Long-Term Durability of Cement-Treated Soil Used in Offshore Airport Island Construction

Abstract

1. Introduction

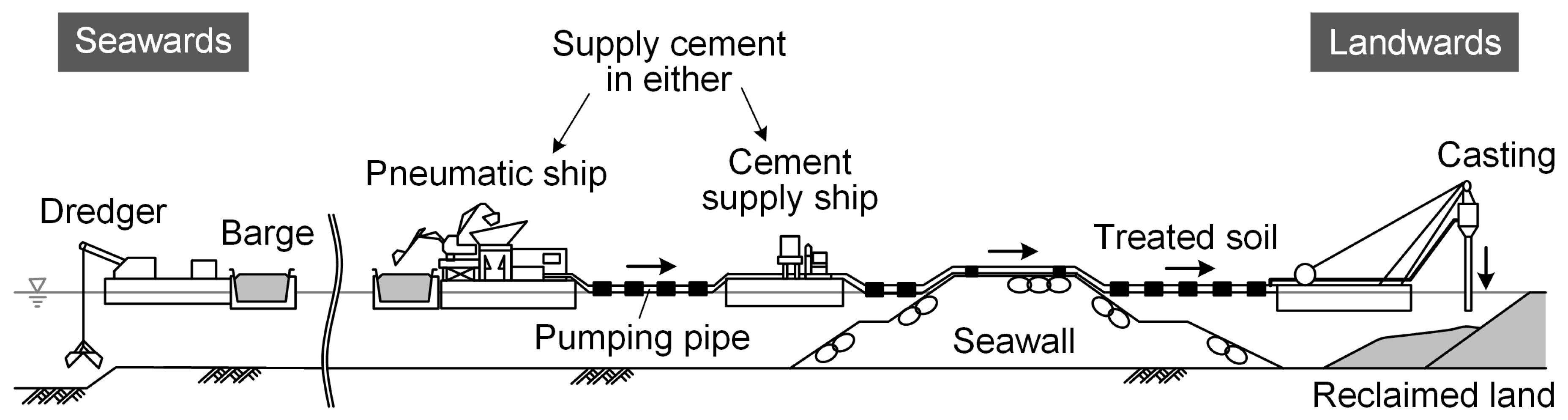

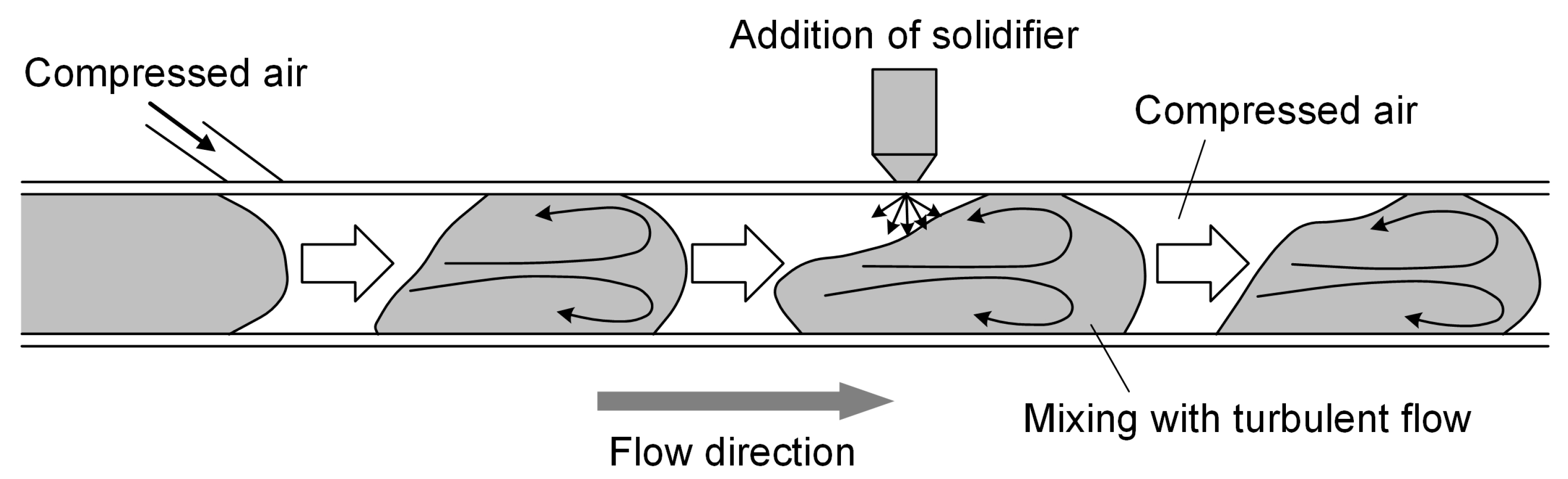

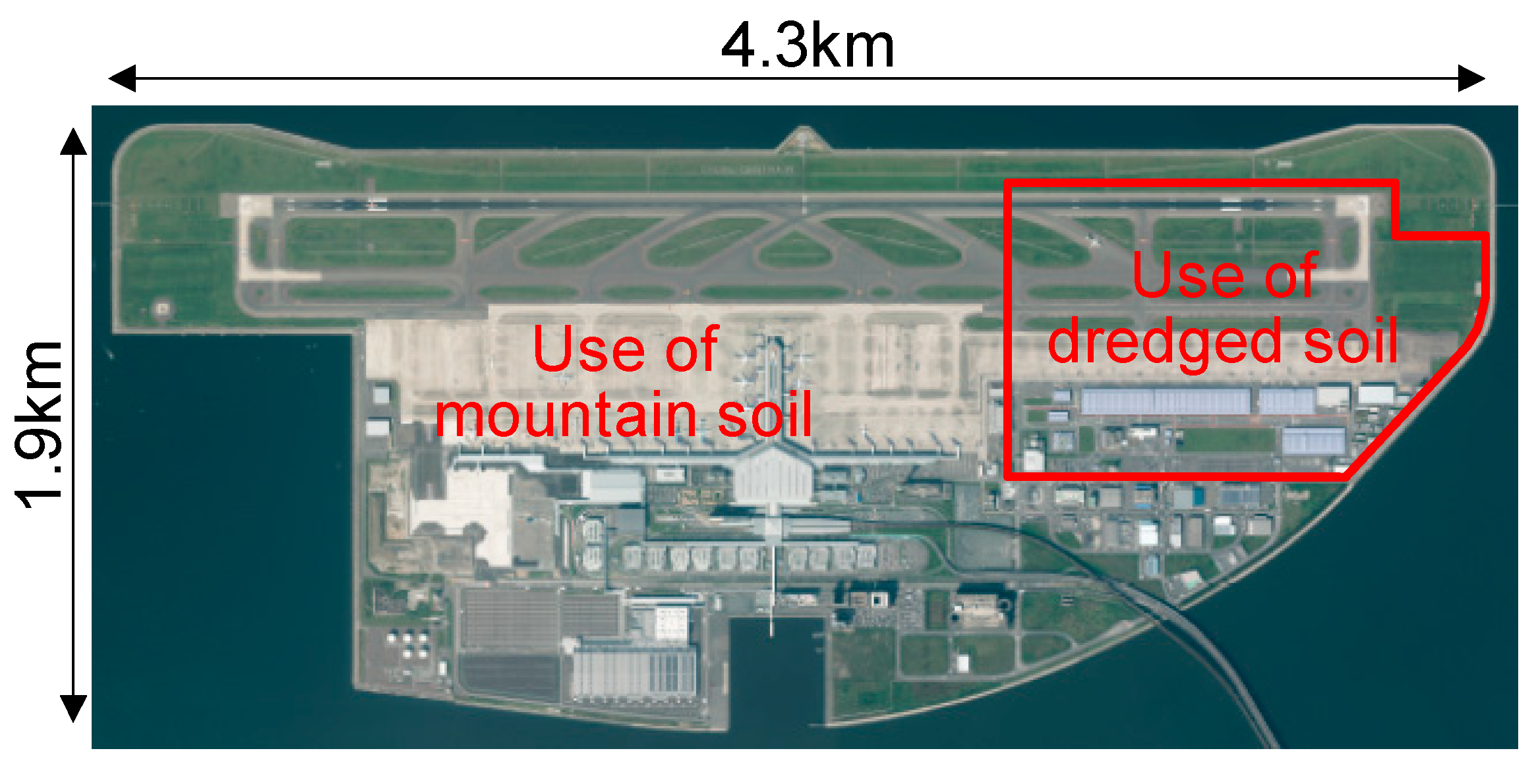

2. Pneumatic Flow Mixing Method and Construction of Airport Island

2.1. Overview of Pneumatic Flow Mixing Method

2.2. Construction Work on Airport Island

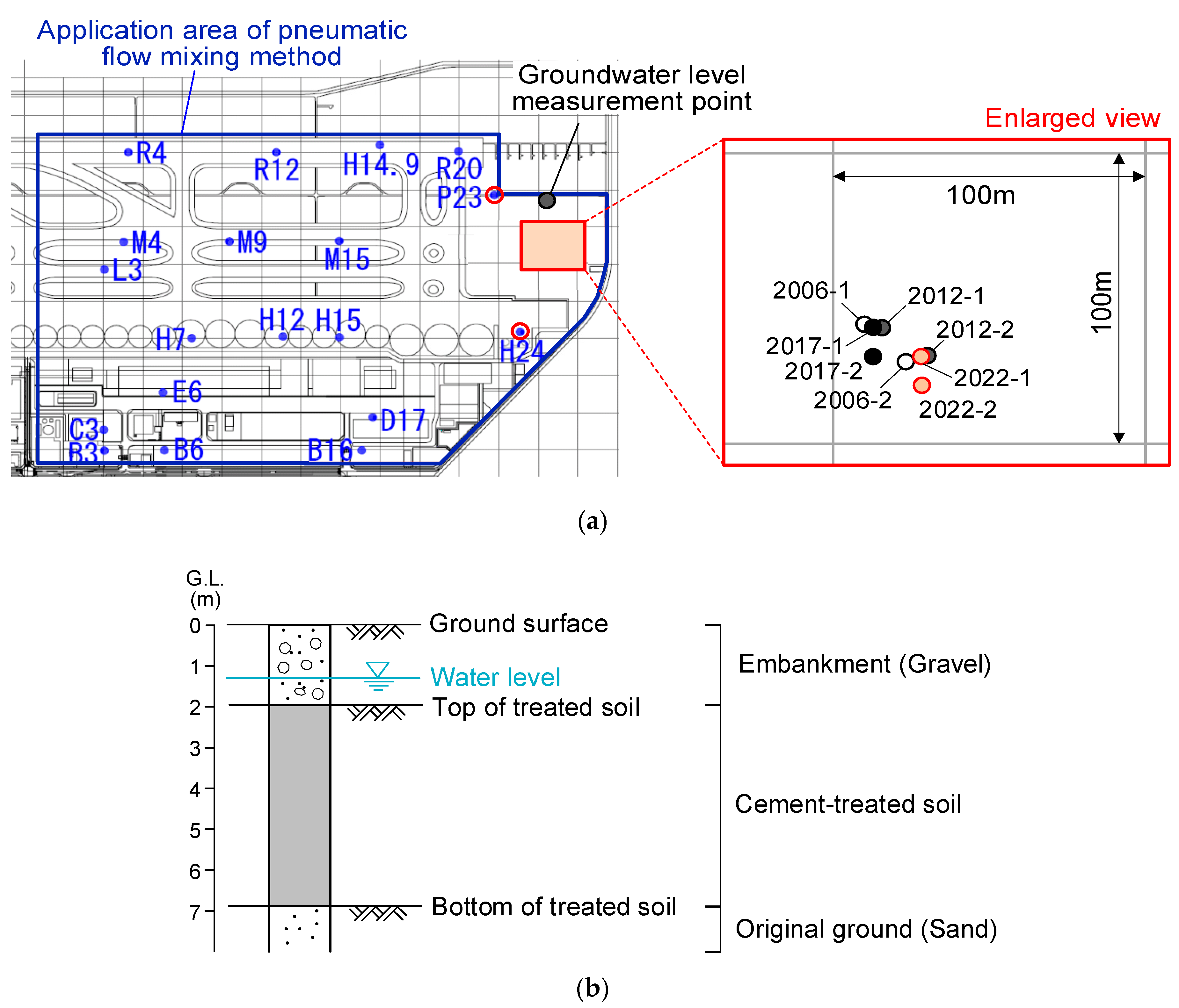

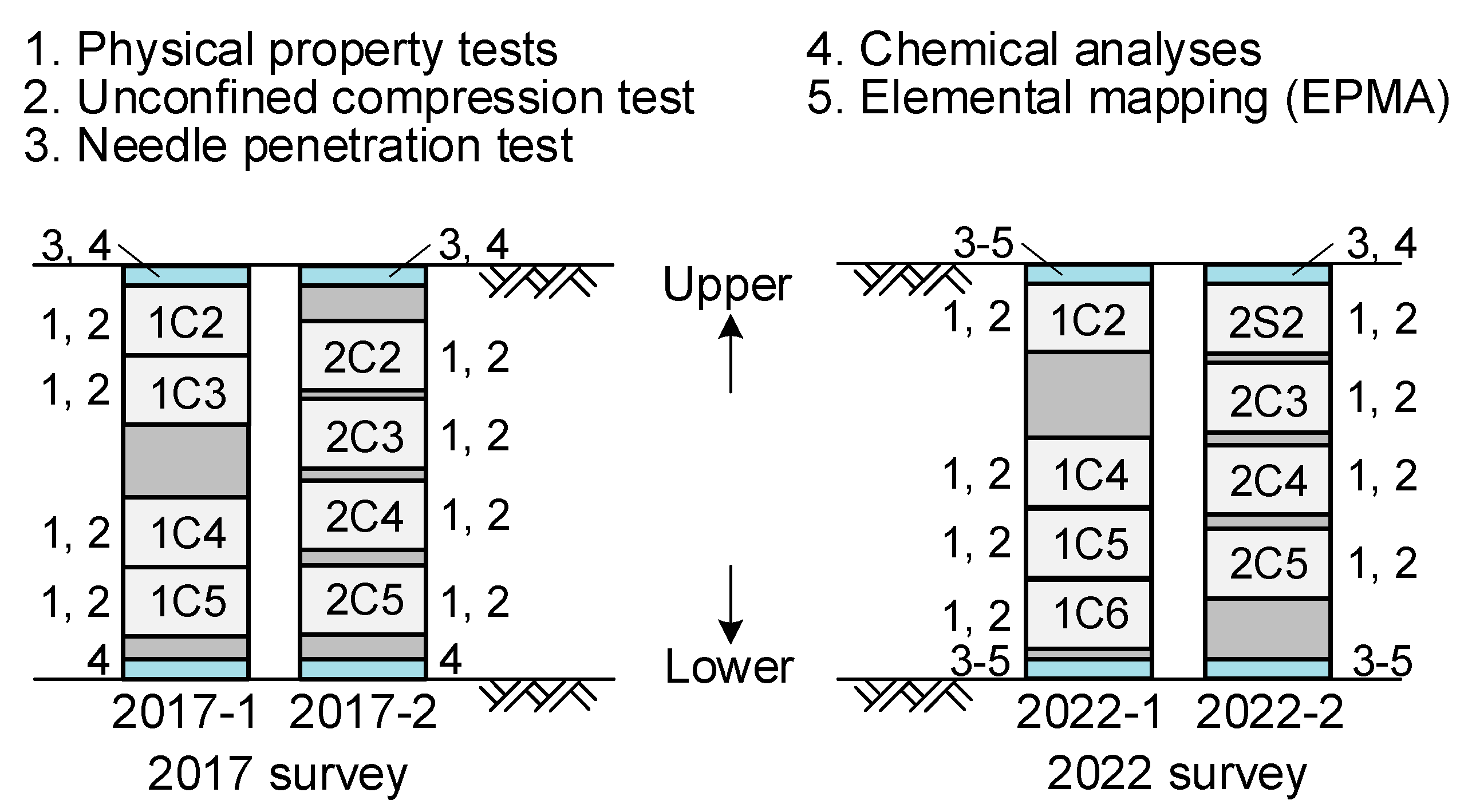

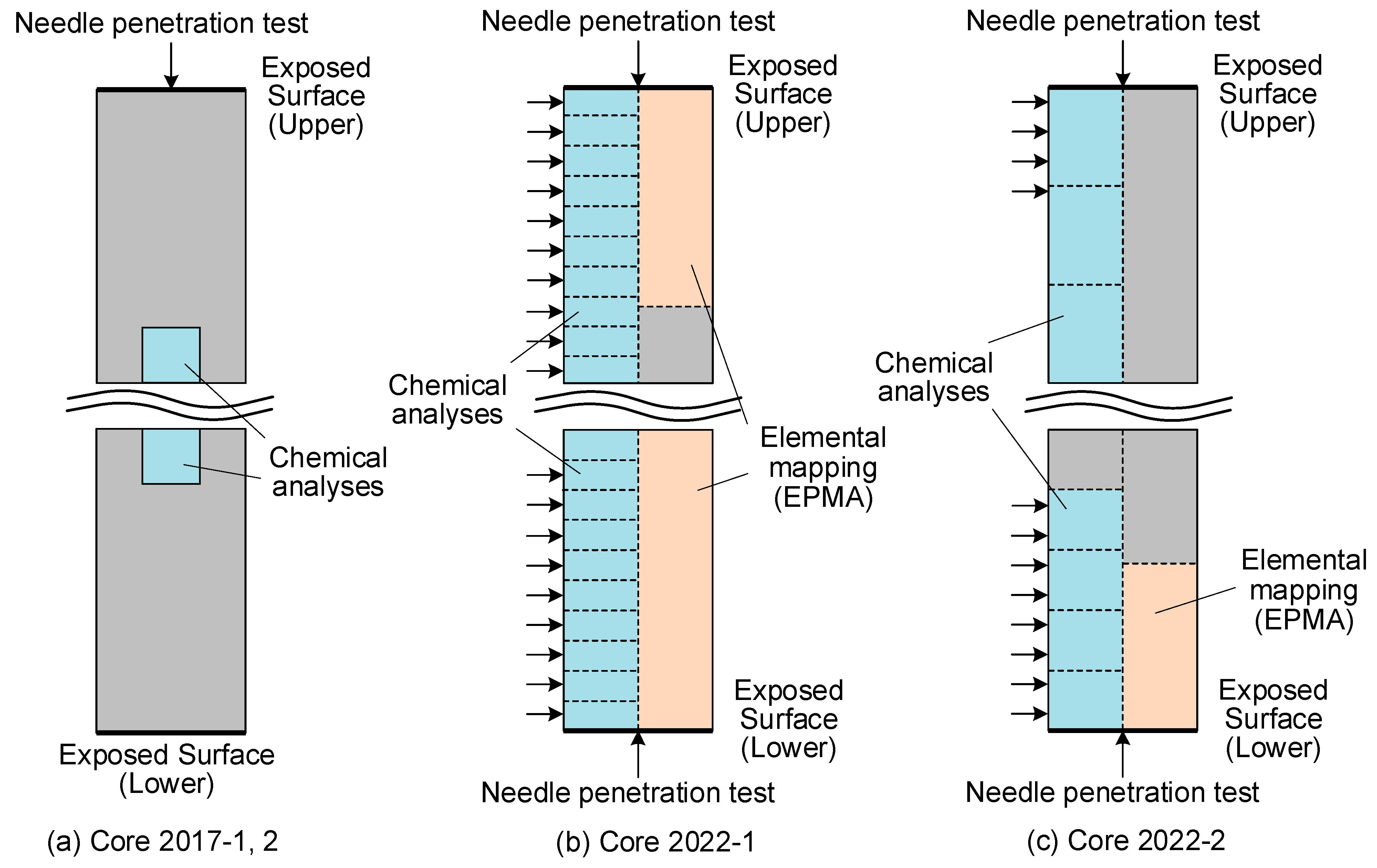

3. Survey Locations and Methods

4. Long-Term Properties of the Interior of Cement-Treated Soil

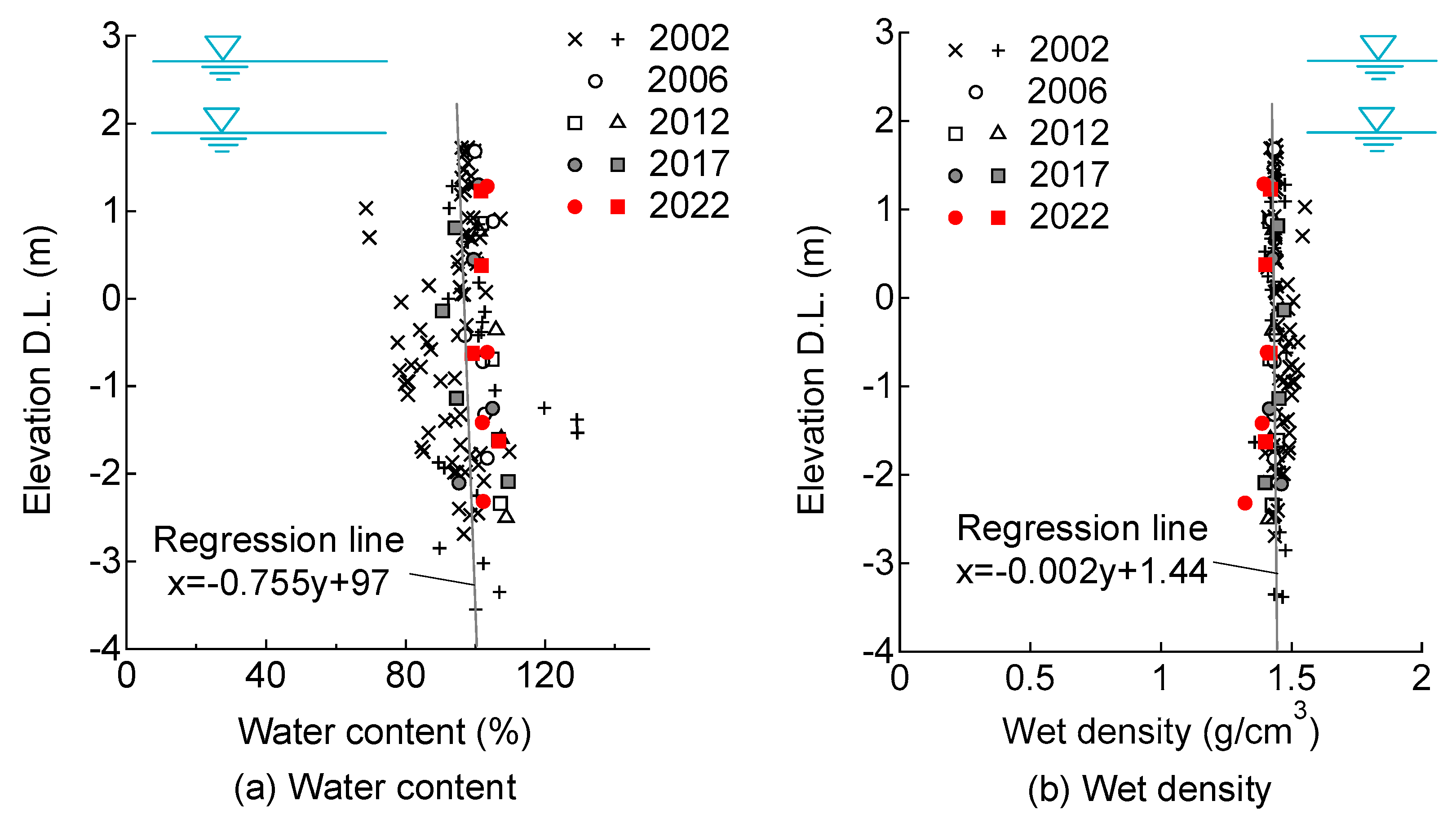

4.1. Groundwater, Water Content, and Wet Density of Soil

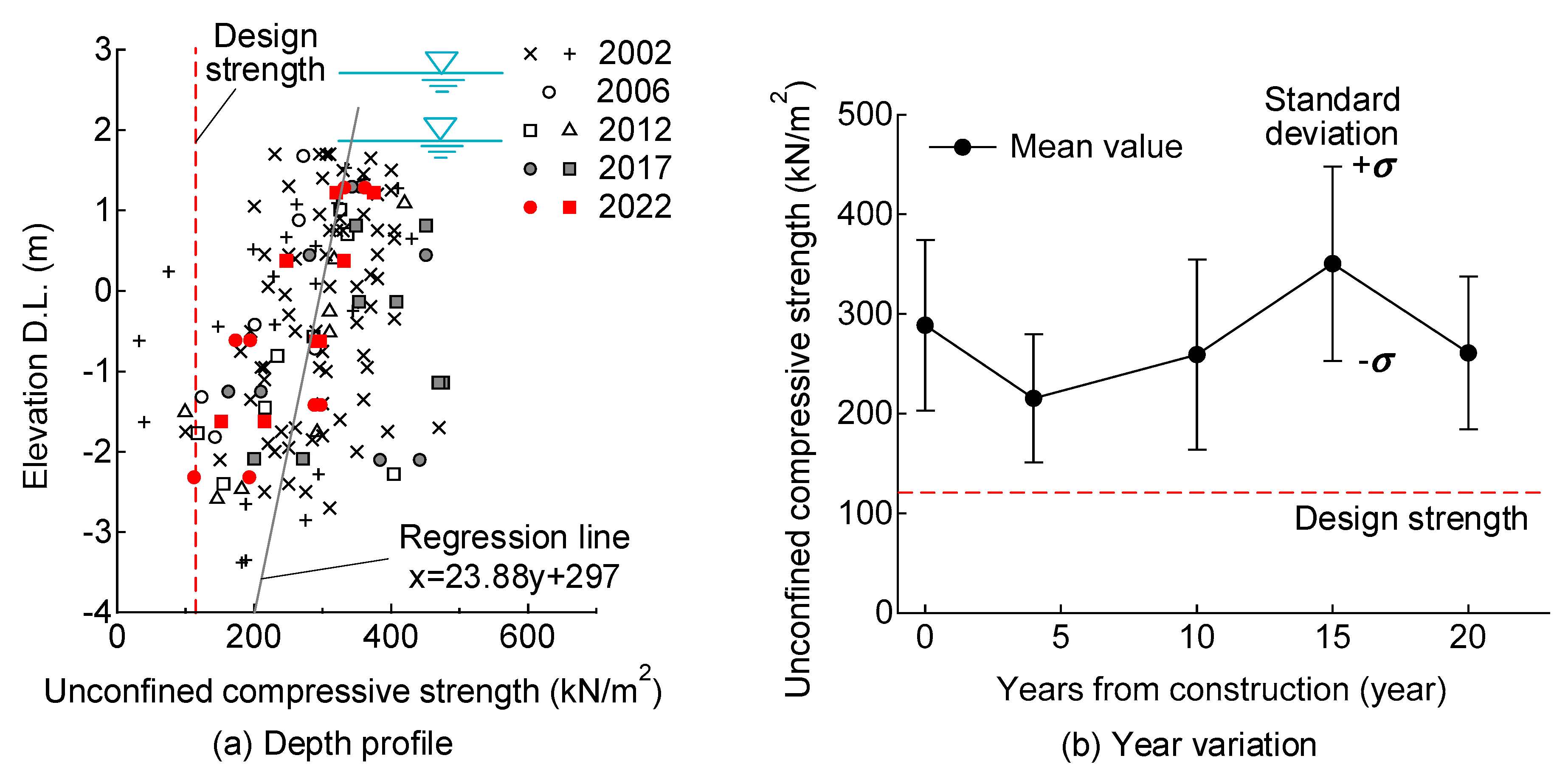

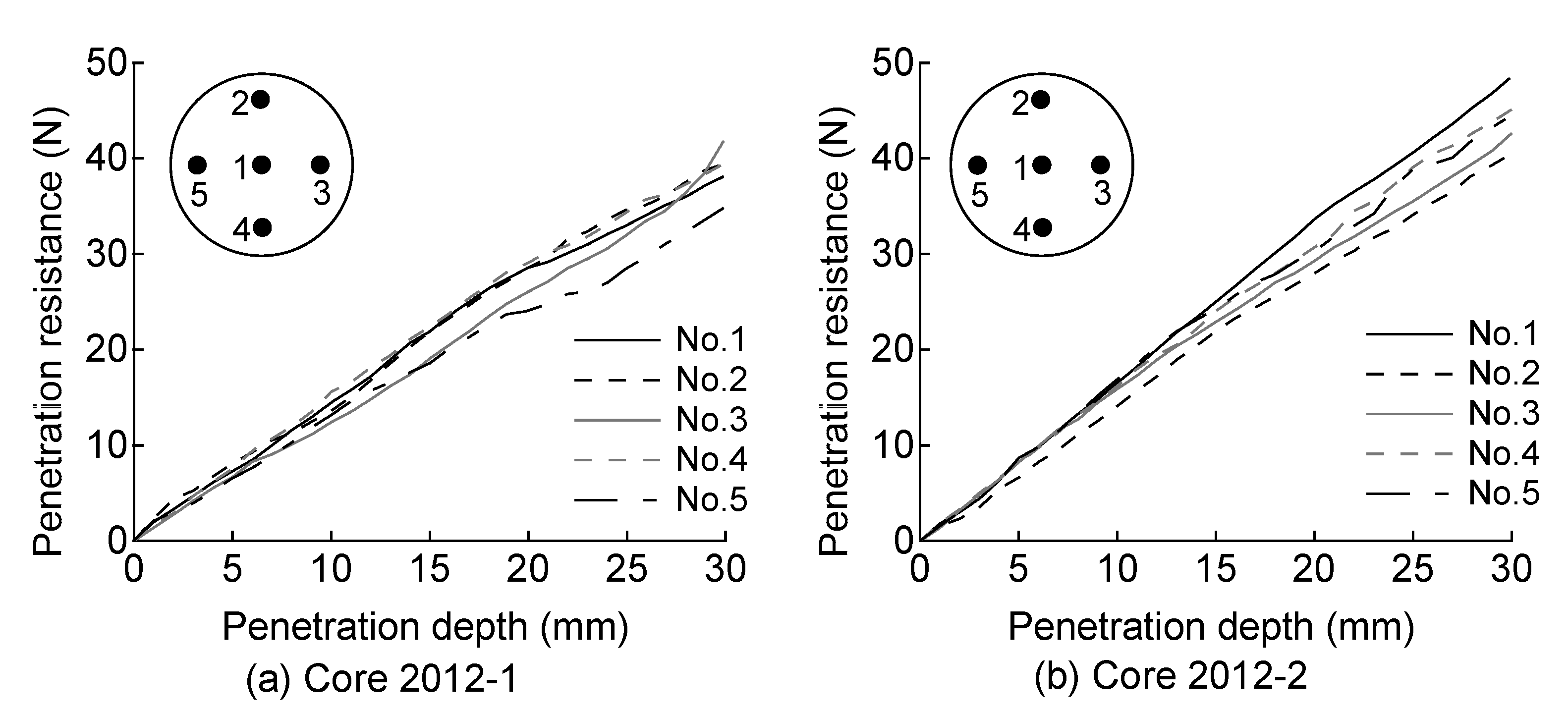

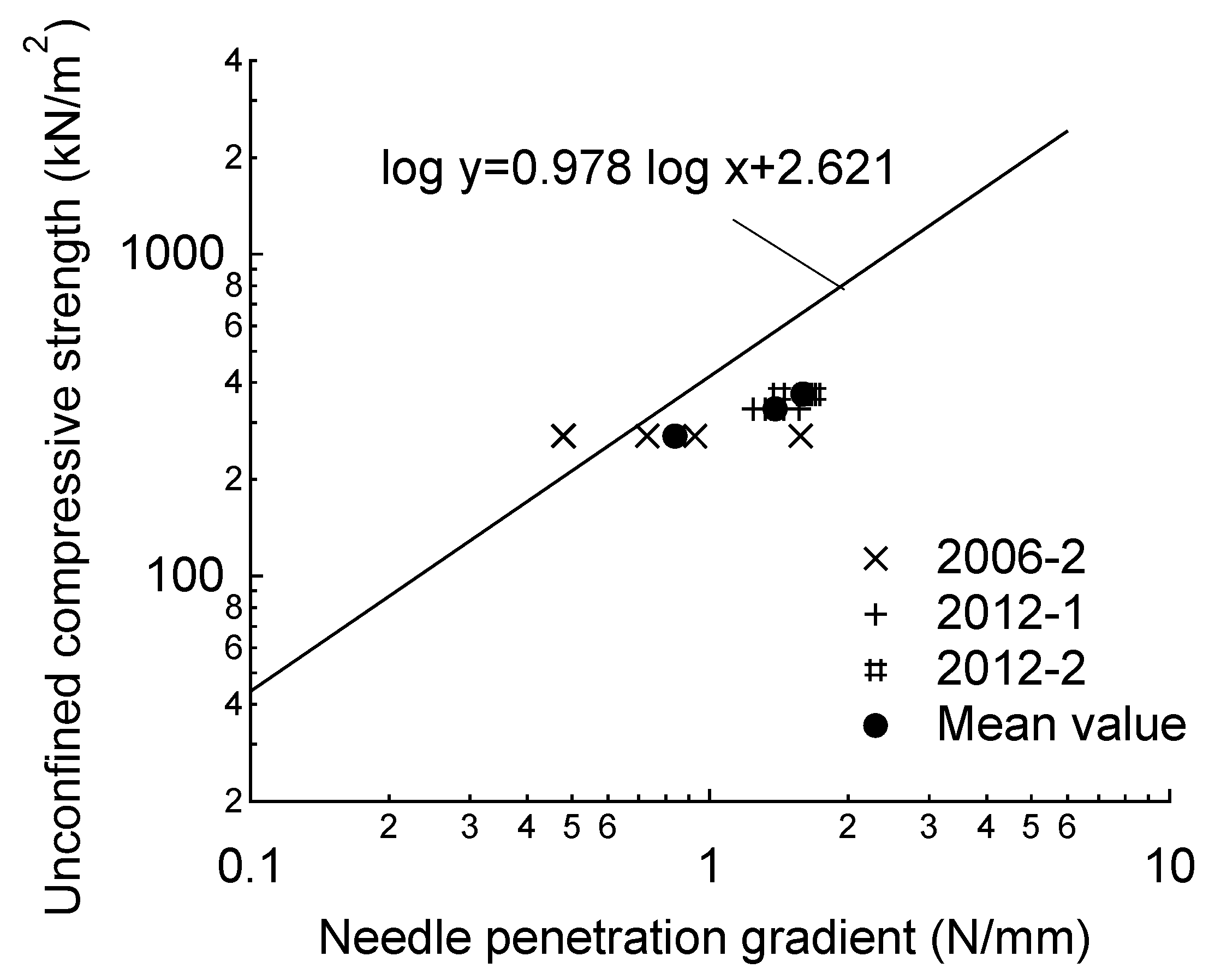

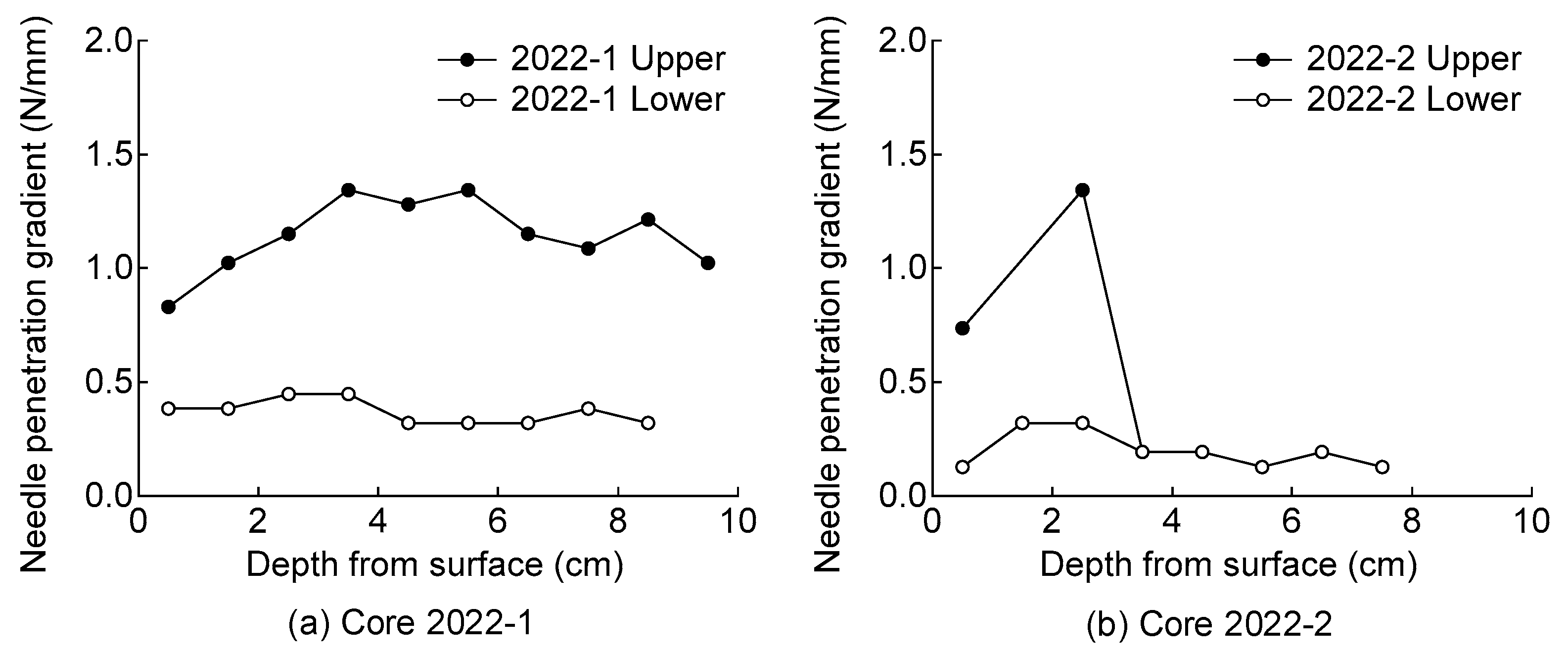

4.2. Unconfined Compressive Strength and Needle Penetration Resistance

5. Long-Term Properties of the Surface of Cement-Treated Soil

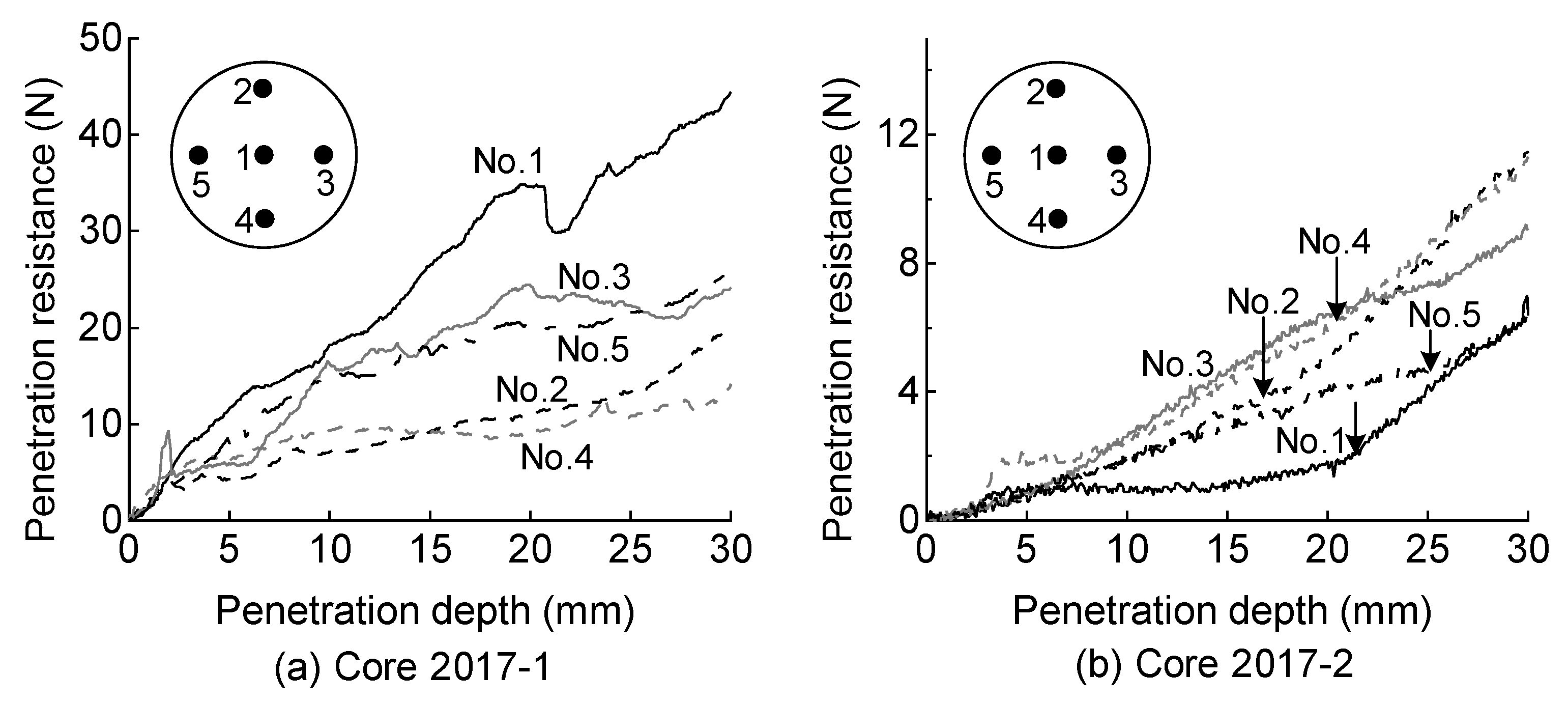

5.1. 15 Year Survey Results

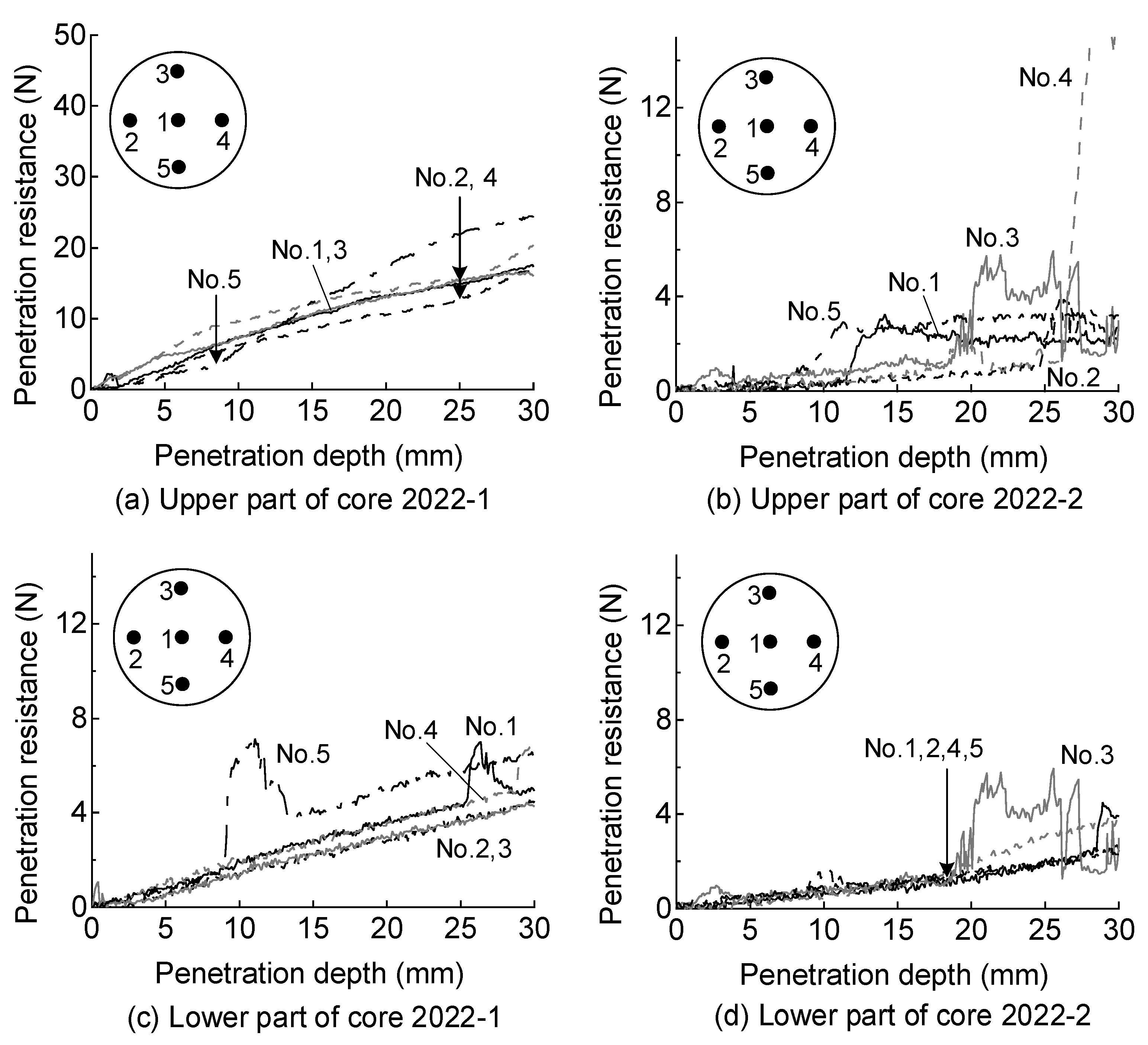

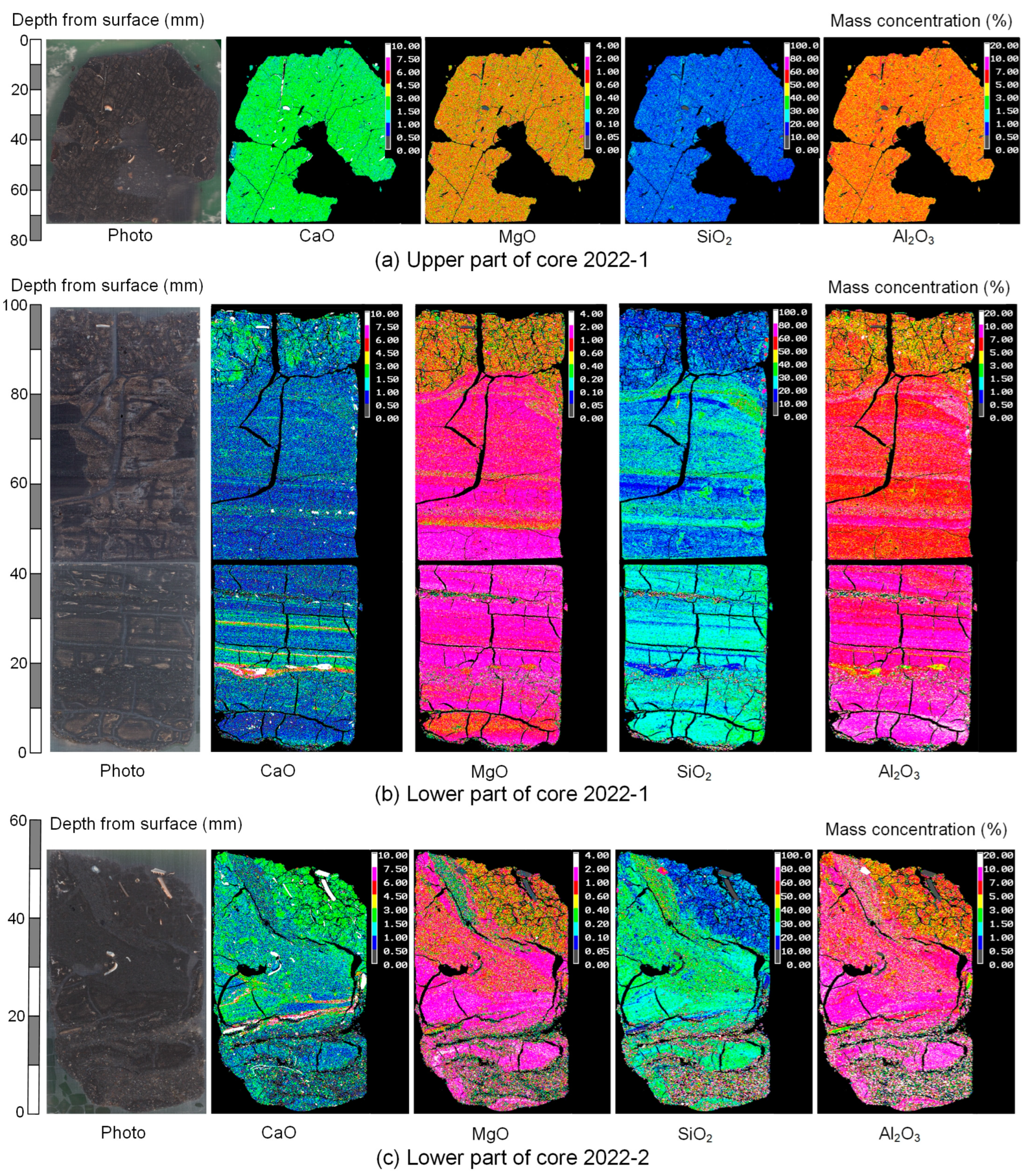

5.2. 20 Year Survey Results

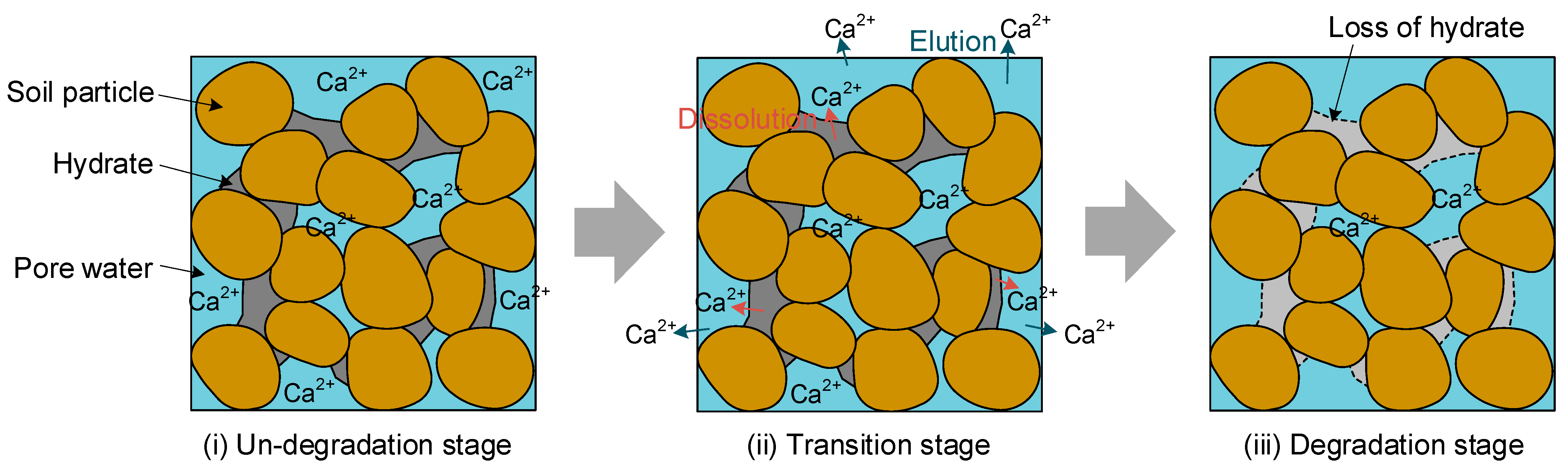

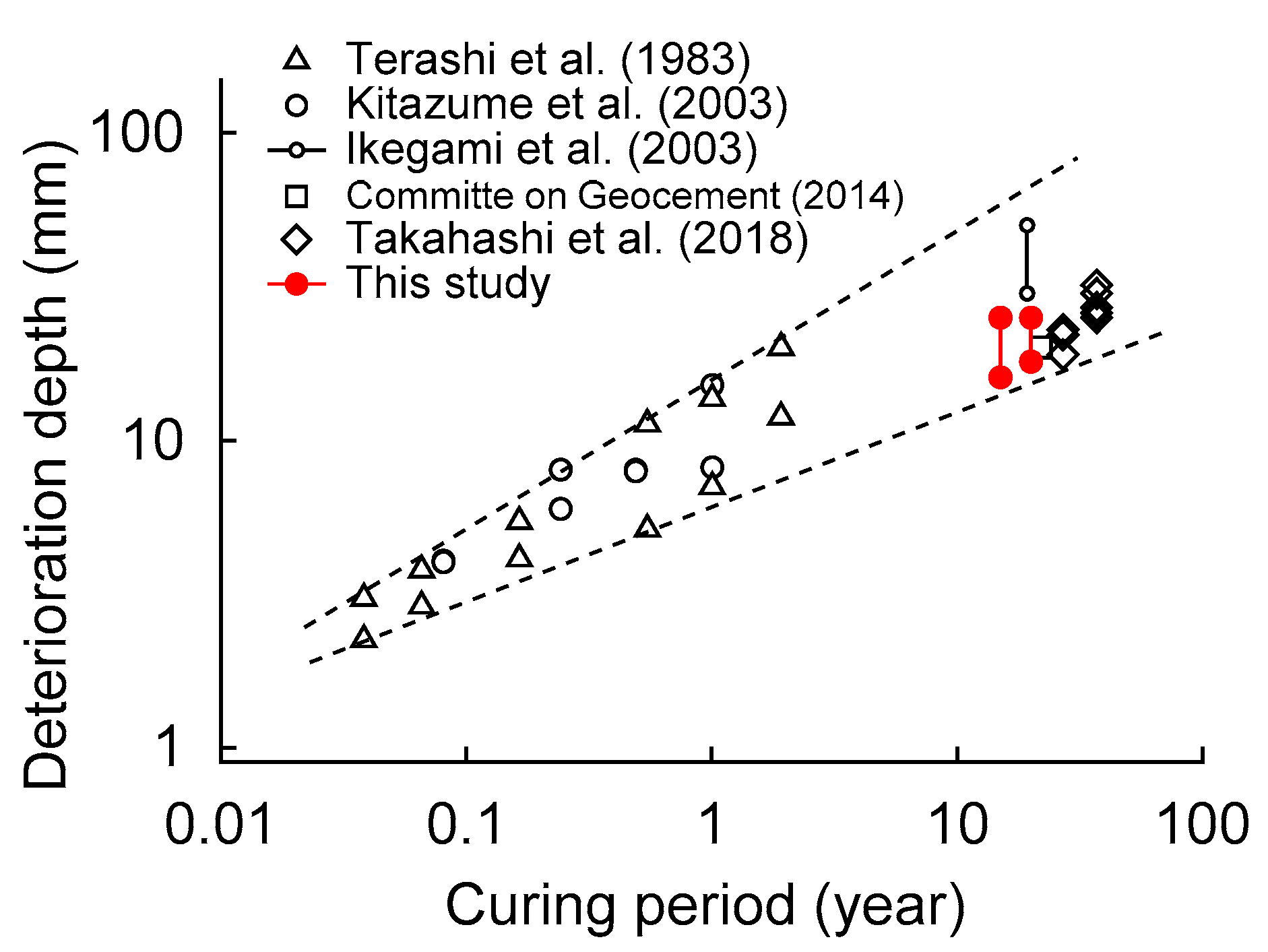

5.3. Deterioration from the Surface of Treated Soil

6. Conclusions

- (1)

- No reduction in the unconfined compressive strength or needle penetration gradient was observed in the interiors of treated soil samples, and there was no sign of deterioration.

- (2)

- Some degradation was observed on the top and bottom exposed surfaces of the treated soil, similar to that of soil after other treatments. In addition to needle penetration and chemical tests, elemental mapping using an EPMA was performed to determine the degree of degradation. The depth of degradation 20 years after construction was approximately 18–25 mm.

- (3)

- Although the amount of cement added in the pneumatic flow mixing method was relatively small, the degradation depth was within the range of the degradation depth over time investigated in previous studies and was not significant.

- (4)

- The artificial island at Central Japan International Airport has a 2 m thick soil cover on top of the improved soil, and a reduction in strength of this magnitude would not affect the stability of the ground as a whole. In other words, it was confirmed to be durable at least during the first 20 years of construction.

- (5)

- Based on the results to date, it is unlikely that the degree or extent of strength reductions of the treated soil will change abruptly; however, from the perspective of the long-term maintenance of the airport facilities, it is important to continuously investigate the long-term behaviour of the improved ground. Airport facilities demand high performance from the ground, and if there is an accelerated deterioration trend, measures need to be taken.

- (6)

- There are only a few examples and reports on the long-term strength and durability of treated soils in the field; therefore, this study provides valuable data. The test results are particularly important for understanding the durability of the pneumatic flow mixing method. This method contributes to sustainability in terms of the effective use of dredged soil and less cement addition, and it would be more sustainable if it has long-term durability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Takahashi, H. Ground Improvement for Coastal Engineering; CRC Press: Boca Raton, FL, USA, 2023; pp. 1–196. [Google Scholar]

- Kitazume, M. The Pneumatic Flow Mixing Method; CRC Press/Balkema: London, UK, 2017; pp. 1–233. [Google Scholar] [CrossRef]

- Maher, A.; Kitazume, M.; Janbaz, M.; Miskewitz, R.; Douglas, S.; Yang, D. Utilization of pneumatic flow tube mixing technique (PFTM) for processing and stabilization of contaminated harbor sediment. Mar. Georesources Geotechnol. 2016, 36, 271–279. [Google Scholar] [CrossRef]

- Shihata, S.A.; Baghdadi, Z.A. Long-term strength and durability of soil cement. J. Mater. Civ. Eng. 2001, 13, 161–165. [Google Scholar] [CrossRef]

- Kitazume, M.; Nakamura, T.; Terashi, M.; Ohishi, K. Laboratory tests on long-term strength of cement treated soil. In Proceedings of the 3rd International Conference on Grouting and Ground Treatment, New Orleans, LA, USA, 10–12 February 2003; pp. 586–597. [Google Scholar]

- Hayashi, H.; Nishikawa, J.; Ohishi, K.; Terashi, M. Field observation of long-term strength of cement treated soil. In Proceedings of the 3rd International Conference on Grouting and Ground Treatment, New Orleans, LA, USA, 10–12 February 2003; pp. 598–609. [Google Scholar]

- Ikegami, M.; Ichiba, T.; Ohishi, K.; Terashi, M. Long-term strength change of cement treated soil at Daikoku Pier. In Proceedings of the Soft Ground Engineering in Coastal Areas, Yokosuka, Japan, 28–29 November 2002; pp. 241–246. [Google Scholar]

- Rajasekaran, G. Sulphate attack and ettringite formation in the lime and cement stabilized marine clays. Ocean Engineering 2005, 32, 1133–1159. [Google Scholar] [CrossRef]

- Nakamura, T.; Kitazume, M. Laboratory tests on durability of cement treated soils. In Technical Note of the Port and Airport Research Institute; No. 1128; Port and Airport Research Institute: Yokosuka, Japan, 2006; pp. 1–13. (In Japanese) [Google Scholar]

- Hara, H.; Suetsugu, D.; Hayashi, S.; Matsuda, H. Deterioration mechanism of cement-treated soil under seawater. J. Jpn. Soc. Civ. Eng. Ser. C (Geosph. Eng.) 2013, 69, 469–479. (In Japanese) [Google Scholar]

- Committee on Geocement. A study on long term stability of soil–cement columns improved by geocement, cement and concrete. Cem. Concr. 2014, 804, 9–14. (In Japanese) [Google Scholar]

- Cui, X.; Zhang, N.; Li, S.; Zhang, J.; Tang, W. Deterioration of soil-cement piles in a saltwater region and its influence on the settlement of composite foundations. J. Perform. Constr. Facil. 2016, 30, 04014195. [Google Scholar] [CrossRef]

- Takahashi, H.; Morikawa, Y.; Fujii, N.; Kitazume, M. Thirty-seven-year investigation of quicklime-treated soil produced by deep mixing method. Ground Improv. 2018, 171, 135–147. [Google Scholar] [CrossRef]

- Kitazume, M.; Joyo, T.; Mizoguchi, M. Characteristics of soil improved by pneumatic flow mixing method after 4 years (translated by authors). In Proceedings of the 61st Annual Conference of the Japan Society of Civil Engineers, Kusatsu, Japan, 20–22 September 2006; pp. 305–306. (In Japanese). [Google Scholar]

- Morikawa, Y.; Yokoe, S.; Kito, J. Characteristics of soil improved by pneumatic flow mixing method after 10 years (translated by authors). In Proceedings of the 67th Annual Conference of the Japan Society of Civil Engineers, Nagoya, Japan, 5–7 September 2012; pp. 451–452. (In Japanese). [Google Scholar]

- Morikawa, Y.; Takahashi, H.; Yokoe, S.; Kito, J. Characteristics of soil improved by pneumatic flow mixing method after 15 years (translated by authors). In Proceedings of the 73rd Annual Conference of the Japan Society of Civil Engineers, Sapporo, Japan, 29–31 August 2018; pp. 451–452. (In Japanese). [Google Scholar]

- Sato, T.; Kato, H. Application of the pneumatic flow mixing method to land development for Central Japan International Airport. In Proceedings of the 2002 International Symposium on Underwater Technology, Tokyo, Japan, 16–19 April 2002; pp. 93–98. [Google Scholar] [CrossRef]

- Kitazume, M.; Satoh, T. Development of a pneumatic flow mixing method and its application to Central Japan International Airport construction. Ground Improv. 2003, 7, 39–148. [Google Scholar] [CrossRef]

- Sato, T. Development and application of pneumatic flow mixing method to reclamation for offshore airport. In Technical Note of the Port and Airport Research Institute; No. 1076; Port and Airport Research Institute: Yokosuka, Japan, 2004; pp. 1–81. (In Japanese) [Google Scholar]

- Japanese Geotechnical Society. Method For Unconfined Compression Test of Soils (JIS A1216). In Japanese Geotechnical Society Standards—Laboratory Testing Standards of Geomaterials; JGS 0511; Japanese Geotechnical Society: Tokyo, Japan, 2015; pp. 1–6. [Google Scholar]

- Japanese Geotechnical Society. Method For Needle Penetration Test. In Japanese Geotechnical Society Standards–Geotechnical and Geoenvironmental Investigation Methods; JGS 3431; Japanese Geotechnical Society: Tokyo, Japan, 2018; pp. 1–5. [Google Scholar]

- Japanese Geotechnical Society. Test Method for Ph of Suspended Soils. In Japanese Geotechnical Society Standards–Laboratory Testing Standards of Geomaterials; JGS 0211; Japanese Geotechnical Society: Tokyo, Japan, 2018; pp. 1–5. [Google Scholar]

- Japanese Geotechnical Society. Test Method for Electric Conductivity of Suspended Soils. In Japanese Geotechnical Society Standards–Laboratory Testing Standards of Geomaterials; JGS 0212; Japanese Geotechnical Society: Tokyo, Japan, 2018; pp. 1–4. [Google Scholar]

- Maruto Co., Ltd. Penetrometer for Soft Rock: Model SH-70 Instruction Manual; Maruto Co., Ltd.: Tokyo, Japan, 2006; pp. 1–3. (In Japanese) [Google Scholar]

- Takahashi, H.; Morikawa, Y.; Uemura, T. Trial tests to promote degradation of cement treated soil by percolation technique. In Proceedings of the Deep Mixing, Online, 1–17 June 2021; pp. 15–17. [Google Scholar]

| Test | Part | 2002 | 2006 | 2012 | 2017 | 2022 |

|---|---|---|---|---|---|---|

| Water content test | Interior | x | x | x | x | x |

| Test for bulk density of soil | Interior | x | x | x | x | x |

| Unconfined compression test | Interior | x | x | x | x | x |

| Needle penetration test | Interior | x | x | |||

| Surface | x | x | ||||

| Near surface | x | |||||

| Chemical analysis of suspension | Near surface | x | x | |||

| EPMA | Near surface | x | ||||

| Analysis of groundwater | Boring hole | x |

| Core | Part | pH | Ca2+ (ppm) | EC (mS/cm) |

|---|---|---|---|---|

| 2017-1 | Upper | 9.0 | 160 | 2.7 |

| Lower | 8.9 | 200 | 4.2 | |

| 2017-2 | Upper | 8.9 | 190 | 2.0 |

| Lower | 8.7 | 130 | 2.6 |

| Core and Part | Depth from Exposed Surface (cm) | pH | Ca2+ (ppm) | Na+ (ppm) | EC (mS/cm) |

|---|---|---|---|---|---|

| 2022-1 (Upper) | 0–1 | 9.1 | 150 | 79 | 1.0 |

| 1–2 | 9.1 | 170 | 80 | 1.0 | |

| 2–3 | 9.4 | 190 | 90 | 1.1 | |

| 3–4 | 9.4 | 190 | 90 | 1.1 | |

| 4–5 | 9.5 | 190 | 88 | 1.1 | |

| 5–6 | 9.4 | 190 | 83 | 1.1 | |

| 6–7 | 9.4 | 190 | 86 | 1.1 | |

| 7–8 | 9.4 | 190 | 85 | 1.1 | |

| 8–9 | 9.4 | 190 | 86 | 1.1 | |

| 9–10 | 9.7 | 200 | 87 | 1.1 | |

| 2022-1 (Lower) | 0–1 | 8.3 | 130 | 660 | 4.3 |

| 1–2 | 8.1 | 120 | 640 | 4.4 | |

| 2–3 | 8.3 | 150 | 730 | 5.0 | |

| 3–4 | 8.2 | 160 | 770 | 5.2 | |

| 4–5 | 8.1 | 150 | 720 | 4.8 | |

| 5–6 | 8.2 | 160 | 830 | 5.3 | |

| 6–7 | 8.3 | 110 | 500 | 3.5 | |

| 7–8 | 8.2 | 150 | 730 | 4.8 | |

| 8–9 | 8.4 | 170 | 770 | 4.9 | |

| 9–10 | 8.4 | 180 | 860 | 5.1 | |

| 2022-2 (Upper) | 0–3.3 | 9.2 | 45 | 40 | 0.46 |

| 3.3–6.6 | 9.2 | 39 | 28 | 0.30 | |

| 6.6–10 | 9.3 | 31 | 19 | 0.22 | |

| 2022-2 (Lower) | 0–2 | 8.4 | 320 | 1400 | 8.4 |

| 2–4 | 8.9 | 340 | 1400 | 8.2 | |

| 4–6 | 8.3 | 320 | 1400 | 8.0 | |

| 6–8 | 8.5 | 330 | 1500 | 7.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Takahashi, H.; Sato, I.; Morikawa, Y.; Ozawa, A. Long-Term Durability of Cement-Treated Soil Used in Offshore Airport Island Construction. Appl. Sci. 2023, 13, 8081. https://doi.org/10.3390/app13148081

Takahashi H, Sato I, Morikawa Y, Ozawa A. Long-Term Durability of Cement-Treated Soil Used in Offshore Airport Island Construction. Applied Sciences. 2023; 13(14):8081. https://doi.org/10.3390/app13148081

Chicago/Turabian StyleTakahashi, Hidenori, Itsuki Sato, Yoshiyuki Morikawa, and Akira Ozawa. 2023. "Long-Term Durability of Cement-Treated Soil Used in Offshore Airport Island Construction" Applied Sciences 13, no. 14: 8081. https://doi.org/10.3390/app13148081

APA StyleTakahashi, H., Sato, I., Morikawa, Y., & Ozawa, A. (2023). Long-Term Durability of Cement-Treated Soil Used in Offshore Airport Island Construction. Applied Sciences, 13(14), 8081. https://doi.org/10.3390/app13148081