Discovery and Classification of Defects on Facing Brick Specimens Using a Convolutional Neural Network

Abstract

:1. Introduction

- -

- application of the developed augmentation algorithm to increase the accumulated database of images of facing bricks [47];

- -

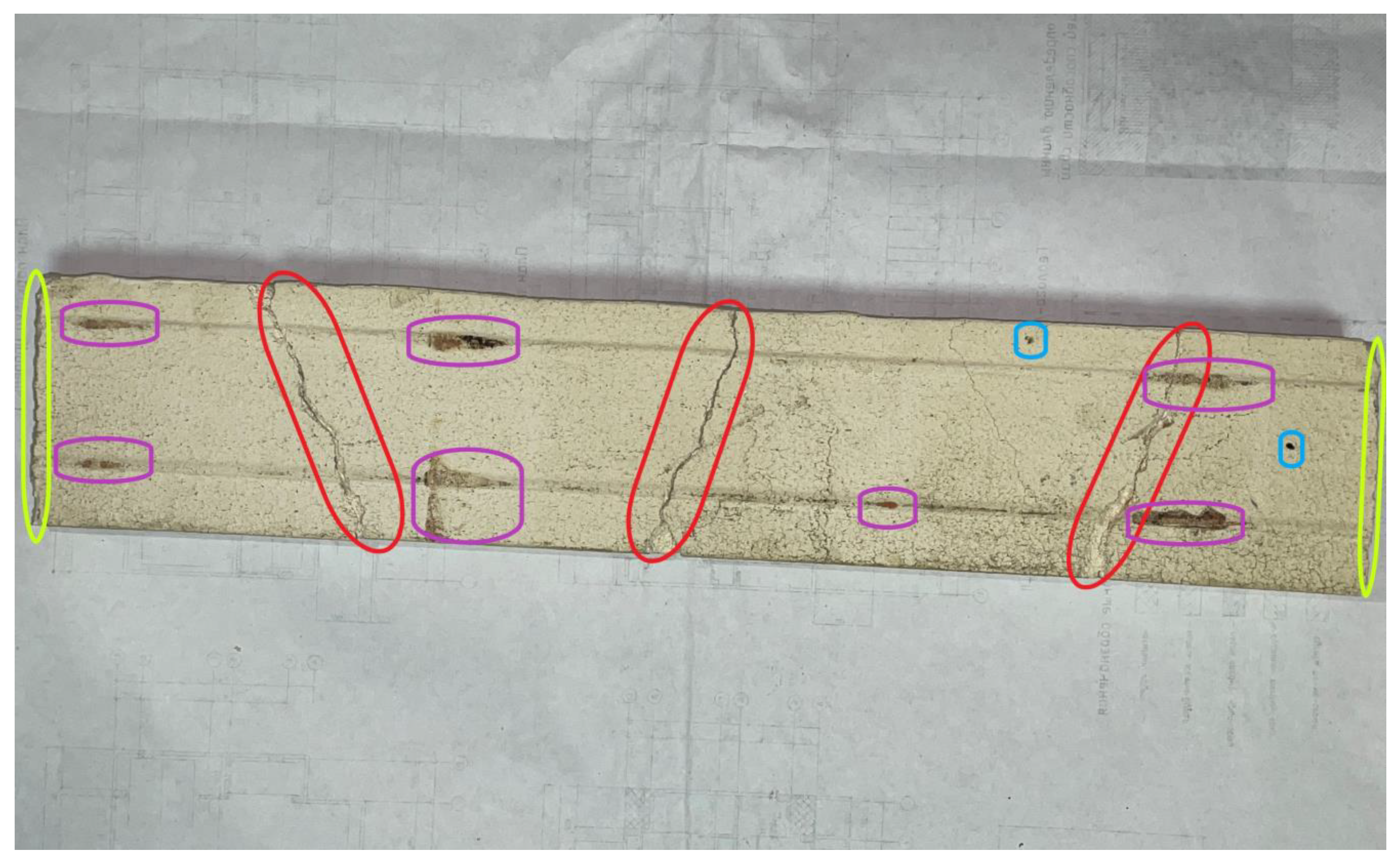

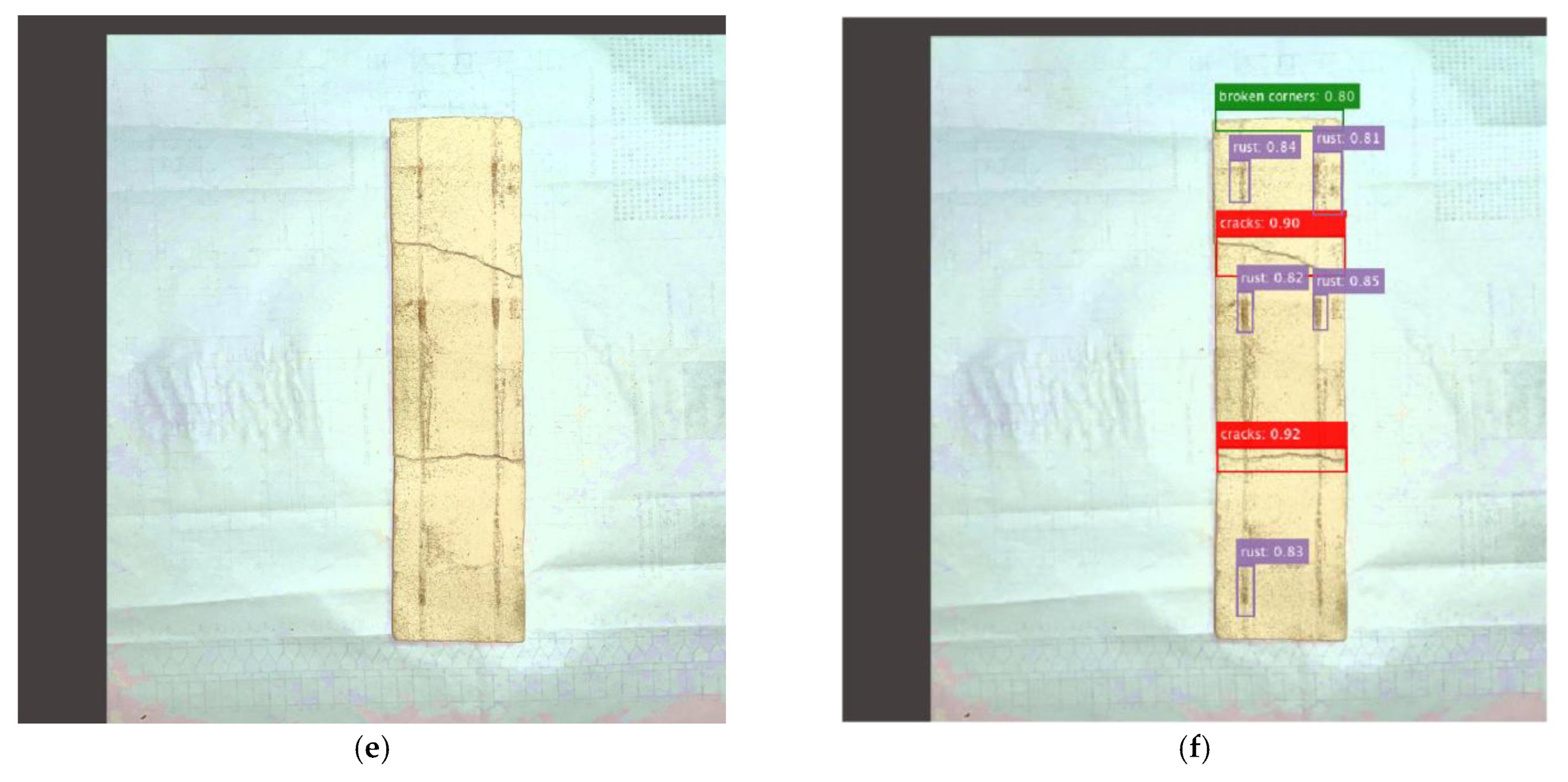

- development of an algorithm that allows the detection of foreign inclusions, broken corners, cracks, and uneven coloring, including the presence of rusty spots on facing bricks;

- -

- creation, optimization, and testing of the computer vision model based on the CNN YOLOv5s.

- -

- creating a database of images of facing brick samples;

- -

- substantiation and description of the selected YOLOv5s detector;

- -

- carrying out the process of augmentation to expand the training data set;

- -

- implementation, optimization, debugging, and testing of the algorithm using the CNN YOLOv5s;

- -

- determination of the quality of the metrics of the implemented model.

2. Materials and Methods

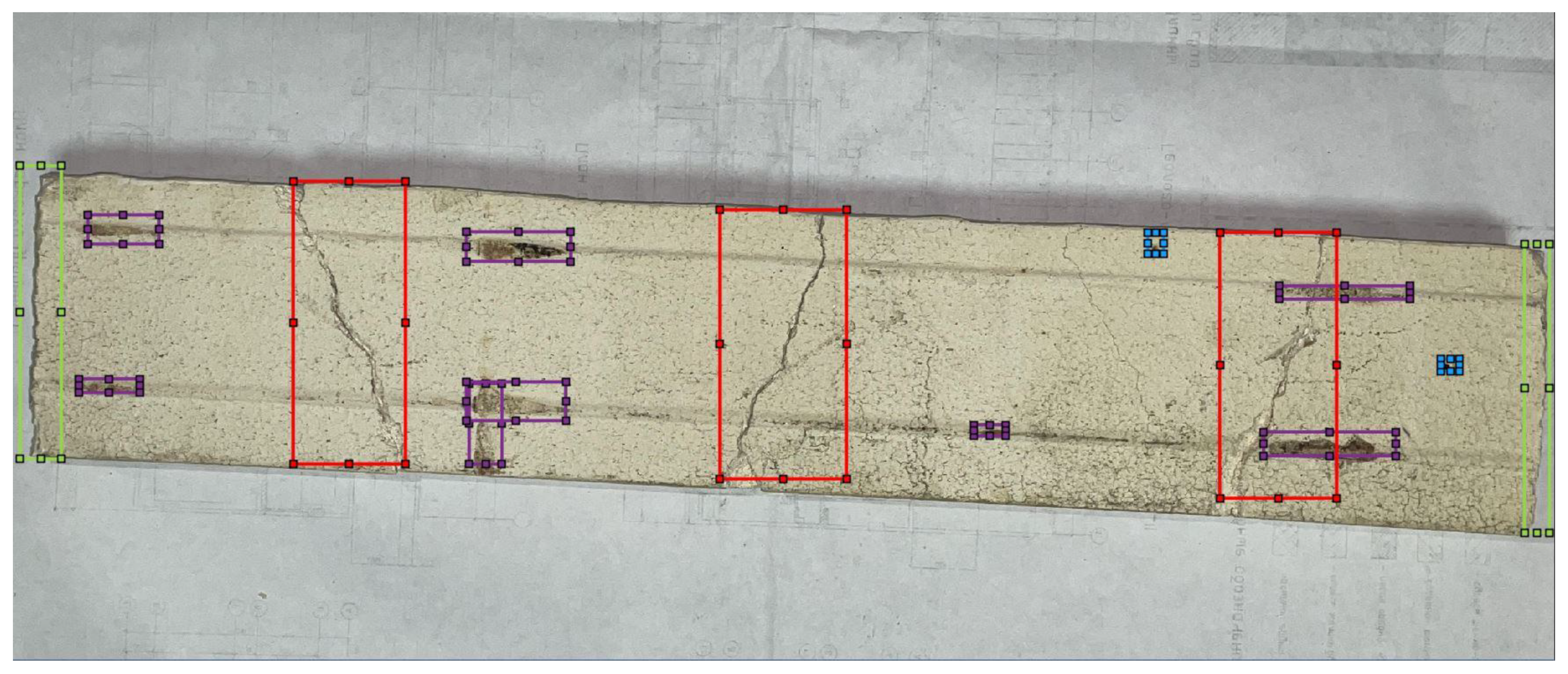

2.1. Markup and Image Augmentation

2.1.1. Image Markup

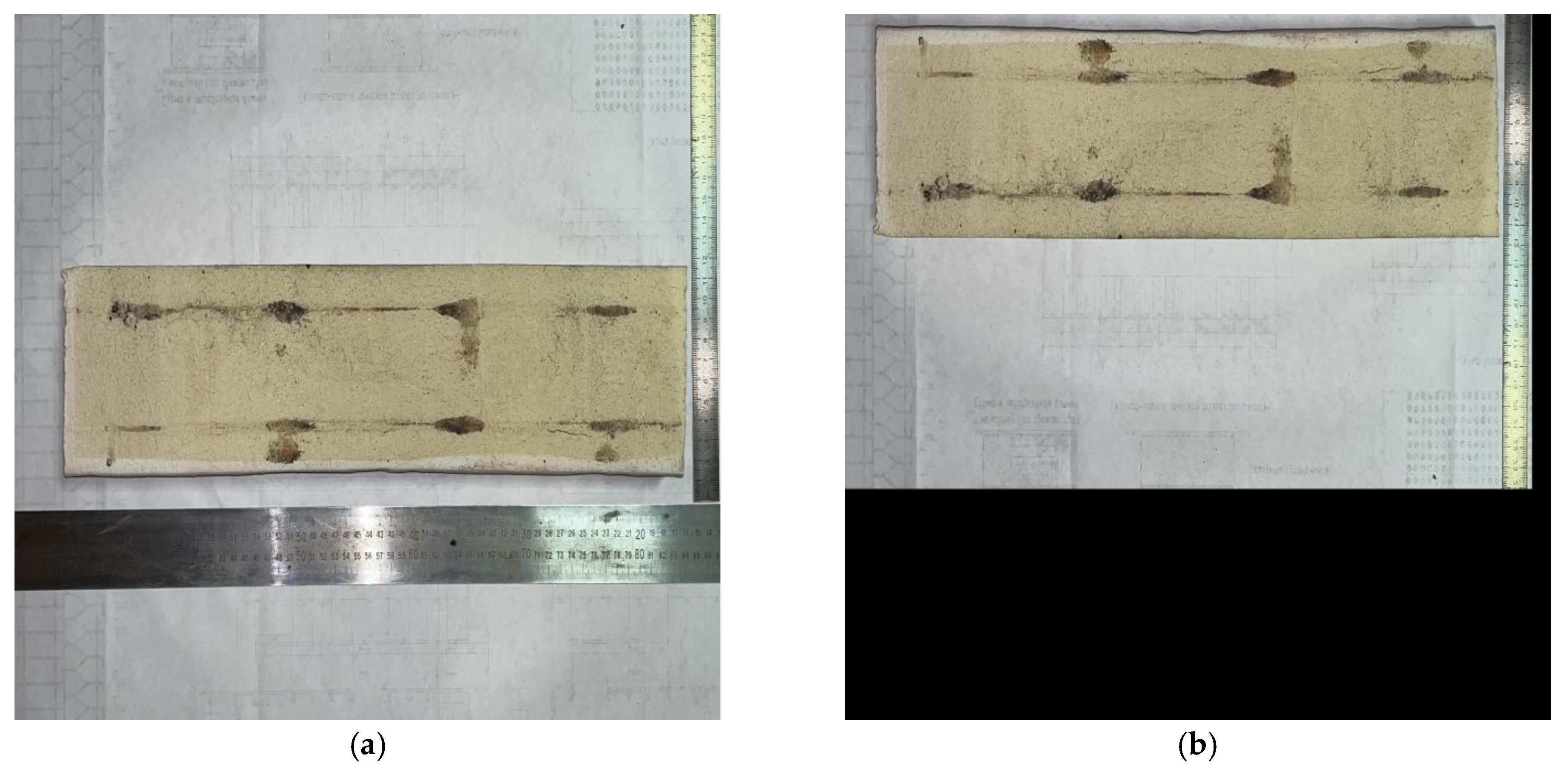

2.1.2. Image Augmentation

- Adding original photos without changes to the training set.

- Image representation horizontally and vertically.

- Shift of the original image by a random value along the Ox and Oy axes.

- Rotation of the image at angles: 90°, 180°, and 270°.

- Application of filters to change brightness, contrast, and saturation.

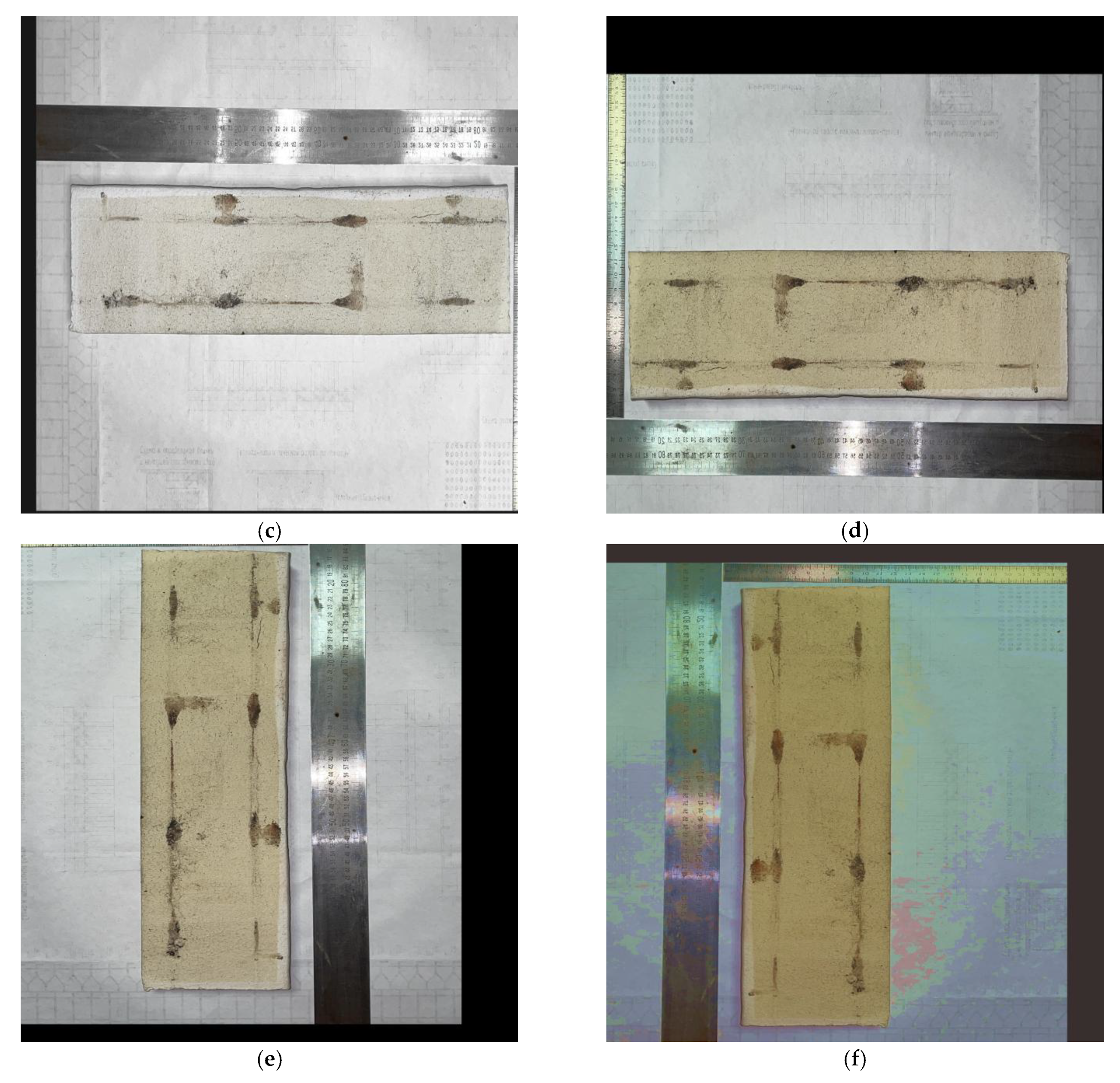

2.2. Development of an Intelligent Algorithm Based on the YOLOv5s Convolutional Neural Network

3. Results and Discussion

3.1. Description of Facing Brick

3.2. Implementation, Optimization, Debugging, and Testing of the Algorithm Using the CNN YOLOv5s

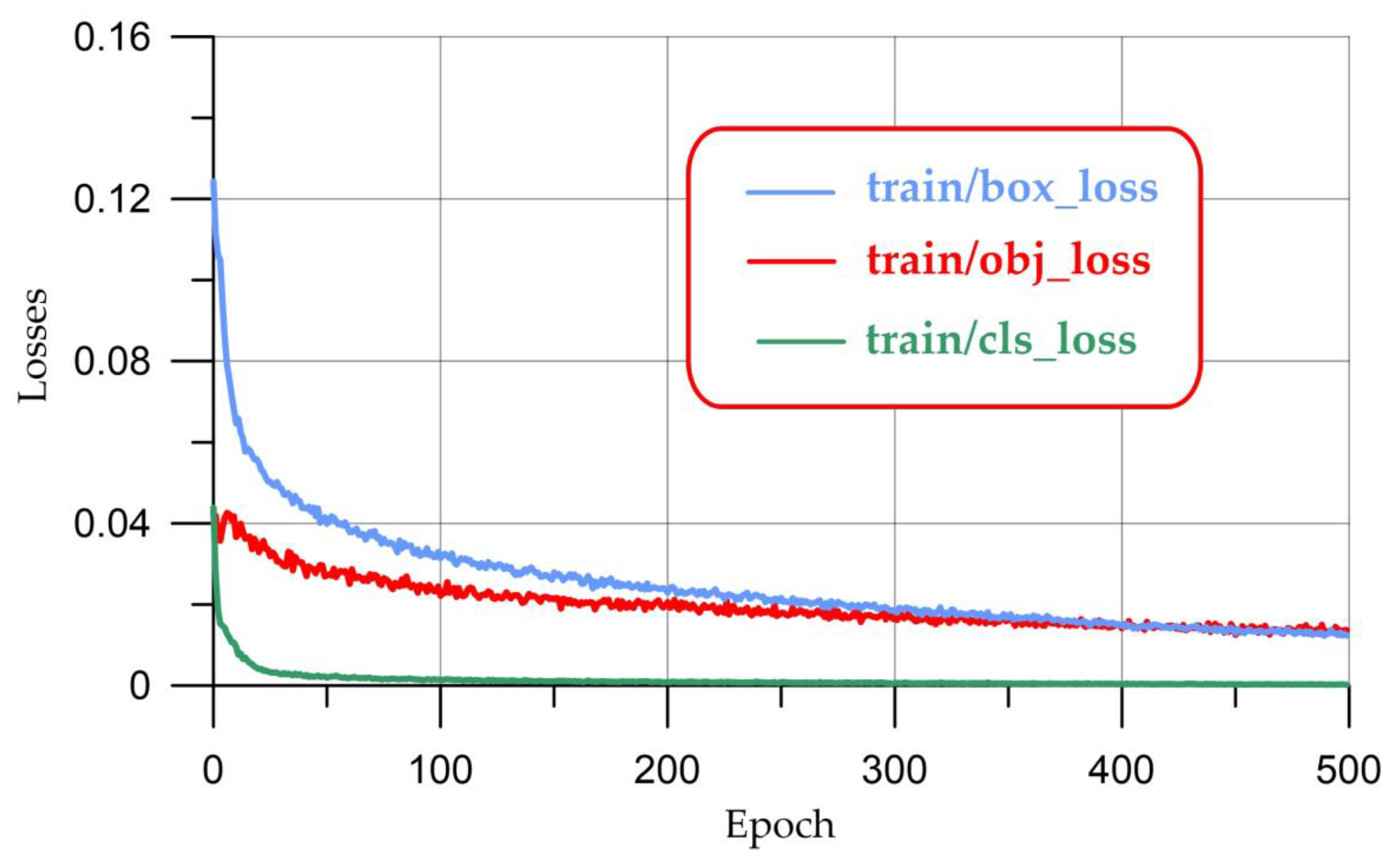

- -

- box_loss—loss of regression of the bounding box (root mean square error);

- -

- obj_loss—confidence in the presence of an object is a loss of objectivity;

- -

- cls_loss—classification loss (Cross Entropy).

4. Conclusions

- (1)

- An empirical database of images of facing bricks has been created, which has various violations of the structure and appearance which have arisen at the production stage during technological processing, packaging, transportation, and storage.

- (2)

- We developed, optimized, and tested a computer vision model based on the YOLOv5s convolutional neural network. By applying a custom augmentation algorithm, synthetic images were created for the training dataset. The application of the developed algorithm in practice became possible with the help of a model trained on its own set of data obtained by simulating the shooting conditions, the angle of rotation, object deformation, and light distortion by image processing methods.

- (3)

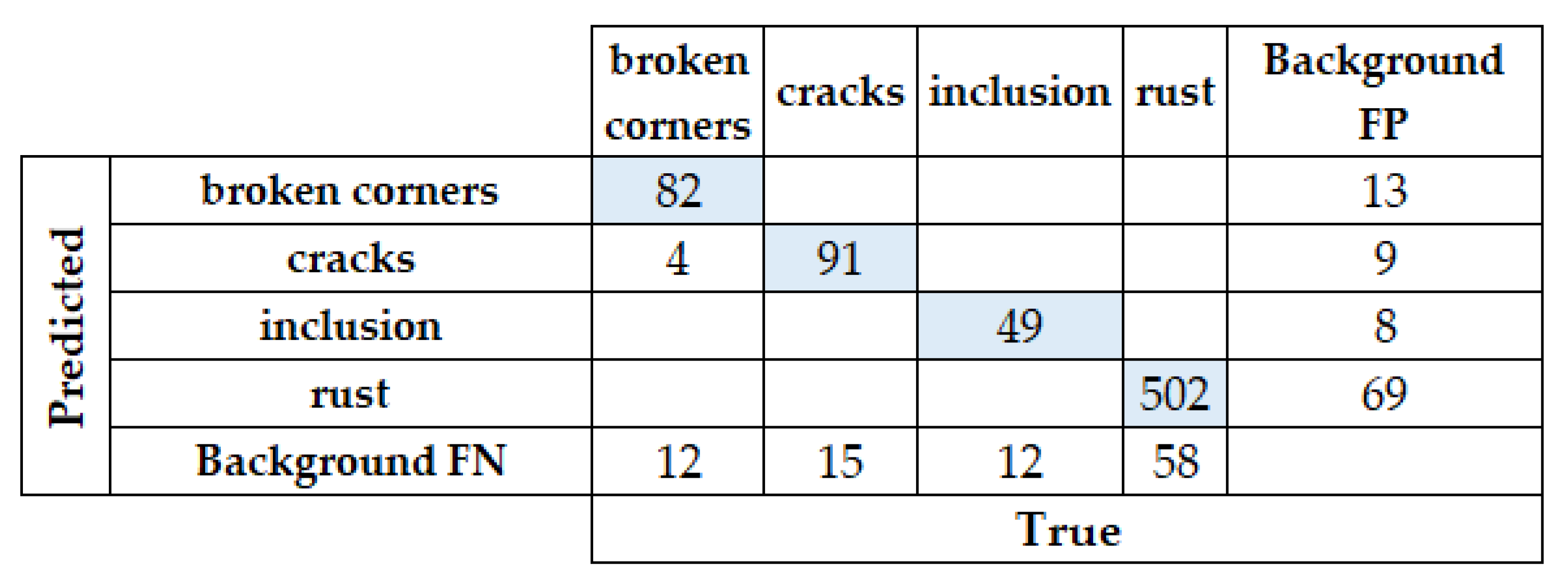

- The developed algorithm detects defects both in images taken under normal shooting conditions and in the presence of color/light distortions. In the work, it was taken into account that defects that are small in size can be missed by a specialist when marking and, therefore, will not be taken into account in the process of training a neural network. Careful markup of these objects is required, which was performed in this study, which made it possible to achieve an accuracy of mAP0.50 = 87% for the “inclusion” class.

- (4)

- The developed algorithm has a high accuracy in the problems of detection and classification of defects: mAP0.50 = 87% and mAP0.50:0.95 = 72%.

- (5)

- Behind the conclusion about the quality of products based on intelligent control, there is always a specialist who can adequately respond outside the machine protocol, taking into account the real factors of production, transportation, and storage of products.

5. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Beskopylny, A.; Lyapin, A.; Anysz, H.; Meskhi, B.; Veremeenko, A.; Mozgovoy, A. Artificial Neural Networks in Classification of Steel Grades Based on Non-Destructive Tests. Materials 2020, 13, 2445. [Google Scholar] [CrossRef]

- Peixoto, J.; Sousa, J.; Carvalho, R.; Santos, G.; Mendes, J.; Cardoso, R.; Reis, A. Development of an Analog Gauge Reading Solution Based on Computer Vision and Deep Learning for an IoT Application. Telecom 2022, 3, 564–580. [Google Scholar] [CrossRef]

- Hütten, N.; Meyes, R.; Meisen, T. Vision Transformer in Industrial Visual Inspection. Appl. Sci. 2022, 12, 11981. [Google Scholar] [CrossRef]

- Ai, D.; Xue, J.; Wang, M. Multiple-Parallel Morphological Anti-Aliasing Algorithm Implemented in FPGA. Telecom 2022, 3, 526–540. [Google Scholar] [CrossRef]

- Salem, T.; Dragomir, M. Digital Twins for Construction Projects—Developing a Risk Systematization Approach to Facilitate Anomaly Detection in Smart Buildings. Telecom 2023, 4, 135–145. [Google Scholar] [CrossRef]

- Hadi, M.U. Practical Demonstration of 5G NR Transport Over-Fiber System with Convolutional Neural Network. Telecom 2022, 3, 103–117. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Shcherban’, E.M.; Stel’makh, S.A.; Mailyan, L.R.; Meskhi, B.; Razveeva, I.; Kozhakin, A.; El’shaeva, D.; Beskopylny, N.; Onore, G. Detecting Cracks in Aerated Concrete Samples Using a Convolutional Neural Network. Appl. Sci. 2023, 13, 1904. [Google Scholar] [CrossRef]

- Jaber, A.; Sattarpanah Karganroudi, S.; Meiabadi, M.S.; Aminzadeh, A.; Ibrahim, H.; Adda, M.; Taheri, H. On Smart Geometric Non-Destructive Evaluation: Inspection Methods, Overview, and Challenges. Materials 2022, 15, 7187. [Google Scholar] [CrossRef]

- Ciaburro, G.; Iannace, G. Machine-Learning-Based Methods for Acoustic Emission Testing: A Review. Appl. Sci. 2022, 12, 10476. [Google Scholar] [CrossRef]

- Zhou, S.; Zeng, Y.; Li, S.; Zhu, H.; Liu, X.; Zhang, X. Surface Defect Detection of Rolled Steel Based on Lightweight Model. Appl. Sci. 2022, 12, 8905. [Google Scholar] [CrossRef]

- Yang, L.; Huang, X.; Ren, Y.; Huang, Y. Steel Plate Surface Defect Detection Based on Dataset Enhancement and Lightweight Convolution Neural Network. Machines 2022, 10, 523. [Google Scholar] [CrossRef]

- Guo, Z.; Wang, C.; Yang, G.; Huang, Z.; Li, G. MSFT-YOLO: Improved YOLOv5 Based on Transformer for Detecting Defects of Steel Surface. Sensors 2022, 22, 3467. [Google Scholar] [CrossRef]

- Chen, F.; Deng, M.; Gao, H.; Yang, X.; Zhang, D. ACA-Net: An Adaptive Convolution and Anchor Network for Metallic Surface Defect Detection. Appl. Sci. 2022, 12, 8070. [Google Scholar] [CrossRef]

- Gillich, N.; Tufisi, C.; Sacarea, C.; Rusu, C.V.; Gillich, G.-R.; Praisach, Z.-I.; Ardeljan, M. Beam Damage Assessment Using Natural Frequency Shift and Machine Learning. Sensors 2022, 22, 1118. [Google Scholar] [CrossRef]

- Yang, F.; Shi, D.; Lo, L.-Y.; Mao, Q.; Zhang, J.; Lam, K.-H. Auto-Diagnosis of Time-of-Flight for Ultrasonic Signal Based on Defect Peaks Tracking Model. Remote Sens. 2023, 15, 599. [Google Scholar] [CrossRef]

- Hu, J.; Qiao, P.; Lv, H.; Yang, L.; Ouyang, A.; He, Y.; Liu, Y. High Speed Railway Fastener Defect Detection by Using Improved YoLoX-Nano Model. Sensors 2022, 22, 8399. [Google Scholar] [CrossRef]

- Wei, D.; Wei, X.; Jia, L. Automatic Defect Description of Railway Track Line Image Based on Dense Captioning. Sensors 2022, 22, 6419. [Google Scholar] [CrossRef]

- Li, L.; Wang, Z.; Zhang, T. GBH-YOLOv5: Ghost Convolution with BottleneckCSP and Tiny Target Prediction Head Incorporating YOLOv5 for PV Panel Defect Detection. Electronics 2023, 12, 561. [Google Scholar] [CrossRef]

- Fu, Y.; Li, X.; Ma, X. Deep-Learning-Based Defect Evaluation of Mono-Like Cast Silicon Wafers. Photonics 2021, 8, 426. [Google Scholar] [CrossRef]

- Xu, S.; Deng, J.; Huang, Y.; Ling, L.; Han, T. Research on Insulator Defect Detection Based on an Improved MobilenetV1-YOLOv4. Entropy 2022, 24, 1588. [Google Scholar] [CrossRef]

- Zohra, F.T.; Salim, O.; Masoumi, H.; Karmakar, N.C.; Dey, S. Health Monitoring of Conveyor Belt Using UHF RFID and Multi-Class Neural Networks. Electronics 2022, 11, 3737. [Google Scholar] [CrossRef]

- Li, G.; Zhao, S.; Zhou, M.; Li, M.; Shao, R.; Zhang, Z.; Han, D. YOLO-RFF: An Industrial Defect Detection Method Based on Expanded Field of Feeling and Feature Fusion. Electronics 2022, 11, 4211. [Google Scholar] [CrossRef]

- Huang, C.-Y.; Lin, I.-C.; Liu, Y.-L. Applying Deep Learning to Construct a Defect Detection System for Ceramic Substrates. Appl. Sci. 2022, 12, 2269. [Google Scholar] [CrossRef]

- Yadav, D.P.; Kishore, K.; Gaur, A.; Kumar, A.; Singh, K.U.; Singh, T.; Swarup, C. A Novel Multi-Scale Feature Fusion-Based 3SCNet for Building Crack Detection. Sustainability 2022, 14, 16179. [Google Scholar] [CrossRef]

- Mo, D.-H.; Wu, Y.-C.; Lin, C.-S. The Dynamic Image Analysis of Retaining Wall Crack Detection and Gap Hazard Evaluation Method with Deep Learning. Appl. Sci. 2022, 12, 9289. [Google Scholar] [CrossRef]

- Teng, S.; Liu, Z.; Li, X. Improved YOLOv3-Based Bridge Surface Defect Detection by Combining High- and Low-Resolution Feature Images. Buildings 2022, 12, 1225. [Google Scholar] [CrossRef]

- Du, F.-J.; Jiao, S.-J. Improvement of Lightweight Convolutional Neural Network Model Based on YOLO Algorithm and Its Research in Pavement Defect Detection. Sensors 2022, 22, 3537. [Google Scholar] [CrossRef]

- Wang, W.; Su, C.; Fu, D. Automatic detection of defects in concrete structures based on deep learning. Structures 2022, 43, 192–199. [Google Scholar] [CrossRef]

- Islam, M.M.; Hossain, M.B.; Akhtar, M.N.; Moni, M.A.; Hasan, K.F. CNN Based on Transfer Learning Models Using Data Augmentation and Transformation for Detection of Concrete Crack. Algorithms 2022, 15, 287. [Google Scholar] [CrossRef]

- Park, M.J.; Kim, J.; Jeong, S.; Jang, A.; Bae, J.; Ju, Y.K. Machine Learning-Based Concrete Crack Depth Prediction Using Thermal Images Taken under Daylight Conditions. Remote Sens. 2022, 14, 2151. [Google Scholar] [CrossRef]

- Mailyan, L.R.; Stel’makh, S.A.; Shcherban’, E.M.; Khalyushev, A.K.; Smolyanichenko, A.S.; Sysoev, A.K.; Parinov, I.A.; Cherpakov, A.V. Investigation of Integral and Differential Characteristics of Variatropic Structure Heavy Concretes by Ultrasonic Methods. Appl. Sci. 2021, 11, 3591. [Google Scholar] [CrossRef]

- Meoni, A.; D’Alessandro, A.; Saviano, F.; Lignola, G.P.; Parisi, F.; Ubertini, F. Strain Monitoring and Crack Detection in Masonry Walls under In-Plane Shear Loading Using Smart Bricks: First Results from Experimental Tests and Numerical Simulations. Sensors 2023, 23, 2211. [Google Scholar] [CrossRef] [PubMed]

- Bartoň, V.; Dvořák, R.; Cikrle, P.; Šnédar, J. Predicting the Durability of Solid Fired Bricks Using NDT Electroacoustic Methods. Materials 2022, 15, 5882. [Google Scholar] [CrossRef] [PubMed]

- Khotiaintsev, S.; Timofeyev, V. Assessment of Cracking in Masonry Structures Based on the Breakage of Ordinary Silica-Core Silica-Clad Optical Fibers. Appl. Sci. 2022, 12, 6885. [Google Scholar] [CrossRef]

- Loverdos, D.; Sarhosis, V. Automatic image-based brick segmentation and crack detection of masonry walls using machine learning. Autom. Constr. 2022, 140, 104389. [Google Scholar] [CrossRef]

- Hallee, M.J.; Napolitano, R.K.; Reinhart, W.F.; Glisic, B. Crack Detection in Images of Masonry Using CNNs. Sensors 2021, 21, 4929. [Google Scholar] [CrossRef]

- Dang, L.M.; Wang, H.; Li, Y.; Nguyen, L.Q.; Nguyen, T.N.; Song, H.-K.; Moon, H. Deep learning-based masonry crack segmentation and real-life crack length measurement. Constr. Build. Mater. 2022, 359, 129438. [Google Scholar] [CrossRef]

- Ziying, M.; Shaolin, H.; Xiaomin, H.; Ye, K. Fine Crack Detection Algorithm Based on Improved SSD. Int. J. Data Sci. Technol. 2022, 8, 43–47. [Google Scholar] [CrossRef]

- Duragkar, A.; Guhe, S.; Sortee, A.; Singh, S.; Chandankhede, C. Comparison Between YOLOv5 and SSD for Pavement Crack Detection. Lect. Notes Netw. Syst. 2023, 520, 257–263. [Google Scholar] [CrossRef]

- Xu, X.; Zhao, M.; Shi, P.; Ren, R.; He, X.; Wei, X.; Yang, H. Crack Detection and Comparison Study Based on Faster R-CNN and Mask R-CNN. Sensors 2022, 22, 1215. [Google Scholar] [CrossRef]

- Rajadurai, R.-S.; Kang, S.-T. Automated Vision-Based Crack Detection on Concrete Surfaces Using Deep Learning. Appl. Sci. 2021, 11, 5229. [Google Scholar] [CrossRef]

- Stel’makh, S.A.; Shcherban’, E.M.; Beskopylny, A.N.; Mailyan, L.R.; Meskhi, B.; Razveeva, I.; Kozhakin, A.; Beskopylny, N. Prediction of Mechanical Properties of Highly Functional Lightweight Fiber-Reinforced Concrete Based on Deep Neural Network and Ensemble Regression Trees Methods. Materials 2022, 15, 6740. [Google Scholar] [CrossRef] [PubMed]

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Mailyan, L.R.; Meskhi, B.; Razveeva, I.; Chernil’nik, A.; Beskopylny, N. Concrete Strength Prediction Using Machine Learning Methods CatBoost, k-Nearest Neighbors, Support Vector Regression. Appl. Sci. 2022, 12, 10864. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Mailyan, L.R.; Stel’makh, S.A.; Shcherban’, E.M.; Razveeva, I.F.; Beskopylny, N.A.; Dotsenko, N.A.; El’shaeva, D.M. The Program for Determining the Mechanical Properties of Highly Functional Lightweight Fiber-Reinforced Concrete Based on Artificial Intelligence Methods. Russian Federation Computer Program 2022668999. 14 October 2022. Available online: https://www.fips.ru/registers-doc-view/fips_servlet?DB=EVM&DocNumber=2022668999&TypeFile=html (accessed on 7 March 2023).

- Demidchik, N.N.; Tulepbergenov, D.B.; Kintonova, A.Z.; Glazyrina, N.S.; Furayeva, I.I.; Senkovskaya, A.A. Using Yolo for Mask Recognition. In Proceedings of the 2022 International Conference on Smart Information Systems and Technologies (SIST), Nur-Sultan, Kazakhstan, 28–30 April 2022. [Google Scholar]

- Dlužnevskij, D.; Stefanovič, P.; Ramanauskaitė, S. Investigation of YOLOv5 Efficiency in iPhone Supported Systems. Baltic J. Modern Computing 2021, 9, 333–344. [Google Scholar] [CrossRef]

- Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M.; Razveeva, I.F.; Kozhakin, A.N.; Beskopylny, N.A.; Onore, G.S. Image Augmentation Program. Russian Federation Computer Program 2022685192. 21 December 2022. Available online: https://www.fips.ru/registers-doc-view/fips_servlet?DB=EVM&DocNumber=2022685192&TypeFile=html (accessed on 7 March 2023).

- Wang, H.; Lin, Y.; Xu, X.; Chen, Z.; Wu, Z.; Tang, Y. A Study on Long-Close Distance Coordination Control Strategy for Litchi Picking. Agronomy 2022, 12, 1520. [Google Scholar] [CrossRef]

- Zhu, L.; Geng, X.; Li, Z.; Liu, C. Improving YOLOv5 with Attention Mechanism for Detecting Boulders from Planetary Images. Remote Sens. 2021, 13, 3776. [Google Scholar] [CrossRef]

- EN 771-1:2011+A1:2015 Specification for Masonry Units—Part 1: Clay Masonry Units. Available online: https://standards.iteh.ai/catalog/standards/cen/c5c16e11-db44-4a0f-9c98-f94f78ffb7c8/en-771-1-2011a1-2015 (accessed on 24 April 2023).

- EN 771-2:2011+A1:2015 Specification for Masonry Units—Part 2: Calcium Silicate Masonry Units. Specifications. Available online: https://standards.iteh.ai/catalog/standards/cen/820e5c2e-548e-4ca6-8123-6e069f095b96/en-771-2-2011a1-2015 (accessed on 24 April 2023).

- Ali, S.B.; Wate, R.; Kujur, S.; Singh, A.; Kumar, S. Wall Crack Detection Using Transfer Learning-based CNN Models. In Proceedings of the 2020 IEEE 17th India Council International Conference (INDICON), New Delhi, India, 10–13 December 2020. [Google Scholar]

- Vrochidou, E.; Sidiropoulos, G.; Ouzounis, A.; Lampoglou, A.; Tsimperidis, I.; Papakostas, G.; Sarafis, I.; Kalpakis, V.; Stamkos, A. Towards Robotic Marble Resin Application: Crack Detection on Marble Using Deep Learning. Electronics 2022, 11, 3289. [Google Scholar] [CrossRef]

- Piyathilaka, L.; Preethichandra, D.M.G.; Izhar, U.; Kahandawa, G. Real-Time Concrete Crack Detection and Instance Segmentation using Deep Transfer Learning. Eng. Proc. 2020, 2, 91. [Google Scholar] [CrossRef]

| Num | Parameter | Value |

|---|---|---|

| 1 | Number of images in the training set | 300 (60%) |

| 2 | Number of images in the validation set | 100 (20%) |

| 3 | Number of images in the test set | 100 (20%) |

| 4 | BatchSize | 10 |

| 5 | Number of epochs | 500 |

| 6 | Number of iterations | 5000 |

| 7 | Learning rate | 0.01 |

| 8 | Solver | Stochastic gradient descent |

| Num | Parameter | Instances | mAP0.50 | mAP0.50:0.95 |

|---|---|---|---|---|

| 1 | all | 825 | 0.87 | 0.72 |

| 2 | broken corners | 98 | 0.84 | 0.68 |

| 3 | cracks | 106 | 0.89 | 0.84 |

| 4 | inclusion | 61 | 0.86 | 0.60 |

| 5 | rust | 560 | 0.88 | 0.77 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Beskopylny, A.N.; Shcherban’, E.M.; Stel’makh, S.A.; Mailyan, L.R.; Meskhi, B.; Razveeva, I.; Kozhakin, A.; El’shaeva, D.; Beskopylny, N.; Onore, G. Discovery and Classification of Defects on Facing Brick Specimens Using a Convolutional Neural Network. Appl. Sci. 2023, 13, 5413. https://doi.org/10.3390/app13095413

Beskopylny AN, Shcherban’ EM, Stel’makh SA, Mailyan LR, Meskhi B, Razveeva I, Kozhakin A, El’shaeva D, Beskopylny N, Onore G. Discovery and Classification of Defects on Facing Brick Specimens Using a Convolutional Neural Network. Applied Sciences. 2023; 13(9):5413. https://doi.org/10.3390/app13095413

Chicago/Turabian StyleBeskopylny, Alexey N., Evgenii M. Shcherban’, Sergey A. Stel’makh, Levon R. Mailyan, Besarion Meskhi, Irina Razveeva, Alexey Kozhakin, Diana El’shaeva, Nikita Beskopylny, and Gleb Onore. 2023. "Discovery and Classification of Defects on Facing Brick Specimens Using a Convolutional Neural Network" Applied Sciences 13, no. 9: 5413. https://doi.org/10.3390/app13095413

APA StyleBeskopylny, A. N., Shcherban’, E. M., Stel’makh, S. A., Mailyan, L. R., Meskhi, B., Razveeva, I., Kozhakin, A., El’shaeva, D., Beskopylny, N., & Onore, G. (2023). Discovery and Classification of Defects on Facing Brick Specimens Using a Convolutional Neural Network. Applied Sciences, 13(9), 5413. https://doi.org/10.3390/app13095413