Metamodelling of Manufacturing Processes and Automation Workflows towards Designing and Operating Digital Twins

Abstract

1. Introduction

2. State of the Art

2.1. Technology Modelling and Workflows

2.2. Metamodelling Protocols

- “Cyber-physical systems are the integration of computation and physical processes. Embedded computers and networks monitor and control the physical processes, usually with feedback loops where physical processes affect computations and vice versa.” [39]

- “A global infrastructure for the information society, enabling advanced services by interconnecting (physical and virtual) things based on existing and evolving interoperable information and communication technologies.” [40]

2.3. Technologies

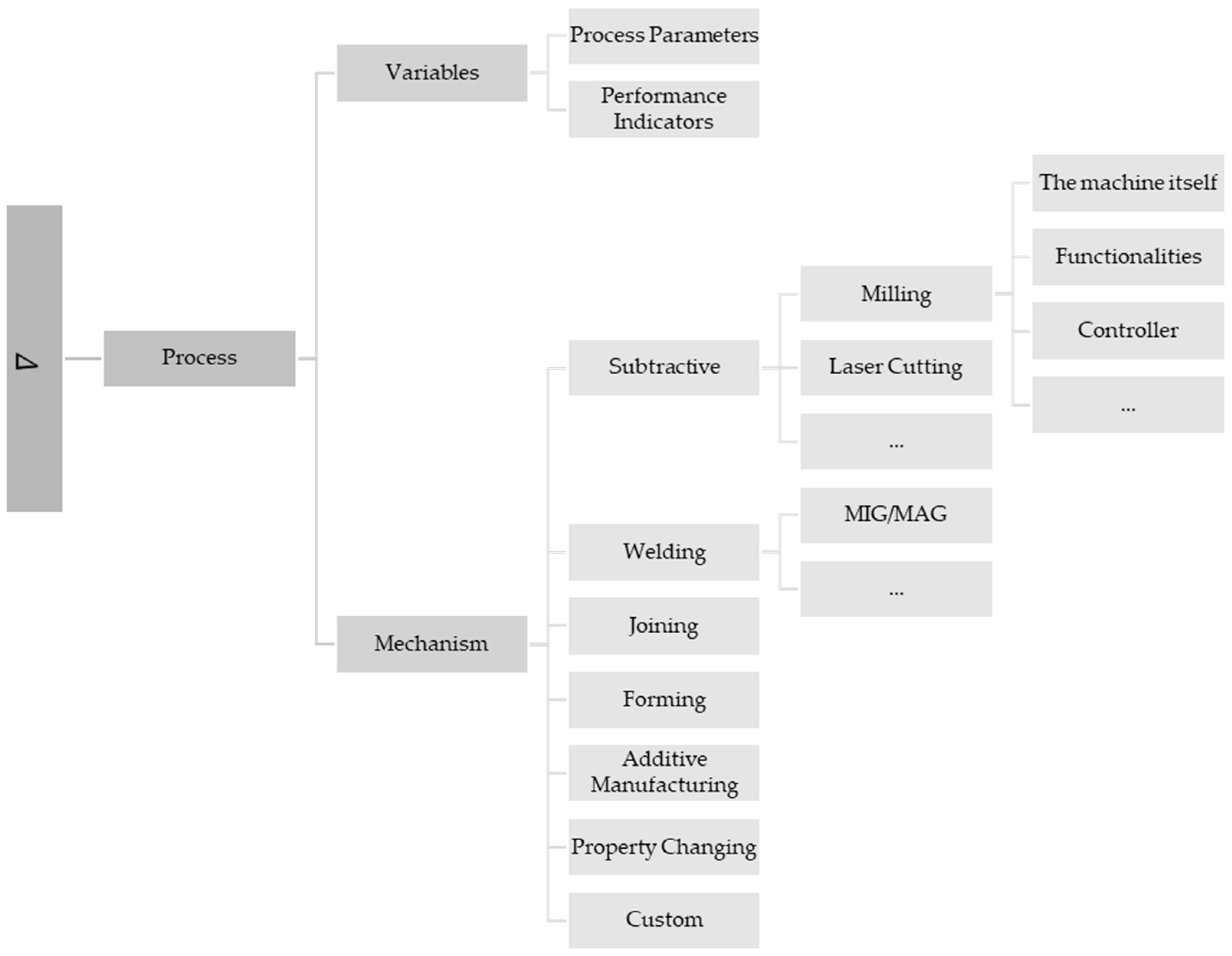

2.3.1. Category 1 (Manufacturing Processes)

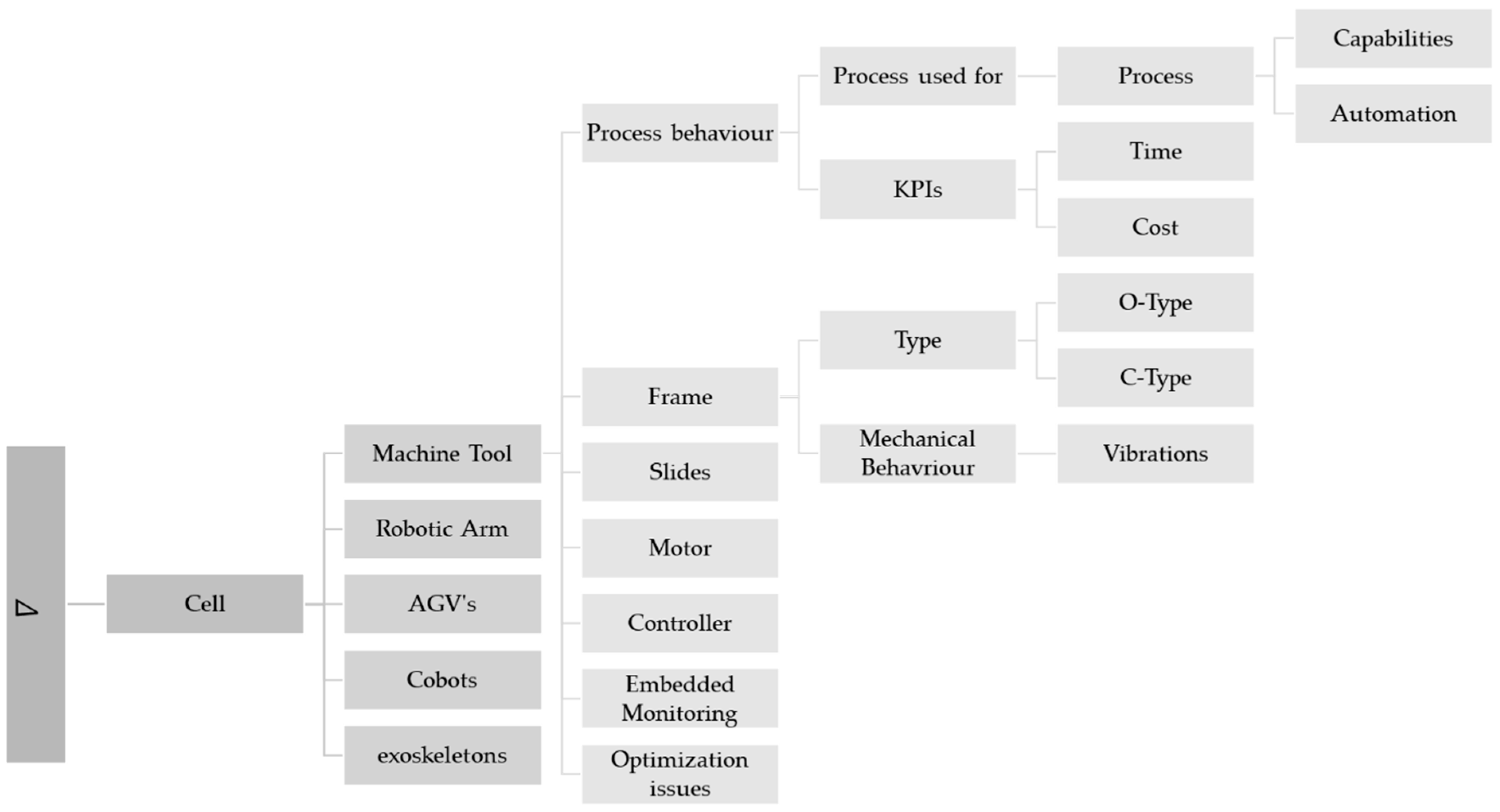

2.3.2. Category 2 (Cell-Related Equipment)

2.3.3. Category 3 (Auxiliary Functionalities)

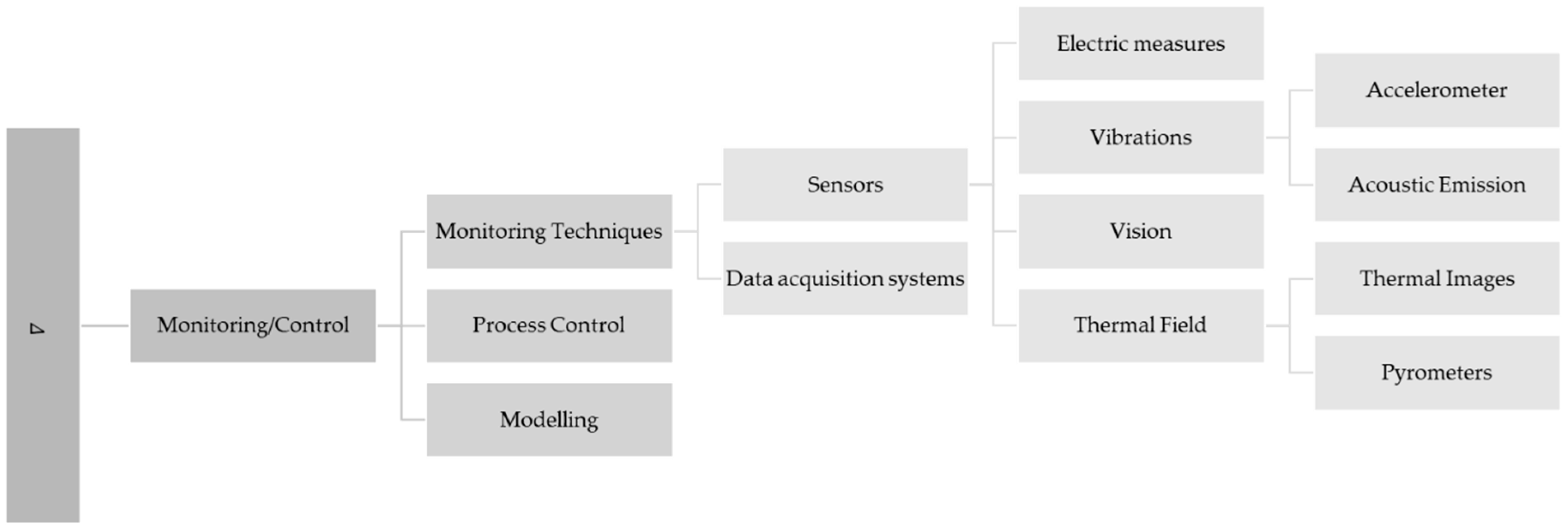

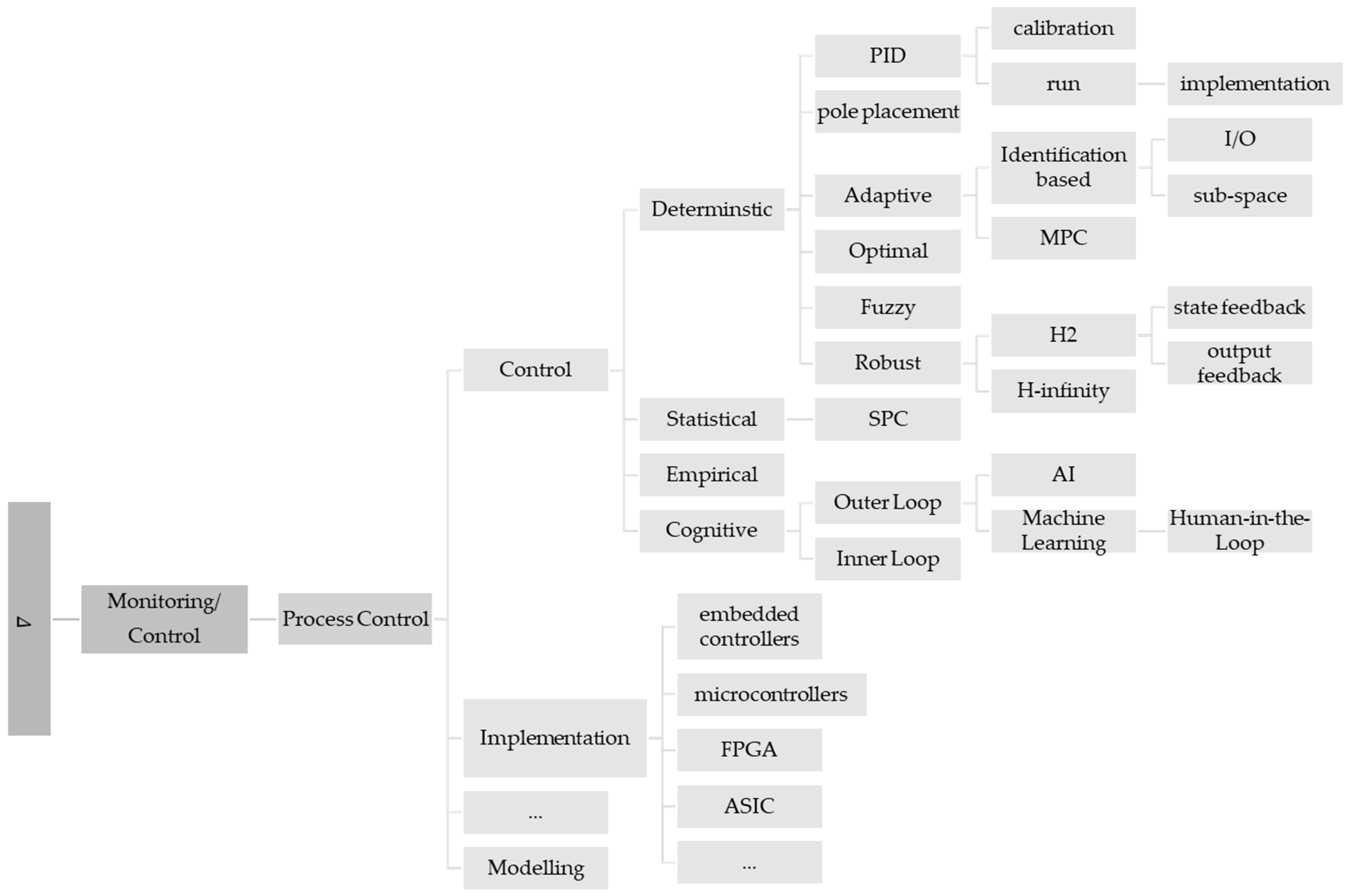

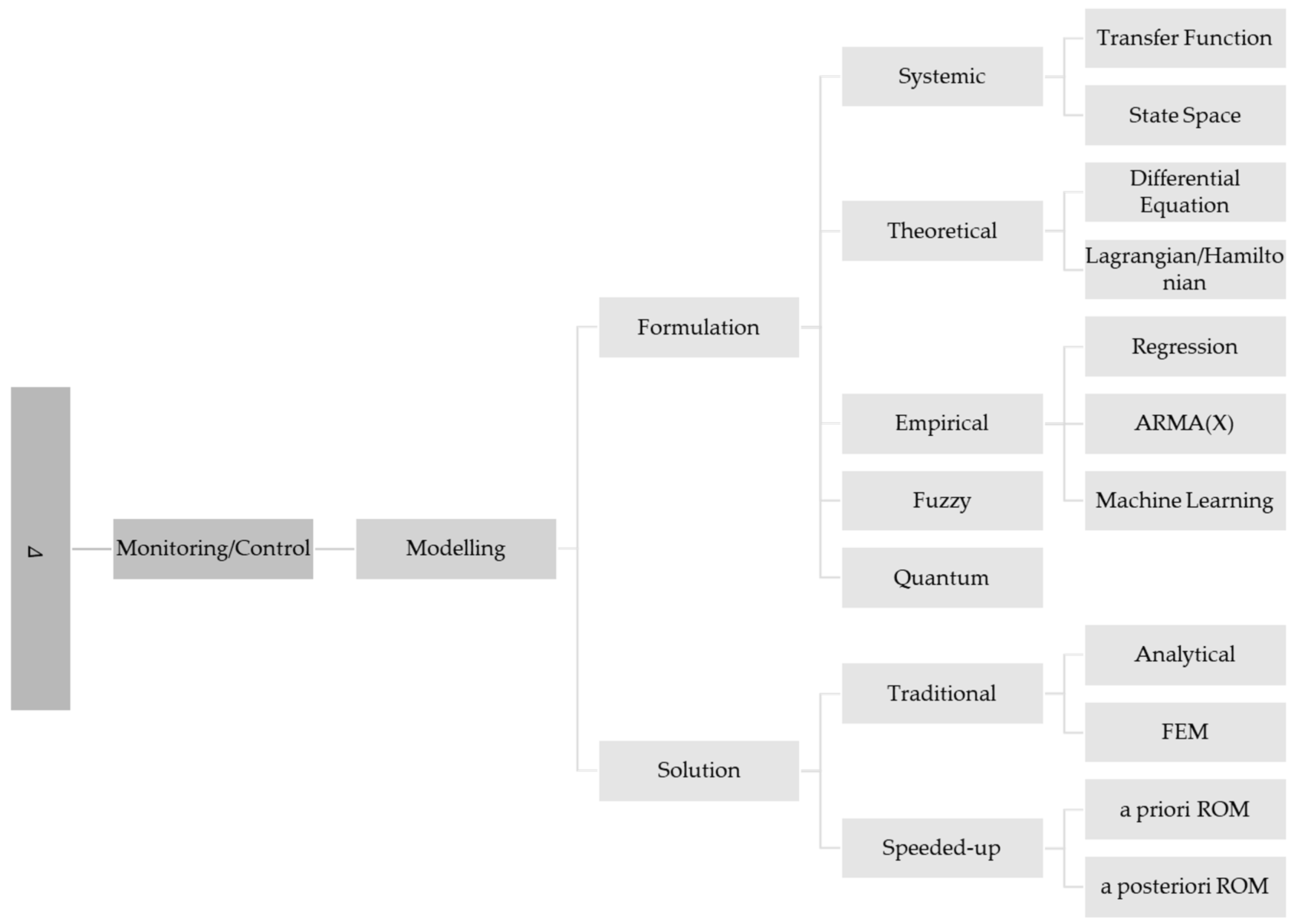

2.3.4. Category 4 (Monitoring/Control as Operations)

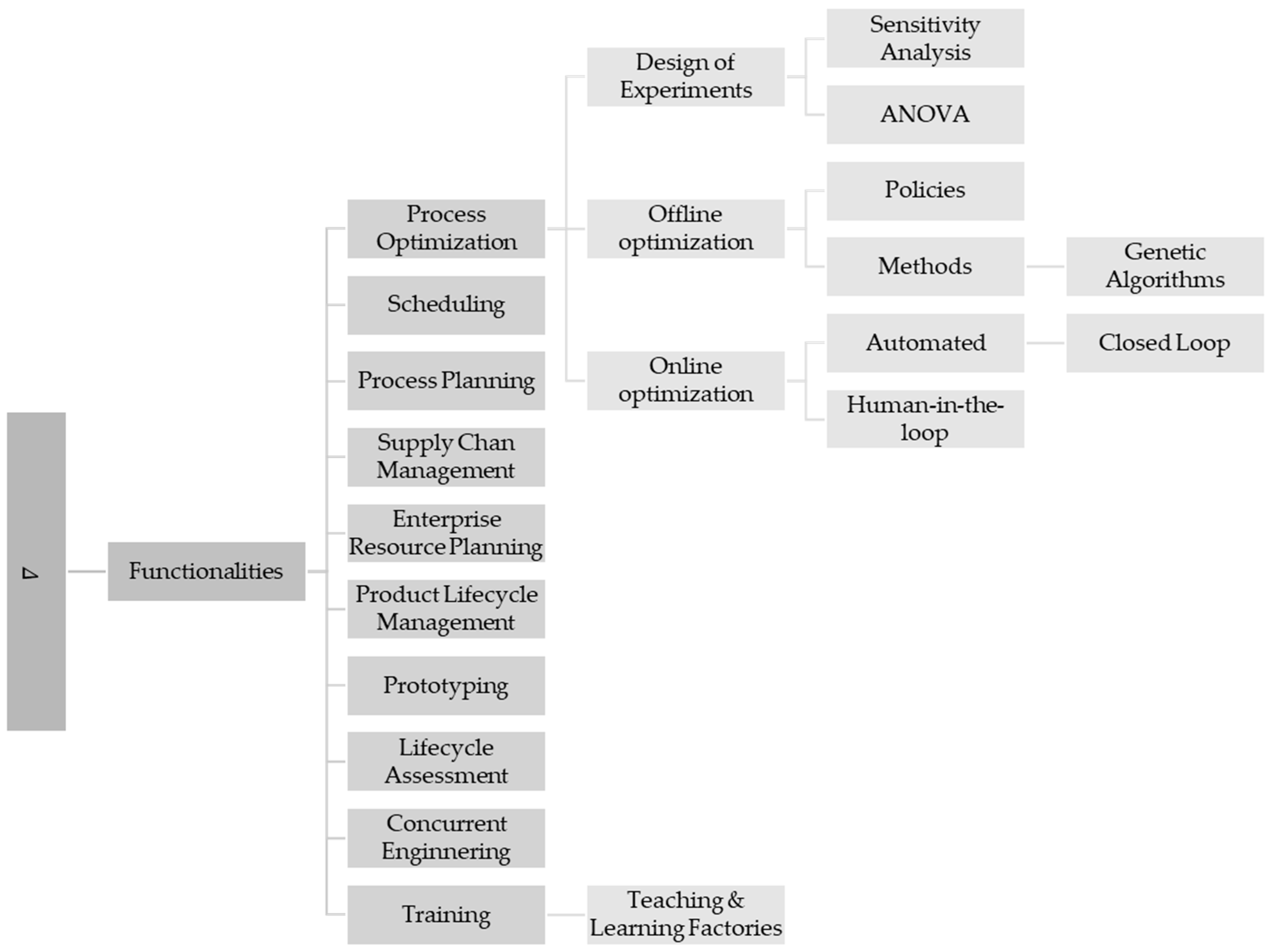

2.3.5. Category 5 (Functionalities and Manufacturing Operations)

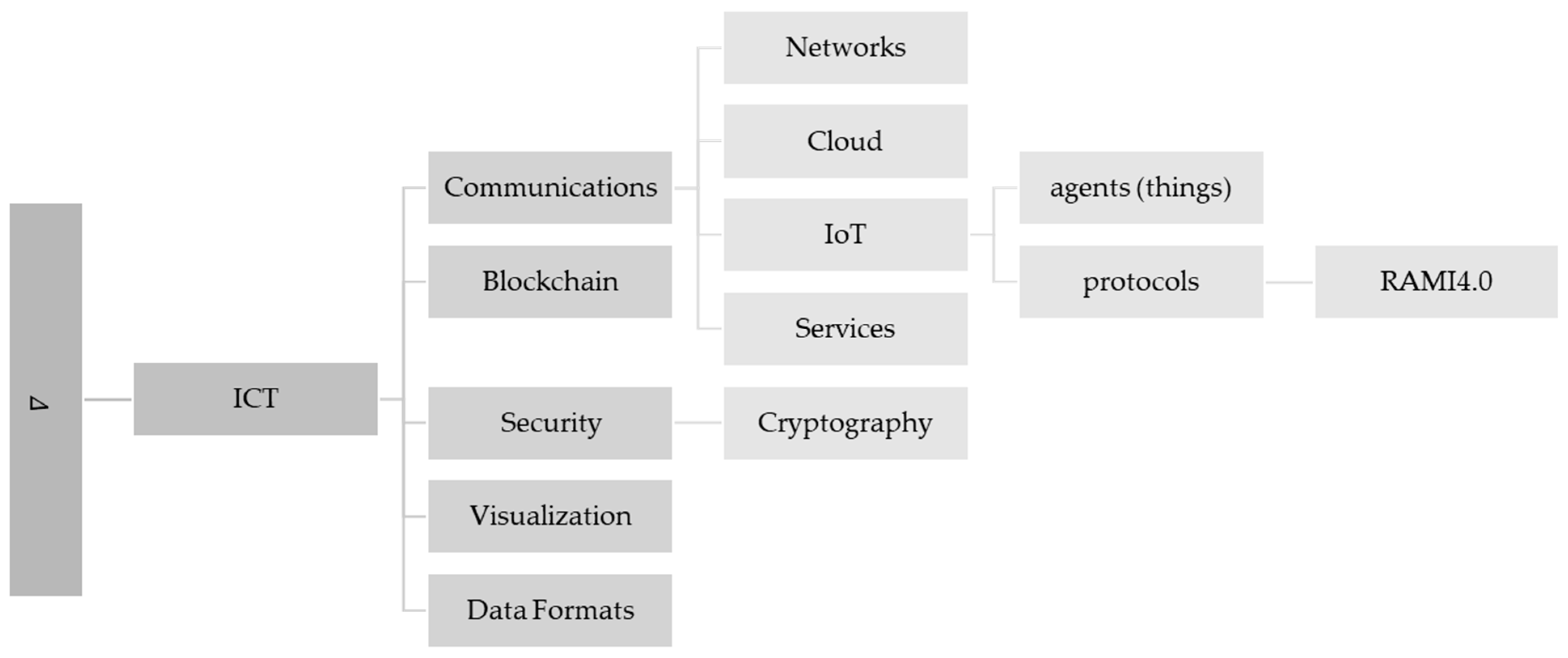

2.3.6. Category 6 (ICT)

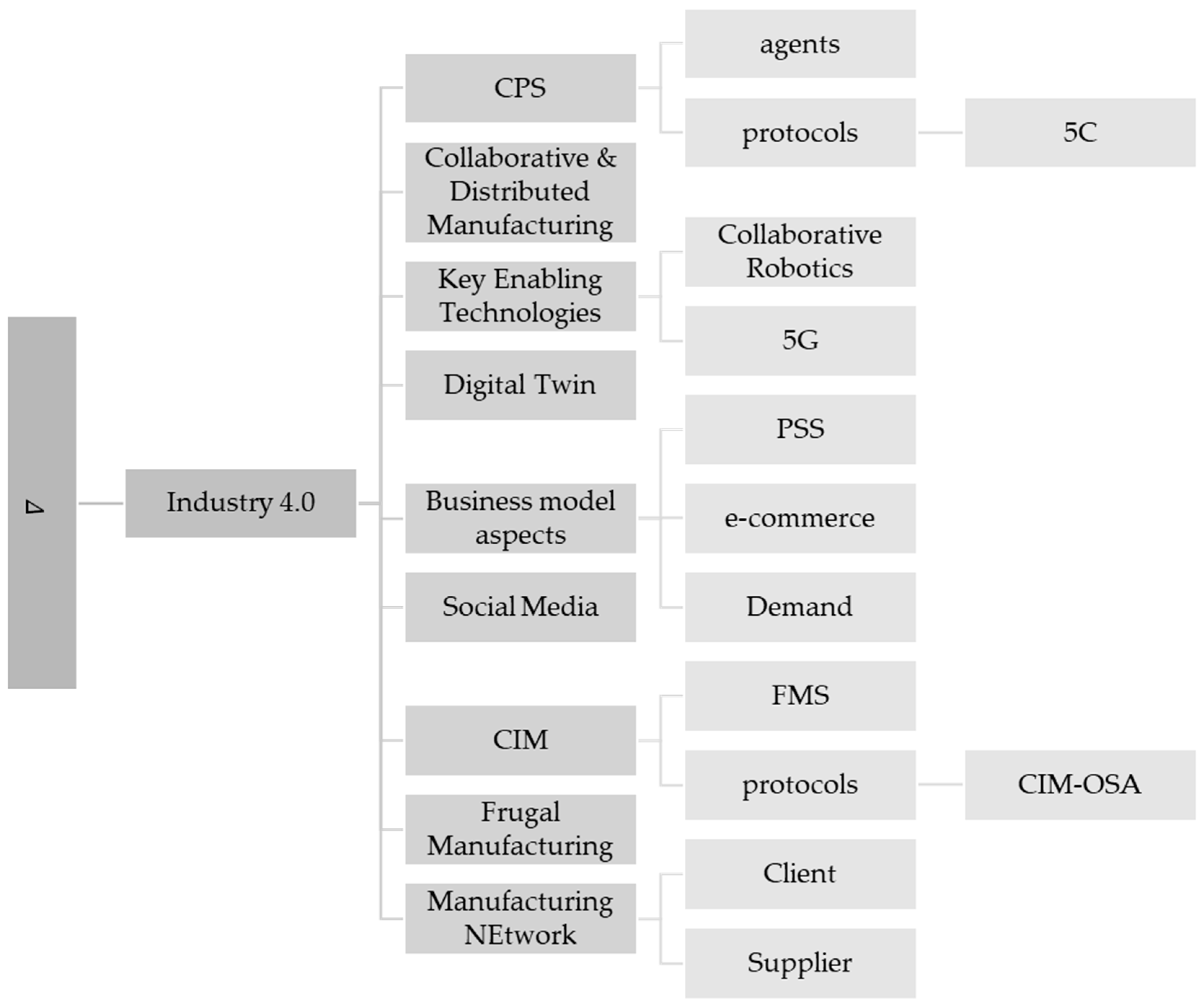

2.3.7. Category 7 (Industry 4.0)

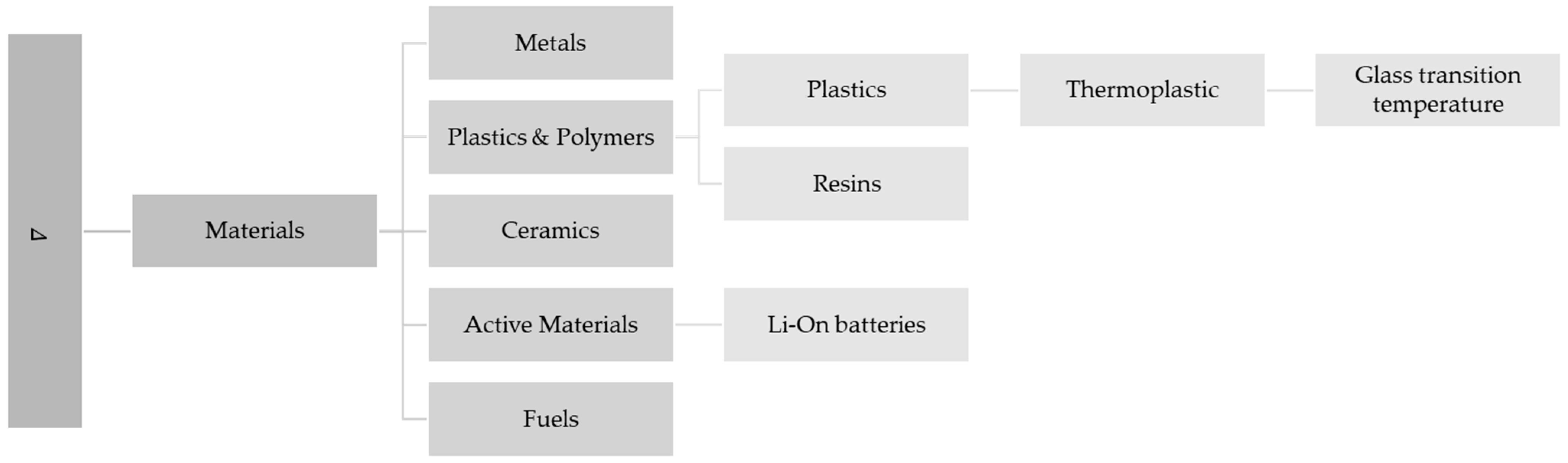

2.3.8. Category 8 (Materials)

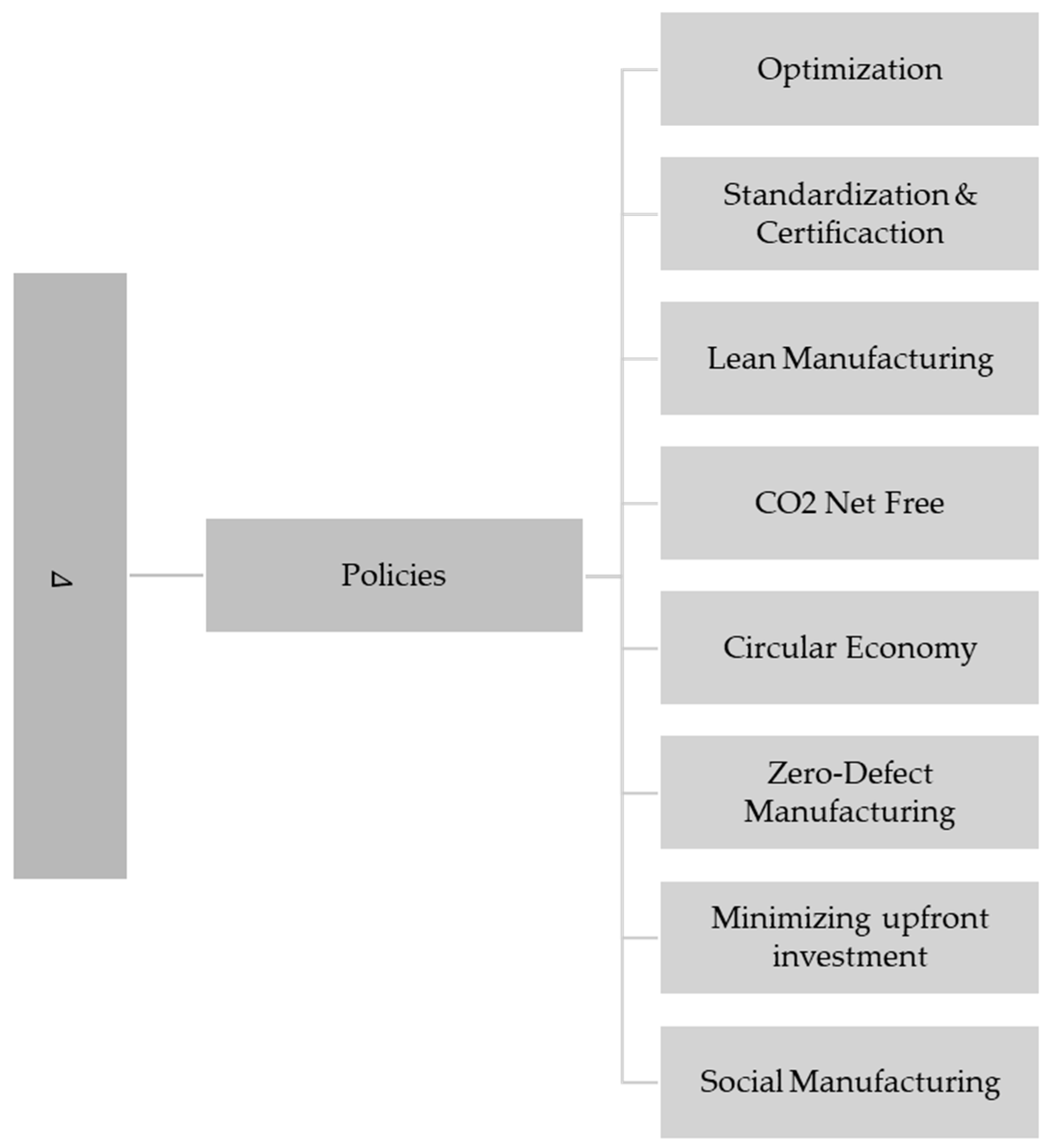

2.3.9. Category 9 (Policies)

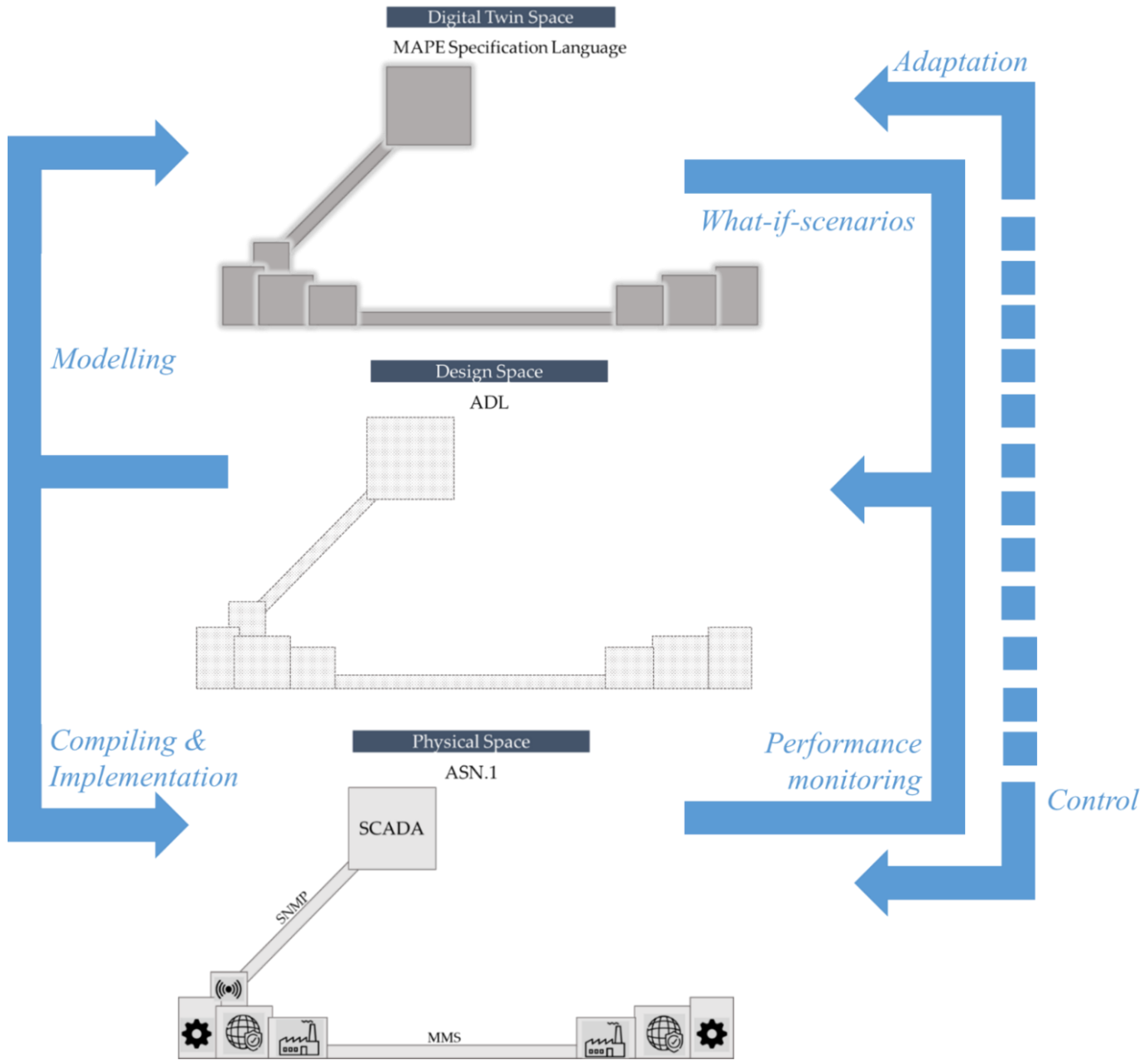

3. Approach

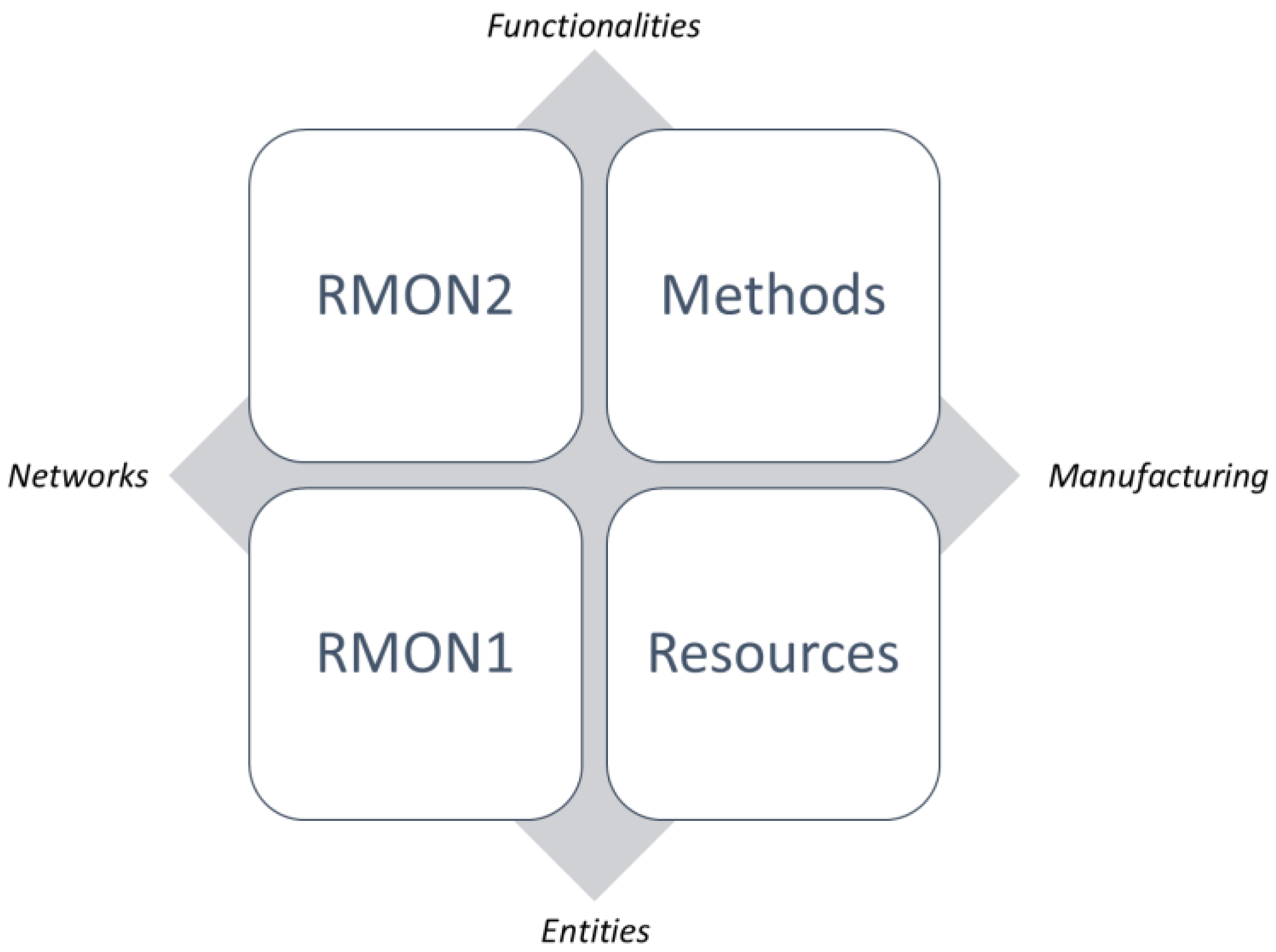

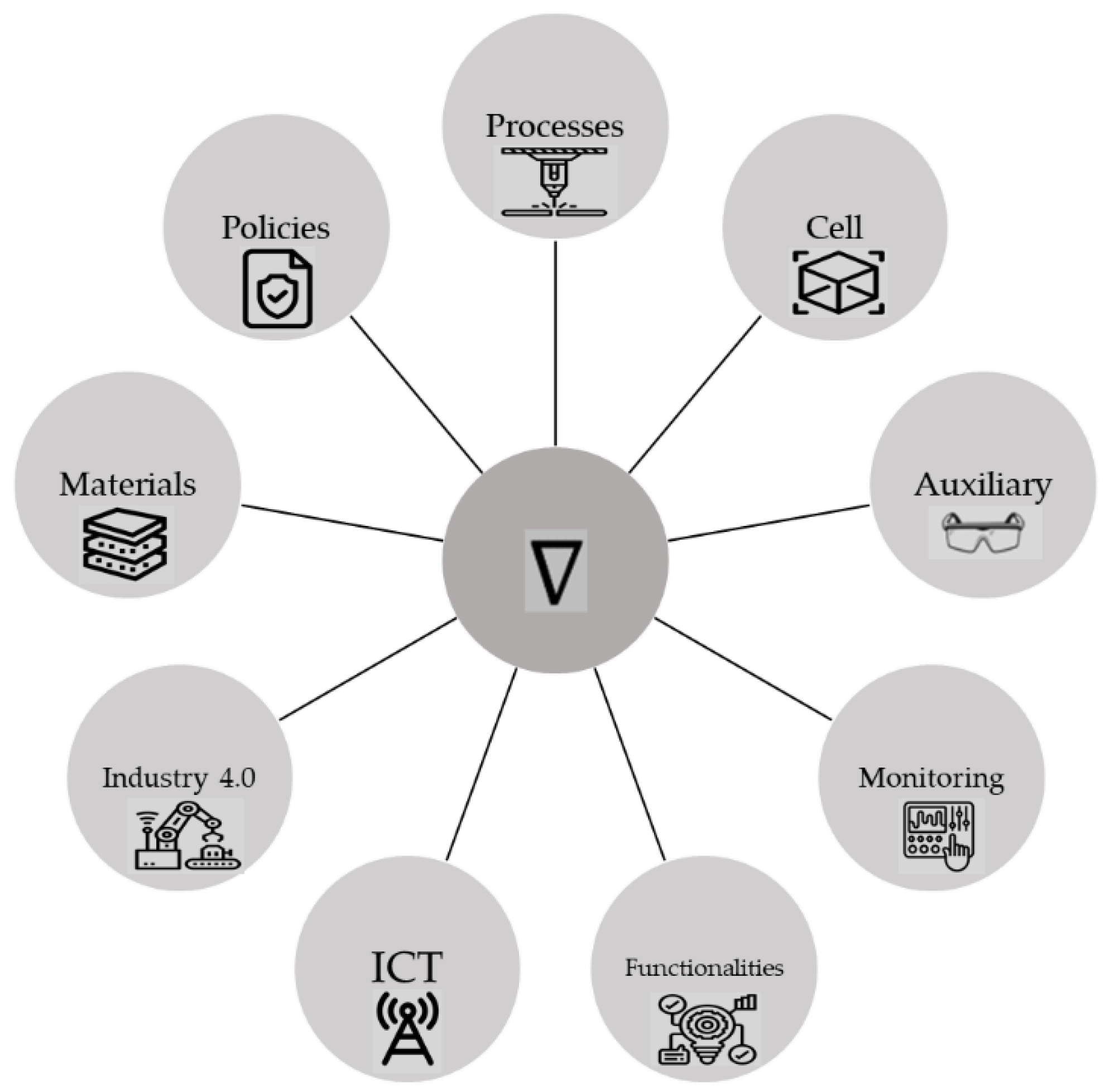

3.1. Classification of Technologies

3.2. Knowledge Database

4. Case Studies

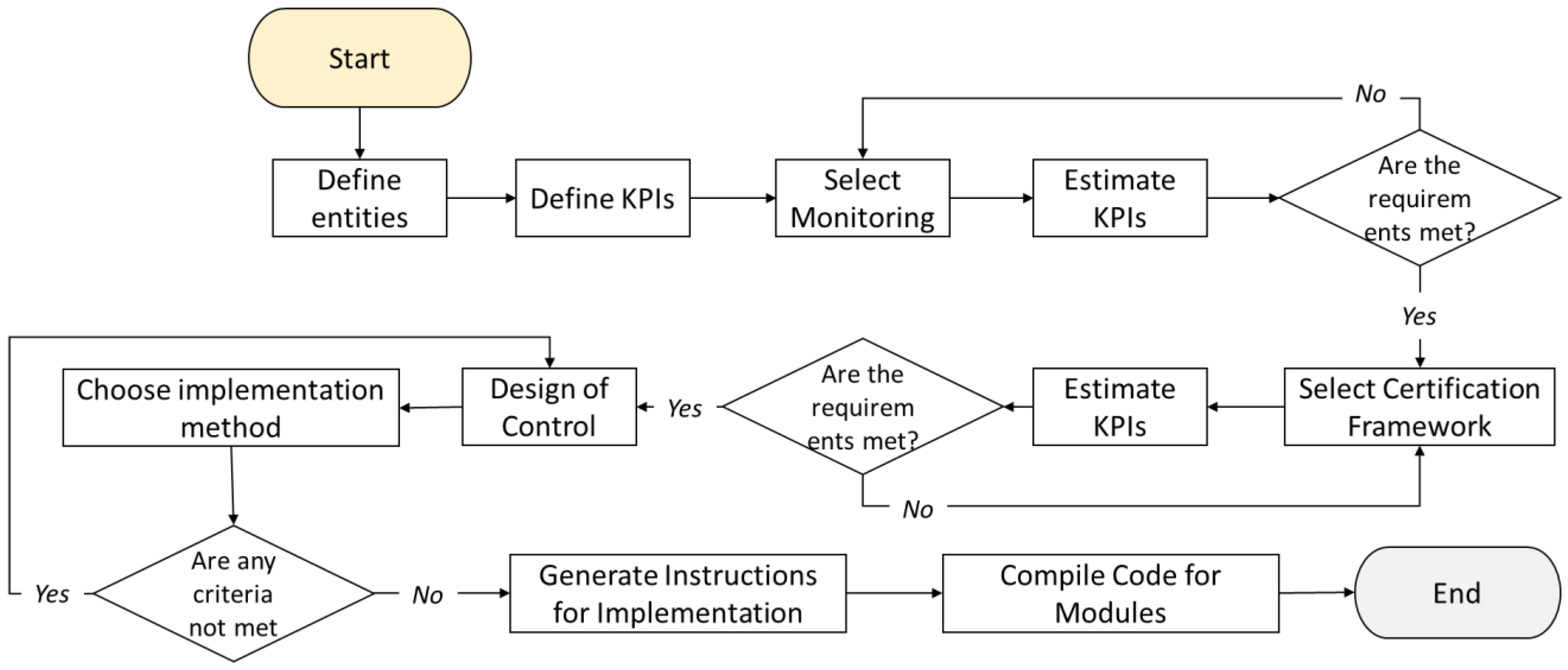

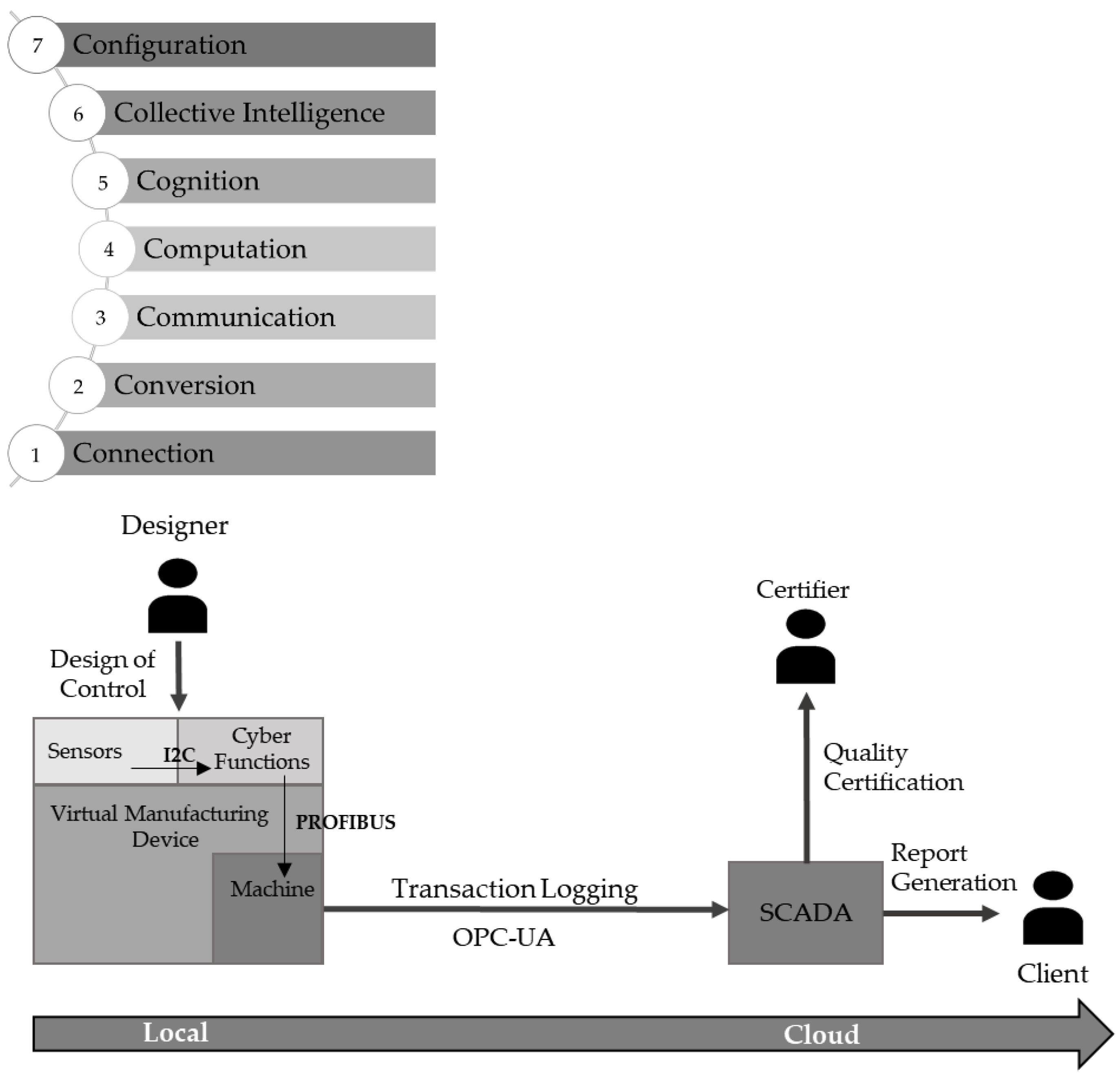

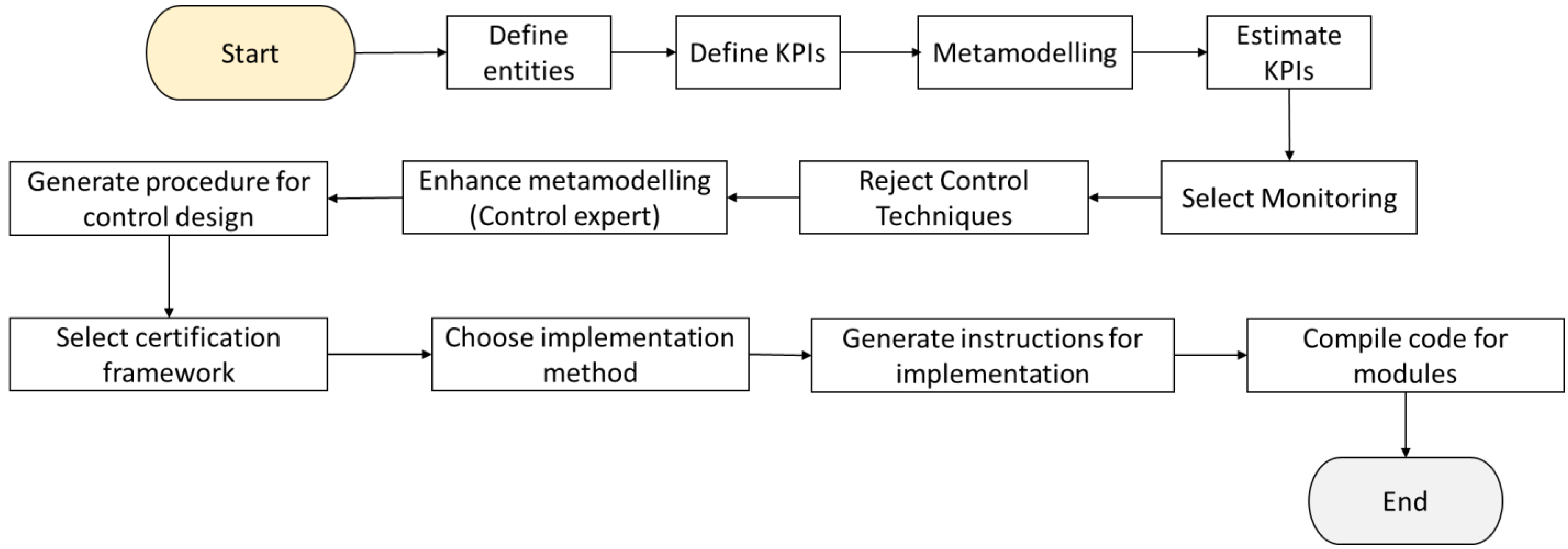

4.1. Process Monitoring/Control and Policies Integration

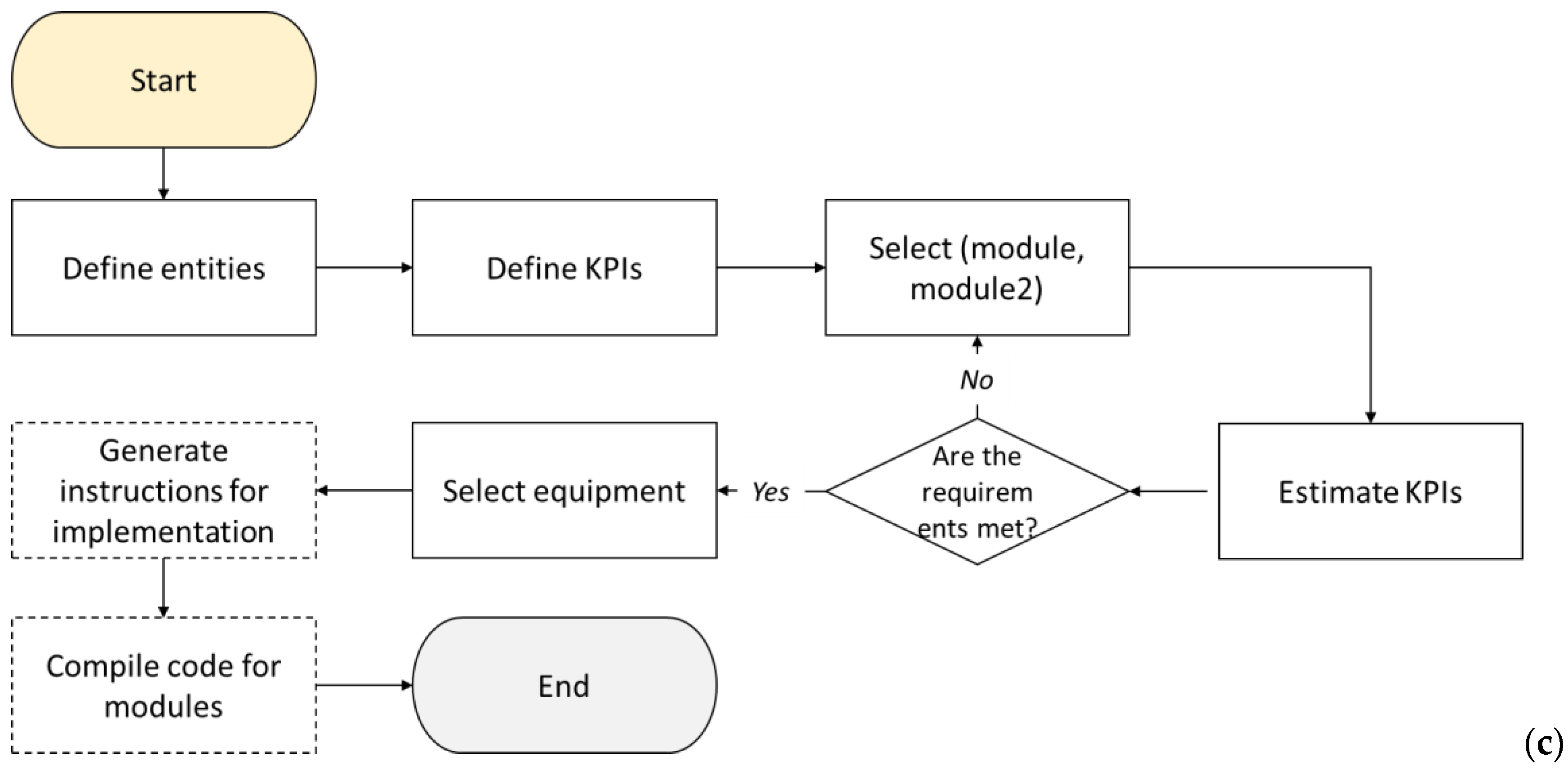

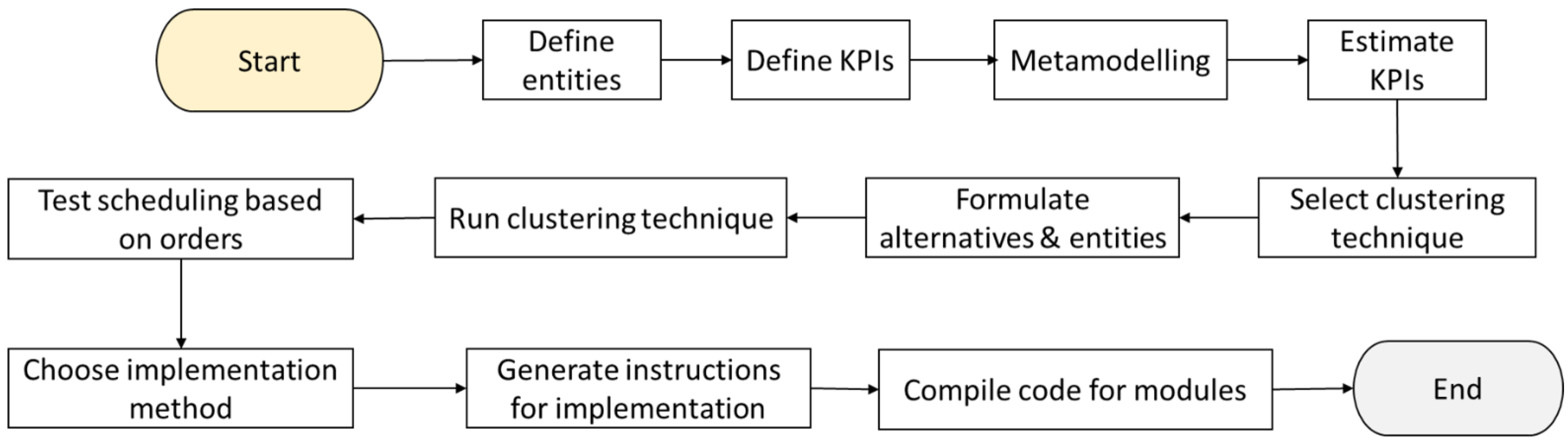

4.2. Process Chain Manipulation

- Certification: Data acquisition capabilities and communication devices;

- Lifecycle assessment (LCA): energy consumption monitoring, as well as traceability system for the parts;

- Zero Defect Manufacturing: sensors’ inclusion during, before and after processing, as well as data traceability technique.

5. Results and Discussion

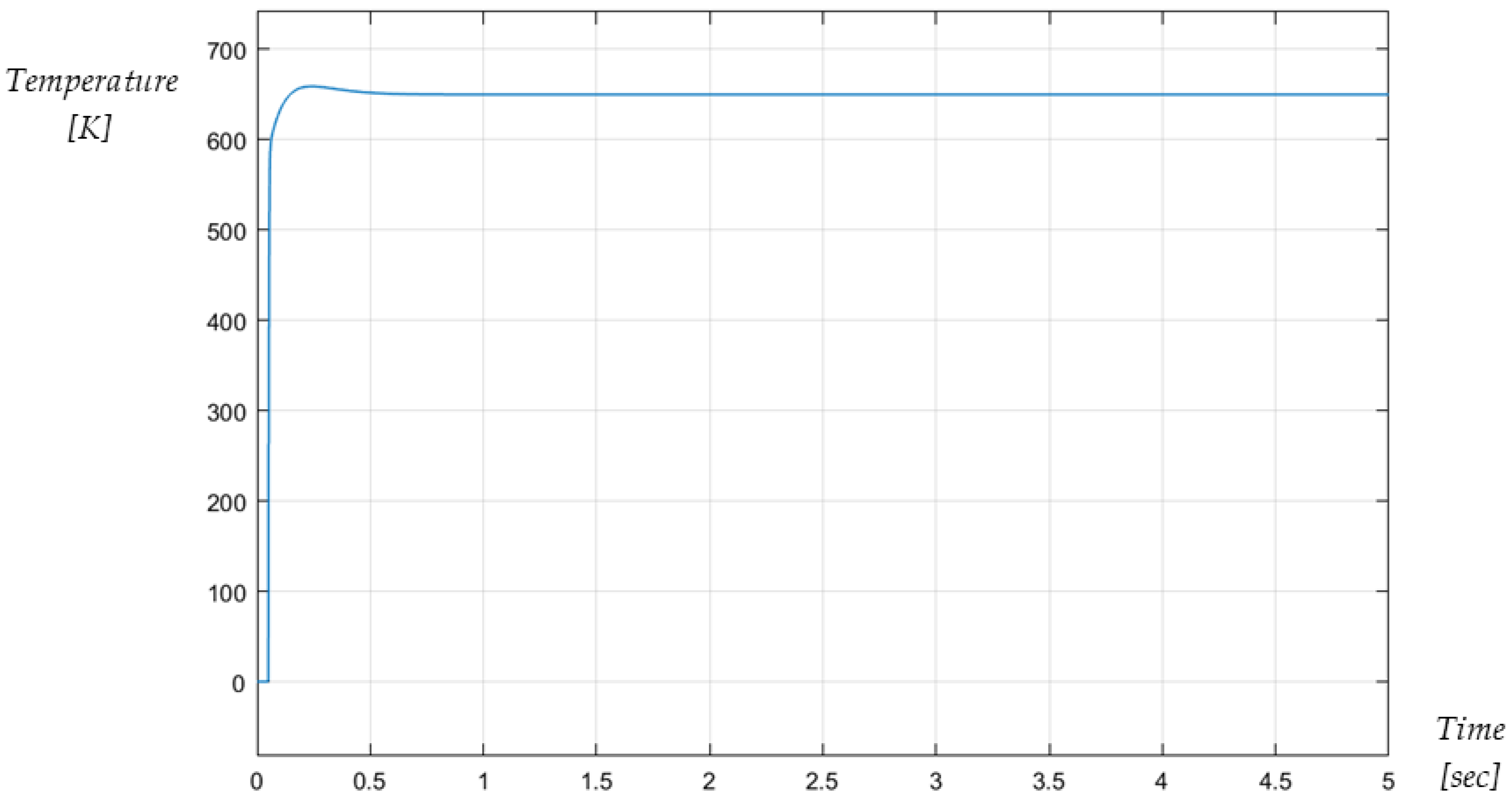

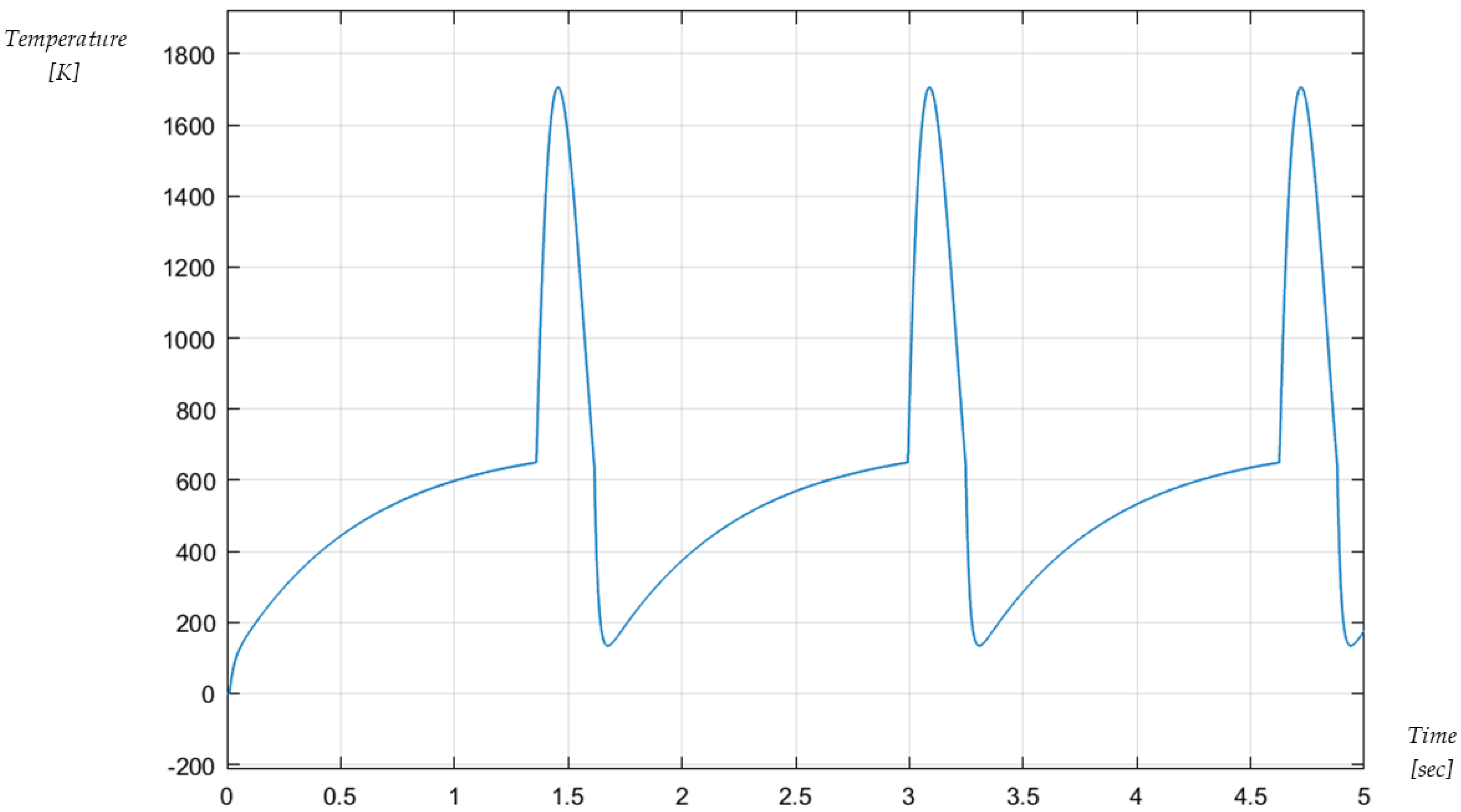

5.1. Process Monitoring and Control

5.2. Process Chain Manipulation

5.3. Business Aspects (Complexity and Cost)

6. Conclusions and Future Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Papakostas, N.; Constantinescu, C.; Mourtzis, D. Novel industry 4.0 technologies and applications. Appl. Sci. 2020, 10, 6498. [Google Scholar] [CrossRef]

- Mourtzis, D.; Angelopoulos, J.; Panopoulos, N. Smart Grids as product-service systems in the framework of energy 5.0-a state-of-the-art review. Green Manuf. Open 2022, 1, 5. [Google Scholar] [CrossRef]

- Ferrera, E.; Rossini, R.; Baptista, A.J.; Evans, S.; Hovest, G.G.; Holgado, M.; Lezak, E.; Lourenço, E.J.; Masluszczak, Z.; Schneider, A.; et al. Toward industry 4.0: Efficient and sustainable manufacturing leveraging MAESTRI total efficiency framework. In Sustainable Design and Manufacturing 2017: Selected Papers on Sustainable Design and Manufacturing 4; Springer International Publishing: Cham, Switzerland, 2017; pp. 624–633. [Google Scholar]

- Stavropoulos, P.; Foteinopoulos, P.; Papacharalampopoulos, A.; Bikas, H. Addressing the challenges for the industrial application of additive manufacturing: Towards a hybrid solution. Int. J. Lightweight Mater. Manuf. 2018, 1, 157–168. [Google Scholar] [CrossRef]

- Psarommatis, F.; May, G.; Dreyfus, P.A.; Kiritsis, D. Zero defect manufacturing: State-of-the-art review, shortcomings and future directions in research. Int. J. Prod. Res. 2020, 58, 1–17. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Spetsieris, A.; Papacharalampopoulos, A. A Circular Economy based Decision Support System for the Assembly/Disassembly of Multi-Material Components. In Procedia CIRP; Elsevier B.V.: Amsterdam, The Netherlands, 2020; pp. 48–53. [Google Scholar]

- Papacharalampopoulos, A.; Bikas, H.; Michail, C.; Stavropoulos, P. On the generation of validated manufacturing process optimization and control schemes. In Proceedings of the CIRPe 2020–8th CIRP Global Web Conference–Flexible Mass Customisation, Leuven, Belgium, 14–16 October 2020. [Google Scholar]

- Rao, S.K.; Prasad, R. Impact of 5G Technologies on Industry 4.0. Wirel. Pers. Commun. 2018, 100, 145–159. [Google Scholar] [CrossRef]

- Schleinkofer, U.; Klöpfer, K.; Schneider, M.; Bauernhansl, T. Cyber-physical systems as part of frugal manufacturing systems. In Procedia CIRP; Elsevier B.V.: Amsterdam, The Netherlands, 2019; pp. 264–269. [Google Scholar]

- Mourtzis, D.; Fotia, S.; Boli, N.; Pittaro, P. Product-service system (PSS) complexity metrics within mass customization and Industry 4.0 environment. Int. J. Adv. Manuf. Technol. 2018, 97, 91–103. [Google Scholar] [CrossRef]

- Frank, A.G.; Mendes, G.H.S.; Ayala, N.F.; Ghezzi, A. Servitization and Industry 4.0 convergence in the digital transformation of product firms: A business model innovation perspective. Technol. Forecast. Soc. Chang. 2019, 141, 341–351. [Google Scholar] [CrossRef]

- La Torre, M.; Sabelfeld, S.; Blomkvist, M.; Dumay, J. Rebuilding trust: Sustainability and non-financial reporting and the European Union regulation. Meditari Account. Res. 2020, 28, 701–725. [Google Scholar] [CrossRef]

- Zheng, T.; Ardolino, M.; Bacchetti, A.; Perona, M. The applications of Industry 4.0 technologies in manufacturing context: A systematic literature review. Int. J. Prod. Res. 2021, 59, 1922–1954. [Google Scholar] [CrossRef]

- Weforum Site. Available online: https://www.weforum.org/agenda/2018/11/people-are-the-future-of-production-manufacturing/ (accessed on 5 December 2022).

- Cimini, C.; Pirola, F.; Pinto, R.; Cavalieri, S. A human-in-the-loop manufacturing control architecture for the next generation of production systems. J. Manuf. Syst. 2020, 54, 258–271. [Google Scholar] [CrossRef]

- Sancho-Zamora, R.; Hernández-Perlines, F.; Peña-García, I.; Gutiérrez-Broncano, S. The Impact of Absorptive Capacity on Innovation: The Mediating Role of Organizational Learning. Int. J. Environ. Res. Public Health 2022, 19, 842. [Google Scholar] [CrossRef]

- Sancho-Zamora, R.; Gutiérrez-Broncano, S.; Hernández-Perlines, F.; Peña-García, I. A Multidimensional Study of Absorptive Capacity and Innovation Capacity and Their Impact on Business Performance. Front. Psychol. 2021, 12, 751997. [Google Scholar] [CrossRef]

- World Bank Site. Available online: https://openknowledge.worldbank.org/bitstream/handle/10986/28341/9781464811609.pdf?sequence=4&isAllowed=y (accessed on 1 December 2022).

- Mourtzis, D. Introduction to cloud technology and Industry 4.0. In Design and Operation of Production Networks for Mass Personalization in the Era of Cloud Technology; Elsevier: Amsterdam, The Netherlands, 2022; pp. 1–12. [Google Scholar]

- Qi, Q.; Tao, F.; Hu, T.; Anwer, N.; Liu, A.; Wei, Y.; Wang, L.; Nee, A. Enabling technologies and tools for digital twin. J. Manuf. Syst. 2019, 58, 3–21. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Lee, J.; Bagheri, B.; Jin, C. Introduction to cyber manufacturing. Manuf. Lett. 2016, 8, 11–15. [Google Scholar]

- Fisher, O.; Watson, N.; Porcu, L.; Bacon, D.; Rigley, M.; Gomes, R.L. Cloud manufacturing as a sustainable process manufacturing route. J. Manuf. Syst. 2018, 47, 53–68. [Google Scholar] [CrossRef]

- Connected Factories Site. Available online: https://www.connectedfactories.eu/autonomous-smart-factories-pathway (accessed on 20 November 2022).

- Cordis Database (Avangard Deliverable D1.3). Available online: https://cordis.europa.eu/project/id/869986 (accessed on 20 February 2021).

- Bao, J.; Guo, D.; Li, J.; Zhang, J. The modelling and operations for the digital twin in the context of manufacturing. Enterp. Inf. Syst. 2019, 13, 534–556. [Google Scholar] [CrossRef]

- König, S.; Vogel-Heuser, B.; Fieg, E.; Hahn, M.; Kopp, O. Modelling Production Workflows in Automotive Manufacturing. In Proceedings of the IEEE 23rd Conference on Business Informatics (CBI), Bolzano, Italy, 1–3 September 2021; Volume 2, pp. 39–46. [Google Scholar]

- Hu, H.; Li, Z. Modeling and scheduling for manufacturing grid workflows using timed Petri nets. Int. J. Adv. Manuf. Technol. 2009, 42, 553–568. [Google Scholar] [CrossRef]

- Atluri, V.; Huang, W.K. An authorization model for workflows. In European Symposium on Research in Computer Security; Springer: Berlin/Heidelberg, Germany, 1996; pp. 44–64. [Google Scholar]

- Keddis, N.; Kainz, G.; Zoitl, A.; Knoll, A. Modeling production workflows in a mass customization era. In Proceedings of the IEEE International Conference on Industrial Technology (ICIT) 2015, Seville, Spain, 17–19 March 2015; pp. 1901–1906. [Google Scholar]

- Afanasyev, A.; Voit, N. Multiagent system to analyse manufacturing process models. In Uncertainty Modelling in Knowledge Engineering and Decision Making: Proceedings of the 12th International FLINS Conference 2016; World Scientific: Singapore, 2016; pp. 444–449. [Google Scholar]

- Voit, N.N. Development of timed RT-grammars for analysis of business process at manufacturing and in cyber-physical systems. In Proceedings of the International Conference on Computing Networking and Informatics (ICCNI) 2017, Lagos, Nigeria, 29–31 October 2017; pp. 1–5. [Google Scholar]

- Prades, L.; Romero, F.; Estruch, A.; García-Domínguez, A.; Serrano, J. Defining a methodology to design and implement business process models in BPMN according to the standard ANSI/ISA-95 in a manufacturing enterprise. Procedia Eng. 2013, 63, 115–122. [Google Scholar] [CrossRef]

- Bernstein, W.Z.; Tamayo, C.D.; Lechevalier, D.; Brundage, M.P. Incorporating unit manufacturing process models into life cycle assessment workflows. Procedia CIRP 2019, 80, 364–369. [Google Scholar] [CrossRef]

- Preuveneers, D.; Joosen, W.; Ilie-Zudor, E. Identity management for cyber-physical production workflows and individualized manufacturing in industry 4.0. In Proceedings of the Symposium on Applied Computing 2017, Marrakech, Morocco, 4–6 April 2017; pp. 1452–1455. [Google Scholar]

- Afanasyev, A.; Ukhanova, M.; Ionova, I.; Voit, N. Processing of design and manufacturing workflows in a large enterprise. In Proceedings of the International Conference on Computational Science and Its Applications, Trieste, Italy, 3–6 July 2017; Springer: Cham, Switzerland, 2018; pp. 565–576. [Google Scholar]

- Korambath, P.; Wang, J.; Kumar, A.; Hochstein, L.; Schott, B.; Graybill, R.; Baldea, M.; Davis, J. Deploying kepler workflows as services on a cloud infrastructure for smart manufacturing. Procedia Comput. Sci. 2014, 29, 2254–2259. [Google Scholar] [CrossRef]

- Leusin, M.; Frazzon, E.; Uriona Maldonado, M.; Kück, M.; Freitag, M. Solving the Job-Shop Scheduling Problem in the Industry 4.0 Era. Technologies 2018, 6, 107. [Google Scholar] [CrossRef]

- Lee, E.A. Cyber physical systems: Design challenges. In Proceedings of the 11th IEEE International Symposium on Object and Component-Oriented Real-Time Distributed Computing (ISORC) IEEE, Orlando, FL, USA, 5–7 May 2008; pp. 363–369. [Google Scholar]

- Standardization Sector-ITU Series Y: Global Information Infrastructure, Internet Protocol Aspects and Next-Generation Networks Next Generation Networks–Frameworks and Functional Architecture Models. International Telecommunication Union, Geneva, Switzerland. 2012. Available online: https://www.itu.int/rec/T-REC-Y.2060-201206-I (accessed on 7 December 2022).

- Lee, J.; Bagheri, B.; Kao, H.A. A Cyber-Physical Systems architecture for Industry 4.0-based manufacturing systems. Manuf. Lett. 2015, 3, 18–23. [Google Scholar] [CrossRef]

- Ahmadi, A.; Cherifi, C.; Cheutet, V.; Ouzrout, Y. A review of CPS 5 components architecture for manufacturing based on standards. In Proceedings of the International Conference on Software, Knowledge, Information Management & Applications (SKIMA 2018), IEEE, Phnom Penh, Cambodia, 3–5 December 2018. [Google Scholar]

- Josifovska, K.; Yigitbas, E.; Engels, G. A Digital Twin-Based Multi-Modal UI Adaptation Framework for Assistance Systems in Industry 4.0. In Proceedings of the 21st International Conference on Human-Computer Interaction 2019, Orlando, FL, USA, 26–31 July 2019; p. 11568. [Google Scholar]

- Mourtzis, D. Simulation in the design and operation of manufacturing systems: State of the art and new trends. Int. J. Prod. Res. 2020, 58, 1927–1949. [Google Scholar] [CrossRef]

- Knipp, R.S.; Crowder, R.S. The Manufacturing Automation Protocol and its application in continuous processes. ISA Trans. 1989, 28, 29–36. [Google Scholar] [CrossRef]

- Ahmed Halepoto, I.; Ali Sahito, A.; Soomro, M.; Khaskheli, S.; Shankar Chowdhry, B. Design and Modeling of Substation Time Critical Information Dissemination Model using Publisher-subscriber Communication Service Mapping. Indian J. Sci. Technol. 2016, 9, 1–6. [Google Scholar] [CrossRef]

- Code, P.; Prix, C. Communication Networks and Systems for Power Utility Automation–Part 8-1: Specific Communication Service Mapping (SCSM)–Mappings to MMS (ISO 9506-1 and ISO 9506-2) and to ISO/IEC 8802-3 Réseaux et Systèmes de Communication Pour l’Automatisation des Systèmes électriques–; International Electrotechnical Commission: Geneva, Switzerland, 2011. [Google Scholar]

- Gondim, J.J.; de Oliveira Albuquerque, R.; Orozco, A.L.S. Mirror saturation in amplified reflection Distributed Denial of Service: A case of study using SNMP, SSDP, NTP and DNS protocols. Future Gen. Comput. Syst. 2020, 108, 68–81. [Google Scholar] [CrossRef]

- Michaloski, J.; Proctor, F.; Arinez, J.; Berglund, J. Toward the ideal of automating production optimization. In AASME International Mechanical Engineering Congress and Exposition; American Society of Mechanical Engineers (ASME): San Diego, CA, USA, 2013. [Google Scholar]

- Wortmann, A.; Barais, O.; Combemale, B.; Wimmer, M. Modeling languages in Industry 4.0: An extended systematic mapping study. Softw. Syst. Model. 2020, 19, 67–94. [Google Scholar] [CrossRef]

- Chen, D.; Panfilenko, D.V.; Khabbazi, M.R.; Sonntag, D. A model-based approach to qualified process automation for anomaly detection and treatment. In Proceedings of the IEEE 21st International Conference on Emerging Technologies and Factory Automation (ETFA), Berlin, Germany, 6–9 September 2016. [Google Scholar]

- Kovalenko, O.; Wimmer, M.; Sabou, M.; Lüder, A.; Ekaputra, F.J.; Biffl, S. Modeling AutomationML: Semantic Web technologies vs. Model-Driven Engineering. In Proceedings of the IEEE 20th Conference on Emerging Technologies & Factory Automation (ETFA), Luxembourg, 8–11 September 2015. [Google Scholar]

- Felser, M.; Rentschler, M.; Kleineberg, O. Coexistence Standardization of Operation Technology and Information Technology. Proc. IEEE 2019, 107, 962–976. [Google Scholar] [CrossRef]

- ITU Site-X.693: Information Technology-ASN.1 Encoding Rules: XML Encoding Rules (XER). Available online: https://www.itu.int/rec/T-REC-X.693/en (accessed on 18 January 2021).

- Sørensen, J.T.; Jaatun, M.G. An analysis of the manufacturing messaging specification protocol. In Lecture Notes in Computer Science; Springer: Berlin/Heidelberg, Germany, 2008; pp. 602–615. [Google Scholar]

- Sisconet Site. Available online: https://www.sisconet.com/wp-content/uploads/2016/03/mmsovrlg.pdf (accessed on 18 January 2021).

- Zeid, A.; Sundaram, S.; Moghaddam, M.; Kamarthi, S.; Marion, T. Interoperability in Smart Manufacturing: Research Challenges. Machines 2019, 7, 21. [Google Scholar] [CrossRef]

- Bing-Hai, Z.; Li-Feng, X.; Chuan-Meng, Y. DCOM and MMS-based control software architecture for automated manufacturing system. Int. J. Adv. Manuf. Technol. 2006, 27, 951–959. [Google Scholar] [CrossRef]

- RMON2 MIB Group. Available online: https://www.ibm.com/support/knowledgecenter/SSGNTH_4.0.1/com.ibm.netcool_ssm_4.0.1.doc/rg/reference/appRMON2_overview_r.html#xF584403700 (accessed on 18 January 2021).

- Pullan, T.T.; Bhasi, M.; Madhu, G. Object-oriented modelling of manufacturing information system for collaborative design. Int. J. Prod. Res. 2012, 50, 3328–3344. [Google Scholar] [CrossRef]

- NIST Site. Available online: https://nvlpubs.nist.gov/nistpubs/Legacy/IR/nistir7258.pdf (accessed on 18 January 2021).

- Arcaini, P.; Mirandola, R.; Riccobene, E.; Scandurra, P. Model-Based Testing for MAPE-K adaptation control loops. In Proceedings of the 2020 IEEE International Conference on Software Testing, Verification and Validation Workshops (ICSTW), Porto, Portugal, 24–28 October 2020; pp. 43–51. [Google Scholar]

- Loskyll, M.; Heck, I.; Schlick, J.; Schwarz, M. Context-Based Orchestration for Control of Resource-Efficient Manufacturing Processes. Futur. Internet 2012, 4, 737–761. [Google Scholar] [CrossRef]

- Pauker, F.; Mangler, J.; Rinderle-Ma, S.; Pollak, C. centurio.work-Modular Secure Manufacturing Orchestration. In Proceedings of the 16th International Conference on Business Process Management, Sydney, Australia, 9–14 September 2018. [Google Scholar]

- Rosa, M.; Barbosa, M.A.C.; Teixeira, M. Service-based manufacturing systems: Modelling and control. Int. J. Prod. Res. 2019, 57, 3421–3434. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Bikas, H.; Avram, O.; Valente, A.; Chryssolouris, G. Hybrid subtractive–additive manufacturing processes for high value-added metal components. Int. J. Adv. Manuf. Technol. 2020, 111, 645–655. [Google Scholar] [CrossRef]

- Ahuett-Garza, H.; Kurfess, T. A brief discussion on the trends of habilitating technologies for Industry 4.0 and Smart manufacturing. Manuf. Lett. 2018, 15, 60–63. [Google Scholar] [CrossRef]

- Bigliardi, B.; Bottani, E.; Casella, G. Enabling technologies, application areas and impact of industry 4.0: A bibliographic analysis. In Procedia Manufacturing; Elsevier B.V.: Amsterdam, The Netherlands, 2020; pp. 322–326. [Google Scholar]

- Chen, B.; Wan, J.; Shu, L.; Li, P.; Mukherjee, M.; Yin, B. Smart Factory of Industry 4.0: Key Technologies, Application Case, and Challenges. IEEE Access 2017, 6, 6505–6519. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. Literature review of Industry 4.0 and related technologies. J. Intell. Manuf. 2020, 31, 127–182. [Google Scholar] [CrossRef]

- Oztemel, E.; Gursev, S. A Taxonomy of Industry 4.0 and Related Technologies. In Industry 4.0: Current Status and Future Trends; IntechOpen: Rijeka, Croatia, 2020; Volume 45. [Google Scholar]

- Wan, J.; Cai, H.; Zhou, K. Industrie 4.0: Enabling technologies. In Proceedings of the 2015 International Conference on Intelligent Computing and Internet of Things, Harbin, China, 17–18 January 2015; pp. 135–140. [Google Scholar]

- Qian, F.; Zhong, W.; Du, W. Fundamental Theories and Key Technologies for Smart and Optimal Manufacturing in the Process Industry. Engineering 2017, 3, 154–160. [Google Scholar] [CrossRef]

- Nguyen, T.N.; Zeadally, S.; Vuduthala, A. Cyber-physical cloud manufacturing systems with digital-twins. IEEE Internet Comput. 2021, 26, 15–21. [Google Scholar] [CrossRef]

- Stentoft, J.; Jensen, K.W.; Philipsen, K.; Haug, A. Drivers and barriers for Industry 4.0 readiness and practice: A SME perspective with empirical evidence. In Proceedings of the 52nd Hawaii International Conference on System Sciences, Maui, HI, USA, 8–11 January 2019. [Google Scholar]

- Eswaran, M.; Bahubalendruni, M.R. Challenges and opportunities on AR/VR technologies for manufacturing systems in the context of industry 4.0: A state of the art review. J. Manuf. Syst. 2022, 65, 260–278. [Google Scholar] [CrossRef]

- Terry, S.; Lu, H.; Fidan, I.; Zhang, Y.; Tantawi, K.; Guo, T.; Asiabanpour, B. The Influence of Smart Manufacturing towards Energy Conservation: A Review. Technologies 2020, 8, 31. [Google Scholar] [CrossRef]

- Walden, R.; Lie, S.; Pandolfo, B.; Lee, T.; Lockhart, C. Design Research Units and Small to Medium Enterprises (SMEs): An Approach for Advancing Technology and Competitive Strength in Australia. Des. J. 2018, 21, 247–265. [Google Scholar] [CrossRef]

- Bikas, H.; Lianos, A.K.; Stavropoulos, P. A design framework for additive manufacturing. Int. J. Adv. Manuf. Technol. 2019, 103, 3769–3783. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Foteinopoulos, P. Modelling of additive manufacturing processes: A review and classification. Manuf. Rev. 2018, 5, 2. [Google Scholar] [CrossRef]

- Xu, J.; Luo, Y.; Zhu, L.; Han, J.; Zhang, C.; Chen, D. Effect of shielding gas on the plasma plume in pulsed laser welding. Meas. J. Int. Meas. Confed. 2019, 134, 25–32. [Google Scholar] [CrossRef]

- Apostolos, F.; Alexios, P.; Georgios, P.; Panagiotis, S.; George, C. Energy efficiency of manufacturing processes: A critical review. Procedia CIRP 2013, 7, 628–633. [Google Scholar] [CrossRef]

- Papacharalampopoulos, A.; Giannoulis, C.; Stavropoulos, P.; Mourtzis, D. A Digital Twin for Automated Root-Cause Search of Production Alarms Based on KPIs Aggregated from IoT. Appl. Sci. 2020, 10, 2377. [Google Scholar] [CrossRef]

- Papacharalampopoulos, A.; Stavropoulos, P. Towards a digital twin for thermal processes: Control-centric approach. Procedia CIRP 2020, 86, 110–115. [Google Scholar] [CrossRef]

- Papacharalampopoulos, A.; Michail, C.; Stavropoulos, P. Manufacturing Process Control Through a Digital Twin: Encoding Issues. In Proceedings of the TESConf 2020—9th International Conference on Through-Life Engineering Services, Cranfield, UK, 3–4 November 2020. [Google Scholar]

- Frank, M.; Drikakis, D.; Charissis, V. Machine-Learning Methods for Computational Science and Engineering. Computation 2020, 8, 15. [Google Scholar] [CrossRef]

- Papacharalampopoulos, A.; Stavropoulos, P. Manufacturing Process Optimization via Digital Twins: Definitions and Limitations. In Proceedings of the International Conference on Flexible Automation and Intelligent Manufacturing, Detroit, MI, USA, 19–23 June 2022; pp. 342–350. [Google Scholar]

- Papacharalampopoulos, A.; Stavropoulos, P.; Petrides, D. Towards a digital twin for manufacturing processes: Applicability on laser welding. Procedia CIRP 2020, 88, 110–115. [Google Scholar] [CrossRef]

- Sancarlos, A.; Cameron, M.; Abel, A.; Cueto, E.; Duval, J.L.; Chinesta, F. From ROM of electrochemistry to AI-based battery digital and hybrid twin. Arch. Comput. Methods Eng. 2021, 28, 979–1015. [Google Scholar] [CrossRef]

- Rüßmann, M.; Lorenz, M.; Gerbert, P.; Waldner, M.; Justus, J.; Engel, P.; Harnisch, M. Industry 4.0 The Future of Productivity and Growth in Manufacturing Industries. Boston Consult. Group 2015, 9, 54–89. [Google Scholar]

- Da Xu, L.; Xu, E.L.; Li, L. Industry 4.0: State of the art and future trends. Int. J. Prod. Res. 2018, 56, 2941–2962. [Google Scholar]

- Anyfantis, K.; Stavropoulos, P.; Foteinopoulos, P.; Chryssolouris, G. An approach for the design of multi-material mechanical components. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2019, 233, 960–974. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Michail, C.; Papacharalampopoulos, A. Towards predicting manufacturing effect on hybrid part efficiency: An automotive case. Procedia CIRP 2020, 85, 156–161. [Google Scholar] [CrossRef]

- Yin, S.; Cavaliere, P.; Aldwell, B.; Jenkins, R.; Liao, H.; Li, W.; Lupoi, R. Cold spray additive manufacturing and repair: Fundamentals and applications. Addit. Manuf. 2018, 21, 628–650. [Google Scholar] [CrossRef]

- Lindström, J.; Kyösti, P.; Birk, W.; Lejon, E. An Initial Model for Zero Defect Manufacturing. Appl. Sci. 2020, 10, 4570. [Google Scholar] [CrossRef]

- Nascimento, D.L.M.; Alencastro, V.; Quelhas, O.L.G.; Caiado, R.G.G.; Garza-Reyes, J.A.; Lona, L.R.; Tortorella, G. Exploring Industry 4.0 technologies to enable circular economy practices in a manufacturing context: A business model proposal. J. Manuf. Technol. Manag. 2019, 30, 607–627. [Google Scholar] [CrossRef]

- Yang, S.; Raghavendra, M.R.A.; Kaminski, J.; Pepin, H. Opportunities for industry 4.0 to support remanufacturing. Appl. Sci. 2018, 8, 1177. [Google Scholar] [CrossRef]

- Huang, S.; Wang, B.; Li, X.; Zheng, P.; Mourtzis, D.; Wang, L. Industry 5.0 and Society 5.0—Comparison, complementation and co-evolution. J. Manuf. Syst. 2022, 64, 424–428. [Google Scholar] [CrossRef]

- IEEE Standards Site. Available online: https://standards.ieee.org/wp-content/uploads/import/documents/tutorials/oid.pdf#:~:text=An%20Object%20Identifier%20is%20a%20name%20used%20to,organizationally%20derived%2C%20and%20assigned%2C%20assignments%20beyond%20the%20OUI (accessed on 30 June 2022).

- Ye, X.; Hong, S.H. An AutomationML/OPC UA-based Industry 4.0 solution for a manufacturing system. In Proceedings of the 23rd International Conference on Emerging Technologies and Factory Automation (ETFA), Torino, Italy, 4–7 September 2018; Volume 1, pp. 543–550. [Google Scholar]

- Stavropoulos, P.; Papacharalampopoulos, A.; Michail, C.; Vassilopoulos, V.; Alexopoulos, K.; Perlo, P. A two-stage decision support system for manufacturing processes integration in microfactories for electric vehicles. Procedia Manuf. 2021, 54, 106–111. [Google Scholar] [CrossRef]

- EFFRA Innovation Portal. Available online: https://portal.effra.eu/results/list/result (accessed on 18 January 2021).

- IBM Developer. Available online: https://developer.ibm.com/technologies/iot/articles/what-are-digital-twins/ (accessed on 18 January 2021).

- Stavropoulos, P.; Papacharalampopoulos, A.; Kampouris, K.; Papaioannou, C.; Bekiaris, T.; Porevopoulos, N. A Teaching Factory on Context-aware Design of Automation for Sustainable Manufacturing Processes. In Proceedings of the 12th Conference on Learning Factories (CLF 2022), Singapore, 11–13 April 2022; Available online: https://ssrn.com/abstract=4072720 (accessed on 18 January 2021). [CrossRef]

- Stavropoulos, P.; Papacharalampopoulos, A.; Michail, C.K.; Chryssolouris, G. Robust additive manufacturing performance through a control oriented digital twin. Metals 2021, 11, 708. [Google Scholar] [CrossRef]

- García-Díaz, A.; Panadeiro, V.; Lodeiro, B.; Rodríguez-Araújo, J.; Stavridis, J.; Papacharalampopoulos, A.; Stavropoulos, P. OpenLMD, an open source middleware and toolkit for laser-based additive manufacturing of large metal parts. Robot. Comput. -Integr. Manuf. 2018, 53, 153–161. [Google Scholar] [CrossRef]

- Fysikopoulos, A.; Stavropoulos, P.; Papacharalampopoulos, A.; Calefati, P.; Chryssolouris, G. A process planning system for energy efficiency. In Proceedings of the 14th International Conference on Modern Information Technology in the Innovation Processes of the Industrial Enterprises, Budapest, Hungary, 24–26 October 2012; pp. 24–26. [Google Scholar]

- Stavropoulos, P.; Chantzis, D.; Doukas, C.; Papacharalampopoulos, A.; Chryssolouris, G. Monitoring and control of manufacturing processes: A review. Procedia CIRP 2013, 8, 421–425. [Google Scholar] [CrossRef]

- Leng, J.; Ruan, G.; Jiang, P.; Xu, K.; Liu, Q.; Zhou, X.; Liu, C. Blockchain-empowered sustainable manufacturing and product lifecycle management in industry 4.0: A survey. Renew. Sustain. Energy Rev. 2020, 132, 110112. [Google Scholar] [CrossRef]

- Pfrommer, J.; Ebner, A.; Ravikumar, S.; Karunakaran, B. Open source OPC UA PubSub over TSN for realtime industrial communication. In Proceedings of the 23rd international conference on emerging technologies and factory automation (IEEE ETFA), Torino, Italy, 4–7 September 2018; Volume 1, pp. 1087–1090. [Google Scholar]

- Borase, R.P.; Maghade, D.K.; Sondkar, S.Y.; Pawar, S.N. A review of PID control, tuning methods and applications. Int. J. Dyn. Control. 2021, 9, 818–827. [Google Scholar] [CrossRef]

- Yin, D.; Ming, X.; Zhang, X. Understanding Data-Driven Cyber-Physical-Social System (D-CPSS) Using a 7C Framework in Social Manufacturing Context. Sensors 2020, 20, 5319. [Google Scholar] [CrossRef]

- Basinger, K.L.; Keough, C.B.; Webster, C.E.; Wysk, R.A.; Martin, T.M.; Harrysson, O.L. Development of a modular computer-aided process planning (CAPP) system for additive-subtractive hybrid manufacturing of pockets, holes, and flat surfaces. Int. J. Adv. Manuf. Techn. 2018, 96, 2407–2420. [Google Scholar] [CrossRef]

- ManufacturingTomorrow Site. Available online: https://www.manufacturingtomorrow.com/article/2020/07/iiot-protocols-comparing-opc-ua-to-mqtt/15534 (accessed on 18 January 2021).

- Amruthnath, N.; Gupta, T. Modified Rank Order Clustering Algorithm Approach by Including Manufacturing Data. IFAC-Pap. 2016, 49, 138–142. [Google Scholar] [CrossRef]

- Avallone, L.; Mercandelli, M.; Santiccioli, A.; Kennedy, M.P.; Levantino, S.; Samori, C. A comprehensive phase noise analysis of bang-bang digital PLLs. IEEE Trans. Circuits Syst. I Regul. Pap. 2021, 68, 2775–2786. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Mourtzis, D. Digital twins in industry 4.0. In Design and Operation of Production Networks for Mass Personalization in the Era of Cloud Technology; Elsevier: Amsterdam, The Netherlands, 2022; pp. 277–316. [Google Scholar]

- Petrides, D.; Papacharalampopoulos, A.; Stavropoulos, P.; Chryssolouris, G. Dematerialisation of products and manufacturing-generated knowledge content: Relationship through paradigms. Int. J. Prod. Res. 2018, 56, 86–96. [Google Scholar] [CrossRef]

- Stavropoulos, P.; Papacharalampopoulos, A.; Vasiliadis, E.; Chryssolouris, G. Tool wear predictability estimation in milling based on multi-sensorial data. Int. J. Adv. Manuf. Technol. 2016, 82, 509–521. [Google Scholar] [CrossRef]

| Category | Symbol | Technology/Operation | Comment |

|---|---|---|---|

| Level 1 | A1 | Milling machine | A combination of process and machine tool |

| A2 | RGB Camera 1 | A vision systems subclass 2 | |

| A3 | Controller | It refers to the implementation—from the machine point of view | |

| A4 | IoT Communications | - | |

| A5 | PID 3 Motion Control | - | |

| A6 | FPGA 4 | To implement control | |

| A7 | Ziegler–Nichols algorithm | To calibrate the PID controller | |

| A8 | Matlab | It is part of ICT | |

| A9 | Closed-Loop System | - | |

| Level 2 | B1 | Enhanced Milling Machine | Integrating Level 1 modules B1 = (A1, A3, A5, A6) |

| B2 | Closed-Loop System operation | B2 = (A2, A4, A6) | |

| Method 1 | M1 | Design a PID Controller for the Milling Machine | M1 = (B1, A7, A8) |

| Method 2 | M2 | Run the PID Controller for Milling Machine | M2 = (A1, A9, B3) |

| Scenario 1 | Scenario 2 | … | |

|---|---|---|---|

| Condition 1 (Large Diameters) | … | … | |

| Condition 2 (Small Diameters) | True | … | … |

| Condition 3 (Large Tolerance) | … | … | |

| Condition 4 (Small Tolerance) | True | … | … |

| Condition 5 (OPC-UA) | True | … | … |

| Condition 6 (MQTT [114]) | … | … | |

| … | … | … | |

| Condition N | … | … | |

| Action 1 (Choose Lathe 1) | X | ||

| Action 2 (Choose Lathe 2) | |||

| … |

| Part | Process 1 Milling | Process 2 Welding | Process 3 Drilling | Sensor 1 Electric Current | Sensor 2 CMM | Agent 1 Logging to Blockchain | Agent 2 QR Engraver | Agent 3 QR Reader | … |

|---|---|---|---|---|---|---|---|---|---|

| #1 | X | X | X | X | X | … | |||

| #2 | X | X | X | X | |||||

| #3 | X | X | X | X | X | X | |||

| … | … |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stavropoulos, P.; Papacharalampopoulos, A.; Sabatakakis, K.; Mourtzis, D. Metamodelling of Manufacturing Processes and Automation Workflows towards Designing and Operating Digital Twins. Appl. Sci. 2023, 13, 1945. https://doi.org/10.3390/app13031945

Stavropoulos P, Papacharalampopoulos A, Sabatakakis K, Mourtzis D. Metamodelling of Manufacturing Processes and Automation Workflows towards Designing and Operating Digital Twins. Applied Sciences. 2023; 13(3):1945. https://doi.org/10.3390/app13031945

Chicago/Turabian StyleStavropoulos, Panagiotis, Alexios Papacharalampopoulos, Kyriakos Sabatakakis, and Dimitris Mourtzis. 2023. "Metamodelling of Manufacturing Processes and Automation Workflows towards Designing and Operating Digital Twins" Applied Sciences 13, no. 3: 1945. https://doi.org/10.3390/app13031945

APA StyleStavropoulos, P., Papacharalampopoulos, A., Sabatakakis, K., & Mourtzis, D. (2023). Metamodelling of Manufacturing Processes and Automation Workflows towards Designing and Operating Digital Twins. Applied Sciences, 13(3), 1945. https://doi.org/10.3390/app13031945