Reactive Ion Etching of X-Cut LiNbO3 in an ICP/TCP System for the Fabrication of an Optical Ridge Waveguide

Abstract

1. Introduction

2. Materials and Methods

2.1. Numerical Simulations for Developing the Topology of Optical Waveguides on an LNOI Substrate

2.2. Sample Preparation

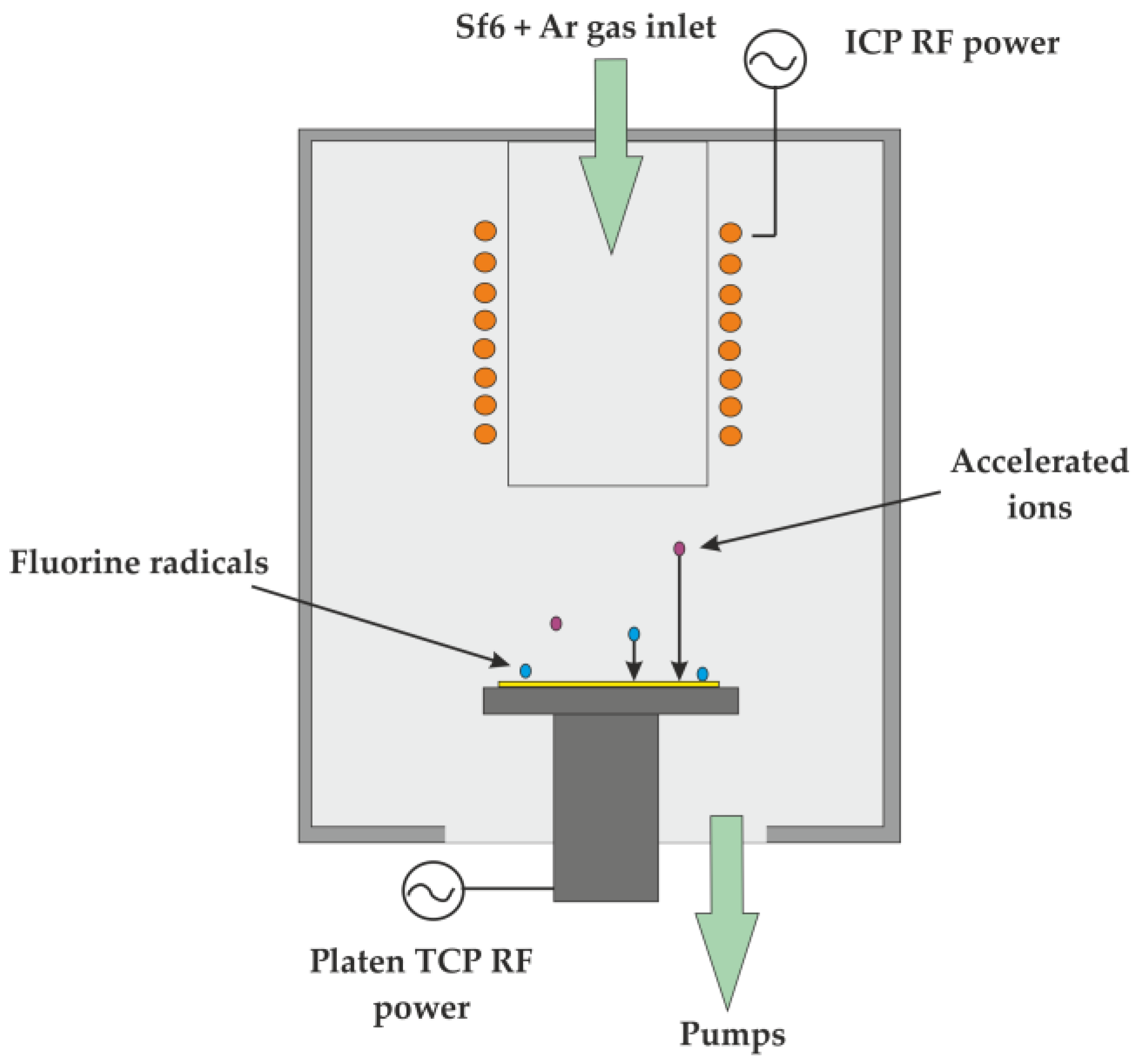

2.3. Reactive Ion Etching

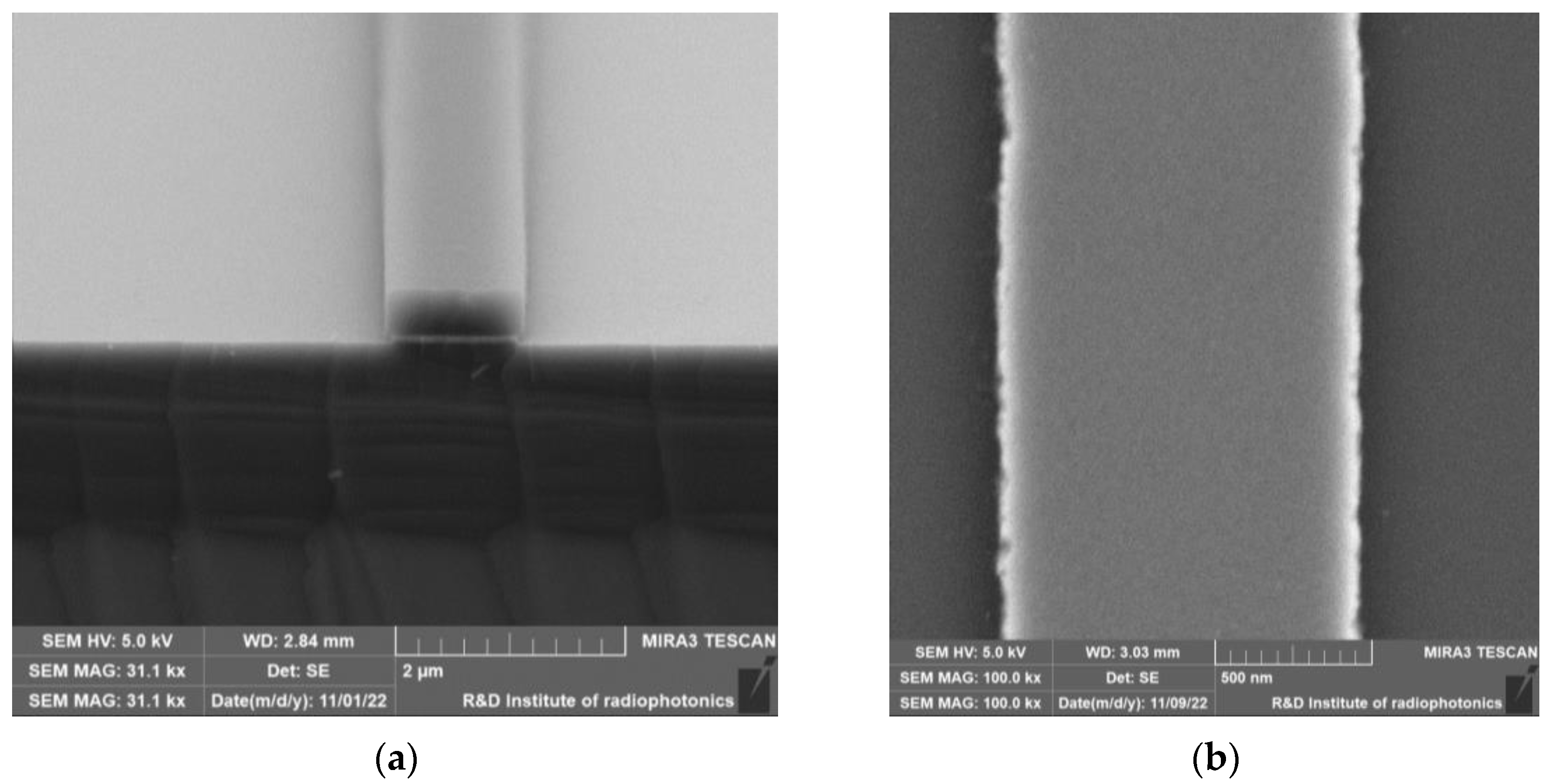

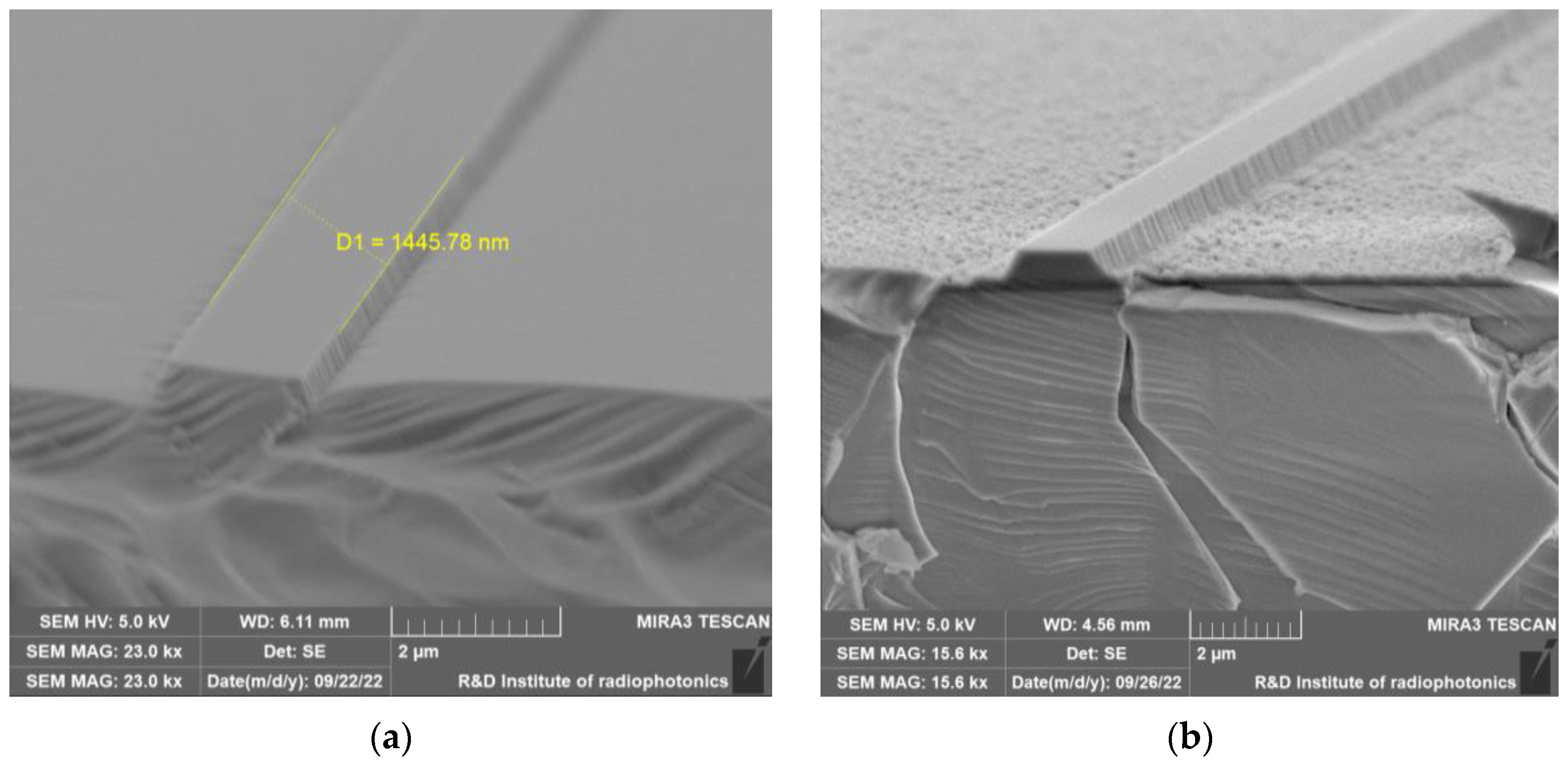

3. Results

4. Discussion

- The mask selectivity was equal to 1:5.3 during the etching with recipe #13, and after the reduction in the pressure during the etching with recipe #14, the mask selectivity improved to 1:8.

- The surface roughness in the near-waveguide region dramatically increased when recipe #14 was used.

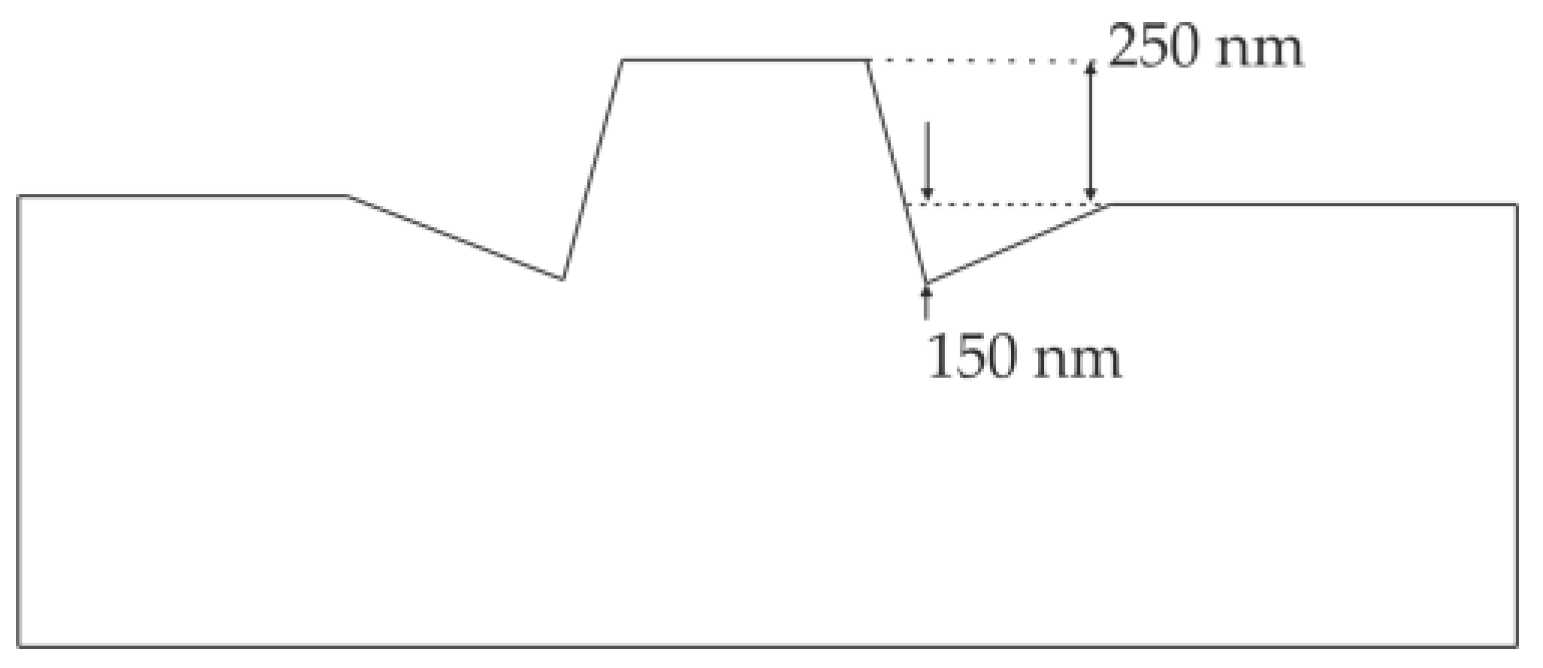

- During the etching with recipe #13, microtrenches were formed along the waveguide base. A schematic representation of the waveguide profile obtained with recipe #13 is shown in Figure 7.

- Diffusion of the fluorine radicals from the plasma to the sample surface via a plasma sheath.

- Adsorption of fluorine radicals on the surface of the LiNbO3.

- Diffusion of adsorbed atoms into the near-surface layer.

- The chemical reaction of fluorine with Li, Nb and O atoms and the formation of volatile fluorides and oxyfluorides (NbF5, NbOF3, OF2) and non-volatile LiF.

- Swelling of the near-surface layer due to the accumulation of volatile compounds [23].

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Han, H.; Yang, F.; Liu, C.; Wang, Z.; Jiang, Y.; Chai, G.; Ruan, S.; Xiang, B. High-Performance Electro-Optical Mach–Zehnder Modulators in a Silicon Nitride—Lithium Niobate Thin-Film Hybrid Platform. Photonics 2022, 9, 500. [Google Scholar] [CrossRef]

- Project LOLIPOP Officially Integrated at Lionix International. Available online: https://www.lionix-international.com/about-us/news/project-lolipop-officially-inaugurated/ (accessed on 5 December 2022).

- CORDIS EU Research Results. European Electro-Optic and Nonlinear PIC Platform Based on Lithium Niobate. Available online: https://cordis.europa.eu/project/id/101016138 (accessed on 5 December 2022).

- Wu, R.; Wang, M.; Xu, J.; Qi, J.; Chu, W.; Fang, Z.; Zhang, J.; Zhou, J.; Qiao, L.; Chai, Z.; et al. Long Low-Loss-Litium Niobate on Insulator Waveguides with Sub-Nanometer Surface Roughness. Nanomaterials 2018, 8, 910. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Fang, Z.; Zhou, J.; Liang, Y.; Zhou, Y.; Wang, Z.; Liu, J.; Huang, T.; Bao, R.; Yu, J.; et al. On-Chip Integrated Yb3+-Doped Waveguide Amplifiers on Thin Film Lithium Niobate. Micromachines 2022, 13, 865. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Liu, Y.; Tu, D.; Yu, Z.; Wei, Q.; Li, Z. Linearity-Enhanced Dual-Parallel Mach–Zehnder Modulators Based on a Thin-Film Lithium Niobate Platform. Photonics 2022, 9, 197. [Google Scholar] [CrossRef]

- Hui, H.; Ricken, R.; Sohler, W. Etching of lithium niobate: From ridge waveguides to photonic crystal structures. In Proceedings of the ECIO 14th European Conference on Integrated Optics, Eindhoven, The Netherlands, 11 June 2008. [Google Scholar]

- Ulliac, G.; Calero, V.; Ndao, A.; Baida, F.I.; Bernal, M.-P. Argon plasma inductively coupled plasma reactive ion etching study for smooth sidewall thin film lithium niobate waveguide application. Opt. Mater. 2016, 53, 1–5. [Google Scholar] [CrossRef]

- Krasnokutska, I.; Tambasco, J.-L.J.; Peruzzo, A. Ultra-low loss photonic circuits in lithium niobate on insulator. Opt. Express 2018, 26, 897–904. [Google Scholar] [CrossRef]

- Gui, L.; Hu, H.; Garcia-Granda, M.; Sohler, W. Local periodic poling of ridges and ridge waveguides on X-and Y-Cut LiNbO3 and its application for second harmonic generation. Opt. Express 2009, 17, 3923–3928. [Google Scholar] [CrossRef]

- Aryal, A.; Stricklin, I.; Behzadirad, M.; Branch, D.W.; Siddiqui, A.; Busani, T. High-Quality Dry Etching of LiNbO3 Assisted by Proton Substitution through H2-Plasma Surface Treatment. Nanomaterials 2022, 12, 2836. [Google Scholar] [CrossRef]

- Deng, J.; Guangyuan, S.; Danner, A.J. Dry etching of LiNbO3 using inductively coupled plasma. In Proceedings of the 2010 Photonics Global Conference, Orchard, Singapore, 14 December 2010. [Google Scholar]

- Deng, J.; Wei, J.; Guangyuan, S.; Son, J.; Yang, H.; Danner, A.J. Deep anisotropic LiNbO3 etching with SF6/Ar inductively coupled plasmas. J. Vac. Sci. Technol. B 2012, 30, 011208. [Google Scholar] [CrossRef]

- Pal, S.; Das, B.K. Fabrication of ridge waveguide in X-cut LiNbO3 for nonlinear optic applications. In Proceedings of the Photonics 2010: Tenth International Conference on Fiber Optics and Photonics, 8173, Guwahati, India, 23 August 2011. [Google Scholar] [CrossRef]

- Ulliac, G.; Guichardaz, B.; Rauch, J.Y.; Queste, S.; Benchbanane, S.; Courjal, N. Ultra-smooth LiNbO3 micro and nano structures for photonic applications. Microelectron. Eng. 2011, 88, 2417–2419. [Google Scholar] [CrossRef]

- Belokrylov, M.E.; Kozlov, A.A.; Karnaushkin, P.V.; Konstantinov, Y.A.; Ponomarev, R.S.; Turov, A.T. Improving the Selected Stages of Integrated-Optic Chip Structure Formation and Its Interfacing with Optical Fibers. IJEETC 2022, 11, 167–174. [Google Scholar] [CrossRef]

- Siew, S.Y.; Cheung, E.; Liang, H.; Bettiol, A.; Toyoda, N.; Alshehri, B.; Dogheche, Y.; Danner, A.J. Ultra-low loss ridge waveguides on lithium niobate via argon ion milling and gas clustered ion beam smoothening. Opt. Express 2018, 26, 4421–4430. [Google Scholar] [CrossRef] [PubMed]

- Kostritskii, S.M.; Korkishko, Y.N.; Fedorov, V.A.; Mitrokhin, V.P.; Sevostyanov, O.G.; Chirkova, I.M.; Stepanenko, O.; De Micheli, M. Subsurface disorder and electro-optical properties of proton-exchanged LiNbO3 waveguides produced by different techniques. J. Eur. Opt. Soc.-Rapid Public 2014, 9, 14055. [Google Scholar] [CrossRef]

- Korkishko, Y.N.; Fedorov, V.A.; Kostritskii, S.M.; Alkaev, A.N.; Maslennikov, E.I.; Paderin, E.M.; Apraksin, D.V.; Laurell, F. Proton exchanged LiNbO3 and LiTaO3 optical waveguides and integrated optic devices. Microelectron. Eng. 2003, 69, 228–236. [Google Scholar] [CrossRef]

- Hu, H.; Milenin, A.P.; Wehrspohn, R.B.; Hermann, H.; Sohler, W. Plasma etching of proton-exchanged lithium niobate. J. Vac. Sci. Technol. A 2006, 24, 1012–1015. [Google Scholar] [CrossRef]

- Nagata, H.; Mitsugia, N.; Shima, K.; Tamai, M.; Haga, E.M. Growth of crystalline LiF on CF4 plasma etched LiNbO3 substrates. J. Cryst. Growth 1998, 187, 573–576. [Google Scholar] [CrossRef]

- Shima, K.; Mitsugi, N.; Nagata, H. Surface precipitates on single crystal LiNbO3 after dry etching by CHF3 plasma. J. Mater. Res. 1998, 13, 527–529. [Google Scholar] [CrossRef]

- Gulyaev, V.V.; Dikerev, J.I.; Rubinstein, V.M.; Tsvetkov, S.M.; Bormontov, E.N. High-rate plasma chemical etching of lithium niobate. Condens. Matter Interphases 2010, 12, 360–368. [Google Scholar]

- Dong, P.; Qian, W.; Liao, S.; Liang, H.; Kung, C.; Feng, N.; Shafiiha, R.; Fong, J.; Feng, D.; Krishnamoorthy, A.; et al. Low loss shallow-ridge silicon waveguides. Opt. Express 2010, 18, 14474–14479. [Google Scholar] [CrossRef]

- Barbarin, Y.; Leijtens, X.J.M.; Bente, E.A.J.M.; Louzao, C.M.; Kooiman, J.R.; Smit, M.K. Extremely small AWG demultiplexer fabricated on InP by using a double-etch process. IEEE Photon. Technol. Lett. 2004, 16, 2478–2480. [Google Scholar] [CrossRef]

- Ciminelli, C.; Dell’Olio, F.; Passaro, V.M.N.; Armenise, M.N. Fully three-dimensional accurate modeling of scattering loss in optical waveguides. Opt. Quantum Electron. 2009, 41, 285–298. [Google Scholar] [CrossRef]

- Kim, D.J.; Lee, J.-M.; Song, J.H.; Pyo, J.; Kim, G. Crosstalk reduction in a shallow-etched silicon nanowire AWG. IEEE Photon. Technol. Lett. 2008, 20, 1615–1617. [Google Scholar] [CrossRef]

- Hunsperger, R.G. Losses in optical waveguides. In Integrated Optics: Theory and Technology, 6th ed.; Springer: New York, NY, USA, 2009; pp. 107–128. [Google Scholar]

- Zelmon, D.E.; Small, D.L.; Jundt, D. Infrared corrected Sellmeier coefficients for congruently grown lithium niobate and 5 mol.% magnesium oxide—Doped lithium niobate. JOSA B 1997, 14, 3319–3322. [Google Scholar] [CrossRef]

- Tan, C.Z. Determination of refractive index of silica glass for infrared wavelengths by IR spectroscopy. J. Non-Cryst. Solids 1998, 223, 158–163. [Google Scholar] [CrossRef]

- Witmer, J.D.; Valery, J.A.; Arrangoiz-Arriola, P.; Sarabalis, C.J.; Hill, J.T.; Safavi-Naeini, A.H. High-Q photonic resonators and electro-optic coupling using silicon-on-lithium-niobate. Sci. Rep. 2017, 7, 46313. [Google Scholar] [CrossRef]

- Watanabe, M.; Shaw, D.M.; Collins, G.J. Reduction of microtrenching and island formation in oxide plasma etching by employing electron beam charge neutralization. Appl. Phys. Lett. 2001, 79, 2698–2700. [Google Scholar] [CrossRef]

- Racka-Szmidt, K.; Stonio, B.; Żelazko, J.; Filipiak, M.; Sochacki, M. A review: Inductively coupled plasma reactive ion etching of silicon carbide. Materials 2021, 15, 123. [Google Scholar] [CrossRef]

- Mohammadi, Z.; Shah, V.A.; Jennings, M.R.; Fisher, C.A.; Mawby, P.A. Elimination of microtrenching in trenches in 4H-silicon carbide using shadow masking. Mater. Sci. Forum 2015, 821–823, 533–536. [Google Scholar] [CrossRef]

- Atomic Radius of Chemical Elements. Available online: https://material-properties.org/atomic-radius-of-chemical-elements/ (accessed on 1 December 2022).

- Kushner, M.J. Monte-Carlo simulation of electron properties in rf parallel plate capacitively coupled discharges. J. Appl. Phys. 1983, 54, 4958–4965. [Google Scholar] [CrossRef]

- Hoekstra, R.J.; Kushner, M.J. Predictions of ion energy distributions and radical fluxes in radio frequency biased inductively coupled plasma etching reactors. J. Appl. Phys. 1996, 79, 2275–2286. [Google Scholar] [CrossRef]

- Spencer, O.S.; Plint, C.A. Formation energy of individual cation vacancies in LiF and NaCl. J. Appl. Phys. 1969, 40, 168–172. [Google Scholar] [CrossRef]

- Mushinsky, S.; Petukhov, I.; Kichigin, V.; Sidorov, D.; Semenova, O.; Ponomarev, R. Influence of the Pretreatment of Lithium Niobate Surface with Plasma and Ultraviolet Radiation on the Proton Exchange in Benzoic Acid Melts. In Proceedings of the IEEE 22nd International Conference of Young Professionals in Electron Devices and Materials (EDM), Souzga, The Altai Republic, Russia, 16 August 2021; pp. 283–286. [Google Scholar] [CrossRef]

- Eltoukhy, A.H.; Greene, J.E. Diffusion enhancement due to low-energy ion bombardment during sputter etching and deposition. J. Appl. Phys. 1980, 51, 4444–4452. [Google Scholar] [CrossRef]

| Ref. # | Plasma Type | Etching Gases | Profile Quality | LiNbO3 |

|---|---|---|---|---|

| [7] | ICP | C4F8/He (1:1) | Nearly vertical sidewalls; high surface roughness (because of the high level of LiF redeposition) | X-cut |

| [8] | ICP/RIE | Ar | Sidewall angle ~70°; significant surface roughness | X-cut |

| [9] | ICP/RIE | CHF3/Ar | Sidewall angle ~75°; relatively smooth surfaces (RMS surface roughness <2 nm) | Z-cut |

| [10] | ICP | C4F8/He | Nearly vertical sidewalls; very high surface roughness | X-cut |

| [11] | ICP | CHF3/Ar | Perfect aspect ratio; smooth surfaces (RMS surface roughness = 10.262 nm) | X-cut, PE LiNbO3 |

| [12] | ICP | CHF3/Ar or SF6/Ar | Nearly vertical sidewalls; smooth surfaces | X-cut, PE LiNbO3 |

| [13] | ICP/RIE | SF6/Ar | Sidewall angle ~90°; smooth surfaces | X-cut, PE LiNbO3 |

| [14] | ICP/RIE | SF6/Ar or CHF3/Ar | Nearly vertical sidewalls; significant surface roughness | X-cut |

| [15] | ICP/RIE | CF4/He | Sidewall angle ~75°; smooth surfaces (RMS surface roughness = 10 nm, estimated using SEM observation) | X-cut, PE LiNbO3 |

| [16] | ICP/RIE | SF6/Ar | Relatively high surface roughness | Y-cut |

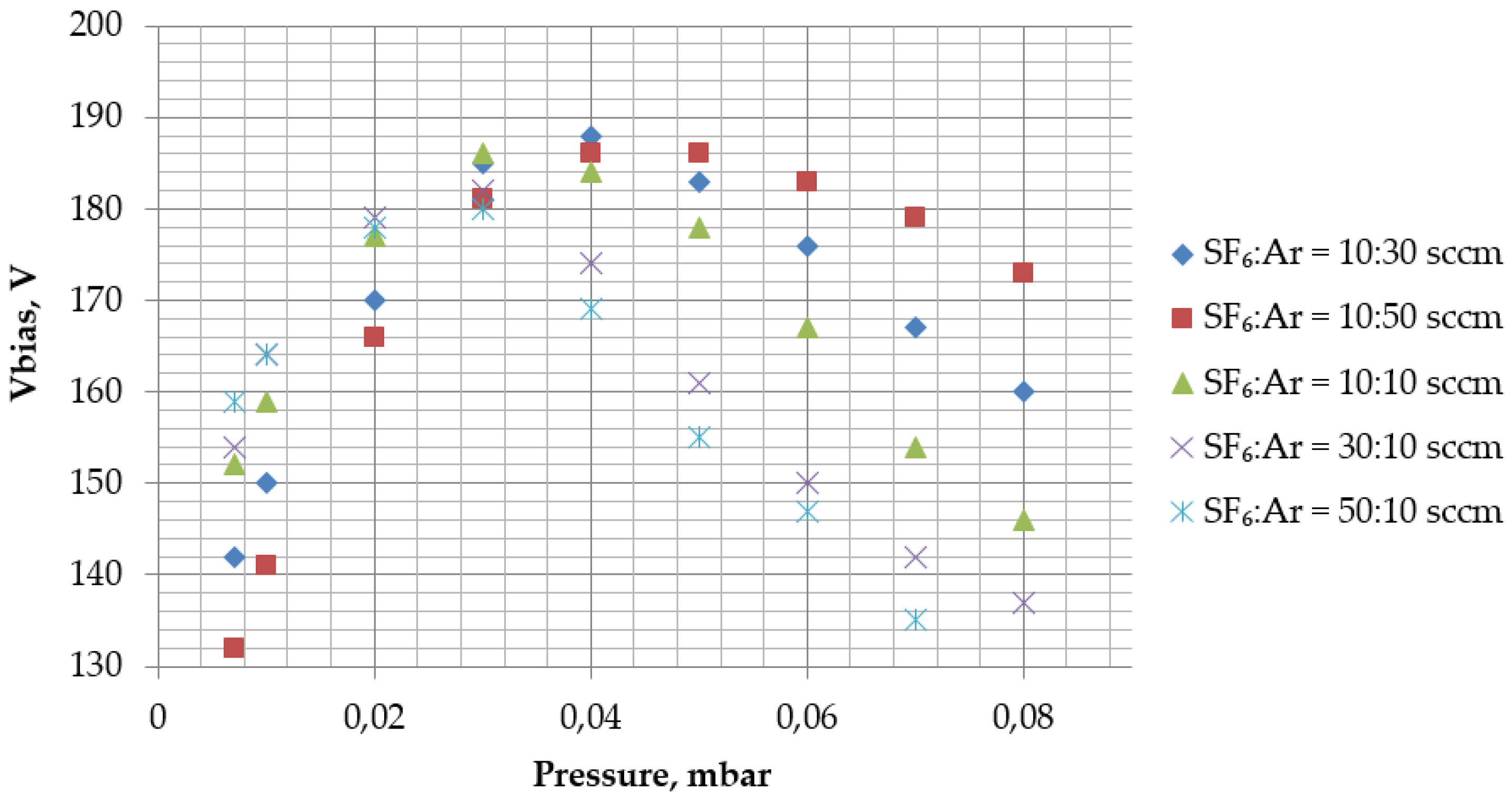

| Recipe | ICP (W) | TCP (W) | P (mbar) | SF6 Flow (sccm) | Ar Flow (sccm) | Sidewall Angle (°) | LER (nm) | Surface Roughness |

|---|---|---|---|---|---|---|---|---|

| 13 | 500 | 100 | 0.03 | 10 | 30 | ~61 | 20–30 | Smooth |

| 14 | 500 | 100 | 0.007 | 10 | 30 | ~75 | 20–30 | High roughness |

| 15 | 500 | 200 | 0.03 | 10 | 30 | ~72 | 20–30 | Relatively smooth |

| 16 | 500 | 100 | 0.03 | 10 | 50 | ~59 | 20–30 | Relatively smooth |

| 17 | 350 | 200 | 0.03 | 10 | 50 | ~58 | 20–30 | Relatively smooth |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kozlov, A.; Moskalev, D.; Salgaeva, U.; Bulatova, A.; Krishtop, V.; Volyntsev, A.; Syuy, A. Reactive Ion Etching of X-Cut LiNbO3 in an ICP/TCP System for the Fabrication of an Optical Ridge Waveguide. Appl. Sci. 2023, 13, 2097. https://doi.org/10.3390/app13042097

Kozlov A, Moskalev D, Salgaeva U, Bulatova A, Krishtop V, Volyntsev A, Syuy A. Reactive Ion Etching of X-Cut LiNbO3 in an ICP/TCP System for the Fabrication of an Optical Ridge Waveguide. Applied Sciences. 2023; 13(4):2097. https://doi.org/10.3390/app13042097

Chicago/Turabian StyleKozlov, Andrei, Dmitrii Moskalev, Uliana Salgaeva, Anna Bulatova, Victor Krishtop, Anatolii Volyntsev, and Alexander Syuy. 2023. "Reactive Ion Etching of X-Cut LiNbO3 in an ICP/TCP System for the Fabrication of an Optical Ridge Waveguide" Applied Sciences 13, no. 4: 2097. https://doi.org/10.3390/app13042097

APA StyleKozlov, A., Moskalev, D., Salgaeva, U., Bulatova, A., Krishtop, V., Volyntsev, A., & Syuy, A. (2023). Reactive Ion Etching of X-Cut LiNbO3 in an ICP/TCP System for the Fabrication of an Optical Ridge Waveguide. Applied Sciences, 13(4), 2097. https://doi.org/10.3390/app13042097