Substitution of Pork Fat with Beeswax-Structured Oleogels in Semi-Smoked Sausages

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methodology

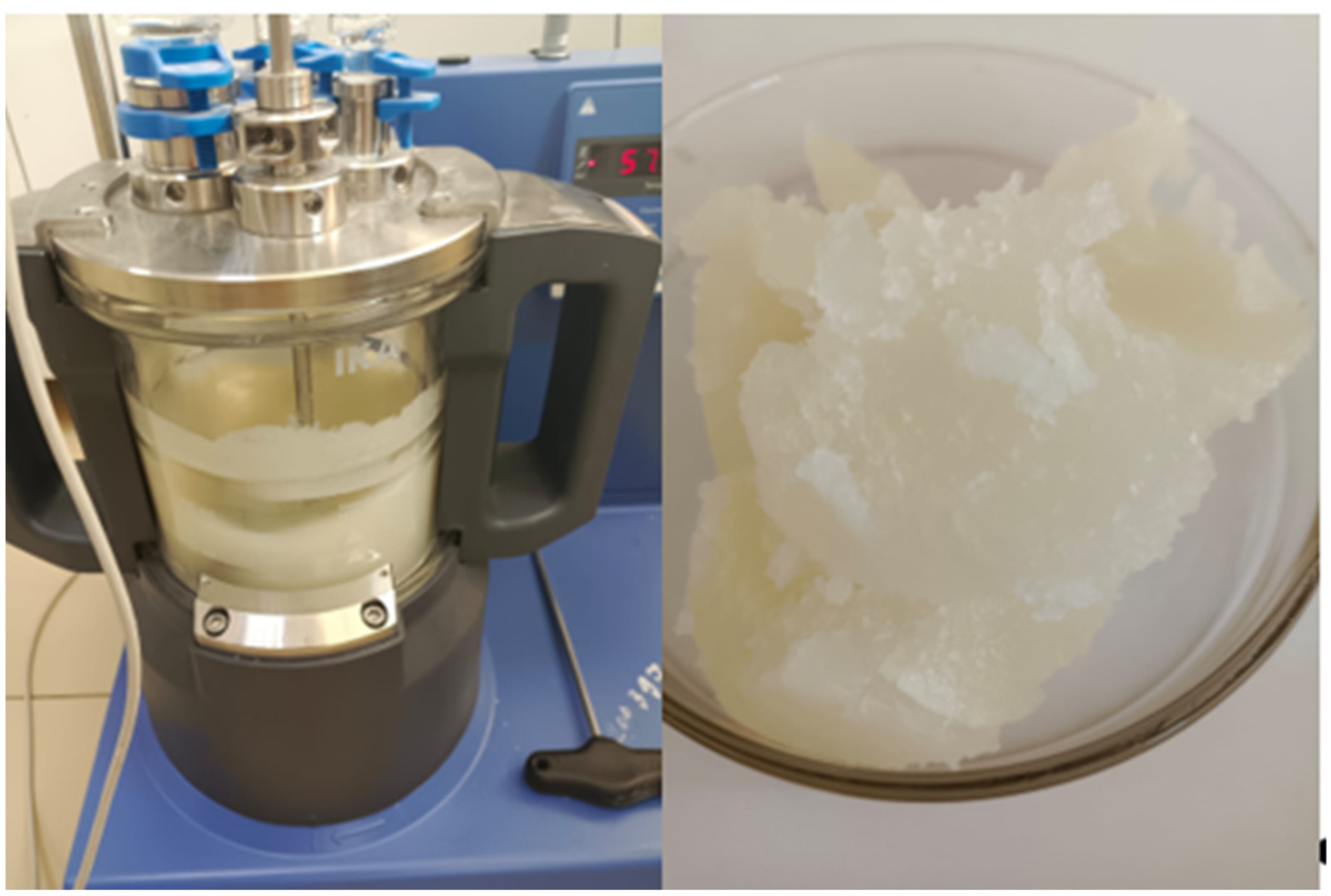

2.2.1. Oleogel Preparation

2.2.2. Sausage Preparation

2.2.3. Physicochemical Parameters and pH

2.2.4. Fatty Acid Determination

2.2.5. Microstructure Analysis

2.2.6. Sensory Analysis

2.2.7. Statistical Analysis

3. Results and Discussion

3.1. Physicochemical Characteristics of Semi-Smoked Sausages

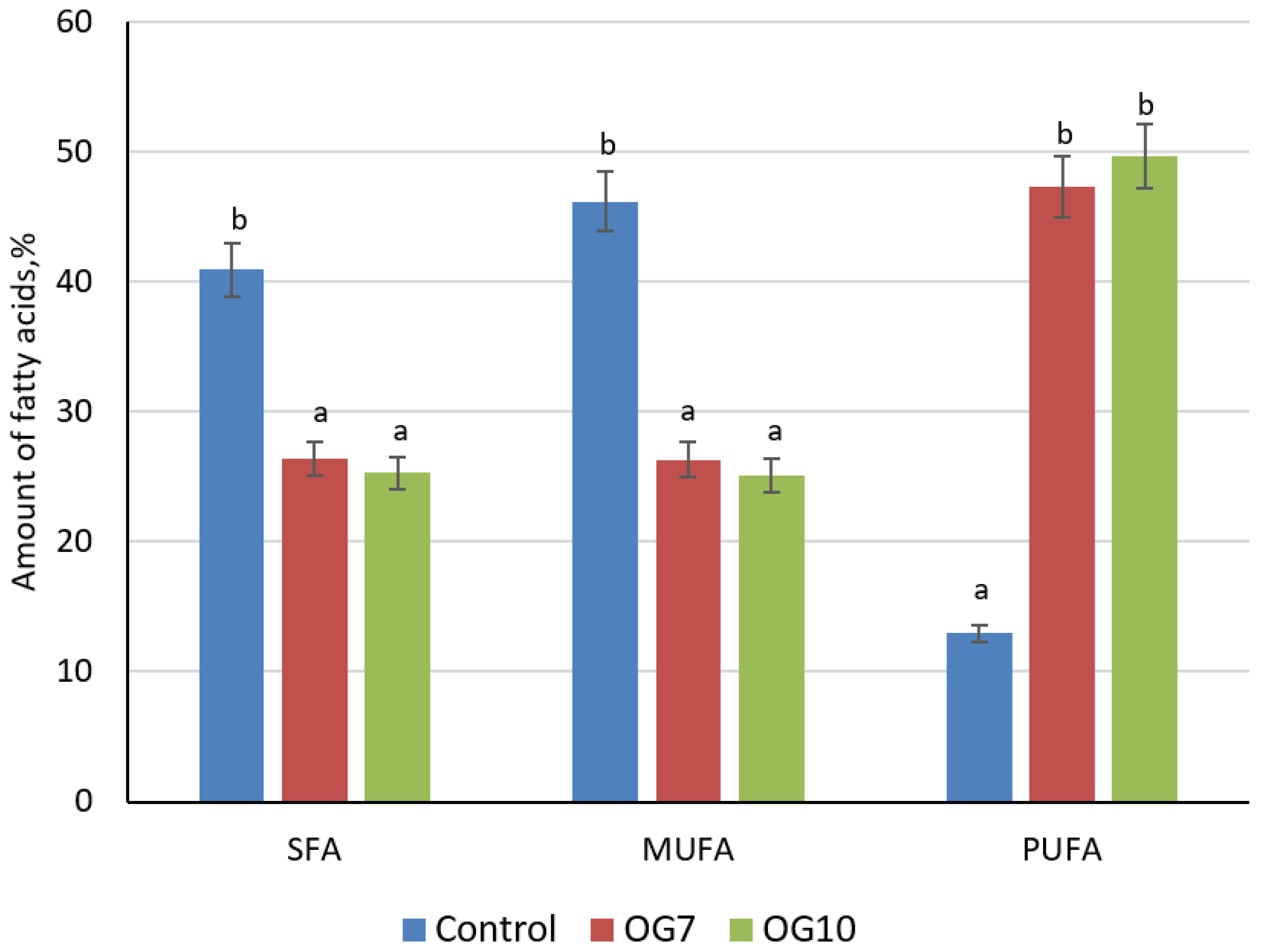

3.2. Fatty Acid Composition of Semi-Smoked Sausages

3.3. Microstructure of Semi-Smoked Sausages

3.4. Sensory Characteristics of Semi-Smoked Sausages

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nacak, B.; Öztürk-Kerimoğlu, B.; Yıldız, D.; Çağındı, Ö.; Serdaroğlu, M. Peanut and linseed oil emulsion gels as potential fat replacer in emulsified sausages. Meat Sci. 2021, 176, 108464. [Google Scholar] [CrossRef] [PubMed]

- Chomanov, U.; Kenenbay, G.; Tursynov, A.; Zhumalieva, T.; Tultabayev, N.; Suychinov, A. Nutritive profile of canned goat meat food with added carrot. Appl. Sci. 2022, 12, 9911. [Google Scholar] [CrossRef]

- Pehlivanoglu, H.; Demirci, M.; Toker, O.S.; Konar, N.; Karasu, S.; Sagdic, O. Oleogels, a promising structured oil for decreasing saturated fatty acid concentrations: Production and food-based applications. Crit. Rev. Food Sci. Nutr. 2018, 58, 1330–1341. [Google Scholar] [CrossRef] [PubMed]

- Bascuas, S.; Morell, P.; Hernando, I.; Quiles, A. Recent trends in oil structuring using hydrocolloids. Food Hydrocoll. 2021, 118, 106612. [Google Scholar] [CrossRef]

- World Health Organization (WHO). Draft Guidelines on Saturated Fatty Acid and Trans-Fatty Acid Intake for Adults and Children. 2018. Available online: https://extranet.who.int/dataform/upload/surveys/666752/files/Draft%20WHO%20SFATFA%20guidelines_04052018%20Public%20Consultation(1).pdf (accessed on 8 February 2023).

- WHO. Global Initiative on Diet, Physical Activity and Health; World Health Organization: Geneva, Switzerland, 2013; Available online: http://www.who.int/gho/ncd/risk_factors/unhealthy_diet_text/en/ (accessed on 8 February 2023).

- Grasso, S.; Brunton, N.P.; Lyng, J.G.; Lalor, F.; Monahan, F.J. Healthy processed meat products—Regulatory, reformulation and consumer challenges. Trends Food Sci. Technol. 2014, 39, 4–17. [Google Scholar] [CrossRef]

- Igenbayev, A.; Amirkhanov, S.; Ospankulova, G.; Kardenov, S.; Baytukenova, S.; Shariati, M.A. Determination of the fatty acid composition and fatty acids trans-isomers in the horse, stall horse, mutton, beef and pork meat. Potravin. Slovak J. Food Sci. 2022, 16, 800–809. [Google Scholar] [CrossRef]

- Guo, J.; Cui, L.; Meng, Z. Oleogels/emulsion gels as novel saturated fat replacers in meat products: A review. Food Hydrocoll. 2022, 137, 108313. [Google Scholar] [CrossRef]

- Badar, I.H.; Liu, H.; Chen, Q.; Xia, X.; Kong, B. Future trends of processed meat products concerning perceived healthiness: A review. Compr. Rev. Food Sci. Food Saf. 2021, 20, 4739–4778. [Google Scholar] [CrossRef]

- Choi, Y.S.; Choi, J.H.; Han, D.J.; Kim, H.Y.; Lee, M.A.; Kim, H.W.; Jeong, J.Y.; Kim, C.J. Effects of replacing pork back fat with vegetable oils and rice bran fiber on the quality of reduced-fat frankfurters. Meat Sci. 2010, 84, 557–563. [Google Scholar] [CrossRef]

- Herrero, A.M.; Carmona, P.; Pintado, T.; Jiménez-Colmenero, F.; Ruíz-Capillas, C. Olive oil-in-water emulsions stabilized with caseinate: Elucidation of protein–lipid interactions by infrared spectroscopy. Food Hydrocoll. 2011, 25, 12–18. [Google Scholar] [CrossRef]

- Dominguez, R.; Agregan, R.; GonCalves, A.; Lorenzo, J.M. Effect of fat replacement by olive oil on the physico-chemical properties, fatty acids, cholesterol and tocopherol content of pâté. Grasas Y Aceites 2016, 67, e152. [Google Scholar] [CrossRef]

- Co, D.; Marangoni, A.G. Organogels: An Alternative Edible Oil-Structuring Method. J. Am. Oil Chem. Soc. 2012, 89, 749–780. [Google Scholar] [CrossRef]

- Patel, A.R.; Cludts, N.; Bin Sintang, M.D.; Lewille, B.; Lesaffer, A.; Dewettinck, K. Polysaccharide-based oleogels prepared with an emulsion-templated approach. Chemphyschem A Eur. J. Chem. Phys. Phys. Chem. 2014, 15, 3435–3439. [Google Scholar] [CrossRef]

- Storz, T.A.; Zetzl, A.K.; Barbut, S.; Cattaruzza, A.; Marangoni, A.G. Edible oleogels in food products to help maximize health benefits and improve nutritional profiles. Lipid Technol. 2012, 24, 151–154. [Google Scholar] [CrossRef]

- Li, L.; Liu, G.; Lin, Y. Physical and bloom stability of low-saturation chocolates with oleogels based on different gelation mechanisms. LWT—Food Sci. Technol. 2021, 140, 110807. [Google Scholar] [CrossRef]

- Shao, L.; Bi, J.; Dai, R.; Li, X. Effects of fat/oil type and ethylcellulose on the gel characteristic of pork batter. Food Res. Int. 2020, 138, 109788. [Google Scholar] [CrossRef]

- Mattice, K.D.; Marangoni, A.G. Oleogels in Food; Encyclopedia of Food Chemistry; Academic Press: Cambridge, MA, USA, 2019; pp. 255–260. [Google Scholar] [CrossRef]

- Park, C.; Jimenez-Flores, R.; Maleky, F. Quantifications of oleocolloid matrices made of whey protein and oleogels. Foods 2020, 9, 1697. [Google Scholar] [CrossRef]

- Ferro, A.C.; Okuro, P.K.; Badan, A.P.; Cunha, R.L. Role of the oil on glyceryl monostearate based oleogels. Food Res. Int. 2019, 120, 610619. [Google Scholar] [CrossRef]

- Tarté, R.; Paulus, J.S.; Acevedo, N.C.; Prusa, K.J.; Lee, S. High-oleic and conventional soybean oil oleogels structured with rice bran wax as alternatives to pork fat in mechanically separated chicken-based bologna sausage. LWT—Food Sci. Technol. 2020, 131, 109659. [Google Scholar] [CrossRef]

- Chen, X.W.; Guo, J.; Wang, J.M.; Yin, S.W.; Yang, X.Q. Controlled volatile release of structured emulsions based on phytosterols crystallization. Food Hydrocoll. 2016, 56, 170–179. [Google Scholar] [CrossRef]

- Franco, D.; Martins, A.J.; López-Pedrouso, M.; Cerqueira, M.A.; Purriños, L.; Pastrana, L.M.; Vicente, A.A.; Lorenzo, J.M. Evaluation of linseed oil oleogels to partially replace pork backfat in fermented sausages. J. Sci. Food Agric. 2019, 100, 218–224. [Google Scholar] [CrossRef] [PubMed]

- López-Pedrouso, M.; Lorenzo, J.M.; Gullón, B.; Campagnol, P.C.B.; Franco, D. Novel strategy for developing healthy meat products replacing saturated fat with oleogels. Curr. Opin. Food Sci. 2021, 40, 40–45. [Google Scholar] [CrossRef]

- Kouzounis, D.; Lazaridou, A.; Katsanidis, E. Partial replacement of animal fat by oleogels structured with monoglycerides and phytosterols in frankfurter sausages. Meat Sci. 2017, 130, 38–46. [Google Scholar] [CrossRef] [PubMed]

- Yang, D.X.; Chen, X.W.; Yang, X.Q. Phytosterol-based oleogels self-assembled with monoglyceride for controlled volatile release. J. Sci. Food Agric. 2017, 98, 582–589. [Google Scholar] [CrossRef]

- Yılmaz, E.; Öğütcü, M. Comparative analysis of olive oil organogels containing beeswax and sunflower wax with breakfast margarine. J. Food Sci. 2014, 79, E1732–E1738. [Google Scholar] [CrossRef]

- Fayaz, G.; Goli, S.A.H.; Kadivar, M.; Valoppi, F.; Barba, L.; Calligaris, S.; Nicoli, M.C. Potential application of pomegranate seed oil oleogels based on monoglycerides, beeswax and propolis wax as partial substitutes of palm oil in functional chocolate spread. LWT 2017, 86, 523–529. [Google Scholar] [CrossRef]

- Da Pieve, S.; Calligaris, S.; Eco, E.; Nicoli, M.C.; Marangoni, A.G. Shear nanostructuring of monoglyceride organogel. Food Biophys. 2010, 5, 211–217. [Google Scholar] [CrossRef]

- Dassanayake, K.; Kodali, D.R.; Ueno, S. Formation of oleogels based on edible lipid materials. Curr. Opin. Colloid Interface Sci. 2011, 16, 432–439. [Google Scholar] [CrossRef]

- Manzoor, S.; Masoodi, F.A.; Rashid, R.; Naqash, F.; Ahmad, M. Oleogels for the development of healthy meat products: A review. Appl. Food Res. 2022, 2, 100212. [Google Scholar] [CrossRef]

- Martins, A.J.; Lorenzo, J.M.; Franco, D.; Pateiro, M.; Domínguez, R.; Munekata, P.; Pastrana, L.M.; Vicente, A.A.; Cunha, R.L.; Cerqueira, M.A. Characterization of enriched meat-based pâté manufactured with oleogels as fat substitutes. Gels 2020, 6, 17. [Google Scholar] [CrossRef]

- Zetzl, A.K.; Marangoni, A.G.; Barbut, S. Mechanical properties of ethylcellulose oleogels and their potential for saturated fat reduction in frankfurters. Food Funct. 2012, 3, 327–337. [Google Scholar] [CrossRef] [PubMed]

- Barbut, S.; Wood, J.; Marangoni, A. Quality effects of using organogels in breakfast sausage. Meat Sci. 2016, 122, 84–89. [Google Scholar] [CrossRef] [PubMed]

- Sarkisyan, V.; Sobolev, R.; Frolova, Y.; Malinkin, A.; Makarenko, M.; Kochetkova, A. Beeswax fractions used as potential oil gelling agents. J. Am. Oil Chem. Soc. 2021, 98, 281–296. [Google Scholar] [CrossRef]

- Fratini, F.; Cilia, G.; Turchi, B.; Felicioli, A. Beeswax: A minireview of its antimicrobial activity and its application in medicine. Asian Pac. J. Trop. Med. 2016, 9, 839–843. [Google Scholar] [CrossRef]

- Abdolmaleki, K.; Alizadeh, L.; Nayebzadeh, K.; Baranowska, H.M.; Kowalczewski, P.Ł.; Mousavi Khaneghah, A. Potential application of hydrocolloid-based oleogel and beeswax oleogel as partial substitutes of solid fat in margarine. Appl. Sci. 2022, 12, 12136. [Google Scholar] [CrossRef]

- Gao, Y.; Lei, Y.; Wu, Y.; Liang, H.; Li, J.; Pei, Y.; Li, Y.; Li, B.; Luo, X.; Liu, S. Beeswax: A potential self-emulsifying agent for the construction of thermal-sensitive food W/O emulsion. Food Chem. 2021, 349, 129203. [Google Scholar] [CrossRef]

- Gao, Y.; Li, M.; Zhang, L.; Wang, Z.; Yu, Q.; Han, L. Preparation of rapeseed oil oleogels based on beeswax and its application in beef heart patties to replace animal fat. Lwt 2021, 149, 111986. [Google Scholar] [CrossRef]

- Gómez-Estaca, J.; Pintado, T.; Jiménez-Colmenero, F.; Cofrades, S. Assessment of a healthy oil combination structured in ethyl cellulose and beeswax oleogels as animal fat replacers in low-fat, PUFA-enriched pork burgers. Food Bioprocess Technol. 2019, 12, 1068–1081. [Google Scholar] [CrossRef]

- Moghtadaei, M.; Soltanizadeh, N.; Goli, S.A.H. Production of sesame oil oleogels based on beeswax and application as partial substitutes of animal fat in beef burger. Food Res. Int. 2018, 108, 368–377. [Google Scholar] [CrossRef]

- Giacomozzi, A.S.; Palla, C.A.; Carrín, M.E.; Martini, S. Physical properties of monoglycerides oleogels modified by concentration, cooling rate, and high-intensity ultrasound. J. Food Sci. 2019, 84, 2549–2561. [Google Scholar] [CrossRef]

- Pușcaș, A.; Mureșan, V.; Socaciu, C.; Muste, S. Oleogels in Food: A Review of Current and Potential Applications. Foods 2020, 9, 70. [Google Scholar] [CrossRef] [PubMed]

- Yılmaz, E.; Öğütcü, M. Properties and Stability of Hazelnut Oil Organogels with Beeswax and Monoglyceride. J. Am. Oil Chem. Soc. 2015, 91, 1007–1017. [Google Scholar] [CrossRef]

- ISO 1442; Determination of Moisture Content. International Organization for Standardization: Geneva, Switzerland, 1997.

- ISO 937; Determination of Nitrogen Content. International Organization for Standardization: Geneva, Switzerland, 1978.

- ISO 936; Determination of Ash Content. International Organization for Standardization: Geneva, Switzerland, 1998.

- AOCS Official Procedure Am 5-04. In Rapid Determination of Oil/Fat Utilizing High Temperature Solvent Extraction; American Oil Chemists Society: Urbana, IL, USA, 2005.

- Folch, J.; Lees, M.; Sloane Stanley, G.H. A simple method for the isolation and purification of total lipids from animal tissues. J Biol Chem 1957, 226, 497–509. [Google Scholar] [CrossRef] [PubMed]

- Rao, M.V.; Gault, N.F.S.; Kennedy, S. Changes in the ultrastructure of beef muscle as influenced by acidic conditions below the ultimate pH. Food Struct. 1989, 8, 115–124. [Google Scholar]

- ISO 8589; Sensory Analysis—General Guidance for the Design of Test Rooms. International Organization for Standardization: Geneva, Switzerland, 2007.

- Sun, H.; Xu, J.; Lu, X.; Xu, Y.; Regenstein, J.M.; Zhang, Y.; Wang, F. Development and characterization of monoglyceride oleogels prepared with crude and refined walnut oil. LWT 2022, 154, 112769. [Google Scholar] [CrossRef]

- Zampouni, K.; Soniadis, A.; Dimakopoulou-Papazoglou, D.; Moschakis, T.; Biliaderis, C.G.; Katsanidis, E. Modified fermented sausages with olive oil oleogel and NaCl–KCl substitution for improved nutritional quality. LWT 2022, 158, 113172. [Google Scholar] [CrossRef]

- Ferro, A.C.; de Souza Paglarini, C.; Pollonio, M.A.R.; Cunha, R.L. Glyceryl monostearate-based oleogels as a new fat substitute in meat emulsion. Meat Sci. 2021, 174, 108424. [Google Scholar] [CrossRef]

- Wolfer, T.L.; Acevedo, N.C.; Prusa, K.J.; Sebranek, J.G.; Tarté, R. Replacement of pork fat in frankfurter-type sausages by soybean oil oleogels structured with rice bran wax. Meat Sci. 2018, 145, 352–362. [Google Scholar] [CrossRef]

- Panagiotopoulou, E.; Moschakis, T.; Katsanidis, E. Sunflower oil organogels and organogel-in-water emulsions (Part II): Implementation in frankfurter sausages. LWT—Food Sci. Technol. 2016, 73, 351–356. [Google Scholar] [CrossRef]

- Salter, A.M.; Mangiapane, E.H.; Bennett, A.J.; Bruce, J.S.; Billett, M.A.; Anderton, K.L.; Marenah, C.B.; Lawson, N.; White, D.A. The effect of different dietary fatty acids on lipoprotein metabolism: Concentration-dependent effects of diets enriched in oleic, myristic, palmitic and stearic acids. Br. J. Nutr. 1998, 79, 195–202. [Google Scholar] [CrossRef]

- German, J.B.; Dillard, C.J. Saturated fats: What dietary intake? Am. J. Clin. Nutr. 2004, 80, 550–559. [Google Scholar] [CrossRef] [PubMed]

- Miura, K.; Stamler, J.; Nakagawa, H.; Elliott, P.; Ueshima, H.; Chan, Q.; Brown, I.J.; Tzoulaki, I.; Saitoh, S.; Dyer, A.R.; et al. Relationship of dietary linoleic acid to blood pressure: The international study of macro-micronutrients and blood pressure study. Hypertension 2008, 52, 408–414. [Google Scholar] [CrossRef] [PubMed]

- Marangoni, F.; Agostoni, C.; Borghi, C.; Catapano, A.L.; Cena, H.; Ghiselli, A.; La Vecchia, C.; Lercker, G.; Manzato, E.; Pirillo, A.; et al. Dietary linoleic acid and human health: Focus on cardiovascular and cardiometabolic effects. Atherosclerosis 2020, 292, 90–98. [Google Scholar] [CrossRef] [PubMed]

- Oh, I.; Lee, J.; Lee, H.G.; Lee, S. Feasibility of hydroxypropyl methylcellulose oleogel as an animal fat replacer for meat patties. Food Res. Int. 2019, 122, 566–572. [Google Scholar] [CrossRef]

- Igenbayev, A.; Okuskhanova, E.; Nurgazezova, A.; Rebezov, Y.; Kassymov, S.; Nurymkhan, G.; Tazeddinova, D.; Mironova, I.; Rebezov, M. Fatty acid composition of female Turkey muscles in Kazakhstan. J. World’s Poult. Res. 2019, 9, 78–81. [Google Scholar] [CrossRef]

- Rodrigues, I.; Gonçalves, L.A.; Carvalho, F.A.; Pires, M.; Rocha, Y.J.P.; Barros, J.C.; Trindade, M.A. Understanding salt reduction in fat-reduced hot dog sausages: Network structure, emulsion stability and consumer acceptance. LWT-Food Sci. Technol. Int. 2020, 26, 123–131. [Google Scholar] [CrossRef]

- Pintado, T.; Cofrades, S. Quality characteristics of healthy dry fermented sausages formulated with a mixture of olive and chia oil structured in oleogel or emulsion gel as animal fat replacer. Foods 2020, 9, 830. [Google Scholar] [CrossRef]

- Okuskhanova, E.; Caporaso, N.; Yessimbekov, Z.; Assenova, B.; Smolnikova, F.; Rebezov, M.; Shariati, M.A.; Usman Khan, M.; Thiruvengadam, M. Functional and physical properties of oil-in-water emulsion based on sodium caseinate, beef rumen and sunflower oil and its effect on nutritional quality of forcemeat. J. Dispers. Sci. Technol. 2021, 44, 429–437. [Google Scholar] [CrossRef]

- Salminen, H.; Herrmann, K.; Weiss, J. Oil-in-water emulsions as a delivery system for n-3 fatty acids in meat products. Meat Sci. 2013, 93, 659–667. [Google Scholar] [CrossRef]

- Ropciuc, S.; Dranca, F.; Oroian, M.A.; Leahu, A.; Codină, G.G.; Prisacaru, A.E. Structuring of Cold Pressed Oils: Evaluation of the Physicochemical Characteristics and Microstructure of White Beeswax Oleogels. Gels 2023, 9, 216. [Google Scholar] [CrossRef]

- Badem, Ş.; Baştürk, A. Oxidative stability and characterization of oleogels obtained from safflower oil-based beeswax and rice bran wax and their effect on the quality of cake samples. J. Am. Oil Chem. Soc. 2023. [Google Scholar] [CrossRef]

| Ingredient | Control | OG 7 | OG 10 |

|---|---|---|---|

| Horse meat | 26 | 26 | 26 |

| Beef | 26 | 26 | 26 |

| Chicken meat | 25 | 25 | 25 |

| Pork fat | 20 | 13 | 10 |

| Oleogel | 0 | 7 | 10 |

| Starch | 3 | 3 | 3 |

| Food salt | 1 | 1 | 1 |

| Sodium nitrite | 0.008 | 0.008 | 0.008 |

| Tyrolean flavor | 0.04 | 0.04 | 0.04 |

| Almi colorant | 0.5 | 0.5 | 0,5 |

| Nitrite salt | 1 | 1 | 1 |

| Complex spices “Krakowskie combi” | 0.15 | 0.15 | 0.15 |

| Complex spices Kreiner Spice Combi | 0.09 | 0.09 | 0.09 |

| Name of Fatty Acid | Quantity, % |

|---|---|

| Saturated fatty acids, % | 20.141 ± 1.007 |

| C 14:0 myristic | 0.190 ± 0.010 |

| C 15:0 pentadecanoic | 0.026 ± 0.001 |

| C 16:0 palmitic acid | 12.168 ± 0.608 |

| C 17:0 margarine | 0.027 ± 0.001 |

| C 18:0 stearic | 7.114 ± 0.356 |

| C 20:0 arachinic | 0.074 ± 0.004 |

| C 23:0 tricosanic | 0.540 ± 0.027 |

| Monounsaturated fatty acids, % | 17.248 ± 0.862 |

| C 16:1 (cis-9) palmitoleic | 0.037 ± 0.002 |

| C 17:1 (cis-10) margarinoleic | 0.016 ± 0.0004 |

| C 18:1 (cis-9) oleic | 17.101 ± 0.855 |

| C 20:1 (cis-11) eicosene | 0.094 ± 0.005 |

| Polyunsaturated fatty acids, % | 62.611 ± 3.131 |

| C 18:2n6c linoleic | 62.568 ± 3.128 |

| C 18:3n6Y-linolenic | 0.044 ± 0.002 |

| Indicator | Control | OG7 | OG10 | p-Value |

|---|---|---|---|---|

| Moisture, % | 55.26 ± 0.86 | 57.23 ± 0.92 | 56.80 ± 1.14 | >0.50 |

| Protein, % | 19.81 ± 0.35 | 19.52 ± 0.23 | 19.49 ± 0.31 | >0.25 |

| Fat, % | 18.05 ± 0.27 | 17.90 ± 0.33 | 17.83 ± 0.17 | >0.25 |

| Carbohydrate, % | 3.25 ± 0.35 | 3.26 ± 0.11 | 3.30 ± 0.15 | >0.25 |

| Ash, % | 2.46 ± 0.04 | 2.39 ± 0.03 | 2.47 ± 0.04 | >0.25 |

| Energy value, kCal/kJ/100 g | 254.62/1065.33 | 252.18/1054.36 | 251.58/1050.18 | |

| pH | 6.17 ± 0.09 | 6.08 ± 0.10 | 6.13 ± 0.08 | >0.25 |

| Name of Fatty Acid | Control | OG7 | OG10 | p-Value |

|---|---|---|---|---|

| SFA, %: | 40.90 | 26.37 | 25.27 | |

| C 10:0 caprine | 0.04 ± 0.00 | nd | nd | |

| C 12:0 lauric | 0.05 ± 0.00 b | 0.04 ± 0.00 a | nd | <0.05 |

| C 14:0 myristic | 1.27 ± 0.02 c | 1.10 ± 0.01 b | 0.87 ± 0.01 a | <0.01 |

| C 15:0 pentadecanoic | 0.08 ± 0.00 a | 0.13 ± 0.00 c | 0.11 ± 0.00 b | <0.05 |

| C 16:0 palmitinic | 24.28 ± 0.39 c | 18.01 ± 0.20 b | 16.89 ± 0.19 a | <0.01 |

| C 17:0 margarine | 0.28 ± 0.01 c | 0.21 ± 0.01 b | 0.17 ± 0.00 a | <0.01 |

| C 18:0 stearic | 14.42 ± 0.22 b | 6.31 ± 0.09 a | 6.69 ± 0.06 a | <0.001 |

| C 20:0 arachinic | nd | 0.06 ± 0.00 b | 0.03 ± 0.00 a | <0.05 |

| C 21:0 geneicosan | 0.40 ± 0.01 b | 0.13 ± 0.00 a | 0.12 ± 0.00 a | <0.05 |

| C 22:0 begene | 0.06 ± 0.00 a | 0.06 ± 0.00 a | 0.06 ± 0.00 a | >0.50 |

| C23:0 tricosan | nd | 0.32 ± 0.00 a | 0.32 ± 0.00 a | >0.50 |

| MUFA, % | 46.15 | 26.32 | 25.08 | |

| C 14:1 (cis-9) myristoleic | nd | 0.06 ± 0.00 b | 0.05 ± 0.00 a | <0.05 |

| C 15:1 (cis-10) pentadecenoic | nd | 0.04 ± 0.00 a | 0.03 ± 0.00 a | >0.50 |

| C 16:1 (cis-9) palmitoleic | 1.99 ± 0.02 b | 1.87 ± 0.03 b | 1.54 ± 0.02 a | <0.05 |

| C 17:1 (cis-10) margarinoleic | 0.26 ± 0.00 c | 0.19 ± 0.00 b | 0.17 ± 0.00 a | <0.05 |

| C 18:1 (cis-9) oleic | 43.27 ± 0.74 b | 23.87 ± 0.33 a | 22.99 ± 0.25 a | <0.01 |

| C 20:1 (cis-11) eicosene | 0.62 ± 0.01 b | 0.23 ± 0.00 a | 0.19 ± 0.00 a | <0.001 |

| C 22:1 (cis-13) erucic | nd | nd | 0.03 ± 0.00 | |

| C 24:1 selacholic | nd | 0.06 ± 0.00 a | 0.06 ± 0.00 a | >0.50 |

| PUFA, % | 12.95 | 47.32 | 49.64 | |

| C 18:2n6t linoleidine | 0.03 ± 0.00 b | nd | 0.01 ± 0.00 a | <0.05 |

| C 18:2n6c linoleic | 12.37 ± 0.21 a | 45.29 ± 0.87 b | 47.89 ± 0.79 b | <0.001 |

| C 18:3n6 Y-linolenic | 0.32 ± 0.00 a | 1.65 ± 0.02 c | 1.36 ± 0.02 b | <0.001 |

| C18:3n3 linolenic | 0.03 ± 0.00 | nd | nd | |

| C 20:3n6c (cis-8,11,14) eicosatriene | nd | 0.31 ± 0.01 a | 0.32 ± 0.01 a | >0.50 |

| C 20:3n3c (cis-11,14,17) eicosatrieno | 0.20 ± 0.00 b | 0.06 ± 0.00 a | 0.06 ± 0.00 a | <0.05 |

| Indicator | Control | OG7 | OG10 | p-Value |

|---|---|---|---|---|

| Appearance | 4.93 ± 0.08 b | 4.90 ± 0.05 b | 4.69 ± 0.07 a | <0.05 |

| Taste | 4.90 ± 0.06 a | 4.89 ± 0.08 a | 4.84 ± 0.04 a | >0.50 |

| Flavor and aroma | 4.86 ± 0.08 a | 4.86 ± 0.05 a | 4.81 ± 0.05 a | >0.50 |

| Consistency | 4.86 ± 0.06 b | 4.83 ± 0.07 b | 4.70 ± 0.05 a | <0.05 |

| Color | 4.85 ± 0.04 a | 4.83 ± 0.05 a | 4.75 ± 0.08 a | >0.50 |

| View on the cut | 4.90 ± 0.07 b | 4.87 ± 0.05 b | 4.68 ± 0.08 a | <0.05 |

| Juiciness | 4.88 ± 0.05 b | 4.86 ± 0.05 b | 4.72 ± 0.05 a | <0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Igenbayev, A.; Ospankulova, G.; Amirkhanov, S.; Aldiyeva, A.; Temirova, I.; Amirkhanov, K. Substitution of Pork Fat with Beeswax-Structured Oleogels in Semi-Smoked Sausages. Appl. Sci. 2023, 13, 5312. https://doi.org/10.3390/app13095312

Igenbayev A, Ospankulova G, Amirkhanov S, Aldiyeva A, Temirova I, Amirkhanov K. Substitution of Pork Fat with Beeswax-Structured Oleogels in Semi-Smoked Sausages. Applied Sciences. 2023; 13(9):5312. https://doi.org/10.3390/app13095312

Chicago/Turabian StyleIgenbayev, Aidyn, Gulnazym Ospankulova, Shyngys Amirkhanov, Akmaral Aldiyeva, Indira Temirova, and Kumarbek Amirkhanov. 2023. "Substitution of Pork Fat with Beeswax-Structured Oleogels in Semi-Smoked Sausages" Applied Sciences 13, no. 9: 5312. https://doi.org/10.3390/app13095312

APA StyleIgenbayev, A., Ospankulova, G., Amirkhanov, S., Aldiyeva, A., Temirova, I., & Amirkhanov, K. (2023). Substitution of Pork Fat with Beeswax-Structured Oleogels in Semi-Smoked Sausages. Applied Sciences, 13(9), 5312. https://doi.org/10.3390/app13095312