1. Introduction

Most materials used in high-value engineering applications are chosen for their mechanical performance. The material is optimised in terms of the chemical composition and the processing routes used to achieve the desired microstructure to deliver the performance needed by the part when it is in service. Knowing the material state is challenging as there are a large number of processing steps performed to produce the final part, and they are performed on the raw material, the alloyed billet, heat treatments pre- and post-machining; all of these steps can change the material state and so influence the performance of the part.

For additive manufacturing (AM), the challenges are even more pronounced, as the material state is formed during the manufacturing process, which is inherently hard to control and so traditional approaches for quality control and assurance are difficult to apply. There are a number of different AM processes that have very different characteristics in terms of the influence on the material state, the range and type of defects, and the surface finish achieved. They can be categorized by their material feed-stock, e.g., wire, blown powder, or powder bed, and their method of energy input, e.g., arc, e-beam, and laser. Aside from traditionally manufactured machined and etched samples, this paper looks at samples from two AM methods, wire additive manufacturing and laser powder bed fusion, and details of the samples used are given in

Section 2.3. Wire arc additive manufacturing (WAAM) uses wire feed-stock and an electrical arc to melt and weld the new material to the previously built layers [

1]. Wire laser AM (WLAM) is similar to WAAM except that the wire feedstock is melted by a high-power laser beam [

2]. They have relatively fast deposition rates, with rates in excess of

possible; however, this comes at the cost of resolution and part complexity. Laser powder bed fusion (L-PBF) uses a laser to melt metal powder a layer at a time to build the part. This has high spatial resolution, allowing for very complex geometries to be built, but with smaller build volumes and lower rates of deposition compared to WAAM

[

3].

A multitude of defect mechanisms threaten the integrity of a build, which can include obvious geometrical errors to the more subtle internal porosity [

4], micro-cracking [

1], and heterogeneous microstructure formation [

5].

The ability to determine the material state is a limiting factor in the application of these manufacturing methods to safety-critical parts despite the wealth of advantages they have over traditional manufacturing methods.

It is useful to break the types of material non-conformity down into two categories, defects and microstructural. The first is concerned with physical defects both through the volume and on the surface, for example, cracking and porosity. For the detection of such issues, there is a mature non-destructive evaluation (NDE) industry, utilising tools including eddy current [

6] and dye penetrant [

7] for surface defects, whilst internal defects and porosity are inspected by X-ray [

8] and conventional ultrasound.

Processing steps for both traditional and additive manufacturing affect the microstructure of the final part and can cause deviations between the intended crystalline microstructure and that of the real part. Common microstructural non-conformities include grain size, texturing, and the presence of microtextured regions, all of which act to reduce the performance of the part. Traditional statistical qualification processes for metallic materials are well defined [

9], requiring extensive testing, which can take several years to complete with costs running into the millions [

10]. This is typically based around mechanical testing to establish the components yield and ultimate tensile strength [

11] and is performed over a large number of specimens to obtain high confidence in performance across each build set. For example, small sections of material are prepared and polished, and the microstructure is imaged with electron backscatter diffraction (EBSD) [

12]. Clearly, this raises two key issues; firstly, additive manufacturing has many benefits that make it especially attractive when low production runs are required, even producing one-off components [

13], making established qualification regimes an unsuitable approach [

14]. Turning this problem on its head also presents a significant opportunity; if the material that sees service, be it machined or additively produced, can be characterised, there is an opportunity to realise a new paradigm in material efficiency, removing the need for material design tolerances to ensure safety.

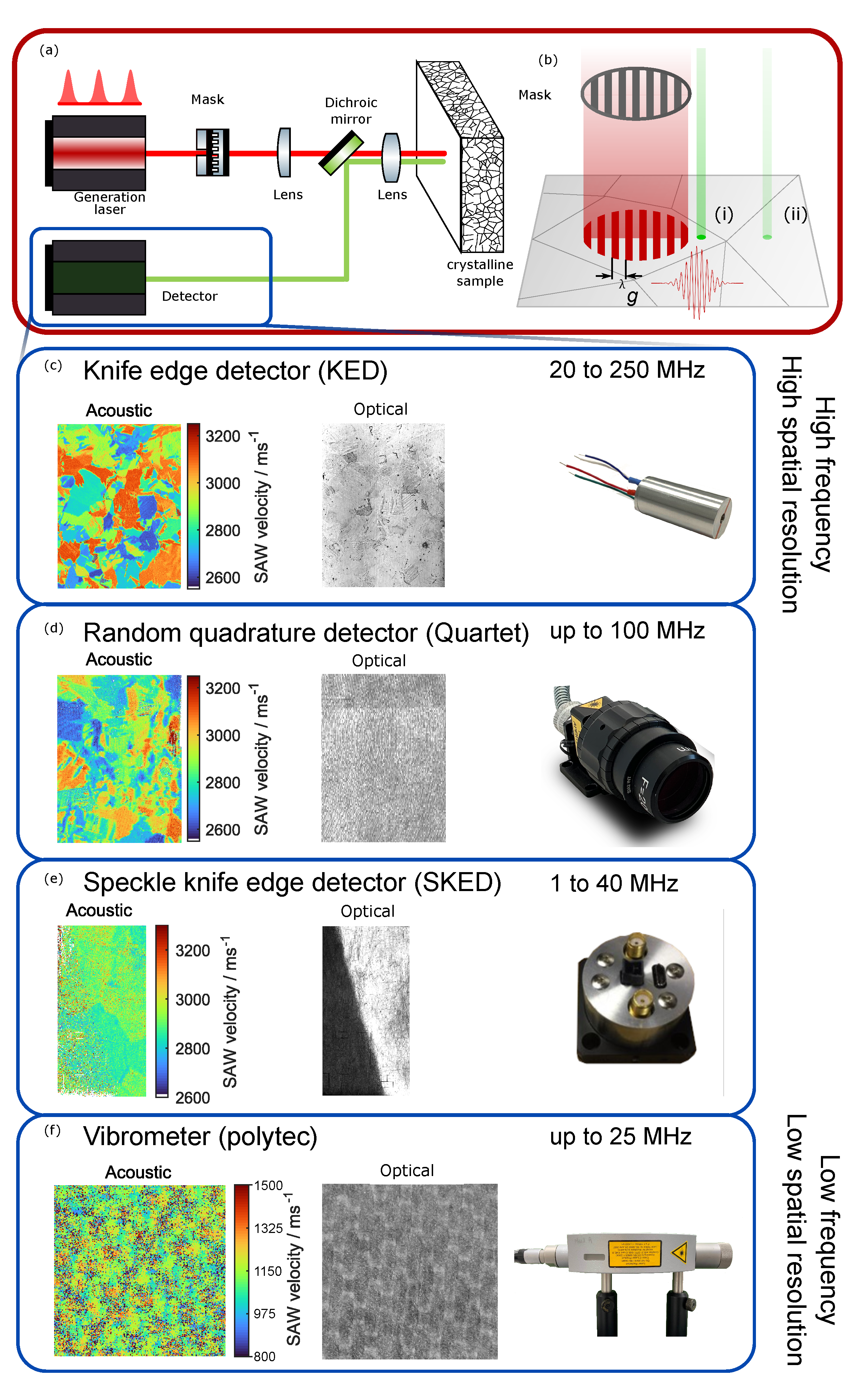

Spatially resolved acoustic spectroscopy (SRAS) [

15,

16] is a laser ultrasound technique using surface acoustic waves (SAWs) to measure material microstructure. SAWs are generated with a fixed wavelength, meaning the waves that propagate have a frequency determined by the acoustic velocity of the material at the generation location. As this does not rely on the time of flight, this produces a simple and robust measurement.

Measuring the velocity allows spatial maps of the material microstructure to be obtained as the SAW phase velocity varies with the crystallographic orientation for most materials. Beyond grain maps, if more measurements for a range of SAW propagation directions are taken, then the crystal orientation [

17,

18], and more recently, the single crystal elasticity matrix [

19], can also be obtained. SRAS has been applied to a range of engineering materials and their alloys, e.g., titanium, nickel, steel, and silicon [

18,

20,

21]. Samples are typically prepared before scanning, for example, sliced, ground flat, or lightly polished. The smooth surface is currently required as the knife edge detector (KED) that is usually used only works with specular reflections (see

Section 2.1 and

Section 2.2). While this preparation is acceptable for research specimens, the preparation of real parts is undesirable as it affects their function.

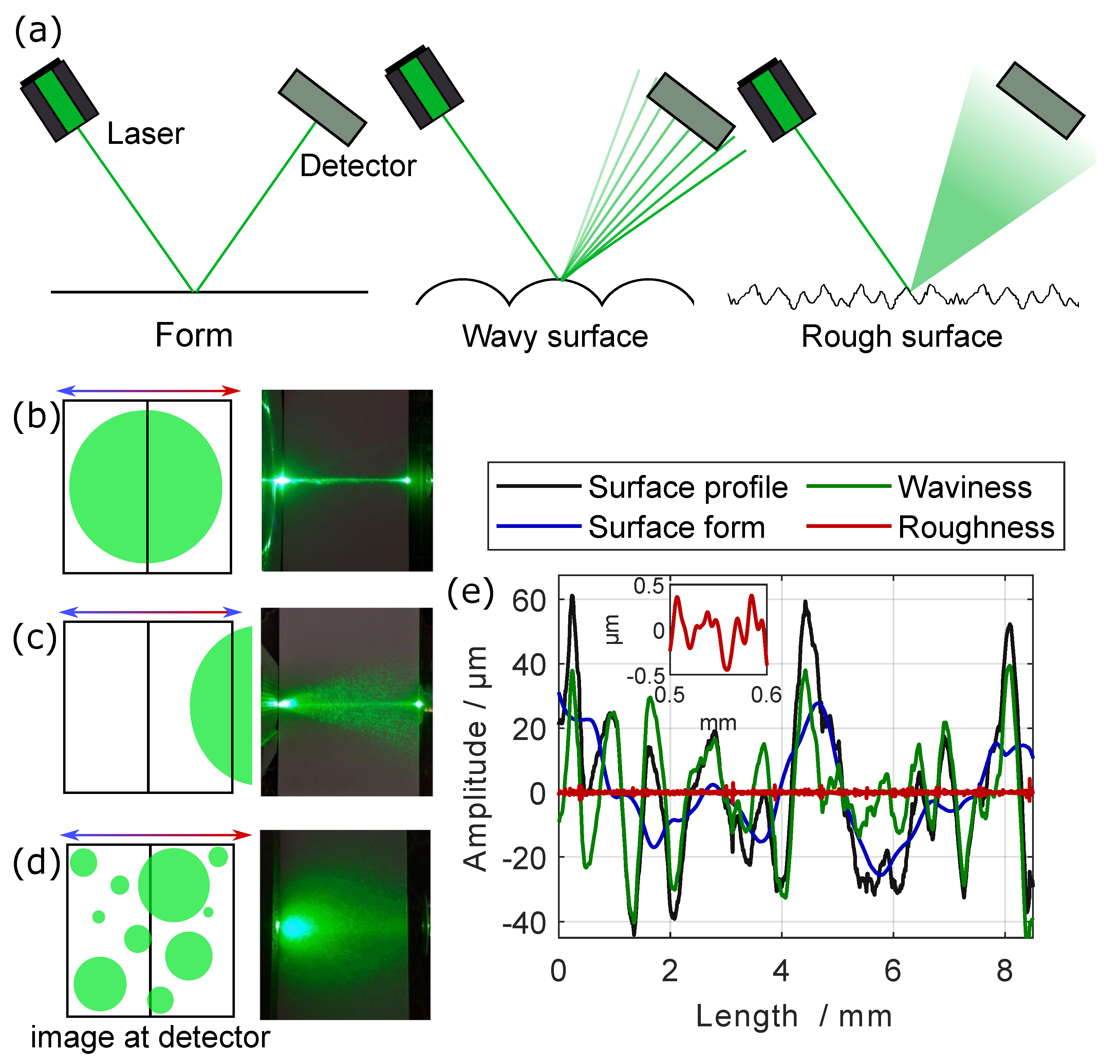

Translating SRAS measurements from prepared and polished surfaces to those of real parts introduces a number of new challenges. These can impact the form of the instrument (curved surfaces require complex sample handling), while others have a more fundamental impact on how the measurement can be performed. This includes the impact of the optically rough surface found on most real parts. The roughness is determined by how the material was made (if additively manufactured) or how the part was machined and the treatments it might have experienced. The scale of the roughness determines the challenge it imposes for both the generation and propagation of ultrasound, as well as the impact on the detection laser beam. This will be discussed in more detail in

Section 2.1, but briefly, roughness of the surface can modify the ultrasound generation process by changing the effective wavelength and thereby reduce the efficiency of the generation process. Extremely rough surfaces can have additional effects on the measurement; they may increase the attenuation, change the apparent velocity, or interfere with the ultrasound generation process [

22]. For the detection process, the main effect is the scattering of the detection laser beam, not only reducing the light return to the detector but also producing optical speckles, which not all detection schemes can tolerate.

This paper presents progress on using SRAS on optically rough surfaces for machined, etched, and additively manufactured parts (via WAAM, WLAM, and L-PBF). The challenges and limitations imposed by the surface on the spatial and velocity resolution, as well as the impact on scan speed, are also discussed.

3. Results

The results presented start with the standardised roughness comparators measured with the same instrument and detector; they explore the impact that different surface preparations have on the ability to perform measurements. These are followed by measurements on a variety of sample surfaces that exhibit different degrees of form, waviness, and roughness.

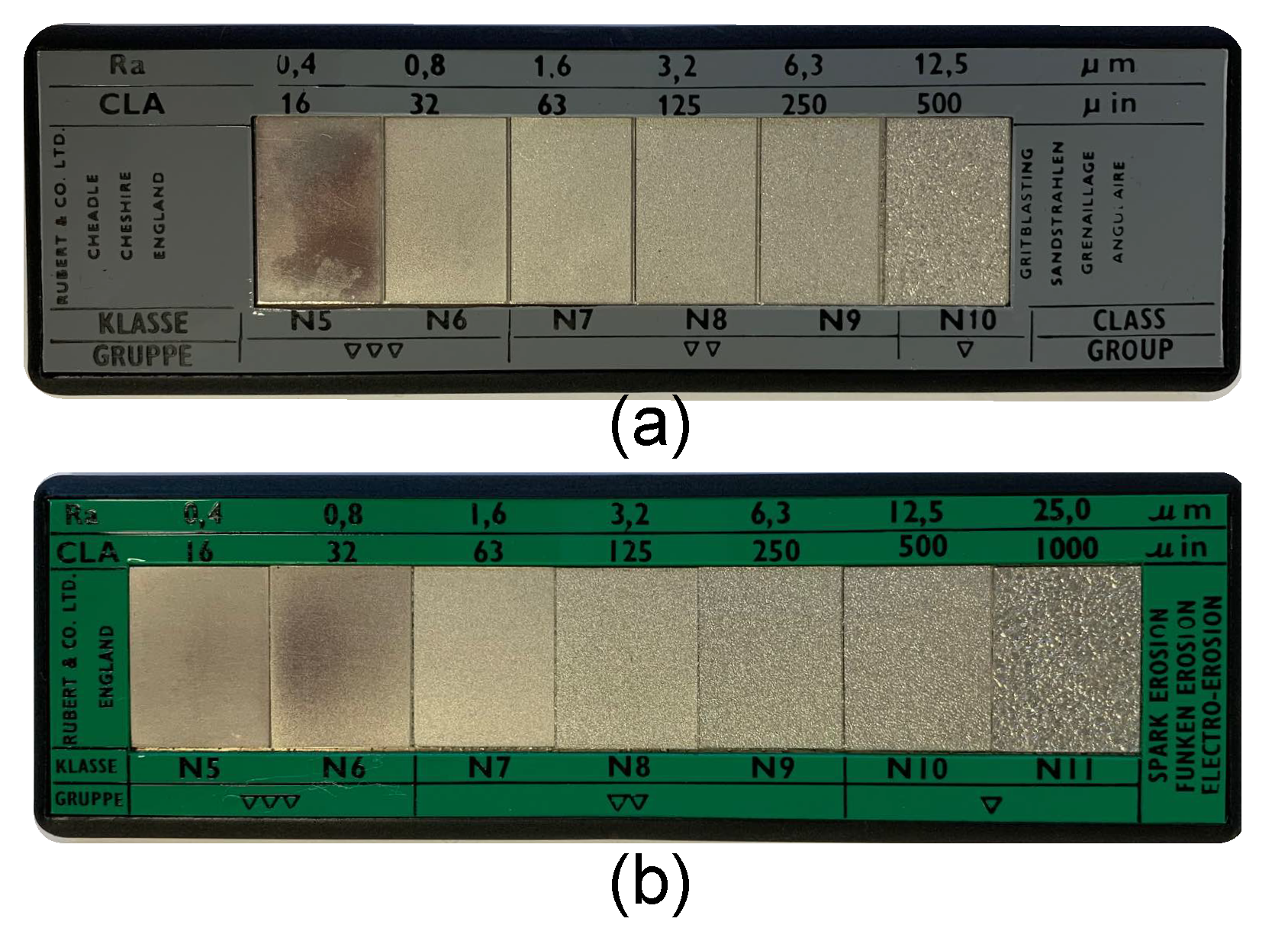

3.1. Roughness Comparators

The effects of a rough surface on the optical generation and detection of surface acoustic waves can first be demonstrated by examining the results from SRAS measurements from the shot-blast comparator.

Figure 4a demonstrates the simple effect of increasing roughness resulting in less light being returned to the detector. It is seen that the average light returned from the sample decreases with increasing roughness up to

and then stabilises around 15% for increasing levels of roughness. The data dropout represents the number of unmeasurable pixels across the surface and is seen to increase with increasing roughness, unlike the light return level, which does not plateau. For this surface type with increasing roughness, there is a decreasing number of positions on the surface that will produce a measurement; however, the level of light returned from the measurable positions will remain roughly constant.

Figure 4b plots the standard deviation of the velocity for pixels where the light return is over a chosen threshold against the number of averages used. The first conclusion to draw from this figure is that for a given number of averages, the standard deviation of the velocity increases with increasing roughness. As the number of averages increases, the standard deviation of the velocity decreases; however, it does not drop as quickly as would be expected if the noise was uncorrelated. A 100-fold increase in averages should produce a 10-fold reduction in the standard deviation for random noise, but the drop is around 2–3 times. There are a number of possible reasons for this; for the rougher samples there are two effects, an increase in the acoustic attenuation, leading to a reduction in signal level at the detection location, and secondly, the roughness causes a drop in the return light level, leading to a higher level of noise in the detection channel. Additionally, the data come from different spatial locations on the sample, and although we believe the grain size is very small compared to the measurement resolution, variations in the material could also lead to a plateau in the standard deviation of the velocity with averages. Another source of noise is the Q-switch in the generation laser being picked up by the detection electronics, and as this repeats with each generation event. This noise is (partially) coherent and so does not average away as quickly as uncorrelated noise. For the samples where the light return is lower, the effect of the background noise is more marked, and even with a large number of averages, the velocity standard deviation is still quite high. However, reasonable results are still obtained with velocity standard deviation below ∼50 ms

, achievable for all samples; this represents an error on the mean of ∼2700 ms

of below 2%.

Figure 4c plots the mean velocity for

between

and

; the velocity is seen to decrease from ∼2715 to ∼2630 ms

. There are two possible hypotheses that may explain this change in wave speed. The first may be related to the defocus in the generation patch, meaning the wavelength of the acoustic wave generated is not consistent. The second possibility is a dispersion of the SAW due to the roughness. The second effect seems more plausible, as for the roughest samples, the focus position was checked. Furthermore, to obtain a change of

from defocus would require a 10% change in acoustic wavelength. However, for the case of dispersion due to surface roughness, this is expected to only reduce the velocity of the wave and so is the likely cause of the small shift in mean velocity observed.

Finally,

Figure 4d summarises these effects by overlaying SRAS velocity maps from each surface onto a photograph of the comparator. The overall quality of the measurement decreases with increasing roughness as more dropouts are seen, and the shift in mean velocity is apparent for the roughest samples.

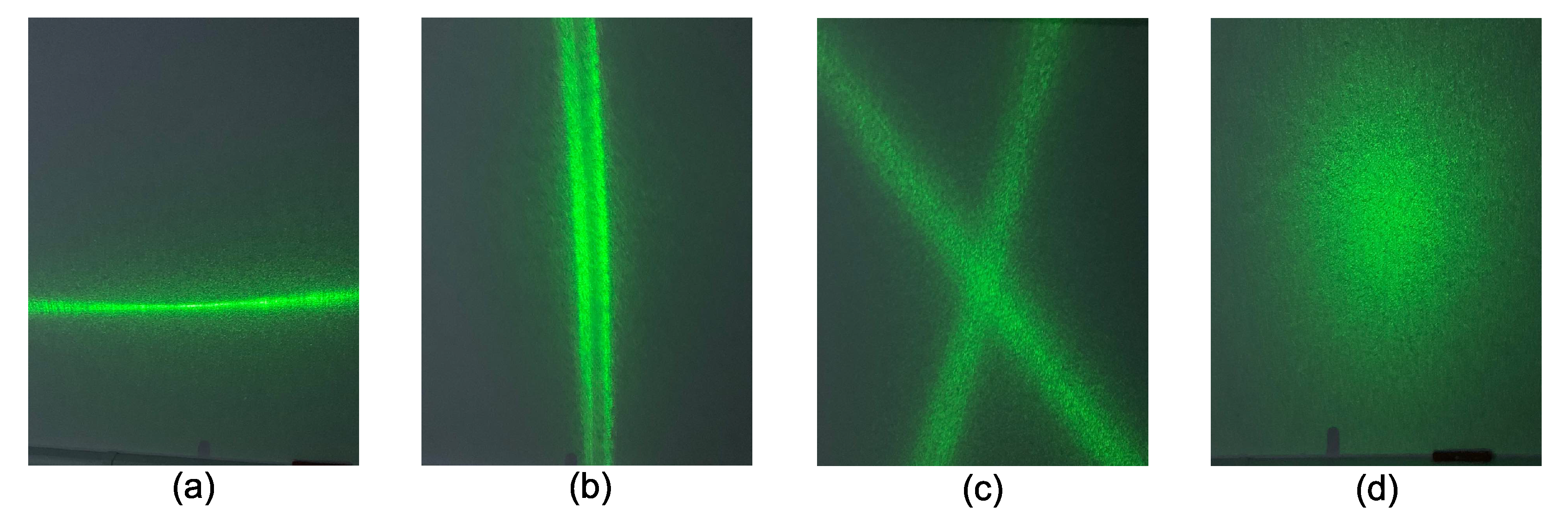

It would be desirable to have a direct relationship between surface roughness and the quality of the ultrasonic measurement.

Figure 5 shows that the roughness does not correlate with the SNR obtained. It is easy to demonstrate why this is the case by examining the reflected beams from surfaces of the same notional roughness.

Figure 6a–d show an image of the reflected beam from four samples that all have an

of

. It can clearly be seen that machining methods in particular can impart a strong directionality onto the reflection.

Tabulated results for the comparators are given in

Table 3 and

Table 4, reporting the average single-shot SNR when there is sufficient light returned from a point on the surface and the percentage of lost data points for each sample. These tables present the difficulty of working on different surface types and degrees of roughness. The SNR table explains how good data are likely to be from this surface if sufficient light is returned, and the dropout table explains how good an image of the surface is likely to be.

In general, if light is returned to the detector, then the single-shot SNR is good from ∼11 to 27 dB. For most surfaces, the SNR is similar across the range of roughness levels present. In some cases, the roughest surface actually produces higher SNR data, for example, in grinding, which is likely due to the increase in the correlation length for the roughest sample; the feature sizes look significantly coarser to the eye, reducing the impact of the roughness on the ultrasound propagation.

Two samples show a marked drop in SNR with increasing roughness (grit blasting and spark erosion). These surface preparations show that as the roughness increases, as does the feature size (or correlation length); this is essentially starting as a surface where small-scale roughness dominates and then becomes a surface where waviness dominates, eventually producing features with such large scale they can be considered the form. Roughness leads to some scattering of the light, which, coupled with large surface angles for wavy features, leads to even more light being reflected outside of the collection optics, leading to a significant drop in light return.

For two samples, honing and turning, the surfaces have very pronounced curvature, so there is a large change in surface height across the sample. This leads to a large number of lost points when the surface goes out of focus. When the surface is in focus, the data have generally good SNR. These types of surfaces would benefit from being able to ensure the sample is at the focal plane and normal to the surface. This requirement is discussed further in

Section 4.1.

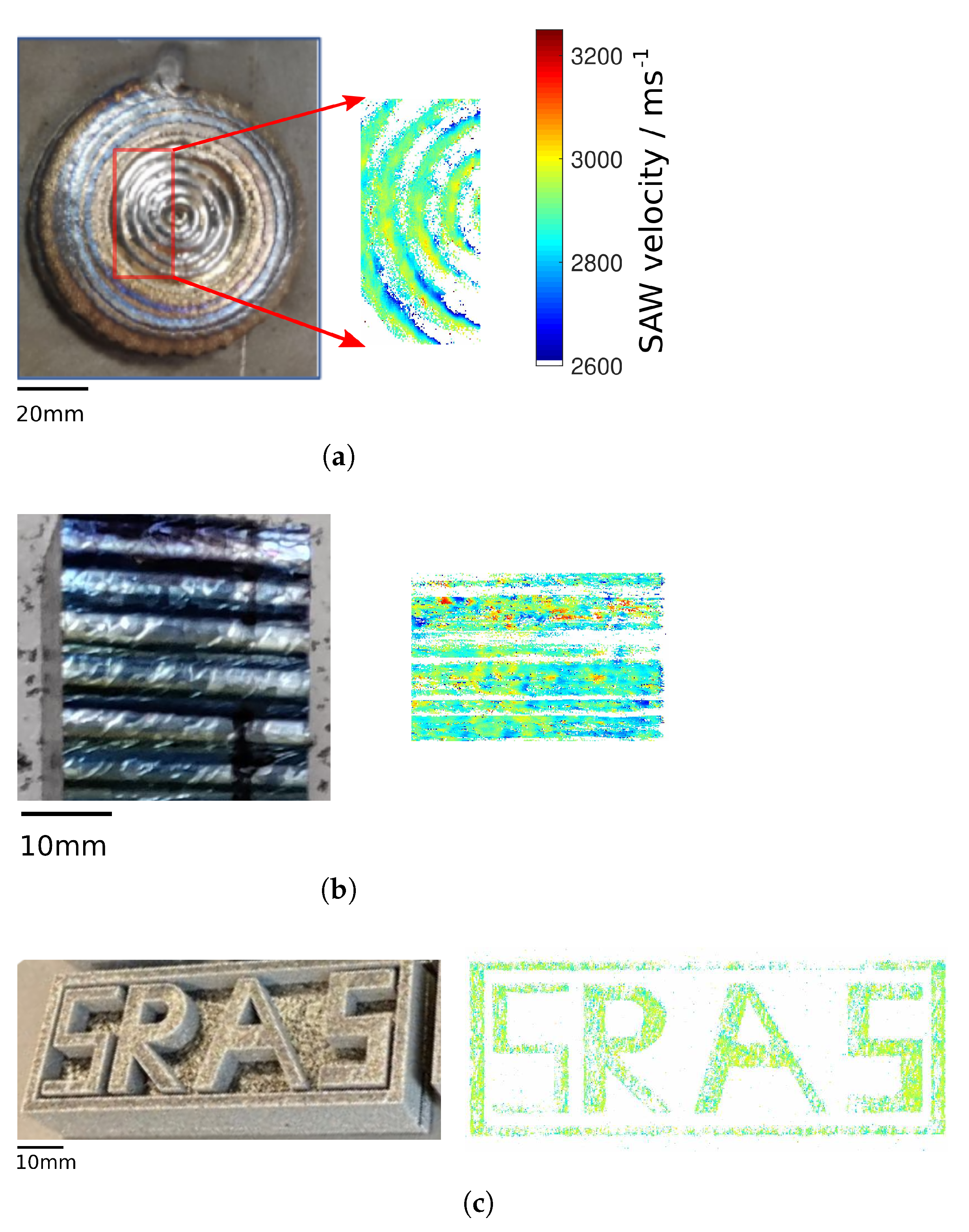

3.2. Wavy Samples

WAAM samples have varying degrees of

form, with high levels of

waviness but less overall fine-scale

roughness.

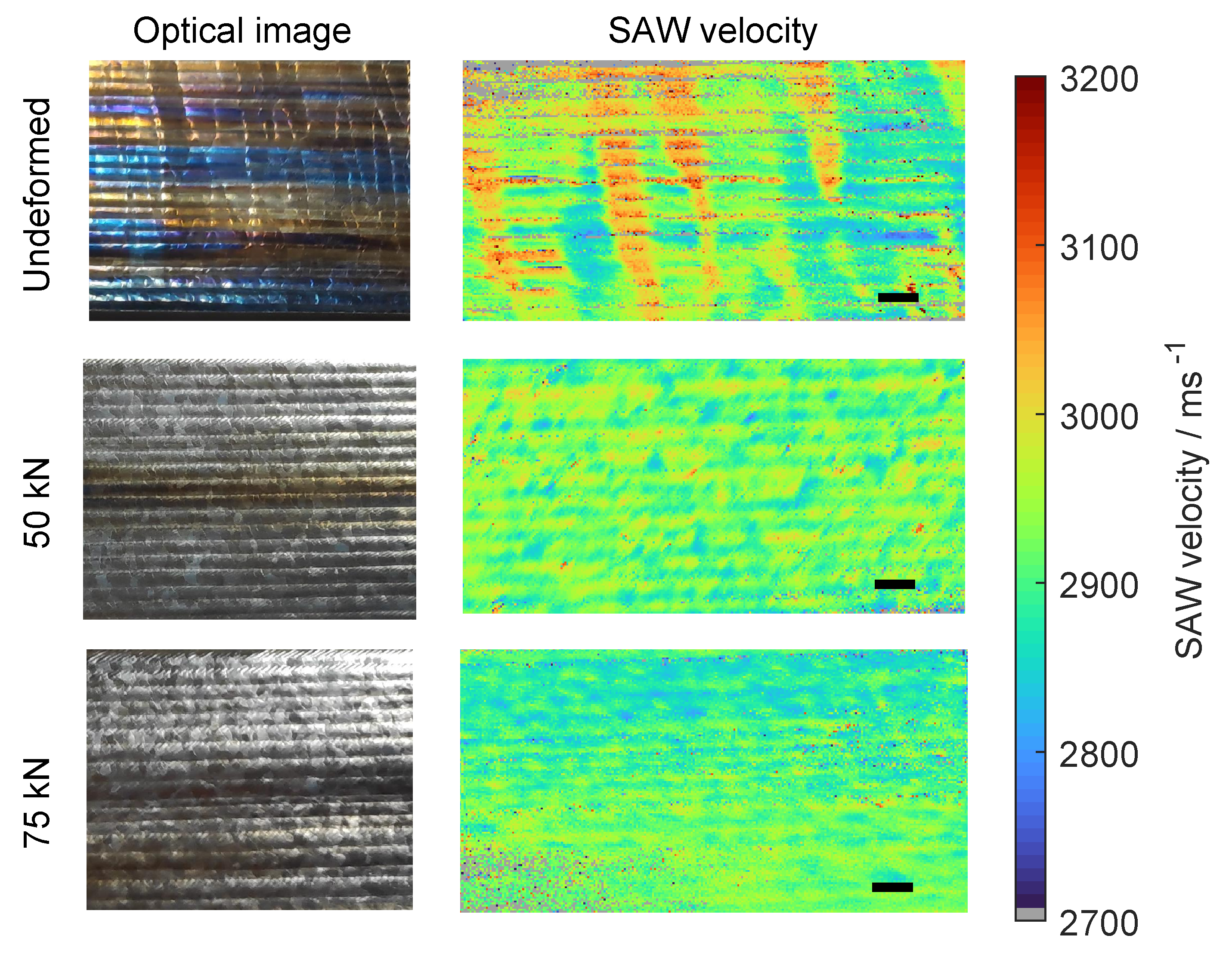

Figure 7 shows the optical micrographs from three WAAM samples with different processing parameters. The top sample is built layer-by-layer without a rolling pass. The middle and bottom samples have an interpass rolling stage with 50 kN and 75 kN force applied, respectively. The optical images clearly show the layer-by-layer nature of the build and for the undeformed sample, additional significant colouration of the surface due to surface oxide/nitride layers forming during the time spent at elevated temperatures.

The velocity maps show the underlying texture of the samples; for the undeformed case, there is the presence of large prior-

grains, i.e., the long columnar growth that continues up through the layers as the sample is built. The interpass rolling stage prevents this from happening, where the influence of this grain refinement step breaks up the grains and produce a finer texture. These scans on the as-built surface show the same information as previous work on polished specimens [

40].

There are some drop outs in the data, caused by the change in angle of the surface at the bead joins, the wavy nature of the side wall means the light is sometimes reflected out of the instrument. The local roughness is not influencing the measurement as the surface on the small scale is quite smooth. The discolouration of the undeformed sample had little impact on the determination of the velocity as it only reduced the return light level of the probe laser by less than 20%.

3.3. Rough Samples

The etched sample has no

form or

waviness, just fine-scale

roughness from the etching process.

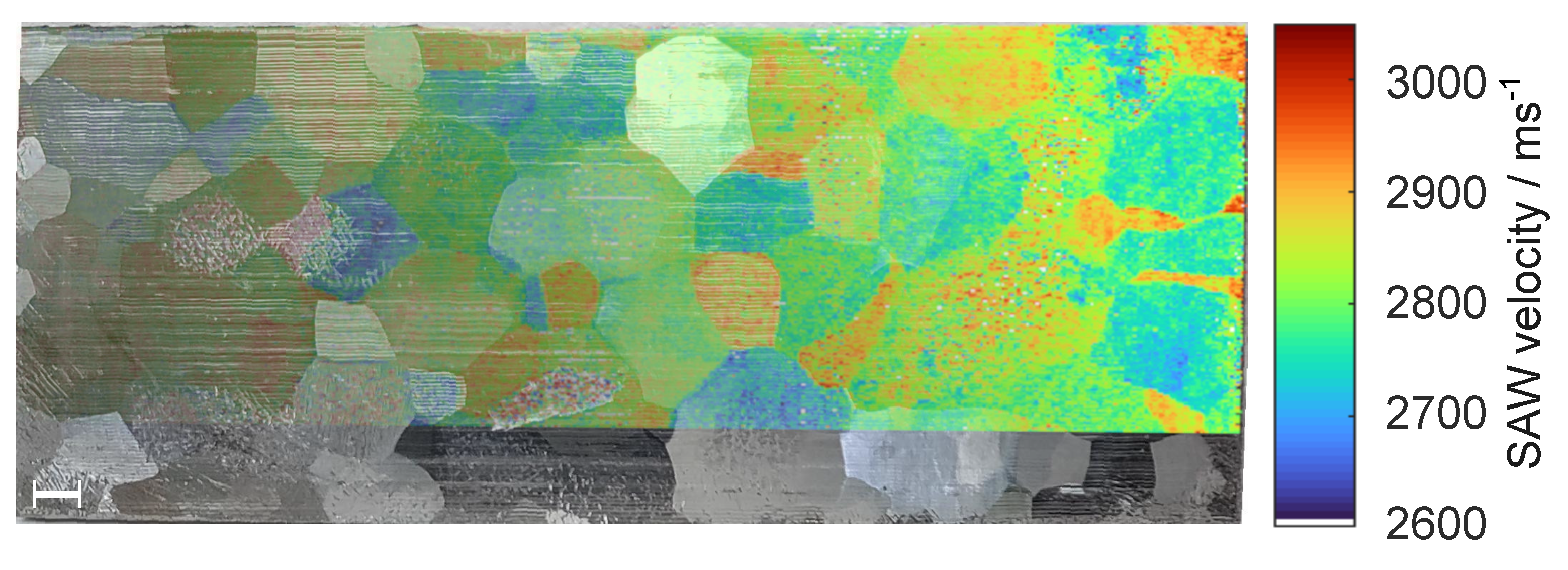

Figure 8 shows a velocity map captured from the etched Ti-6246 specimen overlaid on to a photograph of the surface, with the grain structure visible thanks to etching. The etching process produces roughness on a fine scale with different materials and processes producing different feature sizes scattering the light to different degrees. For this sample, despite the strong contrast in reflectance and the roughness imparted on the surface from the etching process, the SRAS measurement is still possible, with minimal data dropout of 4% and clear contrast between the grains in the SAW velocity map.

L-PBF samples were designed to have no form or waviness so that the small-scale roughness could be examined in isolation. L-PBF currently produces very challenging surfaces for laser ultrasound inspection, as the surface roughness is related to the particle size used for the powder layer. For the samples used in this study, this is around and leads to an in the range of –, with a similar correlation length. Given that the acoustic wavelength is around and the focal spot for the probe is around , this has a large impact on both the generation and detection of ultrasound.

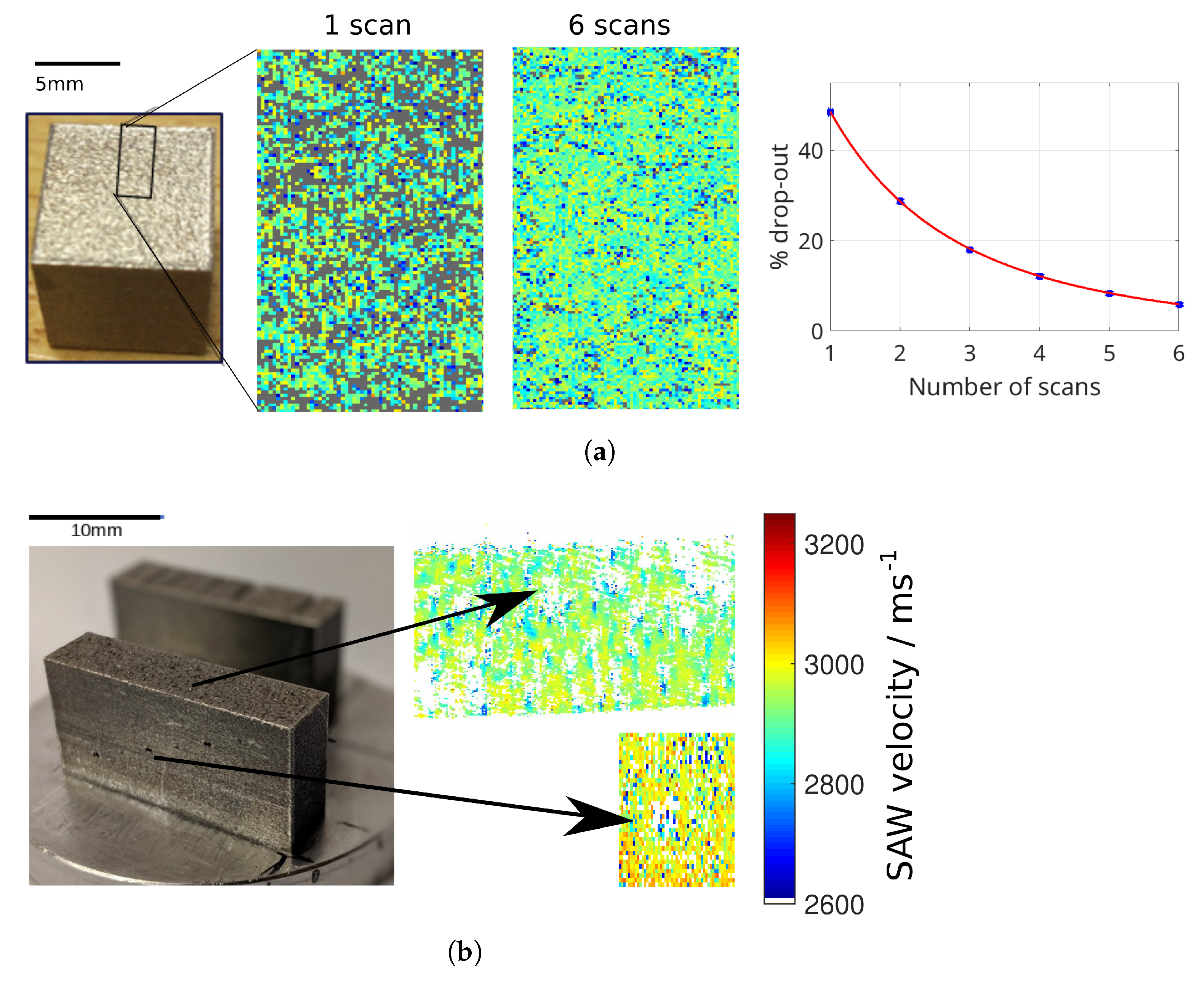

Figure 9a shows two samples made via L-PBF. The left shows a top surface scan on a Ti-6Al-4V cube scanned using the SKED (see

Figure 2b). Here, there are a considerable number of dropouts due to the extremely rough surface. The velocity measured shows little contrast due to the small grain size and strong texturing, in line with previous results in polished specimens [

44]. By changing the detection spot distance from the generation patch, it is possible to combine scans to reduce the drop-out rate. The combination of six scans reduces the dropout from around 50% to below 10% at the cost of total scan time.

Figure 9b shows results using the Quartet detector on an AlSi10Mg sample made with internal defects [

42], the velocity map of the top, and a small section of the side wall around the side hole feature. Again, there are some drop outs, but the texture information is visible in the velocity maps. The two velocity maps are plotted on the same velocity scale, indicating a difference in the dominant crystallographic plane between the two faces.

3.4. Wavy and Rough

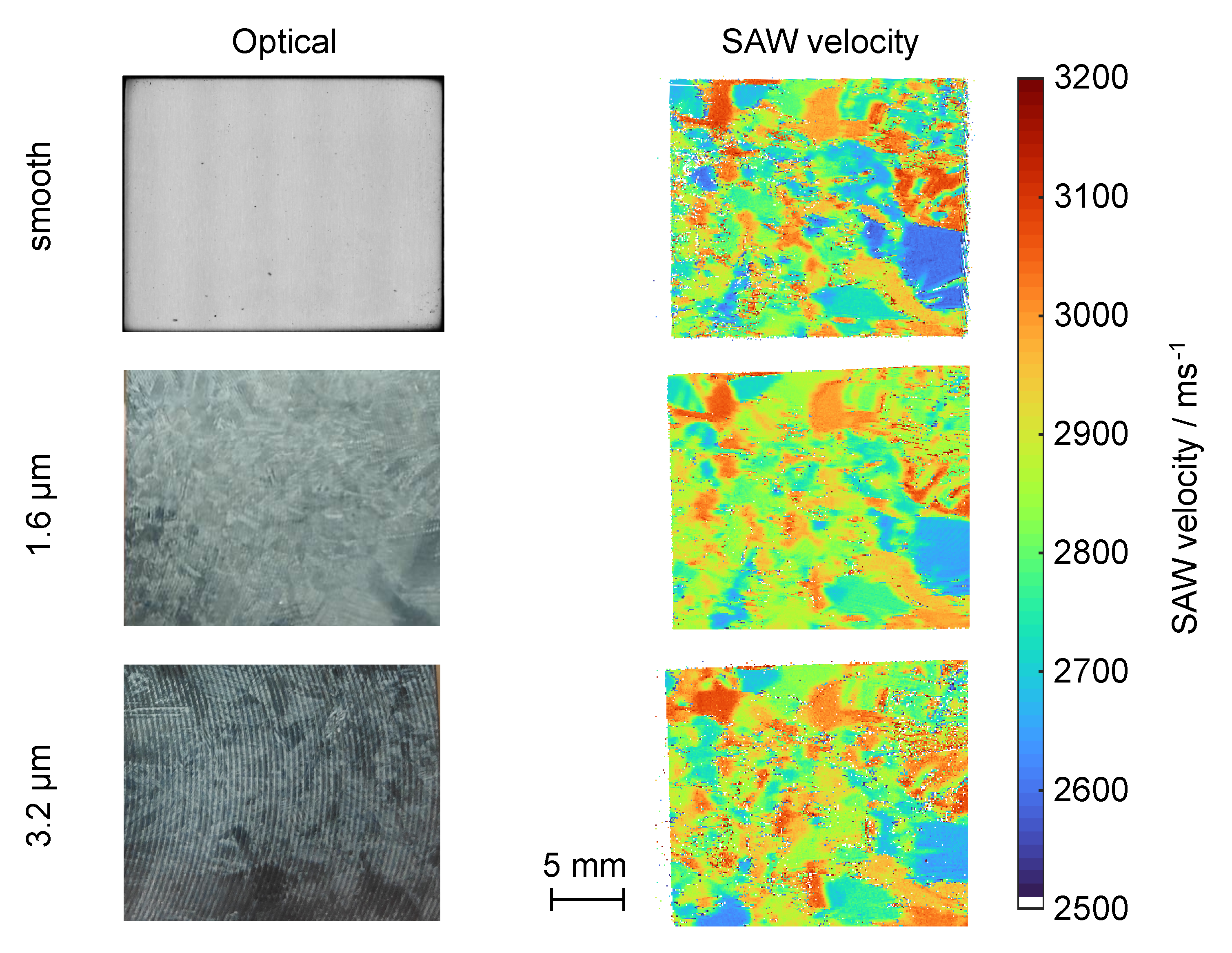

The machined samples presented here are predominantly flat with little form, but depending on the machining depth, they can have waviness along with fine-scale roughness.

A commercially pure titanium sample with three surface conditions, polished (top row) and milled to

s of 1.6 and 3.2

m, has been measured. The left column of

Figure 10 shows the optical maps from each surface, with the right-hand side presenting the corresponding velocity map. The rough surface maps are very similar to that in the polished state. Variations between the pictures are due to several factors; for example, removal of material from the polished state exposes slightly different grains, which is particularly noticeable where the features are small. Additionally, small variations in the sample placement in the instrument lead to small rotational differences that influence the velocity to different degrees depending on the plane of each grain. A small change in the rotation of the sample for the large blue grain, which appears to be aligned with the prism plane, can cause a larger shift in velocity than for other grains.

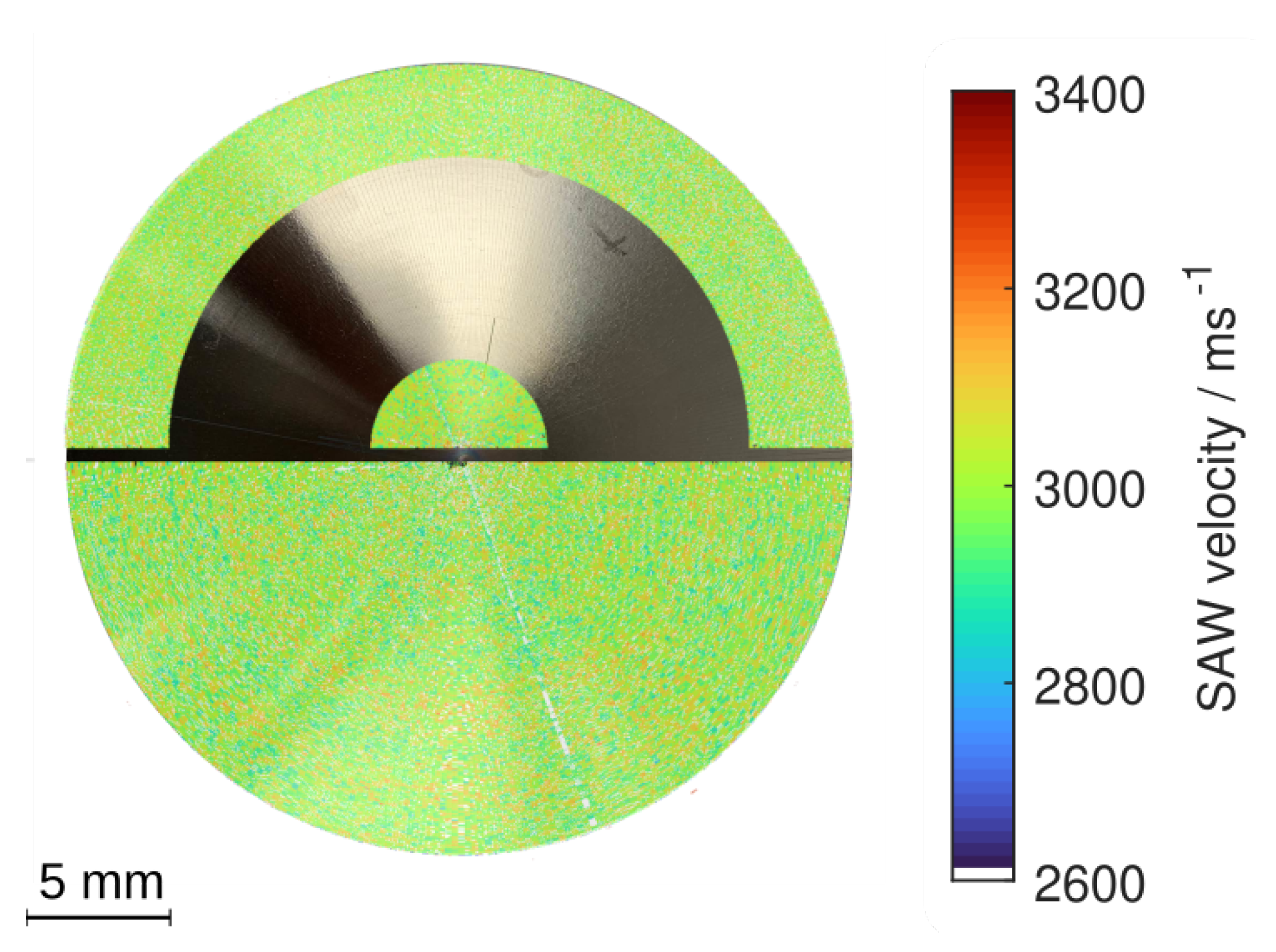

A machined titanium (Ti-6Al-4V) billet slice (

) was scanned. A selection of the optical image is overlaid on the velocity map in

Figure 11. This sample was scanned by rotating the billet and scanning a ring of data before moving the SRAS head sideways across the centre line of the sample. This was to produce data sets to mimic in silico scanning in a commercial lathe. The wave propagation direction changes for each position on the sample, and in this case, the waves are propagating towards the centre of the sample. Despite the surface roughness, 90% of the surface produces valid SRAS measurements, and the machining lines are not shown in the velocity maps. The structure within the velocity maps shows the fine microstructural texture of the material.

The lower half of the billet reports the results of scanning radially. Maintaining a constant angle between scan lines, this means that the pixel size increases from the centre towards the outer edge. In contrast, the upper half of the scan is such that constant pixel size is maintained across the scan area. Therefore, the outer and inner rings are consistent. Careful choice of scan strategy is required to obtain well-sampled data.

4. Discussion and Conclusions

The following section discusses the challenges of using SRAS for the inspection of real parts and considers the source of the challenges from samples with waviness and roughness and possible solutions. The time to inspect compared to the build time is also considered, as well as other effects encountered when inspecting close to the build in AM, such as elevated temperature. Finally, prospects for the future are given.

4.1. Challenges Due to Waviness

The previous section showed the capability of SRAS measurements on a range of surface finishes. It is clear that for many real parts, the fact that these surfaces represent small-scale roughness is not an impediment to microstructural imaging.

The current versions of the instrument suffer mostly from challenges from the form and waviness of the samples. This is because, for large changes in the sample surface position (as the form changes) the measurement surface goes out of focus, or the light reflects and leaves the optical system due to the change in surface gradient. Some examples of this are shown in

Figure 12.

The influence of changes in focus could be reduced by incorporating an auto-focus system, either via image analysis of the surface and the generation fringe pattern, or by sensing the stand-off distance variation from the sample via other means. Adding this to the instrument will allow the measurement surface to be kept at the optimal distance and so greatly improve signal integrity.

Maintaining the measurement plane normal to the surface to combat changes in form and waviness is more challenging. For parts where there is a CAD model, registering the part in the measurement volume and using a robotic manipulator to present the surface normal to the laser head would allow the impact of changes in surface gradient to be reduced. Combining this with auto-focus would produce a very robust measurement system.

There are still challenges from wire-based AM samples where the side wall of the sample is wavy and the exact form of this is unknown and therefore hard to follow. In

Figure 12a, the waviness of the WLAM sample shows clear drop outs, but the data from the upper flat regions are good. Similarly, for the WAAM sample in

Figure 12b, the variation in layer thickness and bead curvature would be difficult to follow without a dedicated surface following system built into the instrument. Again, where the curvature is small and the sample is in focus, the data obtained are still good as the roughness is well within the operating range of the instrument.

4.2. Challenges Due Roughness

Of the materials presented, L-PBF presents the biggest challenge from the small-scale roughness perspective (

Figure 12c). However, it is important to note that the optimisation of the L-PBF process to reduce surface roughness is an ongoing research domain, and within the last few years clear progress has been made. Therefore, it is realistic to foresee a future where the ever-increasing capability of detector systems and smoother as-built surfaces of L-PBF mean that measurements on unprepared parts become routine.

In addition, the surface roughness of L-PBF components are lower than any other powder based-technique [

45]. The results presented in this paper deal only with L-PBF and not other varieties of powder-bed manufacture, such as selective laser sintering (SLS), but it is reasonable to assume the roughness seen in SLS components would prove a greater challenge to SRAS measurements.

The dropouts are primarily caused by loss of detection light and so multiple scans can be combined and stacked to reduce this effect as discussed earlier. Another approach is to broaden the detection laser spot into a line or a number of spots spaced wider than the correlation length of the roughness so that some light will always return to the sample for each scan location.

4.3. Resolution

As previously detailed by Smith et al. [

16], the spatial resolution of an SRAS measurement is approximately equal to half the diameter of the generation patch. Therefore, to increase spatial resolution, two approaches are available. First, the number of fringes can be reduced; however, this results in a broadband signal and a greater error in velocity measurement. The second approach is to use a smaller acoustic wavelength, giving a smaller patch size for the same number of fringes, but this introduces two separate challenges. Using smaller wavelengths requires the detection of higher frequencies, and so the bandwidth of the detector used in the measurement can become a limiting factor. As shown in

Figure 2, whilst prepared surfaces can be measured in the hundreds of MHz by the KED, and indeed other solutions exist to measure SAWs in the GHz regime [

46], rough surfaces are limited to

, with many detectors having an upper limit below

. Additionally, the attenuation of the SAW as it propagates must also be considered. The short propagation distances in SRAS help to minimise the influence of attenuation, and increasing the frequency to improve resolution will eventually lead to the attenuation dominating. As derived and observed experimentally by Huang and Maradudin [

22], the attenuation of a SAW due to roughness varies with the frequency to the fourth power in the stochastic regime; further detail on the can be found in the recent work of Sarris et al. [

47].

The results presented in this work have an approximate spatial resolution of ; the inherent flexibility of the SRAS instruments makes it possible to switch between optimising for spatial resolution and optimising for velocity resolution. The need to work at lower frequencies usually means spatial resolution is often sacrificed for samples with rough surfaces. The velocity resolution is determined by the number of fringes used in the generation pattern and the SNR achieved via averaging, and so a trade-off between spatial resolution and scan time is usually made.

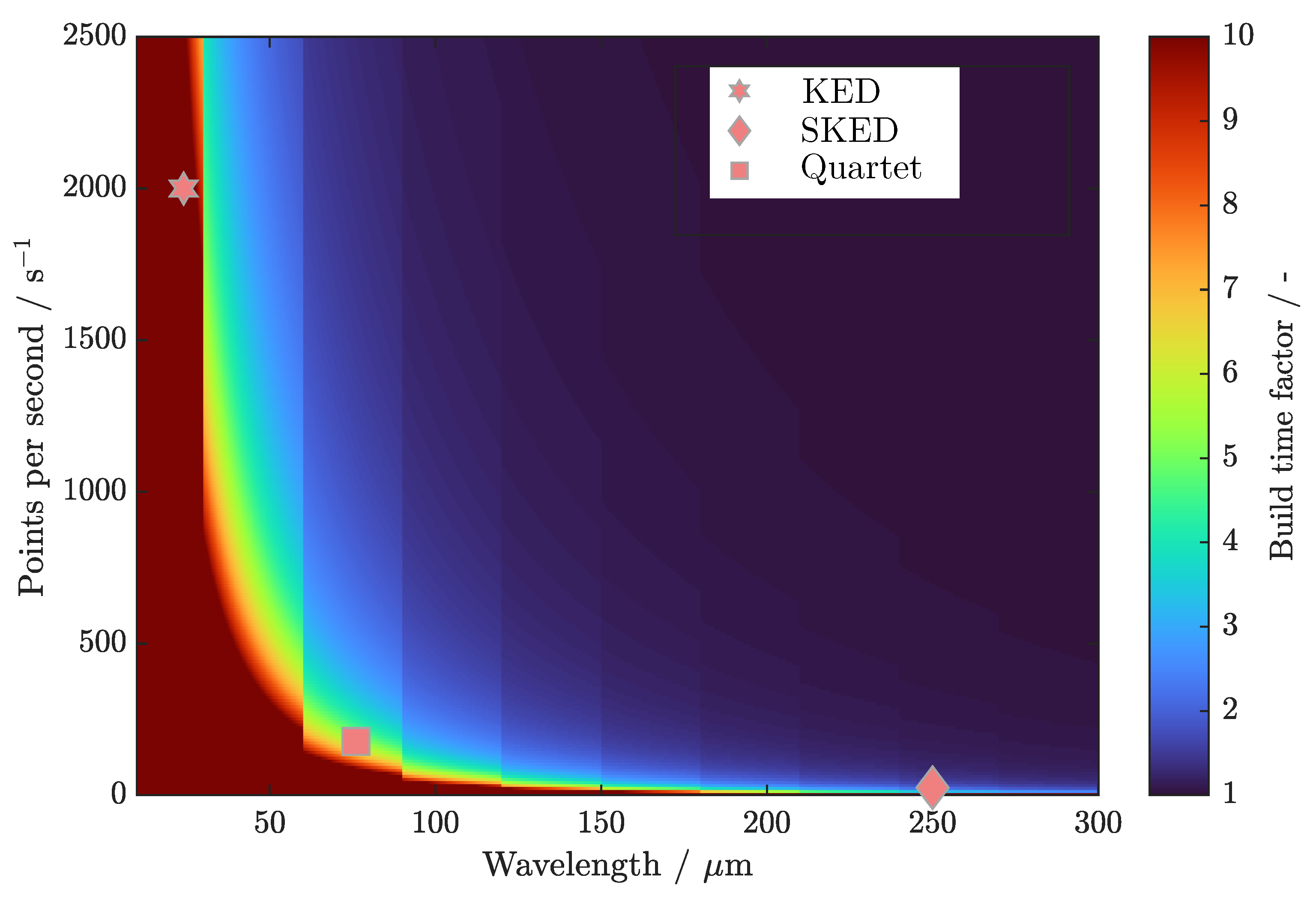

4.4. Scan Speed Compared to Manufacturing Speed

An obvious question to ask is what the speed of an SRAS scan is. Whilst it is plain that a ‘fast’ scan is more amenable to integration within a manufacturing process, some context can be provided by using L-PBF as worked example. This allows the speed of an SRAS scan to be compared to the speed of the AM deposition. Whilst the example herein focuses on L-PBF, a similar methodology could be applied to other methods of additive manufacturing or machining, so long as the processing rates of the manufacturing operation are known.

Colosimo et al. developed a model for assessing the economic impact of in silico monitoring tools in AM [

3]. The authors conducted a series of studies to estimate the failure rate of typical AM components. They then calculated the break-even point of a hypothetical inspection system as a function of this failure rate. The conclusion was an estimation that ∼9% savings in the cost of additive components could be achieved by the use of in silico monitoring. All of the tools the authors considered were passive, observing the emission spectra of the build process. These are essentially ‘free’ measurements in that there is no temporal impact on the build; therefore, only the cost of the equipment needs to be considered. However, a prospective SRAS system will need to scan the sample, causing some addition to the manufacturing time, hence the importance of the time element of the model compared to those in the existing literature. To generate the build time information shown below, a sample build similar to the Airbus A320 nacelle hinge bracket discussed in the work of Tomlin and Meyer [

48] was defined. This bracket was later used by Colosimo et al. as a case study example in the aforementioned study [

3]. The part takes approximately 36 h to fabricate.

To estimate the time spent inspecting the sample build, the ‘speed’ of the inspection system must be defined. The ‘speed’ of the SRAS system can be essentially broken down into the rate of data acquisition and the number of data points to be captured. The speed of acquisition is a function of the number of averages required and the repetition rate of the generation laser. The number of points to be captured is primarily dependent on the size of the specimen and the acoustic wavelength (as this in turn defines the spatial resolution).

Figure 13 plots the impact on build time as a function of points acquired per second and the wavelength of inspection. To give some context, parameters from the results presented earlier in this paper are marked on this figure.

The closer to one the ratio is, the smaller the impact of inspection on the total build time. On first inspection, it would seem desirable to work as close to the lower right-hand side as possible in order to minimise the temporal penalty of inspection; however, increasing the wavelength of inspection leads to a decreased resolution and decreased measurement fidelity. The discontinuities arise because with increasing wavelength, more build layers can be inspected per scan. Therefore, increasing the acquisition rate of the SRAS system is the preferable way to increase scan speeds. The number of parameter points per second shown in

Figure 13 is simply

.

On a smooth surface, the primary influence on the points per second is the repetition rate of the generation laser. In the ‘on-the-fly’ scanning approach [

16], as used by the smooth surface system, one pulse is equivalent to one measurement point—thus, a 5 kHz repetition rate laser allows 5000 measurements per second. However, on rough surfaces, the signal-to-noise ratio (SNR) is significantly lower and necessitates averaging of the acoustic waveform to improve SNR.

It would be preferable to correlate the number of averages needed with surface roughness and integrate this within the model; however, as previously discussed, this relationship is extremely complex.

4.5. Temperature

As discussed, the ability to make SRAS measurements on rough surfaces raises the possibility of integrating SRAS within the manufacturing process, which increases the final challenge discussed in this work, i.e., temperature. The acoustic velocity of material is sensitive to the temperature, and thus the use of laser ultrasound in steel mills, L-PBF chambers, and direct energy deposition (DED) systems requires calibration of the temperature. By way of example, the SAW velocity on the (001) plane of nickel at temperatures between 100 and displays a near-linear trend of . Thus, a temperature instability of a few degrees can become the limiting factor in the accuracy velocity measurements and orientation determination.

Experimental results presented in this work have been at nominal room temperature, but this was not controlled and probably spans a range of between 5 and 10 C. To work at higher temperatures would require accurately measuring the temperature during a scan so that the temperature effect can be calibrated.

4.6. Future Perspectives

The images presented here show that real surface conditions of parts are no longer an impediment to imaging the microstructure. Future generations of SRAS instruments will be able to deal with the complex shapes of parts, allowing the surface microstructure to be determined on the part before being put into service. This will allow decisions on inspection and maintenance schedules at the part level, reducing costs and time associated with inspection. It will also accelerate the adoption of additively manufactured components into safety-critical areas, as the performance of the part will be known because the part can be inspected during the build process, generating a digital twin of the part containing information on the remaining defects and microstructure within the part. The availability of optical detectors that can work on a wide range of surface finishes means that imaging the microstructure of real parts is now possible.