A Comprehensive Safety Analysis Study for Concrete Core Dams

Abstract

1. Introduction

- (1)

- Virtual element method

- (2)

- Initial flow method

- (3)

- Grid correction method

- (4)

- Element permeability matrix adjustment method

1.1. Proposed Calculation Model

1.1.1. Theoretical Model

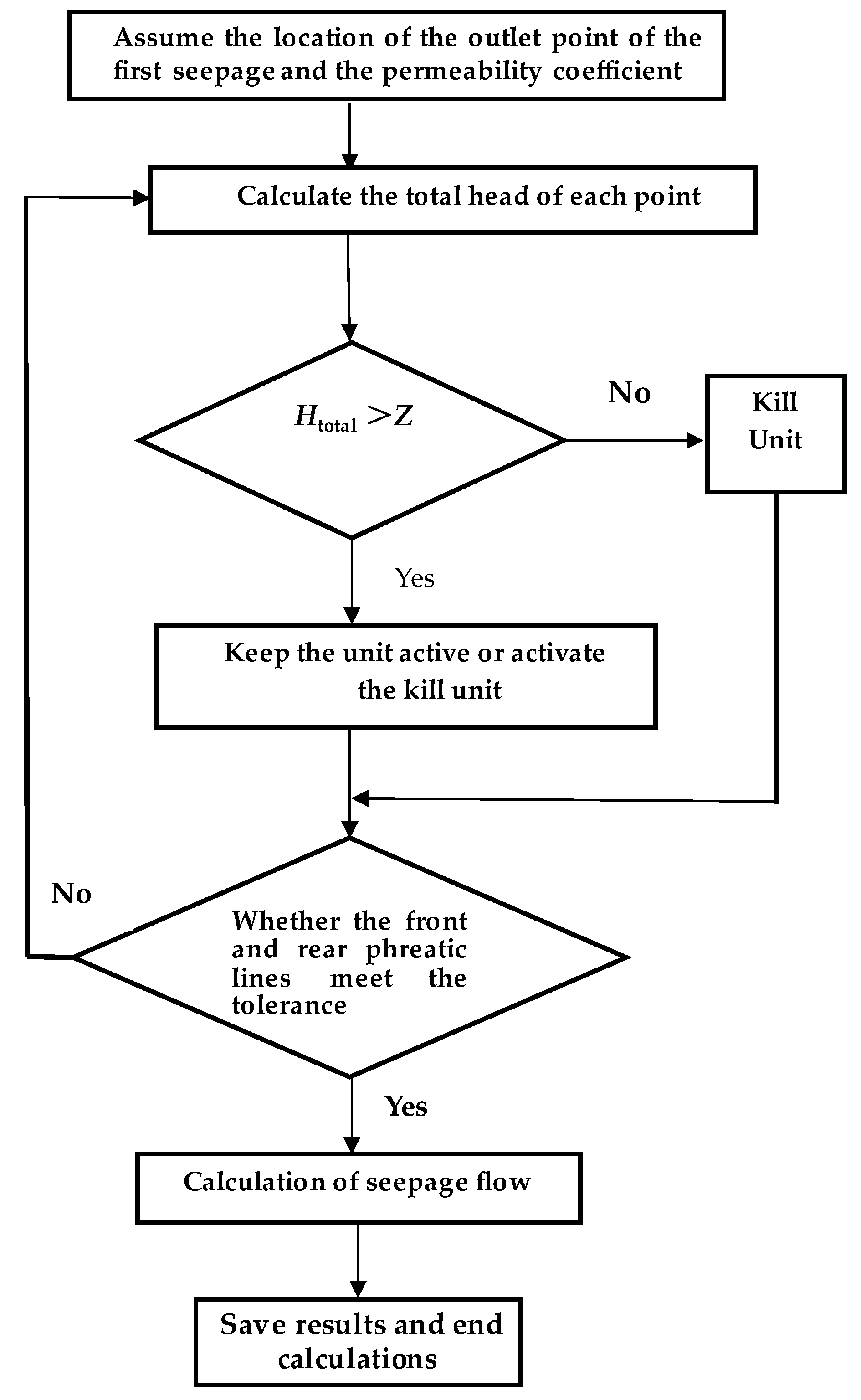

1.1.2. Proposed Method

2. Calculation

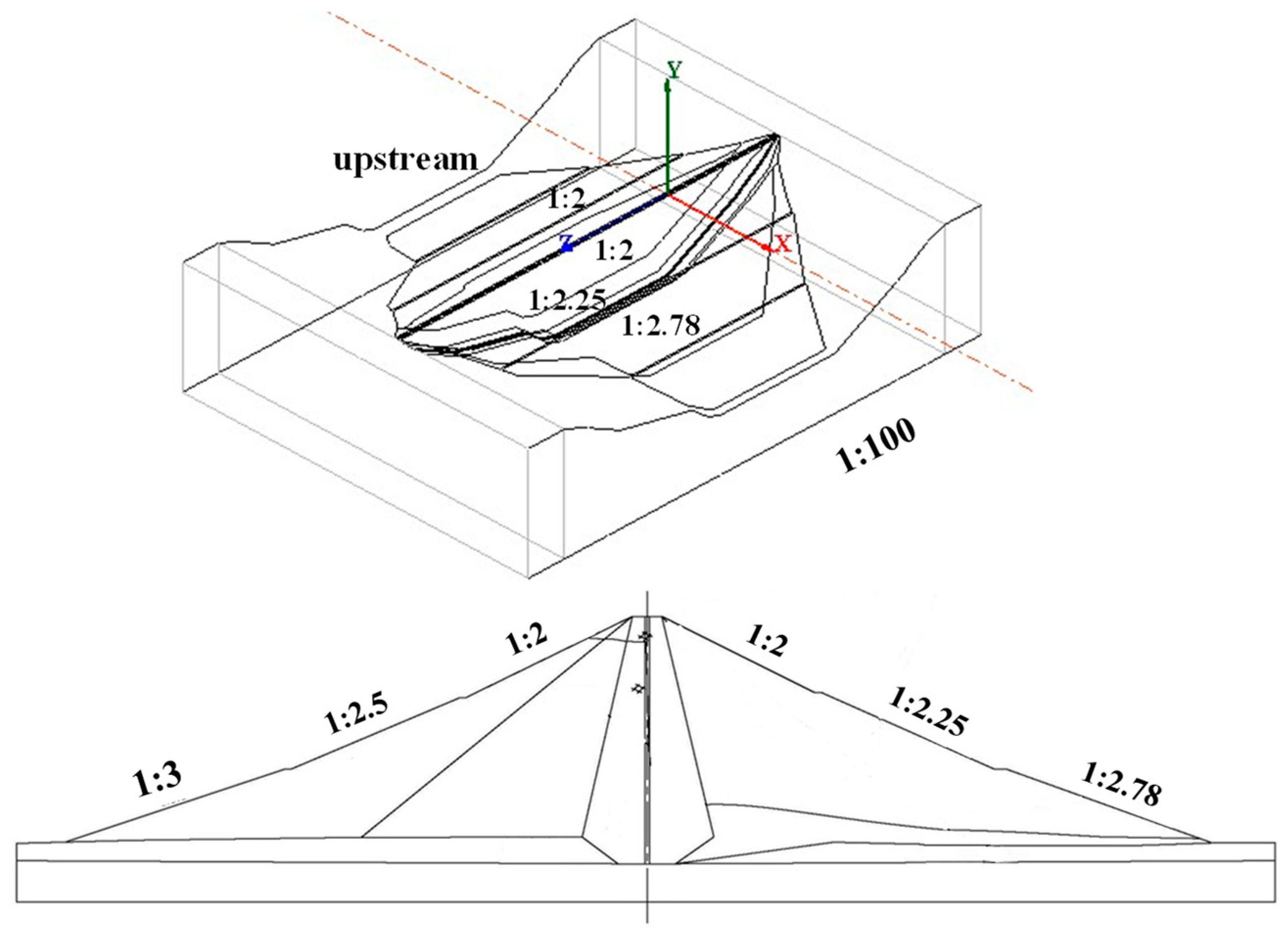

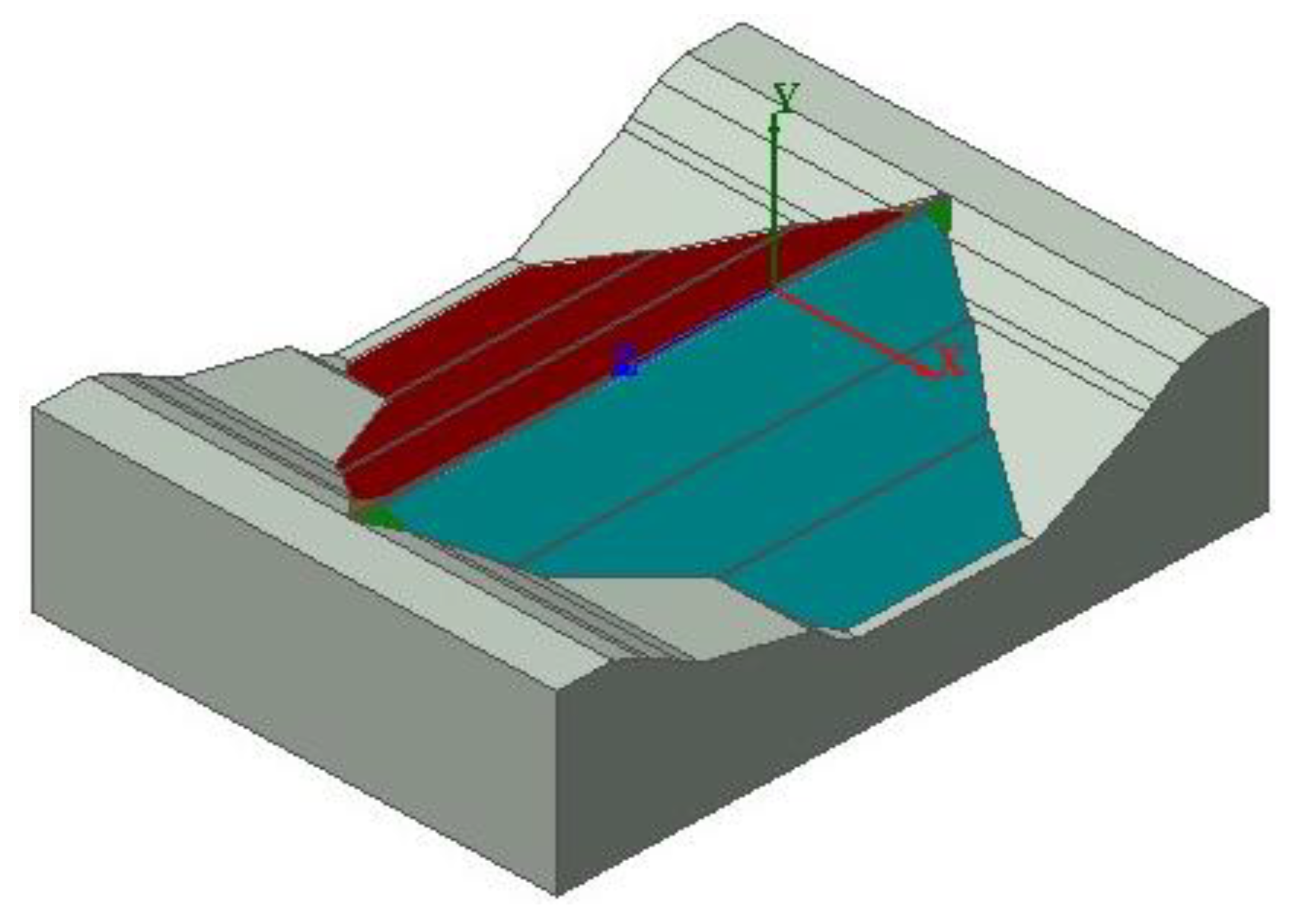

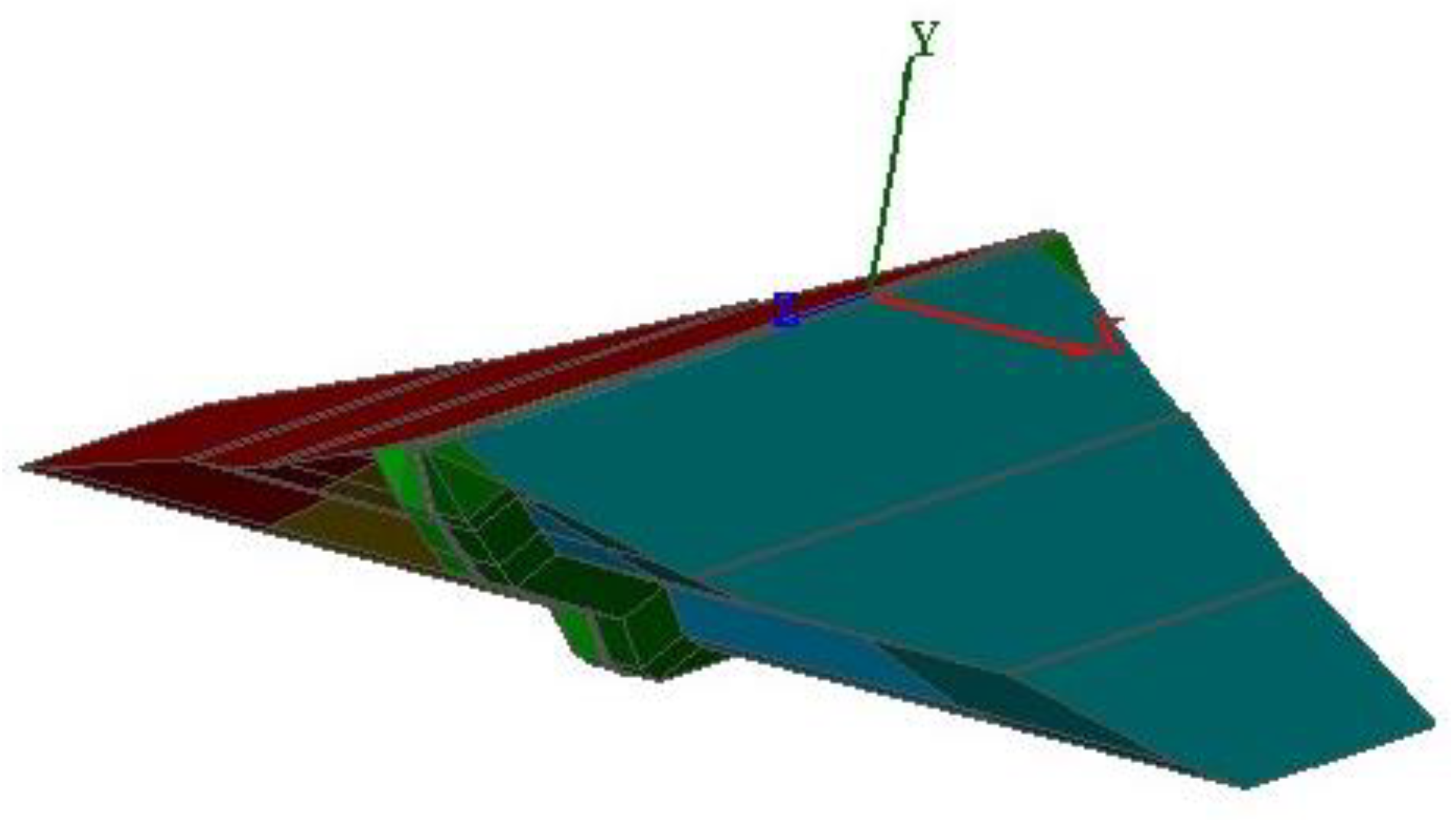

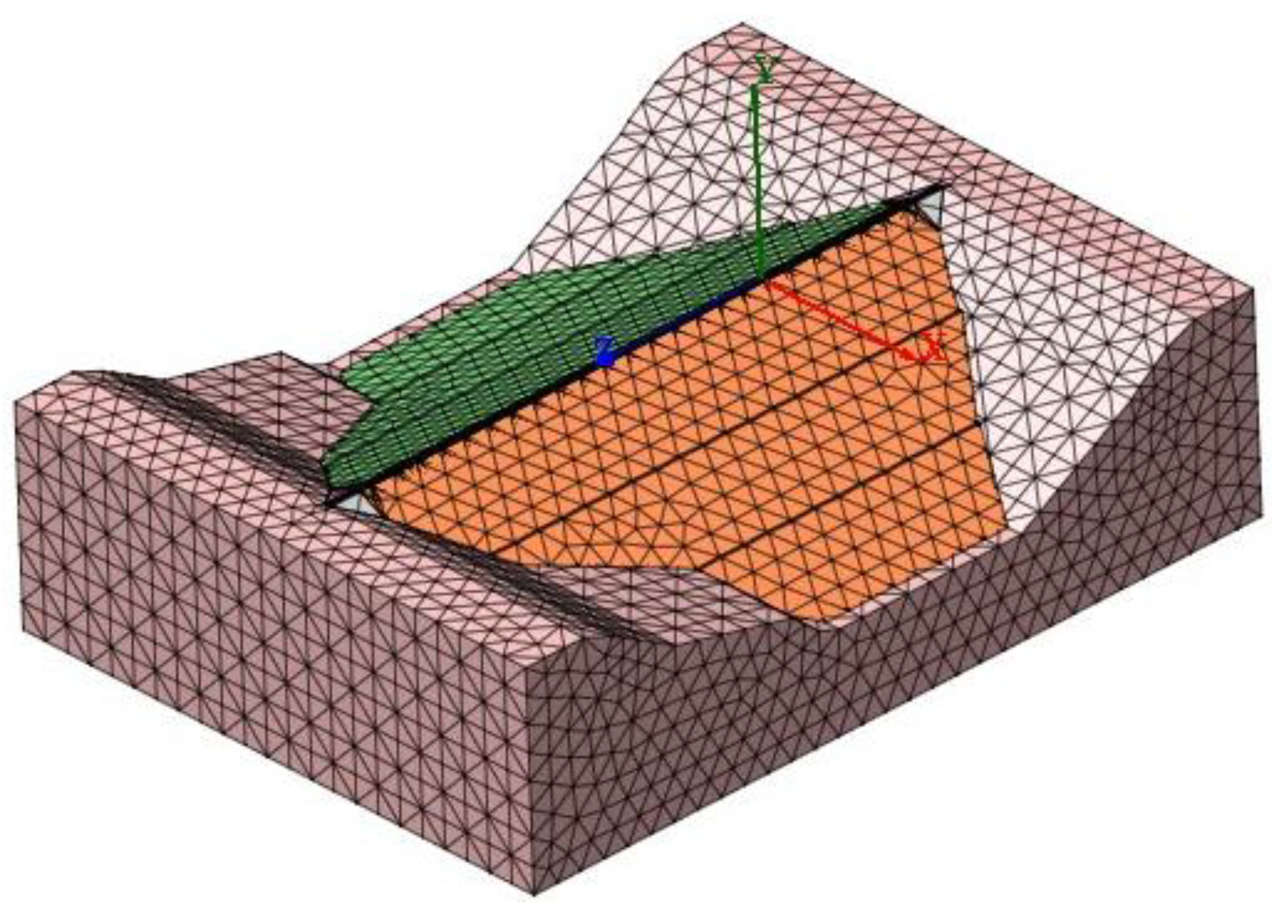

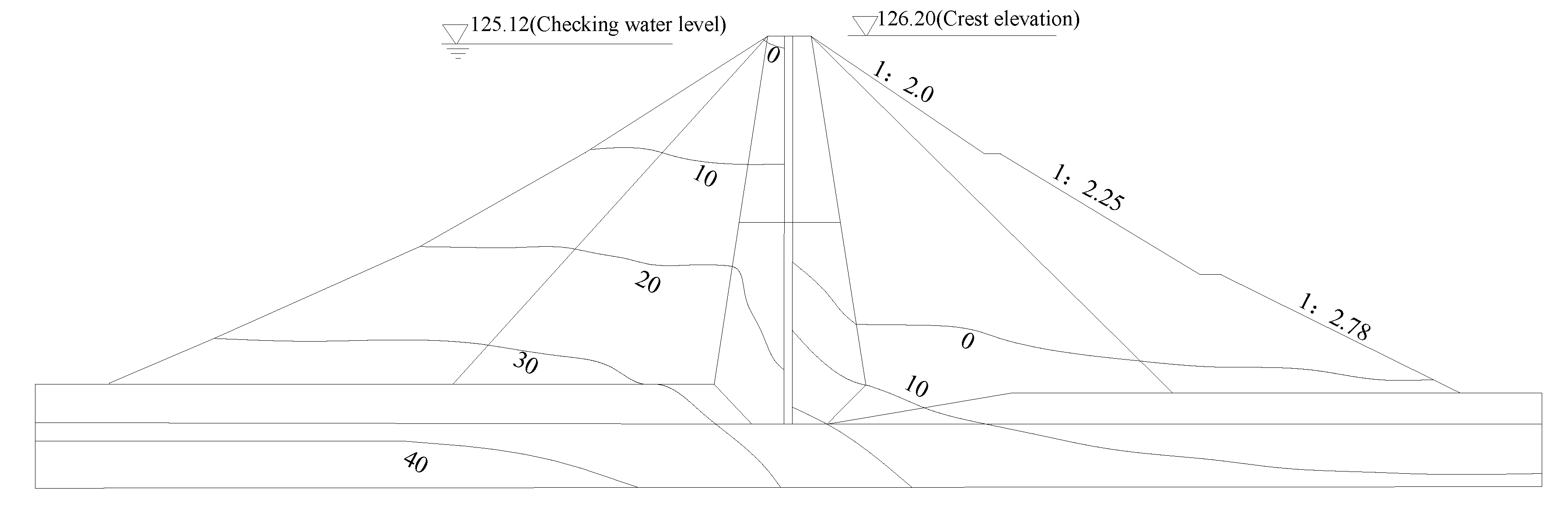

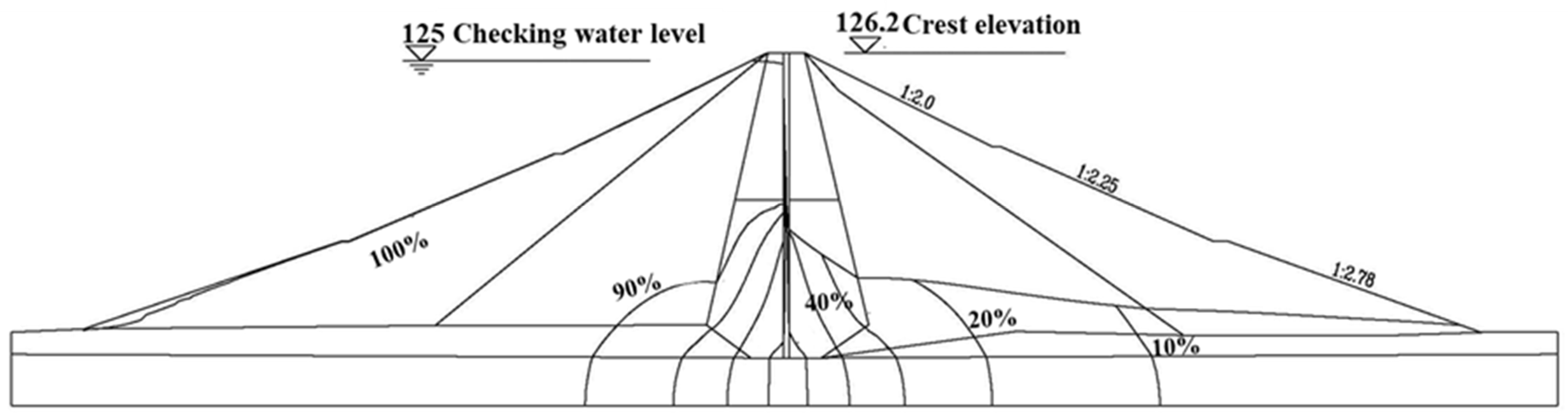

Finite Element Model

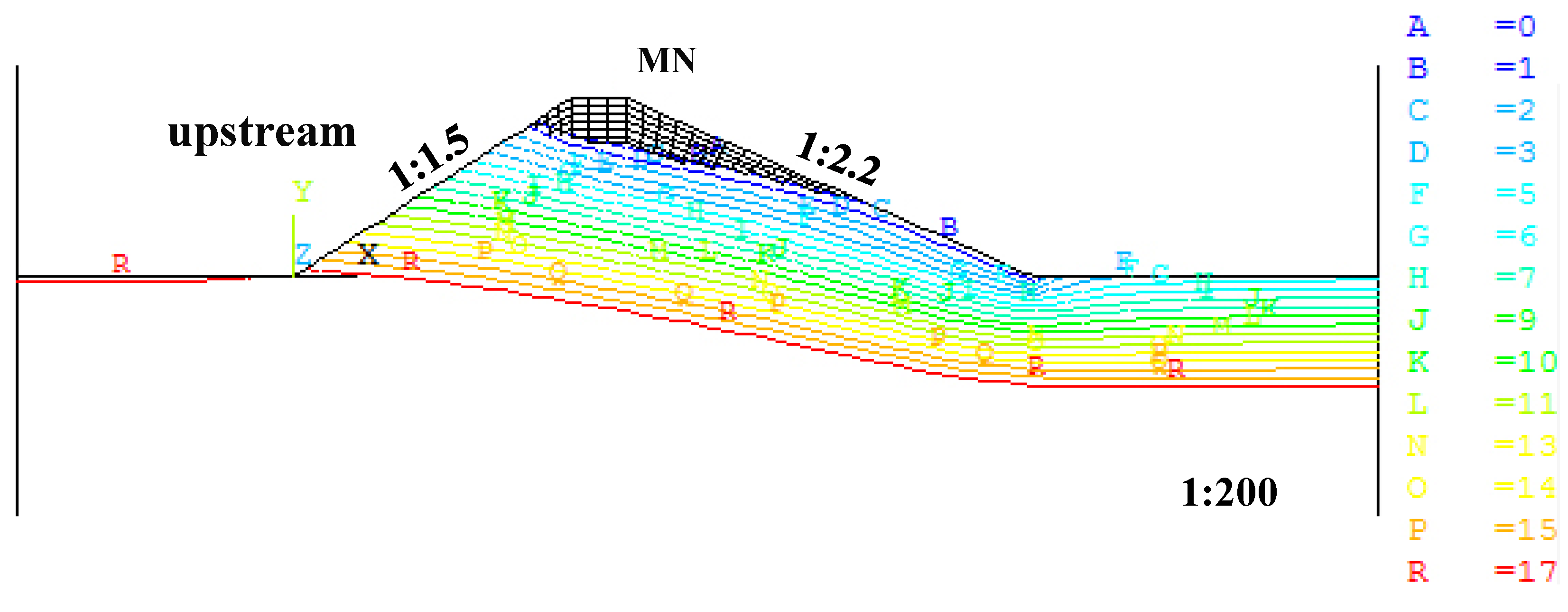

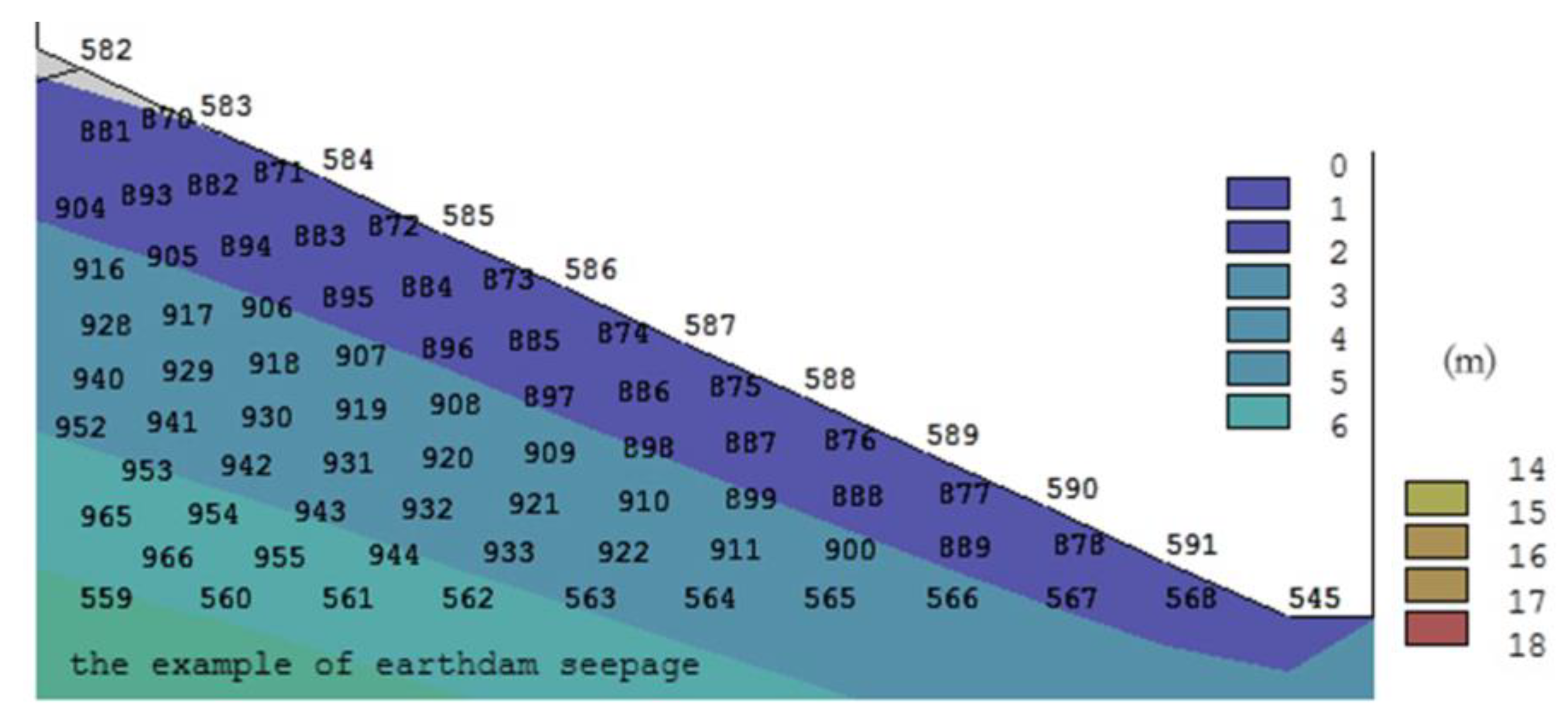

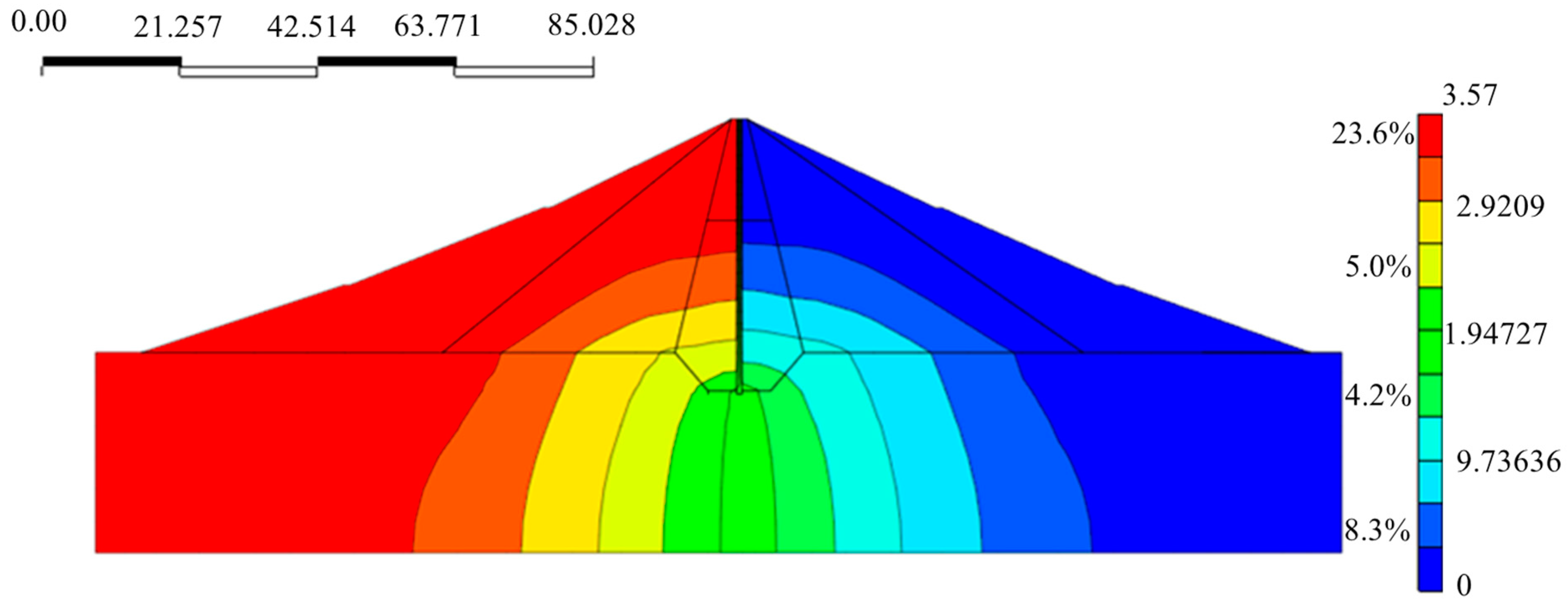

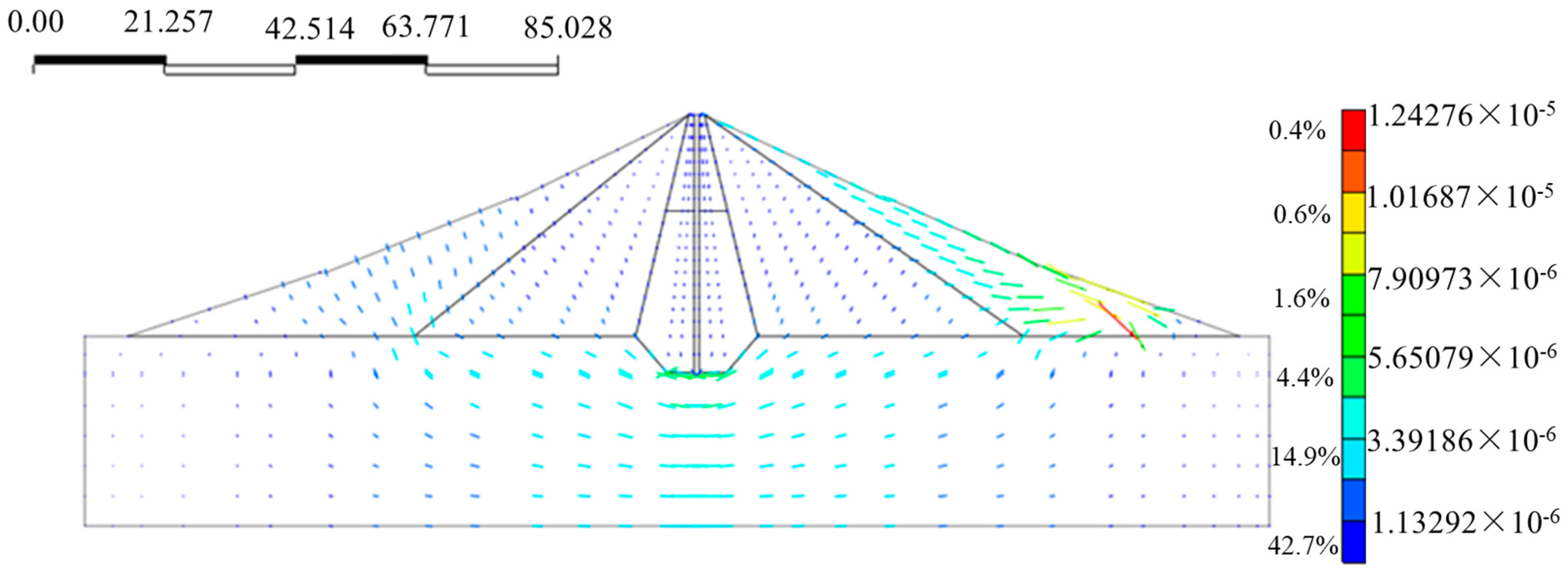

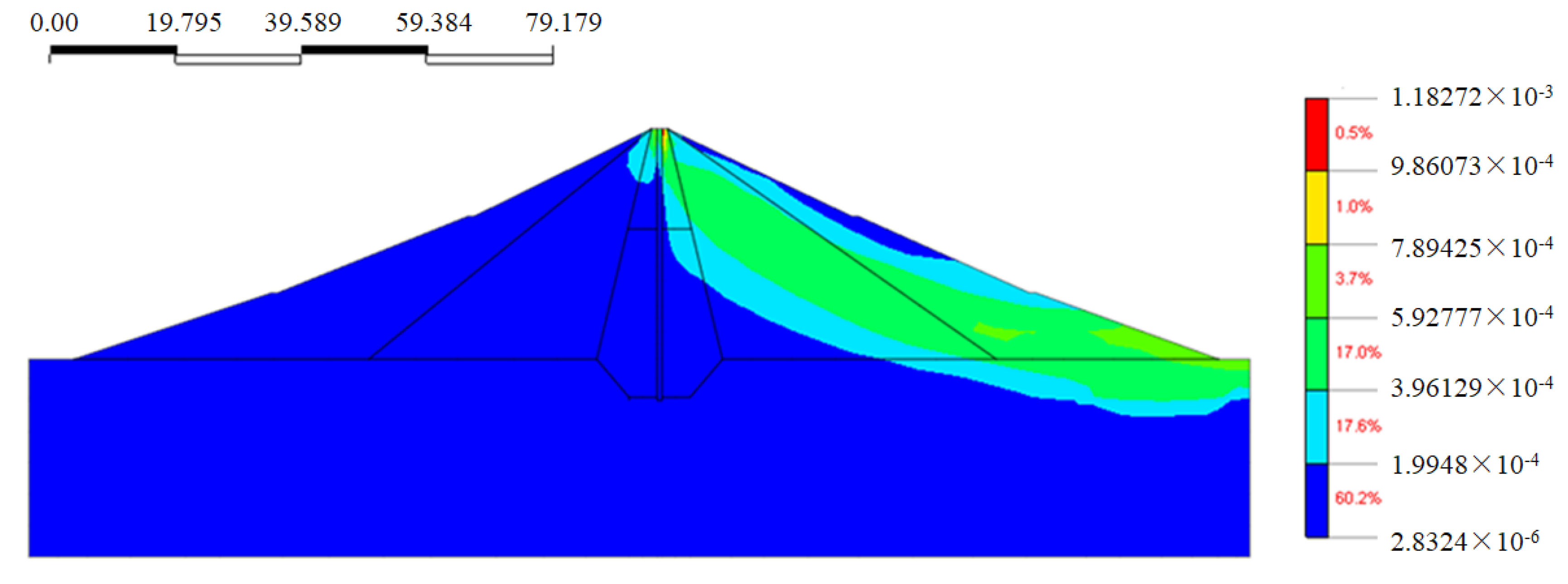

3. Seepage Analysis

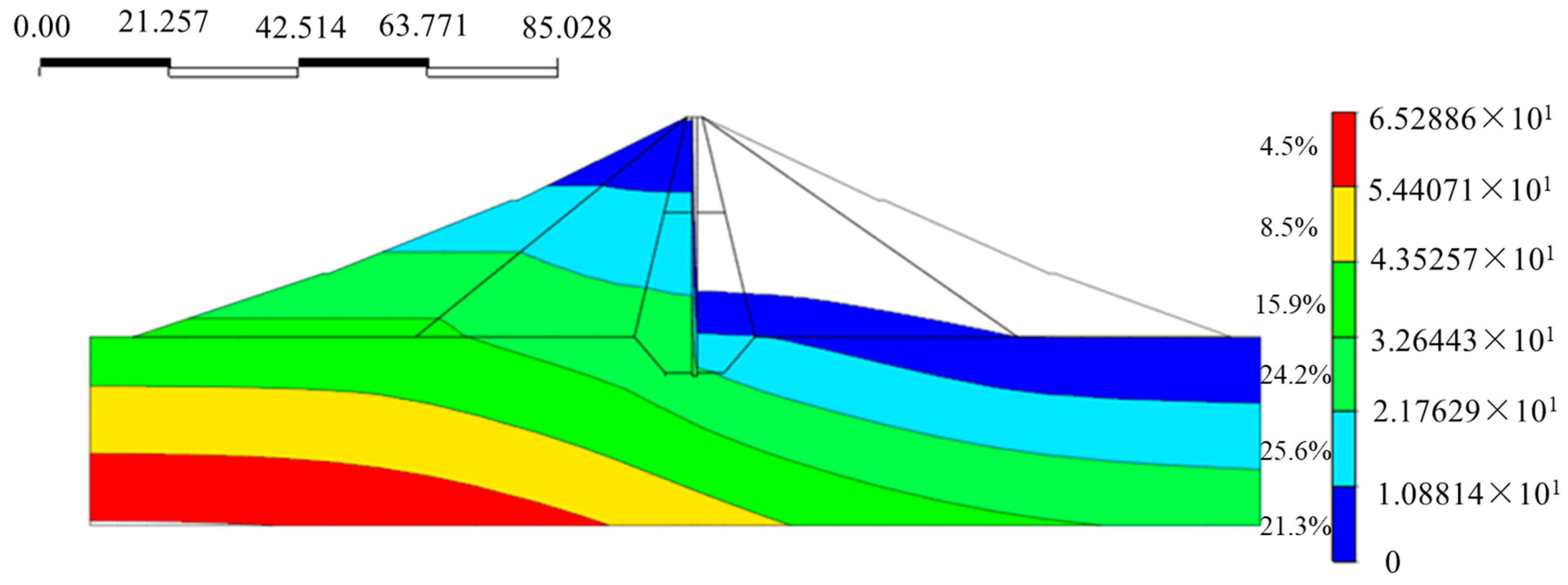

4. Stability Analysis

5. The Influence of Elastic Modulus to Concrete Diaphragm Wall

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Altunisik, A.C.; Sesli, H. Dynamic response of concrete gravity dams using different water modelling approaches: Westergaard, lagrange and euler. Comput. Concr. 2015, 16, 429–448. [Google Scholar] [CrossRef]

- Zhong, D.; Sun, Y.; Li, M. Dam break threshold value and risk probability assessment for an earth dam. Nat. Hazards 2011, 59, 129–147. [Google Scholar] [CrossRef]

- Khazaee, A.; Lotfi, V. Time harmonic analysis of dam-foundation systems by perfectly matched layers. Struct. Eng. Mech. 2014, 50, 349–364. [Google Scholar] [CrossRef]

- Le, T.M.H.; Gallipoli, D.; Sanchez, M.; Wheeler, S.J. Stochastic analysis of unsaturated seepage through randomly heterogeneous earth embankments. Int. J. Numer. Anal. Methods Géoméch. 2012, 36, 1056–1076. [Google Scholar] [CrossRef]

- Ni, Y.; Xia, Y.; Lin, W.; Chen, W.; Ko, J. SHM benchmark for high-rise structures: A reduced-order finite element model and field measurement data. Smart Struct. Syst. 2012, 10, 411–426. [Google Scholar] [CrossRef]

- Li, X.; Ni, Y.-Q.; Wong, K.; Chan, K. Structural health rating (SHR)-oriented 3D multi-scale finite element modeling and analysis of Stonecutters Bridge. Smart Struct. Syst. 2015, 15, 99–117. [Google Scholar] [CrossRef]

- Sevim, B.; Altunisik, A.C.; Bayraktar, A. Construction stages analyses using time dependent material properties of concrete arch dams. Comput. Concr. 2014, 14, 599–612. [Google Scholar] [CrossRef]

- Zhu, H.-H.; Yin, J.-H.; Dong, J.-H.; Zhang, L. Physical modelling of sliding failure of concrete gravity dam under overloading condition. Géoméch. Eng. 2010, 2, 89–106. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, M.Y.; Pan, Y.; Yao, K. Large-Scale 3D Random Finite Element Analysis of Embankment Seepage Stability. In Advancements in Geotechnical Engineering, Proceedings of the 6th GeoChina International Conference on Civil & Transportation Infrastructures: From Engineering to Smart & Green Life Cycle Solutions, Nanchang, China, 19–21 July 2021; Springer: Berlin/Heidelberg, Germany, 2021; pp. 1–13. [Google Scholar]

- Wang, R.-H.; Li, D.-Q.; Wang, M.-Y.; Liu, Y. Deterministic and Probabilistic Investigations of Piping Occurrence during Tunneling through Spatially Variable Soils. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part A Civ. Eng. 2021, 7, 04021009. [Google Scholar] [CrossRef]

- Bullen, T.D.; Wang, Y. Dam foundation water quality and seepage as a result of water-rock interaction. Water-Rock Interact. 2007, 1–2, 1691–1694. [Google Scholar]

- Mazars, J.; Grange, S. Modeling of reinforced concrete structural members for engineering purposes. Comput. Concr. 2015, 16, 683–701. [Google Scholar] [CrossRef]

- Su, H.; Wen, Z.; Wang, F. Fractal behavior identification for monitoring data of dam safety. Struct. Eng. Mech. 2016, 57, 529–541. [Google Scholar] [CrossRef]

- Yu, Y.; Xie, L.; Zhang, B. Stability of earth–rockfill dams: Influence of geometry on the three-dimensional effect. Comput. Geotech. 2005, 32, 326–339. [Google Scholar] [CrossRef]

- Tang, D.; Gordan, B.; Koopialipoor, M.; Armaghani, D.J.; Tarinejad, R.; Pham, B.T.; Van Huynh, V. Seepage Analysis in Short Embankments Using Developing a Metaheuristic Method Based on Governing Equations. Appl. Sci. 2020, 10, 1761. [Google Scholar] [CrossRef]

- Gazdzicki, M.; Gorenstein, M. Transparency, mixing and reflection of initial flows in relativistic nuclear collisions. Phys. Lett. B 2006, 640, 155–161. [Google Scholar] [CrossRef]

- Desai, B.; Lenka, S. Quantification of blast furnace hearth drainage parameters through physical model study. Ironmak. Steelmak. 2007, 34, 269–271. [Google Scholar] [CrossRef]

- Zhao, J.; Zhang, B.; Mao, S.; Chen, S. The Divergence-Free Nonconforming Virtual Element for the Stokes Problem. SIAM J. Numer. Anal. 2019, 57, 2730–2759. [Google Scholar] [CrossRef]

- Li, X. Modified initial flow method for FEM analysis of unconfined seepage. J. Hydraul. Eng. 2007, 38, 961–965. [Google Scholar]

- Chen, H.; Zheng, P.; Sun, X.; Xiao, J.; Zhu, T.; Sun, J.; Zhu, J.; Li, Z.; Cao, Y.; Yan, J. Characterize the grid inefficiency correction of Frisch grid ionization chamber with Garfield and SRIM. J. Instrum. 2022, 17, P03023. [Google Scholar] [CrossRef]

- Fu, Y.; Zhou, Z.; Wu, Y. Improved adjustment method of compound element conductivity matrix for calculating 3D seepage field with free surface. Chin. J. Geotech. Eng. 2009, 31, 1434–1439. [Google Scholar]

- Mascarenhas, P.V.S.; Cavalcante, A.L.B. Stochastic Foundation to Solving Transient Unsaturated Flow Problems Using a Fractional Dispersion Term. Int. J. Géoméch. 2022, 22, 04021262. [Google Scholar] [CrossRef]

- Huang, P.; Zhang, Y. Analysis of seepage characteristics of mine fractures based on geothermal utilization. Bulg. Chem. Commun. 2017, 49, 44–48. [Google Scholar]

- Li, M.-Y.; Pan, J.; Niu, Y.-G. Sensitivity analysis of system wind penetration to thermal generation ramp rates. In Proceedings of the 2017 IEEE Manchester PowerTech, Manchester, UK, 18–22 June 2017; pp. 1–6. [Google Scholar] [CrossRef]

| Void Pressure Value M (unit: m) | Permeability Coefficient Index D |

|---|---|

| −10.00 | −4.20 |

| −9.00 | −3.80 |

| −8.00 | −3.10 |

| −7.00 | −2.70 |

| −6.00 | −2.300 |

| −5.00 | −2.20 |

| −4.00 | −1.50 |

| −3.00 | −1.30 |

| −2.00 | −8.10 |

| −1.00 | −4.20 |

| 0.00 | 0.00 |

| No. | Material | Permeability Coefficient/cm s−1 |

|---|---|---|

| I | Sand-gravel stratum | 0.5 |

| II3 | Pebbly silty clay | 2.31 × 10−4 |

| II2 | Inner core (>110 m) | 9.06 × 10−4 |

| Inner core (<110 m) | 1.07 × 10−4 | |

| III | Dam foundation | 8.90 × 10−4 |

| IV | Concrete anti-seepage wall | 1.00 × 10−7 |

| Material | Natural Unit Weight (kN/m3) | Saturated Unit Weigh (kN/m3) | Shear Strength | |

|---|---|---|---|---|

| C (kPa) | φ (°) | |||

| Sandy gravel I | 19.0 | 21.0 | 0 | 33 |

| mud gravel soil clay II3 | 19.3 | 19.8 | 21.0 | 24.0 |

| Core wall soil II2 | 19.6 | 19.85 | 21.0 | 24.0 |

| Mud sandy gravel soil of dam foundation III | 18.0 | 20.0 | 0 | 30° |

| Working Conditions | Li Zheng Software with Seepage Pressure | FEM | |

|---|---|---|---|

| Considering Osmotic Pressure | Without Considering Osmotic Pressure | ||

| Design flood level (124.33 m) | 1.49 | 1.5375 | 1.7625 |

| Check flood level (125.12 m) | 1.49 | 1.5125 | 1.7375 |

| Material No. | γ | K | Kur | n | Rf | c | φ° | K0 | G | F | d |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 18.3 | 850 | 1020 | 0.40 | 0.75 | 0 | 30 | 0.47 | 0.36 | 0.16 | 6.0 |

| 2 | 18.1 | 210 | 252 | 0.60 | 0.85 | 21.0 | 24 | 0.72 | 0.35 | 0.10 | 1.9 |

| 3 | 18.2 | 950 | 1140 | 0.37 | 0.72 | 0 | 28 | 0.46 | 0.37 | 0.17 | 6.0 |

| 4 | 10.8 | 750 | 900 | 0.41 | 0.75 | 0 | 30 | 0.48 | 0.35 | 0.16 | 6.0 |

| 5 | 8.7 | 180 | 216 | 0.62 | 0.85 | 20.5 | 24 | 0.74 | 0.34 | 0.10 | 1.9 |

| 6 | 10.7 | 860 | 1032 | 0.36 | 0.72 | 0 | 28 | 0.47 | 0.36 | 0.17 | 6.0 |

| 7 | 22.0 | 10,000 15,000 20,000 30,000 50,000 80,000 | 12,000 18,000 24,000 36,000 60,000 96,000 | 0.00 | 0.00 | 500 | 30 | 0.00 | 5000 7500 10,000 15,000 25,000 40,000 | 0.00 | 0.0 |

| Calculation Software | Elastic Modulus (MPa) | Maximum Compressive Stress (MPa) | Maximum Tension Stress (MPa) |

|---|---|---|---|

| SDAP | 1000 | 0.95 | 0.21 |

| 1500 | 1.09 | 0.47 | |

| 2000 | 1.28 | 0.76 | |

| 2500 | 1.33 | 0.92 | |

| 3000 | 1.49 | 1.09 | |

| 5000 | 2.22 | 2.01 | |

| 8000 | 3.12 | 2.43 | |

| FEM | 1000 | 0.81 | 0.28 |

| 1500 | 0.88 | 0.41 | |

| 2000 | 1.06 | 0.56 | |

| 2500 | 1.14 | 0.74 | |

| 3000 | 1.24 | 0.87 | |

| 5000 | 2.10 | 1.87 | |

| 8000 | 3.32 | 2.31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, M.; Wang, D.; Gu, C. A Comprehensive Safety Analysis Study for Concrete Core Dams. Appl. Sci. 2023, 13, 1679. https://doi.org/10.3390/app13031679

Yang M, Wang D, Gu C. A Comprehensive Safety Analysis Study for Concrete Core Dams. Applied Sciences. 2023; 13(3):1679. https://doi.org/10.3390/app13031679

Chicago/Turabian StyleYang, Meng, Dong Wang, and Chongshi Gu. 2023. "A Comprehensive Safety Analysis Study for Concrete Core Dams" Applied Sciences 13, no. 3: 1679. https://doi.org/10.3390/app13031679

APA StyleYang, M., Wang, D., & Gu, C. (2023). A Comprehensive Safety Analysis Study for Concrete Core Dams. Applied Sciences, 13(3), 1679. https://doi.org/10.3390/app13031679