Abstract

The mileage of China’s high-speed railways is increasing, and trains running only during the day cannot satisfy the need. In the existing train organization and maintenance modes, overnight trains and maintenance constructions strongly interact with each other and are difficult to coordinate. Although some overnight trains run on a high-speed railway (HSR), currently, they are all sunset-departure and sunrise-arrival trains, and none of them depart in the night by passenger’s habits. Only a one-way line is occupied by night, except rendezvous; the opposite direction line resources are idled. According to this feature, a double-track one-direction mode on the HSR was proposed based on the reverse running ability of the train control system to coordinate the train operation and maintenance. A mathematical model was established, and a heuristic algorithm based on simulated annealing was designed. The validity of the model was verified on the section from Xuzhoudong to Xi’anbei of Xuzhou-Lanzhou HSR, as an example. The results showed that 10 pairs of overnight sleeper trains and some freight trains can run, and the maintenance disruption is not less than 180 min. The proposed method can provide a new method to coordinate the overnight operation and maintenance of the HSR and increase the capacity of HSRs.

1. Introduction

With the increasing mileage of China’s high-speed railways, mileage and coverage are also increasing. Compared with other countries with high-speed rails, China’s high-speed railway has a large operation area and a long distance, and long-distance cross-line trains can make distant city connections directly. Compared to air transport, rail transport has certain advantages in terms of leaving luggage restrictions and keeping communications open, but daytime runs cannot implement the connection to extra long-distance cities, and some long-distance trips for interconnected cities, for instance, 2760 km Beijing to Kunming, leave in the morning and arrive in the evening. It takes a whole diurnal ride on trains; thus, the sunset-departure and sunrise-arrival sleeper Electric Multiple Unit (EMU) trains are favored by the majority of passengers. High-speed rail freight is more flexible than air freight in some respects. All stations along the railway can send and receive goods, and if high-speed rail freight can be carried out at night, it greatly improves the efficiency of logistics.

At the same time, in order to ensure the safety, all China’s high-speed railways currently arrange a daily four-hour maintenance disruption. The general maintenance disruptions are usually arranged between 00:00 and 06:00 after midnight, which limits the operation of overnight trains, and daily operation is unrealizable. More than half of 250 km/h sleeper EMU trains can only run during the daytime and even in the form of ‘sleeper as seats’, wasting the sleeping function of these trains.

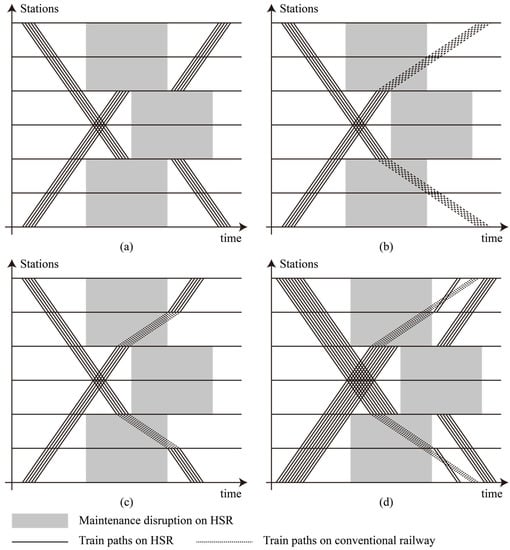

China’s economy continues to grow, and both passenger and freight transport demand are increasing rapidly. It is the general trend to realize the overnight operation of high-speed railways. How to solve the problem of high-speed railways running overnight trains is a hot topic for scholars to study at present, with scholars focusing on the organization of train running and the optimization of maintenance disruptions’ operation. In terms of operating organization, the current research mainly involved the following aspects. Three modes were discussed in [1], including waiting for maintenance disruption to finish on a high-speed railway station, which is shown in Figure 1a; transferring from a high-speed railway to conventional railways before maintenance disruption and arriving at the destination through conventional railways shown in Figure 1b; transferring to a conventional railway before maintenance disruption and then back to the high-speed railway after maintenance disruption as Figure 1c shows, and [2] compares the three methods and their applicable scene. A combination of operation modes was studied in [3], and by fusing the above three modes, a hybrid mode can be obtained as shown in Figure 1d.

Figure 1.

Three modes and the hybrid mode in the current research. (a) Waiting for maintenance disruption; (b) transfer to conventional railways before maintenance disruption; (c) transfer to conventional railway then back to high-speed railway; (d) hybrid mode.

In addition to the above methods, the method in [4] proposed operation in a single-track during maintenance disruption, and they analyzed and compared the adaptability and safety. In [5], a mixed integer linear programming model was used to identify the operation modes and the timetable of sunset-departure and sunrise-arrival trains by integrating the time selection of regular maintenance on high-speed railways. A nonlinear mixed integer programming model was established in [6] to realize the collaborative optimization of overnight train operation and maintenance disruption in the condition of the undetermined train operation mode.

None of these methods have been used in practice, or they have already been abandoned. Waiting for maintenance disruption on a high-speed railway station takes a long time, wastes time, and reduces cost performance. Due to the maintenance disruption period of conventional railway lines usually being short and being arranged in any time period, the transfer to conventional railways has been used before, including the EMU trains from Shanghai to Xi’an and Lanzhou. In the section of Shanghai to Xuzhou, the traditional Beijing-Shanghai railway instead has of the Beijing-Shanghai high-speed railway, but it can easily lead to interference between the high-speed railway with the conventional railway, resulting in a decrease in punctuality. Safety issues also need to be considered. EMU trains running at high-speed cause pressure on some freight trains, but if EMU trains run at a lower speed, then there is no advantage to ordinary trains. Thus, this method is currently deprecated. Operation on a single track during maintenance disruption is unable to carry out large-scale maintenance operations, and scheduling is complicated; speed limits are also required.

There is also some research on the adjustment of maintenance construction. The theoretical feasibility of set maintenance disruption every other day is demonstrated in [7], combined with construction projects and time requirements, and a linear programming model for the integration of a train diagram and a comprehensive maintenance window was established in [8]. A trapezoidal mode and a maintenance disruption during daytime hours also appeared in a number of studies, but they are more limited and have no practical application value. The demand-based periodic operation in [9] is now being used, and in the operating method currently implemented, periodic maintenance disruption was set up to realize periodic overnight train operation. An overnight sleeper EMU train on a high-speed rail runs towards two main directions, including from Beijing to Guangzhou and from Shanghai to Shenzhen, and it operates from Friday to Monday. During this period, there is only inspection without maintenance, generally maintenance disruption compressed to a minimum of 2 h, and full maintenance disruption sets from Tuesday to Thursday, which provide at least 4 h of time to complete all inspection and repair operations. The work in [10] illustrated the difficulty of expanding service hours in some sections due to the inability to further compress the maintenance disruption.

Generally, the above methods cannot solve the contradiction between overnight trains and maintenance disruption, and none of them fully explored the capabilities of a high-speed rail at night. A new research idea is urgently needed.

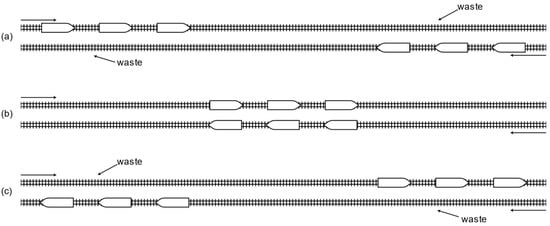

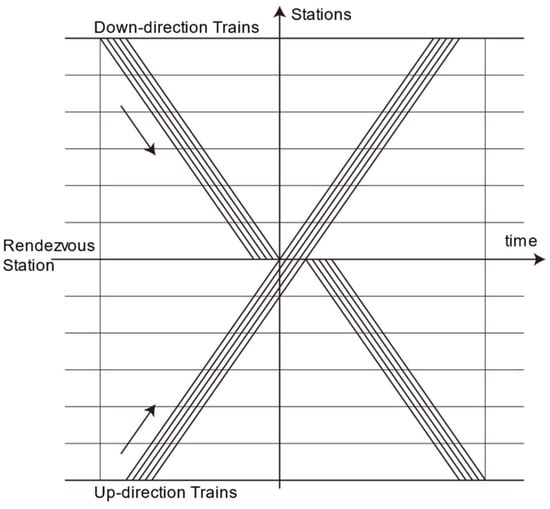

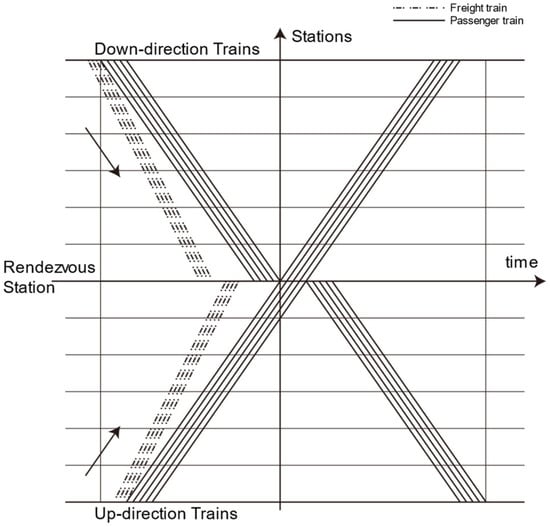

On the basis of passengers’ travel preference, to obtain enough sleep, trains that leave and arrive at night are usually pointless; thus, the sunset-departure and sunrise-arrival trains usually depart from 19:00 to 23:00 and arrive from 06:00 to 09:00 the next day. In the current operating modes, all overnight trains in the same direction run in a group. Departure and arrival times are relatively concentrated, and only one-direction line is used except for the rendezvous, which leads to the resources in the opposite direction being idled as, Figure 2 shows.

Figure 2.

Waste of the current mode. (a) The line ahead of the train group is wasted when trains run from both ends before the rendezvous; (b) during the rendezvous; (c) the line behind the trains is wasted after the rendezvous.

Meanwhile, [11] mentioned the hardware conditions of the China Train Control System (CTCS), which has five levels from 0 to 4 that allow reverse running under certain conditions on most existing lines, although minor software changes are required if there are a large number of trains running in reverse.

Making full use of wasted capacity on the reverse line can be a breakthrough to solve the problem, and it is groundbreaking that we came up with our method. We propose a novel method called the “double-track One-direction” organization mode for the overnight train on a high-speed railway. We built a mathematical model and, according to the case study, verified the feasibility and effectiveness of our method. It can effectively solve the conflict between overnight train operation and the maintenance of a high-speed railway, and it can increase the capacity of HSRs.

Compared to existing methods, our method has no interfere with the operation of other railway lines; thus, the train diagram is easy to plan. There is no need to adjust the existing maintenance mode, and it does not cost too much for an equipment update or personnel training simultaneously. It can improve the capacity and economic benefit of railways to a certain extent and provides a brand-new idea for the follow-up researchers.

The rest of this paper is structured as follows. In the following section (Section 2), the implementation method of the double-track one-direction is presented. Section 3 introduces the mode in detail and constructs the mathematical model. A case study is given in Section 4 to illustrate the method. Finally, Section 5 shows the conclusions.

2. Implementation Method for Double-Track One-Direction

The double-track one-direction mode means that trains can run in the same direction on dual tracks and can rendezvous at an appropriate station Just as treats the double track railway as two single track railways.

2.1. Overview of the Method

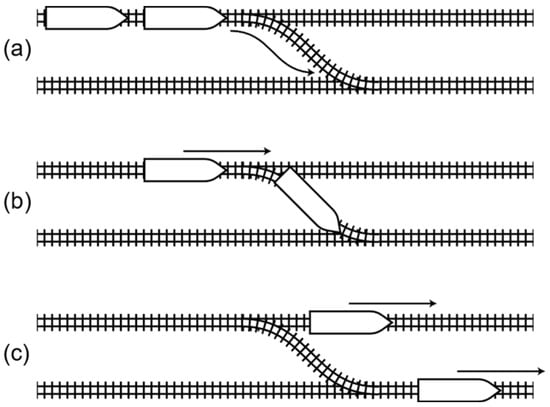

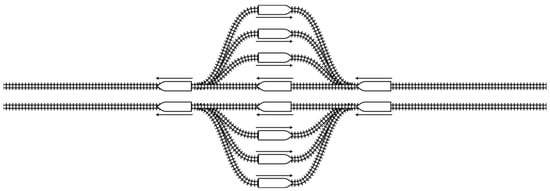

When the trains arrive at the node station of the double-track one-direction section, half of the trains transfer into another line, and the trains on the two tracks of the double-track railway run in the same direction. The process is shown in Figure 3.

Figure 3.

The process of entering the mode. (a) A part of trains enters the reverse line through the connecting line; (b) the rest of the trains continued to operate on normal way; (c) all trains entered the double-track one-direction operation mode.

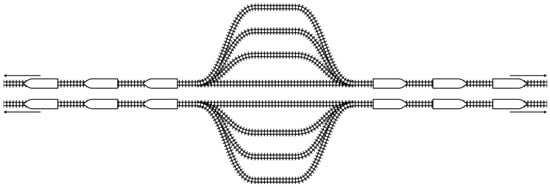

An appropriate station for a rendezvous during the whole section should be selected. When rendezvousing, trains in one direction enter the arrival and departure tracks and wait, restarting after trains in the opposite direction pass the rendezvous station. This process is shown in Figure 4, Figure 5 and Figure 6. In this way, a double-track high-speed railway line can be regarded as two single-track railways, and a single-track railway with CTCS-2 as [12] described can run in both directions directly.

Figure 4.

Schematic diagram before the rendezvous.

Figure 5.

Schematic diagram of the rendezvous.

Figure 6.

Schematic diagram after the rendezvous.

Via a coordinated optimization between the overnight train schedule and maintenance disruption, a sufficient maintenance disruption and the maximum number of overnight trains were finally achieved. Sleeper EMU trains now in operation all run at 250 km/h; meanwhile, 350 km/h sleeper trains and freight trains have completed manufacturing. When high-speed railway lines run at 350 km/h, the impact of trains running at 250 km/h on the operation order should be reduced. By properly compiling the operation train diagrams, the 250 km/h sleeper EMU trains can mainly operate after the evening peak and before the morning peak at night.

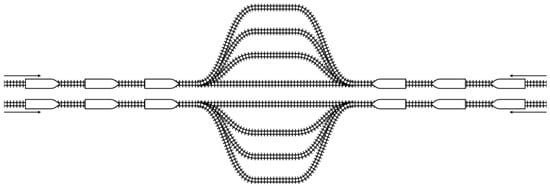

A collaborative optimization model centered on the rendezvous station according to the characteristics of the double-track one-direction mode should be established. Trains are unrestricted during the time period other than maintenance disruption, and it is also possible to arrive at the station node from different directions. This paper did not take into account what happens besides this period of time and did not specify the actual start and end time of the mode, but it only considered the operation mode and overall structure during the double-track one-direction section. The overall structure is shown in Figure 7.

Figure 7.

Overall structure of the double-track one-direction.

2.2. General Conditions of the Mode

The problem is difficult to solve as the compilation of the high-speed railway operation diagram is a huge systematic project that requires the comprehensive consideration of all factors. Therefore, in order to facilitate the research, some simplification of the actual scenario is required on the premise of not affecting the overall structure; thus, this paper was based on the following premises:

- All trains run in pairs and think of each station as a point;

- All trains in the double-track one-direction operation section run on parallel running without mutual transcendence;

- Maintenance disruption cannot separate into discontinuous periods of time;

- The number of arrival and departure tracks in the rendezvous station is usually enough;

- Regardless of the location of the construction personnel on the line and the time required;

- For easy calculation, the time is accurate to minutes.

3. Model Formulation

With the goal including the maximum length of maintenance disruption and minimizing the train passing time for the whole journey, a collaborative optimization model centered on a rendezvous station was established. A heuristic algorithm based on a simulated annealing algorithm was designed to solve this problem.

3.1. Constraint Condition

When the train is running, it needs to meet certain constraint conditions in each time and period.

Since the impact of the stop time on the overall operation of the line cannot be ignored, a start-stop addition should be considered for any stop time greater than zero:

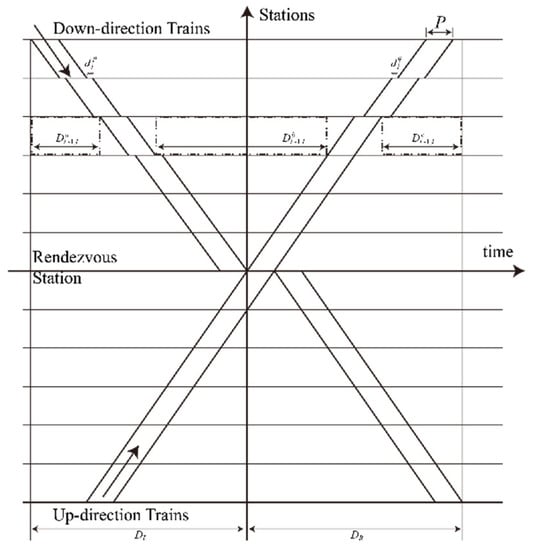

where is the start-stop additional in minutes for 250 km/h train; is the minute in which the down-direction trains stop at station i; and is the minute in which the up-direction trains stop at station Then, the whole journey is separated into two parts divided by the time when first two trains from different directions reach the rendezvous station. The duration of the first half and the duration of the second half with the new constraints are shown as follows:

where is the number of sub-sections in the double-track one-direction section; is the number of rendezvous stations; is the time if the train passes through from the first node station to station at the maximum speed without stopping; is the minute in which the double-track one-direction operates. The sum of the two parts is the total time of the double-track one-direction section as follows:

According to the rule of the double-track one-direction, three parts of time can be used for maintenance disruption in the section from station i − 1 to station i. The first one is before all trains arrive, which is shown as ; the time between the departure of all trains from one direction and the arrival of all trains from another direction is the second part, shown as ; the third one is after all trains depart from the station and is shown as . The three periods can be used for maintenance disruption in the section from station 1 to station and can be represented by the following three formulas:

The relationship between parameters and variables in the above formula are shown in Figure 8.

Figure 8.

Relationship between parameters and variables.

There is also a lot of research on productivity, with the growth of technology and the management level, and the duration can be compressed gradually. Reference [13] discussed the decision support models used for railway track maintenance planning and scheduling and transformed the results into a problem taxonomy. Reference [14] focused on flexible scheduling that considers both maintenance activity and repairman competence under maintenance disruption and employee timetable constraints in the job-shop. The study [15] made full use of the comprehensive inspection train to reduce the time required for daily inspections. The maintenance disruption duration can be reduced by splitting the operating interval, improving the operating skills, increasing the number of personnel, and arranging some inspection tasks in the daytime. Based on the analysis of the minimum construction time of various types in relevant studies [16,17], the minimum allowable maintenance disruption duration theory at the present stage is 180 min.

To ensure that the maintenance disruption duration is the longest while the total time is the shortest, the longest of the three idle periods can be used as the maintenance disruption. In order to reduce interference to the day-time trains, should be selected whenever possible. Because the maintenance disruption can be properly beyond the double-line one-direction operation section, when is the largest in these three sections, but still cannot satisfy the minimum allowable maintenance disruption duration, the larger one from and should be chosen. When and are equal, is the choice. The actual time period selected is represented as follows:

The operation of the overnight train should meet the needs of passengers or freight as much as possible. Adequate sleep time needs to be provided for sleeper EMUs; meanwhile, timeliness needs to be guaranteed for freight EMU. Therefore, the whole operation time of the train should be controlled within a reasonable range. The total duration passing the double-track one-direction section of both the up-direction and down-direction train should be limit between and . Because all the trains in the same direction run in the same mode, it is only needed to study one of them in one direction. This range can be represented by the following equation:

The total amount of passenger trains is represented by as shown in:

where is the minimum train tracking interval of 250 km/h trains in minutes.

Freight can also be taken into account. For the freight EMUs, since there is no need to consider sleep hours and the goods are to be delivered the next morning, goods need to arrive at their destination as quickly as possible and then be sorted. It has been considered to use 350 km/h freight EMU. In order not to conflict with sleeper trains, there is no crossover between them in the train working diagram, and they run in different periods. Cities that act as a rendezvous are usually logistics hubs. A period of time should be added for freight ahead of the sleeper trains starting to run, as it is convenient for goods to converge into this central city, or the trains should return to hubs in order to continue delivering goods outward from hubs the next morning, as Figure 9 shows.

Figure 9.

Period of freight trains.

3.2. Objective Function

To simplify the calculation, freight trains were excluded from the calculation, which is directly attached to the front of the passenger trains’ diagram. Optimization in this paper is mainly about the following aspects: minimizing the total hours of the double-track one-direction section and maximizing the maintenance disruption.

Considering the preparation difficulty of the train working diagram and to reduce the impact on daytime, a maximum allowed duration length for different lines needs to be set:

where indicates the acceptable start time, indicates the acceptable end time, and

A smaller has the least impact on normal operation during the daytime, and this objective function can be expressed as:

To meet the requirements of the daily run, the maintenance disruption must be set in two aspects. First, the total duration of the maintenance disruption period is the maximum, then can be used as much as possible to maximize :

In conclusion, the model of the double-track one-direction operation mode can be summed up in the following formula:

3.3. Algorithm

There are many variables and constraints in the mode and optimization model established in this paper, and the solution is complicated. In order to simplify the calculation and facilitate the algorithm, the start and stop additional time and pass-through time are used constantly. Two other variables are defined. The sum of the train stop time in all stations of the down direction is , and the sum of the train stop time in all stations of the up direction is . It is assumed that a section of high-speed railway implements the operation mode of the double-track one-direction. There are N subsections, and each subsection has three variables including , , and X to further control the computational complexity. Combined with the actual situation of the line and station scale, the value ranges of variables are given respectively: , , . There are alternative schemes in total, and it is relatively difficult to solve directly. In order to reduce the amount of computation, a three-stage heuristic algorithm [18] was designed to solve the model based on the correlation and hierarchy of multiple objective functions, and it was realized through programming.

An improved tabu search algorithm [19] was used to find the best total stop time in the first stage as Algorithm 1 shows. In order to avoid falling into local optimum, the method of random generation was used to regenerate the solution. The scale of the problem was manageable, the taboo table did not clear after recording, no cycle was generated, and the convergence speed was improved. In the calculation of the first two stages, if it had no limit to .

| Algorithm 1 Improved tabu search algorithm to calculate total duration |

| Input: Record form U; Taboo form F; The maximum number of iterations max_i; Output: , ; for i in [0, max_i] and all in U are different do Flag = 1; for Flag = 1 or , in F do Randomly generate initial solutions , with Equations (10) and (11); Flag = 0 end for Calculate ; if i = 0 then Store , and in the form U; Store and in the form F; end if if then Store , and in the form U; end if if then Store and in the form F; end if end for |

The simulated annealing algorithm is widely used in the optimization of high-speed railway operation schemes [20,21]. The simulated annealing algorithm [22] was used in the second stage of the algorithm to determine the specific stop time at each station as shown in Algorithm 2. Two matrices, dp = [] and dq = [], were built to represent the stopping scheme in both directions from the first station to station . Within a given value range, random numbers dp0 and dq0 with 1 row and columns that satisfied Equations (1) and (2), and , were randomly generated as the initial solution, which shows the stopping time of the train from stations 1 to N. The new solution was generated in the same way as the original solution. The cooling method adopted an equal ratio of uniform speed cooling .

| Algorithm 2 Find the stop time for each station |

| Input: The initial temperature T; The temperature adjustment parameters α; The iteration termination parameter λ; The initial optimal solution and ; Output: The optimal solution dp_best and dq-best; for The optimal solution appears λ times in a row or T < do Randomly generate initial solutions , ; ; Calculate the objective function value by dp, dq; Add random perturbations and generate neighborhood solutions dp_new and dq_new; Calculate the objective function value ; if then Accept it as a new solution by dp0 = dp_new and dq0 = dq_new; else Decide whether to accept it as a new solution by ; end if if then Update the optimal solution with and ; end if Update the temperature T = αT; end for |

Parameters of the simulated annealing algorithm are as follows: initial temperature , temperature decay function parameter , length of Markov chain , final temperature .

Through the above steps, the stopping time of each station can be obtained, and the overall plan of train operation can be obtained according to the stopping time of each station obtained in the second stage, as Algorithm 3 shows.

| Algorithm 3 Find the number of trains |

| Input: The initial value and X Output: The optimal solution ; for in X do if then Calculate the value ; if < then Update the value = ; Get a new with = ; end if end if end for Calculate the value ; |

4. Case Study

We used the Xuzhou-Lanzhou high-speed railway of China as an example to illustrate the validity of our method.

4.1. Case Introduction

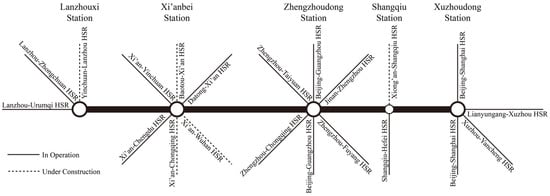

The Xuzhou-Lanzhou high-speed railway is an important route through central China with a length of 1434 km, of which the Xuzhou to Baoji section is 1033 km long with a designed speed of 350 km/h and the Baoji to Lanzhou section is 401 km long with a designed speed of 250 km/h. Currently, the section from Xuzhou to Xi’an runs at a maximum speed of 310 km/h, while the section from Xi’an to Lanzhou runs at 250 km/h. The Yangtze River Delta, the Central Plains, and the Guanzhong regions are interconnected by the Xuzhou-Lanzhou high-speed railway. It connects the economically developed eastern regions with the labor exporting regions of the central and western regions. Using this line as a case has practical value. It has four main node stations connected with other lines, including Xuzhoudong, Zhengzhoudong, Xi’anbei, and Lanzhouxi. Figure 10 shows the diagram of the Xuzhou-Lanzhou high-speed railway and other lines connected with the Xuzhou-Lanzhou high-speed railway.

Figure 10.

Diagram of the Xuzhou-Lanzhou high-speed railway.

The speed was calculated using uniform values to simplify the calculation. Differences in train performance were not considered. The average speed of trains without stopping was 235 km/h with a maximum speed of 250 km/h and 330 km/h when the maximum speed was 350 km/h. The time to each station according to the speed was calculated. Mileage, pass-through time, and number of arrival and departure tracks of each station are shown in Table 1.

Table 1.

Parameters of the Xuzhou-Lanzhou high-speed railway.

Mileage and pass-through time calculated between the Xuzhoudong station and the current station.

Because Xi’an is closer to the boundary of the high-speed railway network, the passenger flow is unbalanced between the two sides, and there is no need to run so many overnight trains on the west side. Zhengzhou as the center is more reasonable.

In this section, = 4, and the numerical range of variables in the algorithm is as follows: , , , other parameter values: , , , , .

4.2. Results

All trains rendezvous at the Zhengzhoudong Station, and the double-track one-direction section is from Xuzhoudong to Xi’anbei. The optimal solution of the objective function obtained by calculation and manual correction was converted into tabular form as shown in Table 2.

Table 2.

The optimal solution of the fully operational diagram.

Because of the limited number of arrival and departure tracks, the same amount of time can be consumed by slowing down instead of stopping at stations.

Entering the double-track one-direction operation too early or too late may affect the operation of other trains. According to the actual operation situation, the operation period of the double-track one-direction mode should be limited from 23:30 to 05:30 of the next day as far as possible.

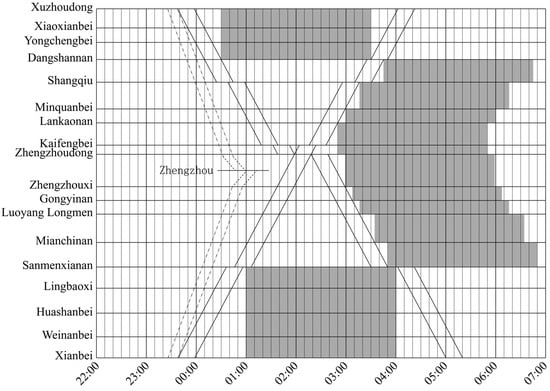

On the premise of ensuring the maintenance disruption of 180 min in each section, passenger trains are allowed 20 min for the entire journey in each direction. When equals 5 min, 10 pairs of trains can be accommodated. Figure 11 shows the fully operational diagram.

Figure 11.

Fully operational diagram.

Down-direction trains passing this section used 5 h and 23 min, and the average speed was 161 km/h; the up-direction trains used 5 h and 24 min, and the average speed reached 197 km/h. The double-track one-direction operation section started at 23:38 and ended at 05:20. All of the maintenance disruption was finished by 06:50, satisfying the current schedule, and it did not affect the morning and evening trains.

According to the sleeping habits of passengers, the full time of the sunset-departure and sunrise-arrival trains controlled in 10–13 h is quite reasonable. A distance range of 2000~2600 km is suitable for 250 km/h trains. The double-track one-direction section took about five hours, and there was still a 500–1000 km range at each end.

Depending on the start time, some freight trains can also be added ahead; another 12 min period can be provided for freight trains, and three pairs of trains can be operated. Because the Zhengzhou Station is more suitable for freight trains than the Zhengzhoudong Station, all freight trains transit into Zhengzhou Station through railway connections, as there are no cargo facilities on the way, non-stop, in this section.

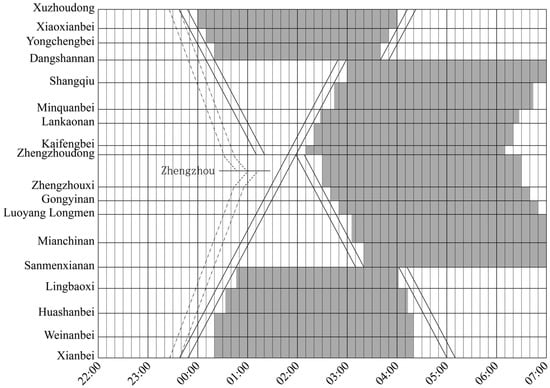

Because of the passenger flow, it is not necessary to run so many overnight trains every day, and the present stage construction technology is imperfect. In order to further ensure the safety of operation, in the data of low passenger flow, the train operating time can be reduced to 10 min. In order to prolong the maintenance disruption, the train can wait for a period of time on the line. In this case, six pairs of trains can be accommodated for, as Figure 12 shows.

Figure 12.

Half-operation diagram.

In the Xuzhou-Xian section of the Xuzhou-Lanzhou HSR, there were two pairs of overnight trains, including Shanghai-Lanzhou and Shanghai-Xi’an, before they were cancelled in 2021 and another Shanghai-Datong was planned. At the beginning of the implementation, the half-operation diagram can be used on peak days. The three pairs of trains cancelled earlier can be resumed. If concerns about high-speed rail safety remain, 240 min or more of maintenance disruption can be offered from Tuesday to Thursday, and passenger train service can be made not be available, which is the same as the current mode of sleeper EMU trains on the Beijing-Guangzhou high-speed railway. With the continuous improvement of the construction process, the daily availability can be gradually realized.

5. Discussion and Conclusions

In this paper, we put forward the groundbreaking double-track one-direction high-speed railway operation mode by making full use of the high-speed railway reverse running ability and realizing the trains run in one direction through double tracks of the railway at night. It is a new idea for correlative research in how to improve the nighttime capacity of high-speed railways. The mode was established as a mathematical model, and a relatively good result was obtained through the algorithm. The cost is relatively small compared to existing methods, and it is relatively easy to further popularize.

Through the analysis of the existing research results, the relevant research has not put forward a very feasible scheme in the aspect of high-speed railway overnight running. Existing research mostly focused on how to shorten nighttime construction times or how to let trains circumvent nighttime construction. They have not tapped into the spare capacity of the high-speed rail itself. Compared to previous methods, our method can make full use of line resources and does not interfere with the operation of other lines, and no additional costs are incurred by and large. It can improve the economic benefits of railway transportation; thus, it has strong theoretical and practical implications.

Under the premise that the maintenance disruption is no less than 180 min and the running time of daytime trains is not occupied, ten pairs of 250 km/h sunset-departure and sunrise-arrival trains would be operated on the section from Xuzhoudong to Xi’anbei of the Xuzhou-Lanzhou high-speed railway, and another six freight trains from Xuzhoudong to Zhengzhou and six from Xi’anbei to Zhengzhou can also be provided. It can effectively utilize the operation capacity of the high-speed railway if the fully operational diagram can be used. About 12,000 beds or seats are being added daily, and high-speed freight of 1440 tons can also be provided. If it can be widely promoted, it can effectively improve the overall capacity of high-speed railway.

However, the method in this paper also has some limitations. It does not comply with the relevant management regulations at present and cannot be put into use immediately. However, regulations can change with the development of technology. As the technology develops, train control systems that do not rely on track circuits will also be put into use, and the new pattern will be easier to use. Furthermore, when the trains that are running normally are delayed to the double-track one-direction period, the train cannot run in the opposite direction, which is bound to interfere with the night running; thus, an emergency plan needs to be formulated.

Some research directions are worth researching continuously in the future. Firstly, the rendezvous stations are not necessarily close to the center of most lines, and how to coordinate the departure time of trains on both sides needs further discussion. It can be combined with the single-track railway operation mode to continue the research.

Secondly, because our method can operate a large number of sleeper trains, the number of sleeper EMU trains is bound to increase substantially; thus, how these trains can be fully utilized during the day is worth studying. It is interesting to study whether the lunch and siesta train can be run between some neighboring big cities, which could be a good choice for some business people. In addition, relevant detection equipment can also be installed for some sleeper trains to replace detection trains.

Next, how to organize cross-line trains on different lines and train network operations is the key to popularizing this method on a large scale.

The other thing is that the calculation parameters of the entire line now are the same. In future work, research can be carried out in many aspects. The study needs to combine the actual operation diagram and line conditions for a more detailed approach, and it should use different parameters in different sections of the same line to make it more efficient and to accommodate more trains.

Author Contributions

Conceptualization, Z.X.; methodology, Z.X.; software, Q.Z. and Z.X.; validation, K.L.; formal analysis, Q.Z.; writing—original draft preparation, Z.X.; writing—review and editing, K.L.; supervision, K.L.; project administration, H.F.; funding acquisition, H.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Natural Science Foundation of China “Joint Fund” Project, grant number U1934216.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Dues to the security of the transportation system, data sharing is not applicable to this article.

Acknowledgments

This work was supported by the National Natural Science Foundation of China “Joint Fund” Project (grant number U1934216), and we would like to thank the anonymous reviewers for their helpful remarks and thank the associate editor and the reviewers for their useful feedback that improved this paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhang, T.W.; Nie, L.; Lu, J. Comprehensive comparison and selection of operation modes of sunset-departure and sunrise-arrival train on high-speed railway. J. Transp. Syst. Eng. Inf. Technol. 2014, 14, 209–216. [Google Scholar]

- Zhang, T.W.; Nie, L.; He, Z.H. Optimization model of organization modes choice of sunset-departure and sunrise-arrival train based on simultaneous integrated maintain time on high-speed railway. J. China Railw. Soc. 2015, 37, 1–9. [Google Scholar]

- Yu, J.; Han, B.M.; Cao, J.M. A study on the combination of operation mode of high-speed night train. Railw. Transp. Econ. 2019, 41, 63–70. [Google Scholar]

- Sun, J.P.; Zhang, C.; Zhang, T.W. The optimization of operation plan of sunset-departure and sunrise-arrival train on high-speed railway based on operation safety. J. Saf. Sci. Technol. 2014, 10, 5–10. [Google Scholar]

- Zhang, C.T.; Gao, Y.; Yang, L.X.; Kumar, U.; Gao, Z.Y. Integrated optimization of train scheduling and maintenance planning on high-speed railway corridors. Omega 2019, 87, 86–104. [Google Scholar] [CrossRef]

- Xu, C.A.; Li, S.D.; Li, S.H.; Ni, S.Q. Collaborative optimization for overnight train operation and maintenance window setting of high-speed railways. J. Southwest Jiaotong Univ. 2021, 56, 744–751. [Google Scholar]

- Li, B.; Meng, F.F.; Yang, X.; Xue, B.; Liu, M. Analysis on High-speed Railway Night Train Operation Scheme based on Window-Waiting Mode. Railw. Transp. Econ. 2017, 39, 18–23+28. [Google Scholar]

- Zhang, L.; Xiong, J.C.; Tang, Y.X.; Zhan, S.G.; Peng, Q.Y. Operation of New High-Speed Sleeper EMU Train and Setting of 4-Hour Comprehensive Maintenance Window. J. Chongqing Jiaotong Univ. Nat. Sci. 2020, 39, 43–49. [Google Scholar]

- Zhu, X.F. Overnight Operation Methods for Chinese High-speed Railways. J. Transp. Eng. Inf. 2019, 17, 98–105+114. [Google Scholar]

- Sun, Y.M.; Jia, Y.G. Collaborative Optimization of High-Speed Railway Window and Maintenance Operation under Conditions of Operating Sleeper EMU Trains. Railw. Transp. Econ. 2016, 38, 7–12. [Google Scholar]

- Tang, T. Train Operating Control System; China Railway Publishing House: Beijing, China, 2012. [Google Scholar]

- Yuan, J.X. Design and Application of CTCS-2 Train Control System in Single-track Railway. Railw. Stand. Des. 2019, 63, 129–133. [Google Scholar]

- Sedghi, M.; Kauppila, O.; Bergquist, B.; Vanhatalo, E.; Kulahci, M. A taxonomy of railway track maintenance planning and scheduling: A review and research trends. Reliab. Eng. Syst. Saf. 2021, 215, 107827. [Google Scholar] [CrossRef]

- An, Y.J.; Chen, X.H.; Li, Y.H.; Zhang, J.; Jiang, J.W. Flexible job-shop scheduling and heterogeneous repairman assignment with maintenance time window and employee timetable constraints. Expert Syst. Appl. 2021, 186, 115693. [Google Scholar] [CrossRef]

- Xu, M.H.; Shuai, B.; Wang, X.; Li, J.; Huang, W.C. A two-stage optimization approach for inspection plan formulation of comprehensive inspection train: The China case. Comput. Ind. Eng. 2021, 159, 107465. [Google Scholar] [CrossRef]

- Yang, K.; Peng, Q.Y.; Lu, G.Y.; Zhao, J. Co-optimization between maintenance curfew and overnight train plan in high speed railway. J. China Railw. Soc. 2015, 37, 1–7. [Google Scholar]

- Yang, K.; Fang, H. Discussion of comprehensive maintenance window’s length of high-speed railway from Beijing to Shanghai. J. Transp. Eng. Inf. 2011, 9, 12–15. [Google Scholar]

- Albrecht, A.R.; Panton, D.M.; Lee, D.H. Rescheduling rail networks with maintenance disruptions using problem space search. Comput. Oper. Res. 2013, 40, 703–712. [Google Scholar] [CrossRef]

- Asma, F.; Hatem, H.; Imed, K.; Atidel, B.H. A hybrid genetic tabu search algorithm for minimising total completion time in a flexible job-shop scheduling problem. Eur. J. Ind. Eng. 2020, 14, 763–781. [Google Scholar]

- Qin, J.; Tan, Y.C.; Zhang, W.; Shen, C.Y.; Zhao, C. Train Planning Optimization for Intercity Railway Based on Space-time Network. J. China Railw. Soc. 2020, 42, 1–10. [Google Scholar]

- Zhou, W.L.; Oldache, M. Integrated Optimization of Line Planning, Timetabling and Rolling Stock Allocation for Urban Railway Lines. Sustainability 2021, 13, 13059. [Google Scholar] [CrossRef]

- Kirkpatrick, S.; Gerlatt, C.D.; Vecchi, M.P. Optimization by simulated annealing. Science 1983, 220, 671–680. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).