A Multivariate Local Descriptor Registration Method for Surface Topography Evaluation

Abstract

1. Introduction

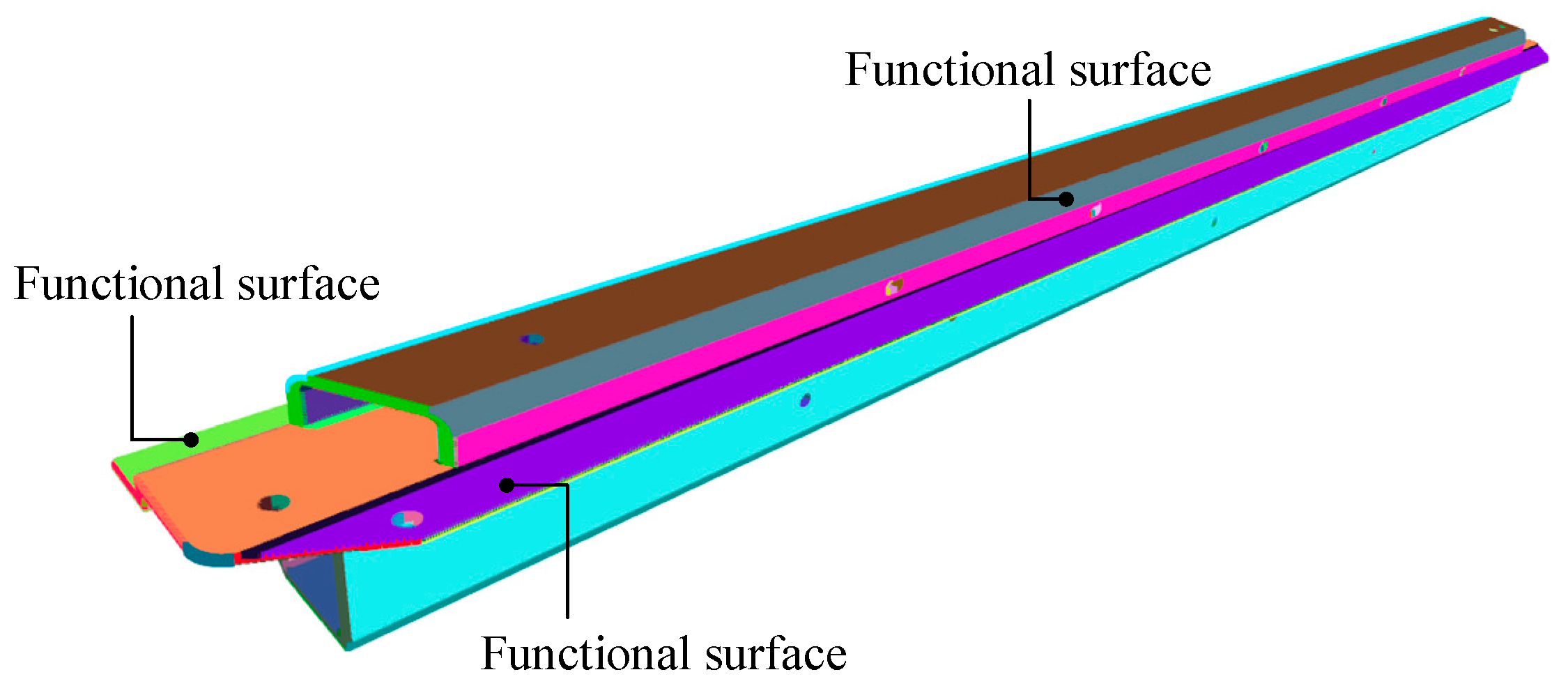

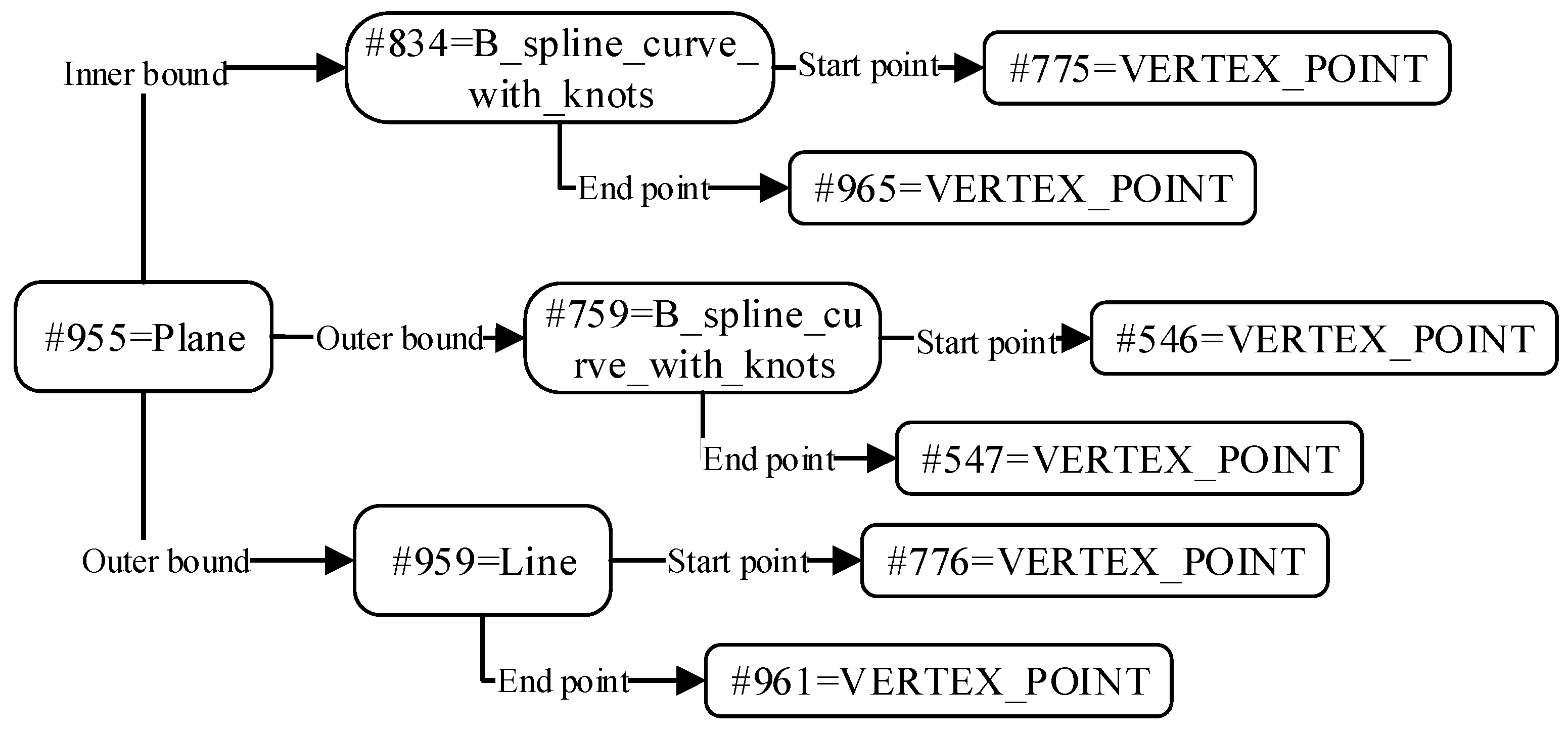

2. Generation of Functional Surfaces and Point Cloud Based on STEP File

2.1. The Division Functional Surface in STEP File

- (1)

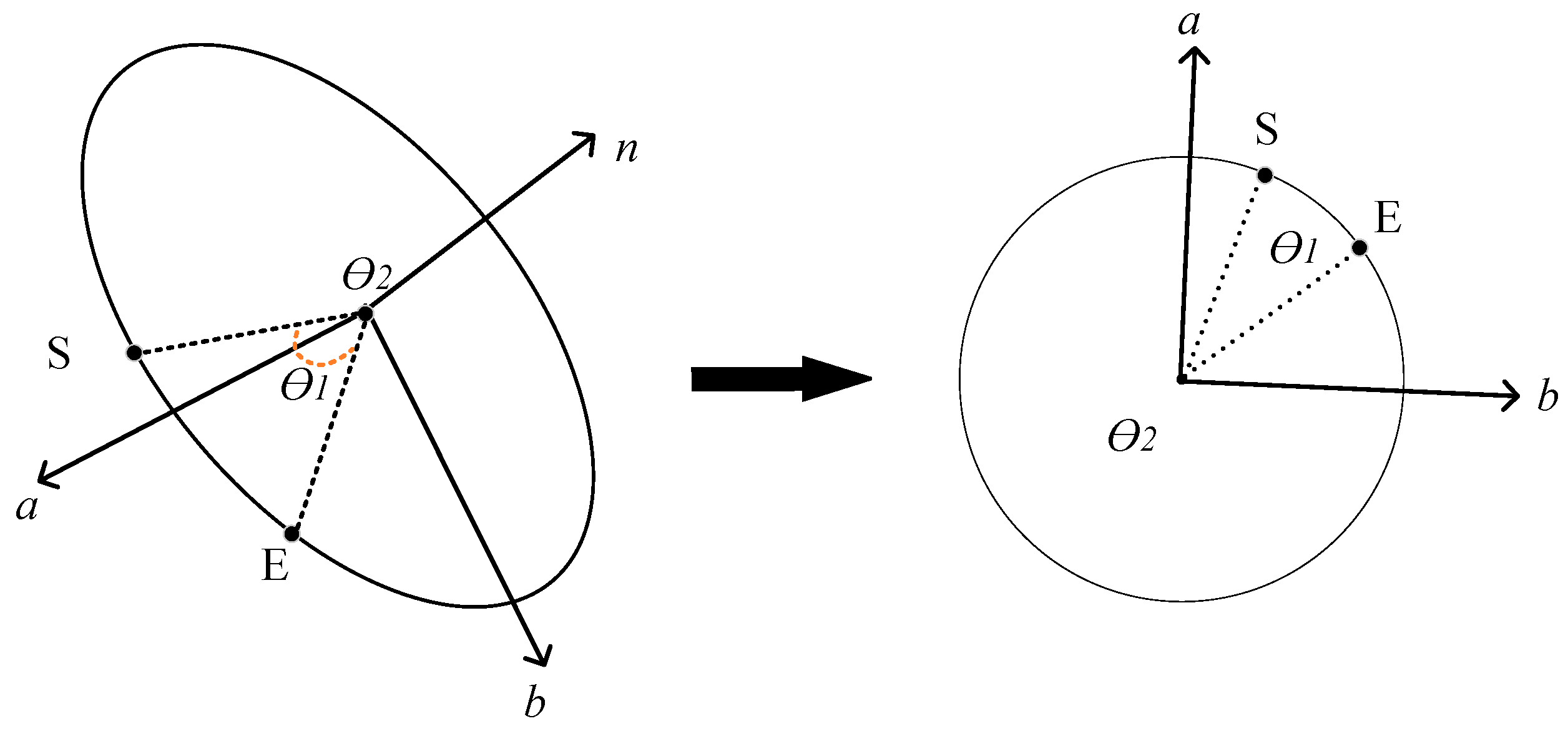

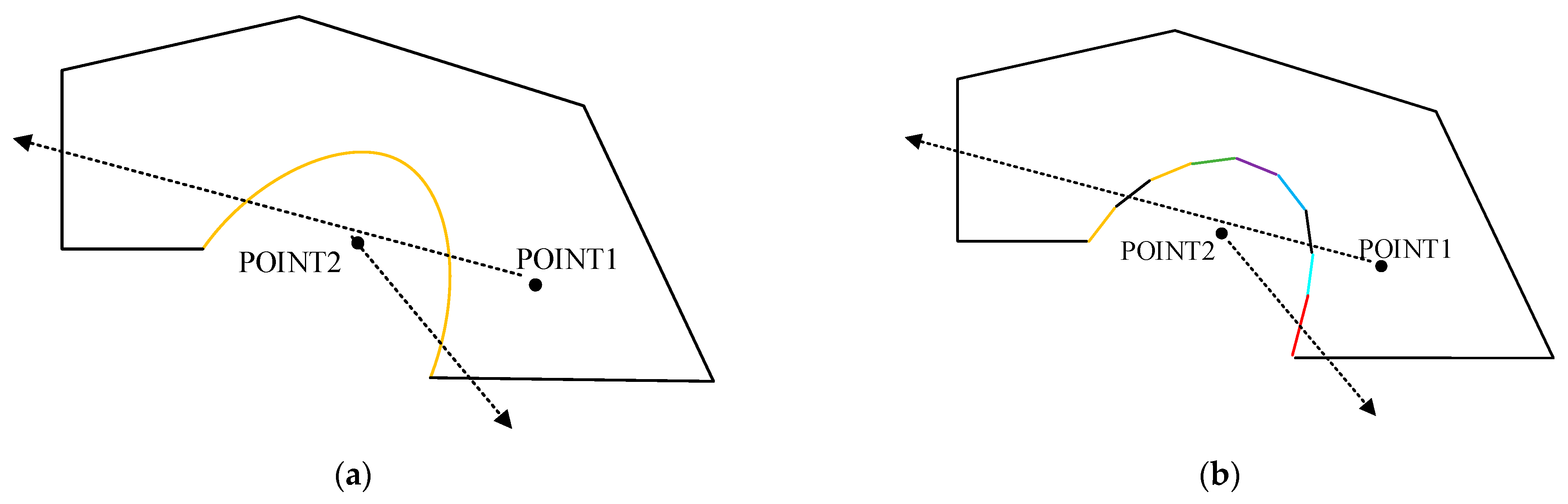

- Calculating two direction vectors perpendicular to each other in the normal direction N of the circle. Selecting any one of the x, y, and z directions of the global coordinates and taking the cross product with N. If the result is not 0, set it as direction a; otherwise, choose another direction to calculate the cross-product. Keep taking N to cross a and direction b, obtaining a, b and N as the local coordinate system of the circle, and then projecting it into a 2D plane in the direction of N, as shown in Figure 3; the transformation formula is expressed as Equation (4), where R = [a, b, N], p is the 3D coordinate point, is the 2D coordinate point, and here is the start point or end point, o is the centre of the circular arc.

- (2)

- In order to remove the z-axis of the local coordinate system, the start and end points of the two-dimensional plane can be obtained and calculate the sine v1 and cosine v2 of the starting point S and the ending point E, respectively.

- (3)

- The equation obtains the results of the final start point and end point (5). Finally, the direction of the edge curve in the STEP file is used to determine the result (if the direction is T, select θ1 in Figure 3, otherwise, select θ2 in Figure 3). The discrete points of a circle can be determined according to the equation of a circle.

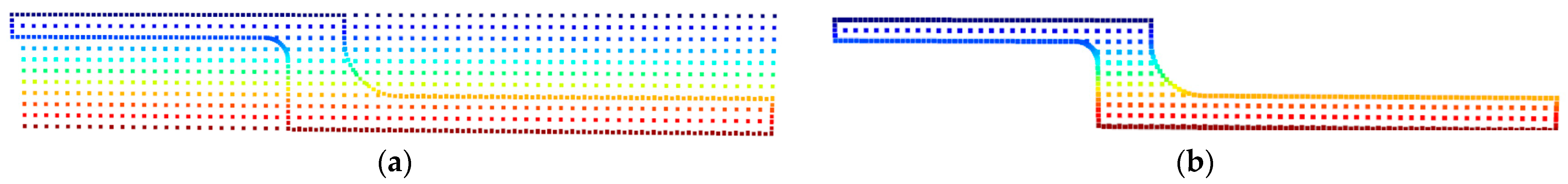

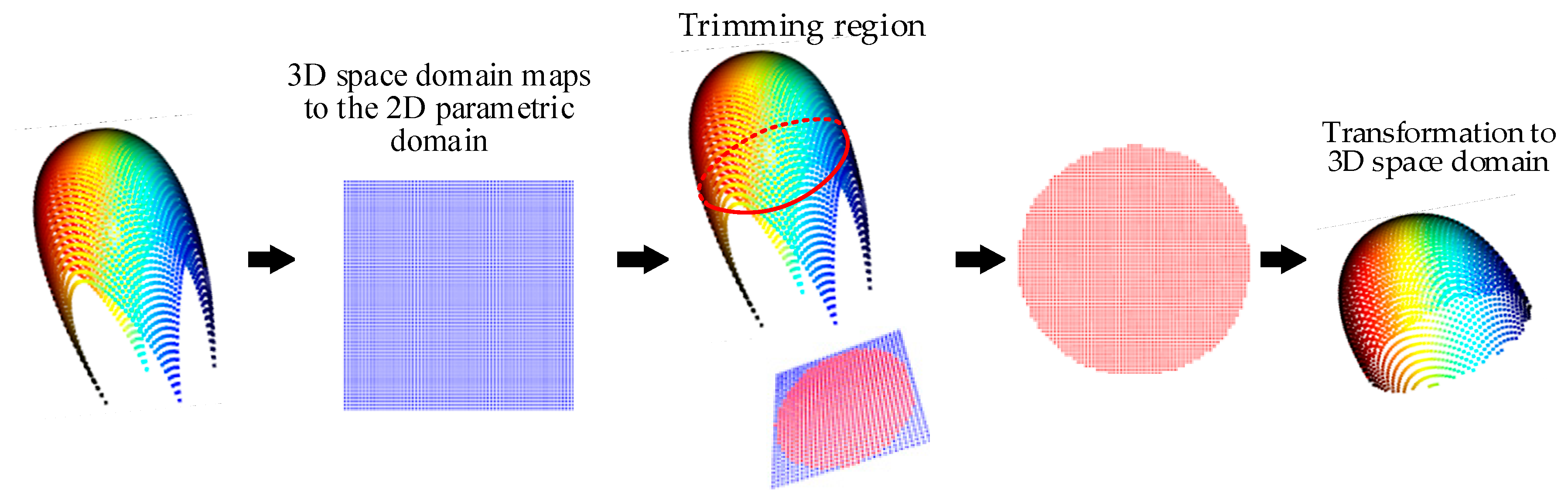

2.2. The Generation and Trimming of Point Cloud

2.2.1. The Filling and Trim of Planar Point Cloud

2.2.2. The Filling and Trim of the Curved Surface Point Cloud

3. Part-in-Whole Point Cloud Registration

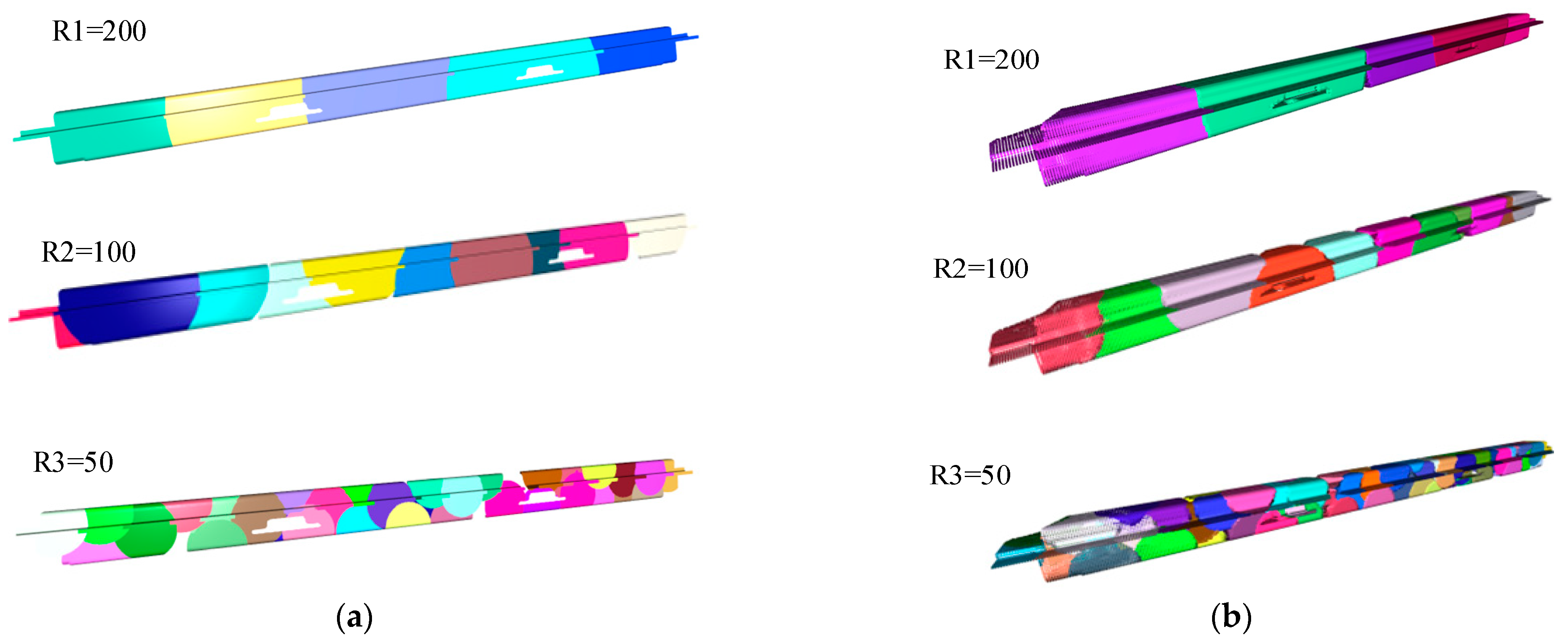

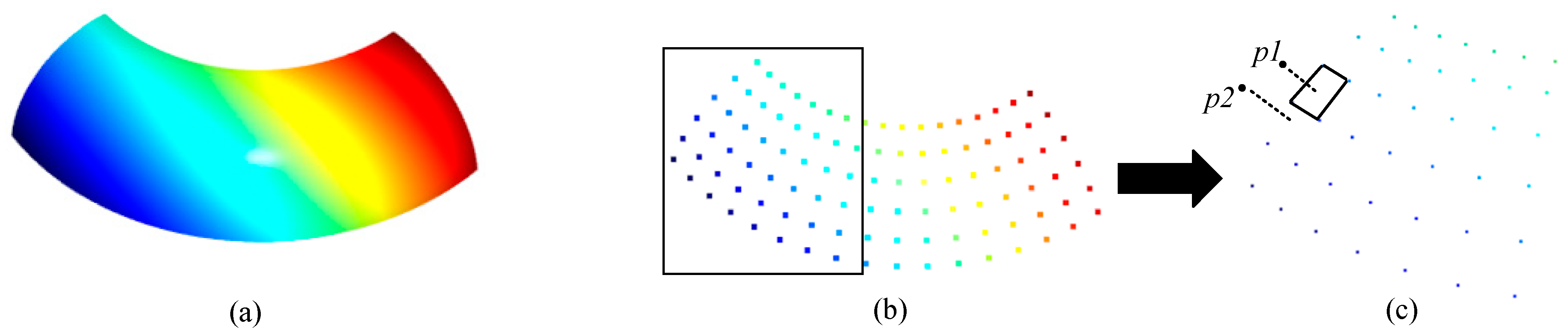

3.1. The Patch of Point Cloud

3.2. Coarse Registration Based on Multivariate Descriptors (MD)

- (1)

- The descriptor sets of multi-scale RSCS of LMPC and global point cloud are calculated, , , where n represents different descriptors, i is RSCS of different scales, k and K are the number of LMPC and whole CAD point cloud at a certain scale.

- (2)

- n descriptors are randomly selected from and to determine the n corresponding relationship. The centre of RSCS is defined as the corresponding point. Supposing n descriptors in determine the most similar corresponding n points in , the weighted average points between the corresponding points of n different descriptors are calculated as the final corresponding points. Then the final corresponding point position in is defined by Equation (11), where wi is the normalised weight of the matching score in corresponding points from n descriptor and ci is the position of the corresponding point from a different descriptor. Figure 9 is a sketch of a weighted average corresponding point with three descriptors, in which the blue is the local point cloud, and the grey is the whole DMPC. In the whole DMPC, different shapes correspond to the corresponding points calculated by different descriptors, and the circular points are the final weighted corresponding points.

- (3)

- After determining the corresponding points, the corresponding points of the s group are randomly selected to obtain the corresponding point set and , according to Equations (15) and (16), the transformation matrices R and T are calculated, where U and V are singular matrices; it is obtained by performing a singular value decomposition on Equation (14).

- (4)

- Using the transformation matrix to carry out a rotation and translation transformation on corresponding points except for s corresponding points, if the distance of k-s corresponding point is less than a certain threshold value after transformation, then the point in the local point cloud is determined to be the inner point; otherwise, it is the outer point, the number of inner points is counted, and si+1 corresponding points are selected in the next round. Repeat the above process. The result is the corresponding points with the most significant number of inner points.

- (5)

3.3. Iterative Closest Point (ICP) Based on Fine Registration

4. Local Point Cloud Segmentation

5. Experimental Verification and Comparisons

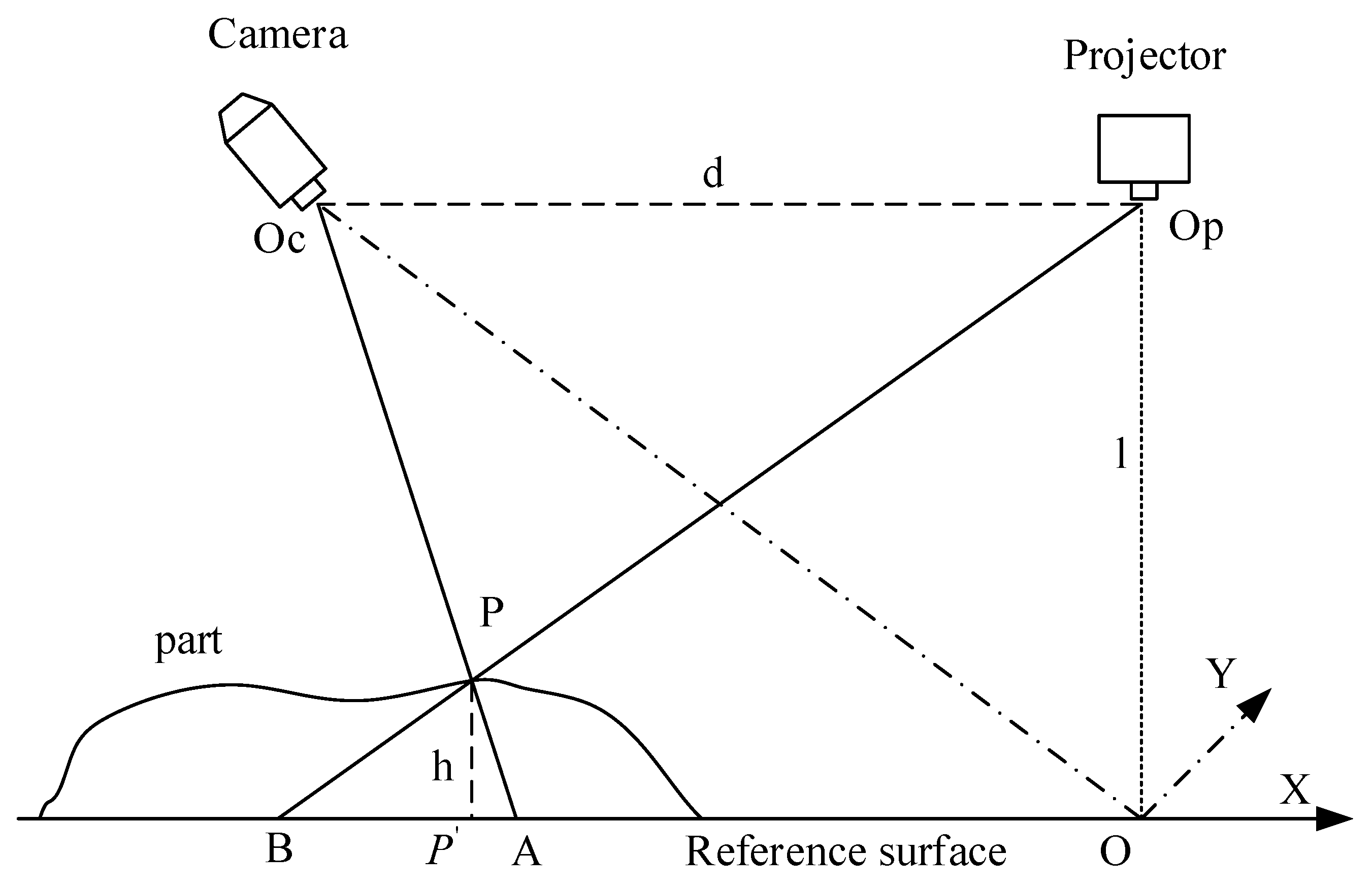

5.1. Experimental Conditions

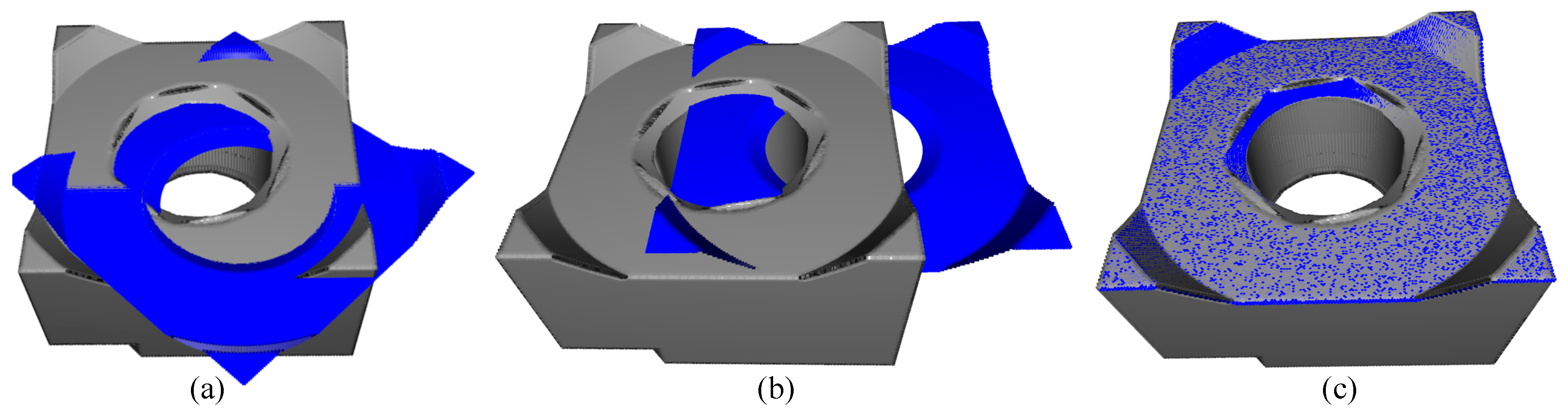

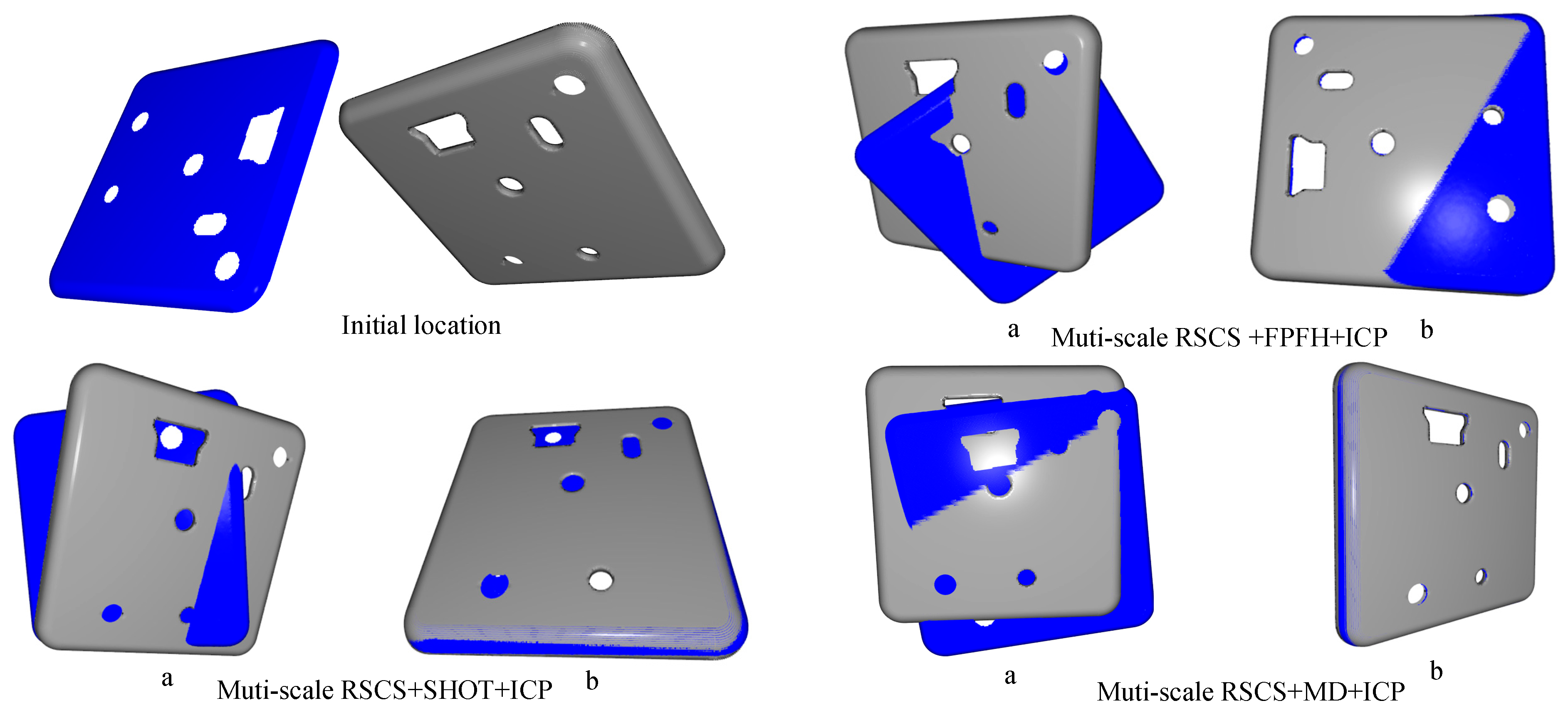

5.2. The Analysis of Registration

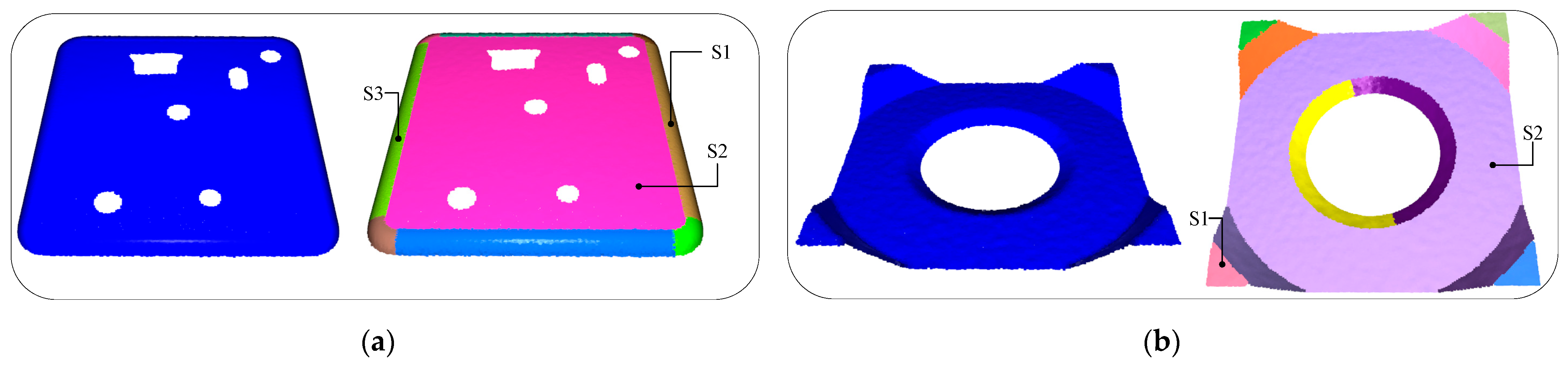

5.3. Point Cloud Segmentation and Error Analysis

6. Discussion

7. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kruth, J.P.; Bartscher, M.; Carmignato, S.; Schmitt, R.; De Chiffre, L.; Weckenmann, A. Computed tomography for dimensional metrology. CIRP Annals 2011, 60, 821–842. [Google Scholar] [CrossRef]

- Si, L.; Yang, H.; Li, Z.; Duan, L. Part point cloud segmentation method based on model registration. J. Physis Conf. Ser. 2021, 1884, 01222. [Google Scholar] [CrossRef]

- Liu, Y.; Blunt, L.; Zhang, Z.; Rahman, H.A.; Gao, F.; Jiang, X. In-Situ areal inspection of powder bed for electron beam fusion system based on fringe projection profilometry. Addit. Manuf. 2020, 31, 100940. [Google Scholar] [CrossRef]

- Jiang, Y.; Karpf, S.; Jalali, B. Time-stretch LiDAR as a spectrally scanned time-of-flight ranging camera. Nat. Photonics 2020, 14, 14–18. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, S. Status, challenges, and future perspectives of fringe projection profilometry. Opt. Lasers Eng. 2020, 135, 106193. [Google Scholar] [CrossRef]

- Peng, J.; Liu, X.; Deng, D.; Guo, H.; Cai, Z.; Peng, X. Suppression of projector distortion in phase-measuring profilometry by projecting adaptive fringe patterns. Opt. Express 2016, 24, 21846. [Google Scholar] [CrossRef]

- Yang, S.; Liu, M.; Song, J.; Yin, S.; Ren, Y.; Zhu, J.; Chen, S. Projector distortion residual compensation in fringe projection system. Opt. Lasers Eng. 2019, 114, 104–110. [Google Scholar] [CrossRef]

- Shi, J.; Zhu, X.; Wang, H.; Song, L.; Guo, Q. Label enhanced and patch based deep learning for phase retrieval from single frame fringe pattern in fringe projection 3D measurement. Opt. Express 2019, 27, 28929–28943. [Google Scholar] [CrossRef]

- Jeught, S.; Dirckx, J. Deep neural networks for single shot structured light profilometry. Opt. Express 2019, 27, 17091. [Google Scholar] [CrossRef]

- Brown, C.A.; Hansen, H.N.; Jiang, X.J.; Blateyron, F.; Berglund, J.; Senin, N.; Bartkowiak, T.; Dixon, B.; Le Goïc, G.; Quinsat, Y.; et al. Multiscale analyses and characterizations of surface topographies. CIRP Ann. 2018, 67, 839–862. [Google Scholar] [CrossRef]

- Peta, K.; Mendak, M.; Bartkowiak, T. Discharge Energy as a Key Contributing Factor Determining Microgeometry of Aluminum Samples Created by Electrical Discharge Machining. Crystals 2021, 11, 1371. [Google Scholar] [CrossRef]

- Kang, H.; Li, Z.-M.; Liu, T.; Zhao, G.; Jing, J.; Yuan, W. A novel multiscale model for contact behavior analysis of rough surfaces with the statistical approach. Int. J. Mech. Sci. 2021, 212, 106808. [Google Scholar] [CrossRef]

- Fang, X.; Luo, Q.; Zhou, B.; Li, C.; Tian, L. Research progress of automated visual surface defect detection for industrial metal planar materials. Sensors 2020, 20, 5136. [Google Scholar] [CrossRef] [PubMed]

- Shao, J.; Zhang, W.; Mellado, N.; Grussenmeyer, P.; Li, R.; Chen, Y.; Wan, P.; Zhang, X.; Cai, S. Automated markerless registration of point clouds from TLS and structured light scanner for heritage documentation. J. Cult. Herit. 2019, 35, 16–24. [Google Scholar] [CrossRef]

- Xu, H.; Yu, L.; Hou, J.; Fei, S. Automatic reconstruction method for large scene based on multi-site point cloud stitching. Measurement 2019, 131, 590–596. [Google Scholar] [CrossRef]

- Chen, Z.; Du, F. Measuring principle and uncertainty analysis of a large volume measurement network based on the combination of iGPS and portable scanner. Measurement 2017, 104, 263–277. [Google Scholar] [CrossRef]

- Xie, Q.; Zhang, Y.; Cao, X.; Xu, Y.; Lu, D.; Chen, H.; Wang, J. Part-in-whole point cloud registration for aircraft partial scan automated localization. Comput.-Aided Des. 2021, 137, 103042. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, H.; Zhao, A.; Xie, Q.; Wang, J. Local Scanning Point Cloud Localization of Aircraft Skins Based on Multi-descriptor Voting Rapid robot vision positioning method for large free-form surface parts. China Mech. Eng. 2021, 32, 2724–2730, 2771. [Google Scholar]

- Lin, J.; Wu, L.; Yang, M.; Zhang, X.; Jiang, K. Rapid robot vision positioning method for large free-form surface parts. Jisuanji Jicheng Zhizao Xitong/Comput. Integr. Manuf. Syst. CIMS 2021, 27, 1951–1958. [Google Scholar]

- Rusu, R.B.; Marton, Z.C.; Blodow, N.; Beetz, M. Persistent Point Feature Histograms for 3D Point Clouds; IOS Publishing: Amsterdam, The Netherlands.

- Salti, S.; Tombari, F.; Di Stefano, L. SHOT: Unique signatures of histograms for surface and texture description. Comput. Vis. Image Underst. 2014, 125, 251–264. [Google Scholar] [CrossRef]

- Wohlkinger, W.; Vincze, M. Ensemble of shape functions for 3d object classification. In Proceedings of the 2011 IEEE International Conference on Robotics and Biomimetics, Karon Beach, Thailand, 7–11 December 2011; pp. 2987–2992. [Google Scholar]

- Qie, Y.; Qiao, L.; Anwer, N. Enhanced invariance class partitioning using discrete curvatures and conformal geometry. Comput.-Aided Des. 2021, 133, 102985. [Google Scholar] [CrossRef]

- Asiabanpour, B.; Mokhtar, A.; Hayasi, M.; Kamrani, A.; Nasr, E.A. An overview on five approaches for translating cad data into manufacturing information. J. Adv. Manuf. Syst. 2009, 8, 89–114. [Google Scholar] [CrossRef]

- Zhao, Y.; Xu, X.; Kramer, T.; Proctor, F.; Horst, J. Dimensional metrology interoperability and standardization in manufacturing systems. Comput. Stand. Interfaces 2011, 33, 541–555. [Google Scholar] [CrossRef]

- Zhou, Q.; Yang, J.; Wu, J.; Tian, Y.; Wang, J.; Jiang, H.; Li, K.-C. An improved algorithm to convert CAD model to MCNP geometry model based on STEP file. Ann. Nucl. Energy 2015, 78, 81–88. [Google Scholar] [CrossRef]

- Al-Wswasi, M.; Ivanov, A. A novel and smart interactive feature recognition system for rotational parts using a STEP file. Int. J. Adv. Manuf. Technol. 2019, 104, 261–284. [Google Scholar] [CrossRef]

- Prochazkova, J.; Procházka, D. The Implementation of Cylinder and Cone as NURBS Surfaces in Engineering Software. In Proceedings of the Symposium on Computer Geometry, Cagliari, Italy, 26–28 June 2006. [Google Scholar]

- Ebrahimi, A.; Loghmani, G.B. Shape modeling based on specifying the initial B-spline curve and scaled BFGS optimization method. Multimed. Tools Appl. 2018, 77, 30331–30351. [Google Scholar] [CrossRef]

- Broyden, C.G. The convergence of a class of double-rank minimization algorithms 1. general considerations. IMA J. Appl. Math. 1970, 6, 76–90. [Google Scholar] [CrossRef]

- Da, F.; Gai, S. Raster Projection 3D Precision Measurement; Science Press: Beijng, China, 2011. [Google Scholar]

- Elbaz, G.; Avraham, T.; Fischer, A. 3D point cloud registration for localization using a deep neural network auto-encoder. In Proceedings of the IEEE Conference on Computer Vision and pattern Recognition, Honolulu, HI, USA, 21–26 July 2017. [Google Scholar]

- Rusu, R.B.; Blodow, N.; Beetz, M. Fast point feature Histograms (FPFH) for 3D registration. In Proceedings of the 2009 IEEE International Conference on Robotics and Automation, Kobe, Japan, 12–17 May 2009; pp. 3212–3217. [Google Scholar]

- Ao, S.; Hu, Q.; Yang, B.; Markham, A.; Guo, Y. Spinnet: Learning a general surface descriptor for 3d point cloud registration. In Proceedings of the IEEE/CVF Conference on Computer Vision and Pattern Recognition, Nashville, TN, USA, 20–25 June 2021. [Google Scholar]

- Besl, P.J.; McKay, N.D. Method for registration of 3-D shapes. Spie 1992, 1611, 586–606. [Google Scholar] [CrossRef]

- ISO 16610-21:2011; Geometrical Product Specifications (GPS)-Filtration-Part 21: Linear Profile Filters: Gaussian Filters. International Organization for Standardization: London, UK, 2011.

- Li, Z.; Xu, Y.; Zhang, C.; Kong, C.; Macleod, I.; Li, T.; Jiang, X.; Guo, B.; Lu, J. A robust areal residual-restrained variational mode decomposition for filtering on surface texture analysis. Surf. Topogr. Metrol. Prop. 2023, 11, 014005. [Google Scholar] [CrossRef]

- Su, X.; Zhang, Q. Dynamic 3-D shape measurement method: A review. Opt. Lasers Eng. 2010, 48, 191–204. [Google Scholar] [CrossRef]

- ISO 25178-2:2012; Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters. International Organization for Standardization: Geneva, Switzerland, 2021.

- Mao, J.; Cao, Y.; Yang, J. Implementation uncertainty evaluation of cylindricity errors based on geometrical product specification (GPS). Measurement 2009, 42, 742–747. [Google Scholar] [CrossRef]

| The Scale of RSCS | Registration Error |

|---|---|

| 20-scale RSCS+MD+ICP | 2.095 |

| 50-scale RSCS+MD+ICP | 4.233 |

| 80-scale RSCS+MD+ICP | 4.856 |

| The Type of Descriptor | Registration Error |

|---|---|

| a_Muti-scale RSCS+SHOT+ICP | 6.499 |

| a_Muti-scale RSCS+FPFH+ICP | 6.211 |

| a_Muti-scale RSCS+MD+ICP | 4.279 |

| b_Muti-scale RSCS+SHOT+ICP | 4.556 |

| b_Muti-scale RSCS+FPFH+ICP | 6.988 |

| b_Muti-scale RSCS+MD+ICP | 2.095 |

| Features | Flatness | Cylindricity | sq Parameter in Roughness |

|---|---|---|---|

| a_S1 | - | 0.881 | 0.219 |

| a_S2 | 1.037 | - | 1.298 |

| a_S3 | - | 0.945 | 0.207 |

| b_S1 | 0.713 | - | 0.813 |

| b_S2 | 0.545 | - | 0.762 |

| Features | Micrometer | CMM | Profilometer | Proposed Method |

|---|---|---|---|---|

| a_S2 | 1.067 | 1.011 | 1.103 | 1.037 |

| b_S1 | 0.842 | 0.702 | 0.801 | 0.713 |

| b_S2 | 0.539 | 0.578 | 0.612 | 0.545 |

| Features | Micrometer | CMM | Profilometer | Proposed Method |

|---|---|---|---|---|

| a_S1 | 0.892 | 0.856 | 1.020 | 0.881 |

| a_S3 | 1.035 | 0.921 | 1.142 | 0.945 |

| Features | Micrometer | CMM | Profilometer | Proposed Method |

|---|---|---|---|---|

| a_S1 | 0.216 | 0.301 | 0.203 | 0.219 |

| a_S2 | 1.354 | 1.326 | 1.276 | 1.298 |

| a_S3 | 0.235 | 0.244 | 0.198 | 0.207 |

| b_S1 | 0.873 | 0.854 | 0.801 | 0.813 |

| b_S2 | 0.852 | 0.832 | 0.732 | 0.762 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kong, C.; Xu, Y.; Li, Z.; Zhang, C.; Li, T.; Macleod, I.; Jiang, X.; Tang, D.; Lu, J. A Multivariate Local Descriptor Registration Method for Surface Topography Evaluation. Appl. Sci. 2023, 13, 3311. https://doi.org/10.3390/app13053311

Kong C, Xu Y, Li Z, Zhang C, Li T, Macleod I, Jiang X, Tang D, Lu J. A Multivariate Local Descriptor Registration Method for Surface Topography Evaluation. Applied Sciences. 2023; 13(5):3311. https://doi.org/10.3390/app13053311

Chicago/Turabian StyleKong, Chao, Yuanping Xu, Zhuowei Li, Chaolong Zhang, Tukun Li, Iain Macleod, Xiangqian Jiang, Dan Tang, and Jun Lu. 2023. "A Multivariate Local Descriptor Registration Method for Surface Topography Evaluation" Applied Sciences 13, no. 5: 3311. https://doi.org/10.3390/app13053311

APA StyleKong, C., Xu, Y., Li, Z., Zhang, C., Li, T., Macleod, I., Jiang, X., Tang, D., & Lu, J. (2023). A Multivariate Local Descriptor Registration Method for Surface Topography Evaluation. Applied Sciences, 13(5), 3311. https://doi.org/10.3390/app13053311