Ecological and Economic Assessment of the Reuse of Steel Halls in Terms of LCA

Abstract

1. Introduction

Brief Description of Environmental Performance Assessment Methods

- 1/

- planning and organization (adopting an environmental policy, setting goals),

- 2/

- assessment (gathering data on processes and waste, creating variants of solutions),

- 3/

- analysis of feasibility variants (technical and economic analysis),

- 4/

- implementation (project implementation, implementation effectiveness assessment).

- Eco-indicator method (Eco-indicator 99, ReCiPe) [32];

- ASEET method of integrated indicators of economic and ecological efficiency in architectural, socio-economic, ecological and technical space [33];

- Method of cumulative energy intensity indicators [34];

- Analysis of cumulative energy consumption and pollutant emissions over the full life cycle of the building [35];

- Method of valuation of ecological effects, which includes:

2. Purpose, Assumptions and Research Method

2.1. Purpose of the Research

2.2. The Course of EET Assessment in LCA Methodology

- no net emissions of greenhouse gases by 2050,

- economic growth decoupled from resource use,

- no person and no place left behind.

2.3. Main Criteria of the Ecological Evaluation of MASH

3. Subject of the Research, Basic Assumptions

3.1. Stage I (Defining the Purpose and Scope)

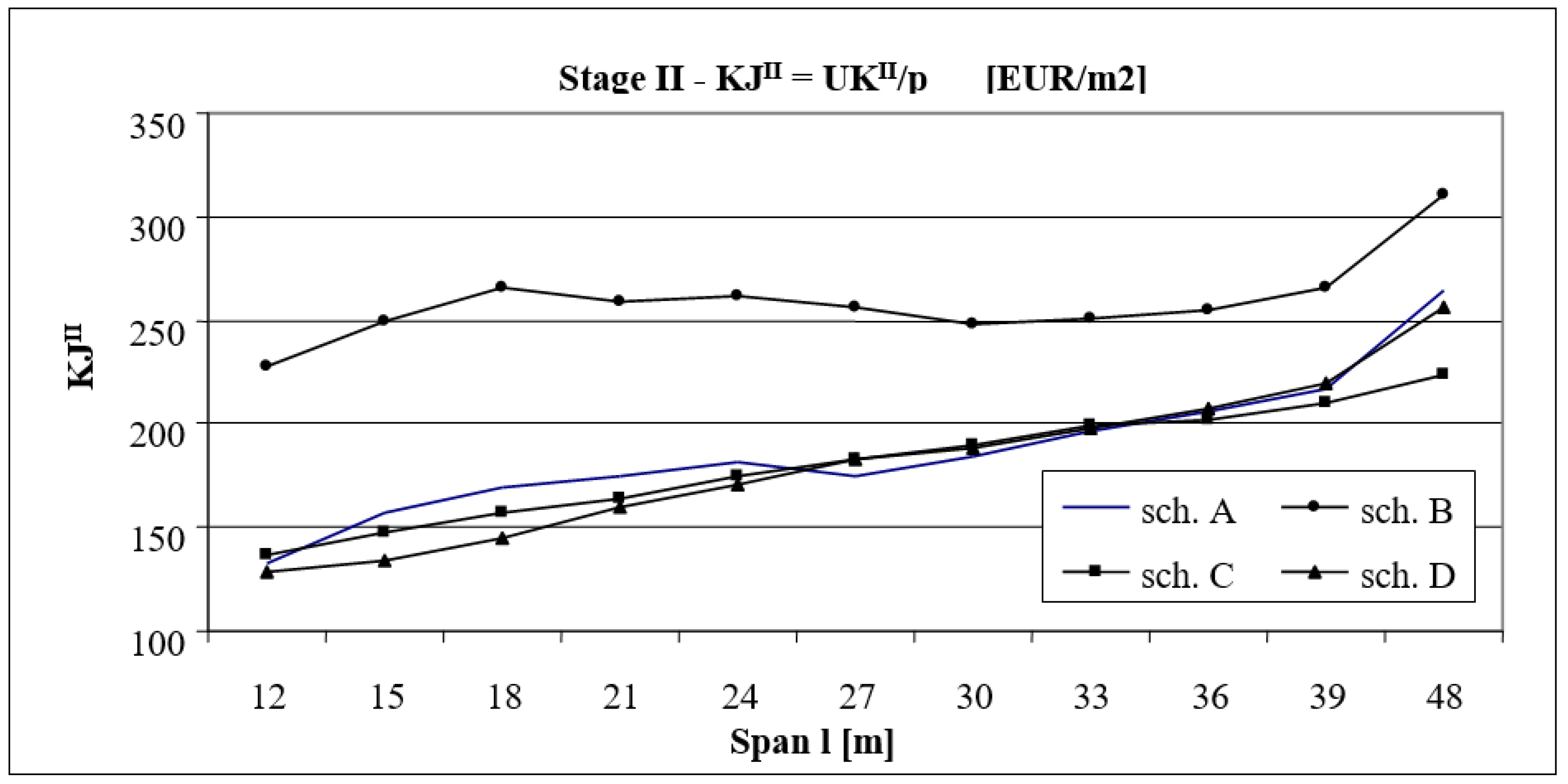

3.2. Stage II (LCIA-Life Cycle Inventory Analysis): Determination, Collection and Analysis of the Required Data

- -

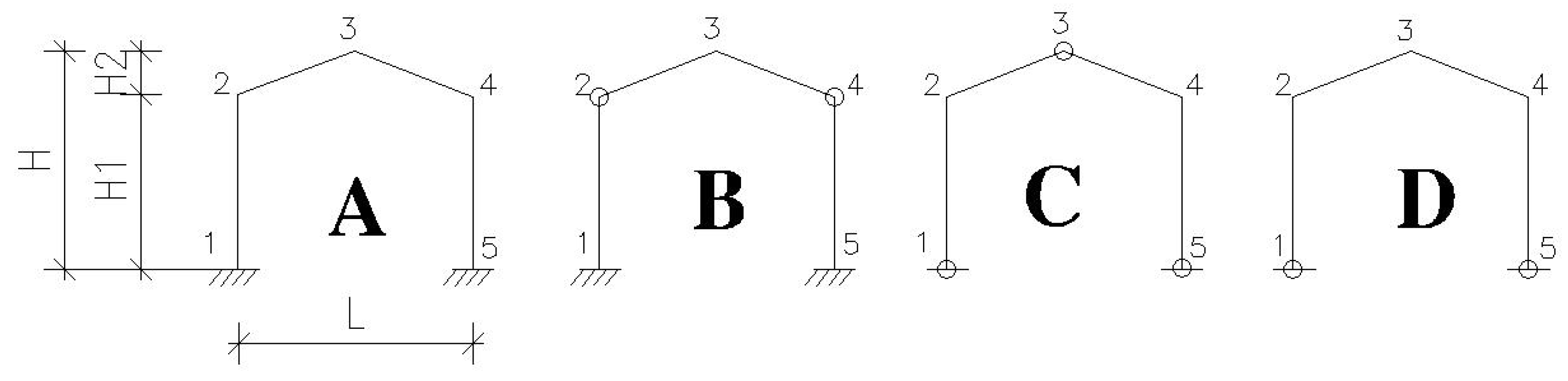

- “A” scheme—rigid frame;

- -

- “B” scheme—frame with rigid columns on the support and articulation at the transom;

- -

- “C” scheme—triple-joint frame;

- -

- “D” scheme—rigid frame at the transom column nodes and articulated on the support.

- Steel profiles of the hall cross system: HEA prismatic profiles,

- Type of structural steel: St3S (mullions, transoms, gusset plates, welds),

- Foundations: Concrete C16/20 (B-20), structural steel A-II.

- •

- Geometric—dimensions calculated in the axes of elements:

- -

- height H = H1 + H2 [m], (H1 = 4.5 m, H2 = 1.5 m).

- -

- frame spacing S = 5.0 m.

- -

- variable span, the same for each scheme, from L = 12.0 m to 48.0 m.

- •

- Loads—equal for each scheme, i.e., wind, snow, roof loads, including purlins and bracings.

- •

- Own weights—suitable for the structural scheme.

- •

- Support compliance was presented as the intended relative displacement of support A with permissible values dx = −2 cm and dy = 2 cm (due to the disassembly conditions and the changeability of settlement during re-foundation).

- •

- The following ground conditions and foundations were adopted:

- -

- foundation level hp = 0.80 m. p.p.t.,

- -

- soils with low bearing capacity (Pd—Id = 0.3, φ = 15o, ρ = 1.65 t/m3),

- -

- strong soils (Pav—Id = 0.60, φ = 31o, ρ = 2.00 t/m3).

- •

- •

- •

- The price of construction and assembly works—as the average values from I quarter 22′, the following were adopted:

- -

- data for the steel skeleton (as of 03.2022) [43] (initially adopted to be produced with the material 12.76 euro/kg, assembly 1.5–3.5 euro/kg, material 8.50 euro/kg);

- -

- for reinforced concrete foundations (workmanship, material)—100.00 euro/m3, the execution with the material was initially adopted.

- •

- Other data according to technical standards and norms.

- C16/20 (B-20) concrete and A-I steel were adopted.

- Static and strength calculations were made using the computer program ROBOT Structural Analysis Professional 2019, ARCadia BIM v.14.

- Industry standards for the valuation of workshop works for steel structures,

- Cost Estimated Material Outlays (CEMO) for individual construction works, adopting the outlay costs (LME—labor, material, equipment) in IV qu. 2021. Calculations of material expenditure were carried out with the use of the NORMA computer program [65].

3.3. Stage III (LCIA)—Life Cycle Impact Assessment

- -

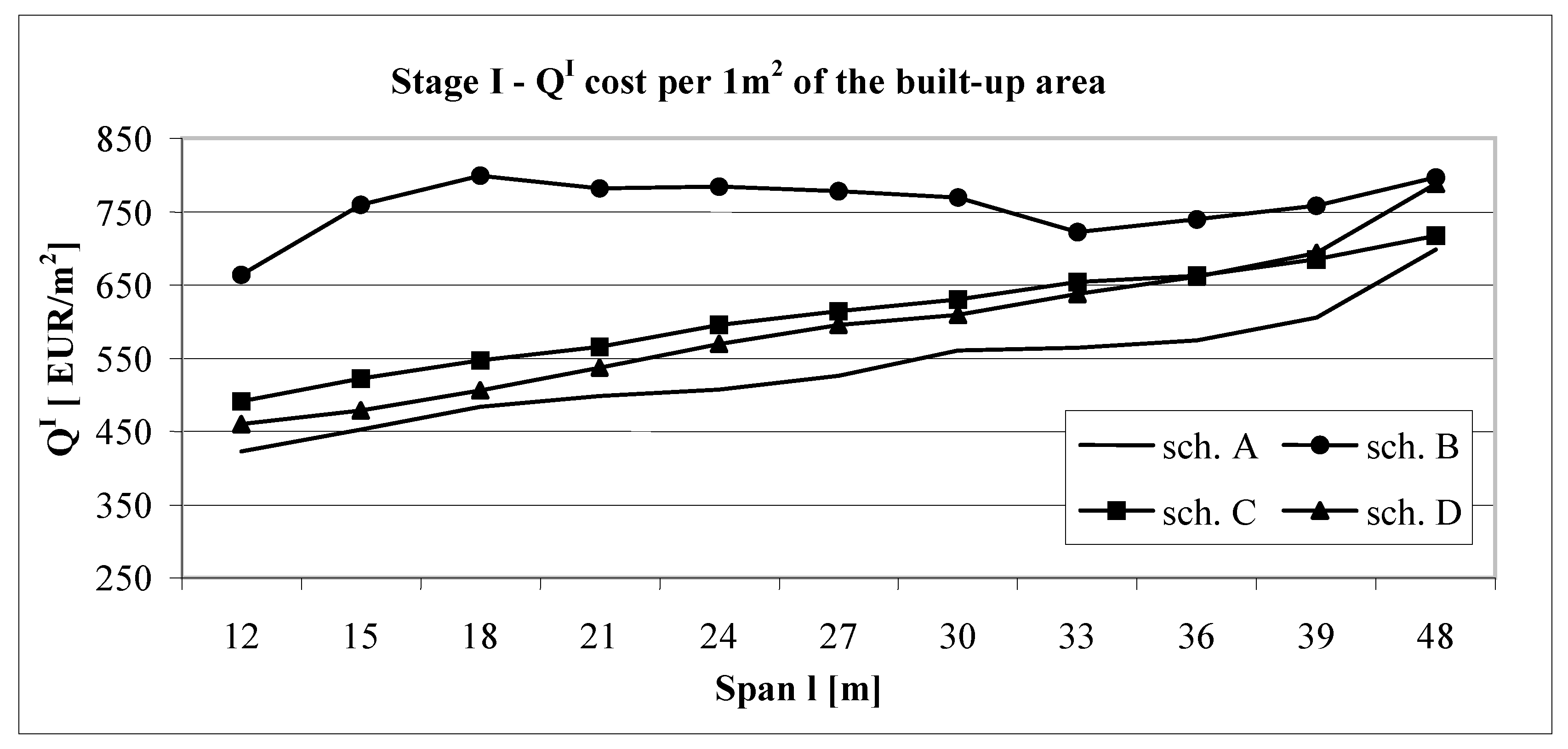

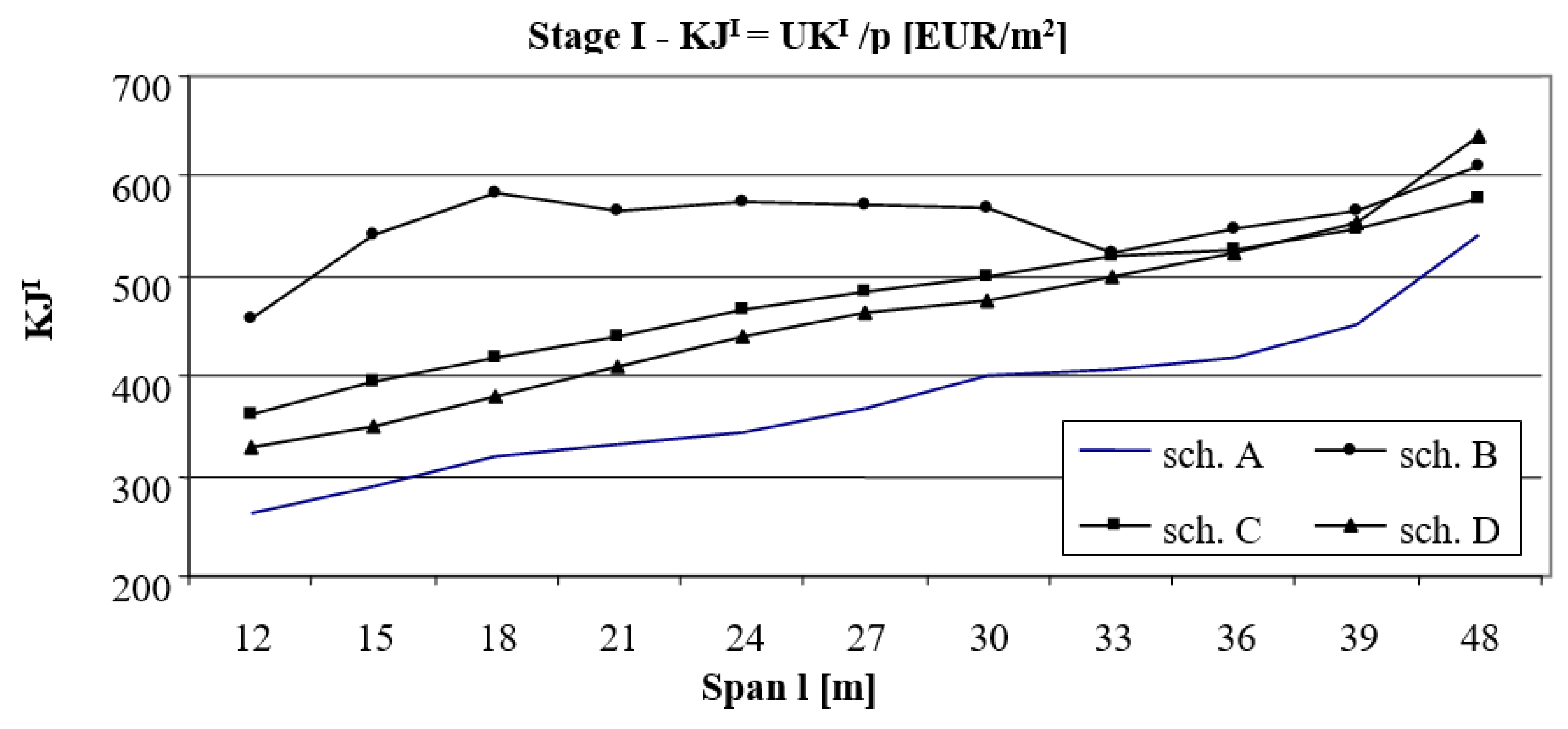

- QIk,l—total cumulative energy and material cost value of the construction of the MASH steel hall for the selected static scheme “k” and span “l”,

- -

- ΣCIs,r,z = ΣCIsi + ΣCIri + ΣCIzi—cost of producing the mass of MK structure elements (mullions, transoms, welds) calculated for the normative state of loads and displacements, taking into account the unit price of the mass for the i-th mullion, transom and weld,

- -

- ΣCFIi (ΣRFIi)—cost of the total mass of foundations made (RFIi total mass of foundations removed after the first assembly), CFi—mass of the i-th foundation,

- -

- ΣWIi—total cost of producing i-th structural elements in the workshop,

- -

- ΣTIi—total cost of transporting i-th structural elements in a specific process of the construction cycle:

- -

- Tw—raw material transport to the workshop,

- -

- Tm—transport of elements for assembly with the costs of operational storage,

- -

- ΣMIi—cost equivalent of the assembly of the i-th load-bearing element of the hall,

- -

- EPI—cost equivalent of the biologically active surface lost. The analysis adopted the equivalent of development = area with the assimilation intensity of the grass surface,

- -

- p—built-up area.

- -

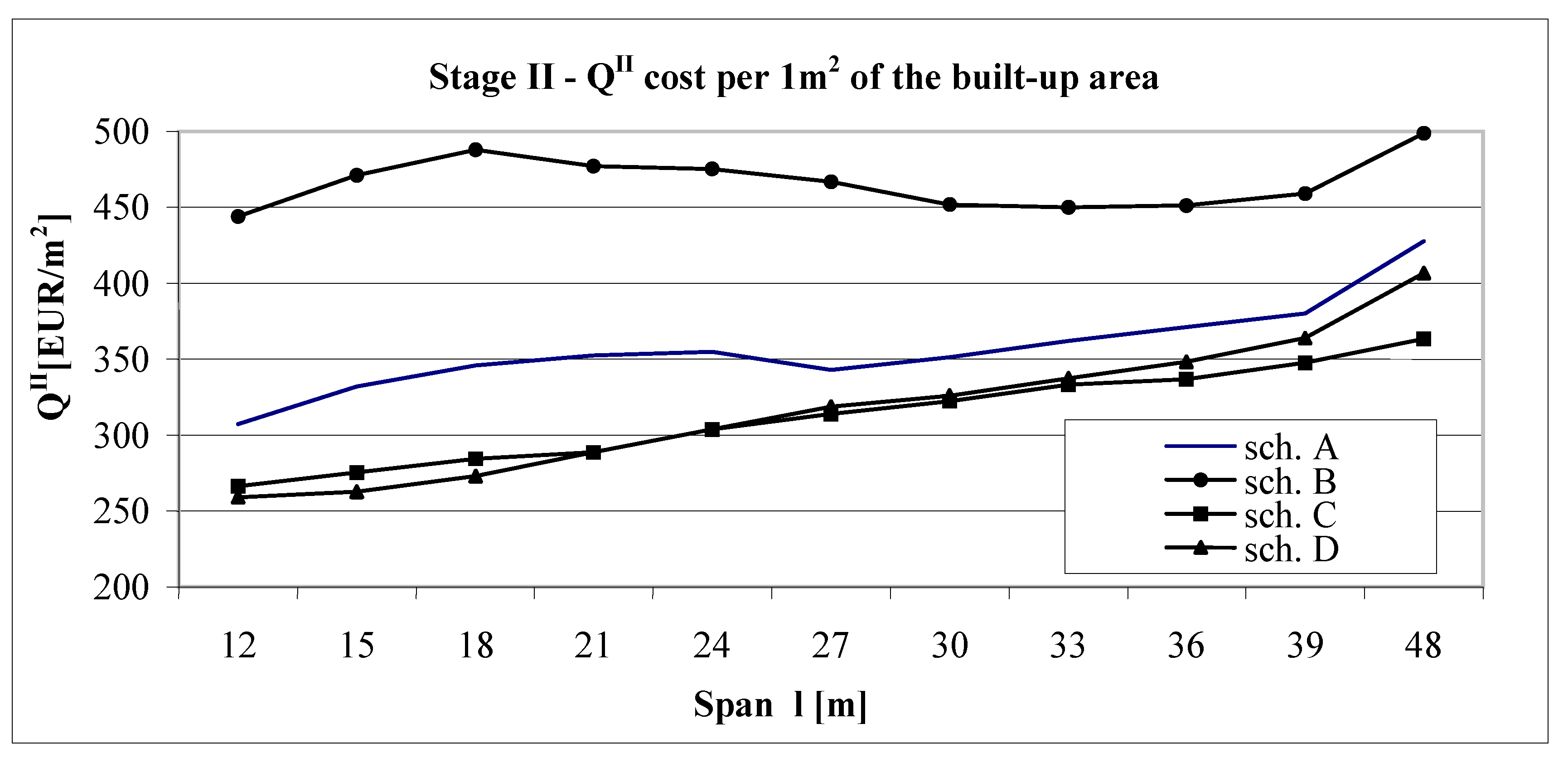

- QIIk,l—cumulative equivalent energy and material cost in the second phase of MASH structure life for the selected scheme “k” and span “l”.

- -

- ΣCFIIi (RFII)—total mass cost of foundations made during secondary assembly (RFII total mass of foundations removed after subsequent assembly),

- -

- ΣΔCIIs,r,z = ΣΔCIIsi + ΣΔCIIri + ΣΔCIIzi—total cost of inspection and protection of the structure ΔMK resulting from the necessity to eliminate the stress of the structure due to assembly imperfections,

- -

- ΣWIIi—modification in the workshop or assembly of specific i-th structural elements,

- -

- ΣTIImi—cost of transporting all elements of the hall for reassembly with the costs of operational storage,

- -

- ΣMIIi—cost of assembly of steel load-bearing elements of the hall in a new location,

- -

- ΣDIi—cost of dismantling the steel load-bearing elements of the originally assembled hall,

- -

- EPII—cost equivalent of the biologically active area lost for the built-up area of the re-assembled hall,

- -

- p—built-up area.

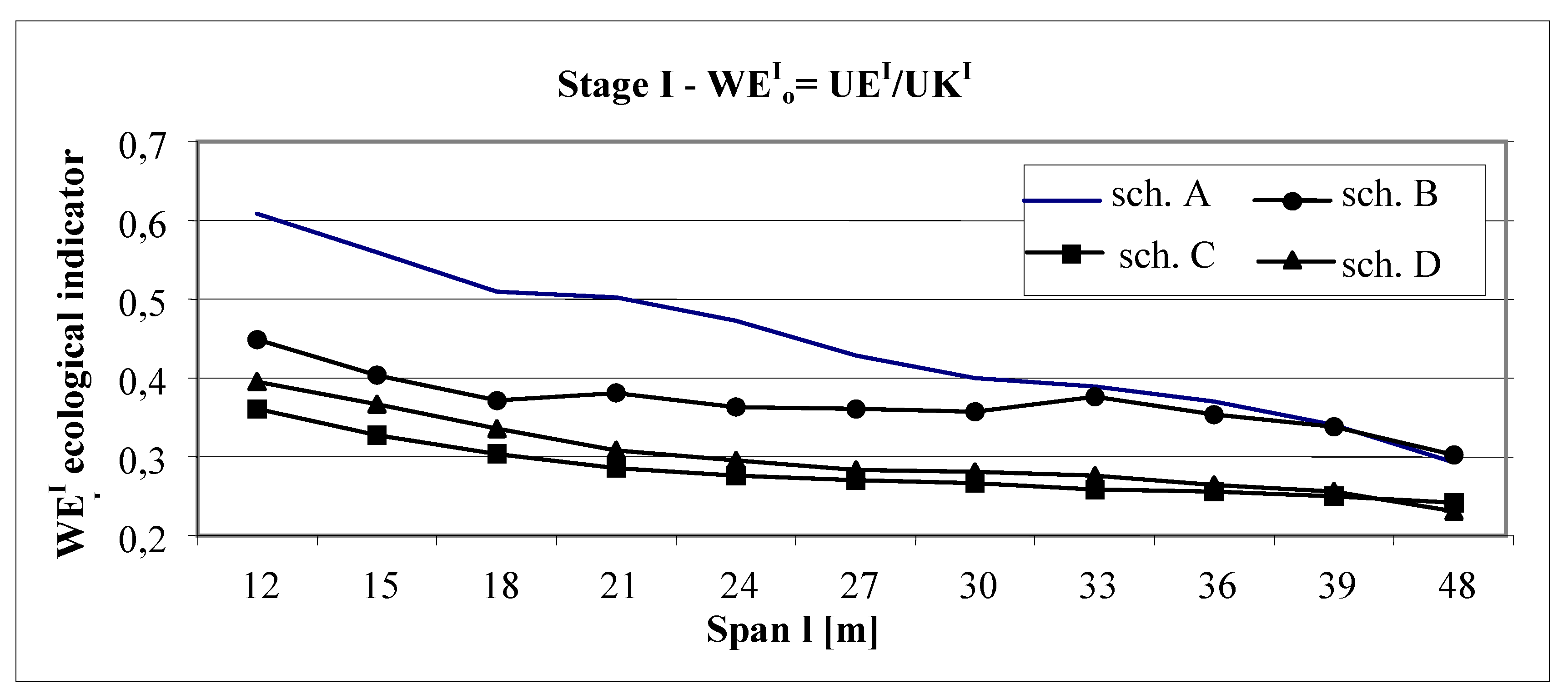

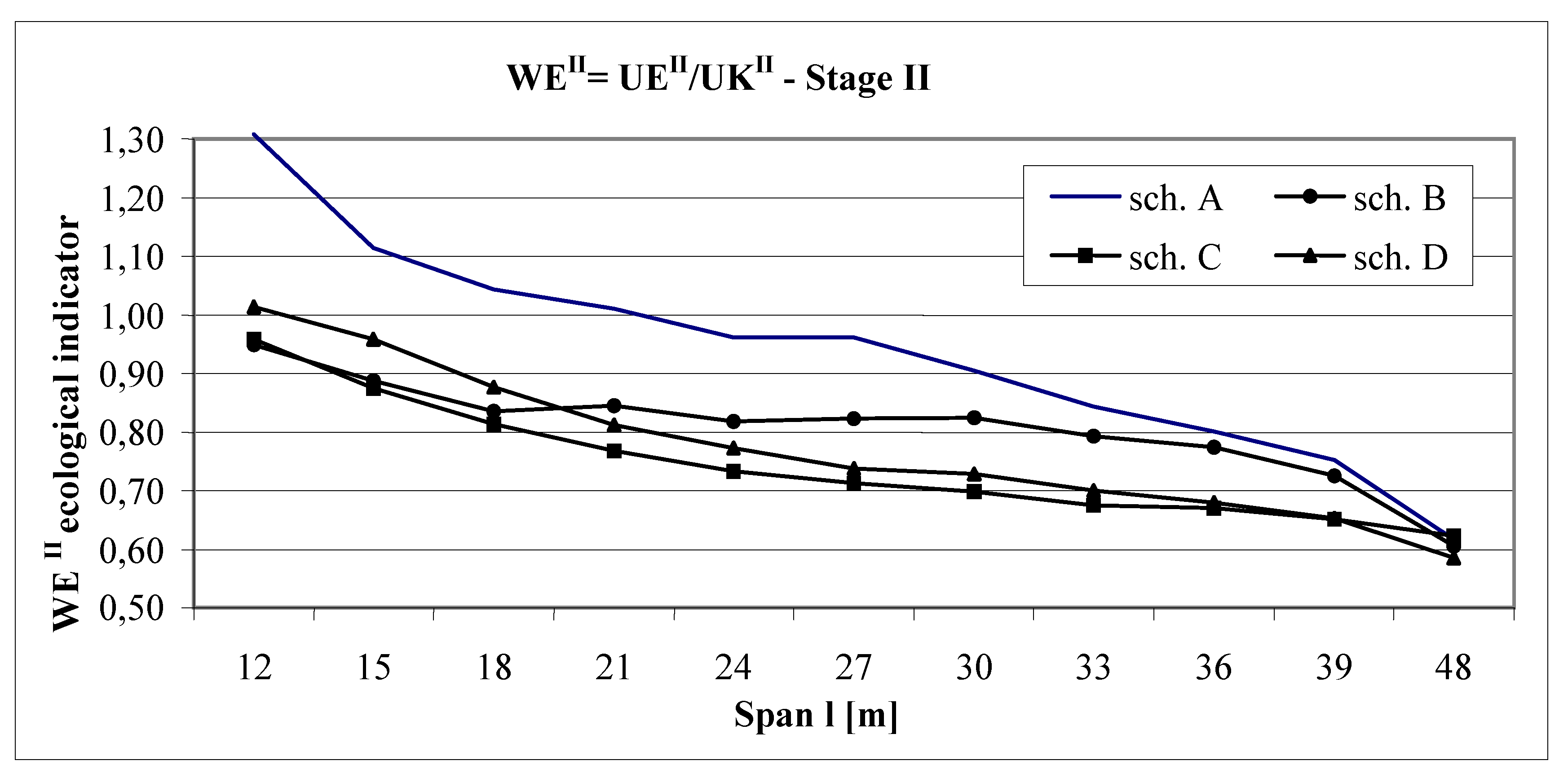

3.4. STAGE IV (LCI—Life Cycle Interpretation)—Interpretation of Results

- The lower envelope characterizes halls with the lowest ecological costs:

- -

- type B for L = 12–13.5 m, WEIIo k,l = 0.95–1.1

- -

- type C for L = 13.5–39 m, WEIIo k,l = 0.85–0.65

- -

- type D for L = 39–48 m, WEIIo k,l = 0.65–0.55

- The upper envelope characterizes the scheme with the highest ecological cost:

- -

- type A for L = 12–48 m, WEIIo k,l = 1.35–0.65.

4. Stage V—Conclusions, Summary, Recommendations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| C2C— | Cradle to Cradle® is a trademark of McDonough Braungart Design, Chemistry, |

| C2G— | cradle to grave |

| CE— | circular economy |

| CEAP— | Circular Economy Action Plan |

| CEMO— | Cost Estimated Material Outlays |

| CP— | Cleaner Production |

| DFE— | design for the environment |

| EAB— | ecological amortization of buildings |

| EAU— | Ecological Accounting Units |

| EET— | assessment of cumulative ecological, economic and technical parameters |

| EPDs— | environmental product declarations |

| LCA— | life cycle assessment |

| LCI— | life cycle inventory |

| LCIA— | life cycle impact assessment |

| LE— | linear economy |

| LLC— | life cycle cost |

| LSF— | Light steel frame in building systems |

| MAO— | Multiple Assembly Objects |

| MASH— | multi-assembly steel halls |

| OSC— | Off-site construction, system for Off-Site Construction Projects |

| QI,II— | determines the total cumulative cost of the hall after life cycle I and II |

| PLA— | Product Line Analysis |

| TQEM— | Total Quality Environmental Management |

| UE— | share of ecological costs of environmental regeneration in the process of execution and operation of MASH |

| UK— | share of economic costs for the execution and assembly of the MASH facility structure (original hall structure cost) |

| WE— | generalized ecological indicator |

References

- Tam, V.W.Y.; Tam, C.M. Evaluations of existing waste recycling methods: A Hong Kong study. Build. Environ. 2006, 41, 1649–1660. [Google Scholar] [CrossRef]

- Stahel, W.R. The Circular Economy: A User’s Guide; Routledge: Oxfordshire, UK, 2019; ISBN 9780367200176. [Google Scholar]

- Jelčić Rukavina, M.; Skejić, D.; Kralj, A.; Ščapec, T.; Milovanović, B. Development of Lightweight Steel Framed Construction Systems for Nearly-Zero Energy Buildings. Buildings 2022, 12, 929. [Google Scholar] [CrossRef]

- Sun, J.; Han, B.; Ekwaro-Osire, S.; Zhang, H.-C. Design for Environment: Methodologies, Tools, and Implementation. J. Integr. Des. Process Sci. 2003, 7, 59–75. [Google Scholar]

- Yilmaz, M.; Bakış, A. Sustainability in Construction Sector. Procedia Soc. Behav. Sci. 2015, 195, 2253–2262. [Google Scholar] [CrossRef]

- Weerasuriya, A.U.; Zhang, X.; Wang, J.; Lu, B.; Tse, K.T.; Liu, C.-H. Performance evaluation of population-based metaheuristic algorithms and decision-making for multi-objective optimization of building design. Build. Environ. 2021, 198, 107855. [Google Scholar] [CrossRef]

- Brachet, A.; Schiopu, N.; Clergeau, P. Biodiversity impact assessment of building’s roofs based on Life Cycle Assessment methods. Build. Environ. 2019, 158, 133–144. [Google Scholar] [CrossRef]

- McCollough, J. Determinants of a throwaway society—A sustainable consumption issue. J. Socio-Econ. 2012, 41, 110–117. [Google Scholar] [CrossRef]

- Tesfamariam, S.; Goda, K. (Eds.) Handbook of Seismic Risk Analysis and Management of Civil Infrastructure Systems; Woodhead Publishing Limited: Sawston, UK, 2013. [Google Scholar] [CrossRef]

- Girão Coelho, A.M.; Pimentel, R.; Ungureanu, V.; Hradil, P.; Kesti, J. European Recommendations for Reuse of Steel Products in Single-Storey Buildings, 1st ed.; ECCS—European Convention for Constructional Steelwork: Brussels, Belgium, 2020; Available online: https://www.steelconstruct.com/wp-content/uploads/PROGRESS_Design_guide_final-version.pdf (accessed on 3 May 2022).

- Fiedor, B.; Czaja, S.; Graczyk, A.; Jakubczyk, Z. Podstawy Ekonomii Środowiska i Zasobów Naturalnych (Fundamentals of Economics of the Environment and Natural Resources); Wyd. C.H. Beck: Warszawa, Poland, 2002. (In Polish) [Google Scholar]

- Cullen, J.; Drewniok, M. Structural Steel Reuse. Steel and the Circular Economy; The Building Centre: London, UK, 2016; Available online: https://steel-sci.com/assets/downloads/structural-steel-reuse/161130-bcsa-cullen%20002.pdf (accessed on 3 May 2022).

- Tingley, D.D.; Allwood, J. Reuse of structural steel: The opportunities and challenges. In Proceedings of the European Steel Environment & Energy Congress, Teeside University, Middlesbrough, UK, 15–17 September 2014. [Google Scholar]

- Górka, K.; Poskropko, B.; Radecki, W. Ochrona Środowiska; PWE: Warszawa, Poland, 2001. (In Polish) [Google Scholar]

- Bokhari, S.; Geltner, D. Characteristics of Depreciation in Commercial and Multi-Family Property: An Investment Perspective. Real Estate Econ. 2016, 46, 745–782. [Google Scholar] [CrossRef]

- Allwood, J.; Cullen, J. Sustainable Materials: With Both Eyes Open; UIT Cambridge Ltd.: Cambridge, UK, 2012. [Google Scholar]

- Tingley, D.D.; Davison, B. Design for deconstruction and material reuse. Proc. Inst. Civ. Eng. Energy 2011, 164, 195–204. [Google Scholar] [CrossRef]

- Brown, D.G.; Pimentel, R.J.; Sansom, M.R. Structural Steel Reuse Assessment, Testing and Design Principles. 2019. Available online: https://steel-sci.com/assets/downloads/steel-reuse-event-8th-october-2019/SCI_P427.pdf (accessed on 5 May 2022).

- Stephan, A.; Athanassiadis, A. Towards a more circular constructionsector: Estimating and spatialising current and future non-structural materialreplacement flows to maintain urban building stocks. Resour. Conserv. Recycl. 2018, 129, 248–262. [Google Scholar] [CrossRef]

- Foster, G. Circular economy strategies for adaptive reuse of cultural heritage buildings to reduce environmental impacts. Resour. Conserv. Recycl. 2020, 152, 104507. [Google Scholar] [CrossRef]

- Upadhayay, S.; Alqassimi, O. A Study on Assessing a Business Viability for Transition to a Circular Economy. Westcliff Int. J. Appl. Res. 2020, 4, 78–94. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circulareconomy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Wu, H.; Zuo, J.; Zillante, G.; Wang, J.; Yuan, H. Status quo and future directions of construction and demolition waste research: A critical review. J. Clean. Prod. 2019, 240, 118163. [Google Scholar] [CrossRef]

- Reisinger, J.; Kugler, S.; Kovacic, I.; Knoll, M. Parametric Optimization and Decision Support Model Framework for Life Cycle Cost Analysis and Life Cycle Assessment of Flexible Industrial Building Structures Integrating Production Planning. Buildings 2022, 12, 162. [Google Scholar] [CrossRef]

- Sammut-Bonnici, T. Wiley Encyclopedia of Management—Volume 12 Strategic Management; John Wiley & Sons, Ltd.: New York, NY, USA, 2015. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions the European Green Deal, COM/2019/640; European Commission: Brussels, Belgium, 2019.

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions a New Circular Economy Action Plan for a Cleaner and More Competitive Europe COM/2020/98 Final; European Commission: Brussels, Belgium, 2020.

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The circular economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Burman, M.; Braimah, N. Pathways to circular construction: An integrated management of construction and demolition waste for resource recovery. J. Clean. Prod. 2020, 244, 118710. [Google Scholar] [CrossRef]

- Vieira, L.C.; Amaral, F.G. Barriers and strategies applying Cleaner Production: A systematic review. J. Clean. Prod. 2016, 113, 5–16. [Google Scholar] [CrossRef]

- Klöpffer, W.; Grahl, B. Life Cycle Assessment (LCA): A Guide to Best Practice; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2014; 440p. [Google Scholar] [CrossRef]

- Adamczyk, J.; Dylewski, R. Ecological and Economic Benefits of the “Medium” Level of the Building Thermo-Modernization: A Case Study in Poland. Energies 2020, 13, 4509. [Google Scholar] [CrossRef]

- Sobierajewicz, P. Kształtowanie Zabudowy Miejskiej o Zwiększonej Efektywności Ekologicznej i Energetycznej: Architektura, Rozwój, Społeczeństwo, Ekologia; Oficyna Wydaw. Uniwersytetu Zielonogórskiego: Zielona Góra, Poland, 2013; p. 274. [Google Scholar]

- Arvidsson, R.; Svanström, M. A framework for energy use indicators and their reporting in life cycle assessment. Integr. Environ. Assess. Manag. 2016, 12, 429–436. [Google Scholar] [CrossRef]

- Hertwich, E.G.; Gibon, T.; Bouman, E.A.; Arvesen, A.; Suh, S.; Heath, G.A.; Bergesen, J.D.; Ramirez, A.; Vega, M.I.; Shi, L. Integrated life-cycle assessment of electricity-supply scenarios confirms global environmental benefit of low-carbon technologies. Proc. Natl. Acad. Sci. USA 2014, 112, 6277–6282. [Google Scholar] [CrossRef] [PubMed]

- PAEC. Final Report on Environmental Accounting and Reporting; Parliament of Victoria: Melbourne, VIC, Australia, 2002. Available online: http://www.parliament.vic.gov.au/papers/govpub/VPARL1999-2002No141.pdf (accessed on 9 May 2022).

- Sagarduy, G.; Bandinelli, S.; Lerchundi, R. Product-line Analysis: Do we go ahead? In Proceedings of the Software Product Lines: Economics, Architectures, and Implications, Workshop #15 at 22nd International Conference on Software Engineering (ICSE), Limerick, Ireland, 10 June 2000. [Google Scholar]

- Sherif, Y.S.; Kolarik, W.J. Life Cycle Costing: Concept and Practice. Omega 1981, 9, 287–296. [Google Scholar] [CrossRef]

- Braungart, M.; McDonough, W. Cradle to Cradle: Remaking the Way We Make Things; North Point Press: New York, NY, USA, 2002. [Google Scholar]

- Kacprzak, M. Chapter: Cradle to Cradle Marketplace, Biodegradable Waste Management in the Circular Economy; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2022; pp. 13–18. ISBN1 9781119679844. ISBN2 9781119679523. [Google Scholar] [CrossRef]

- Diaz-Granados, J. Encyclopedia of Sustainable Management; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Jurkait, K.; Stiglmair, J. Cradle-to-Cradle in Building Services. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012013. [Google Scholar] [CrossRef]

- Lowe, E.A.; Evans, L.K. Industrial ecology and industrial ecosystems. J. Clean. Prod. 1995, 3, 47–53. [Google Scholar] [CrossRef]

- Sertyesilisik, B.; Sertyesilisik, E. Eco industrial Development: As a Way of Enhancing Sustainable Development. J. Econ. Dev. Environ. People 2016, 5, 6–27. [Google Scholar] [CrossRef]

- Srinivasan, R.; Ingwersen, W.; Trucco, C.; Ries, R.; Campbell, D. Comparison of energy-based indicators used in life cycle assessment tools for buildings. Build. Environ. 2014, 79, 138–151. [Google Scholar] [CrossRef]

- EU Ecolabel Home. Available online: https://ec.europa.eu/environment/topics/circular-economy/eu-ecolabel-home_en (accessed on 4 May 2022).

- Pinto, J.L.Q.; Matias, J.C.O.; Pimentel, C.; Azevedo, S.G.; Govindan, K. Just in Time Factory; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Public Procurement for a Circular Economy 2017. Available online: https://ec.europa.eu/environment/gpp/pdf/CP_European_Commission_Brochure_webversion_small.pdf (accessed on 12 November 2022).

- Bilal, M.; Oyedele, L.O.; Akinade, O.O.; Ajayi, S.O.; Alaka, H.A.; Owolabi, H.A.; Qadir, J.; Pasha, M.; Bello, S.A. Big data architecture for construction waste analytics (CWA): A conceptual framework. J. Build. Eng. 2016, 6, 144–156. [Google Scholar] [CrossRef]

- Konstrukcje Stalowe hal Wielkopowierzchniowych—Inżynier Budownictwa. Available online: https://inzynierbudownictwa.pl/konstrukcje-stalowe-hal-wielkopowierzchniowych/ (accessed on 12 November 2022).

- Kim, H.-W.; Dong, L.; Jung, S.; Park, H.-S. The Role of the Eco-Industrial Park (EIP) at the National Economy: An Input-Output Analysis on Korea. Sustainability 2018, 10, 4545. [Google Scholar] [CrossRef]

- Life and the Circular Economy, European Commission, Environment Directorate General. 2017. Available online: https://ec.europa.eu/environment/archives/life/publications/lifepublications/flippingbook/circulareconomy/HTML/files/assets/common/downloads/publication.pdf (accessed on 15 May 2022).

- Pozacenowe Kryteria Oceny Ofert. Poradnik z Katalogiem Dobrych Praktyk; Urząd Zamówień Publicznych: Warszawa, Poland, 2020. (In Polish) [Google Scholar]

- Gawęcki, A.; Garstecki, A.; Gawęcki, M. Optymalizacja Systemu Lekkich hal Stalowych, Opracowanie, 6; Instytut Podstawowych Problemów Techniki PAN: Warszawa, Poland, 1978. (In Polish) [Google Scholar]

- Biegus, A. Projektowanie konstrukcji budowlanych według Eurokodów. Builder 2010, 4, 1–48. (In Polish) [Google Scholar]

- Heinisuo, M.; Laine, V.; Lehtimäki, E. Enlargement of the component method into 3D. In Proceedings of the Nordic Steel Construction Conference (NSCC 2009), Malmö, Sweden, 2–4 September 2009; pp. 430–437. [Google Scholar]

- PN-EN 1993-1-1: 2006; Eurokod 3: Projektowanie Konstrukcji Stalowych Część 1–1: Reguły Ogólne i Reguły dla Budynków. Polish Committee for Standardization: Warszawa, Poland, 2006.

- PN-EN 1993-1-8: 2006; Eurokod 3: Projektowanie Konstrukcji Stalowych. Część 1–8: Projektowanie Węzłów. Polish Committee for Standardization: Warszawa, Poland, 2006.

- Bogucki, W.; Żyburtowicz, M. Tablice do Projektowania Konstrukcji Metalowych; Arkady: Warszawa, Poland, 2008. (In Polish) [Google Scholar]

- Heller, H. Bautechnische Tabellen Interaktiv—WINTAB RA 2.0 Rahmenformeln; Ernst & Sohn: Berlin, Germany, 2001. [Google Scholar]

- Kindmann, R.; Stracke, M. Verbindungen im Stahl- und Verbundbau, 2. Auflage; Ernst und Sohn: Berlin, Germany, 2009. [Google Scholar]

- PN-EN 1090-2+A1:2012; Wykonanie Konstrukcji Stalowych i Aluminiowych—Część 2: Wymagania Techniczne Dotyczące Konstrukcji Stalowych. Polish Committee for Standardization: Warszawa, Poland, 2012.

- PN-EN 1997-1:2008; Eurokod 7—Projektowanie Geotechniczne—Część 1: Zasady Ogólne. Polish Committee for Standardization: Warszawa, Poland, 2008.

- PN-EN 1992-1-1:2008; Eurokod 2, Projektowanie Konstrukcji z Betonu, Część 1-1: Reguły Ogólne i Reguły dla Budynków. Polish Committee for Standardization: Warszawa, Poland, 2008.

- SECOCENBUD. Available online: www.sekocenbud.pl/produkty/wydawnictwa-sekocenbud/ (accessed on 20 April 2022).

- Biegus, A. Projektowanie Konstrukcji Stalowych Według Eurokodu 3, Materiały Dydaktyczne; Politechnika Wrocławska WBLiW: Wrocław, Poland, 2010; Available online: http://www.metale.pwr.wroc.pl/files/A.Biegus-Polaczenia_Srubowe.pdf (accessed on 25 April 2022).

- Shah, R.A.; Pitroda, D.J. Recycling of Construction Materials for Sustainability. In Proceedings of the Conference: National Conference on Recent Trends in Engineering & Technology (NCRTET), BVM Engineering College, Vallabh Vidyanagar, India, 13–14 May 2011. [Google Scholar]

- Shinde, D.S.; Kadam, A.; Wadke, A.; Wani, A. A Study on Sustainable Construction Practices and Management. In Proceedings of the Conference: IOP Conference, Coimbatore, India, 12–13 February 2022. [Google Scholar]

- Patel, V.; Solanki, J. Just in Time Concept Used in Construction Project. Int. Res. J. Eng. Technol. 2020, 7, 3298–3303. [Google Scholar]

| UEI | UKI |

|---|---|

| ΣRFIi + EPI | ΣCIsi + ΣCIri + ΣCIzi + ΣCFIi + ΣWIi + ΣTIwi + ΣTImi + ΣMIi |

| UEII | UKII |

|---|---|

| ΣRFIIi + EPII | ΣΔCIIsi + ΣΔCIIri + ΣCIIzi + ΣCFIIi + ΣWIIi + ΣTIImi + ΣMIIi+ ΣDIi |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sobierajewicz, P.; Adamczyk, J.; Dylewski, R. Ecological and Economic Assessment of the Reuse of Steel Halls in Terms of LCA. Appl. Sci. 2023, 13, 1597. https://doi.org/10.3390/app13031597

Sobierajewicz P, Adamczyk J, Dylewski R. Ecological and Economic Assessment of the Reuse of Steel Halls in Terms of LCA. Applied Sciences. 2023; 13(3):1597. https://doi.org/10.3390/app13031597

Chicago/Turabian StyleSobierajewicz, Piotr, Janusz Adamczyk, and Robert Dylewski. 2023. "Ecological and Economic Assessment of the Reuse of Steel Halls in Terms of LCA" Applied Sciences 13, no. 3: 1597. https://doi.org/10.3390/app13031597

APA StyleSobierajewicz, P., Adamczyk, J., & Dylewski, R. (2023). Ecological and Economic Assessment of the Reuse of Steel Halls in Terms of LCA. Applied Sciences, 13(3), 1597. https://doi.org/10.3390/app13031597