1. Introduction

Digital factory and virtual reality, or DFVR, instructs mechanical engineering students on the fundamentals of virtual reality [

1]; virtual reality is mostly used in the shipbuilding, aviation, and automobile industries. Many of these industrial companies have modified the idea of the digital factory (DF) to suit themselves [

2].

As collaboration is an important business item that has significant implications for a product’s development process, the concepts of digital factory and virtual reality can be used. One consequence of quality business relationships is that the engineering or manufacturing environment, and their design and production resources if physical distribution is possible, are networked and well-integrated within the enterprise. The result of a collaborative production environment is a multidisciplinary division of the team; they are properly distributed and organized in cooperation with the aim of achieving a common goal [

3,

4].

The virtual product design and integration of the environment require a lot of involvement from different product lifecycle teams and functions. This environment provides the necessary tools that are well geographically dispersed and co-located. The environment that is distributed is highly heterogeneous; it consists of designers, engineers, resources, and models distributed and not centralized in one place or group within the company, and it is offered via computer networks [

5].

Advances in IT permitted stakeholders to be more effective in communicating, acquiring, and sharing a wide range of resources during development [

6]. Software vendors can provide “custom” software packages for individual businesses. Different industries have different development products that need a common framework to enable them to be effective, regardless of their product strategy, organizational structure, and/or geographic location. Two important elements in this changing environment are increased product sophistication and variation. Cost minimization is the key to the rapid development and sales of new products. [

7].

Digital manufacturing is a key point of integration between PLM systems and various manufacturing applications and devices that allow products and information to be exchanged between design and manufacturing groups. This alignment allows manufacturing companies to achieve their time-to-market and volume targets, as well as realize cost savings by reducing costly downstream changes [

8].

The key to the analysis of any problem is the identification of such functions performed and the relationships between them [

9]. A collaborative engineering development process involves a set of activities and functions arranged in a specific order and with clearly defined inputs and outputs. Each activity in a process takes a set of inputs and transforms them into an output of some value. A process is considered necessary when the output of the process satisfies the average customer and product requirements and management and cost objectives [

10,

11].

Global communication networks and mergers implement the process of electronics and information systems. In the environment in which people live, business and production are carried out. The production world of this century is a networked information world—inside and outside enterprises are connected to all market participants [

12].

Digital manufacturing enables product, process, plant, and resource information to be assigned, viewed, and taken over by change processes, with a consistent and comprehensive approach. Digital production enables the production of parts and processes that are to be optimized in a controlled environment [

13].

A VR-based strategy for effective production planning is presented and discussed. The layout planning may be evaluated in real-time in terms of things such as ergonomics, martial flow, and surface usage economy. The proposed strategy was developed using the author’s extensive industry experience as a digital manufacturing engineer and after lengthy consultation with subject matter specialists [

14].

Virtual reality (VR) and human simulation in digital manufacturing emerged as a result of developments in digital mockup simulation technologies during the 1990s. The development of DMU has led to a new paradigm that integrates processes, resources, knowledge, and simulation models [

15]. Despite the constraints of our physical world, virtual reality (VR) can also creatively display complex content or useful data [

16]. The improvement of collaborative practices in 3D virtual worlds with VR with a focus on the education and manufacturing sectors in the smart factory is one of the goals of this paper. This goal is based on the fact that features of the real environment can be replicated in the virtual world through a digital twin and new, customizable, and valuable ways of working [

17]. Virtual reality (VR) is an artificially created, unreal digital world that is used in an interactive virtual setting. Immersion and presence are its two key components, and it is intended to mimic real life [

18]. The degree of objective sensory fidelity offered by a VR device is what is meant by immersion. Each user feels their presence as a result of being fully immersed in the digital world [

19,

20].

Research and development in digital manufacturing have been greatly enhanced by VR technology. The field that first attracted researchers’ attention was virtual manufacturing. It has been demonstrated that VR-based tools can be used for process analysis, assembly training, and welding simulation [

21].

Kim et al. also produced virtual assembly simulation systems that concentrate on the digital shipbuilding and marine industries, and they incorporate advanced simulation functions [

21].

Another important area of interest has been human motion simulation for incorporating human elements in simulation environments [

22,

23,

24]. People who are spread out may now share and display data, interact realistically, and make decisions in the context of product and process design activities online thanks to the development of shared virtual environments [

24].

The concept and implementation of collaborative manufacturing environments based on virtual reality (VR) and augmented reality (AR), which are suitable for human-oriented production systems, have also been the subject of research [

25,

26]. Many traditional factories use automated machines such as barcode scanners, cameras, and digitized production equipment in various parts of their operations. However, these devices are not interconnected. People, assets, and data management systems in a traditional factory operate separately from each other and must be manually coordinated and integrated on an ongoing basis.

Intelligent factory automation represents workflows that are created, and instructions are sent to devices within the system after data collection and analysis. These devices can be within the four walls of the factory or across the campus in the logistics or manufacturing links of the supply chain. Intelligent workflows and processes are continuously monitored and optimized. If a news item highlights an increase in demand for a particular product, it can be recommended that the 3D printer’s workflows increase the priority of producing that item. In the event of a delay in raw material supply, rotation of inventory buffers can be performed to avoid disruption.

Given the current situation, where every company is considering its investments in manpower or the purchase of equipment (and also the safety of personnel at work), this document is intended to show that by using digital tools and simulations, a company can re-evaluate, among other things, its other investment plans, e.g., simulating the impact of expanding the production line or modifying the ergonomics of the equipment operator’s area or the actual enlargement—sizing of larger production areas, through to the overall material flow of goods—from receipt, through storage, processing, final product, handling and dispatch. Hence, this research is a hot topic in certain segments of the industry, as we state in the conclusion of the introduction section of the paper.

The purpose of this paper is to demonstrate the VR and digital factory approach and the possibilities of simulating a real digital factory environment, including VR in planning, material flow management, and workforce, taking into account the ergonomics of the environment and personnel. This approach makes possible the interaction between the real enterprise and the digital enterprise, where both the dimensions of the enterprise and all the processes that take place in this enterprise can be directly simulated using software in order to reduce time and save money.

This document addresses the problem of efficient use of the so-called Digital Factory to streamline the processes that take place in current conditions—efficiency in terms of productivity, use of working time, staff/service, and capacity of machinery and equipment—but also, for example, the overall energy efficiency of the factory. On the processes that are running in the manufacturing company, where large downtimes occur, the process that slows down the overall production the most was selected. This process was simulated in a digital environment, and the times that production will achieve after the proposed modification of that part of the production were simulated.

This paper focuses on designing a more efficient spatial arrangement of workplaces in a selected organization to eliminate redundant material flows and wastage of production areas. This should reduce the cost of production, reduce production time and ultimately reduce the overall cost of the production process and the operation of the production floor. Virtual Reality (VR) is used in this article to simulate a digital factory for decision making and improving efficiency.

2. Background Information

The research of this article includes the use of TX Plant Simulation for the improvement of the production process in terms of efficiency. It also demonstrates the possibility of using a digital factory by means of virtual reality to provide further assistance in process improvement. In order to use virtual reality for the optimization and testing of the production process, the authors deemed it essential to simulate the operation of the production process in TX Plant Simulation.

Plant simulation and virtual reality are two distinct technologies that can be used in combination to enhance various aspects of manufacturing and industrial processes. Using the tools that are currently available to simulate different industrial processes calls for knowledge and skill in the area. This purely technical skill is not possessed by many industrial actors. Thus, many researchers worked to create novel solutions that allow for abstraction between the methods and simulation techniques and non-technical stakeholders in order to enable them to participate in the analysis, optimization, and validation of simulation models of various processes [

27].

2.1. TX Plant Simulation

PLM (Product Lifecycle Management) Siemens is a software platform developed by Siemens Digital Industries Software that helps organizations manage the entire lifecycle of a product, from ideation and design through to manufacturing, maintenance, and eventual retirement. PLM Siemens provides a comprehensive set of tools and capabilities for managing product data, processes, and collaboration across different teams and stakeholders. Some of the key features of PLM Siemens include:

Design and Engineering: The software provides tools for creating and managing product designs, including 3D modeling, simulation, and analysis capabilities.

Manufacturing: PLM Siemens offers tools for creating and managing manufacturing processes, including process planning, production scheduling, and quality management.

Maintenance and Service: The software helps organizations manage product maintenance and service activities, including maintenance planning, repair management, and service documentation [

28].

PLM Siemens is used by a wide range of organizations across various industries, including those of automotive, aerospace, defense, and consumer goods. It can help organizations improve efficiency, reduce costs, and accelerate the time-to-market for new products.

Tecnomatix Plant Simulation is a software tool used for modeling, simulating, and analyzing manufacturing processes. Developed by Siemens Digital Industries Software, Tecnomatix Plant Simulation allows users to create digital models of manufacturing systems and simulate various scenarios to optimize production efficiency and reduce costs. With Tecnomatix Plant Simulation, users can create 2D and 3D models of manufacturing processes, including production lines, supply chain networks, and logistics systems. The software features a comprehensive library of predefined objects and components, making it easy to model complex manufacturing processes quickly.

Tecnomatix Plant Simulation enables users to simulate various scenarios and analyze the performance of their manufacturing processes. With the software’s powerful analysis tools, users can identify bottlenecks and inefficiencies in their production systems, optimize production schedules, and reduce lead times. One of the key features of Tecnomatix Plant Simulation is its ability to integrate with other software tools and systems. The software can interface with enterprise resource planning (ERP) systems, manufacturing execution systems (MES), and other production planning software tools, allowing users to optimize their manufacturing processes end-to-end. Tecnomatix Plant Simulation is a powerful software tool for manufacturers looking to improve efficiency, reduce costs, and optimize their production processes.

2.2. Virtual Reality

VR technology can be used to improve a wide range of production processes in the digital factory, including design and prototyping. VR technology can be used to create virtual prototypes of products and production processes. This allows designers and engineers to test different design options and identify potential problems before they are physically built, which can save time and money in the production process.

Virtual Reality (VR) can be classified in various ways, depending on the context and perspective of the classification. Here are a few common ways to classify virtual reality. Firstly, based on the level of immersion. VR can be classified into fully immersive, semi-immersive, and non-immersive VR. Fully immersive VR offers the highest level of immersion, where the user is completely immersed in a virtual world, often using a VR headset and hand-held controllers. Semi-immersive VR provides a partially immersive experience, where the user interacts with a virtual environment using a screen or projection. Non-immersive VR involves the use of a computer screen or mobile device to display a virtual environment [

29].

Secondly, VR can be classified based on the type of hardware used, such as head-mounted displays (HMDs), haptic devices, and motion tracking systems. Thirdly, VR can be classified based on its application, such as gaming, training and simulation, education, healthcare, and entertainment.

Lastly, VR can be classified based on the degree of interactivity, such as passive, interactive, and immersive. Passive VR involves the user observing a virtual environment without interacting with it. Interactive VR allows the user to interact with the virtual environment using input devices such as controllers or touchscreens. Immersive VR provides a high level of interactivity, where the user can fully engage with the virtual environment and interact with it in a more natural way. In VR-based process simulation, as shown in

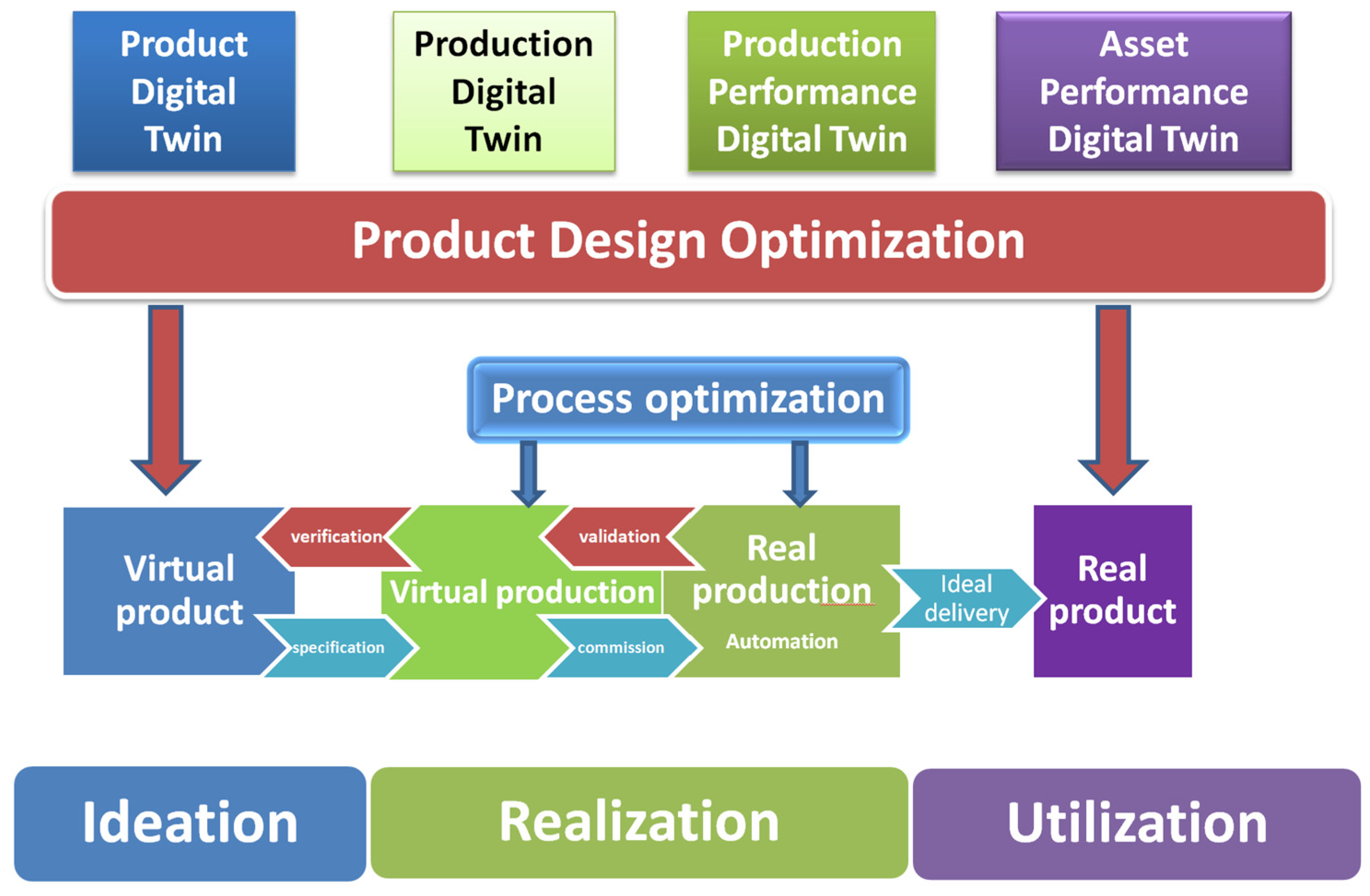

Figure 1, there are two classifications of categories, which have their specific characteristics in this process.

The first classification is the types of human–machine interfaces, which are visual, acoustic, and touch interfaces. The visual interface is classified as head-mounted and not head-mounted. Touch interface should be defined as tactile feedback and proprioceptive feedback. Modelling and simulation are used with methods managing virtual objects and interactive feedback. Managing virtual objects are known to be based on rules and knowledge and on a physical basis. Interactive feedback uses such methods as visualization, sonification and touch rendering [

30,

31,

32].

VR technology has the potential to improve a wide range of production processes in the digital factory, from training and design to quality control and maintenance. By providing workers with a more immersive and interactive experience, VR can help digital factories to operate more efficiently, ultimately leading to cost savings, improved product quality, and increased customer satisfaction.

VR technology has shown promising results in improving production processes in the digital factory, and it has several advantages over traditional methods of training, design, and maintenance.

Compared to traditional methods, VR technology offers a more immersive and interactive experience, allowing workers to gain hands-on experience in a safe and controlled environment. This can reduce the risk of accidents and injuries and increase worker confidence and skill levels. Additionally, VR simulations can be repeated multiple times, allowing workers to practice and refine their skills until they are confident in their ability to perform tasks in the real world. This can improve productivity and reduce the likelihood of errors or quality issues.

VR technology can also be used to create virtual prototypes of products and production processes, allowing designers and engineers to test different design options and identify potential problems before they are physically built. This can save time and money in the production process, as well as improve the quality and reliability of products. Furthermore, VR technology can be used to simulate different scenarios and identify potential inefficiencies in the production process. This can help managers and engineers optimize the flow of materials, equipment, and workers, ultimately increasing efficiency and reducing wastage.

Compared to other technologies, such as augmented reality or traditional simulation software, VR technology offers a more immersive and interactive experience. It allows workers to experience a realistic, three-dimensional environment that closely simulates the real world, which can improve learning and the retention of information. Additionally, VR technology can be used with a wide range of devices, including virtual reality headsets, which can provide a more immersive experience than other technologies.

While there may be limitations and challenges associated with the use of VR technology in the digital factory, it has been shown to be effective in improving production processes, and it has several advantages over traditional methods and other technologies.

The potential benefits of using VR technology in the digital factory, such as improved safety, efficiency, and collaboration, can outweigh the drawbacks, such as high initial costs and technical limitations. However, it is important for stakeholders to carefully consider the potential benefits and drawbacks and to address any ethical concerns that may arise.

2.3. Digital Factory

The research object of the present article is a digital factory. A digital factory is a type of manufacturing facility that leverages advanced digital technologies, such as artificial intelligence (AI), machine learning, the Internet of Things (IoT), robotics, and big data analytics, to optimize production processes and improve efficiency.

Here are some characteristics of a digital factory:

Advanced automation: A digital factory uses a high degree of automation to streamline production processes and reduce the need for human intervention.

Data-driven decision making: A digital factory collects and analyzes data from various sources to make informed decisions about production processes and resource allocation.

Interconnected systems: A digital factory’s various systems, such as production machines, sensors, and software, are interconnected and communicate with each other to optimize performance.

Agile operations: A digital factory is designed to be flexible and able to adapt quickly to changing market demands and production requirements.

Collaborative robots: Collaborative robots, or cobots, are a key feature of a digital factory. They work alongside human workers to improve efficiency and safety.

Virtual simulation: A digital factory uses virtual simulation to optimize production processes and reduce the risk of errors or downtime.

Predictive maintenance: A digital factory uses data analytics and machine learning to predict maintenance needs and prevent equipment failures before they occur.

Digital factory is characterized by its ability to leverage advanced digital technologies to optimize production processes, increase efficiency, and improve product quality.

A digital factory is a modern manufacturing facility that employs advanced digital technologies to optimize production processes and improve efficiency. The use of these technologies, such as artificial intelligence (AI), machine learning, the Internet of Things (IoT), robotics, and big data analytics, enables the factory to operate more efficiently and cost effectively and with higher quality than traditional factories.

One of the key characteristics of a digital factory is its high degree of automation. By leveraging AI and robotics, the factory can streamline production processes, reduce waste, and improve consistency. This means that less human intervention is needed in the production process, freeing up workers to focus on more complex tasks and reducing the risk of errors caused by human error [

29,

31,

32]. A fully integrated, collaborative manufacturing system that can respond in real time to changing factory conditions, supply chain management, and customer demand management is known as a “digital factory” or “digital manufacturing environment [

33,

34]”.

Data is also a key component of a digital factory. The factory collects data from a variety of sources, such as sensors, machines, and software, and uses this data to make informed decisions about production processes and resource allocation. The use of data analytics enables the factory to identify areas of inefficiency and waste, as well as opportunities for improvement.

Another characteristic of a digital factory is its interconnected systems. All the factory’s systems, from production machines to sensors to the software, are interconnected and communicate with each other in real-time. This enables the factory to optimize performance by adjusting production processes and resource allocation as needed.

A digital factory is also designed to be agile and flexible. With changing market demands and production requirements, the factory can adapt quickly to meet new challenges. This means that the factory can respond to changes in demand and production requirements more quickly than traditional factories, enabling it to stay competitive in a rapidly changing market. Collaborative robots are another key feature of a digital factory. These robots work alongside human workers to improve efficiency and safety. They can perform repetitive or dangerous tasks, freeing up human workers to focus on more complex or creative tasks.

Virtual simulation is also a key feature of a digital factory. Using virtual simulations, the factory can optimize production processes and reduce the risk of errors or downtime. By testing production processes in a virtual environment before implementing them in the physical factory, the factory can identify potential issues and make adjustments before any physical production occurs. Finally, a digital factory uses predictive maintenance to prevent equipment failures before they occur. By using data analytics and machine learning to predict maintenance needs, the factory can reduce downtime and improve equipment reliability.

3. Methodology

The present research used virtual reality, which was used in a laboratory equipped with SIEMENS PLM digital technology at the Technical University in Košice, Faculty of Aviation, Department of Aeronautical Engineering.

Implementing the production process simulation is important for improving the effectiveness of the organization’s production process. However, it is first necessary to more effectively locate each individual workspace in the production hall. The primary feature of the upgrade is the utilization of the production hall’s core area, which has previously only been used for transporting fibers, and it would slow down the entire production process. It is appropriate to rely on the idea of so-called lean manufacturing while trying to improve the productivity of the production process in a particular organization. Lean manufacturing’s fundamental objective is to establish the most stable production process feasible, with the lowest possible operating, maintenance, energy, and human resource costs, with continuous improvement and lean production.

Virtual Reality (VR) technology can be used in a digital factory to improve production processes in a variety of ways. By simulating different scenarios, VR can provide workers with the ability to visualize and interact with production processes in a way that is both immersive and informative.

Figure 2 shows product design optimization.

One way VR can improve production processes is through training. In a digital factory, VR can be used to provide workers with hands-on training in a safe, controlled environment. This allows workers to become familiar with production processes and equipment before they start working on the factory floor. VR training can also reduce the risk of accidents and improve overall safety in the factory.

Another way VR can improve production processes is through virtual prototyping. With VR, designers and engineers can create and test virtual prototypes of products and production processes before they are physically built. This can save time and money by identifying potential problems early in the design process, enabling designers to make changes before the product is manufactured.

VR can also be used to optimize production processes. By simulating different scenarios, VR can help identify inefficiencies in the production process and suggest improvements. For example, VR can simulate the movement of materials and products through the factory to identify potential bottlenecks and suggest ways to optimize the flow of materials and products.

4. Application of TX Plant Simulation to Improve the Performance of the Production Process

Ensuring an organization’s manufacturing process depends on the effective design of the manufacturing base, i.e., the manufacturing layout. Improper layout design results in cluttered and redundant material flows, unnecessary worker movements, wastage of production areas, etc. Ultimately, these imperfections lead to increased logistics costs and, therefore, increased overall production costs.

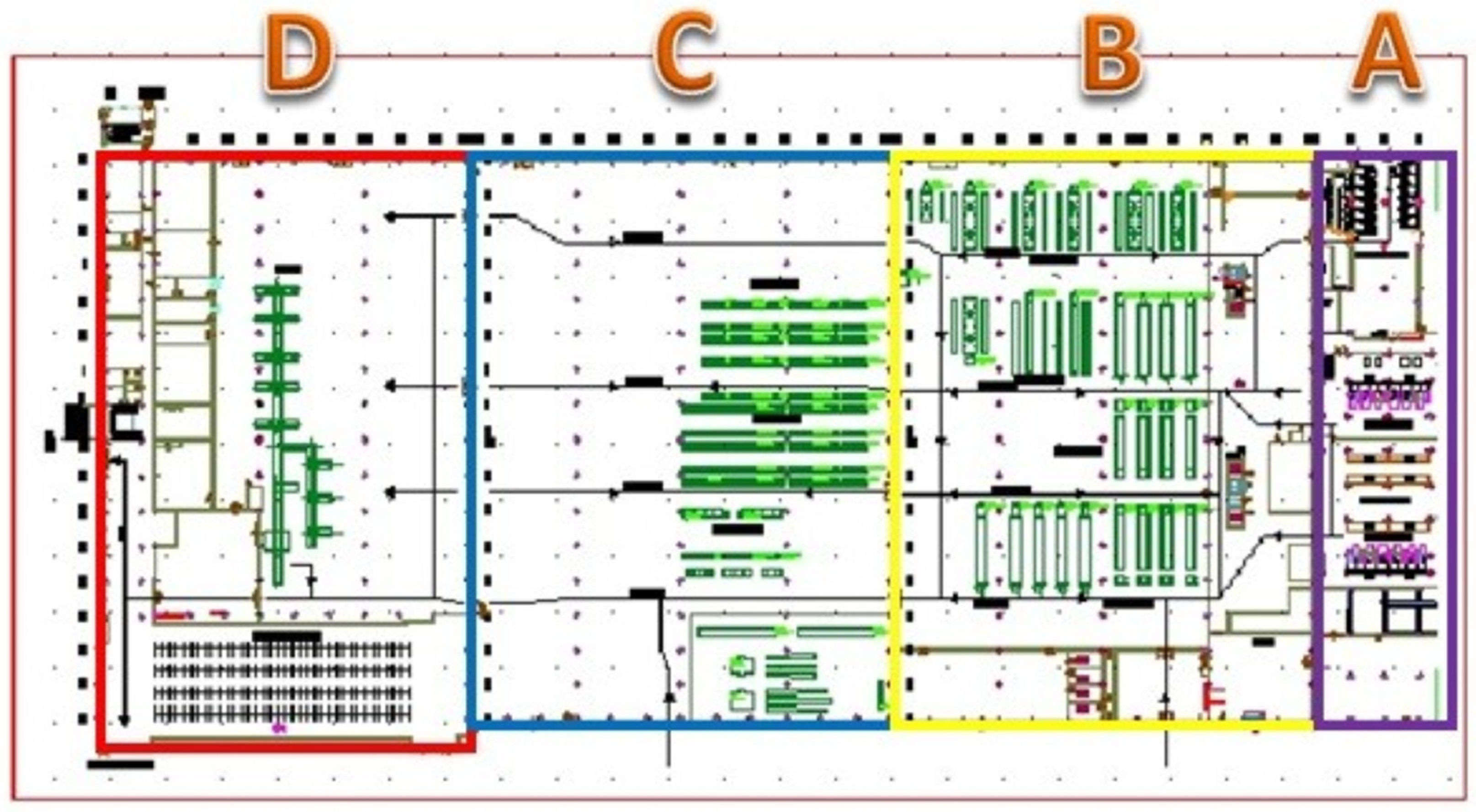

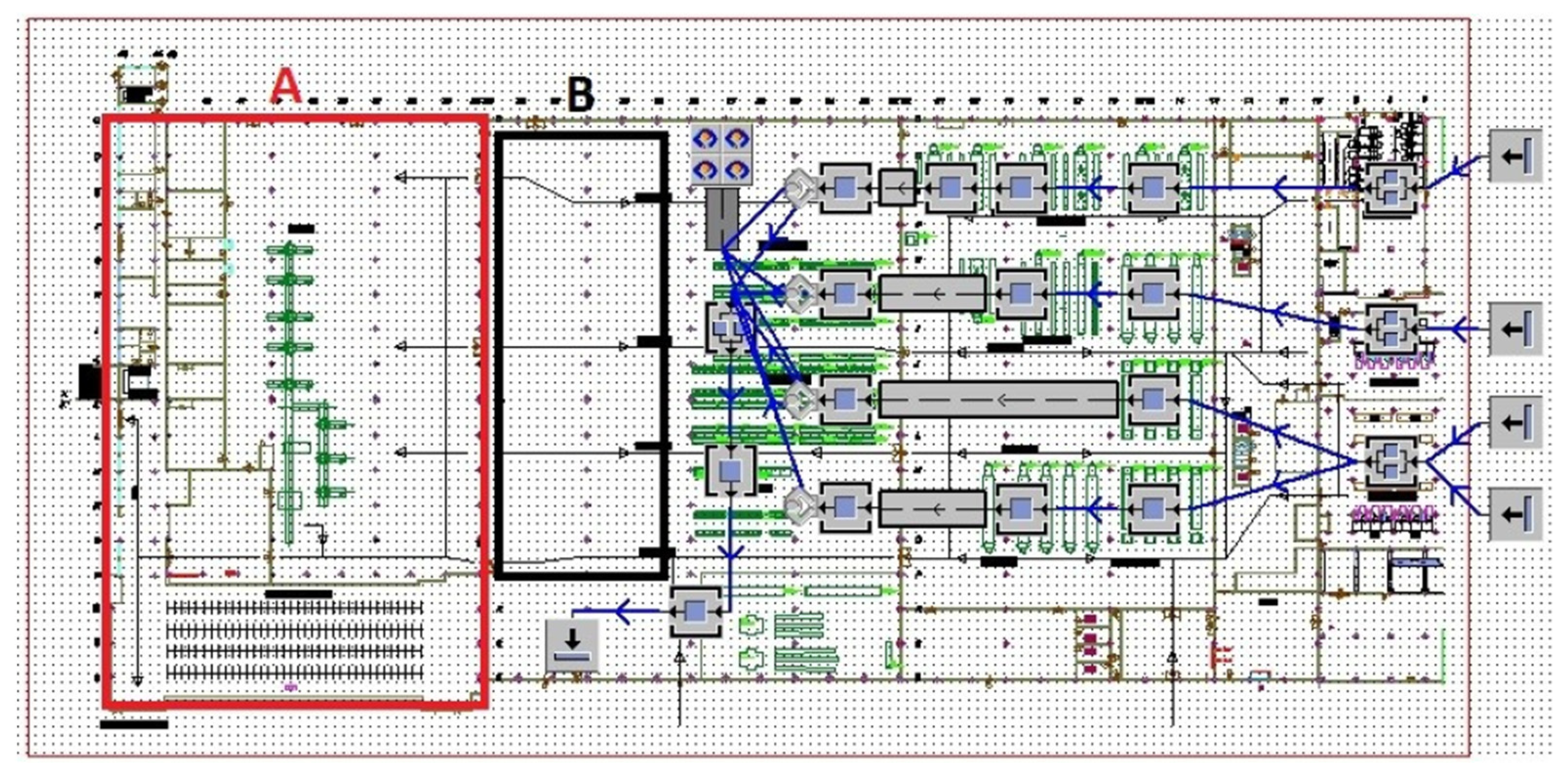

Primarily, it is necessary to present what the production hall of the chosen organization looks like and to closely describe the wings in which the individual processes are performed. In order to introduce the production hall, its technical drawing developed in CAD system will be used (

Figure 3). In

Figure 3, it is possible to see the floor plan of the production hall and its division into individual sectors. This figure shows the direction of the material flow in the hall, and it also features marked locations, which demonstrate the placement of the machines for the production, treatment, inspection and packaging of the fibers [

28].

Figure 3 shows a hall divided into four sectors, which are separated by colors. The production takes place from right to left. It starts in sector A, which is marked in purple. This sector is located one floor above the other three sectors. In sector A, a synthetic fiber is produced from granulate, which is melted under high pressure and at high temperature and extruded through the so-called nozzles (metal circular plates with a number of small holes in a circular shape) in cooling shafts that go from sector A to a floor below to another sector. In these shafts, the produced fiber is cooled, and it slowly descends to the fiber treatment machines located in sector B.

Sector B is marked with yellow color and is located on the ground floor. Fiber treatment machines are located in this section. The fiber is adjusted according to customer requirements. The oiling, siliconizing, braiding, stretching and dyeing of the fiber are conducted here. This sector has the highest density of machines and lines. The treated fiber continues through conveyor belts to sector C.

Through sector C, which is marked in blue, the fiber passes on conveyor belts further to sector D. This part of the hall serves only to move the fibers from one process to another. In sector D, marked in red, the inspection of fibers is performed together with the subsequent packaging of individual spools and the packaging of entire pallets. Sector D also includes the organization’s storage facilities and the dispatch of goods. In

Figure 3, it is possible to see the direction of material flow, which is shown by the black arrows.

The problem of the chosen organization and the place where the improvement needs to be implemented is sector C. It is a part of the hall with large dimensions, but it is not used to its full potential. There are only four conveyor belts that pass through the sector. There are empty trolleys for the transport of material and manufactured products present, but there is no production process performed here. Conveyor belts on such a long route (approx. 95 m) considerably slow down the whole process of fiber production. Workers inspecting the fiber must wait an unnecessarily long time to be able to inspect it. This will also be shown in the simulations or the resulting graphs from the simulations, which will be presented in other parts of the work. The equipment in the entire production hall is not optimally and efficiently distributed. In order to shorten the time of the production process and fully utilize sector C, it is necessary to modify the production process that is currently in operation.

4.1. Simulation of the Production Process

For the simulation of the production process, we used the PLM software Tecnomatrix Plant Simulation, which was developed for this purpose. The process was simulated in 2D and the program used a drawing of the production hall of the selected organization as a basis for the layout of individual machines, lines, and conveyor belts according to the actual layout.

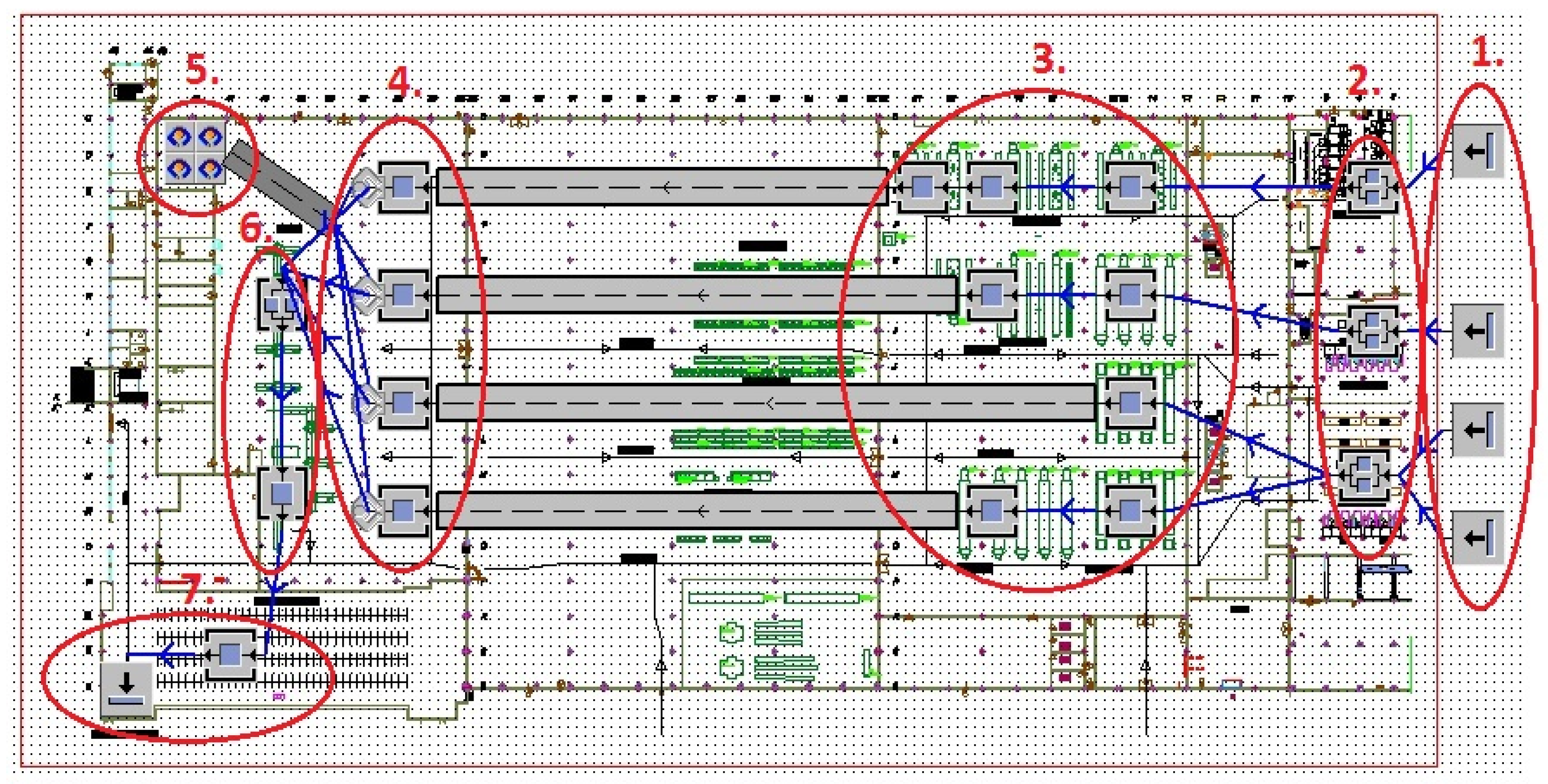

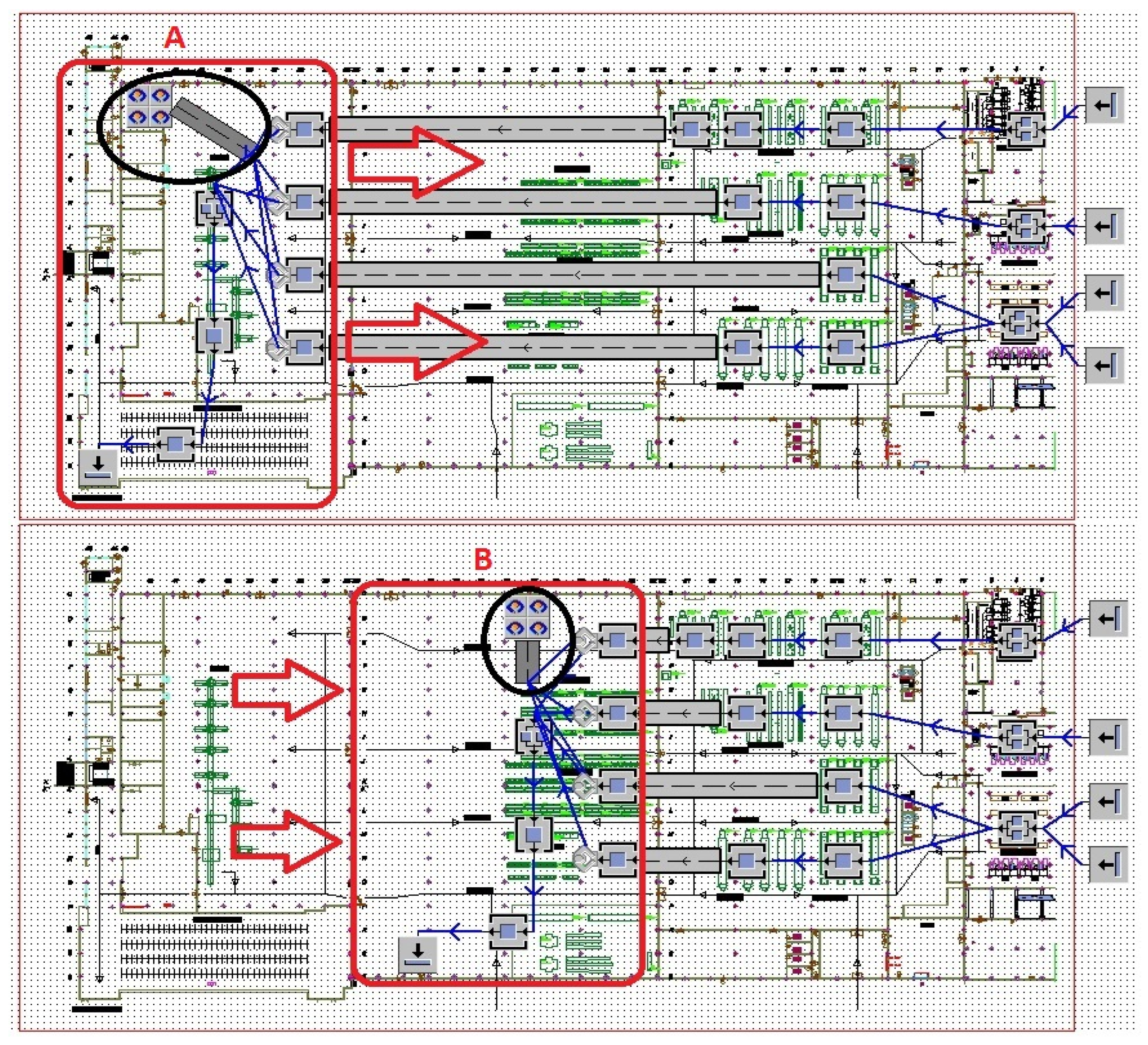

Figure 4 shows the model of the whole production process in the hall of the organization, along with the marked direction of material flow. Then, in order to highlight the ongoing activities and processes and provide a smooth transition to the simulation, we describe the actual production activity taking place on the production floor.

The simulation method concentrates on the production step that is most important, or the step that slows down a certain production hall’s production process the most. This entails specifically the movement of the filament on sliding belts across the long center area of the production hall, while the filaments A, C, and D are still being transported. The filament designated B is already at the inspection station.

The figure shows a model of the production process with marked objects in the production hall. The objects marked by the number “1” are containers in which the granulate is located and from which this granulate is poured into the machines to produce fiber itself, which are marked with the number “2”. Here, the granulate becomes a fiber, which continues for treatment. The fiber treatment machines are marked by the number “3”. From there, the fiber is moved by belts for inspection by workers. The inspection workplaces are marked by the number “4”, and the number “5” marks the place reserved for workers from where they go to inspect the thread to the inspection workplaces. The number “6” indicates packaging machines, and the number “7” represents the storage and dispatch of fiber in the storage areas.

It is clear from

Figure 4 that everything essential takes place outside the central part of the production hall, which is shown in

Figure 4 and marked in blue and by the letter C. Since the process of the simulation process cannot be shown in its entirety,

Figure 5 shows a critical part of the production process, which is to be improved by the present study.

During the simulation process, the most critical part, which slows down the whole production, is when the fiber is moved on the belts through the middle part of the production hall. While fiber B arrived at the inspection site, fibers A, C, and D are still being transported through the long central part of the production hall. Workers who inspect the product will set off from the spot marked “E” only after the fiber arrives at the inspection site. This is also because the place reserved for inspectors is located at a considerable distance from the place of inspection. The controller worker receives a message from a computer in his reserved place that the thread is ready for inspection at his inspection workplace. Only then does the worker arrive at the inspection site, and this also takes a lot of time due to the disproportionately large distance between the place reserved for the inspectors and the inspection site. However, the other inspectors must wait for the A, C, and D fibers to be transported to their workplaces. It is at this stage of the production process that time, energy, and human resources are wasted, and a proposal for improvement will be focused on this phase.

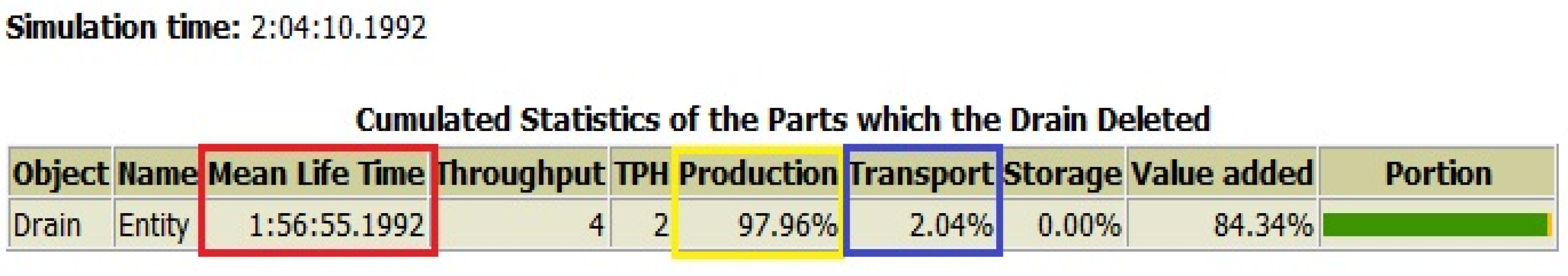

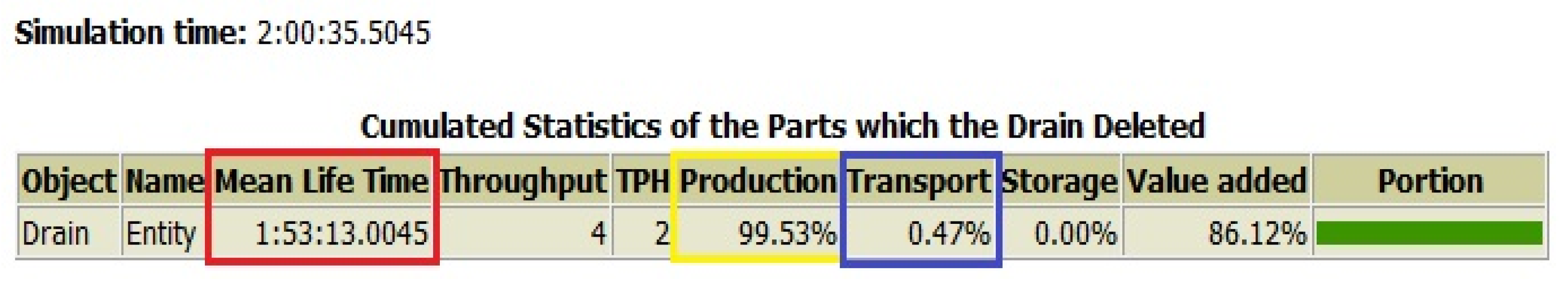

After the simulation, Tecnomatix Plant Simulation can generate a lot of information about the simulation, graphs, tables and statistics. A very important piece of information is the duration of the entire production process, which is marked in red in

Figure 6.

According to

Figure 6, the duration of the production process is one hour, fifty-six minutes and fifty-five seconds. This is the time from when the granulate is poured into the fiber production machine until the fiber is shipped away. Another important piece of information is the splitting of all production time into production and transport. In

Figure 6, the production is marked in yellow and its percentage value is 97.96, and the transport of material (fibers), the percentage value of which is 2.04, is marked in blue. The aim of the improvement is to reduce the production time and to reduce the percentage of transport, which is reflected in the increase of the percentage of production.

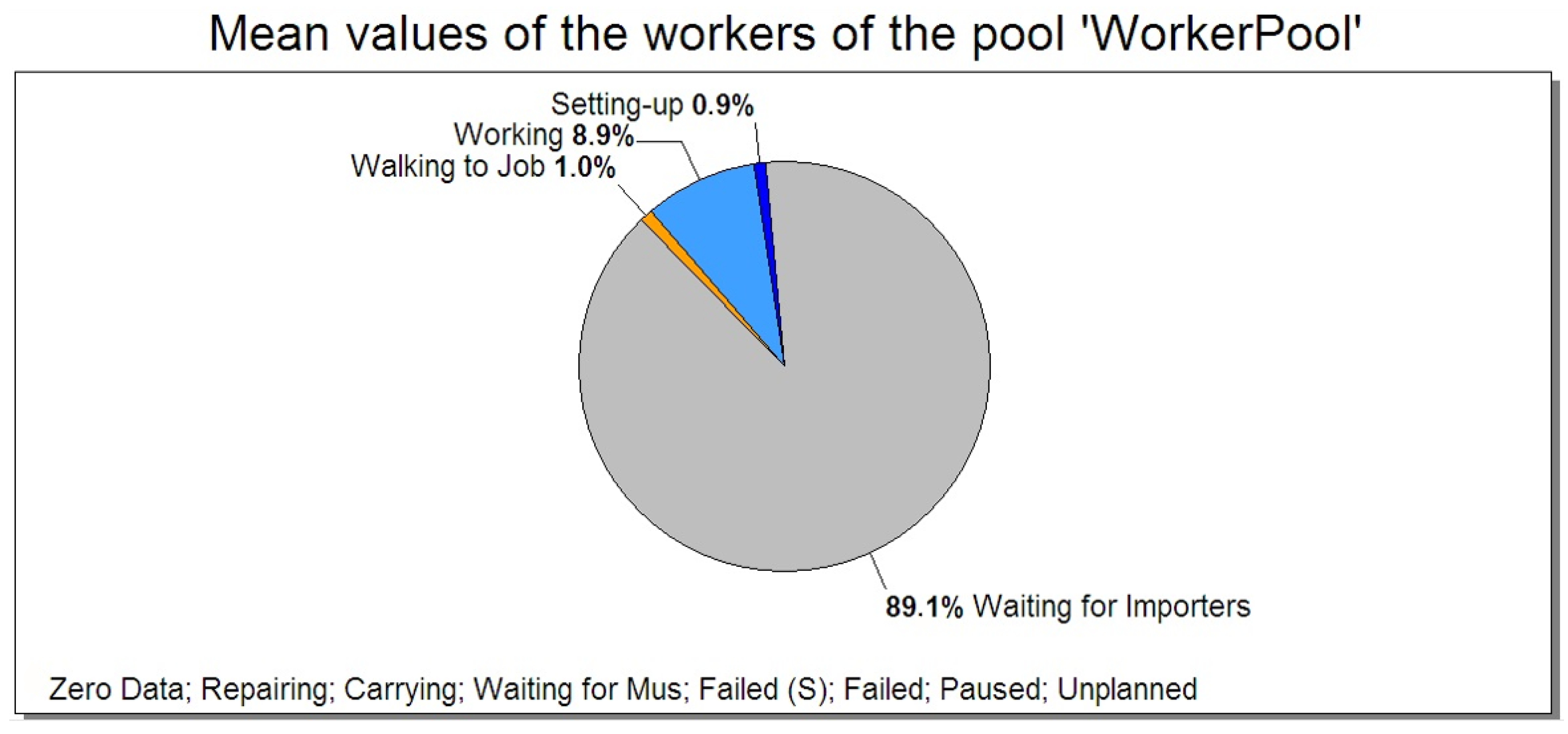

As already mentioned, the inefficient location of the space reserved for fiber inspectors and the long wait time for the fibers to be ready for inspection can be seen in the pie chart (

Figure 7), which shows the percentage distribution of inspector activities during the whole production process.

It is clear from the graph that the vast majority, i.e., 89.1%, of the time through the production process is spent by the controller waiting for the fiber. This is shown in gray in the graph. The orange color shows time walking to the workplace, which is 1%. The distance that workers must walk to the workplace is about 26 m. The light blue color shows the work, which is 8.9%, 0.9% of the total time spent preparing for the inspection—this is shown in dark blue.

4.2. Increasing the Efficiency of the Simulated Production Process

In order to increase the efficiency of the organization’s production process, it is necessary to re-implement the production process simulation. First, however, the individual workplaces in the production hall must be located more efficiently. The main aspect of the improvement is the use of the central part of the production hall, which so far only serves to transport fibers and slows down the entire production process.

When increasing the efficiency of the production process in a selected organization, it is appropriate to rely on the principle of so-called lean manufacturing.

The main goal of lean manufacturing is to optimally set up as stable a production process as possible, with the lowest possible procurement, operating, maintenance, energy and human resources costs. Lean production, with the continuous improvement of production processes, identifies and avoids wastage, i.e., avoiding or modifying activities that do not bring additional added value or bring potential losses. Lean manufacturing focuses on eliminating wastage from the time when the order is accepted, through the production process, to the delivery of the finished product to the customer. The aim is to meet customer requirements with an emphasis on minimizing activities that would increase the value of the product or service.

In this case, the inspection, packaging, storage and shipping processes were relocated to the central part of the production hall, which significantly reduced the length of the conveyor belts, which slowed down the production process; also, the central part of the production hall was fully utilized. This is shown in

Figure 8.

The inspection, packaging, storage and shipping processes marked in red were moved from one part of the hall (A) to another part of the hall (B), and the length of the conveyor belts was significantly shortened.

Figure 6 also shows that the place reserved for inspectors was relocated, and the distance to their workplaces was also significantly shortened. In this case, the distance between the place reserved for inspectors and the inspection workplace is about 13 m, which is half the distance compared to that in the original location of the workplaces in the production hall. The space reserved for inspectors, together with the route to the inspection workplaces, is marked with black in the picture.

This is where the value of digital factories that are simulated by PLM systems really shines through. If these production processes were simulated while a given production was being developed, all previous harm to the company would be undone, and we can assume that the input costs at the start of the production company’s development would be much lower than the losses currently incurred. An important and crucial component of building a successful business is the accurate sizing of the production halls, modeling of the line architecture, staff ergonomics, and the associated safety and energy efficiency of the production.

4.3. Simulation of the Production Process after Relocation of Workplaces

The course of the simulation of the production process is shown in

Figure 9. The simulation takes place after the changes in the layout of the individual workplaces in the production hall.

Figure 9 shows that the inspectors start working at the inspection workplace almost at once. Workers marked A, B, and C are already inspecting, and the worker marked “D” is moving to the workplace but needs to walk half the distance than that in the simulation with the original workplace layout. It follows that he will arrive at the workplace earlier that before.

This distribution of workplaces should lead to a reduction in the time of the entire production process, an increase in production, and a reduction in the percentage of material transport during the process. After performing this simulation, the program again generated a lot of statistics and graphs. The most important ones in this case are the basic statistics of the production process in

Figure 10.

As we can see, the distribution of workplaces according to lean production really shortened the duration of the production process. After the changes were made, the duration of the process, marked in red in

Figure 10, reached one hour, fifty-three minutes and thirteen seconds. This represents a reduction in time compared to the original workplace layout by three minutes and forty-two seconds. The percentage of production marked with yellow increased by 1.57% compared to the original deployment, and the percentage of material transport decreased from the original 2.04% to the current 0.47% due to the shortening of the length of the conveyor belts, which represents a decrease of 1.57%.

Such values are not a huge leap in increasing process performance, but it must be considered that these results were achieved after simulating a single fiber production process. In the selected organization, however, this process is repeated twenty-four hours a day. In the long run, such distribution of workplaces in a production hall can bring the organization an increase in current profits by tens of thousands of euros per year.

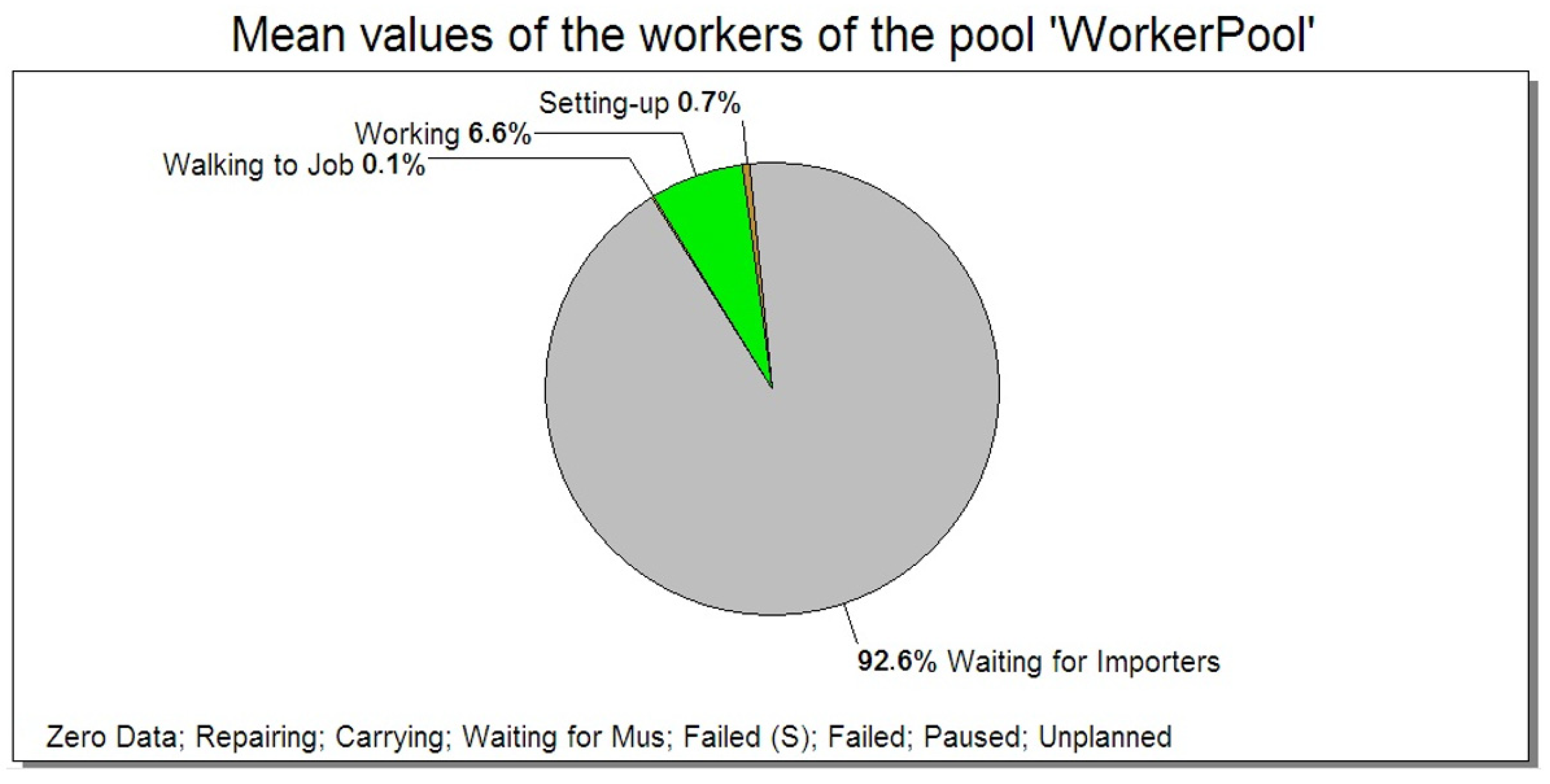

A relocation of individual workplaces and a more efficiently located place reserved for inspectors should also be reflected in the results of the simulation. To compare the statistics of the inspectors and their activities during the production process,

Figure 11 shows the percentage distribution of the controller’s activities over the duration of the entire production process.

From

Figure 11, it is clear that changing the location of the place reserved for inspectors did not decrease, but on the other hand, it increased the waiting time for fibers from the original 89.1% to the current 92.6% (marked with gray). However, time spent walking to the workplace was reduced from the original 1.0% to the current 0.1% (marked with blue); the time required to perform the work was also reduced from 8.9% to 6.6% (marked with green), and the time required to prepare the fiber control also shortened from 0.9% to 0.7% (marked with orange).

Thus, the waiting time for fibers increased by 3.5%, time spent walking to the workplace decreased by 0.9%, time required to perform the work decreased by 2.3%, and the preparation time for fiber inspection decreased by 0.2%.

It can be stated that the relocation of the space reserved for inspectors did not have a significant effect on shortening the time of the production process. Although there were changes in the ratio of the individual activities of the controller during the production process, the shortening of time had only a minimal effect. It follows that the use of the central part of the production hall, and thus the shortening of the length of the conveyor belts, had the greatest effect on increasing the efficiency of the production process. This points most to the fact that transport on long belts through an empty, unused part of the hall was a waste of time, energy (needed to drive the belts), and, to a lesser extent, human resources.

4.4. Use of Empty Spaces

After a more efficient arrangement of workplaces in the production hall, the last part of the production hall remained completely unused (see

Figure 12).

Part of the hall where the machines for the processes of inspection, packaging, storage and dispatch of the product were originally located remained empty. It is marked in red and with the letter “A” in

Figure 12. In addition, after applying the principle of lean production, almost half of the space in the central part of the production hall remained empty. This space is marked in the picture in black and with the letter B.

The area of improvement in sector C, which represents the central part of the production hall, were empty trolleys for the transport of material and manufactured products. In this part of the hall, almost half of the space still remained unused, so empty trolleys for the transport of material could then be stored in this free space, or it could also be used for the temporary storage of work tools, rejects, or unnecessary material.

The part of the production hall that was marked in red and with the letter “A” remained unused. If the selected organization does not plan to expand production capacity, product portfolio, or the otherwise use of these empty spaces, another way to increase the organization’s profits is to rent this part of the hall to another organization. The selected organization no longer needs to worry about the unused part of the hall and spend funds on its maintenance. Ultimately, the chosen organization relieves itself of further losses in the form of maintaining an empty part of the production hall, and it can gain additional financial profits from renting part of the production hall to another organization.

Today, when inventories are being reduced and the business has trained employees, it is proper to utilize the funds provided and maximize the potential of the workforce within the company. Based on such study, the company will also understand that if it has available or empty space where it can expand its portfolio of activities, it will use PLM systems to simulate all of its future investment plans before deciding on the company’s course of action.

4.5. Virtual Reality Simulation of a Digital Factory

VR technology can be a powerful tool for improving production processes in a digital factory. By providing immersive training, enabling virtual prototyping, optimizing production processes, and improving communication and collaboration, VR can help digital factories operate more efficiently, reduce costs, and improve quality. As VR technology continues to advance, we can expect it to become an increasingly important tool for improving production processes in the digital factory of the future.

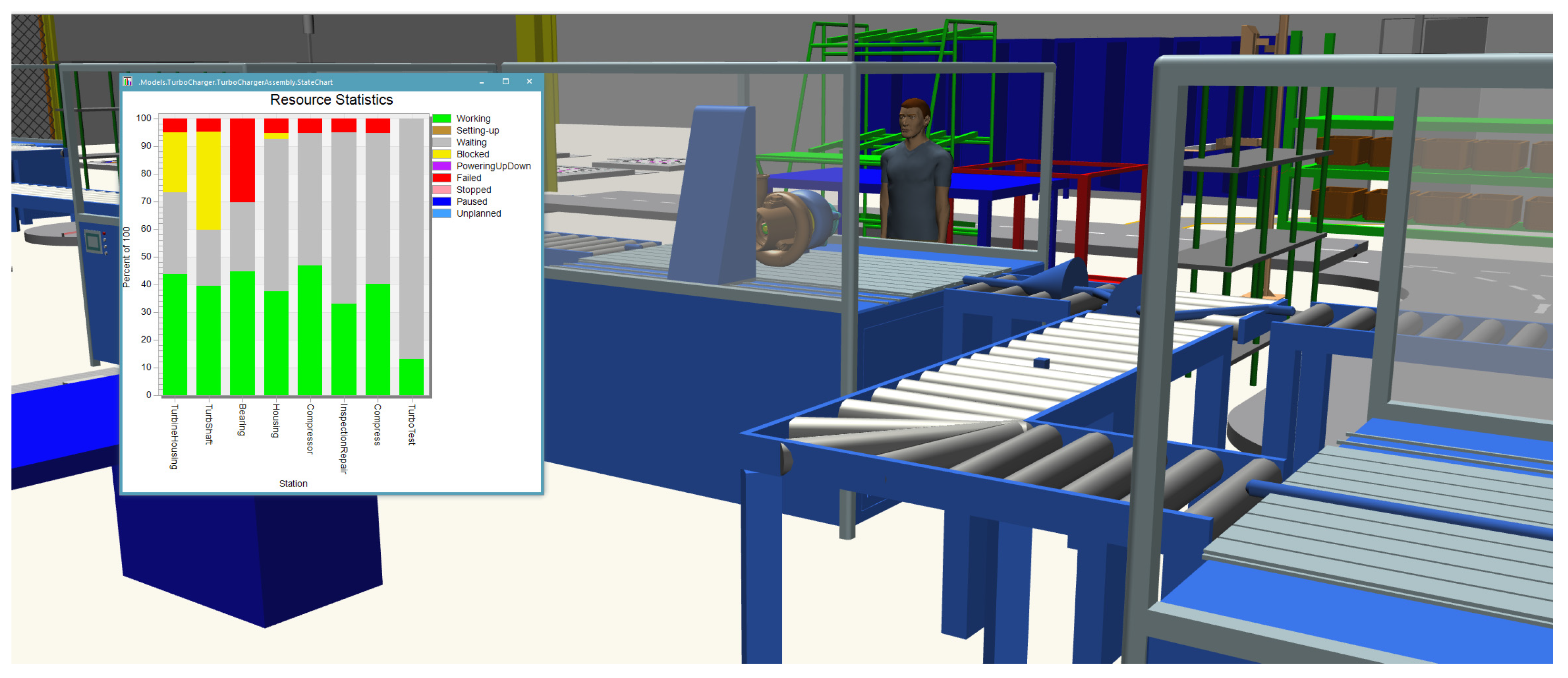

The presented detail of view using virtual reality with Siemens PLM system Tecnomatix is shown in

Figure 13. It presents the manager‘s view of the chosen part of the digital factory, and the manager can check the online data. With the use of virtual reality, the manager can view the processes from various working positions in this factory. He can have a view of all positions of machines, lines, and staff and their ergonomic comfort as well as safety. All these data can be used for planning and calculating, and in the end, it shows the economic work of this company. It is a useful strategy for starting innovative processes in every part of the factory. The processes can also include the training of staff and the updating of all health and safety manuals, and it will be a starting point for the energy-saving strategy of the company. The process of simulating a digital factory ends with setting up a whole new set of rules that allow people to work differently.

VR can be used to improve communication and collaboration between workers. In a digital factory, workers may be located in different locations or work on different shifts. VR can be used to create a shared virtual environment where workers can collaborate and communicate with each other in real time. This can improve teamwork, reduce errors caused by miscommunication, and improve overall productivity.

Figure 14 shows the use of VR, and

Figure 15 demonstrates a detailed view.

In

Figure 14, the engineers collaborating on the project created digital twins where they already work directly in a position where an employee has to inspect the products that pass through the slide belt. The production representative uses VR to monitor the production process from the operator’s position and the position where the employee should stand and perform the work, keeping track of the actual speed of the production process and the data that are needed for the simulation of that process. During the production process, one of the engineers adds the requested statistical data to other engineer‘s field of view to simulate online the possible production processes, possible line errors, adjustments of the line speed, or addition of another machine to the production process.

Figure 15 shows the view from the VR, which is available to the engineer. He views the position where an employee is working. In the left corner, he can see the online data that are providing information about the production process of the line. All of the statistical data can be further processed, analyzed, and used for the creation of measures in a table. It is possible to further work with this data in order to evaluate the processes that are already in place, suggest changes, implement them in the digital factory, re-simulate them, and, once the desired results have been attained, introduce them right into production.

Statistical data of production processes from the PLM program were also shown in parallel during the simulation of the selected production process. Digital factory is a modern manufacturing facility that employs advanced digital technologies to optimize production processes and improve efficiency. The use of automation, data analytics, interconnected systems, agile operations, collaborative robots, virtual simulation, and predictive maintenance enable the factory to operate more efficiently and cost effectively and with higher quality than traditional factories. As technology continues to advance, we can expect digital factories to become even more prevalent and more sophisticated in the years to come.

Table 1 shows all online data operations of chosen processes used by virtual reality technology, where we can monitor the operational processes of selected manufacturing, production, service and training activities. By the means of virtual reality, it is possible to export selected statistical data that could be used for monitoring of selected objects, smart factory design or optimization of energy, ergonomic and economic resources. This data could be useful in creating new similar projects of digital factory design. It can also serve as a tool for the prediction of time, financial, staff and energy wastage.

The statistical data offered by SIEMENS Plant Simulation were generated during the simulation of production processes in the smart factory. The resulting data points to the activities performed in the smart factory, which were generated from the current view through VR into the production process. By changing the position via VR in the smart factory to another production process, the displayed online data will change to the currently selected production activity of the factory.

5. Discussion

Virtual reality (VR) and digital environment technologies are still relatively new and rarely used in everyday situations. However, numerous studies have demonstrated their critical application in the business sector.

This research has created a method for team collaboration and information processing using 3D and VR virtual environment tools in order to demonstrate the flexibility and significance of PLM systems using VR. Using VR to enhance team collaboration, engineers and designers in the field can continue to design and develop manufacturing procedures. Immersive 3D virtual environments can be used to transform previously established virtual environment processes. These environments are anticipated to improve human interaction and communication without requiring participants to be physically present. Instead of continuing to try to simulate interaction on virtual platforms, the experts can concentrate their research on new and distinctive opportunities in virtual environments with VR, as well as on enabling knowledge sharing and collaboration in education, services, meetings, sales and purchasing, and generally in all productive industries where more than one person can interact [

36,

37]. Based on real-world experience, the call for practical potential as it is presented in this paper could be effectively applied to any type of users or businesses, without incurring costs or risks from insufficient training.

There are several benefits for stakeholders. The benefits for science consist of the possibility of simulating processes on the basis of a digital factory using VR, where it is possible to simulate selected business processes in order to prevent financial loss incurred by the company. Considering the benefits for practice, it is possible to apply a digital factory to companies in terms of the expansion or simplification of production in their enterprise. They can simulate individual processes and test the impact of conditions, energy load, ergonomics of employees, energy load of the enterprise and thus decide on the change or innovation of the process.

Another benefit is the application of synergies between the processes that are present in the enterprise and those that are simulated in digital form, so that the results can be compared, processed, continuously improved on the basis of the processes and thus can intervene online in the detailed tasks and decisions in the selected process.

This research’s findings demonstrate practical use for virtual reality and digital factories in various contexts. Therefore, it is crucial to advance with new practical work in this field such that it can continue to demonstrate empirical certainty regarding both the degree of acceptability and the application in real-world situations, with the knowledge that there is momentum for technological advancement in its application.

6. Conclusions

A smart digital factory works by integrating machines, people, and Big Data into a single, digitally connected ecosystem. A smart factory does not just analyze data, it actually learns from experience. It interprets and extracts information from datasets to forecast trends and events and to recommend and implement smart manufacturing workflows and automated processes. The smart factory undergoes continuous procedural improvement in self-correction and self-actualization—it can learn to make itself (and humans) more resilient. It follows that the use of virtual reality in production processes is a more effective and economical demonstration of the digital factory, with the possibility of implementation in the selected company. It is demonstrable that virtual reality technology can be carried out with the help of various research for a specific company in the decision-making process, e.g., for the purchase of technology, training of new employees, expansion of production premises with regard to ergonomics and safety in production, and other specific requirements defined by the production company. The purpose of this document is to demonstrate the VR and digital factory approach and the possibilities of simulating a real digital factory environment, including VR in planning, material flow management, and workforce, taking into account the ergonomics of the environment and personnel. This approach makes possible the interaction between the real enterprise and the digital enterprise, where both the dimensions of the enterprise and all the processes that take place in this enterprise can be directly simulated using software in order to reduce time and save money.

The effectiveness of using digital factory modeling and simulation in PLM was proven before. A company can design the production processes that are necessary to achieve the partial objectives by which the company eliminates the impact of losses and risks. However, there are still limitations that can negatively impact companies, mainly that the preparation of a digital factory simulation and the tracking of individual production processes is a time-consuming and mentally demanding process. The main limitation is the shortage of trained engineers who can efficiently process the data from the production companies and prepare the resulting simulation and, most importantly, design effective solutions.

Since more physically difficult tasks are being replaced by machines, it is increasingly important to ensure the ergonomic comfort of the operator, who should more psychologically oriented within the company to the activities for which he is responsible. Market and customer orientation opens up various possibilities for further research. It is possible to deal in more detail with the virtual solution of individual parts of companies. In today’s contemporary factories, even a tiny lack of attention by the responsible employee can result in hundreds or even thousands of pieces of unwanted wastage.