Hybridizing Lithography-Based Ceramic Additive Manufacturing with Two-Photon-Polymerization

Abstract

1. Introduction

2. Materials and Methods

2.1. Material Preparation and Characterization

2.2. 2PP Printing Setup

2.3. 2PP Printing Process

2.4. Microscopy Analysis and Mechanical Characterization

3. Results and Discussion

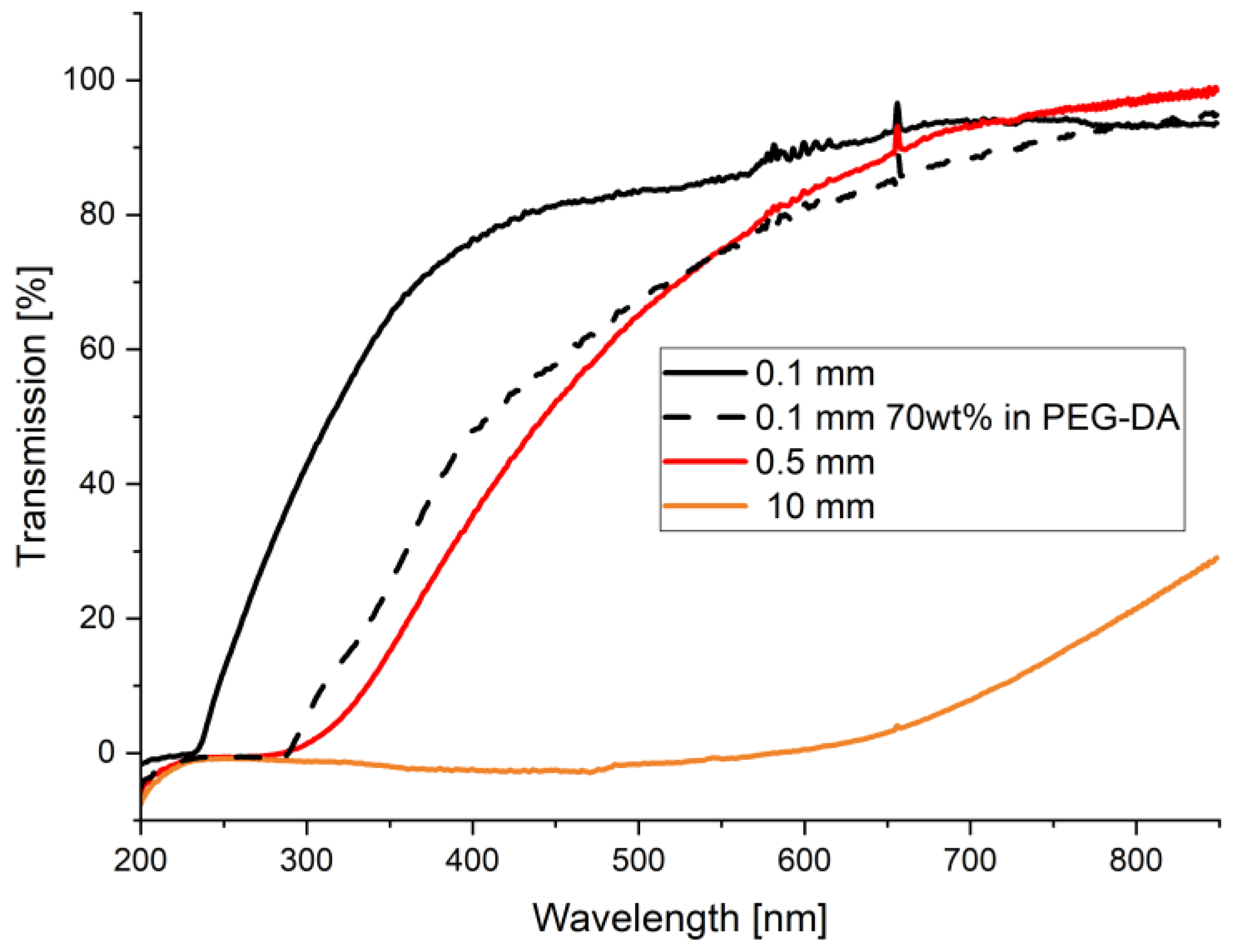

3.1. Transparent YSZ Resin

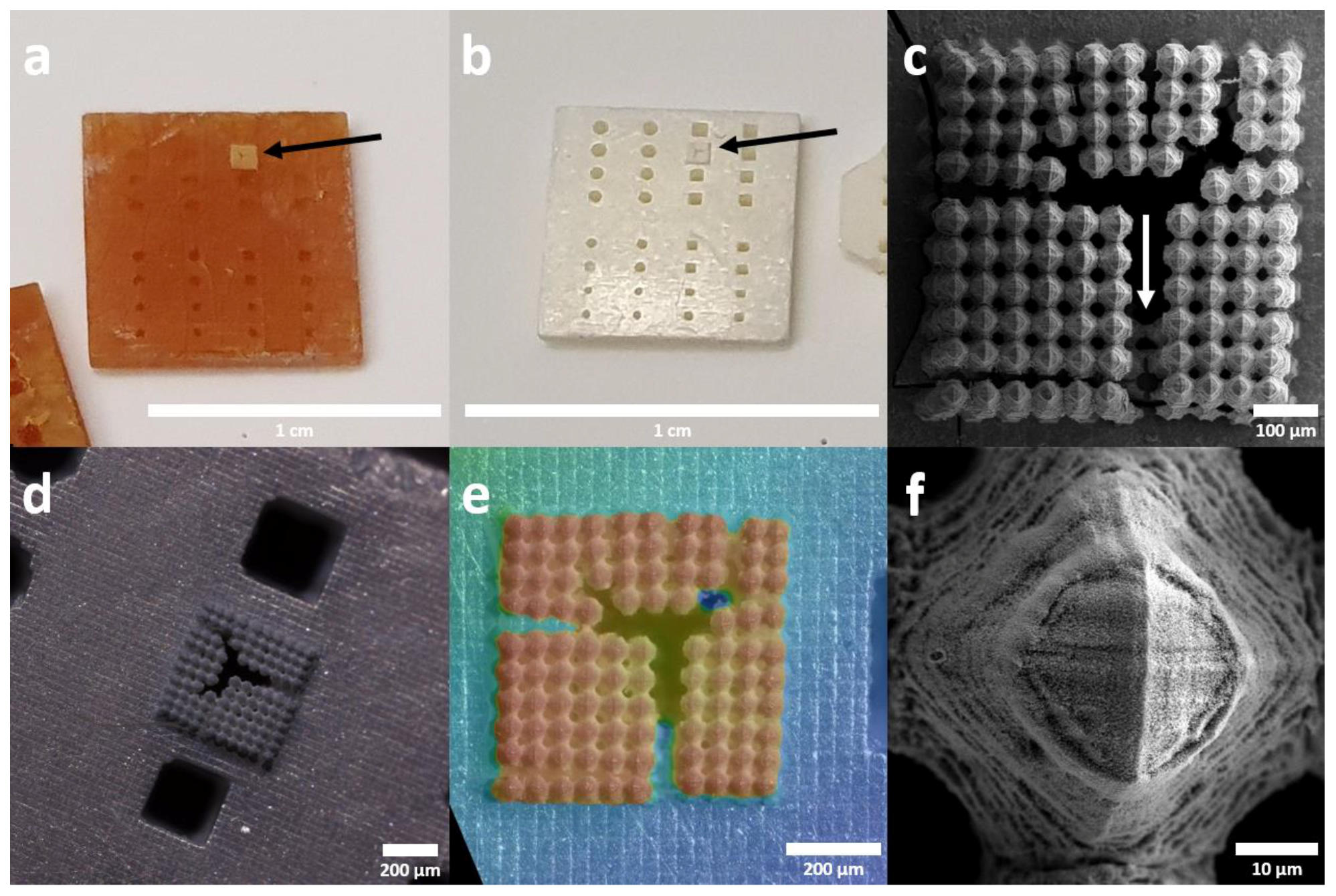

3.2. Hybrid Printing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zocca, A.; Colombo, P.; Gomes, C.M.; Günster, J. Additive Manufacturing of Ceramics: Issues, Potentialities, and Opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- Faraji Rad, Z.; Prewett, P.D.; Davies, G.J. High-resolution two-photon polymerization: The most versatile technique for the fabrication of microneedle arrays. Microsyst. Nanoeng. 2021, 7, 71. [Google Scholar] [CrossRef] [PubMed]

- Carlotti, M.; Mattoli, V. Functional Materials for Two-Photon Polymerization in Microfabrication. Small 2019, 15, 1902687. [Google Scholar] [CrossRef] [PubMed]

- Bauer, J.; Crook, C.; Izard, A.G.; Eckel, Z.C.; Ruvalcaba, N.; Schaedler, T.A.; Valdevit, L. Additive manufacturing of ductile, ultrastrong polymer-derived nanoceramics. Matter 2019, 1, 1547–1556. [Google Scholar] [CrossRef]

- Sänger, J.C.; Pauw, B.R.; Riechers, B.; Zocca, A.; Rosalie, J.; Maaß, R.; Sturm, H.; Günster, J. Entering a New Dimension in Powder Processing for Advanced Ceramics Shaping. Adv. Mater. 2022, 35, 2208653. [Google Scholar] [CrossRef] [PubMed]

- Schwentenwein, M.; Schneider, P.; Homa, J. Lithography-based ceramic manufacturing: A novel technique for additive manufacturing of high-performance ceramics. In Advances in Science and Technology; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2014; Volume 88, pp. 60–64. [Google Scholar]

- Schmidt, J.; Brigo, L.; Gandin, A.; Schwentenwein, M.; Colombo, P.; Brusatin, G. Multiscale ceramic components from preceramic polymers by hybridization of vat polymerization-based technologies. Addit. Manuf. 2019, 30, 100913. [Google Scholar] [CrossRef]

- Schwentenwein, M.; Homa, J. Additive manufacturing of dense alumina ceramics. Int. J. Appl. Ceram. Technol. 2015, 12, 1–7. [Google Scholar] [CrossRef]

- Zanchetta, E.; Cattaldo, M.; Franchin, G.; Schwentenwein, M.; Homa, J.; Brusatin, G.; Colombo, P. Stereolithography of SiOC ceramic microcomponents. Adv. Mater. 2016, 28, 370–376. [Google Scholar] [CrossRef] [PubMed]

- Jonušauskas, L.; Baravykas, T.; Andrijec, D.; Gadišauskas, T.; Purlys, V. Stitchless support-free 3D printing of free-form micromechanical structures with feature size on-demand. Sci. Rep. 2019, 9, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Gandy, P.J.; Klinowski, J. Exact computation of the triply periodic Schwarz P minimal surface. Chem. Phys. Lett. 2000, 322, 579–586. [Google Scholar] [CrossRef]

- Fritzsche, S. Available online: https://github.com/BAMresearch/ScaffoldStructures (accessed on 3 March 2022).

- Dinis, J.C.; Morais, T.F.; Amorim, P.H.J.; Ruben, R.B.; Almeida, H.A.; Inforçati, P.N.; Bártolo, P.J.; Silva, J.V.L. Open source software for the automatic design of scaffold structures for tissue engineering applications. Procedia Technol. 2014, 16, 1542–1547. [Google Scholar] [CrossRef]

- Ultimaker Cura Software. Available online: https://ultimaker.com/de/software/ultimaker-cura (accessed on 1 January 2022).

| Critical Point for Hybrid Process | Influence |

|---|---|

| Particle weight fraction | Same particle weight fraction in 2PP and LCM feedstocks ensures same shrinkage during sintering |

| Polymer composition | Same polymer composition in 2PP and LCM feedstocks ensures homogeneous degassing during debinding |

| Resin Viscosity | The 2PP resin viscosity shouldn’t exceed a certain value that it can penetrate pores in LCM printed substrate |

| Washing and Drying of UV/LCM-part | Washing and Drying needs to be optimized to prevent passivation and roughening of the surface as well as cracking of the substrate |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sänger, J.C.; Schwentenwein, M.; Bermejo, R.; Günster, J. Hybridizing Lithography-Based Ceramic Additive Manufacturing with Two-Photon-Polymerization. Appl. Sci. 2023, 13, 3974. https://doi.org/10.3390/app13063974

Sänger JC, Schwentenwein M, Bermejo R, Günster J. Hybridizing Lithography-Based Ceramic Additive Manufacturing with Two-Photon-Polymerization. Applied Sciences. 2023; 13(6):3974. https://doi.org/10.3390/app13063974

Chicago/Turabian StyleSänger, Johanna Christiane, Martin Schwentenwein, Raúl Bermejo, and Jens Günster. 2023. "Hybridizing Lithography-Based Ceramic Additive Manufacturing with Two-Photon-Polymerization" Applied Sciences 13, no. 6: 3974. https://doi.org/10.3390/app13063974

APA StyleSänger, J. C., Schwentenwein, M., Bermejo, R., & Günster, J. (2023). Hybridizing Lithography-Based Ceramic Additive Manufacturing with Two-Photon-Polymerization. Applied Sciences, 13(6), 3974. https://doi.org/10.3390/app13063974