Bolt Loosening Detection Using Key-Point Detection Enhanced by Synthetic Datasets

Abstract

:1. Introduction

- Many of these methods often have more critical requirements on the camera angle of view or the background where the bolt is located.

- In order to locate the initial condition of the bolts, many methods require manual marks on the bolts or connection plates. This is a significant amount of work considering the large number of bolts applied to engineering projects. Additionally, these marks will gradually fade or even eventually miss out with time, causing them to be unrecognizable.

- For methods using deep learning algorithms for bolt detection, it is well known that establishing sufficiently large datasets is a time and labor-consuming process, especially for key-point detection.

- The accuracy and robustness of many methods are evaluated when detecting one single bolt, while, actually, when used in buildings or mechanical structures, the bolts are often in the form of a matrix of connection plates.

- A virtual experiment platform is built based on Unreal Engine to solve the problem of laborious manual annotation in dataset establishment. The experimental platform can achieve automatic changes to the camera view, automatic saving of bolt images, and automatic labeling of key points. The platform can quickly build a large-scale synthetic dataset and significantly improve the efficiency of image dataset establishment;

- Based on the latest key-point detection technology YOLOv7-pose [37], using different capacities of datasets, we can verify the effectiveness of the algorithm in the bolt key-point detection and verify the effectiveness of the synthetic dataset to improve the accuracy of the model;

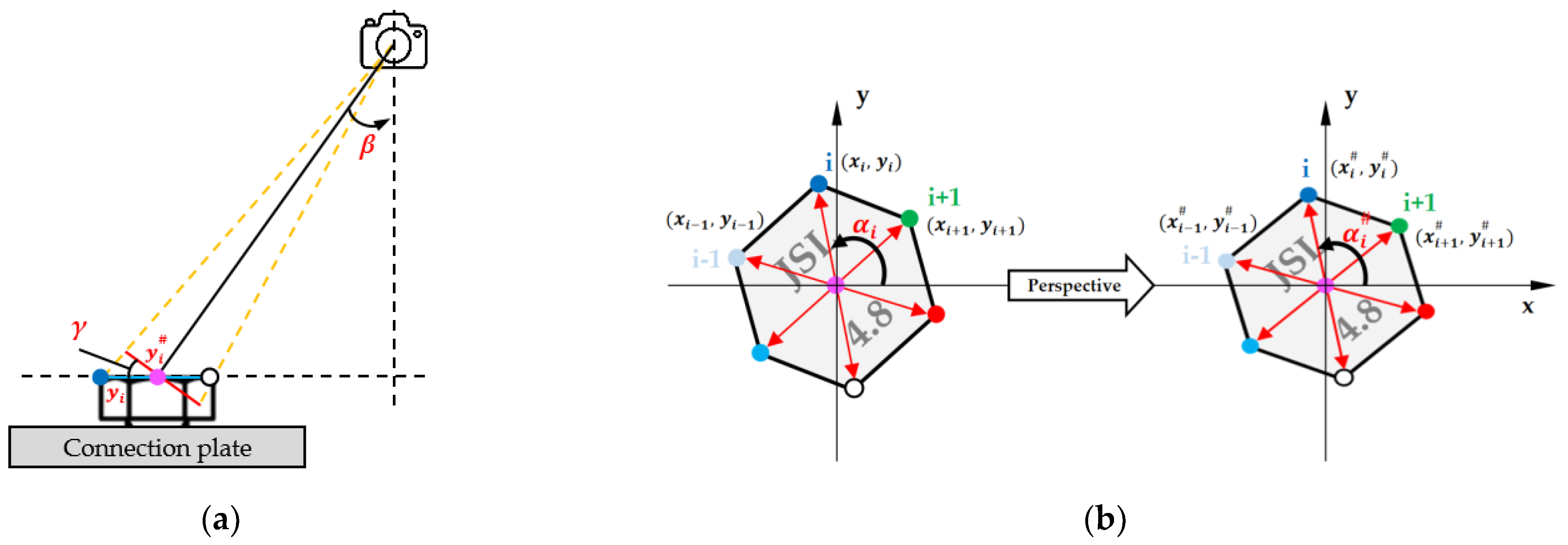

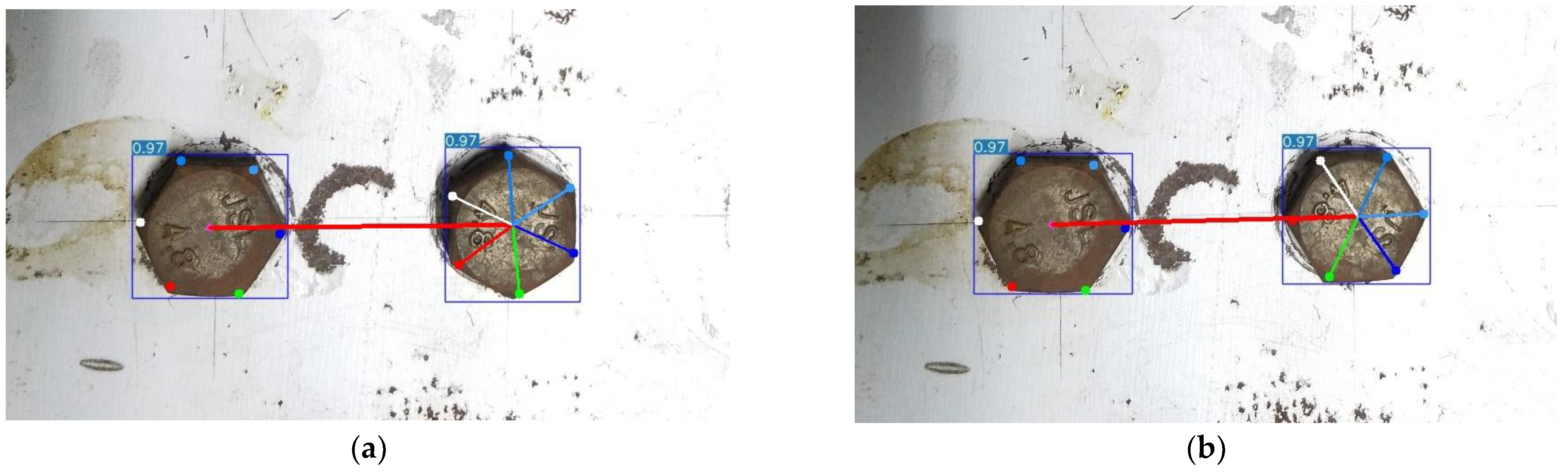

- Based on the information of key points obtained from the detection, a bolt loosening angle calculation method is proposed according to the position relationship between neighboring bolts. This method avoids the necessity of extra manual marks and can correct the perspective errors caused by camera view angle changes. Additionally, the accuracy and stability of the method are verified.

2. Materials and Methods

2.1. Overview

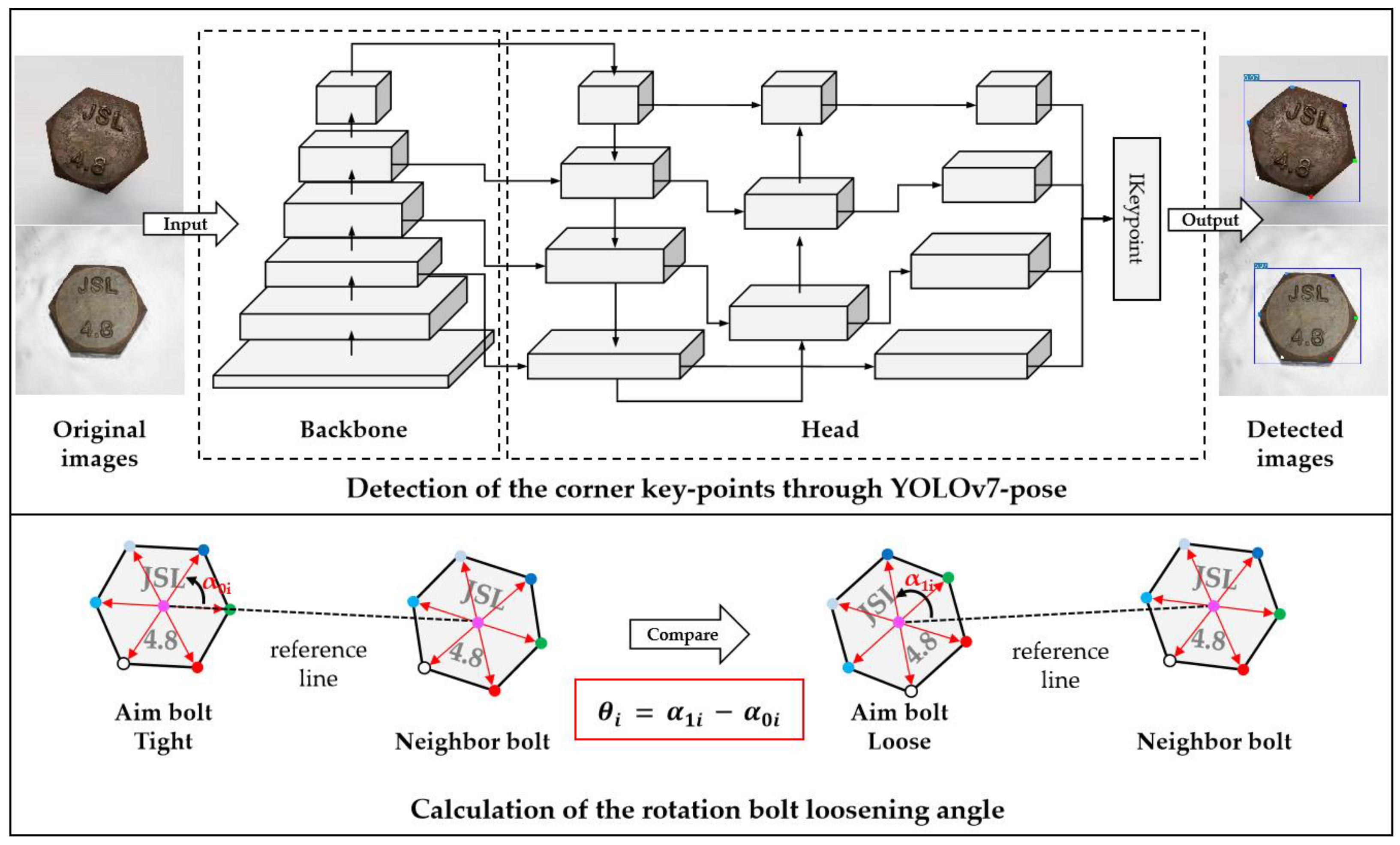

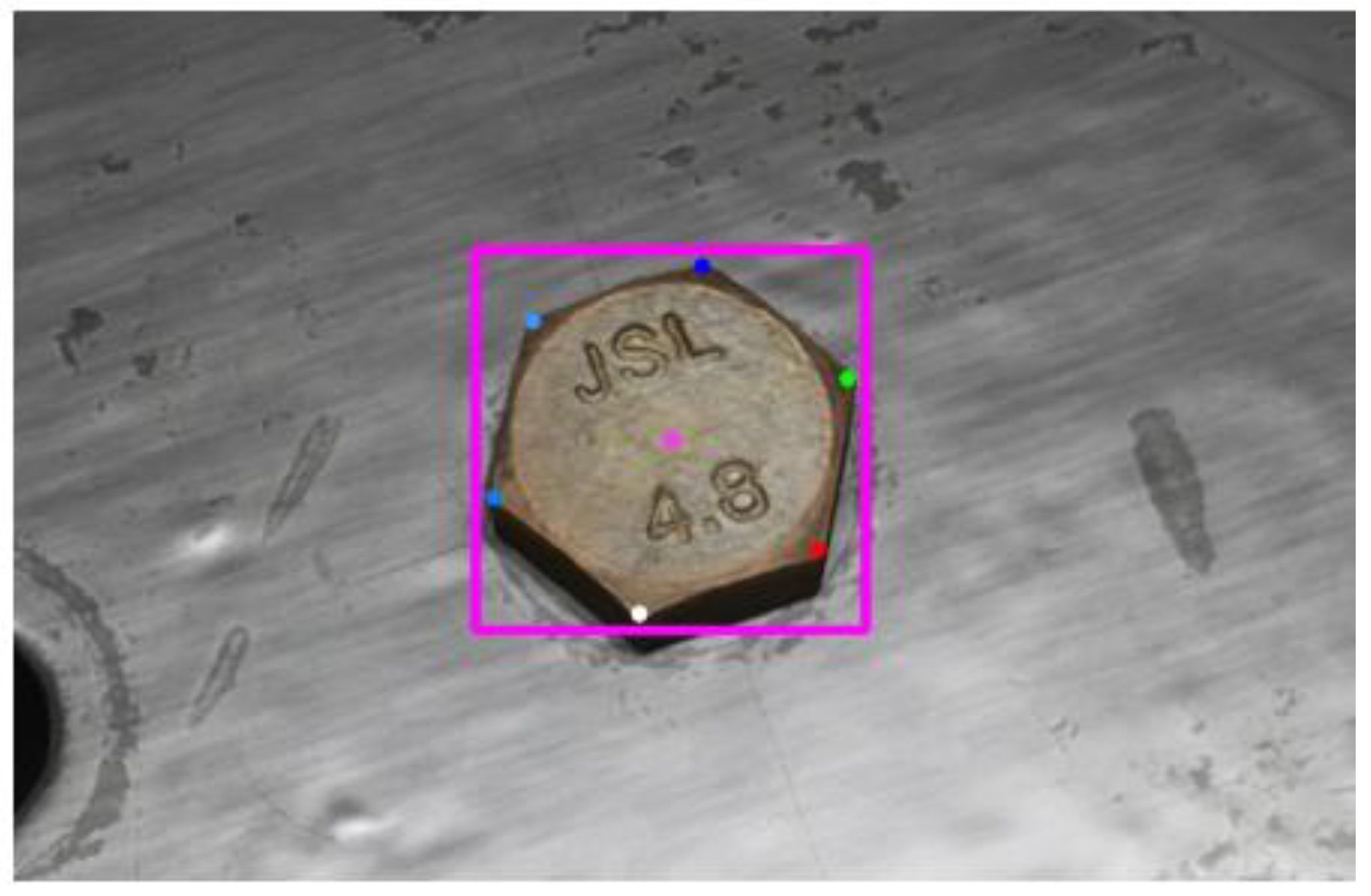

- The detection of the corner key points through YOLOv7-pose. The average coordinates of 6 corner key points are regarded as the center of each bolt;

- According to the position relationship between neighboring the bolts, calculate the rotation angles for the loose bolts.

2.2. Datasets Establishment

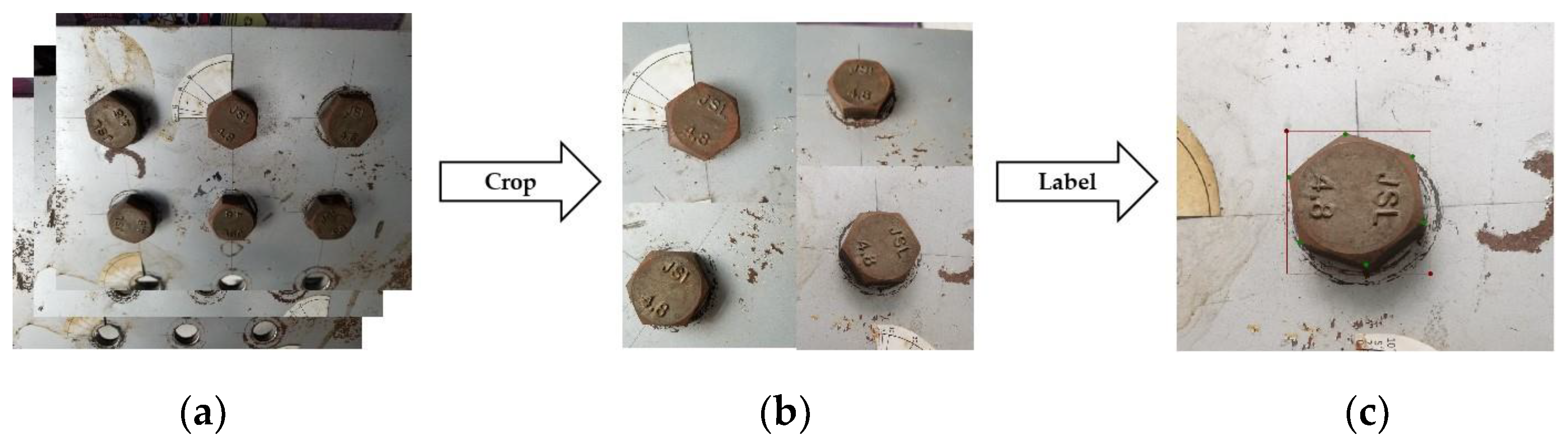

2.2.1. Real Datasets

2.2.2. Synthetic Datasets

- (1)

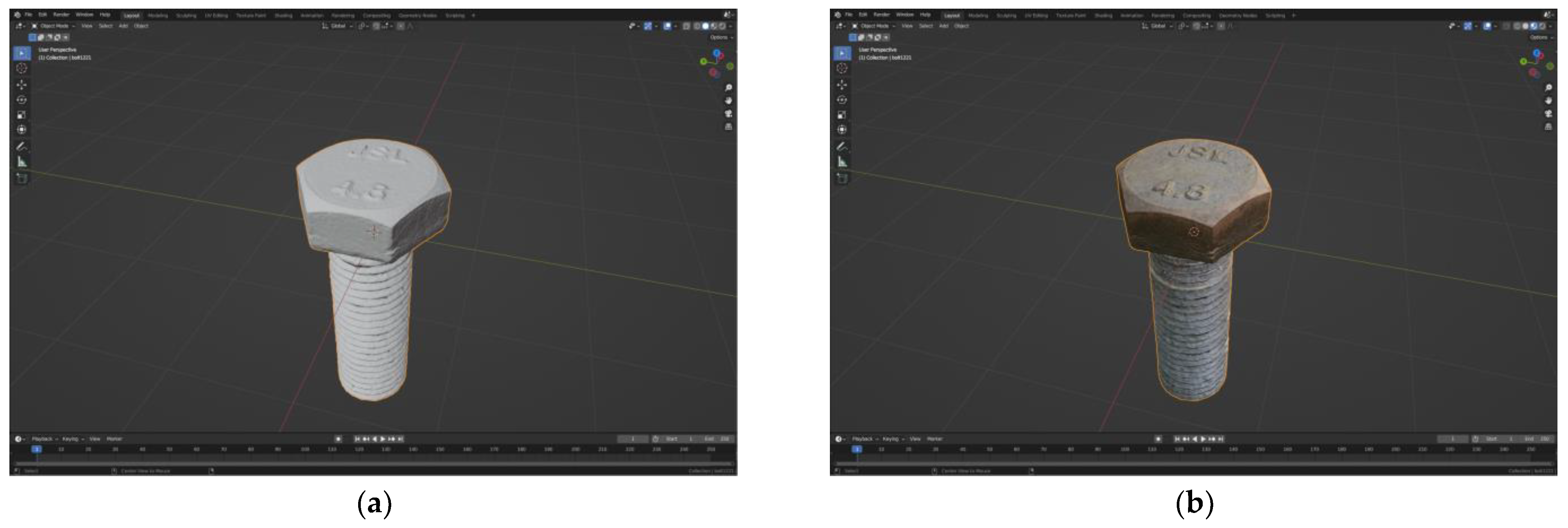

- Bolt high-fidelity modeling

- (2)

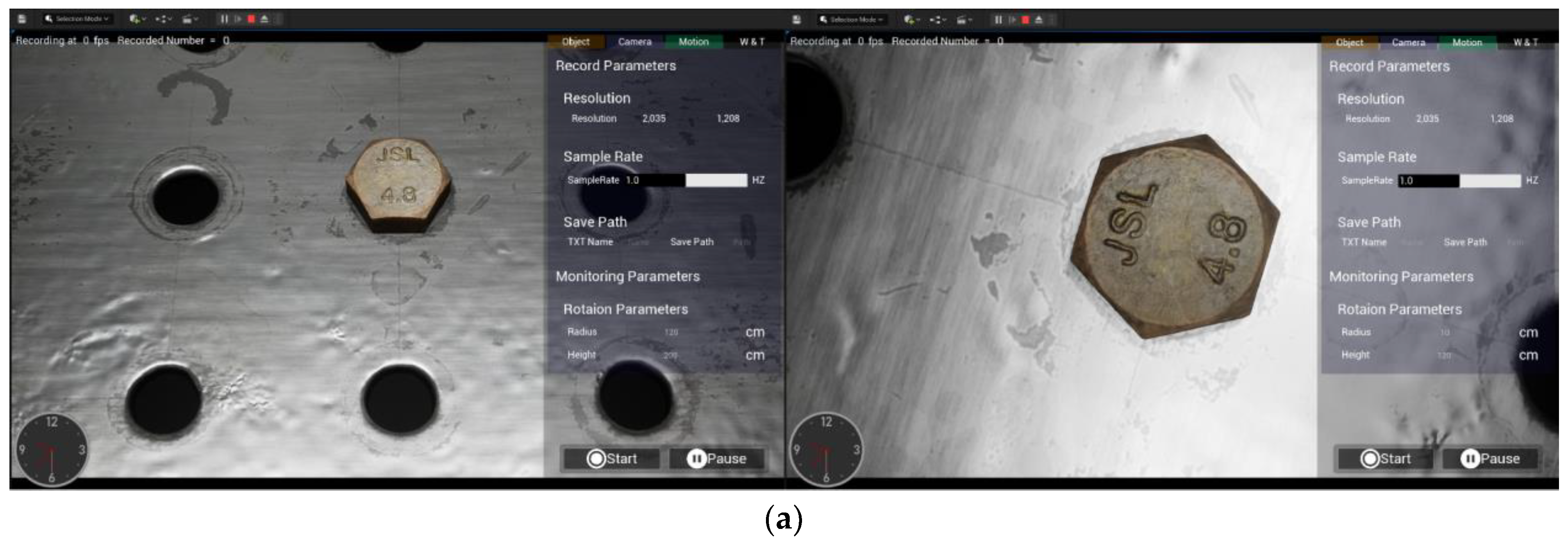

- Virtual experiment platform

- Set the height and view angle of the camera, adjust the rotation angle of the bolt, and keep the camera aligned with the bolt to obtain images of the bolt from different angles, as shown in Figure 8.

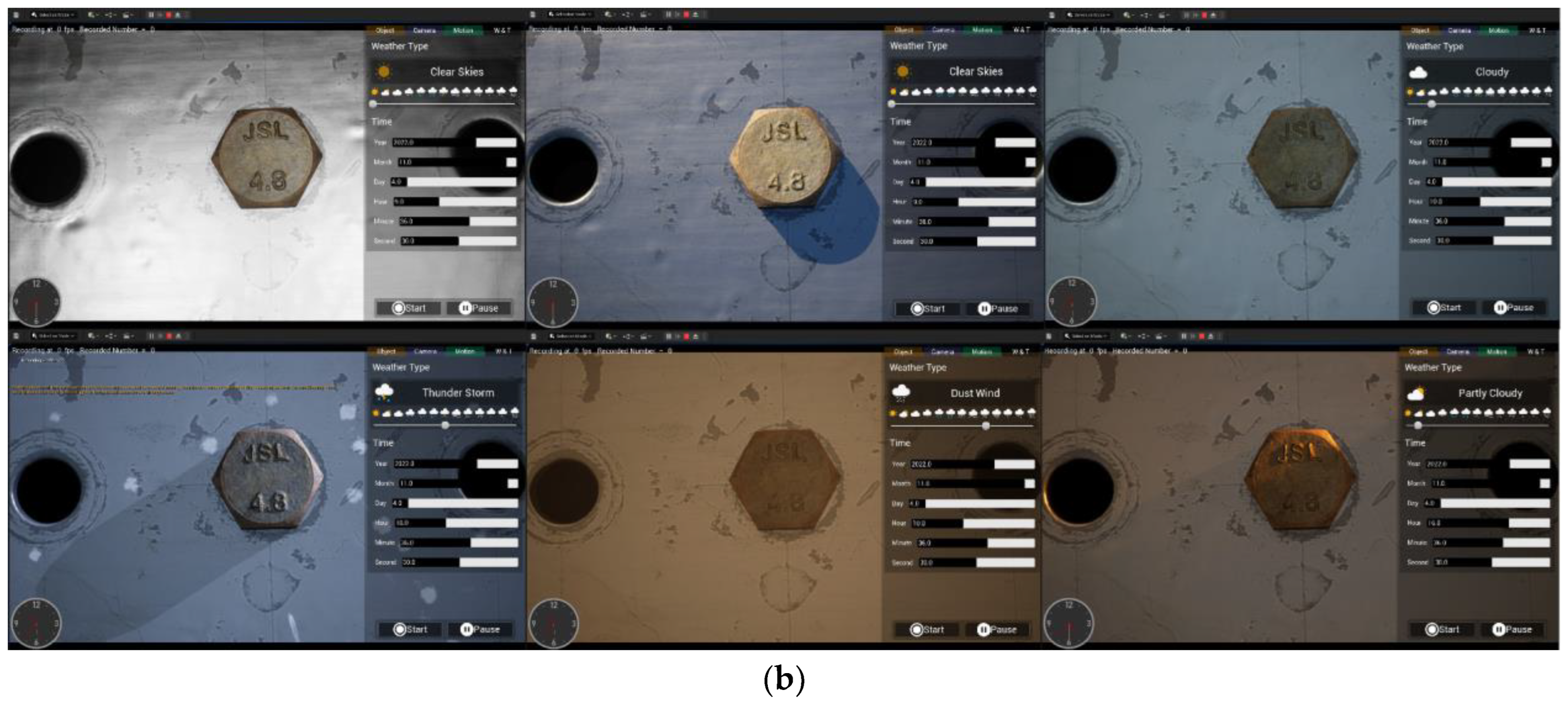

- Change the different simulated weather and time in the site to obtain images of the bolts under different lighting conditions, as shown in Figure 8.

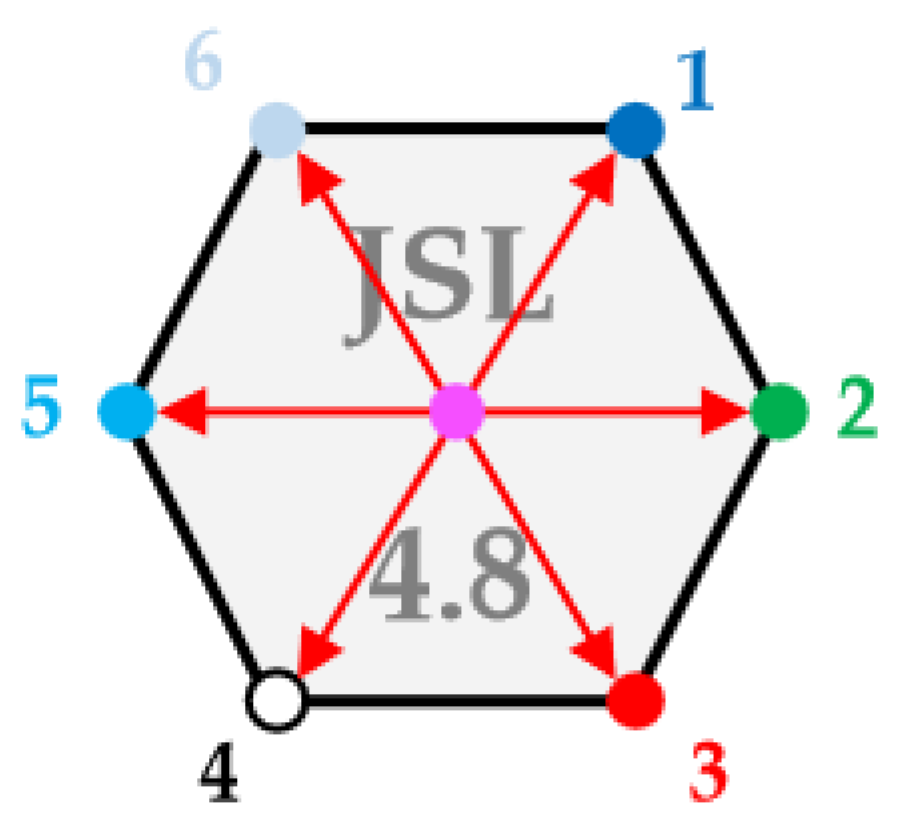

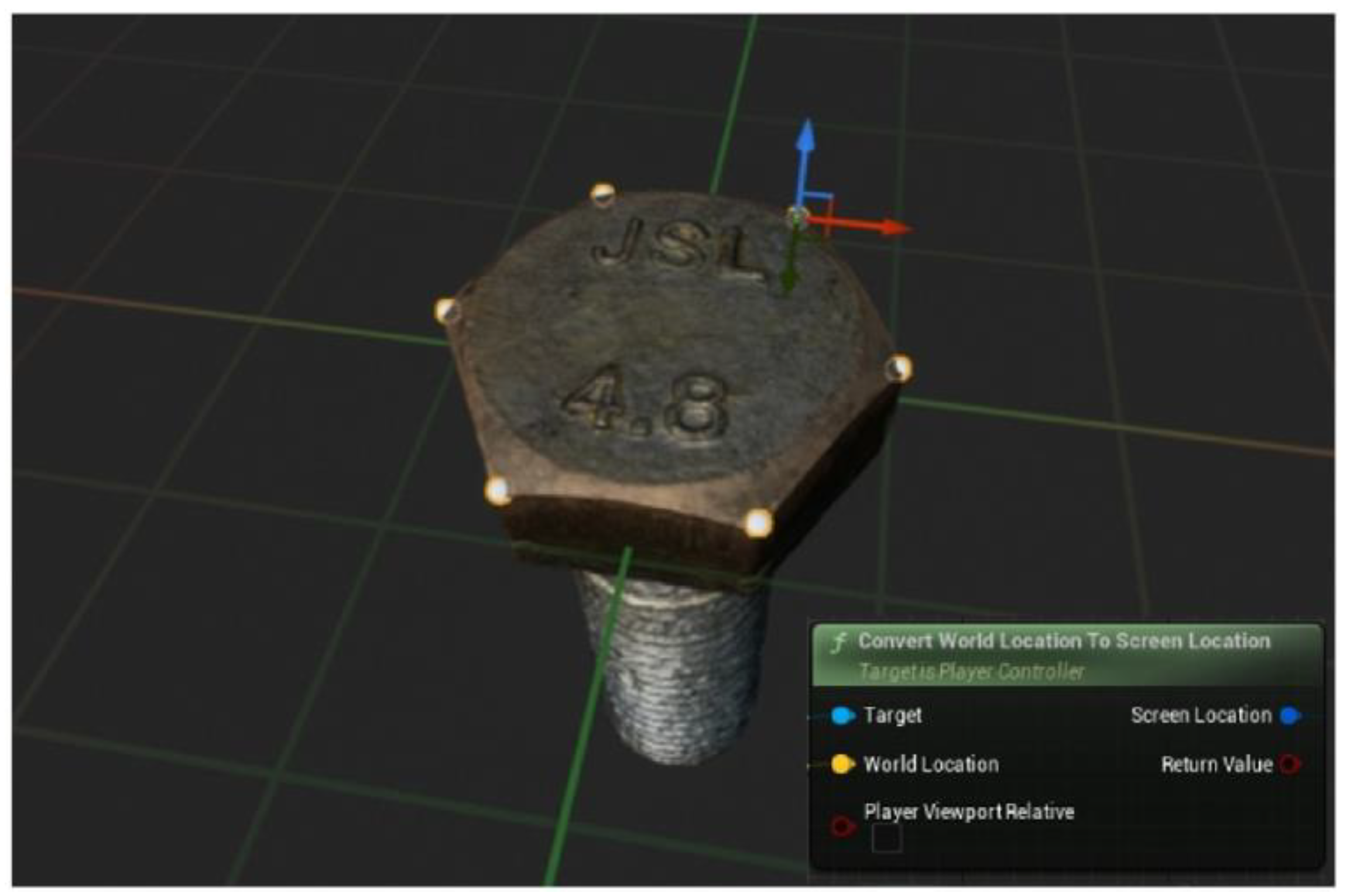

- Six invisible marker objects are fixed on the six corner points of the bolt to label the key points, and the order of the markers is the same as the order of the key points, as shown in Figure 5. Additionally, through the coordinate conversion, the coordinates of the markers in the 3D scene are converted to the coordinates in the camera screen (this function is mainly realized by the function “Convert World Location to Screen Location”, which comes with ue5), as shown in Figure 9.

- Let the camera rotate around the bolt at different angles and automatically take screenshots of the real-time rendered screen by a set time. While capturing the screenshot, the coordinates of the marked objects in the current screen are automatically saved.

- (3)

- Data processing

2.3. Training

2.3.1. YOLOv7-Pose

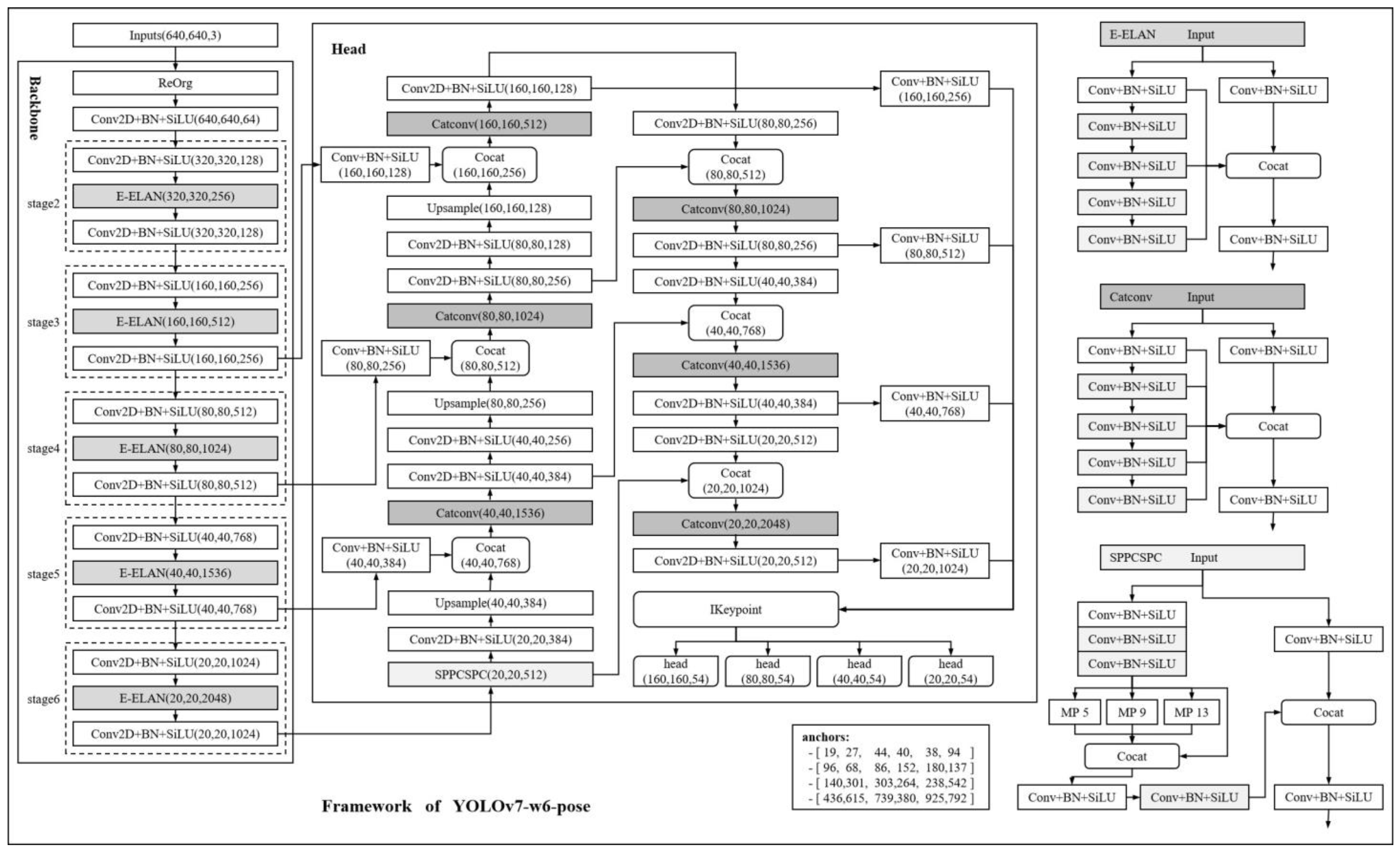

- The optimization of the loss function for evaluating the prediction. The target key-point similarity (OKS) is a common index to evaluate key points. L1 losses have traditionally been used to detect key points. However, L1 losses are not necessarily suitable for optimal OKS. Similarly, L1 losses do not take into account the scale of the target or the type of key points. Since heat map is a probabilistic map, it is not possible to use OKS as a loss in a pure heat map-based approach. OKS can be used as a loss function only when regressing to the key-point location. Therefore, the YOLOv7-pose uses scale-normalized L1 losses to perform key-point regression and obtain excellent accuracy.

- The optimization of the input layer structure. The YOLOv7, relative to YOLOv5, innovatively uses a multi-input stacked convolution structure to optimize the feature extraction in both the backbone and the enhanced feature extraction part (head). Additionally, the number of feature layers is increased from 3 to 4 on YOLOv7-pose, which improves the feature extraction ability of the algorithm at different scales. Finally, the extracted 4 feature maps are classified and regressed using the IKeypoint detection head to obtain the locations of key points. The framework of the YOLOv7-pose is shown in Figure 11.

2.3.2. Training Process

2.4. Calculation of Bolt Loosening Angle

2.4.1. Bolt Corner Points Detection and Bolt Center Calculation

2.4.2. Bolt Loosening Angle Calculation

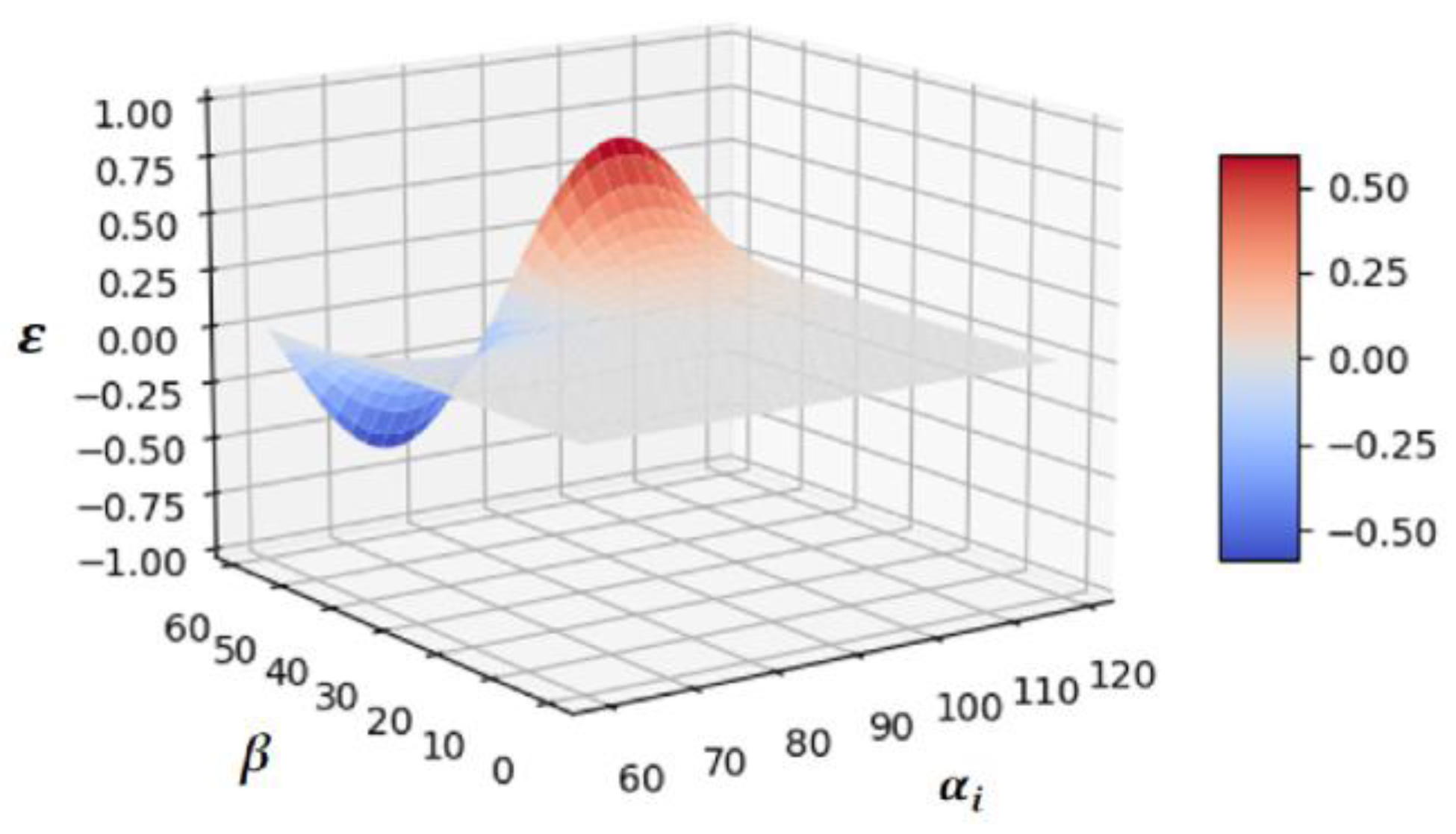

2.4.3. Analysis of Perspective Errors

- The perspective error increases as increases and is almost zero at [0, 20];

- With constant , the error shows a sinusoidal variation as varies. When is equal to 75 or 105, the error is taken to the maximum value;

- As moves closer to 90, the error becomes larger more rapidly;

- When is less than 60, the error angle is less than 0.58; when is less than 45, the error angle is less than 0.09.

3. Results

3.1. Training Results

3.1.1. Training Performance

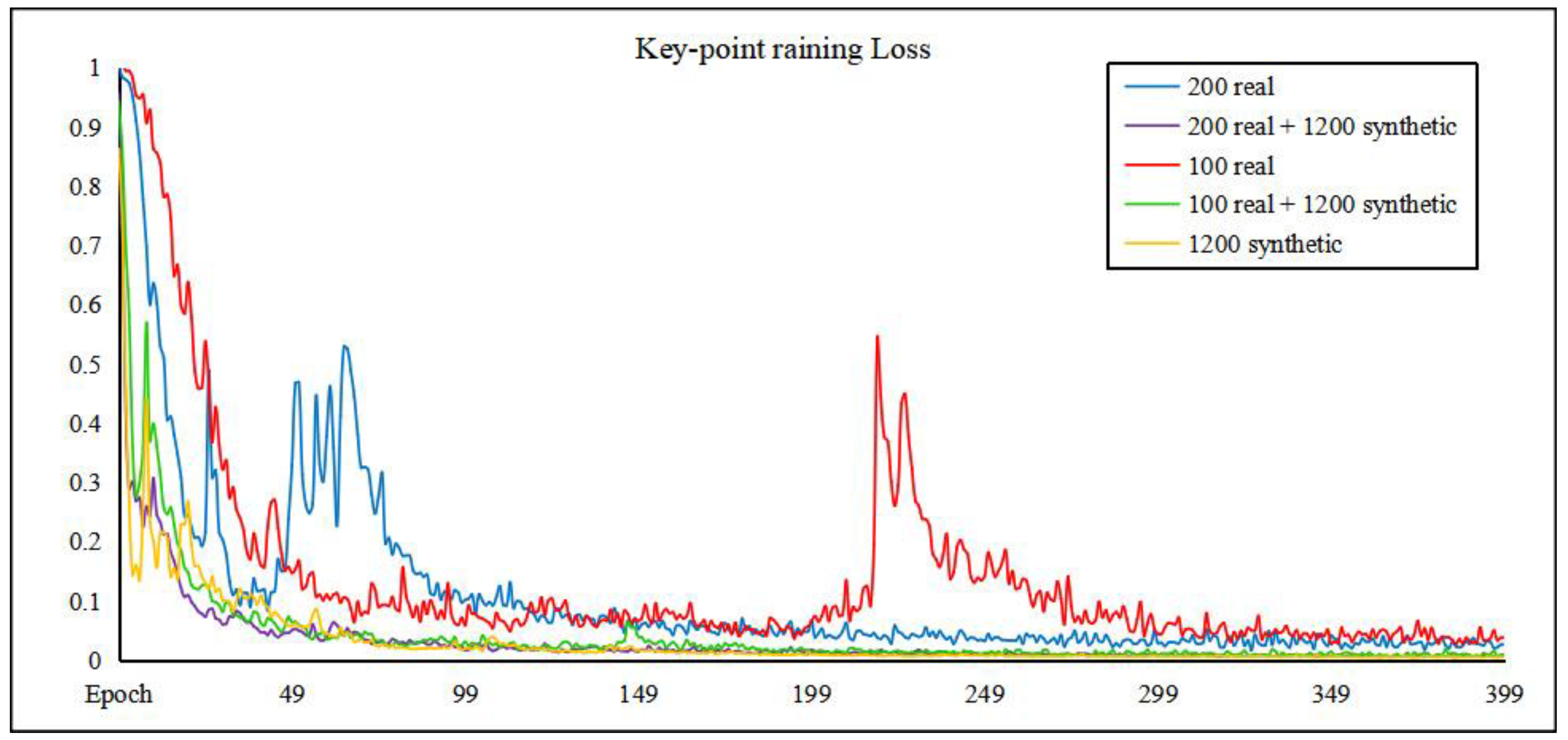

- In the case of a small volume of images in the dataset, when the training is close to convergence, there is a situation where the loss does not fall steadily but suddenly rises, while the mean precision also suddenly falls accordingly, but as the epoch continues to increase, the loss is still able to converge;

- As the dataset increases, the unstable loss decline only occurs in the early stages of training. Additionally, the larger the dataset is, the faster the training converges;

- The “100 real + 1200 synthetic” dataset performs better than the “200 real” dataset in terms of stability and accuracy during training.

3.1.2. Training Effects

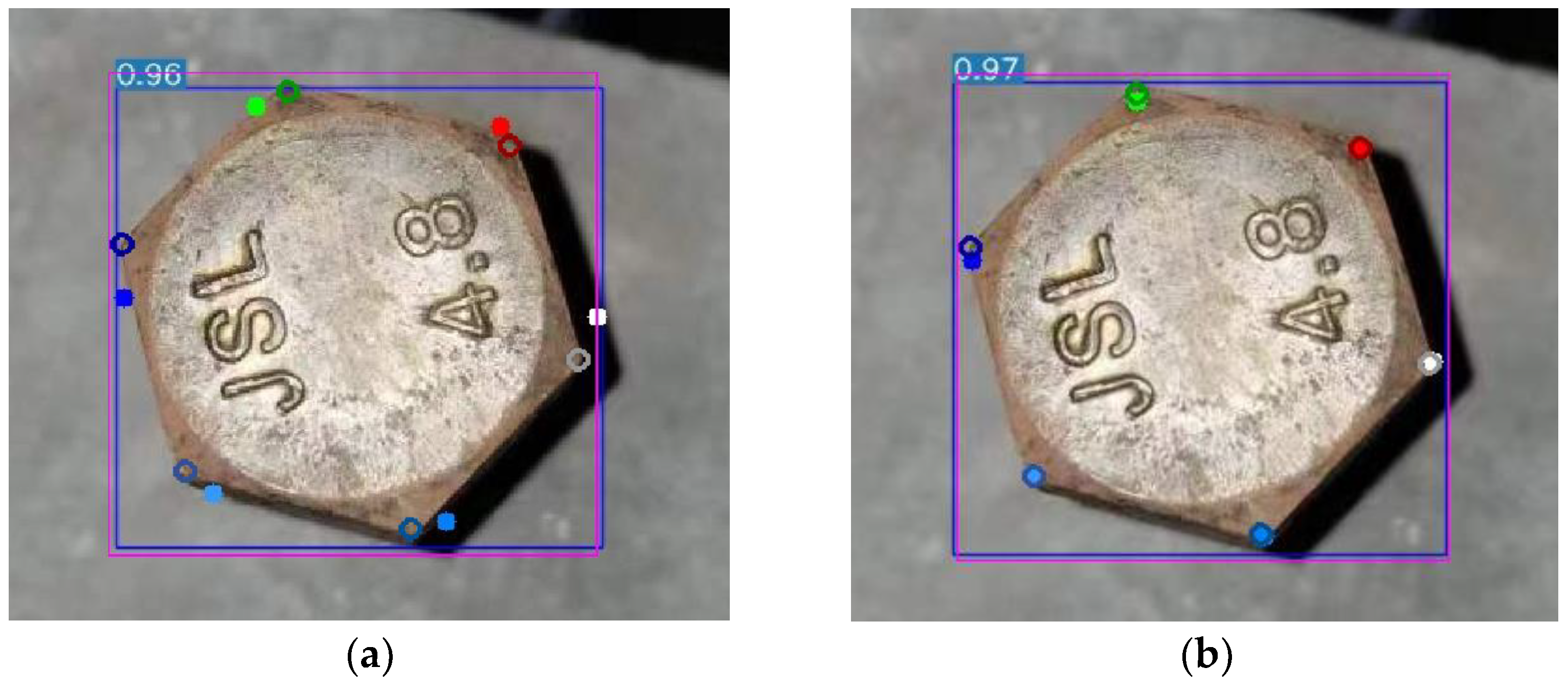

- The YOLOv7-pose model has a very excellent detection performance; even if only 100 images are used for training, it can still obtain a high detection correct rate;

- Without adding real images to the dataset, the model trained from a pure synthetic dataset can identify bolts and key points in real images with relative accuracy when the images are well-lit and clear;

- Compared with Keypoint-RCNN, the YOLOv7-pose shows better performance in the key-point detection correct rate.

- In the detection results of Keypoint-RCNN, there are individual cases where the same corner point is not detected as different and some corner points are not detected correctly, as shown in Figure 19. Such errors would have a significant impact on further angle calculations.

3.1.3. Error Analysis

- The model trained on the “200 real + 1200 synthetic” dataset showed the best performance with not only the smallest error but also the smallest error variance, which is a significant performance improvement compared to the “200 real” model with only real images;

- The performance of the “100 real + 1200 synthetic” model was close to that of the “200 real” model, while the “100 real” model showed poor recognition accuracy;

- Even though the “1200 synthetic” model performed poorly in terms of overall precision, the key-point detection in the images where the bolts were successfully detected did not show large errors, and the accuracy was still relatively good.

- Compared with Keypoint-RCNN, YOLOv7-pose showed better performance with a smaller error and much smaller error variance.

3.2. Result of Bolt Loosening Angle Detection

4. Discussion

- Although the addition of synthetic datasets improves the performance of the model in all aspects of both training and detection, the actual improvement was not as significant as expected. There is still a lot of work ahead before the use of synthetic datasets can fully replace real datasets. This requires greater proficiency in modeling and game engines, as well as the development of deep learning algorithms with better generalization capabilities.

- In order to avoid the use of manual markers, the method in this paper must be used with the neighboring bolt as a reference. However, in some engineering scenarios, there will be situations where only one bolt can be seen. At this time, the proposed method is no longer applicable.

- In actual engineering conditions, when used in buildings or mechanical structures, the bolts are often in the form of a matrix of connection plates. Therefore, the obtained images often have more than two bolts in them. Although the present method is still applicable, the issue of how to efficiently identify and separate neighboring bolts still needs to be addressed in future studies.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bickford, J.; Nassar, S. Handbook of Bolts and Bolted Joints; Taylor & Francis Group: Boca Raton, FL, USA, 1998. [Google Scholar]

- Pan, Y.; Ma, Y.L.; Dong, Y.Q.; Gu, Z.X.; Wang, D.L. A Vision-Based Monitoring Method for the Looseness of High-Strength Bolt. IEEE Trans. Instrum. Meas. 2021, 70, 5013914. [Google Scholar] [CrossRef]

- Huang, J.Y.; Liu, J.H.; Gong, H.; Deng, X.J. A comprehensive review of loosening detection methods for threaded fasteners. Mech. Syst. Signal Process. 2022, 168, 108652. [Google Scholar] [CrossRef]

- Gong, H.; Ding, X.; Liu, J.; Feng, H. Review of research on loosening of threaded fasteners. Friction 2021, 10, 335–359. [Google Scholar] [CrossRef]

- Nikravesh, S.M.Y.; Goudarzi, M. A Review Paper on Looseness Detection Methods in Bolted Structures. Lat. Am. J. Solids Struct. 2017, 14, 2153–2176. [Google Scholar] [CrossRef]

- Miao, R.S.; Shen, R.L.; Zhang, S.H.; Xue, S.L. A Review of Bolt Tightening Force Measurement and Loosening Detection. Sensors 2020, 20, 3165. [Google Scholar] [CrossRef]

- Chaki, S.; Corneloup, G.; Lillamand, I.; Walaszek, H. Combination of longitudinal and transverse ultrasonic waves for in situ control of the tightening of bolts. J. Press. Vessel Technol. 2007, 129, 383–390. [Google Scholar] [CrossRef]

- Chen, D.; Huo, L.; Li, H.; Song, G. A Fiber Bragg Grating (FBG)-Enabled Smart Washer for Bolt Pre-Load Measurement: Design, Analysis, Calibration, and Experimental Validation. Sensors 2018, 18, 2586. [Google Scholar] [CrossRef]

- Meher, U.; Mishra, S.K.; Sunny, M.R. Impedance-based looseness detection of bolted joints using artificial neural network: An experimental study. Struct. Control. Health Monit. 2022, 29, e3049. [Google Scholar] [CrossRef]

- Pal, J.; Sikdar, S.; Banerjee, S.; Banerji, P. A Combined Machine Learning and Model Updating Method for Autonomous Monitoring of Bolted Connections in Steel Frame Structures Using Vibration Data. Appl. Sci. 2022, 12, 11107. [Google Scholar] [CrossRef]

- Hou, X.L.; Guo, W.C.; Ren, S.J.; Li, Y.; Si, Y.; Su, L.Z. Bolt-Loosening Detection Using 1D and 2D Input Data Based on Two-Stream Convolutional Neural Networks. Materials 2022, 15, 6757. [Google Scholar] [CrossRef]

- Ramana, L.; Choi, W.; Cha, Y.J. Automated Vision-Based Loosened Bolt Detection Using the Cascade Detector. In Proceedings of the 35th IMAC Conference and Exposition on Structural Dynamics, Garden Grove, CA, USA, 30 Jnauary–2 February 2017; pp. 23–28. [Google Scholar]

- Nguyen, T.C.; Huynh, T.C.; Ryu, J.Y.; Park, J.H.; Kim, J.T. Bolt-loosening identification of bolt connections by vision image-based technique. In Proceedings of the Nondestructive Characterization and Monitoring of Advanced Materials, Aerospace, and Civil Infrastructure 2016, Las Vegas, NE, USA, 21–24 March 2016. [Google Scholar]

- Cha, Y.J.; You, K.; Choi, W. Vision-based detection of loosened bolts using the Hough transform and support vector machines. Autom. Constr. 2016, 71, 181–188. [Google Scholar] [CrossRef]

- Kong, X.X.; Li, J. An image-based feature tracking approach for bolt loosening detection in steel connections. In Proceedings of the Conference on Sensors and Smart Structures Technologies for Civil, Mechanical, and Aerospace Systems, Denver, CA, USA, 5–8 March 2018. [Google Scholar]

- Kong, X.X.; Li, J. Image Registration-Based Bolt Loosening Detection of Steel Joints. Sensors 2018, 18, 1000. [Google Scholar] [CrossRef]

- Girshick, R.; Donahue, J.; Darrell, T.; Malik, J. Rich feature hierarchies for accurate object detection and semantic segmentation. In Proceedings of the 27th IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Columbus, OH, USA, 23–28 June 2014; pp. 580–587. [Google Scholar]

- Ren, S.Q.; He, K.M.; Girshick, R.; Sun, J. Faster R-CNN: Towards Real-Time Object Detection with Region Proposal Networks. IEEE Trans. Pattern Anal. Mach. Intell. 2017, 39, 1137–1149. [Google Scholar] [CrossRef]

- He, K.M.; Gkioxari, G.; Dollar, P.; Girshick, R. Mask R-CNN. IEEE Trans. Pattern Anal. Mach. Intell. 2020, 42, 386–397. [Google Scholar] [CrossRef]

- Redmon, J.; Divvala, S.; Girshick, R.; Farhadi, A. You Only Look Once: Unified, Real-Time Object Detection. In Proceedings of the 2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Las Vegas, NV, USA, 27–30 June 2016. [Google Scholar]

- Liu, W.; Anguelov, D.; Erhan, D.; Szegedy, C.; Reed, S.; Fu, C.-Y.; Berg, A.C. SSD: Single Shot MultiBox Detector; Springer International Publishing: Berlin/Heidelberg, Germany, 2016; pp. 21–37. [Google Scholar]

- Huynh, T.C.; Park, J.H.; Jung, H.J.; Kim, J.T. Quasi-autonomous bolt-loosening detection method using vision-based deep learning and image processing. Autom. Constr. 2019, 105, 102844. [Google Scholar] [CrossRef]

- Pham, H.C.; Ta, Q.B.; Kim, J.T.; Ho, D.D.; Tran, X.L.; Huynh, T.C. Bolt-Loosening Monitoring Framework Using an Image-Based Deep Learning and Graphical Model. Sensors 2020, 20, 3382. [Google Scholar] [CrossRef]

- Ta, Q.B.; Kim, J.T. Monitoring of Corroded and Loosened Bolts in Steel Structures via Deep Learning and Hough Transforms. Sensors 2020, 20, 6888. [Google Scholar] [CrossRef]

- Zhao, X.F.; Zhang, Y.; Wang, N.N. Bolt loosening angle detection technology using deep learning. Struct. Control. Health Monit. 2019, 26, e2292. [Google Scholar] [CrossRef]

- Yu, Y.B.; Liu, Y.; Chen, J.W.; Jiang, D.; Zhuang, Z.L.; Wu, X.L. Detection Method for Bolted Connection Looseness at Small Angles of Timber Structures based on Deep Learning. Sensors 2021, 21, 3106. [Google Scholar] [CrossRef]

- Wang, J.; Li, L.M.; Zheng, S.B.; Zhao, S.G.; Chai, X.D.; Peng, L.L.; Qi, W.W.; Tong, Q.Q. A Detection Method of Bolts on Axlebox Cover Based on Cascade Deep Convolutional Neural Network. Comput. Model. Eng. Sci. 2022, 134, 1671–1706. [Google Scholar] [CrossRef]

- Deng, X.; Liu, J.; Gong, H.; Huang, J. A novel vision-based method for loosening detection of marked T-junction pipe fittings integrating GAN-based segmentation and SVM-based classification algorithms. J. Intell. Manuf. 2022. [Google Scholar] [CrossRef]

- Sun, Y.H.; Li, M.X.; Dong, R.W.; Chen, W.Y.; Jiang, D. Vision-Based Detection of Bolt Loosening Using YOLOv5. Sensors 2022, 22, 5184. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Sun, X.W.; Loh, K.J.; Su, W.S.; Xue, Z.G.; Zhao, X.F. Autonomous bolt loosening detection using deep learning. Struct. Health Monit. Int. J. 2020, 19, 105–122. [Google Scholar] [CrossRef]

- Yuan, C.; Chen, W.S.; Hao, H.; Kong, Q.Z. Near real-time bolt-loosening detection using mask and region-based convolutional neural network. Struct. Control. Health Monit. 2021, 28, e2741. [Google Scholar] [CrossRef]

- Pan, X.; Yang, T.Y. Image-based monitoring of bolt loosening through deep-learning-based integrated detection and tracking. Comput.-Aided Civ. Infrastruct. Eng. 2022, 37, 1207–1222. [Google Scholar] [CrossRef]

- Li, Y.; Ye, J.; Luo, J. Cascade convolutional neural network based abnormal detection of fasteners. J. Electron. Meas. Instrum. 2019, 33, 171–179. [Google Scholar]

- Wu, Y.; Sun, J.H. A novel bottom-up keypoints based hexagon bolts detection method. In Proceedings of the Applied Optics and Photonics China (AOPC) Conference—MEMS, THz MEMS, and Metamaterials and AI in Optics and Photonics, Beijing, China, 30 November–2 December 2020. [Google Scholar]

- Deng, X.J.; Liu, J.H.; Gong, H.; Huang, J.Y. Detection of loosening angle for mark bolted joints with computer vision and geometric imaging. Autom. Constr. 2022, 142, 104517. [Google Scholar] [CrossRef]

- Gong, H.; Deng, X.J.; Liu, J.H.; Huang, J.Y. Quantitative loosening detection of threaded fasteners using vision-based deep learning and geometric imaging theory. Autom. Constr. 2022, 133, 104009. [Google Scholar] [CrossRef]

- Wang, C.; Alexey, B.; Liao, M.H. YOLOv7: Trainable bag-of-freebies sets new state-of-the-art for real-time object detectors. arXiv 2022, arXiv:2207.02696. [Google Scholar]

- Zheng, C.; Bian, F.; Li, L.; Xie, X.; Liu, H.; Liang, J.; Chen, X.; Wang, Z.; Qiao, T.; Yang, J. Assessment of Generative Adversarial Networks for Synthetic Anterior Segment Optical Coherence Tomography Images in Closed-Angle Detection. Transl. Vis. Sci. Technol. 2021, 10, 34. [Google Scholar] [CrossRef]

- Hu, Q.; Yang, B.; Xie, L.; Rosa, S.; Guo, Y.; Wang, Z.; Trigoni, N.; Markham, A. Learning Semantic Segmentation of Large-Scale Point Clouds with Random Sampling. IEEE Trans. Pattern Anal. Mach. Intell. 2021, 44, 8338–8354. [Google Scholar]

- Geng, Z.; Sun, K.; Xiao, B.; Zhang, Z.; Wang, J. Bottom-Up Human Pose Estimation Via Disentangled Keypoint Regression. In Proceedings of the 2021 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Nashville, TN, USA, 20–25 June 2021; pp. 14671–14681. [Google Scholar]

- Maji, D.; Nagori, S.; Mathew, M.; Poddar, D. YOLO-Pose: Enhancing YOLO for Multi Person Pose Estimation Using Object Keypoint Similarity Loss. In Proceedings of the 2022 IEEE/CVF Conference on Computer Vision and Pattern Recognition Workshops (CVPRW), New Orleans, LA, USA, 19–20 June 2022. [Google Scholar]

- Cao, Z.; Simon, T.; Wei, S.E.; Sheikh, Y.; Ieee. Realtime Multi-Person 2D Pose Estimation using Part Affinity Fields. In Proceedings of the 30th IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Honolulu, HI, USA, 21–26 July 2017; pp. 1302–1310.

- Papandreou, G.; Zhu, T.; Chen, L.C.; Gidaris, S.; Tompson, J.; Murphy, K. PersonLab: Person Pose Estimation and Instance Segmentation with a Bottom-Up, Part-Based, Geometric Embedding Model. In Proceedings of the 15th European Conference on Computer Vision (ECCV), Munich, Germany, 8–14 September 2018; pp. 282–299. [Google Scholar]

- Kreiss, S.; Bertoni, L.; Alahi, A. PifPaf: Composite Fields for Human Pose Estimation. In Proceedings of the 2019 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Long Beach, CA, USA, 15–20 June 2019; pp. 11969–11978. [Google Scholar] [CrossRef] [Green Version]

| Parameters | Value |

|---|---|

| Size | 4032 × 3024 pixels |

| Vertical resolution | 72 dpi |

| Horizontal resolution | 72 dpi |

| Bit depth | 24 |

| Aperture | f/1.8 |

| Category | Version | |

|---|---|---|

| Software | System | Windows 11 |

| Virtual Environment | conda 4.13.0 | |

| Programming | Python 3.9.12 | |

| Deep Learning Framework | Pytorch 1.12.0 | |

| CUDA | Cuda11.6/cuDNN8.0 | |

| Hardware | GPU | NVIDIA GeForce RTX3080 Ti 12G |

| Memory | 32G |

| No. | Training Set | Validation Set |

|---|---|---|

| 1 | 200 real | 50 real |

| 2 | 200 real + 1200 synthetic | 50 real + 100 synthetic |

| 3 | 100 real | 50 real |

| 4 | 100 real + 1200 synthetic | 50 real + 100 synthetic |

| 5 | 1200 synthetic | 100 synthetic |

| Hyp-Parameters | Value | Hyp-Parameters | Value |

|---|---|---|---|

| lr0 | 0.005 | anchor_t | 4.0 |

| lrf | 0.1 | fl_gamma | 0 |

| momentum | 0.937 | hsv_h | 0.015 |

| weight_decay | 0.0005 | hsv_s | 0.7 |

| warmup_epochs | 0.3 | hsv_v | 0.4 |

| warmup_momentum | 0.8 | degrees | 0.0 |

| warmup_bias_lr | 0.1 | translate | 0.1 |

| box gain | 0.05 | scale | 0.2 |

| kpt gain | 0.30 | shear | 0.0 |

| cls gain | 0.05 | perspective | 0.0 |

| cls_pw | 1.0 | flipud | 0.0 |

| obj gain | 0.5 | fliplr | 0.0 |

| obj_pw | 1.0 | mosaic | 0.8 |

| iou_t | 0.20 | mixup | 0.0 |

| Training Set | Bolts | Detect | Kpts | Detect |

|---|---|---|---|---|

| 200 real | 50 | 50 | 50 | 50 |

| 200 real + 1200 synthetic | 50 | 50 | ||

| 100 real | 49 | 49 | ||

| 100 real + 1200 synthetic | 50 | 50 | ||

| 1200 synthetic | 24 | 21 | ||

| 200 real + 1200 synthetic (Keypoint-RCNN) | 50 | 50 | 50 | 45 |

| Training Set | NME | (°) | Var |

|---|---|---|---|

| 200 real | 0.043785 | 2.510472 | 1.951742 |

| 200 real + 1200 synthetic | 0.033903 | 1.943473 | 1.304070 |

| 100 real | 0.061144 | 3.514130 | 9.047428 |

| 100 real + 1200 synthetic | 0.047353 | 2.717504 | 3.644367 |

| 1200 synthetic | 0.070147 | 4.038014 | 15.20069 |

| 200 real + 1200 synthetic (Keypoint-RCNN) | 0.055395 | 3.247408 | 24.88260 |

| No. | True Angle | Detected Angle | Error |

|---|---|---|---|

| 1 | 0 | 0.475 | −0.475 |

| 2 | 15 | 13.554 | 1.446 |

| 3 | 15 | 16.204 | −1.204 |

| 4 | 30 | 30.598 | −0.598 |

| 5 | 30 | 31.818 | −1.818 |

| 6 | 90 | 88.641 | 1.359 |

| 7 | 90 | 91.208 | −1.208 |

| 8 | 180 | 182.875 | −2.875 |

| 9 | 300 | 299.298 | 0.702 |

| 10 | 330 | 328.697 | 1.303 |

| Average * | 1.298 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Q.; Jing, Y.; Zhao, X. Bolt Loosening Detection Using Key-Point Detection Enhanced by Synthetic Datasets. Appl. Sci. 2023, 13, 2020. https://doi.org/10.3390/app13032020

Lu Q, Jing Y, Zhao X. Bolt Loosening Detection Using Key-Point Detection Enhanced by Synthetic Datasets. Applied Sciences. 2023; 13(3):2020. https://doi.org/10.3390/app13032020

Chicago/Turabian StyleLu, Qizhe, Yicheng Jing, and Xuefeng Zhao. 2023. "Bolt Loosening Detection Using Key-Point Detection Enhanced by Synthetic Datasets" Applied Sciences 13, no. 3: 2020. https://doi.org/10.3390/app13032020

APA StyleLu, Q., Jing, Y., & Zhao, X. (2023). Bolt Loosening Detection Using Key-Point Detection Enhanced by Synthetic Datasets. Applied Sciences, 13(3), 2020. https://doi.org/10.3390/app13032020