Abstract

The aim of this paper is to study the effect of the organic matter (OM) content on the effectiveness of the soil stabilization process using the biopolymer xanthan gum. Five different artificial soils with an organic matter content in the range of 1.5 to 7.7% are subjected to unconfined compressive strength (UCS) and oedometer tests to evaluate their strength, stiffness and compressibility, respectively. These results are complemented by an analysis of SEM images. The results from the UCS tests show a positive effect of the stabilization process in terms of strength and stiffness in a range of an OM content of 1.5 to 5.5%, but a detrimental effect for a higher OM content (7.7%) is observed. Due to the hydration of the biopolymer’s hydrogels, the compressibility tends to increase in specimens stabilized with xanthan gum. This effect is amplified for higher OM contents. The results of oedometer tests also show that the stabilization with xanthan gum brings about a significant decrease in the coefficient of consolidation, inducing an increase in the primary consolidation time.

1. Introduction

The construction of many civil engineering structures (such as buildings, ports, airports, bridges, tunnels, among others) on/in problematic soils with poor mechanical behavior requires the implementation of improvement methods to enhance these soils’ characteristics, in order to increase the strength and/or decrease the compressibility. One of the most common techniques used to improve a soil’s properties is chemical stabilization, which consists of a mixture of the natural soil with binders, such as quicklime, fly ash, blast furnace granulated slag and cement (which is the most used), among others. The use of cement is associated with a significant ecological footprint, since: (i) the cement industry is responsible for about 2.6% of the global CO2 emissions [1]; (ii) the use of cement in soil stabilization induces an increase in the pH of the soil treated, which has a negative impact on the natural microbiome and on the vegetation’s development [2]; and (iii) the material produced by the cement-based soil stabilization is irreversible [2], which is not an advantage for construction in an environmentally sensitive area.

To reduce the environmental impact of the use of cement, some alternative techniques have been investigated in the last few years, such as the reuse of materials in the construction industry [3], and the use of biodegradable [4,5] and bio-based materials, among others. One of the most studied bio-based methods consists of the precipitation of calcium carbonate that behaves as a bio-cement. When this material is deposited in the porous spaces of the soil, it creates bonds between the soil particles, inducing an improvement in the mechanical properties of the composite material [6,7,8,9,10,11,12,13,14]. This methodology presents two variants, microbial-induced calcium carbonate precipitation [7,15] and enzyme-induced calcium carbonate precipitation [7,8,9,10,15,16]; in the former, bacteria are added to the soil to produce enzymes, while in the latter, the enzymes are added directly to the soil.

The use of biopolymers (biodegradable polysaccharides produced by living organisms) has emerged as an alternative to the bio-based methodologies, which are also associated with a low ecological footprint. Among the several types of biopolymers studied to solve geotechnical problems (casein and sodium caseinate salt, guar, cationic e-polylysine, gellan, agar, chitosan, curdlan and β-Glucan, Persian gum [17], Zein biopolymer [18], etc.), xanthan gum (XG) is one of the biopolymers most investigated in geotechnical engineering, mainly due to the significant reduction in its market price in the last years [5] and to its ability to mitigate some soil weaknesses; in particular, it:

- (i)

- Decreases the soil’s erosion [19], and in parallel promotes the growth of the vegetation, which also contributes to erosion mitigation [20];

- (ii)

- Decreases the permeability coefficient of the treated soil [21,22,23,24,25,26] due to the hydration of the XG hydrogels, which decreases the soil’s porosity and consequently makes the flow of water in the porous space difficult;

- (iii)

- Improves the mechanical properties of the treated soils, such as sands [23,27], silty sands [28,29], clayed soils [19,27,30], bentonite, kaolinite [26,27,31,32], and residual soils [33,34];

- (iv)

- Some one-dimensional compression tests with a bentonite and a kaolinite stabilized with XG show a decrease in the compressibility after the stabilization with xanthan gum [31]. However, it should be emphasized that not all the results published are consistent with each other; indeed, results of a soft marine soil [30], kaolinite clay [35], sandy soil [23], and silt sand [29] show an increase in the compressibility after stabilization with XG. In terms of the coefficient of consolidation (Cv), results of the treatment of a marine soft soil [30], high plastic soil [36], and kaolinite clay [35] with XG promotes a significant reduction in the Cv; i.e., the stabilization with XG prolongs the time required to the end of the primary consolidation. Additionally, the coefficient of secondary compression of a kaolinite clay increases after the stabilization with xanthan gum [35];

- (v)

- Increases the pH value [34] and the plasticity index [19,26,34], and decreases the specific gravity [34];

- (vi)

- Changes the compaction characteristics, namely, it increases the optimum moisture content and decreases the maximum dry density of a tropical residual soil [34], a dispersive soil [37], and a kaolinite clay [26];

- (vii)

- Increases the undrained shear strength of a kaolinite clay, but decreases the undrained shear strength of a montmorillonite clay [38];

- (viii)

- Decreases the cumulative variation in moisture loss and mass loss in freeze–thaw tests [36];

- (ix)

- Decreases the swelling potential of a high plastic soil [36].

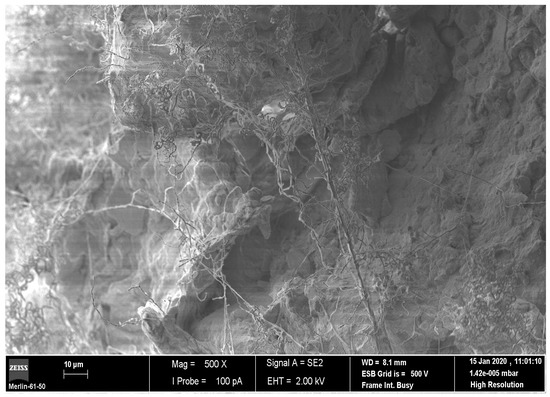

Some research works indicate that the effectiveness of XG in stabilizing soils results from the contribution of two effects: (i) the aggregation of the soil particles due to the deposition of the XG in the voids; and (ii) the bonds established between the XG (hydrogen bonding) and the surfaces of the soil particles, mainly when they are electrically charged, as it occurs in clayed soils [2,27]. These two effects justify the greater effectiveness of the XG in stabilizing clays than coarse-grained soils, since in clays, both effects are cumulative in strengthening the soil. Nevertheless, in coarse-grained soils the improvement of the mechanical properties is only due to the deposition of the XG in the porous space of the soil, inducing the generation of a network of XG fibers, similar to micro-reinforcement of the soil, as illustrated in Figure 1 for a silty sand.

Figure 1.

SEM image of a non-organic silty sand stabilized with 2% of XG.

Some experiments with specimens of silty sand submitted to curing in humid conditions indicate that the stabilization with XG is potentiated for a curing time of 7–14 days and for an XG content of approximately 1% [29]. For a curing time of less than 3 days, a detrimental effect of the stabilization with XG was observed [29].

Although xanthan gum is a biodegradable biopolymer, which is naturally associated with a progressive loss of its properties with elapsed time, some experimental results show a high stability over time in strengthening the soils in dry environments. Indeed, the benefit of XG strengthening such soils tends to grow with curing time [23,27,29,31,37], and even in the long-term (until 730 days) no traces of biodegradability in a sand-XG mixture were observed [27]. On the other hand, the evolution over time of the permeability coefficient (in saturated conditions) did not show results totally consistent with a great stability over time. In fact, the results of Bouazza et al. [22] reveal a decrease in the permeability coefficient of a sandy-XG mixture during the curing time, while the opposite was observed in a clayed soil [24] and a sandy soil [23]. Additionally, the results of Mendonça et al. [25] show a decrease in the permeability coefficient of a sandy soil during the first 14 days of curing time, followed by a slight increase in the permeability coefficient for higher curing times, which may be the consequence of some biodegradability and/or some dehydration of the biopolymer’s hydrogels over time [25,32].

Some previous research has described the efficiency of the treatment of soils with xanthan gum, namely concerning the effect of several factors (such as soil type, curing time, content of XG, among others) on the strengthening, plasticity [30,32] and the permeability coefficient. However, not only is the number of studies about the compressibility of water-soil-XG mixtures in the bibliography limited, there is also a lack of research concerning the effect of the organic matter content on the effectiveness of water-soil-XG mixtures, both in terms of the mechanical properties and of the compressibility characteristics. The main objective and the novelty of this work is to contribute to filling these gaps in the scientific knowledge. Thus, the present study intends to analyze the effectiveness of the use of XG to stabilize five soils, in terms of mechanical properties and compressibility, each with a different organic matter content (1.5, 2.4, 4.1, 5.5 and 7.7%) but a constant particle size distribution. This study is based on the experimental results obtained from unconfined compression strength (UCS) and one-dimensional compression (oedometer) tests, where the behavior of non-stabilized soils is compared with the behavior obtained after stabilization with XG (Table 1). Additionally, images obtained from scanning electron microscopy (SEM) of some specimens are also considered in the analysis.

Table 1.

Testing program. Number of UCS and oedometer tests carried out.

2. Materials and Methods

2.1. Characteristics of the Soils

Table 2 presents the main physical and chemical properties of the five soils used in the experimental work. The reference soil is a natural alluvial soft soil collected in the “Baixo Mondego” area, located in central Portugal. This is an organic soil (OM = 7.7%) with a low pH (3.6) and with a grain size distribution composed predominantly of sand (57%), classified as OH (ASTM D2487-00), i.e., an organic soil with high plasticity. These characteristics affect the behavior of the soil, which exhibits a low undrained shear strength (cu < 25 kPa), high compressibility and high plasticity (wL = 71%; wP = 44.3%) [39,40,41].

Table 2.

Physical and chemical properties of the soils tested.

The reference soil was used to prepare the remaining four artificial soils with five different OM contents, as described in the following sections. Therefore, the five soils used in the experiments have the same grain size distribution. The results presented in Table 2 show the increase in the plasticity (wL and wP) for the higher OM content [42], which matches with other studies [43,44,45,46].

2.2. Characteristiques of the Biopolymer (Xanthan Gum)

The xanthan gum (XG) is a commercial biopolymer produced by the Xanthomonas campestris bacterium and available in powdered form. It is a heteropolysaccharide, composed of glucose, mammose and glucuronic acid [47]; it is usually used as a thickening agent, since when in contact with water it generates viscous hydrogels which promotes an increase in the viscosity [22,30]. XG is active under a wide range of temperature (10°–80°) and pH values (1–13), which promotes its use in agriculture, food and the pharmaceutical industry, cosmetics, drilling lubrication, industrial oils and enhanced oil recovery, among others [22,47].

2.3. Specimen Preparation and Testing

To mitigate the variability usually observed in natural soils, the present work uses remolded samples which maintain the organic matter content, mineralogical composition and grain size distribution composition of the natural soil; but the intrinsic structure of the natural soil is totally destroyed during the remolding process.

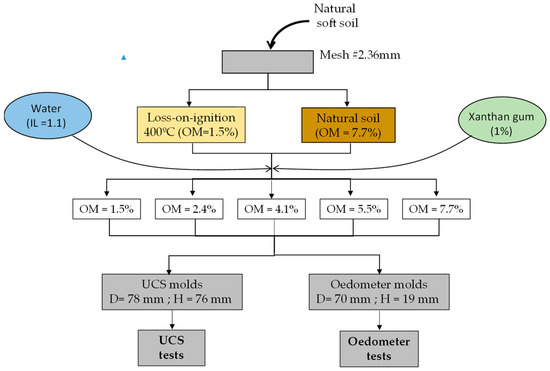

The preparation of the soil used for testing started by sifting the natural soil through a 2.36 mm mesh sieve to remove the larger particles and some shell residues. The OM content of a certain amount of “natural” soil (OM = 7.7%) was destroyed by loss-on-ignition at 400 °C, which was then used to prepare the specimens with different OM contents (1.5–5.5%). The specimens of the soils with the different OM contents were prepared in accordance with the following actions (Figure 2):

Figure 2.

Flow chart of the specimen preparation.

- (i)

- This soil subjected to loss-on-ignition at 400 °C (with an OM content of 1.5%) was mixed with the “natural” soil (OM = 7.7%) in different amounts to obtain the samples of artificial soil with the desired OM content, between 1.5% (lower OM) and 7.7% (natural OM). Naturally, the process of adjustment of the OM content had some iterations, with the re-evaluation and eventual re-adjustment of the OM content;

- (ii)

- In the case of the stabilized samples, an XG content of 1% (ratio of the dry weight of XG to the dry weight of the soil) in powder form was added to the dry artificial soil and mixed well;

- (iii)

- The artificial soil (with the required OM content), with or without XG, was mixed with the distilled water, to obtain a liquidity index of 1.1, during the time necessary to obtain a homogeneous soil-water-XG paste;

- (iv)

- The mixture was introduced into the UCS molds (38 mm in diameter, 76 mm height) and oedometer molds (70 mm in diameter, 19 mm height) in 3 layers and 1 layer, respectively;

- (v)

- Each layer was subjected to tapping (10 times) to remove air bubbles and compacted with 100 kPa for 10 s;

- (vi)

- A superficial scarification of the previous layer was performed to improve the connection between two successive layers in the molds;

- (vii)

- Based on the results of Venda Oliveira and Cabral [29], the stabilized specimens were stored in a plastic bag during 14 days of curing time (only stabilized specimens) inside a room with controlled temperature (20 ± 2 °C) and humidity (95 ± 5%), in order to reduce the suction phenomenon. The unstabilized specimens were not submitted to a curing time;

- (viii)

- After that, the specimens were removed from the molds, both surfaces were trimmed and the quality of the samples was analyzed visually;

- (ix)

- The specimens with the required quality were accepted for testing (UCS and oedometer tests);

- (x)

- The oedometer ring (polished stainless steel) was coated with a thin film of grease prior to the oedometer tests to minimize the friction between it and the soil;

- (xi)

- The oedometer ring was assembled with the specimen, and they were saturated by immersion;

- (xii)

- The displacement transducers (both tests) and the load cell (UCS tests) were set up and adjusted;

- (xiii)

- The UCS and oedometer tests were carried out. The vertical displacement (both tests) and the vertical pressure (UCS test) were recorded by an automatic data acquisition system;

- (xiv)

- A strain controlled test was used in the UCS tests under a strain rate of 1%/min (ASTM2166-05);

- (xv)

- In accordance with ASTM D2435-04, stress increments with a load ratio of 2 were applied in the loading path of the oedometer tests, while in the unloading path a load ratio of 4 was used during the time required to the end of the primary consolidation. The coefficient of consolidation (Cv) was evaluated using Casagrande’s methodology.

For each condition tested, the UCS tests were repeated three times and the oedometer tests were duplicated, which ensured the quality and reproducibility of the tests carried out (Table 1). The conformity/compliance criterion used for the UCS tests states that the results must be within the range ±10% of the average value, which is a more demanding requirement than the ±15% specified in the standard EN-206-1 (2007).

Additionally, in order to study the repercussions of the factors studied on the microstructure, SEM images were analyzed.

3. Results and Discussion

3.1. UCS Tests

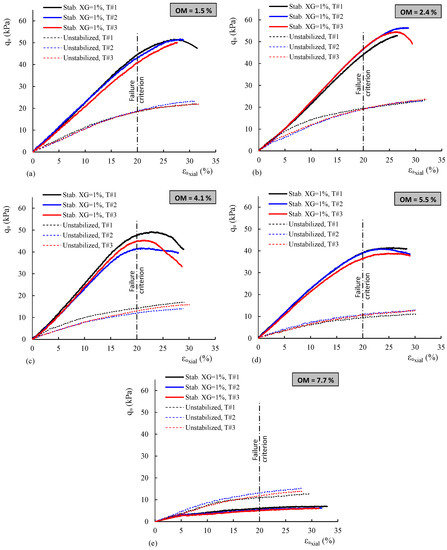

The stress-strain curves of the UCS tests for the unstabilized and stabilized specimens for the various organic matter contents are compared in Figure 3. Despite some scattering, the results clearly indicate a beneficial impact concerning the stabilization with 1% of XG for an OM content in the range of 1.5–5.5%, manifested by a significant increase in strength and stiffness. On the other hand, for a higher OM content (7.7%), a detrimental consequence of the stabilization with XG was observed, indicated by the decrease in mechanical properties (strength and stiffness). Moreover, for the range of OM content of 1.5–5.5%, the results also show that the stabilization with XG tends to decrease the ductility of the stress-strain behavior; in fact, the stabilized soil shows a peak strength followed by a decrease, while a continuous increase in the strength is seen for the unstabilized soil, which is characteristic of ductile behavior. In contrast, stabilized samples with an OM content of 7.7% show clear ductile stress-strain behavior, both for the unstabilized and stabilized soils.

Figure 3.

UCS tests. Effect of organic matter content on the stress-strain behavior: (a) OM = 1.5%; (b) OM = 2.4%; (c) OM = 4.1%; (d) OM = 5.5%; (e) OM = 7.7%.

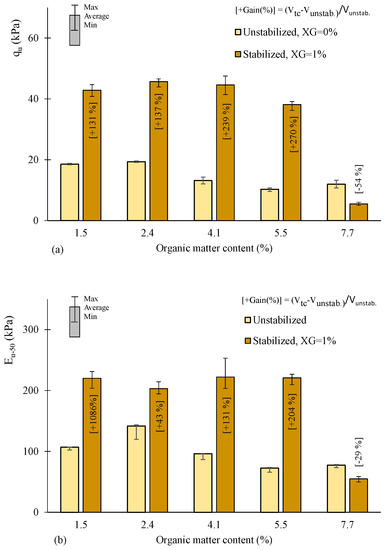

Considering the ductile stress-strain behavior exhibited by the majority of the samples tested, a failure criterion that corresponds to an axial strain (εax) of 20% is used to quantify the unconfined compressive strength (qu). The evolution of qu with the OM content, depicted in Figure 4a, highlights the features previously described, namely, a significant increase in the unconfined compressive strength with positive gains between +131% and +270%, for soils with an OM content of 1.5% and 5.5%, respectively. The opposite of this behavior is seen for the soil with an OM content of 7.7%, described by a loss of strength higher than 50% after stabilization with XG.

Figure 4.

UCS tests. Effect of OM on the evolution of: (a) qu; (b) Eu-50.

The evolution of the secant modulus at 0.5qu (Eu50) with the OM content (Figure 4b) matches with the trend observed in Figure 4a for qu. In fact, the stabilization with XG induced a significant gain of stiffness (from about 109 to 204%) for OM contents in the range of 1.5–5.5%, while for an OM content of 7.7% a reduction of 29% was obtained.

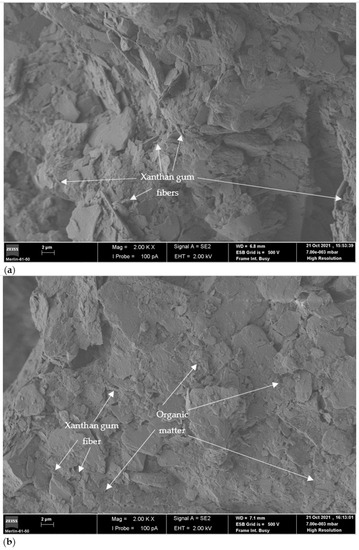

These results indicate that the process of stabilization with XG can be used successfully for soils with a low organic matter content (less than 5.5%), but is counterproductive for higher values of OM content (7.7%). Indeed, after a certain threshold value of OM content (7.7%), the OM that exists in the soil tends to coat the soil particle and partially fill the voids. This prevents the creation of a network of micro-fibers of XG that would create bonds between the soil particles. Simultaneously, the hydration of the biopolymer’s hydrogels that exist in the soil’s porous spaces seems to promote a reduction in the friction between the soil particles, inducing a decrease in the mechanical properties of the stabilized soil. The SEM image of the stabilized soil with an OM content of 7.7% (Figure 5b) confirms a greater coating of the soil particles with OM than that observed with a stabilized soil with an OM content of 1.5% (Figure 5a). Thus, the increase in the OM content makes it difficult to establish a network of bonds, similar to the micro-reinforcement observed in a stabilized non-organic silty sand (Figure 1).

Figure 5.

SEM images (2000X) of soil stabilized with 1% of XG for an OM content of: (a) 1.5%; (b) 7.7%.

3.2. Oedometer Tests

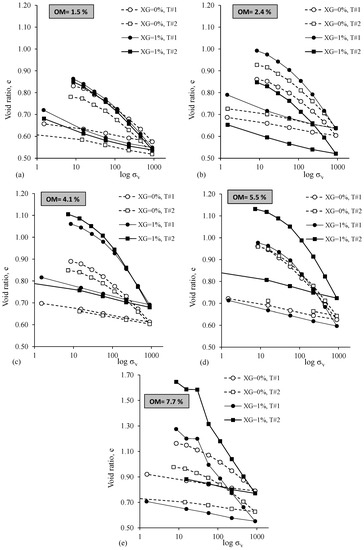

The e-logσ’v curves obtained from the one-dimensional compression (oedometer) tests for the five different organic matter contents are illustrated in Figure 6. Despite some scattering in terms of the evaluation of the void ratio, in qualitative terms there were some similarities in the curves; mainly:

Figure 6.

Oedometer tests. Effect of organic matter content on the e-logσ’v behavior. (a) OM = 1.5%; (b) OM = 2.4%; (c) OM = 4.1%; (d) OM = 5.5%; (e) OM = 7.7%.

- (i)

- a progressive increase in the compressibility with the increase in the vertical stress.

- (ii)

- The increase in the void ratio with the OM content, which agrees with the findings of Venda Oliveira et al. [48].

- (iii)

- The upward movement of the e-logσ’v curves after the stabilization with XG due to the hydration of the biopolymer’s hydrogels, which induces an increase in the void ratio; this tendency matches with the results of Venda Oliveira et al. [29].

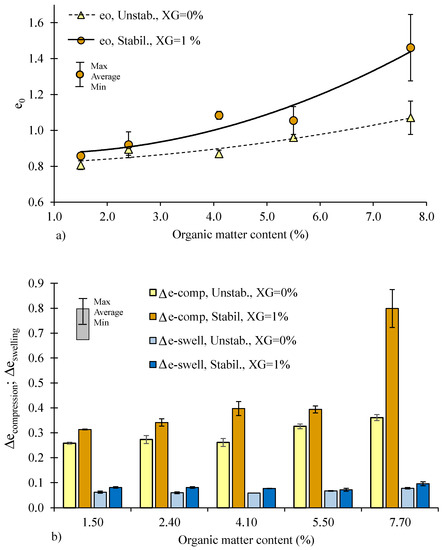

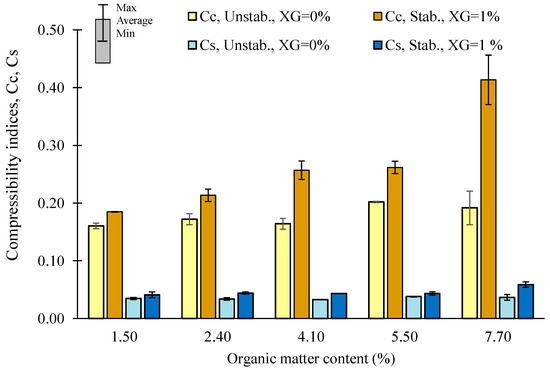

Figure 7 highlights the effect of the OM content on the initial void ratio and on the change in the void ratio during compression (Δecompression) and swelling (Δeswelling). These results clearly show the increase in the initial void ratio after the stabilization of the soil with XG, and this effect is enhanced with the increase in the OM content. In fact, this behavior can be explained by two cumulative factors—the high ability of the organic matter to retain water, and the hydration of the hydrogels of the XG when water is present—which together potentiate a high void ratio for a stabilized soil with a high OM content. Figure 7 also demonstrates that the change in the void ratio (both in compression and swelling) increases after stabilization with XG; although, as expected, with a greater variation for the compression paths than for the swelling paths. Additionally, in the compression paths the Δe increases with the OM content, while in the swelling path the Δe is negligible in relation to the change in the OM content. Figure 8 illustrates the effect of the variation in the OM content on the compression index (Cc) and the swelling index (Cs). Naturally, the tendency observed by Cc and Cs corroborates the features described concerning the evolution of Δecompression and Δeswelling in Figure 7. Indeed, Cc increases after the stabilization of the soil and this effect is amplified for higher OM contents. Moreover, Cs is relatively unaffected by the organic matter content, increasing slightly for the stabilized soil.

Figure 7.

Oedometer tests. Effect of organic matter content on the: (a) initial void ratio, (b) variation of void ratio during compression (9.0 to 902 kPa) and swelling (902 to 1.5 kPa).

Figure 8.

Oedometer tests. Effect of organic matter content on the compressibility indices, Cc and Cs.

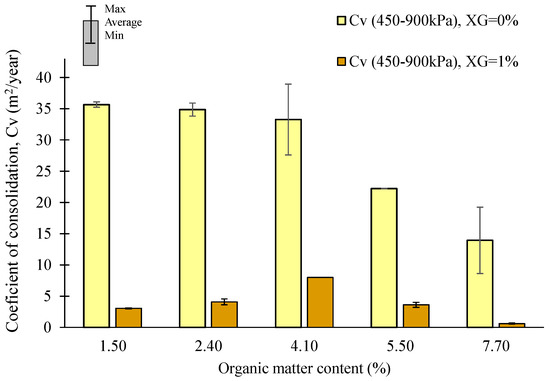

The effect of the stabilization process and the variation in the organic matter content on the coefficient of consolidation (Cv) evaluated for the vertical stress increment between 450 and 900 kPa is presented in Figure 9. In line with other research work [39,48,49], the Cv of the unstabilized soil decreases with the increase in OM content, which corresponds to an increase in the primary consolidation time. This behavior is fundamentally due to the significant ability of the OM to absorb water, which induces a higher void ratio and a higher compressibility. On the other hand, the stabilization process induces a significant decrease in the Cv, which is related to the capacity of the biopolymers to retain water, due to the hydration of the hydrogels. This means that the stabilization of a soil with XG prolongs the time required to complete primary consolidation.

Figure 9.

Oedometer tests. Effect of organic matter content on the coefficient of consolidation (Cv) during the increments in compression stress (405 to 900 kPa).

4. Main Conclusions

Considering the experimental results of the unconfined compressive strength (UCS) tests and one-dimensional compression (oedometer) tests concerning the consequences of changes in the organic matter (OM) content (from 1.5% to 7.7%) on the behavior of unstabilized and stabilized soils with a content of 1% of the biopolymer xanthan gum during 14 days of curing time, the following conclusions were reached:

- (i)

- For an OM content in the range of 1.5–5.5%, there is a positive impact resulting from the stabilization with XG on the mechanical properties, with a significant increase in strength (from 130% to 270%) and stiffness (from 109% to 204%). Moreover, the stabilization with XG induces a decrease in the ductility of the stress-strain behavior characterized by a loss of strength after the peak;

- (ii)

- There is a detrimental impact of the stabilization with XG in terms of mechanical properties for an OM content of 7.7%, while the stress-strain behavior remains ductile. These results seem to indicate that this OM content is sufficient to coat the soil particles, which prevents bonds (i.e., a micro-reinforcement network) being established between the soil particles and the XG, and simultaneously the hydration of the biopolymer hydrogels tends to minimize the friction between the soil particles;

- (iii)

- The stabilization of the soil with XG induces an increase in the initial void ratio; this effect is enhanced by the increase in the OM content, which reflects the effect of two cumulative factors, the ability of the organic matter to retain water, and the hydration of the hydrogels of the XG in the presence of water;

- (iv)

- The stabilization with XG increases the change in the void ratio both in compression (i.e., Cc) and swelling (i.e., Cs), with more significant effects in terms of compression; this behavior is amplified with the increase in the OM content;

- (v)

- In compression, the increase in the OM content induces an increase in the change in the void ratio (i.e., the Cc). The void ratio variation (and the Cs) is negligible for the swelling relative to the change in OM content;

- (vi)

- The coefficient of consolidation (Cv) of the unstabilized soil decreases with the increase in OM content, which is due to the significant ability of the OM to absorb water;

- (vii)

- The stabilization process induces a significant decrease in the Cv, which is related to the considerable capacity of the biopolymers to retain water, due to the hydration of the hydrogels.

Considering the results obtained in this work, it is expected that this technique can be used to improve the properties of the soils with low/medium organic matter content (lower than 5%). Considering that biodegradability is inherent in the use of these bio-based materials, it is expected that this methodology is suitable to apply in provisory works, mainly when a high level of sustainability is required. In this type of work, the biodegradability of the materials used can be a favorable issue, since it annuls all the traces of the work in long term.

Author Contributions

Conceptualization, P.J.V.O.; Investigation: M.J.F.C.C.R.; writing—original draft preparation, M.J.F.C.C.R. and P.J.V.O.; writing—review and editing, P.J.V.O.; supervision, P.J.V.O.; funding acquisition, P.J.V.O. All authors have read and agreed to the published version of the manuscript.

Funding

This work was partly financed by FCT/MCTES (project PTDC/ECI-CON/28382/2017) and through national funds (PIDDAC) under the R&D Unit Institute for Sustainability and Innovation in Structural Engineering (ISISE), under reference UIDB/04029/2020, and under the Associate Laboratory Advanced Production and Intelligent Systems ARISE under reference LA/P/0112/2020.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Acknowledgments

This work had the support of the lab technician J.A. Lopes, Department of Civil Engineering, University of Coimbra.

Conflicts of Interest

The authors declare no conflict of interest.

References

- IPCC. Climate Change 2022—Mitigation of Climate Change, IPCC AR6 WG III. Working Group III Contribution to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; IPCC: Geneva, Switzerland, 2022.

- Chang, I.; Im, J.; Cho, G.C. Introduction of microbial biopolymers in soil treatment for future environmentally-friendly and sustainable geotechnical engineering. Sustainability 2016, 8, 251. [Google Scholar] [CrossRef]

- Gomes, C.; Lopes, M.L.; Venda Oliveira, P.J. Stiffness parameters of municipal solid waste. Bull. Eng. Geol. Environ. 2014, 73, 1073–1087. [Google Scholar] [CrossRef]

- Nugent, R.; Zhang, G.; Gambrell, R. Effect of exopolymers on the liquid limit of clays and its engineering implications. Transp. Res. Rec. 2009, 2101, 34–43. [Google Scholar] [CrossRef]

- Mendonça, A.; Morais, P.V.; Pires, A.C.; Chung, A.P.; Venda Oliveira, P.J. A Review on the Importance of Microbial Biopolymers Such as Xanthan Gum to Improve Soil Properties. Appl. Sci. 2021, 11, 170. [Google Scholar] [CrossRef]

- Al Qabany, A.; Soga, K. Effect of chemical treatment used in MICP on engineering properties of cemented soils. Géotechnique 2013, 63, 331–339. [Google Scholar] [CrossRef]

- Venda Oliveira, P.J.; Costa, M.S.; Costa, J.N.P.; Nobre, M.F. Comparison of the ability of two bacteria to improve the behaviour of a sandy soil. J. Mater. Civ. Eng. 2015, 27, 06014025. [Google Scholar] [CrossRef]

- Venda Oliveira, P.J.; Freitas, L.D.; Carmona, J.P.S.F. Effect of Soil Type on the Enzymatic Calcium Carbonate Precipitation Process Used for Soil Improvement. J. Mater. Civ. Eng. 2016, 29, 04016263. [Google Scholar] [CrossRef]

- Venda Oliveira, P.J.; Neves, J.P.G. Effect of Organic Matter Content on Enzymatic Biocementation Process Applied to Coarse-Grained Soils. J. Mater. Civ. Eng. 2019, 31, 04019121. [Google Scholar] [CrossRef]

- Venda Oliveira, P.J.; Rosa, J.A.O. Confined and unconfined behaviour of a silty sand improved by the enzymatic biocementation method. Transp. Geotech. 2020, 24, 100400. [Google Scholar] [CrossRef]

- Lin, H.; Suleiman, M.T.; Brown, D.G.; Kavazanjian, E., Jr. Mechanical behaviour of sands treated by microbially induced carbonate precipitation. J. Geotech. Geoenviron. Eng. 2016, 142, 04015066. [Google Scholar] [CrossRef]

- van Paassen, L.A.; Ghose, R.; van der Linden, T.J.M.; van der Star, W.R.L.; van Loosdrecht, M.C.M. Quantifying biomediated ground improvement by ureolysis: Large-scale biogrout experiment. J. Geotech. Geoenviron. Eng. 2010, 136, 1721–1728. [Google Scholar] [CrossRef]

- Mortensen, B.M.; Haber, M.J.; DeJong, J.T.; Caslake, L.F.; Nelson, D.C. Effects of environmental factors on microbial induced calcium carbonate precipitation. J. Appl. Microbiol. 2011, 111, 338–349. [Google Scholar] [CrossRef] [PubMed]

- Yasuhara, H.; Neupane, D.; Hayashi, K.; Okamura, M. Experiments and predictions of physical properties of sand cemented by enzymatically-induced carbonate precipitation. Soils Found. 2012, 52, 539–549. [Google Scholar] [CrossRef]

- Jiang, N.J.; Soga, K. The applicability of microbially induced calcite precipitation (MICP) for internal erosion control in gravel–sand mixtures. Geotechnique 2016, 67, 42–55. [Google Scholar] [CrossRef]

- Carmona, J.P.S.F.; Venda Oliveira, P.J.; Lemos, L.J.L.; Pedro, A.M.G. Improvement of a sandy soil by enzymatic CaCO3 precipitation. ICE—Geotech. Eng. 2018, 171, 3–15. [Google Scholar] [CrossRef]

- Ghasemzadeh, H.; Farzaneh, M. Application of novel Persian gum hydrocolloid in soil stabilization. Carbohydr. Polym. 2020, 246, 116639. [Google Scholar] [CrossRef]

- Babatunde, Q.O.; Byun, Y.-H. Soil Stabilization Using Zein Biopolymer. Sustainability 2023, 15, 2075. [Google Scholar] [CrossRef]

- Muguda, S.; Hughes, P.N.; Augarde, C.E.; Perlot, C.; Walter, B.A.; Gallipoli, D. Cross-linking of biopolymers for stabilizing earthen construction materials. Build. Res. Inf. 2022, 50, 502–514. [Google Scholar] [CrossRef]

- Chang, I.; Prasidhi, A.K.; Im, J.; Shin, H.D.; Cho, G.C. Soil treatment using microbial biopolymers for anti-desertification purposes. Geoderma 2015, 253–254, 39–47. [Google Scholar] [CrossRef]

- Khachatoorian, R.; Petrisor, I.G.; Kwan, C.C.; Yen, T.F. Biopolymer plugging effect: Laboratory-pressurized pumping flow studies. J. Pet. Sci. Eng. 2003, 38, 13–21. [Google Scholar] [CrossRef]

- Bouazza, A.; Gates, W.P.; Ranjith, P.G. Hydraulic conductivity of biopolymer-treated silty sand. Géotechnique 2009, 59, 71–72. [Google Scholar] [CrossRef]

- Cabalar, A.F.; Wiszniewski, M.; Skutnik, Z. Effects of Xanthan Gum Biopolymer on the Permeability, Odometer, Unconfined Compressive and Triaxial Shear Behaviour of a Sand. Soil Mech. Found. Eng. 2017, 54, 356–361. [Google Scholar] [CrossRef]

- Dehghan, H.; Tabarsa, A.; Latifi, N.; Bagheri, Y. Use of Xanthan and guar gums in soil strengthening. Clean Technol. Environ. Policy 2019, 21, 155–165. [Google Scholar] [CrossRef]

- Mendonça, A.; Morais, P.V.; Pires, A.C.; Chung, A.P.; Venda Oliveira, P.J. Reducing Soil Permeability Using Bacteria-Produced Biopolymer. Appl. Sci. 2021, 11, 7278. [Google Scholar] [CrossRef]

- Sujatha, E.R.; Atchaya, S.; Sivasaran, A.; Keerdthe, R.S. Enhancing the geotechnical properties of soil using xanthan gum—An eco-friendly alternative to traditional stabilizers. Bull. Eng. Geol. Environ. 2021, 80, 1157–1167. [Google Scholar] [CrossRef]

- Chang, I.; Im, J.; Prasidhi, A.K.; Cho, G.C. Effects of Xanthan gum biopolymer on soil strengthening. Constr. Build. Mater. 2015, 74, 65–72. [Google Scholar] [CrossRef]

- Lee, S.; Chung, M.; Park, H.M.; Song, K.-I.; Chang, I. Xanthan gum Biopolymer as Soil-Stabilization Binder for Road Construction Using Local Soil in Sri Lanka. J. Mater. Civ. Eng. 2019, 31, 06019012. [Google Scholar] [CrossRef]

- Venda Oliveira, P.J.; Cabral, D.J.R. Behaviour of a silty sand stabilized with xanthan gum under unconfined and confined conditions. ICE—Ground Improv. 2023, 176, 3–13. [Google Scholar] [CrossRef]

- Kwon, Y.-M.; Chang, I.; Lee, M.; Cho, G.C. Geotechnical engineering behaviour of biopolymer-treated soft marine soil. Geomech. Eng. 2019, 17, 453–464. [Google Scholar] [CrossRef]

- Latifi, N.; Horpibulsuk, S.; Meehan, C.L.; Abd Majid, M.Z.; Tahir, M.M.; Mohamad, E.T. Improvement of problematic soils with biopolymer-an environmentally friendly soil stabilizer. J. Mater. Civ. Eng. 2017, 29, 04016204. [Google Scholar] [CrossRef]

- Chang, I.; Kwon, Y.-M.; Im, J.; Gye-Chun Cho, G.C. Soil consistency and interparticle characteristics of Xanthan gum biopolymer–containing soils with pore-fluid variation. Can. Geotech. J. 2019, 56, 1206–1213. [Google Scholar] [CrossRef]

- Chang, I.; Jeon, M.; Cho, G.C. Application of microbial biopolymers as an alternative construction binder for earth buildings in underdeveloped countries. Int. J. Polym. Sci. 2015, 2015, 326745. [Google Scholar] [CrossRef]

- Sulaiman, H.; Taha, M.R.; Rahman, N.A.; Taib, A.M. Performance of soil stabilized with biopolymer materials—Xanthan gum and guar gum. Phys. Chem. Earth 2022, 128, 103276. [Google Scholar] [CrossRef]

- Kwon, Y.-M.; Chang, I.; Cho, G.-C. Consolidation and swelling behavior of kaolinite clay containing xanthan gum biopolymer. Acta Geotech. 2023, 1–17. [Google Scholar] [CrossRef]

- Hamza, M.; Nie, Z.; Aziz, M.; Ijaz, N.; Akram, O.; Fang, C.; Ghani, M.U.; Ijaz, Z.; Noshin, S.; Madni, M.F. Geotechnical behavior of high-plastic clays treated with biopolymer: Macro–micro-study. Environ. Earth Sci. 2023, 82, 91. [Google Scholar] [CrossRef]

- Reddy, J.J.; Varaprasad, B.J.S. Long-term and durability properties of xanthan gum treated dispersive soils—An eco-friendly material. Mater. Today Proc. 2021, 44, 309–314. [Google Scholar] [CrossRef]

- Chang, I.; Kwon, Y.-M.; Cho, G.-C. Effect of Pore–Fluid Chemistry on the Undrained Shear Strength of Xanthan Gum Biopolymer-Treated Clays. J. Geotech. Geoenviron. Eng. 2021, 147, 06021013. [Google Scholar] [CrossRef]

- Venda Oliveira, P.J.; Correia, A.A.S.; Garcia, M.R. Effect of organic matter content and curing conditions on the creep behaviour of an artificially stabilized soil. J. Mater. Civ. Eng. 2012, 24, 868–875. [Google Scholar] [CrossRef]

- Correia, A.A.S. Applicability of Deep Mixing Technique to Portuguese Soft Soils. Ph.D. Thesis, University of Coimbra, Coimbra, Portugal, 2011. (In Portuguese). [Google Scholar]

- Vieira, A.F.V. Effect of Organic Matter Content on the Creep Reduction by Preloading: Laboratorial Analysis. Master’s Thesis, University of Coimbra, Coimbra, Portugal, 2016. (In Portuguese). [Google Scholar]

- Reis, M.J.F.C.C. Effect of Organic Matter Content on the Behaviour of Soils Stabilized with the Biopolymer Xanthan Gum. Master’s Thesis, University of Coimbra, Coimbra, Portugal, 2021. (In Portuguese). [Google Scholar]

- Venda Oliveira, P.J.; Correia, A.A.S.; Garcia, M.R. Effect of stress level and binder composition on secondary compression of an artificially stabilized soil. J. Geotech. Geoenviron. Eng. 2013, 139, 810–820. [Google Scholar] [CrossRef]

- Bennett, R.H.; Lehman, L.; Hulbert, M.H.; Harvey, G.R.; Bush, S.A.; Forde, E.B.; Crews, P.; Sawyer, W.B. Interrelationship of organic carbon and submarine sediment geotechnical properties. Mar. Geotechnol. 1985, 6, 61–98. [Google Scholar] [CrossRef]

- Booth, J.S.; Dahl, A.G. A note on the relationships between organic matter and some geotechnical properties of marine sediment. Mar. Geotechnol. 1986, 6, 281–297. [Google Scholar] [CrossRef]

- Coelho, P.A.L.F. Geotechnical Characterization of Soft Soils. Study of the Experimental Site of Quinta do Foja. Master’s Thesis, University of Coimbra, Coimbra, Portugal, 2000. (In Portuguese). [Google Scholar]

- García-Ochoa, F.; Santos, V.E.; Casas, J.A.; Gómez, E. Xanthan gum: Production, recovery, and properties. Biotechnol. Adv. 2000, 18, 549–579. [Google Scholar] [CrossRef] [PubMed]

- Venda Oliveira, P.J.; Vieira, A.F.V.; Correia, A.A.S. Effect of organic matter content on creep mitigation by preloading. ICE—Geotech. Eng. 2017, 170, 305–311. [Google Scholar] [CrossRef]

- Thiyyakkandi, S.; Annex, S. Effect of organic content on geotechnical properties of Kuttanad clay. Electron. J. Geotech. Eng. 2011, 16, 1653–1663. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).