and the duration of cooling was 15 min, which ensured heating of the heat-accumulating material above 270 °C and cooling to 25–30 °C. The heat-accumulating material was placed between two quartz glasses, between which the metal height limiters were also placed, which were used to prevent a decrease in the thickness of the sample during melting of the material. The experimental setup and experimental conditions are shown schematically in Figure 1.

Figure 1.

Schematic representation of the experimental setup and experimental conditions: 1—heater (solid metal plate), 2—quartz glass, 3—height limiters, 4—heat-accumulating material.

The heat-accumulating material was studied at the initial stage and after a certain number of heating and cooling cycles by the X-ray diffraction analysis. The diffraction curves were recorded under static conditions using the desktop powder X-ray diffractometer AERIS Research (Malvern PANalytical, Malvern, UK), equipped with an X-ray tube (Cu Kα radiation, λ = 1.54 Å), operating at a voltage of 40 kV and a PIXcel1D detector (Malvern Panalytical Ltd, Malvern, UK). WAXD curves were recorded in the range of 10–100° with the step of 0.02°.

3. Results and Discussion

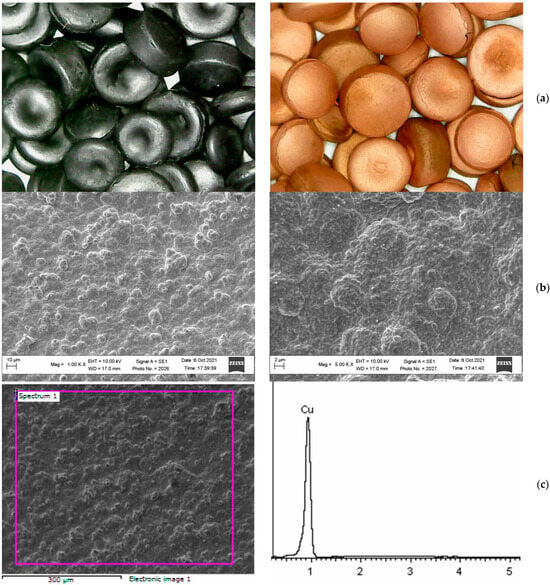

The use of the proposed method of obtaining coppered polyethylene allowed the formation of a continuous layer of copper on the surface of the granules which was confirmed by the results of optical and scanning electron microscopy (Figure 2).

Figure 2.

Optical microscopy of initial and PE coppered granules (a), SEM image of the metallized granule surface (b), and its energy-dispersion analysis (c).

The results of the energy-dispersion analysis show that the surface of the granule was covered with a layer of copper (Figure 2c, Table 1).

Table 1.

Elemental composition of the surface of polyethylene coppered granule.

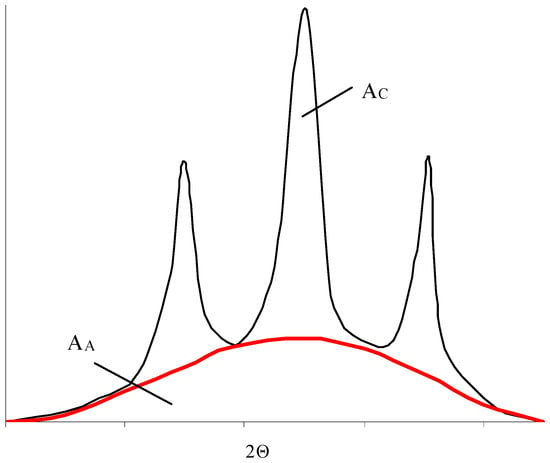

The degree of crystallinity of polymer materials can be estimated using the Nara and Komiya method [36], which involves dividing the diffraction pattern into two parts by a smooth curve connecting the base lines of the peaks (Figure 3). The area above the curve is taken as the crystalline part, and the lower area between the curve and the main line is taken as the amorphous part. The degree of crystallinity in this case is calculated as the ratio of the upper area to the total area described by the diffraction curve.

where XC, AC i AA—are the degree of crystallinity, the area of the crystalline and amorphous regions on the diffraction curve, respectively.

XC = AC/(AC + AA)

Figure 3.

Calculation of the relative degree of crystallinity of polymers (the red line shows the division of the diffraction curve into amorphous and crystalline regions).

WAXSFIT software 1.0 was used to determine the degree of crystallinity of polyethylene in this research [31,37,38]. It allows for unambiguous analyzing of diffraction curves, performing calculations, and determining the structural parameters of crystals. The program decomposes the diffraction curve into separate reflections from crystal lattice planes (crystalline peaks), amorphous components, and background radiation. Based on this decomposition, the degree of polymer crystallinity, crystallite sizes, and interplanar distances can be determined.

The diffraction curves were normalized in all cases during their processing with WAXSFIT. The database built into the program was used to determine the starting parameters for polyethylene. The modeling of the profile of crystalline peaks and amorphous components was performed using the Pearson VII and Gauss + Cauchy functions, respectively. The Rosenbrock method was used to prepare the initial optimization parameters. A single objective (minimization of the sum of squared deviations between the theoretical and experimental curves) and multi-objective (maximization of the field under amorphous components) optimizations were sequentially used. For the final optimal matching of the theoretical and experimental curves, a Hybrid system was used.

The result of the diffraction curve analysis is the determination of parameters of crystalline peaks and amorphous components, including the position of crystalline peaks, the position of amorphous components, the height and width of the peaks, as well as the degree of crystallinity, crystallite sizes and interplanar distances. Based on the positions of individual crystalline peaks determined during the decomposition of the diffraction curve into its components using Bragg’s law, interplanar distances are calculated:

where θ is half of the diffraction angle of the peak position.

d = λ/(2sinθ)

The crystallite sizes are determined using the full width at half maximum of the crystalline peak by the Scherrer equation:

where β is the FWHM of the peak (FWHM is determined as a result of decomposition of the diffraction curve into components).

L = λ/(β sinθ)

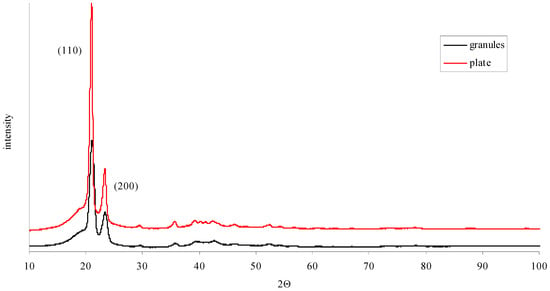

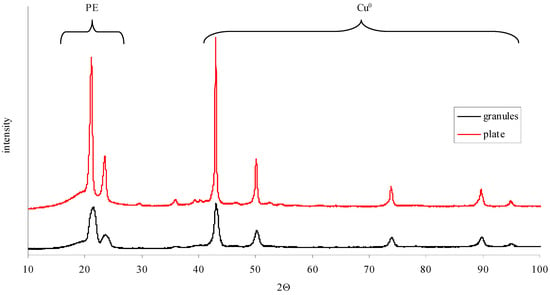

At the first stage of the X-ray diffraction study, a diffraction pattern of initial polyethylene granules and the pressed plate, which was heated and cooled according to the described regime, was obtained (Figure 4, Table 2).

Figure 4.

Diffraction pattern of initial polyethylene granules and the pressed plate that underwent one heating and cooling cycle.

Table 2.

Results of calculations of parameters of crystalline peaks and amorphous phase of polyethylene.

The obtained diffraction pattern is typical for polyethylene and includes three reflections: the amorphous peak at a diffraction angle of about 20° and two crystalline peaks (about 21° and 23.35°). As noted earlier, polyethylene crystallizes with the formation of an orthorhombic crystal structure with lattice dimensions a = 7.406 Å; b = 4.939 Å; c = 2.547 Å, the direction C coincides with the direction of the macromolecule. The presence of crystalline peaks is caused by X-ray diffraction from the (110) and (200) planes. The first peak is superimposed on a wide area of intensity, which is caused by the amorphous part of polyethylene and which corresponds to the predominant arrangement of polyethylene macromolecules in the amorphous state.

If we compare the position of the maximum peaks in the diffraction pattern for polyethylene granules and the plate, it remains virtually the same, but the intensity of the peaks increases for the plate that has undergone one heating/cooling cycle.

Analyzing the diffraction patterns of the metallized polyethylene granules and the plate that was obtained from them and underwent one cycle of heating and cooling (Figure 5, Table 3), it can also be noted that changes in the position of the reflection peak maximums of the crystal structure of polyethylene are insignificant. At that, the peaks responsible for the crystal structure of copper (43°, 50°, 74°, 91°) appear on the diffraction pattern. The intensity of the peaks from the crystal structure of polyethylene is different for metallized granules and plates. The diffraction pattern of metallized granules is characterized by a lower intensity of peaks of the crystalline phase of polyethylene and by their greater width (Table 3).

Figure 5.

Diffraction pattern of metallized polyethylene granules and the plate pressed from them that underwent one heating and cooling cycle.

Table 3.

Results of calculations of the parameters of crystalline peaks and the amorphous phase of polyethylene.

Obtaining the metallized polyethylene granules includes the stage of activation of the polymer surface as a result of their processing in a ball mill with finely dispersed zinc. The activation occurs due to the fixation of zinc particles on the surface of the granules during rotation of the ball mill and the impact action created by the presence of the grinding bodies in it. The result of the impact action on polyethylene granules is the accumulation of internal stresses, accompanied by the destruction of crystallites. The broadening of the peaks in the diffraction patterns of the polyethylene activated in a ball mill (metallized granules) is caused by a decrease in the crystallite size and the accumulation of lattice deformations [36]. Thus, the result of the stage of polyethylene granules activation is the amorphization of the material, as indicated by a decrease in intensity and broadening of the peaks, as well as the calculated crystallite sizes (Table 3). The shift in the position of the peaks is insignificant, which may be due to the absence of changes in the structure of the crystal lattice.

The increase in the degree of crystallinity of the plates, in comparison with the (initial and metallized) polyethylene granules from which they are obtained, can be explained by their slower cooling, which results in the possibility of obtaining a larger number of crystallization centers and a slower crystal growth rate. Granular polymers are produced industrially by rapid cooling.

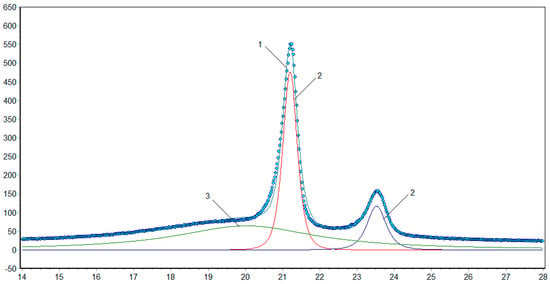

In order to determine the influence of cyclic stability of the developed heat-accumulating material, X-ray diffraction analysis was performed every 100 cycles of heating and cooling. To avoid the possible influence of peaks of the crystalline phase of copper on the calculation of the degree of polyethylene crystallinity, the diffraction curve was limited to the range from 14° to 28°. Figure 6 shows the graphical results of the analysis of the diffraction pattern of the heat-accumulating material after 100 heating and cooling cycles.

Figure 6.

Diffraction pattern of heat-accumulating material after 100 heating and cooling cycles: 1—experimental curve, 2—crystalline peaks, 3—amorphous phase.

The analysis of the results in Table 4 makes it possible to state that the degree of crystallinity of the heat-accumulating material naturally decreases with an increase in the number of heating and cooling cycles. The height of crystalline peaks and the crystallite size also decrease. The peak positions do not shift significantly depending on the number of heating and cooling cycles, which indicates the unchanged crystal structure of the material.

Table 4.

The results of parameter calculations of the crystalline peaks and the amorphous phase of the heat-accumulating material obtained from metallized polyethylene granules as well as the amount of heat accumulated in 1 kg of polyethylene.

The most intense decrease in the degree of crystallinity is observed in the range of 100–400 heating and cooling cycles. The general decrease in the degree of crystallinity is about 2.5 times and is quite significant. The experimental conditions included heating the material to a temperature of about 270 °C, which is approximately 150 °C higher than the melting point of polyethylene. Considering the low thermal stability of organic polymers, heating to high temperatures will lead to thermal destruction of macromolecules, their possible recombination, and cross-linking. The formation of a new structure characterized by defects will complicate the close packing of macromolecules, which will cause a decrease in the degree of crystallinity.

Such a decrease in the crystallinity of polyethylene will naturally affect the efficiency change of the heat-accumulating material usage. To estimate the amount of heat that could be accumulated in the material, it is necessary to calculate the content of the amorphous and crystalline polymer phases.

For a material that does not undergo phase transitions during heating, the amount of stored energy can be calculated following the formula:

where Cp is the specific heat capacity of polyethylene (we will take the average value of the heat capacity in the solid and molten state), and ΔT is the difference between the initial and final heating temperatures (25 and 270 °C, respectively).

Q = Cp · ΔT

The crystalline phase of polyethylene during heating undergoes phase changes and the amount of stored energy will be calculated by the formula:

where ΔH is the enthalpy of phase transition of polyethylene (218 kJ/kg), CpS and CpL—heat capacity of polyethylene in solid and liquid states (2.3 and 2.512 kJ/(kg∙K) respectively), t0—initial heating temperature, tmt—melting temperature of polyethylene (127 °C), tft—final heating temperature.

QC = CpS (tmt − t0) ΔH + CpL (tft − tmt)

To calculate the total amount of heat which polyethylene can accumulate during its heating, it is necessary to take into account the share of heat that will accumulate in the material as a result of the phase transition:

QPE = Q + (QC · SC)

The results of the calculation are shown in Table 4. It can be argued that the amount of heat which the material can accumulate depends on the crystallinity degree and decreases with it.

4. Conclusions

Thus, it can be stated that the heat-accumulating material obtained from the metallized polyethylene granules at the initial stage of operation is characterized by a high degree of crystallinity, which is promising in terms of the possibility of accumulating thermal energy due to the latent heat of phase transition. During the process of cyclic heating and cooling, the degree of crystallinity decreases with high intensity, which is caused by extreme heating temperatures for polyethylene. The results obtained show that the crystal structure of polyethylene does not change during cyclic heating and cooling. The proposed heat-accumulating material has prospects for practical use. However, it is necessary to limit the maximum heating temperature of the material for continuous operation.

Author Contributions

Conceptualization, V.M., A.K., M.K. and L.D.; methodology, V.M., M.K. and L.D.; software, V.M., A.K., M.K.; validation, V.M., A.K., M.K., L.D. and E.S.; formal analysis, V.M., M.K., L.D. and E.S.; investigation, V.M., A.K. and M.K.; resources, V.M., L.D.; data curation, V.M., L.D. and E.S.; writing—original draft preparation, V.M., A.K., M.K., L.D. and E.S.; writing—review and editing, V.M., A.K., M.K., L.D. and E.S.; visualization, V.M., A.K. and L.D.; supervision, V.M., L.D. and E.S.; project administration, V.M. and L.D.; funding acquisition, L.D. and E.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by projects APVV-21-0418 and 018TUKE-4/2024 granted by The Ministry of Education, Science, Research and Sport of the Slovak Republic.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Mourad, A.; Aissa, A.; Said, Z.; Younis, O.; Iqbal, M.; Alazzam, A. Recent advances on the applications of phase change materials for solar collectors, practical limitations, and challenges: A critical review. J. Energy Storage 2022, 49, 104186. [Google Scholar] [CrossRef]

- Deng, Z.; Nian, Y.; Liu, Q.; Cheng, W.L. Numerical analysis of borehole heat exchanger using a single shape-stabilized phase change material in heating and cooling seasons. J. Energy Storage 2023, 70, 107897. [Google Scholar] [CrossRef]

- Lin, S.; Ling, Z.; Li, S.; Cai, C.; Zhang, Z.; Fang, X. Mitigation of lithium-ion battery thermal runaway and inhibition of thermal runaway propagation using inorganic salt hydrate with integrated latent heat and thermochemical storage. Energy 2023, 266, 126481. [Google Scholar] [CrossRef]

- Duquesne, M.; Godin, A.; Palomo del Barrio, E.; Achchaq, F. Crystal growth kinetics of sugar alcohols as phase change materials for thermal energy storage. Energy Procedia 2017, 139, 315–321. [Google Scholar] [CrossRef]

- Shao, X.F.; Yang, S.; Shi, H.Y.; Fan, L.W.; Yuan, Y.P. A comprehensive evaluation on the cycling stability of sugar alcohols for medium-temperature latent heat storage. J. Energy Storage 2023, 64, 107190. [Google Scholar] [CrossRef]

- Cao, L.; Tang, Y.; Fang, G. Preparation and properties of shape-stabilized phase change materials based on fatty acid eutectics and cellulose composites for thermal energy storage. Energy 2015, 80, 98–103. [Google Scholar] [CrossRef]

- Nosova, N.; Roiter, Y.; Samaryk, V.; Varvarenko, S.; Stetsyshyn, Y.; Minko, S.; Stamm, M.; Voronov, S. Polypropylene surface peroxidation with heterofunctional polyperoxides. Macromol. Symp. 2004, 210, 339–348. [Google Scholar] [CrossRef]

- Zhao, M.; Yang, R. N-octanoic acid-based phase change composites synthesized by absorption polymerization for efficient thermal energy storage. J. Energy Storage 2023, 64, 107169. [Google Scholar] [CrossRef]

- Zauner, C.; Hengstberger, F.; Etzel, M.; Lager, D.; Hofmann, R.; Walter, H. Experimental characterization and simulation of a fin-tube latent heat storage using high density polyethylene as PCM. Appl. Energy 2016, 179, 237–246. [Google Scholar] [CrossRef]

- Malovanyy, M.S.; Synelnikov, S.D.; Nagurskiy, O.A.; Soloviy, K.M.; Tymchuk, I.S. Utilization of sorted secondary PET waste-raw materials in the context of sustainable development of the modern city. In IOP Conference Series: Materials Science and Engineering, Innovative Technology in Architecture and Design (ITAD 2020), Kharkiv, Ukraine, 21–22 May 2020; IOP Publishing: Bristol, UK, 2020; p. 012067. [Google Scholar] [CrossRef]

- Nagurskyy, O.; Krylova, H.; Vasiichuk, V.; Kachan, S.; Dziurakh, Y.; Nahursky, A.; Paraniak, N. Safety Usage of Encapsulated Mineral Fertilizers Based on Polymeric Waste. Ecol. Eng. Environ. Technol. 2022, 23, 156–161. [Google Scholar] [CrossRef]

- Nagurskyy, O.; Krylova, H.; Vasiichuk, V.; Kachan, S.; Nahursky, A.; Paraniak, N.; Sabadash, V.; Malovanyy, M. Utilization of Household Plastic Waste in Technologies with Final Biodegradation. Ecol. Eng. Environ. Technol. 2022, 23, 94–100. [Google Scholar] [CrossRef] [PubMed]

- Moravskyi, V.; Kucherenko, A.; Kuznetsova, M.; Dulebova, L.; Spišák, E.; Majerníková, J. Utilization of Polypropylene in the Production of Metal-Filled Polymer Composites: Development and Characteristics. Materials 2020, 13, 2856. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Sun, B.G.; Zheng, X.B.; Singh, P.K.; Ayed, H.; Mouldi, A.; Mohamed, A.; Mehrez, S. Investigation on effect of connection angle of “L” shaped fin on charging and discharging process of PCM in vertical enclosure. Case Stud. Therm. Eng. 2022, 33, 101908. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, Z.; Li, P.; Qin, H.; Heng, W. Multi-parameter heat transfer analysis of molten PCM in an inclined enclosure. Appl. Therm. Eng. 2022, 208, 118209. [Google Scholar] [CrossRef]

- Chaichan, M.T.; Kazem, H.A.; Al-Waeli, A.; Sopian, K. Controlling the melting and solidification points temperature of PCMs on the performance and economic return of the water-cooled photovoltaic thermal system. Sol. Energy 2021, 224, 1344–1357. [Google Scholar] [CrossRef]

- Teja, P.; Gugulothu, S.K.; Reddy, P.; Deepanraj, B.; Sundar, L.S. Computational investigation of the influencing parameters on the melting of phase change material in a square enclosure with built in fin and Al2O3 nanoparticles. Appl. Therm. Eng. 2023, 232, 120942. [Google Scholar] [CrossRef]

- Zheng, S.; Li, S.; Li, M.; Dai, R.; Wei, M.; Tian, R. Experimental and numerical investigation of a rectangular finned-tube latent heat storage unit for Carnot battery. J. Energy Storage 2023, 71, 108092. [Google Scholar] [CrossRef]

- Wang, Z.; Diao, Y.; Zhao, Y.; Chen, C.; Wang, T.; Liang, L. Experimental and numerical studies of thermal transport in a latent heat storage unit with a plate fin and a flat heat pipe. Energy 2023, 275, 127464. [Google Scholar] [CrossRef]

- Sharma, A.; Pitchumani, R.; Chauhan, R. Melting and solidification performance investigation of latent heat storage unit designs for low-temperature solar thermal applications. J. Energy Storage 2023, 66, 107323. [Google Scholar] [CrossRef]

- Diao, Y.; Wang, Z.; Zhao, Y.; Wang, Z.; Chen, C.; Zhang, D. Heat transfer enhancement of a multichannel flat tube-copper foam latent heat storage unit. Appl. Therm. Eng. 2023, 229, 120559. [Google Scholar] [CrossRef]

- Shen, Y.; Liu, S.; Mazhar, A.R.; Wang, J.; Li, Y. Phase change materials embedded with tuned porous media to alleviate overcharging problem of cascaded latent heat storage system for building heating. Energy Build. 2023, 281, 112746. [Google Scholar] [CrossRef]

- Zhu, R.; Jing, D. Numerical study on thermal and melting performances of a horizontal latent heat storage unit with branched tree-like convergent fins. J. Energy Storage 2023, 62, 106889. [Google Scholar] [CrossRef]

- Sharma, A.; Ding, C.; Kim, S.C.; Chauhan, R. Investigation and optimization of solidification performance of concentration tube type latent heat storage unit with herringbone wavy fin designs. Appl. Therm. Eng. 2023, 222, 119924. [Google Scholar] [CrossRef]

- Zhang, C.; Ma, Z.; Qu, Z.; Xu, H.; Yang, Q. Numerical energy and exergy evaluation for a multiple-layer latent heat storage unit enhanced with nanoparticles under different seasons. J. Clean. Prod. 2023, 417, 138098. [Google Scholar] [CrossRef]

- Lauermannová, A.M.; Lojka, M.; Záleská, M.; Pavlíková, M.; Pivák, A.; Pavlík, Z.; Růžička, K.; Jankovský, O. Magnesium oxychloride cement-based composites for latent heat storage: The effect of the introduction of multi-walled carbon nanotubes. J. Build. Eng. 2023, 72, 106604. [Google Scholar] [CrossRef]

- Yu, D.; Qiu, Y.; Zhang, X. Role of nano-copper in discharging performance of latent heat storage unit. Int. Commun. Heat Mass Transf. 2023, 144, 106748. [Google Scholar] [CrossRef]

- Moravskyi, V.; Kucherenko, A.; Kuznetsova, M.; Dulebova, L.; Spišák, E. Obtainment and characterization of metal-coated polyethylene granules as a basis for the development of heat storage systems. Polymers 2022, 14, 218. [Google Scholar] [CrossRef] [PubMed]

- White, J.L.; Choi, D.D. Polyolefins: Processing, Structure Development, and Properties; Carl Hanser Publishers: Munich, Germany, 2005; p. 271. [Google Scholar]

- Rabiej, M. Application of the particle swarm optimization method for the analysis of wide-angle X-ray diffraction curves of semicrystalline polymers. J. Appl. Crystallogr. 2017, 50, 221–230. [Google Scholar] [CrossRef]

- Rabiej, M. Application of a multicriterial optimization to the resolution of X-ray difraction curves of semicrystalline polymers. Polimery 2017, 62, 821–833. [Google Scholar] [CrossRef]

- Kucherenko, A.; Nikitchuk, O.; Dulebova, L.; Moravskyi, V. Activation of polyethylene granules by finely dispersed zinc. Chem. Technol. Appl. Subst. 2021, 4, 191–197. [Google Scholar] [CrossRef]

- Kucherenko, A.; Nikitchuk, O.; Baran, N.; Dulebova, L.; Kuznetsova, M.; Moravskyi, V. Characteristics of metallized polymeric raw materials. In Proceedings of the 11 International Conference on “Nanomaterials: Applications & Properties” (NAP-2021), Odesa, Ukraine, 5–11 September 2021. TM10. [Google Scholar] [CrossRef]

- Moravskyi, V.; Kucherenko, A.; Kuznetsova, M.; Dulebova, L.; Garbacz, T. Formation of copper coating on polymer granules by chemical method. In Proceedings of the 12 International Conference on “Nanomaterials: Applications & Properties” (NAP-2022), Krakow, Poland, 11–16 September 2022. MTFC13. [Google Scholar] [CrossRef]

- Moravskyi, V.; Kucherenko, A.; Kuznetsova, M.; Dziaman, I.; Grytsenko, O.; Dulebova, L. Studying the effect of concentration factors on the process of chemical metallization of powdered polyvinylchloride. East. -Eur. J. Enterp. Technol. 2018, 3, 40–47. [Google Scholar] [CrossRef][Green Version]

- Tadayyon, G.; Zebarjad, S.M.; Sajjadi, S.A. Effect of both nano-size alumina particles and severe deformation on polyethylene crystallinity index. J. Thermoplast. Compos. Mater. 2011, 25, 479–490. [Google Scholar] [CrossRef]

- WAXSFIT—Analysis of X-RAY Diffraction Curves; Version 1.0; Informer Technologies, Inc.: Los Angeles, CA, USA, 2020.

- Rabiej, M.; Rabiej, S. Application of the artificial neural network for identification of polymers based on their X-ray diffraction curves. Comput. Mater. Sci. 2021, 186, 110042. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).