1. Introduction

Among the different kinds of mobile elevating work platforms (MEWP), the scissor lift seems to be very useful and effective in practical usage. However, as in the case of other devices of this kind, the workers are exposed to various hazards. As is reported in the available literature [

1], according to the Census of Fatal Occupational Injuries, a Bureau of Labor Statistics database, in 1992–1999 the number of deaths of construction workers because of different accidents was equal to 339 of which 19% were different accidents with the use of scissor lifts. According to another source [

2], namely, Census of Fatal Occupational Injuries, 306 fatalities between 1992 and 2003 were caused by the usage of the different kinds of aerial lifts, and 78 of these fatalities specifically involved scissor lifts. The causes of these accidents can be quite different [

3], but it seems that the most dangerous is the tip-over of the whole mobile platform [

4]. The overturning can be caused by the wind load [

5,

6]. According to media information, the issue of scissor lifts accidents and safety is described in [

7,

8,

9,

10,

11].

It should be stressed here that according to the different standards (European Standard, Eurocode 1–4 [

12], British Standard, BS 2573-1 [

13], American Society of Civil Engineers, ASCE 7-16 [

14], Japanese standard [

15] or Chinese standard, GB/T 3811-2008 [

16]), the load caused by the wind is treated as static load where the impact of the adjacent structures is omitted. In the case of the mobile elevating work platforms (MEWP), including scissor lifts, the appropriate design rules are defined in the standard EN 280-1:2022 [

17].

However, such a simple approach can be inadequate in comparison with the wind load phenomenon, especially in the case of large-scale engineering structures like gantry cranes, tower cranes, or MEWP of a different kind. Therefore, the important aspect of the analysis of the wind load is the measurement of the wind load in the case of real structures [

18,

19,

20]. Based on these results, the appropriate wind conditions can be imitated in the aerodynamic tunnels, where the scaled models of the real large-scale structures can be tested in order to determine the wind load (forces and moments coefficients) [

21,

22,

23]. Together with the rapid development of computers and software, it is also possible to carry out numerical simulations of the airflow around crane-like structures [

24,

25,

26]. Moreover, having the distribution of the static pressure (caused by wind) on the surface of the studied structure, it is possible to carry out further mechanical analysis based on the fluid-solid interaction [

27].

Here, it should be noted that the papers which are devoted to the impact of the wind load on the scissor lifts are rather rare, thus the below brief survey of the literature also contains works, which consider the actions of the wind on other types of crane-like devices. However, the standard approach is to prepare the scaled model of the real large-scale structure for experimental tests in the aerodynamic tunnel. The obtained results are used to validate the numerical model [

28].

It is worth noting that the wind load, especially the gust of wind, which is very often two times greater in comparison with the mean wind speed and a frequency of about 1 Hz [

19], can also cause the vibration of structures. Chen and Li [

29] studied the displacement of a lattice tower. The results of the nonlinear dynamic analysis show that the displacement obtained from the time-history analysis is higher by about 5–28% in comparison with the static one. Next, Takahashi et al. [

30] studied the runaway of quayside container cranes subjected to transient gusty winds. They also proposed the sliding state while approaching the runaway and after a runaway caused by a wind gust. Chen et al. [

31] studied the interference effect of the different segments of a tower crane subjected to wind load. The wind coefficients of a full-scale model of a tower crane were calculated by CFD, and then the time history of wind loads, simulated through the autoregressive method, was applied to the finite element model of a tower crane. Although the maximum wind load direction of the tower crane was perpendicular to its jib, the obtained results reveal that the maximum along-wind load direction was deflected 30°–60°, and the mean ratio of the absolute value of the across-wind coefficient to the along-wind coefficient of the tower crane was about 8.56%. Su et al. [

32] studied the effect of stochastic dynamic transient gusty winds on the sliding and overturning of quayside container cranes. The main conclusion is that dynamic transient gusty wind-induced peak response follows type III (Weibull) extreme value distribution. Azzi et al. [

33] performed wind tunnel tests on an aeroelastic lattice tower model. The obtained results reveal the resonance contribution could reach a maximum of 18% of the peak response of the tower.

In 2022, several interesting works were published, which concern the problem of the impact of the wind load on crane-like structures. Lu et al. [

34] took into consideration the problem of the outer-attached tower cranes installed on super high-rise buildings and exposed to wind-induced vibration. The numerical CFD simulations and structural FEM calculations were performed. He et al. [

35] presented a study, which concerns a similar problem. To avoid sophisticated finite element analysis of the main building, a modified generalized flexural-shear model (FSM-MS) was proposed to estimate the along-wind and across-wind displacement response of the main building and the response at the connection support of the tower crane. Yeon et al. [

36] studied the lift effect on wind load estimation for a semi-submersible rig. Wind loads on the analyzed rig were calculated under the maritime atmospheric boundary layer. The obtained results match well with those from the wind tunnel within a ±20% error.

The influence of the lifted load on the stability of crane-like devices has also been investigated. Here, two exemplary works can be quoted, namely Monteiro et al. [

37] and Cekus et al. [

38].

At the end of this brief survey of the literature, it is also worth mentioning the wind-induced interference effect (IE). The analysis of this problem provides insights into how the neighborhood’s other structures influence the studied structure by changing the surface pressure caused by the wind. However, the cases of crane-like devices are rarely found. Here, the work by Wu et al. [

39] can be mentioned. The author of this work investigated the wind load and wind-induced dynamic response of three quayside container cranes. Other similar works concerning lattice structures refer to the mutual influence of a system of antennas, for example, Holmes et al. [

40], Carril et al. [

41], and Martín et al. [

42]. The interference factor of microwave antenna dishes is found to be greater than one for some wind directions. The interferon effect has also been investigated for tall buildings [

43], low-rise buildings [

44,

45,

46,

47], cooling towers [

48,

49], and scaffoldings [

50].

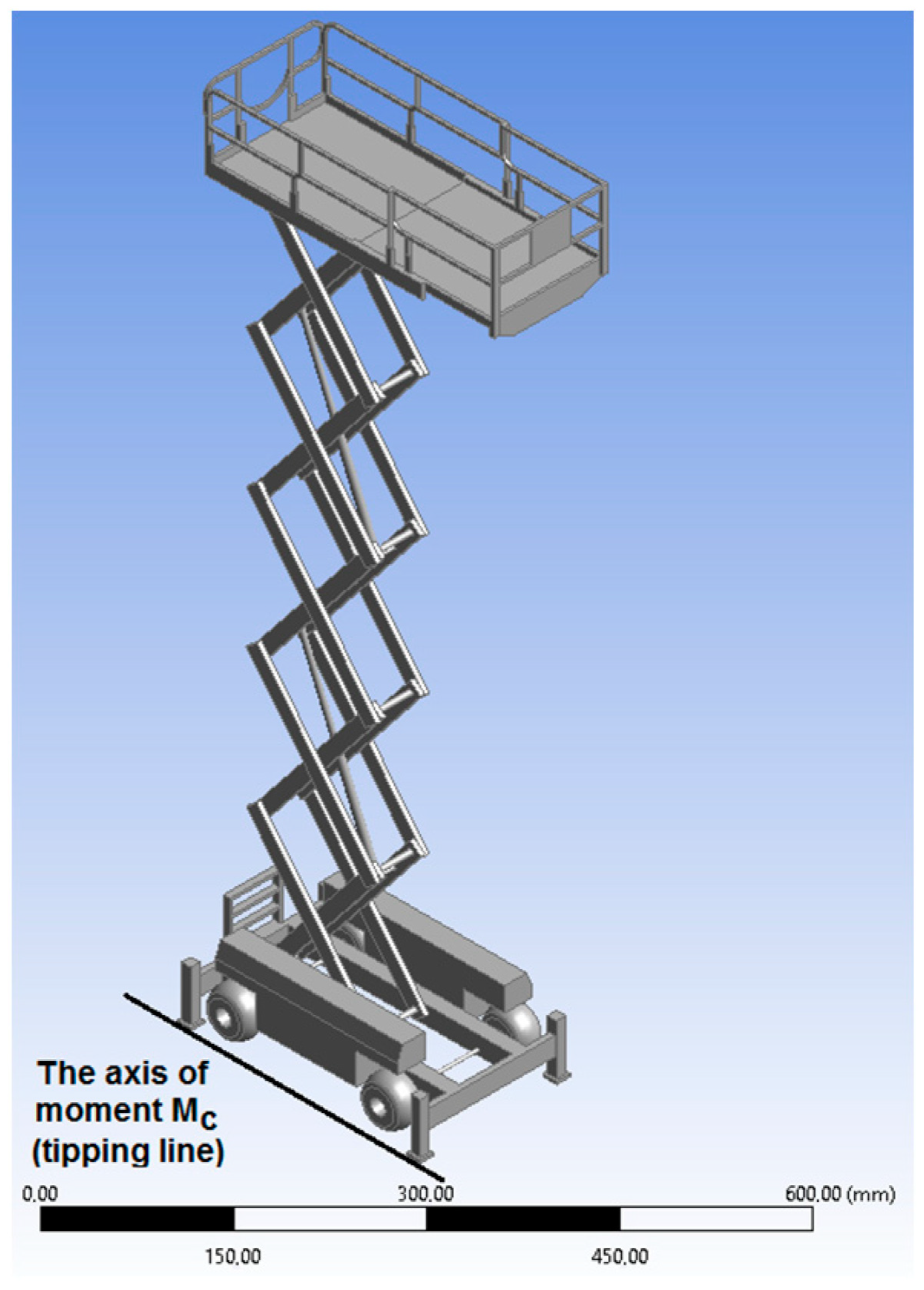

This work should be treated as a continuation of the previous one [

51]. The current work is devoted to the problem of determining the wind speed, which causes the tip-over of the scissor lift in the case when there are no workers on the platform and in the case when there are one, two, or more persons on the platform. The main aim of this effort is to increase the safety of the workers when the device is in service. Basically, the value of the moment induced by the wind, which causes a tip-over of the studied scissor lift, is determined based on the results obtained from the CFD simulation. However, the used numerical model is verified by the experimental tests performed in the aerodynamic tunnel, namely, the values of aerodynamic forces obtained from simulations and experiments are compared. Taking into consideration the geometrical dimensions of the real device, the scaled model of the scissor lift is made. Having verified the numerical model, the critical wind speed value can be determined for a real-scale scissor lift. Moreover, knowing the value of the mean aerodynamic force, which acts on the human being, the impact of the presence of the workers on the platform can also be estimated on the critical wind speed.

2. Materials and Methods

2.1. Object of Investigation

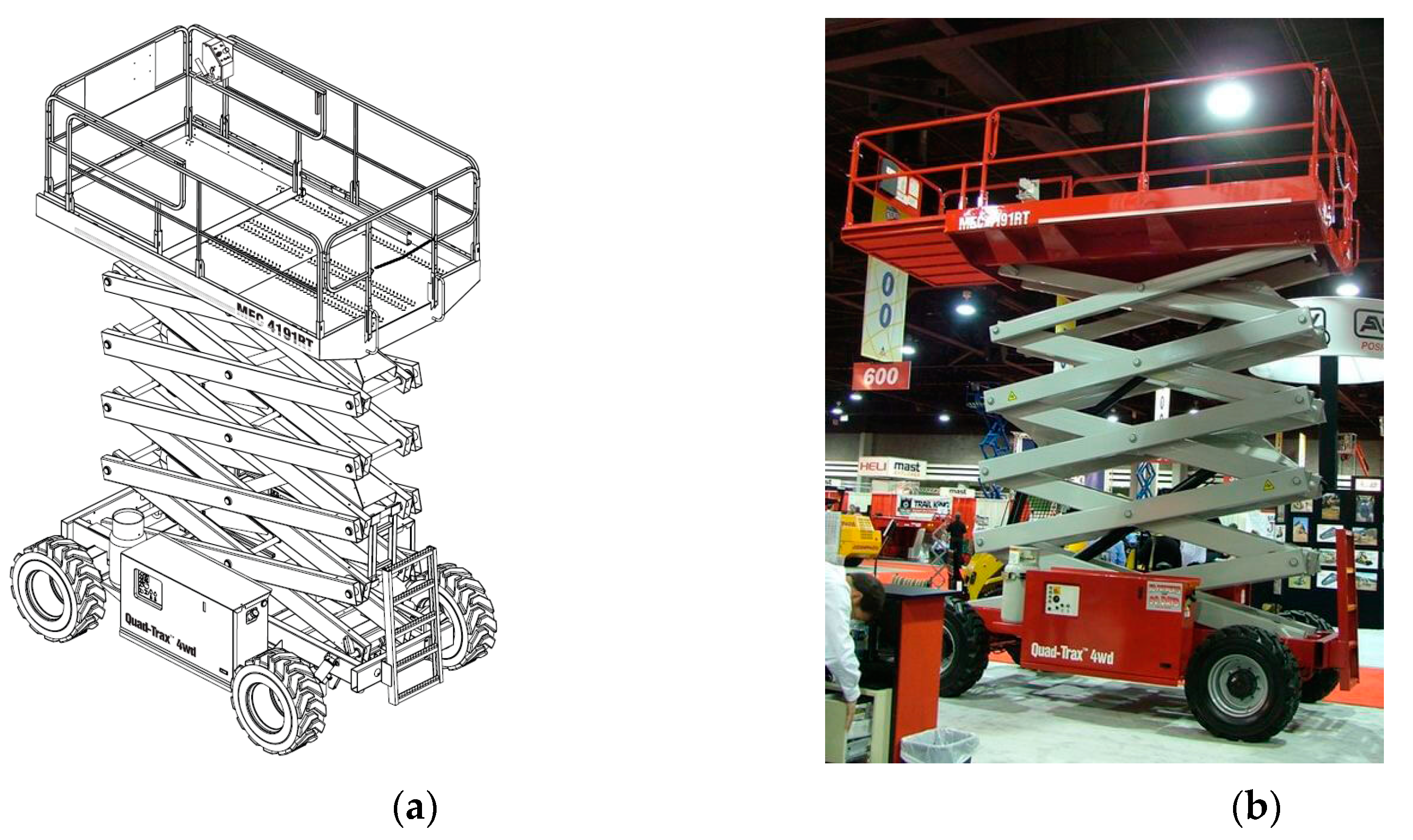

As it was mentioned above, the object of the current analysis, shown in

Figure 1, is the scissor lift MEC 4191RT [

52].

Table 1 presents the technical data and geometric dimensions of the actual structure.

The MEC 4191RT mobile platform is adapted to work in difficult terrain. All four wheels are driven and steerable, equipped with off-road tires. The source of the traction drive is a liquid-cooled diesel engine with a power (Liquid-cooled, Kubota DF752 Dual Fuel or Kubota D1105 Diesel engine) of 8.7 kW. The scissor mechanism is built of two parallel, interconnected scissor kinematic systems, each of which consists of five members. The basic element of the scissor system consists of two double-armed levers (rectangular steel profiles) with arms of identical length connected in the middle with a pin. The members being kinematic pairs relate to each other by the ends of the two-arm levers and by means of pins.

The unfolding and folding of the scissor mechanism are carried out by means of two hydraulic cylinders, one of which is attached to the first pair and the other to the last pair. At the same time, both hydraulic cylinders are coupled to the middle pair. The entire scissor mechanism is connected to the chassis frame at the bottom and to the platform frame at the top. One arm of the lever is connected to the slider moving along the guides, and the other is connected to the frame through a pivot enabling rotation.

The working platform is made of metal. The floor of the working deck is made of special steel mesh, the balustrade is made of rectangular steel profiles. The platform has a manually extended side platform, which increases its surface by about 1/3.

2.2. Experimental Setup

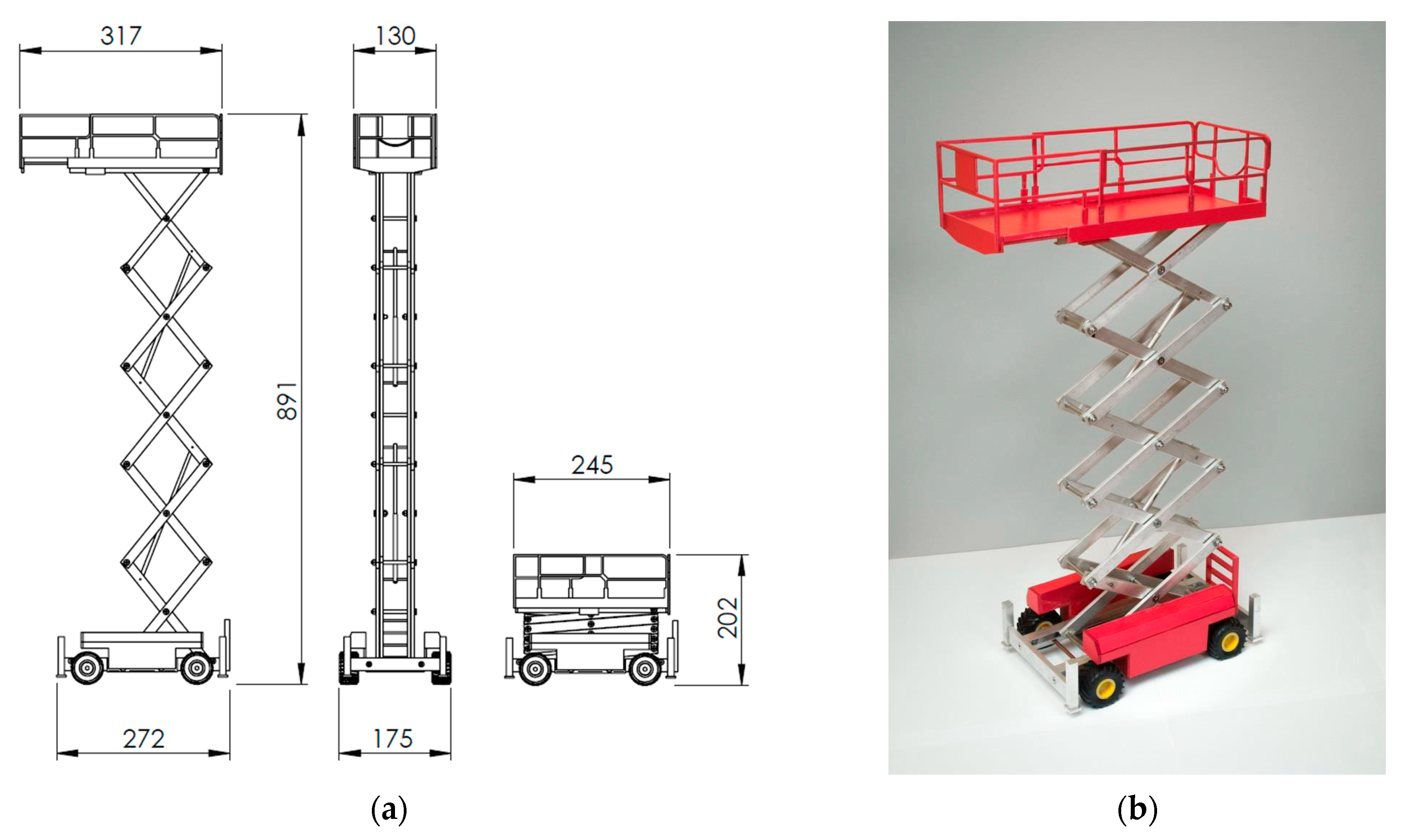

For experimental research in the aerodynamic tunnel, the model of the investigated scissor lift with an approximate scale of 1:14 is prepared. Due to the specificity of the research, it is important to maintain the geometric dimensions of the model in relation to the real object, while some elements were simplified or omitted. Simplifications used in the model: (a) Arms of the scissor mechanism made of full profiles (originally an open rectangular profile), (b) connections of the scissor mechanism members made with the use of screws and bushings (originally pins), (c) stabilizing supports permanently integrated with the chassis (in the original it is possible to disassemble), (d) rigidly mounted road wheels, (e) elements of the platform and covers of the engine and hydraulic system made of 3 mm thick PVC.

Making the scissor mechanism from full profiles and the use of PVC with a thickness inconsistent with the scale of the model is reasonable because the overall dimensions have been preserved, and thus the reference surface, which is needed to determine the force and moment coefficients. Moreover, the whole described simplifications of the scaled model do not affect the surface in the orthogonal projection. The scaled model with the geometrical dimensions is shown in

Figure 2.

The experimental tests are carried out for three configurations of the scissor lift, namely:

configuration 1, where the work platform of the model is positioned 891 mm from the floor level (height measured to the top guardrail, as is shown in

Figure 2 with extended roll-out deck),

configuration 2, the configuration of the scissor lifts the same as in the case of variant 1, but the roll-out deck is retracted, and finally,

configuration 3, where the work platform is positioned 450 mm from the tunnel floor level to the top guardrail with retracted roll-out deck.

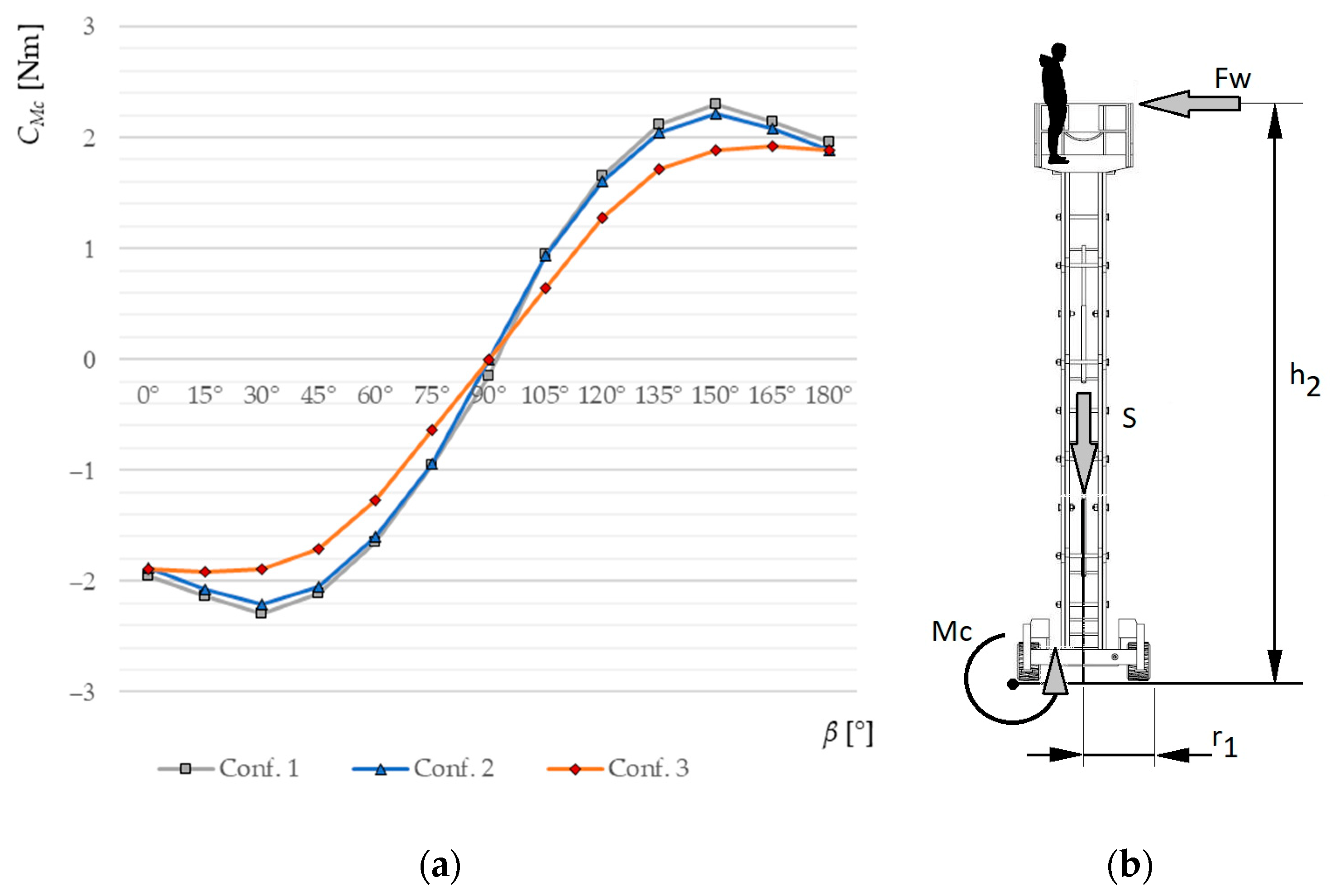

In all mentioned cases, it is assumed that the wind direction varies from 0° to 180° with an increment equal to 15°. At this stage of analysis, the presence of workers on the platform is not considered. The impact of the presence of people will be studied further.

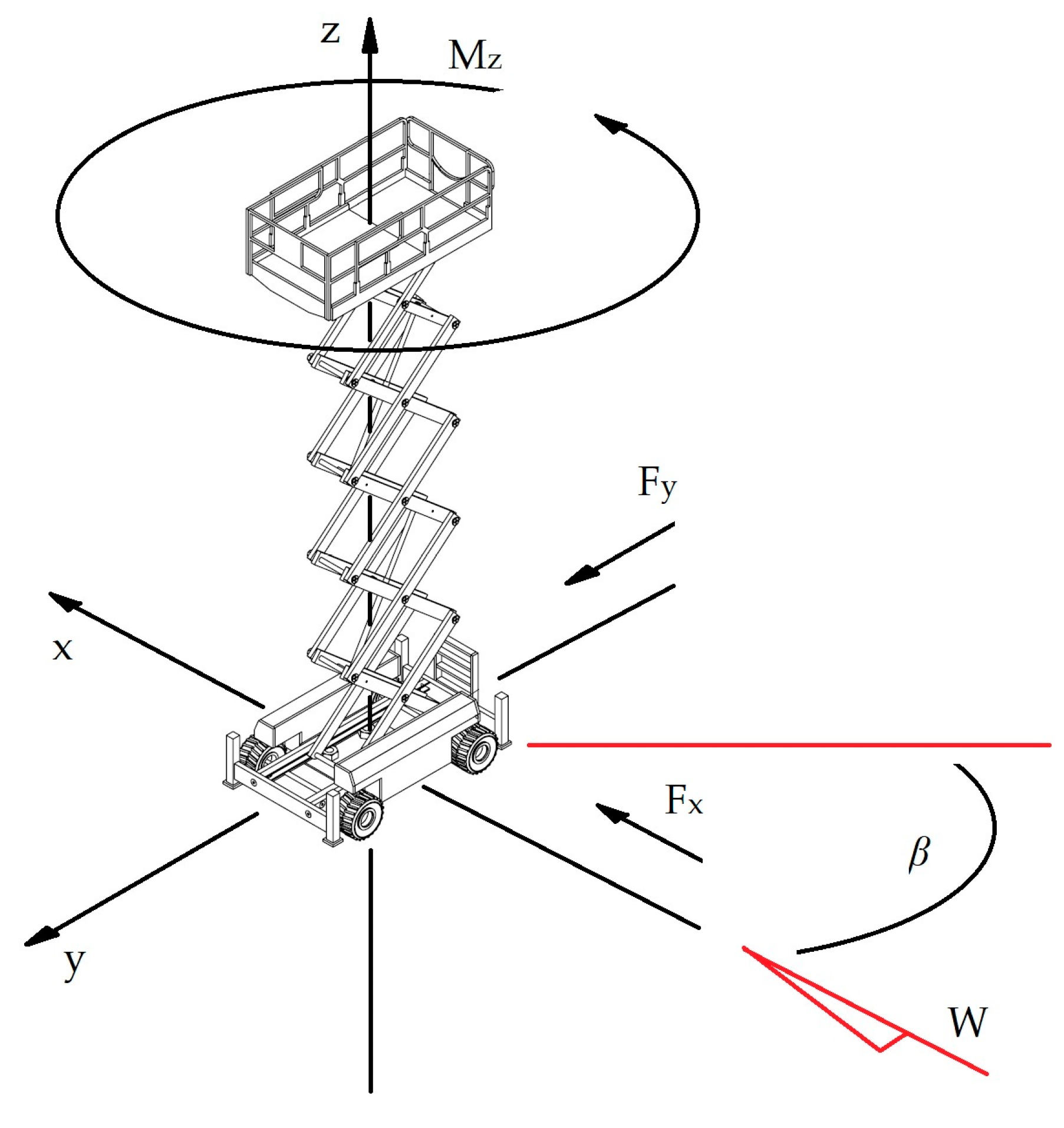

The assumed coordinate system and the way the angle of wind direction is defined are shown in

Figure 3. For the tested model of the scissor lift, the aerodynamic moment

Mz and aerodynamic forces

Fx and

Fy are measured using the three-component aerodynamic balance based on the electric resistance strain gauges [

54]. The orientation of the fixed coordinate system

x,

y,

z is as follows:

x—along wind direction,

y—across wind direction,

z—vertical direction.

The sensitivity of the aerodynamic balance in the range of 0 to 2 N in increments of 0.1 N is 89.4%, in the range of 2 to 10 N in increments of 2 N is 92.9%, and in the range of 10 to 50 N in increments of 10 N is 99.7% [

54]. A similar topic, including research in a wind tunnel, was described in [

55,

56,

57].

2.3. Aerodynamic Tunnel

The experimental tests were carried out in the boundary layer wind tunnel at the Wind Engineering Laboratory at the Cracow University of Technology [

58]. The wind tunnel, with a length of 10 m and a measurement area of 2.2 × 1.4 m, allows for conducting tests in both closed and open circuits. The wind flow was generated by an axial fan with a diameter of 2.7 m and an efficiency of 0.8–0.9, and a blade tip speed of about 100 m/s. The fan was driven by a 200-kW alternating current motor with a nominal speed of 750 rpm, controlled by an inverter. The maximum wind speed was approximately 40 m/s (144 km/h).

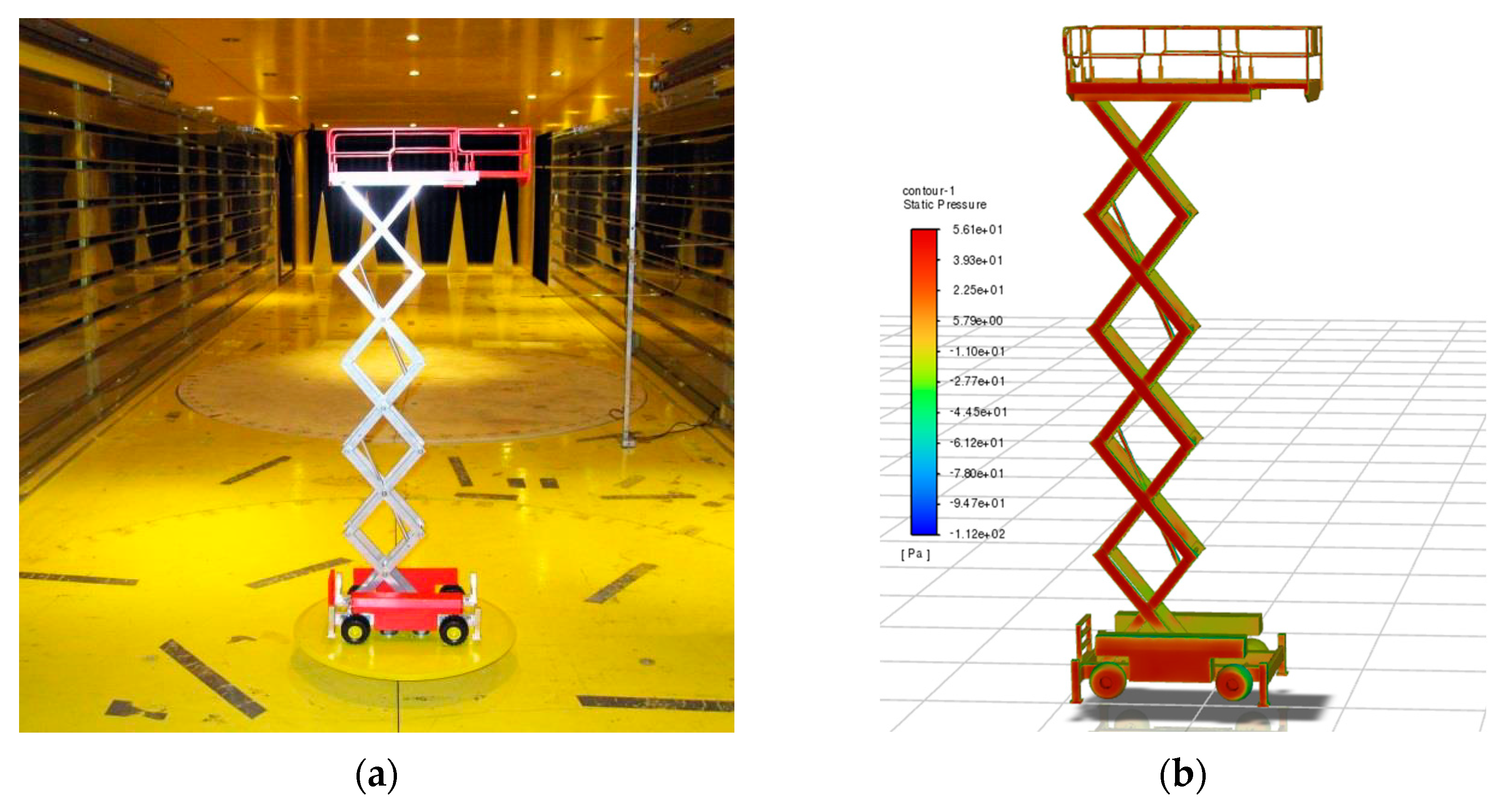

Figure 4 and

Figure 5 show the wind tunnel and CFD simulation with the study models in the 1st and 3rd configurations for the selected angle of wind attack.

Figure 4a shows the mast, where the two wind speed sensors are installed: One of them 0.5 m and the second 0.92 m above the tunnel floor. The intensity of the turbulence was controlled by a system of spires about 0.8 m high and 0.3 m wide (

Figure 4).

2.4. Measurement of the Force Components Acting on the Model and Corresponding Wind Speed

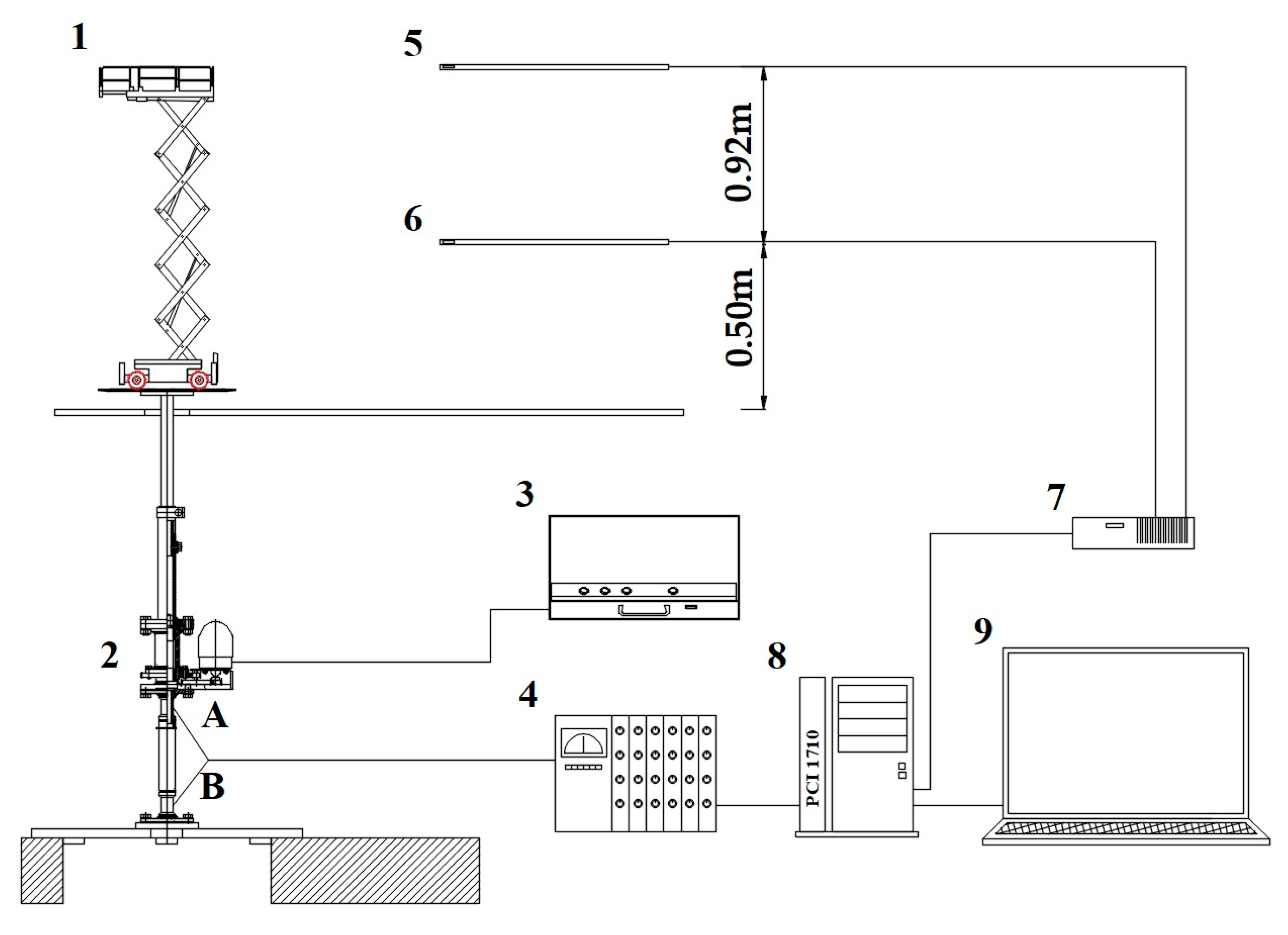

The schema of the applied measuring system is presented in

Figure 6. The model of the scissor lifts 1 was installed on the aerodynamic balance 2. A, B—special segments with strain gauges. It is the device that enables the determination of components

Fx and

Fy of the aerodynamic forces as well as the moment

Mz with respect to the coordinate system shown in

Figure 3. The aerodynamic balance relates to the electronic system 3 controlling the stepper motor of the turntable and with the strain gauge bridge 4 measuring the aerodynamic forces. The wind speed was evaluated via two thermo-anemometer probes 5 and 6, which were connected to the thermo-anemometer ANT 2000 7. Aerodynamic forces and wind speed measurements were recorded via a PCI 1710 card 8 on a PC 9.

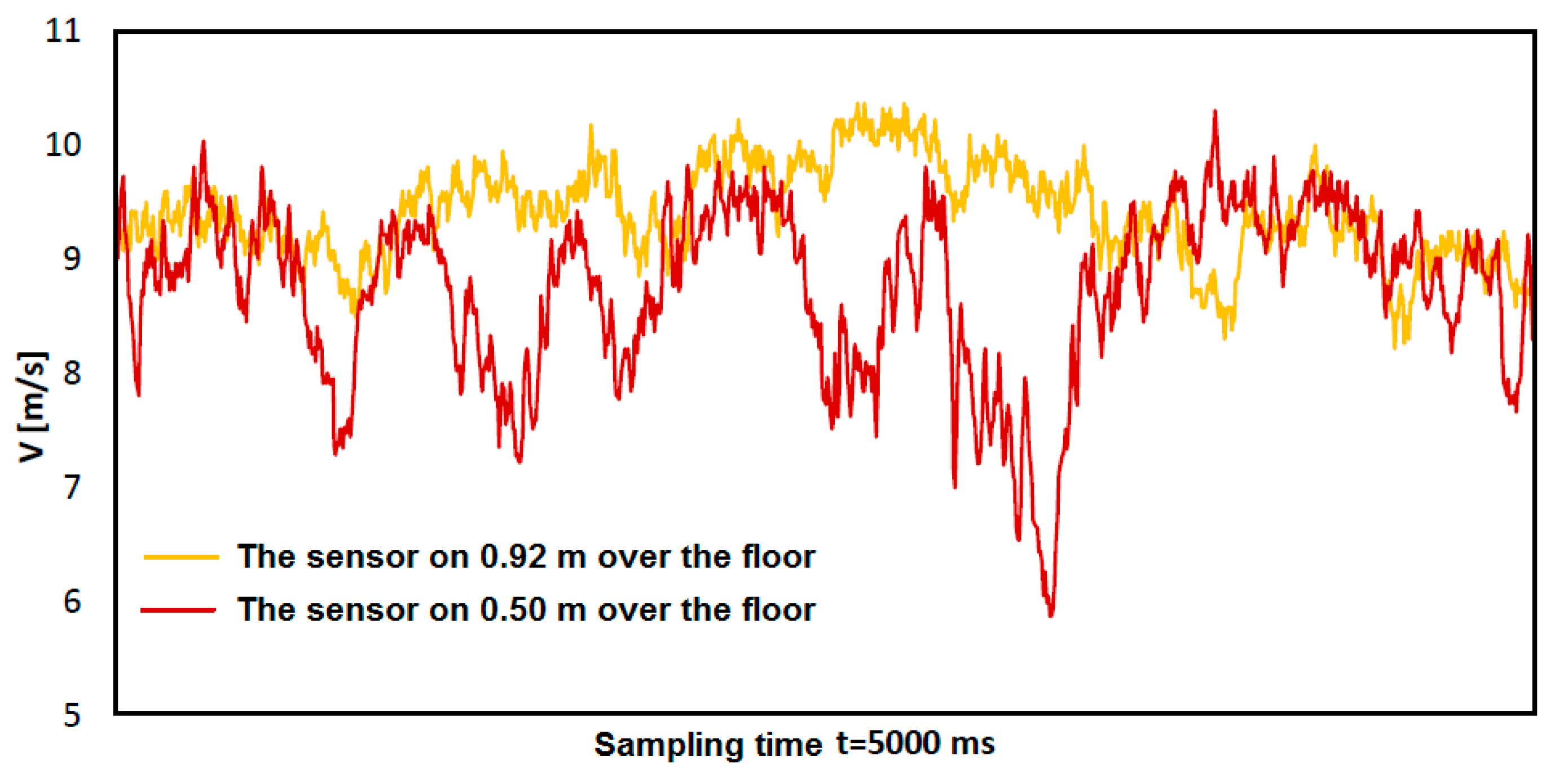

The sampling time of the wind speed is equal to 5000 ms. The exemplary graph of the wind speed variations measured via sensors 5 and 6 is presented in

Figure 7. Here, it should be noted that the average value of the wind speed measured by sensor 6 is about 15% lower in comparison with the value indicated by sensor 5. Moreover, based on the graph in

Figure 7, the average intensity of turbulence

Iv can also be evaluated according to the following formula:

where

σv is the standard deviation of the measuring wind speed and

Vref is the reference speed, which is equal:

where

pref is the reference pressure. The standard deviation can be computed based on the dynamic component

vdyn(

t) of the instantaneous velocity

V(

t), where

V(

t) =

Vref +

vdyn(

t).

The wind speed, which was measured at the point localized 500 mm over the floor of the aerodynamic tunnel, was generally lower in comparison with the wind speed measured at 920 mm over the floor. It was caused by the set of “spires”, which were installed at the beginning of the tunnel in order to induce the initial turbulence. The spires were much wider at the basis in comparison with their summits. Therefore, the wind speed was much more disturbed at the level of 500 mm and, in consequence, the average wind speed was lower.

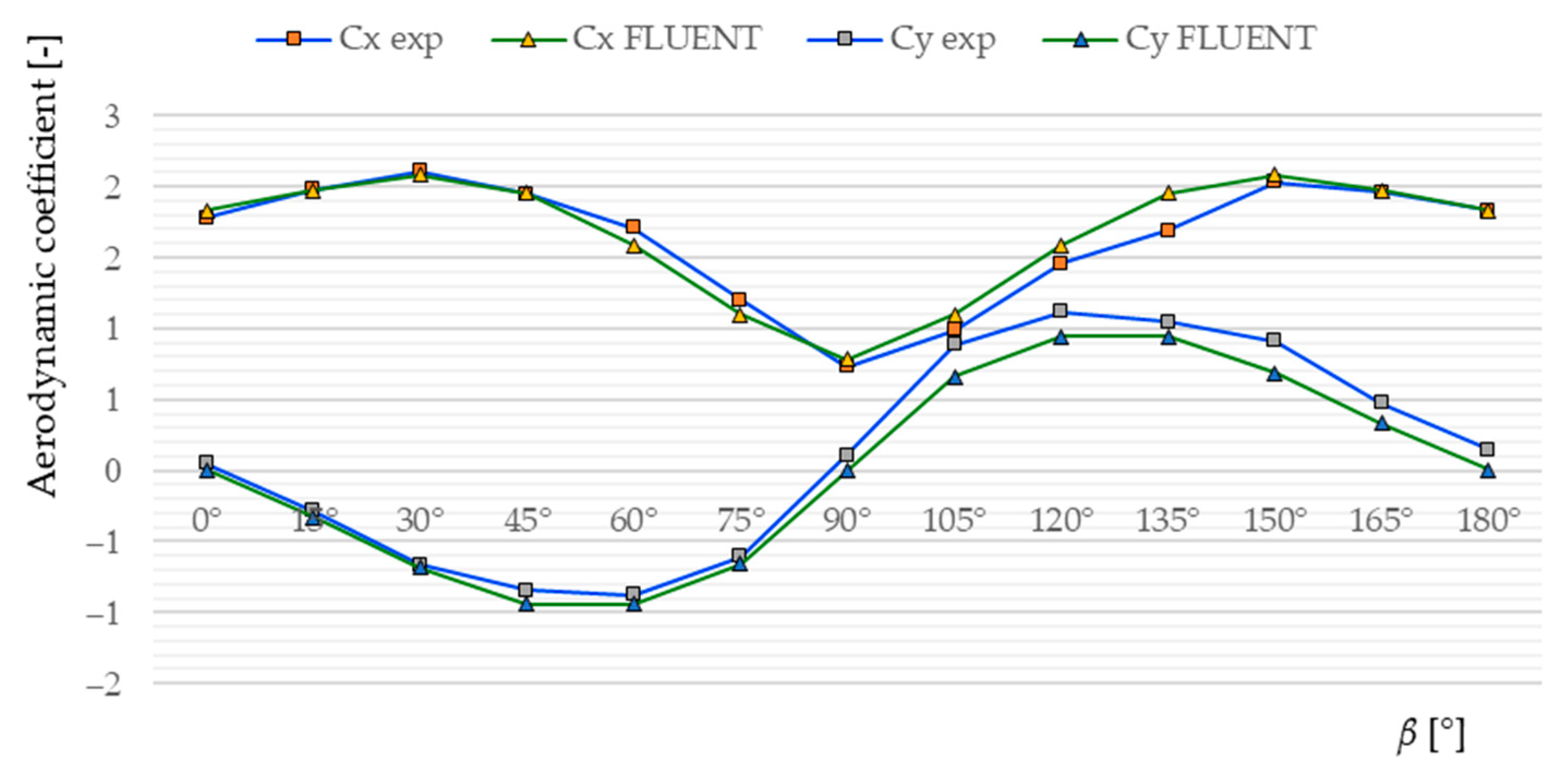

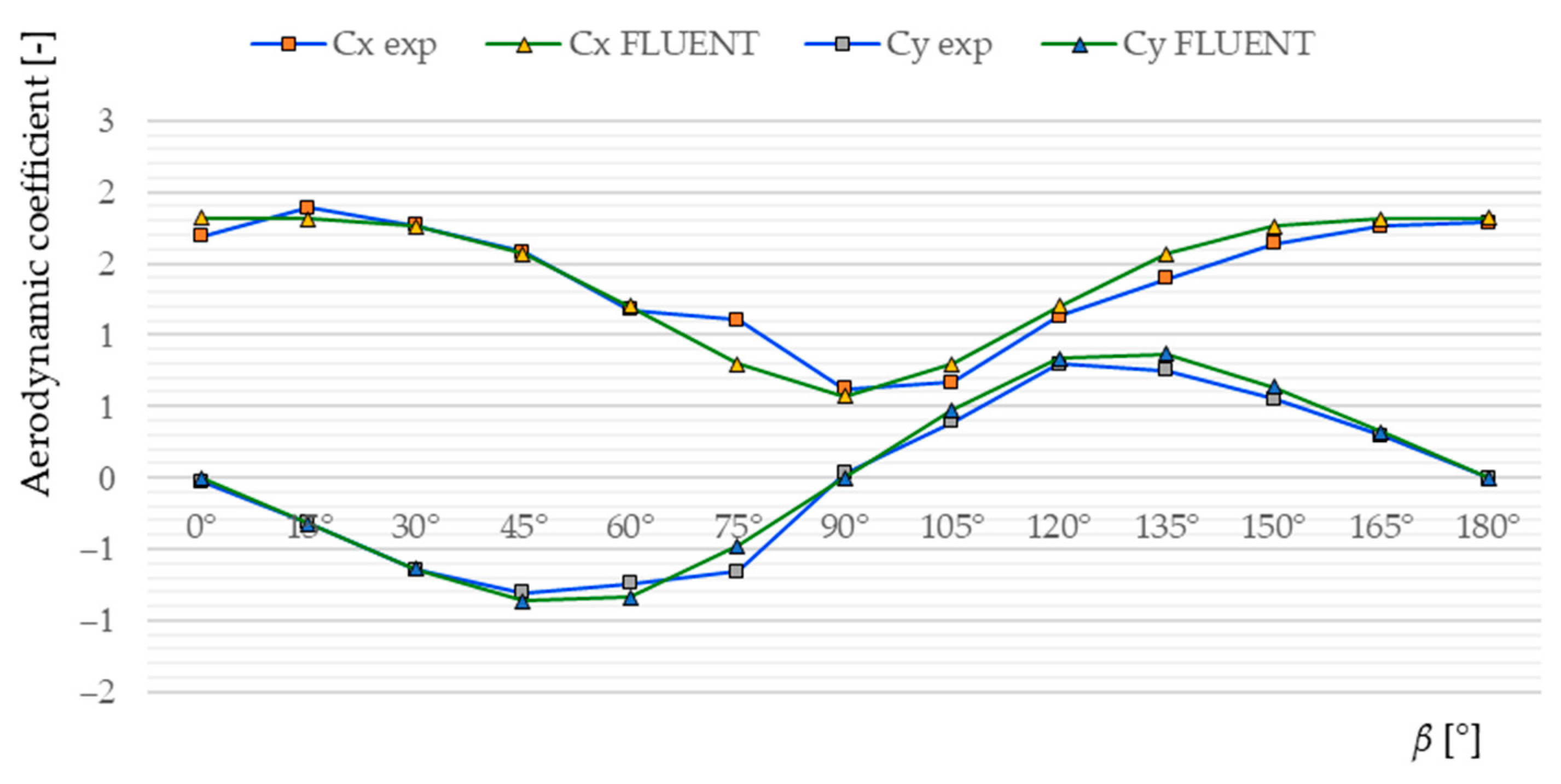

The formulas determining the coefficient of aerodynamic drag

Cx, the coefficient of the lateral aerodynamic force

Cy, the aerodynamic coefficient of torque

CMz, and the aerodynamic coefficient of the moment, which caused the tip-over

MC are as follows:

where:

Fx—aerodynamic drag N,

Fy—lateral force respectively N,

V—the average wind speed m/s,

ρ—the mass air density,

Aref—effective area of one of the supporting structures of the model, i.e., the area of the shadow normal projected by its members on a plane parallel to the wall equal 0.051 m

2,

rref—the reference dimension adopted by convention, the width of the structure of the model equal 0.116 m and

href is half of the total height of the model equal to 0.446 m.

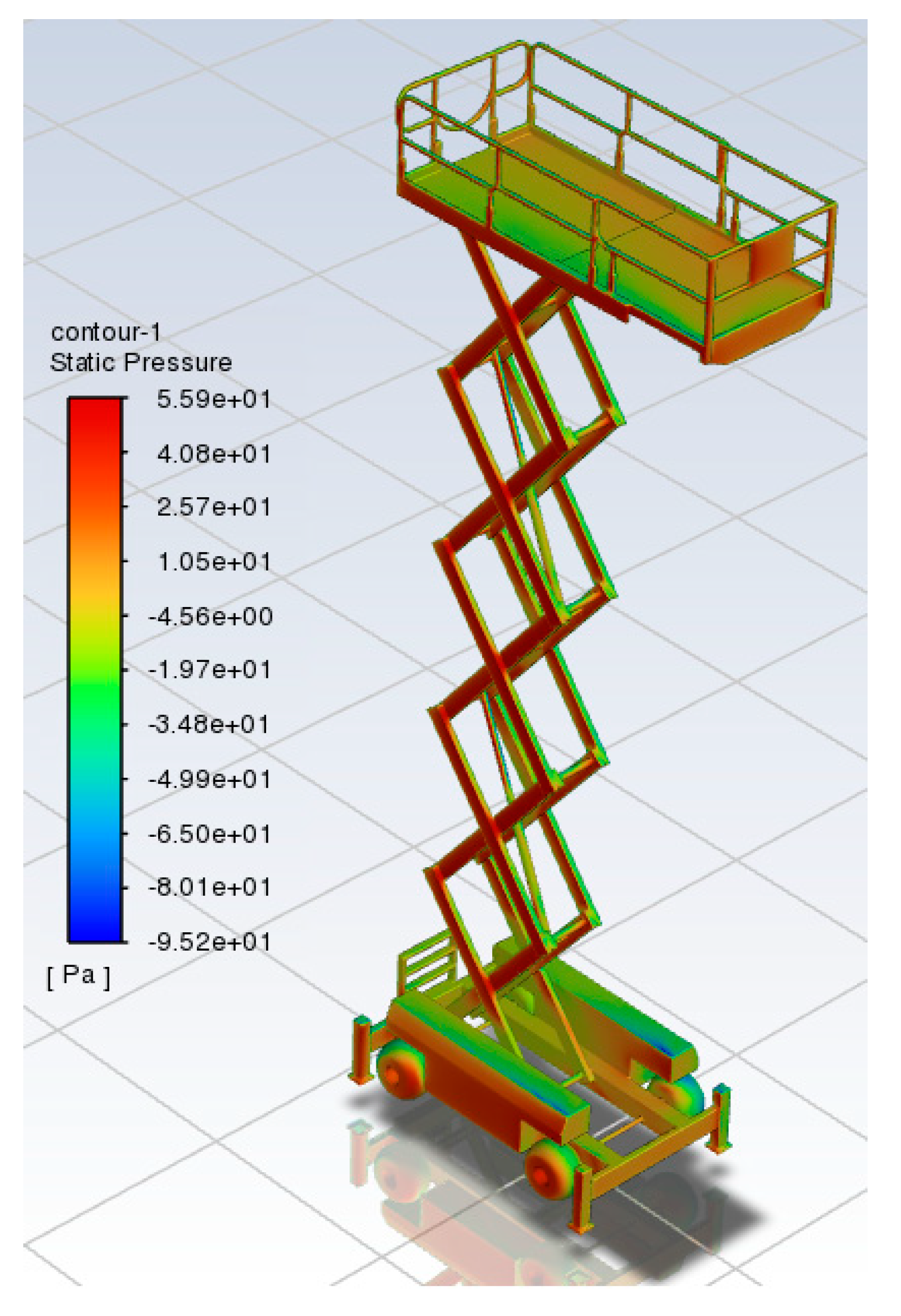

2.5. CFD Simulations

The airflow simulations were carried out with the use of the Fluent software in the ANSYS Workbench R22 environment (

Figure 8). The main aim of these simulations was to determine the aerodynamic forces and moments acting on the studied scissor lift, more specifically, force, and moment coefficients. These quantities were defined by Equation (3).

In the performed simulations, we assumed standard air properties, therefore, ρ = 1.225 kg/m3, T = 15 °C, p0 = 101,325.25 Pa. Moreover, the model of the scissor lift was immersed in a rectangular space filled with air with external dimensions 2.2 × 1.4 m and a length of 2 m, which corresponded to the dimensions of the wind tunnel. The tunnel walls were modeled as stationary boundaries.

One of the most important problems was the appropriate choice of the turbulent model. In the current work, we considered three most frequently applied in practice models, namely: Reynolds stress model, model k-ω, and model k-ε. The first mentioned model, used by Wu et al. [

39], caused the computations to converge unacceptably slowly. The second model, used by He et al. [

35], Yeon et al. [

36], and Monteiro et al. [

37], requires preparing the specific mesh at the boundary conditions. For estimation made for the studied structure, the first layer of the finite volume should be about 7 × 10

−5 m in height. Unfortunately, it leads to an enormous number of nodes and finite element volumes.

Finally, the standard k-ε model with a standard wall function has been used. It is worth noting that this model is still in use, for example, the works of Zan et al. [

26], Chen et al. [

31], Lu et al. [

34]. The application of this model caused the computations are converging relatively quickly. Obtaining the solution demands less than 100 iterations.

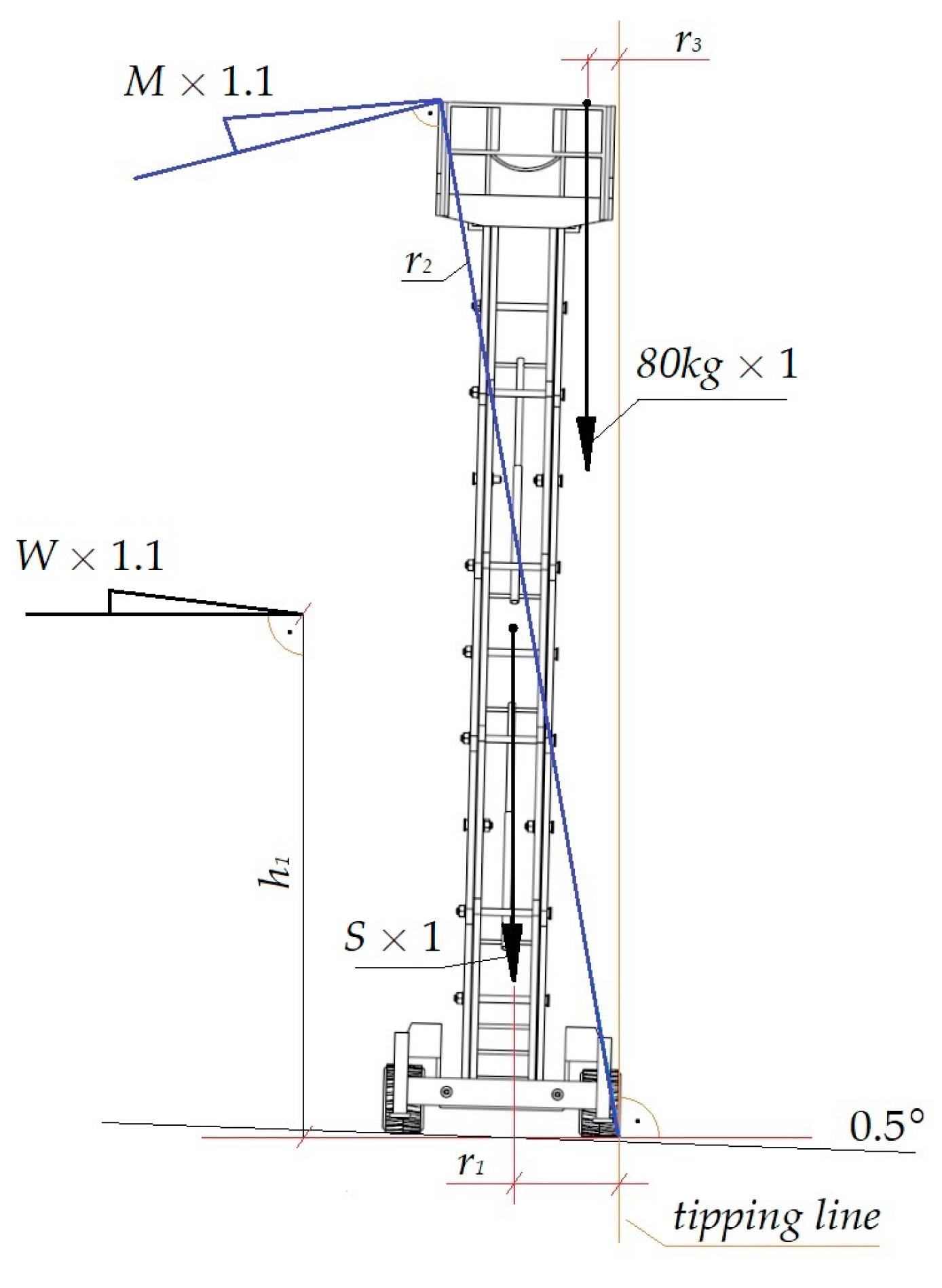

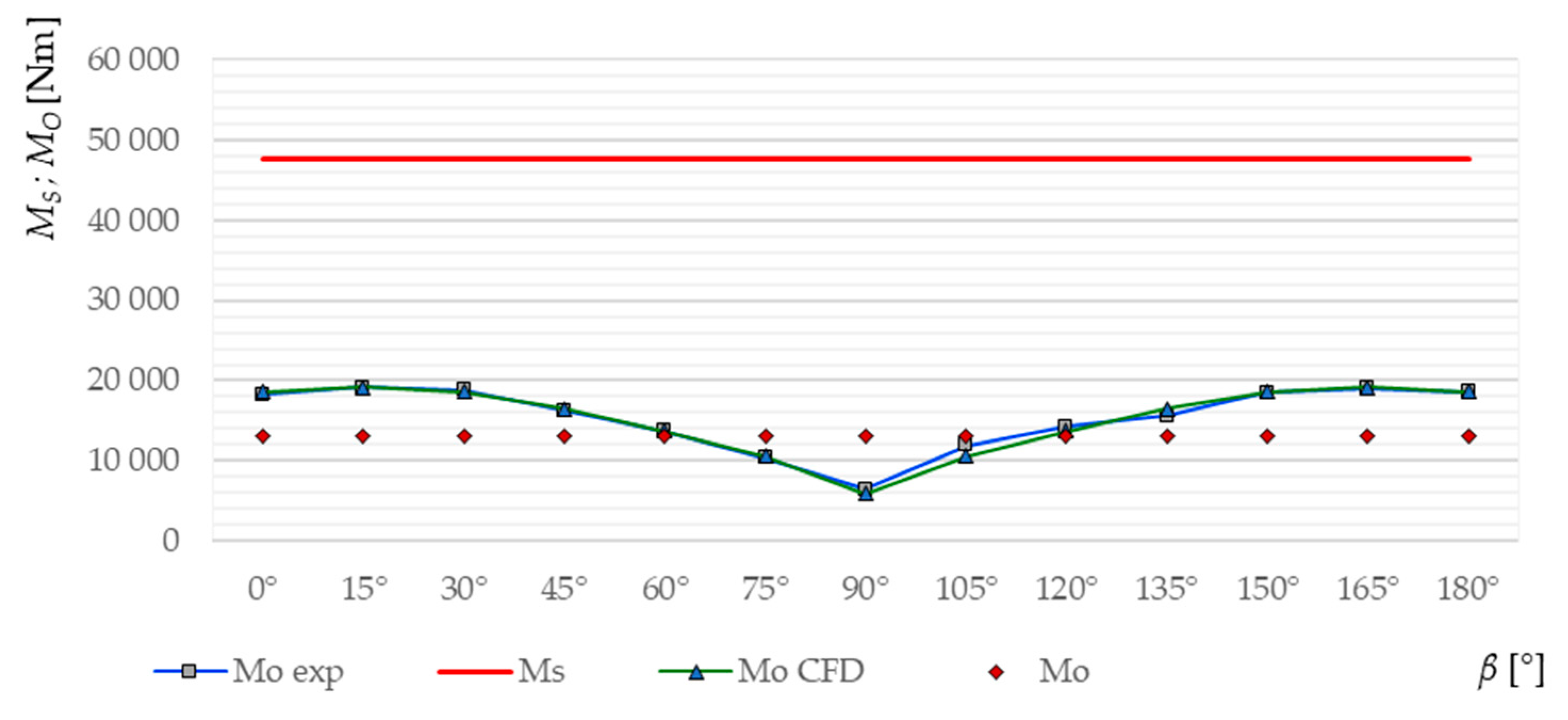

5. Conclusions

The current work concerns the problem of the critical wind speed determination, which can cause the tip-over of the scissor lift. The analysis is performed for the device MEC 4191RT. The estimation of the critical value of the wind speed is based on results obtained from the CFD analysis of the scaled model (assumed approximate scale of the model 1:14) of the scissor lift. The computations are performed with the use of ANSYS Fluent R22. Three different configurations of the scissor list at analyzed, namely: (a) The work platform raised to the maximum height with an additional bridge extended, (b) the work platform raised to the maximum height, and (c) the work platform half raised. The numerical model is verified by the experimental test in the wind tunnel. To verify the CFD results, the values of the

Fx and

Fy components of the aerodynamic forces are compared, which are obtained from numerical simulations and experimental tests. A relatively good agreement is observed. In the case of the force coefficient

Cx, the value of the average error does not exceed 9% for all investigated configurations. It is established that the most dangerous wind direction is the one that makes an angle of 30° with the

X-axis of the global coordinate system,

Figure 3, for all studied configurations of the scissor lift. The lowest critical wind speed is obtained for configuration 1st and is equal to

V1CRT = 22.315 m/s. For other configurations, the critical wind speed is higher and equal to

V2CRT = 22.75 m/s, and

V3CRT = 33.534 m/s, respectively. The impact of the workers on the platform of the scissor lift on the critical wind speed is estimated based on the values of the drag force of the human body, which are available in the literature. The presence of the workers decreases the critical wind speed and, in the case, when the four persons are on the platform, the critical wind speed is equal to

V1CRT = 21.513 m/s,

V2CRT = 21.874 m/s, and

V3CRT = 32.459 m/s for the configurations 1st, 2nd, and 3rd, respectively. The obtained results are in good agreement with these, which are obtained based on code EN 280-1:2022.

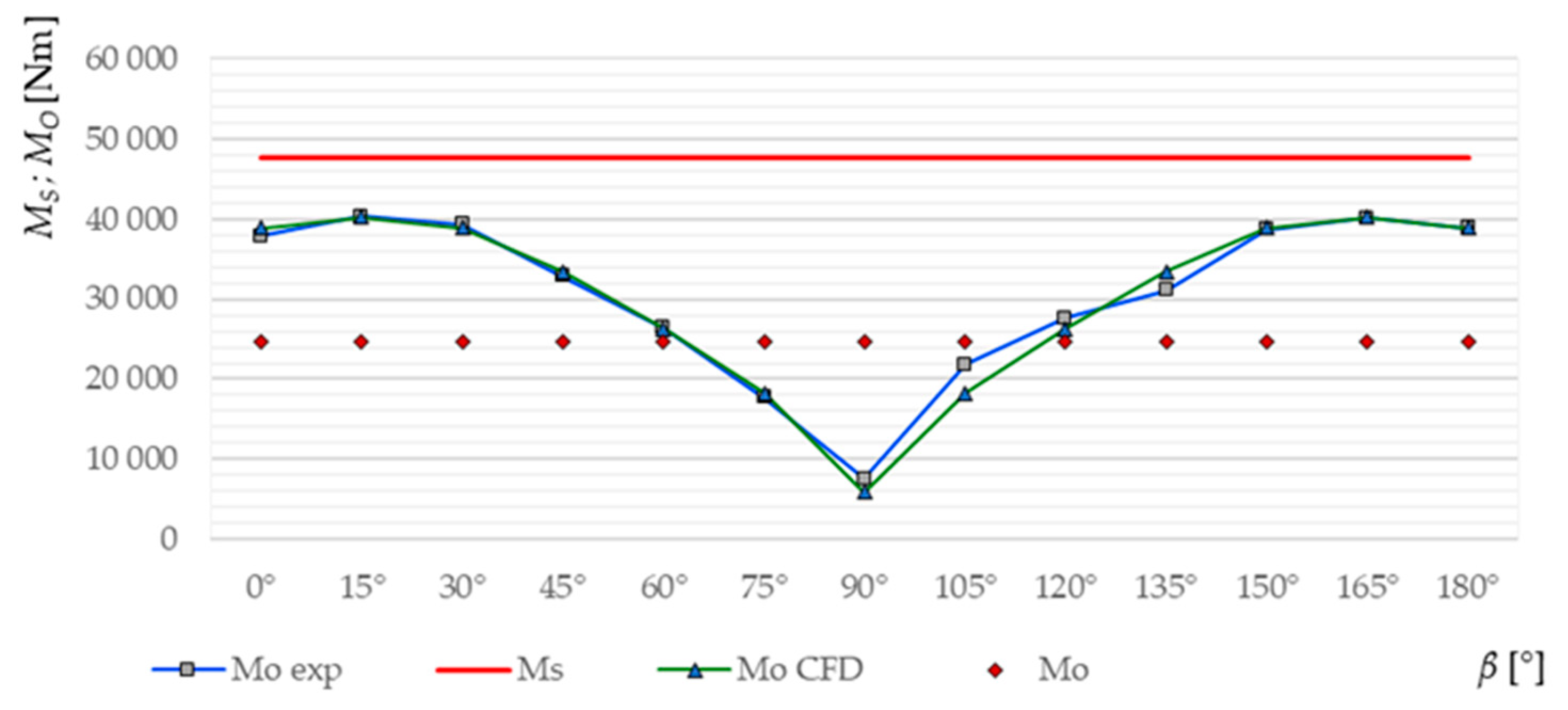

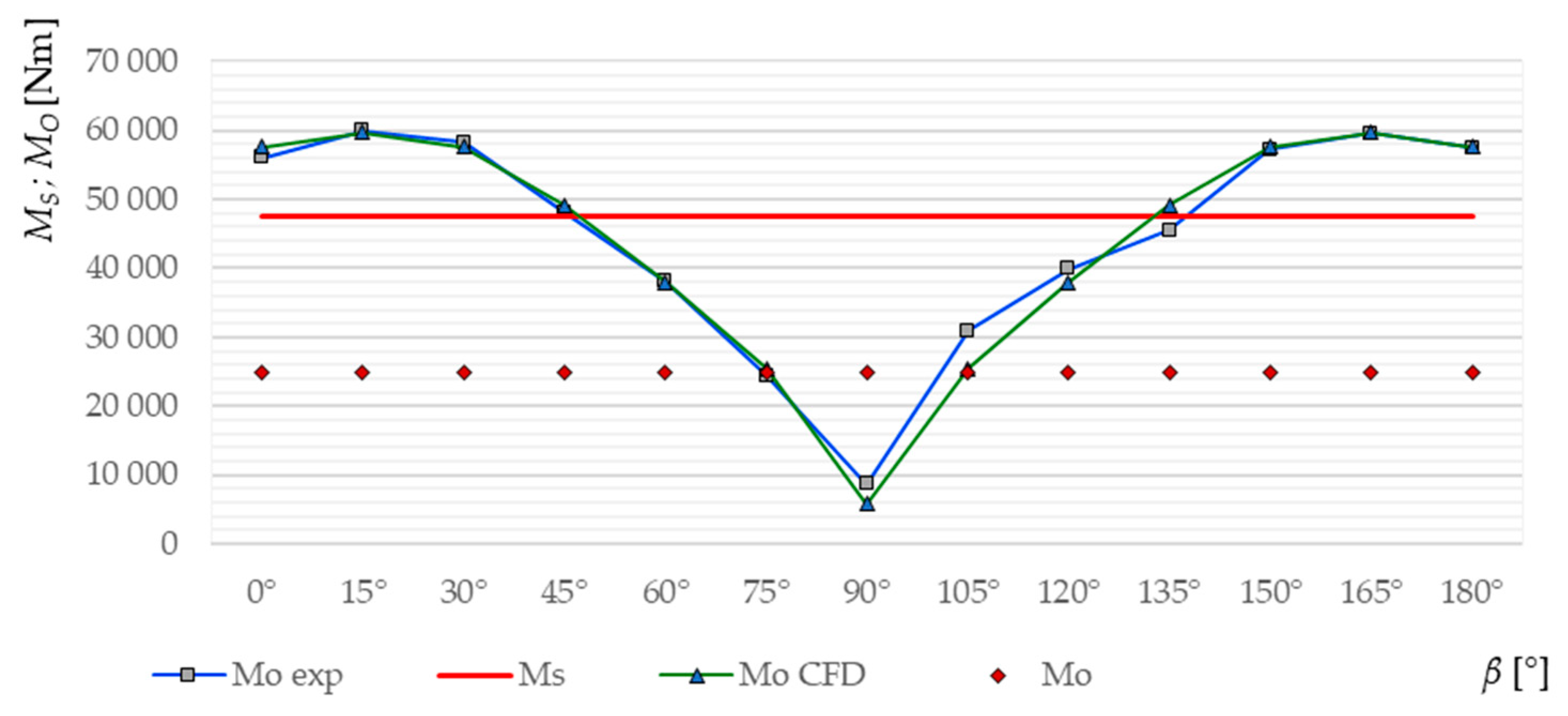

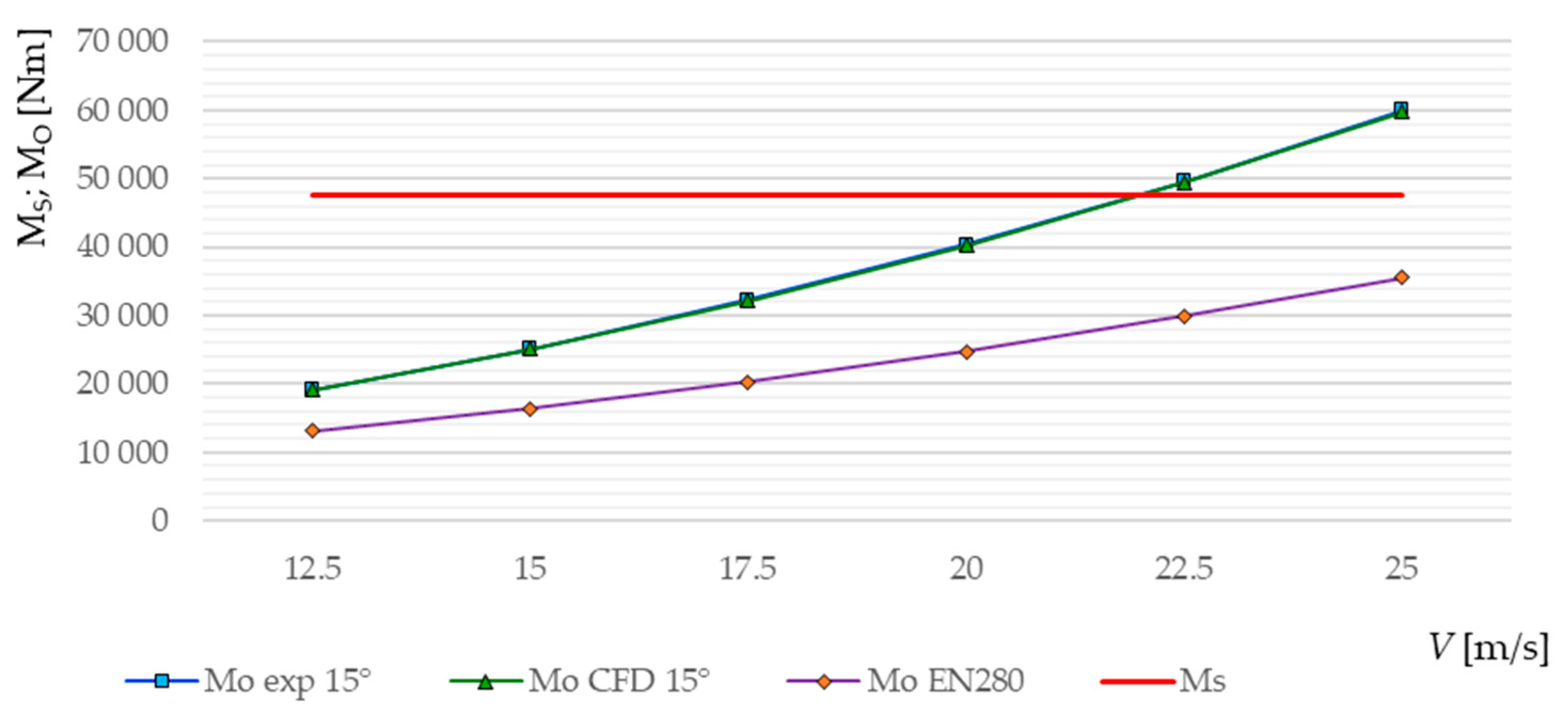

The maximum wind speed that the standard and the manufacturer specify of 12.5 m/s gives a large safety margin, as shown in

Figure 14. In this case, the capsizing moment values obtained from experimental and CFD studies do not differ significantly from the values calculated from the standard (the graph is flattened). The standard gives moment values regardless of wind direction. However, it should be borne in mind that the wind during a sudden change in weather very quickly increases in strength and the terrain and buildings cause turbulence or gust conditions. Currently, every summer in our climatic conditions, there are weather anomalies, where the determination of the wind speed is impossible, much less the direction from which it will hit this supporting structure, which is the scissor lift. It is worth referring to charts in

Figure 14,

Figure 15 and

Figure 16, which describe for which ranges of wind angle of attack the highest values of capsizing moment occur. The proposed system is unable to determine the timing of the speed increase from 12.5 m/s to higher speeds, such as 21.95 m/s. This is the speed that, for an angle of 15°, can add a corresponding moment to the sum of overturning moments, causing a loss of stability in the structure. The time given by the manufacturer that the operator needs to lower the platform from the maximum height is 50 s. The open question is if a structure of this type (operating outdoors in the open air) should not be equipped with a system for continuous measurement of wind speed and wind direction.

In the future, it is planned to study the dynamic response of this structure to strong gusts of wind. Moreover, it will take into consideration the so-called interference effect, which is connected with the existence of other objects (buildings, other crane devices, trees, etc.) which are localized close to the investigated device.