Abstract

In engineering practice, investment activities related to the construction of a building are still limited to the idea of a linear cradle to grave (C2G) economy. The aim of the study is to determine the ecological and economic benefits inherent in the reuse of structural elements of a hall building using the idea of a Cradle to Cradle (C2C) looped circular economy and Life Cycle Assessment (LCA). As a rule, a multiple circulation of materials from which model buildings are made was assumed through successive life cycles: creation, use, demolition and then further use of the elements. This approach is distinguished by minimizing negative impacts as a result of optimizing the mass of the structure—striving to relieve the environment, thus improving economic efficiency and leaving a positive ecological footprint. The assessment of cumulative ecological, economic and technical parameters (EET) methodology of generalized ecological indicator (WE) for quick and practical assessment of the ecological effect of multi-use steel halls, based on LCA, was proposed. The authors of the work attempted to assess the usefulness of such a structure with the example of four types of halls commonly used in the construction industry. The linear stream of C2G (cradle to grave) and then C2C (cradle to cradle) flows was calculated by introducing ecological parameters for comparative assessment. Finally, a methodology for calculating the ecological amortization of buildings (EAB) was proposed. The authors hope that the proposed integrated assessment of technical, economic and ecological parameters, which are components of the design process, will contribute to a new approach, the so-called fast-track pro-environmental project.

1. Introduction

Limited natural resources increase the need for environmentally friendly production of material goods. The work focuses on the quantitative minimization of the waste stream in the design of production processes of hall-type buildings in order to eliminate or reduce, to the necessary minimum, the amount of solid and gaseous waste.

Waste management in accordance with the 3Rs hierarchy (Reduce-Reuse-Recycle) can be used in construction engineering to create a new approach to system design that can significantly reduce environmental impacts [1]. The article attempts to assess the economic and ecological second recycling in the 3Rs waste management hierarchy in accordance with a circular economy (CE) [2]. Equally important, in the context of the reuse of steel elements, is the design phase of the product, striving to optimize the weight of the structure as well as accompanying elements and energy consumption [3]. This approach is known as design for the environment (DFE) [4] and allows for the analysis of the object at all stages of its life cycle, including in the reconstruction (post-exploitation) phase. The 3Rs hierarchy and the considered concept of the Indicative Environmental Assessment (EET) are part of the paradigm of sustainable development in the construction sector. The proposed methodology is aimed at using natural resources in such a state of equilibrium that they do not reach the point of exhaustion or non-renewal [5].

A lot of manufacturing companies, especially in Western Europe, which have introduced integrated Total Quality Environmental Management (TQEM) systems, are creating new concepts for environmentally oriented design. An important role in the process of preparing a pro-ecological construction investment is played by:

- optimization of technical solutions [6],

- impact assessment with a list of ecological effects [7],

- analysis of socio-economic effects (demand for a clean environment) [8],

- risk (feasibility) analysis [9].

The procedures presented are in line with the requirements set by the European Union [10]. The criterion of environmental effects is one of the basic criteria taken into account when granting co-financing from structural and investment funds. Thus, the problem of the impact of structures on the environment has an economic dimension [11], both in terms of macro- and microeconomics.

In the literature on the subject, a depreciation of structural steel reuse can be observed from the point of view of only an economic criterion. Cullen and Drewniok [12] found that the economic cost of large-scale reuse of steel is at least as high as that of new steel. They analyzed economic costs without considering ecological costs. Similar conclusions were reached by Tingley and Allwood [13], who showed that the reuse of building structures is about 25% more expensive, which is a significant barrier to reuse. At the same time, they demonstrated that it is necessary to study the reuse costs for a wider range of projects in order to have a larger evidence base for the costs of reusing steel.

For projects with low ecological values, the production entity generates pollution translated into costs, which are direct external effects [14]. External costs constitute an additional burden for the polluter and are equivalent to the lost component of the natural environment. This state can be called a kind of waste of capital. As a result, a dual mechanism of degradation arises: on the one hand, environmental degradation and, on the other hand, degradation of the economy through an increase in costs and production value.

It is assumed that the average period of depreciation of commercial or production buildings of the hall type is 39 years [15]. Reconstruction or demolition of existing hall facilities, often with a steel structure, results from the reorganization of the functional space (services, production) and adapting them to the current technical and environmental requirements.

In 2019, the construction sector absorbed more than half of the world’s steel production. Allwood and Cullen [16] found that 14% of the world’s steel produced is used in infrastructure and 42% in buildings. Steel used in construction, due to the need to reduce greenhouse gas emissions, should come primarily from previous building structures; however, as research [10,17,18] shows, the reuse of steel sections is at the level of 6%, compared to 93% recycled. Obviously, we can always ask a question whether the demolition of materials and their use will be the trend of the future [19]? However, an increasingly faster transition from a linear economy (LE) [20] with high waste to a circular economy (CE) [21] based on the reuse of materials and recycling [22] is to be expected. Creating a market for building elements with different actors (such as traders, investors, designers, contractors) can prove to be a key solution for multiplying the reuse of these building elements and reducing the environmental pressure of the construction sector [23].

Brief Description of Environmental Performance Assessment Methods

Reducing the environmental impact of processing and manufacturing activities, which consume large amounts of raw materials and energy inputs, is among the most important and difficult issues in the future. Effective measurement control and the introduction of new pro-ecological technologies will help reduce the pressure on the environment. A major achievement in the construction sector is the use of procedures to minimize waste [24]. Benchmarking standard operating procedures have been used for many years to optimize production processes and services [25]. They are implemented in the form of a predetermined organizational chart, consisting of 4 phases, which include, among other things:

- 1/

- planning and organization (adopting an environmental policy, setting goals),

- 2/

- assessment (gathering data on processes and waste, creating variants of solutions),

- 3/

- analysis of feasibility variants (technical and economic analysis),

- 4/

- implementation (project implementation, implementation effectiveness assessment).

The construction sector generates around 35% of the waste mass of the 2502.9 million tons generated in the EU-28 (2016 Eurostat data). Minimizing the amount of generated waste is the goal of the new EU development programs until 2050 (the European Green Deal, Europe’s new agenda for sustainable growth, 2019) [26] based on the circular economy [27,28].

In the case of construction, new paths are defined for the CE strategy [29], which refers to cleaner production (CP) management procedures and are introduced in EU countries despite many barriers [30]. The common LCA methodology [31] contained in the ISO 14040-44 guidelines is used to assess the environmental performance of products to minimize, reduce at source and recycle waste. ISO 14000 environmental management systems are implemented to produce environmental product declarations (EPDs) based on the ISO 14025 standard.

Other methods of environmental impact assessment are also noteworthy, such as:

- Eco-indicator method (Eco-indicator 99, ReCiPe) [32];

- ASEET method of integrated indicators of economic and ecological efficiency in architectural, socio-economic, ecological and technical space [33];

- Method of cumulative energy intensity indicators [34];

- Analysis of cumulative energy consumption and pollutant emissions over the full life cycle of the building [35];

- Method of valuation of ecological effects, which includes:

- -

- Ecological Accounting Units (EAU) [36];

- -

- Product Line Analysis (PLA) [37];

- -

- LCC (Life Cycle Costing) [38].

Using these methods, it is possible to study the impact of products, materials, services and entire industrial processes on the environment in product life cycles in accordance with the idea of a circular economy initiated in the late 1970s [2] and developed in various procedures and methodologies, e.g., M. Braungart and W. McDonough “Cradle to Cradle” [39,40,41]. In construction, it means a physical description of the behavior of industrial systems [42] when raw materials taken from the environment are introduced into the system and pollutants and waste are removed and recycled [43]. A modern approach to industrial ecosystems is characterized by minimizing inflows and outflows from the system by creating eco-industrial parks [44,45].

These environmental assessment methods potentially support the demand, especially for certified Ecolabel products [46,47]. They are a tool for calculating environmental costs, however, in the environments of designers and contractors. Despite the fact that highly developed countries, including the EU, have started to pursue the direction of the circular economy, among others, through green public procurement [48], the market expects science to develop coherent green executive procedures.

There is a lack of simple and quick methods of environmental assessment of buildings and available material databases [49] with ecological parameters on the market. The authors of the study attempted a simple ecological assessment at the stage of design and economic calculation with secondary use of the main structural elements of the building.

2. Purpose, Assumptions and Research Method

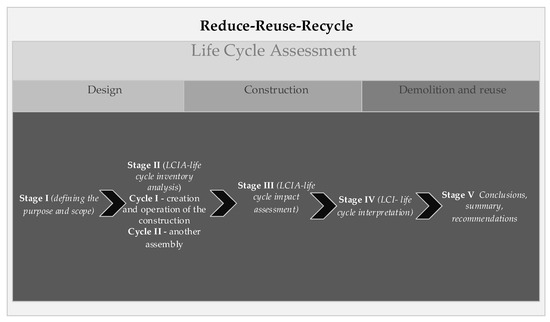

Figure 1 presents the methodological framework of the presented scientific approach to determine the ecological and economic benefits of reusing the structural elements of a steel hall building.

Figure 1.

The methodological framework of the presented scientific approach to determining ecological and economic benefits.

2.1. Purpose of the Research

The aim of the study is to assess the ecological effects of the economic and technical aspects of steel halls in the process of their reuse. Conditions for multi-criteria environmental assessment have been introduced for the structure of hall-type buildings that are demolished and reassembled. Based on the generalized analysis [31], cumulative energy and material indicators were derived as total Qi and partial cost equivalents (UK, UE) in three life phases: construction, demolition and reuse of hall buildings. The full life cycle assessment of steel halls (LCA) is based on methodological assumptions that enable the monitoring of the ecological effects of multiple-assembly buildings. Computational research models are the frame structures of steel halls [50]. The essence of the research is to reuse the existing building elements without the need to incur energy expenditure for their re-production. This approach is in line with the principles of the circular economy (CE) [39,40].

2.2. The Course of EET Assessment in LCA Methodology

The research was limited to analyzing the skeleton of steel halls subjected to the process of multiple assembly. A choice analysis (CA) of the most optimal ecological solution for steel halls was proposed according to the multi-criteria economic, ecological and technical assessment (EET) of cumulative indicators, taking into account the LCA methodological assumptions:

Stage I (defining the purpose and scope)—the purpose specified in point 2.1. The adopted methodological scope of EET:

Ecological—consisting of determining the ecological effects of a building object on the environment, included in the production processes of construction, use and demolition.

Technical—consisting of determining the optimal, with regard to the adopted ecological and economic criteria, technical variant of a building object or its part, e.g., construction, demonstrating the acceptable limits of discrepancy for the adopted optimal architectural and construction solution, resulting from insufficient consideration of ecological parameters.

Economical—consisting of determining the cost expenditure generated by the optimal variant of a multiple-assembly facility for the adopted technical and ecological assumptions.

The method proposed by the authors will make it possible to carry out an integrated indicative ETE assessment, taking into account the building’s depreciation path and indicating the ecological profits that can be generated by hall-type buildings. Ecological depreciation is the reimbursement of the environmental costs incurred in constructing a building at LCA. The measure is the number of times the elements of the structure, housing or equipment are used.

Stage II (LCIA—life cycle inventory analysis):

Within the boundaries of the system, the flows of all materials, energy carriers and construction works used in the construction, use and demolition process were calculated based on the design assumptions of the steel hall models. Ecological costs were estimated for each of these flows.

Cycle I—creation and operation of the construction and operation of the building structure (hall design, cost estimates for selected model assumptions) determines the cumulative cost (QI) as the equivalent of all energy L/E (labor, equipment) and material processes M of the first assembly of the MASH structure.

Cycle II—another assembly (reconstruction or demolition project and erection of a new hall in a different place using the existing hall superstructure) determines the cumulative cost (QII) as the equivalent of all L/E and material M energy processes necessary for the second assembly of the MASH structure.

In the second phase of the hall structure’s life, the following options are possible:

Option 1: change of function, but the superstructure of the hall remains in the same place; only the structure and the casing are renovated.

Option 2: change of function but the superstructure completely or partially dismantled and relocated while the foundations remain.

Option 3: the foundations and the superstructure of the hall are dismantled and moved to another location with the need for renovation.

This study focuses on option number 3.

Stage III (LCIA—life cycle impact assessment)—aggregation of data from cycle I and II of MASH life, presents the division of QI,II cumulative total costs into partial ones as pro-environmental UE and environmentally degrading factors, UK. In the second phase of assembly (II life cycle), the accumulated energy is transferred to the next structure without the need to incur environmental and energy expenditures for the production of new steel elements. It was assumed that the ecological cost effectiveness contained in the repeated use of the main structure of the building translates indirectly into the reduction of the effects of environmental impacts resulting from the inventory of impacts in the LCA method.

Stage IV (LCI—life cycle interpretation) ecological assessment of the adopted structural solutions for multi-assembly steel halls (MASH). The research focused on the comparative analysis from stages II and III as an interpretation of the basic assessment of the environmental impacts of steel structure hall facilities.

Stage V Conclusions, summary, recommendations.

The idea of the method is in line with the development policy of the European Union [46] contained in “The European Green Deal” will transform the EU into a modern, resource-efficient and competitive economy, ensuring:

- no net emissions of greenhouse gases by 2050,

- economic growth decoupled from resource use,

- no person and no place left behind.

2.3. Main Criteria of the Ecological Evaluation of MASH

The criteria adopted for the EET assessment belong to stage II of LCA and result from the preparation of investment projects in the construction industry, starting from technical and economic assumptions, through the construction design and ending with implementation. Thus, the criteria represent the full life cycle of objects; they are divided into:

Location criteria: this refers to the necessity to adapt the functions of the areas for development to the natural conditions and not the other way around. The analysis shows the compensation indicators for the lost biologically active surface.

Criteria for the selection of design solutions: selection of the optimal static and material variant of the hall, enabling its disassembly and reassembly.

Cumulative design ETE criteria: determines the cumulative ecological and economic costs of the energy contained in work, equipment and materials for the primary and secondary MASH design.

Performance technology criteria related to the assembly and disassembly of the structure:

It constitutes the share of the involved work of equipment, labor and auxiliary materials for the modern conditions of the investment implementation, e.g., Just in Time [47].

Reusability criteria: is the basis for a comparative analysis after the first period of operation. The analysis presents indicators that express the amount of energy and mass of structural elements to be reused, as well as material and energy treated as waste [34].

The aforementioned criteria create an interdependent chain of connections in the eco-industrial system (the sum of technological processes, energy and materials, starting from the construction of the object, demolition to subsequent use) [51]. This should be understood as a balancing system of inputs and outputs, the flow of energy and matter between the environment and the industrial system [51,52].

EU regulations apply to the selection of a work contractor or tenants of buildings, taking into account non-price criteria relating to environmental aspects [53].

3. Subject of the Research, Basic Assumptions

3.1. Stage I (Defining the Purpose and Scope)

The design and material assumptions in Section 2.1 and Section 2.2 apply to selected model steel structures to test the EET method. Four static schemes of typical halls found in the investment market were adopted. The LCA path was analyzed on single-span structures in modular span variants ranging from 12.0 m to 48.0 m.

3.2. Stage II (LCIA-Life Cycle Inventory Analysis): Determination, Collection and Analysis of the Required Data

Physical and computational data (Materials and geometry).

The selection of the shape and dimensions of the halls adopted for the analysis was determined, assuming the typical solutions encountered in practice and the optimization work of steel frames [12,54]. The considered structural systems of halls consist of transverse flat frame structures connected with each other by bracing systems. In the analysis below, the transverse structural systems were examined, adopting, for their general stability, the buckling lengths that correspond to the node spacing of the longitudinal and transverse bracings of the halls [55]. This study did not analyze halls with a cooperating roofing made of a corrugated sheet (with the so-called diaphragm) as systems with an increased degree of difficulty in disassembly, which makes them less useful for the needs of multiple assembly. However, this does not prejudge the use of such solutions.

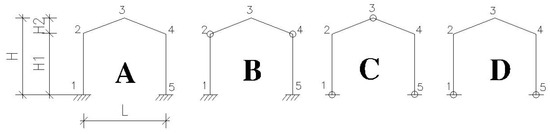

The following geometrical parameters of the bars and the design parameters of the hall nodes were adopted, which created the following flat static diagrams (Figure 2):

Figure 2.

Research diagrams of steel halls.

- -

- “A” scheme—rigid frame;

- -

- “B” scheme—frame with rigid columns on the support and articulation at the transom;

- -

- “C” scheme—triple-joint frame;

- -

- “D” scheme—rigid frame at the transom column nodes and articulated on the support.

Material data:

- Steel profiles of the hall cross system: HEA prismatic profiles,

- Type of structural steel: St3S (mullions, transoms, gusset plates, welds),

- Foundations: Concrete C16/20 (B-20), structural steel A-II.

Technical parameters for the adopted research models:

- •

- Geometric—dimensions calculated in the axes of elements:

- -

- height H = H1 + H2 [m], (H1 = 4.5 m, H2 = 1.5 m).

- -

- frame spacing S = 5.0 m.

- -

- variable span, the same for each scheme, from L = 12.0 m to 48.0 m.

- •

- Loads—equal for each scheme, i.e., wind, snow, roof loads, including purlins and bracings.

- •

- Own weights—suitable for the structural scheme.

- •

- Support compliance was presented as the intended relative displacement of support A with permissible values dx = −2 cm and dy = 2 cm (due to the disassembly conditions and the changeability of settlement during re-foundation).

- •

- The following ground conditions and foundations were adopted:

- -

- foundation level hp = 0.80 m. p.p.t.,

- -

- soils with low bearing capacity (Pd—Id = 0.3, φ = 15o, ρ = 1.65 t/m3),

- -

- strong soils (Pav—Id = 0.60, φ = 31o, ρ = 2.00 t/m3).

- •

- Static calculations were made with the use of the ROBOT computer program. Dimensioning of the steel structure of the halls is based on [40,41].

- •

- Design of foundations according to [41,42],

- •

- The price of construction and assembly works—as the average values from I quarter 22′, the following were adopted:

- -

- data for the steel skeleton (as of 03.2022) [43] (initially adopted to be produced with the material 12.76 euro/kg, assembly 1.5–3.5 euro/kg, material 8.50 euro/kg);

- -

- for reinforced concrete foundations (workmanship, material)—100.00 euro/m3, the execution with the material was initially adopted.

- •

- Other data according to technical standards and norms.

In the present study, it was assumed that the welds maintained the boundary conditions for individual frame nodes [56]. The welds were dimensioned for extreme cross-sectional forces at individual stages of structure operation, in accordance with [57,58], assuming the minimum weld mass [58,59,60,61,62] as the main optimization criterion. The indeformability of the substrate was assumed in the calculations. The welds were dimensioned for extreme nodal forces resulting from the load combinations adopted for the calculations.

- The dimensioning of the foundations was carried out on the basis of the standard [58,63,64].C16/20 (B-20) concrete and A-I steel were adopted.

- Static and strength calculations were made using the computer program ROBOT Structural Analysis Professional 2019, ARCadia BIM v.14.

Calculation of MASH construction costs:

The valuation of the structural elements of the halls, along with their assembly and disassembly for each of the stages of construction, was made on the basis of:

- Industry standards for the valuation of workshop works for steel structures,

- Cost Estimated Material Outlays (CEMO) for individual construction works, adopting the outlay costs (LME—labor, material, equipment) in IV qu. 2021. Calculations of material expenditure were carried out with the use of the NORMA computer program [65].

3.3. Stage III (LCIA)—Life Cycle Impact Assessment

Cycle I—construction of the MASH building/determination of cumulative QI cost equivalents

This stage was limited to the construction of a steel hall, while the costs of its use were omitted as secondary. Operating costs are variable and depend on the manner in which the structure is used (e.g., trade, production hall, etc.).

This is undoubtedly the most important stage of the selection analysis because it should define the optimal structural and ecological solution of the halls. The essence of this phase consists of the proper preparation of the object in terms of its secondary assembly and operation so that the energy accumulated in the mass of the structure is used to restore the lost ecological substance. The EET method was adopted to calculate the QIk,l equivalent energy and material costs in the first phase of the MASH structure for scheme “k” and span “l”.

QIk,l = (ΣCIsi + ΣCIri + ΣCIzi +ΣCFIi + ΣRFIi + ΣWIi + ΣTIwi + ΣTImi + ΣMIi + EPI)/p [EURO/m2]

Construction cost in phase I of QIk,l includes the following components:

- -

- QIk,l—total cumulative energy and material cost value of the construction of the MASH steel hall for the selected static scheme “k” and span “l”,

- -

- ΣCIs,r,z = ΣCIsi + ΣCIri + ΣCIzi—cost of producing the mass of MK structure elements (mullions, transoms, welds) calculated for the normative state of loads and displacements, taking into account the unit price of the mass for the i-th mullion, transom and weld,

- -

- ΣCFIi (ΣRFIi)—cost of the total mass of foundations made (RFIi total mass of foundations removed after the first assembly), CFi—mass of the i-th foundation,

- -

- ΣWIi—total cost of producing i-th structural elements in the workshop,

- -

- ΣTIi—total cost of transporting i-th structural elements in a specific process of the construction cycle:

- -

- Tw—raw material transport to the workshop,

- -

- Tm—transport of elements for assembly with the costs of operational storage,

- -

- ΣMIi—cost equivalent of the assembly of the i-th load-bearing element of the hall,

- -

- EPI—cost equivalent of the biologically active surface lost. The analysis adopted the equivalent of development = area with the assimilation intensity of the grass surface,

- -

- p—built-up area.

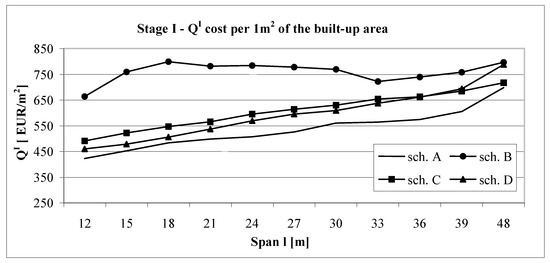

The summary of QIk,l values for schemes A, B, C and D and a span of up to 48 m is presented in Figure 3.

Figure 3.

Cumulative QI cost per 1 m2 of the built-up area.

After cycle I of the hall construction work, the cumulative construction costs of MASH QI presented in Figure 3 reflect only the physical parameters of the adopted typological variants of the hall. At this stage, it is possible to conclude that the halls with rigid frames (scheme A) have the lowest economic cost-to-area ratios at the level of 400- 550 EUR/m2 for spans of 12–30 m, which does not prejudge their selection, as the ecological impacts throughout their life cycle have not been taken into account.

Cycle II—dismantling and reassembly, the second stage of MASH’s work.

At this stage of the analysis, the QIIk,l cumulative costs related to the relocation of the existing facility to another location were calculated.

Assembly errors (manufacturing imperfections) that may occur in support nodes have been taken into account. The change in the stress state of the structure optimized in stage I was examined in terms of achieving a minimum weight. The degree of stress of the structure after the second and subsequent assembly has a significant impact on the change (possible strengthening) of the nodal elements of the hall. Improper preparation of structural welds at the stage of construction may cause imperfections of geometrical contacts [66].

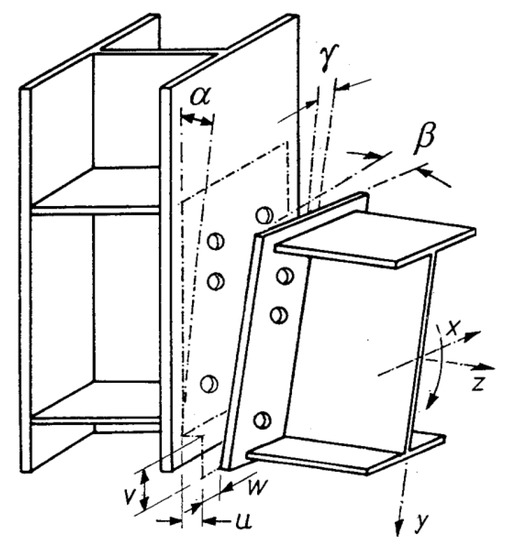

In the process of demolition, the structure is exposed to angle deformation α, β, γ and linear u, w and v of the plates in the assembly joints (Figure 4).

Figure 4.

Scheme of imperfections of angular and linear butt contacts.

Therefore, it is necessary to test and carry out maintenance and measurement adaptation works in workshop conditions to adapt the object for reuse.

Including the criteria listed in chapter 3, the cumulative equivalent energy and material cost QIIk,l was determined in the second life phase of the MASH structure for the scheme “k” and span “l”.

QIIk,l = (ΣΔCIIsi + ΣΔCIIri + ΣΔCIIzi + ΣCFIIi + ΣRFIIi + ΣWIIi + ΣTIImi + ΣMIIi +ΣDIi + EPII)/p [EURO/m2

Energy cost QIIk,l includes the following components:

- -

- QIIk,l—cumulative equivalent energy and material cost in the second phase of MASH structure life for the selected scheme “k” and span “l”.

- -

- ΣCFIIi (RFII)—total mass cost of foundations made during secondary assembly (RFII total mass of foundations removed after subsequent assembly),

- -

- ΣΔCIIs,r,z = ΣΔCIIsi + ΣΔCIIri + ΣΔCIIzi—total cost of inspection and protection of the structure ΔMK resulting from the necessity to eliminate the stress of the structure due to assembly imperfections,

- -

- ΣWIIi—modification in the workshop or assembly of specific i-th structural elements,

- -

- ΣTIImi—cost of transporting all elements of the hall for reassembly with the costs of operational storage,

- -

- ΣMIIi—cost of assembly of steel load-bearing elements of the hall in a new location,

- -

- ΣDIi—cost of dismantling the steel load-bearing elements of the originally assembled hall,

- -

- EPII—cost equivalent of the biologically active area lost for the built-up area of the re-assembled hall,

- -

- p—built-up area.

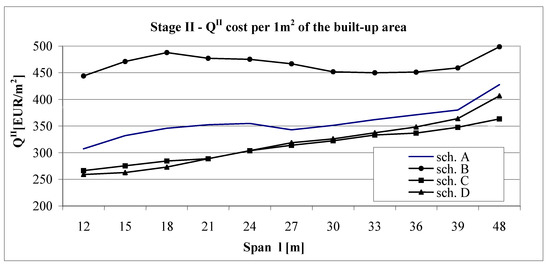

Figure 5 shows the cumulative LME cost (labor, material, equipment) of the structure in the second phase of its operation, i.e., reuse. The cost was summarized for an area of 1 m2 of the MASH building area. From the estimated charts, it is possible to initially accept the hall solutions in schemes C and D due to the favorable price parameters. In particular, halls with a span of 12 m to 30 m should be distinguished. Their price threshold is at the level of 270–330 EUR/m2 of the total value of QIIk,l of the second assembly of MASH.

Figure 5.

Cumulative cost QII of stage II per 1 m2 of the built-up area.

3.4. STAGE IV (LCI—Life Cycle Interpretation)—Interpretation of Results

At each stage of the facility’s life (HSWM-BOMM), the EET analysis presents the distribution of the calculated values of the UE and UK sub-indices as shares of the Qk,l cumulative ecological cost. These are the components responsible for ecological losses and gains.

Interpretation of Cycle I results:

Stage of creating the MASH structure

The cumulative value of QIk,l (Equation (3)) includes the economic and ecological costs associated with the implementation and assembly of the UKI structure as well as environmental regeneration and disposal of UEI construction waste:

QIk,l = (UEI + UKI)/p [EURO/m2]

UEI—share of the ecological costs of environmental regeneration in the process of execution and operation of MASH,

UKI—share of economic costs for the execution and assembly of the MASH facility structure (original hall structure cost).

The shares of UEI and UKI of the cost of building QIk,l presented in Table 1 were examined in terms of environmental impacts in the I cycle of life of MASH and then in the II cycle of life, i.e., another assembly. Ecological costs of UEI are considered necessary in the construction process, directly interfering with the biotic layer of the area on which the building stands. These include the components ΣRFIi + EPI, which will be charged with construction costs in the first phase of life.

Table 1.

Share of UEI ecological (environmental) and UKI economic costs.

Breaking down the cumulative costs of building the hall at UKI and UEI allows making an approximate selection of the MASH structure already in the first phase of construction work. It should be noted that the UKI component contains energy and material elements that are the subject of reuse, e.g., ΣCIsi + ΣCIri + ΣCIzi components and energy lost components such as ΣWIi + ΣTIi + ΣMIi. In the approach to the environmental costs of multiple uses of MASH’s technological and operational elements and processes, this will be of significant importance. Referring to the share of UEI regeneration costs, i.e., restoration of the biologically active surface, it seems right to include them in the pro-ecological costs, despite the destruction of the active layer of the biocenosis by foundation works and the zero state.

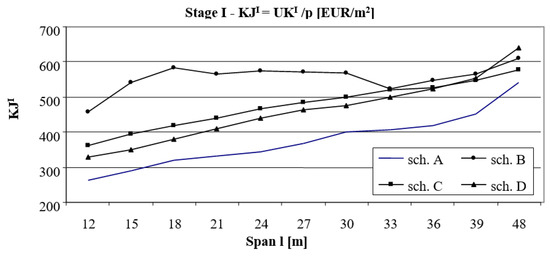

The total share of energy and material involved in the structure of the UKI superstructure itself (part of the building above the ground) of the selected models of hall facilities in Figure 6 is an introduction to the environmental LCA comparative analysis.

Figure 6.

KJI unit cost of creating the UKI structure per 1 m2 of the built-up area [EURO/m2].

The structure of MASH in the first stage of construction, presented in Figure 3 and Figure 6, confirms the initial correctness of the hall selection due to the total energy and material costs of KJI (Equation (4)) of all manufacturing processes for scheme A.

where:

KJI = UKI/p [EURO/m2]

KJI—unit cost of construction creation, [EURO/m2],

UKI—share of economic costs for the execution and assembly of the MASH facility structure (original hall structure cost), [EURO],

p—built-up area, [m2].

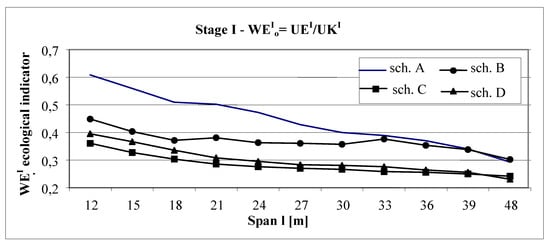

This proves the low impact of the economic costs of foundation work on the total QI accumulated costs. However, one should not forget about the costs of the ecological impacts generated by the construction of the MASH structure. The scope of these impacts is defined by the generalized ecological indicator WEIo (Figure 7) as the ratio of the ecological costs of the UEI to the economic costs of the UKI.

Figure 7.

Ecological generalized WEIo index – cycle I of LCA.

Optimal solutions are contained between the schemes of construction C—with the lowest values of the WEIo index (Equation (5))—and scheme A, which shows the highest level.

WEIo = UEI/UKI

Figure 7 shows that the ecological profitability of construction solutions is the best for the range marked “from below” by schemes C and D—this impact is 37–23%, while for schemes A and B the values of ecological indicators for construction WEIo are the highest and amount to 61–30%. The higher the ecological indicators, the higher the environmental costs generated by the structure.

The presented WEIo index is a value enabling the initial selection of a structure because, as already mentioned, the cumulative QIk,l costs contain partial elements responsible for losses and ecological gains in the MASH construction process. Therefore, it is necessary to carry out a further analysis of the impact of these components on the selection of the optimal structure in the full life cycle and, therefore, in the subsequent assembly phases.

Interpretation of the results of Cycle II of the analysis—option 3 was adopted; therefore, it is the phase of demolition of the MASH building structure, including the foundations.

After calculating the cumulative cost of QIIk,l (Equation (6)), similarly to the first stage, its distribution was examined into:

QIIk,l = (UEII + UKII)/p [EURO/m2]

UEII—ecological cost of compensation for the lost layer of biocenosis (regenerating the environment) in the process of the secondary assembly and operation of MASH,

UKII—economic cost of reassembling the MASH structure elsewhere as a factor that degrades the environment with the use of elements from the first cycle of the facility’s operation.

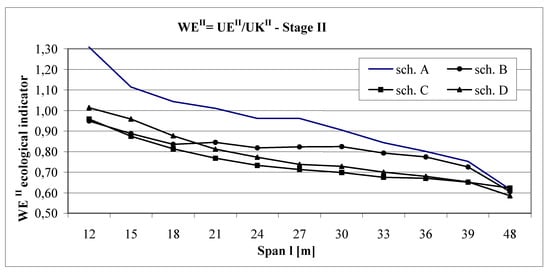

The ratio of ecological to economic costs will be used to search for the optimal design solution from the point of view of the ecological impacts of MASH. The shares of the individual components of QII are presented in the ecological generalized index of cycle II of the work of the WEIIo structure.

WEIIo = UEII/UKII

The table below shows the components UEII and UKII of the cumulative cost QIIk,l.

Table 2 presents the ecological costs ΣRFIIi+ EPII, necessary to regenerate the biologically active area (built-up area). The share of UEII ecological (environmental) costs in the second phase is crucial in the LCA assessment of the hall structure. Generalized ecological indicators [WEIIo k,l ] create a picture (Figure 8) of the impact of individual types of HSWM on ecological costs, included between the envelopes:

Table 2.

Share of UEII ecological and UKII economic costs of LCA cycle II.

Figure 8.

Generalized ecological indicator WEIIo—cycle II.

- The lower envelope characterizes halls with the lowest ecological costs:

- -

- type B for L = 12–13.5 m, WEIIo k,l = 0.95–1.1

- -

- type C for L = 13.5–39 m, WEIIo k,l = 0.85–0.65

- -

- type D for L = 39–48 m, WEIIo k,l = 0.65–0.55

- The upper envelope characterizes the scheme with the highest ecological cost:

- -

- type A for L = 12–48 m, WEIIo k,l = 1.35–0.65.

Ecological indicators WEIIo k,l of the structure are at the level of 0.55–0.65 for the largest spans of 39–48 m, which proves the lowest share of 35–45% of ecological costs in the entire investment.

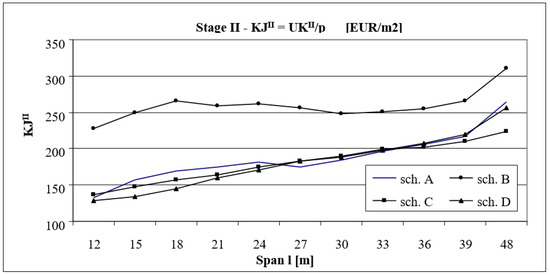

The unit cost of construction is:

where:

KJII = UKII/p [EURO/m2]

KJII—unit cost of construction creation, [EURO/m2]

UKII—economic cost of reassembling the MASH structure elsewhere as a factor that degrades the environment with the use of elements from phase I of the facility’s operation, [EURO],

p—built-up area, [m2].

At the same time, in the second cycle of the hall structure’s life, the UKII economic costs (as shown in Figure 9) are more than twice lower than the new structure and amount to approximately 130–180 EUR/m2 for typical spans from 12–30 m, assuming the implementation of the investment on the Just in time basis [47].

Figure 9.

KJII unit cost of creating the UKII structure per 1 m2 of the built-up area [EURO/m2].

When analyzing stage II, it should be noted that the economic costs incurred to produce a “new” UKII structure in the next phase of its life accelerate the total depreciation of the facility (Equation (9)) and are pro-environmental.

The depreciation ratio (Wa) would be:

Wa = 1 − KJI/(QI + QII)

The better the preparation of the UKI structure to work in phase II, the lower the QII adaptation costs and the faster the environmental depreciation, i.e., Wa decreasing, and vice versa. Thus, the multiplicity of multiple installations (Wkm) (Equation (10)) in order to recover environmental costs can be presented according to the formula:

Wkm = (QI + QII)/KJI

According to the formula (Equation (10)), the lower the value of the assembly multiplication index Wkm, the faster the path of ecological depreciation of the hall structure (this issue is the subject of further research). With each new phase of life (reuse), MASH halls reduce their ecological footprints and start generating ecological profits.

4. Stage V—Conclusions, Summary, Recommendations

The selection of the optimal ecological MASH solution was carried out taking into account the criteria listed in point 2.3. The criterion for reusing the structural elements of the facility is one of the most important. It characterizes objects with pro-ecological features. Adopting that the above-ground parts of the UK hall structure can be moved to another location and reassembled, their foundations remain on the ground and may constitute an obstacle to the redevelopment of the EU territory. Depending on the purpose of the land after the existing structure, the foundations, together with the development area, can be used, for example, as landscape elements or aggregates [67,68]. In most cases, however, the existing foundations with the remaining elements of the technical infrastructure are removed because it is difficult to guarantee their use in newly erected facilities.

Referring to the results of the total cumulative costs QI = 400–500 EUR/m2 from phase I of the construction work in relation to the costs of the secondary cycle QII = 270–330 EUR/m2, this ratio is in favor of reusing the structure and is 67% for all analyzed types of halls. The important conclusions result from comparative studies of the optimal proportions between the construction costs of UK hall structures and the ecological costs of the UE related to restoring the original (initial) state of the environment.

The UKII component of the next assembly of HSWM is a relatively constant parameter and ranges from 48–51% of the cost of a new investment, assuming the implementation of the investment on the Just in time basis [47,69], which was mentioned earlier.

Despite the pro-environmental action in the MASH implementation process, the WEIIo indicators increased from 2.21 to 2.77 times compared to cycle I and will extend the depreciation period of multiple assembly facilities. At the same time, the cases of such halls are recommended for a repeat design cycle in the CE circulation loop in order to reduce UK ecological and UE economic costs.

WEIIo indicators determine the impact of ecological costs on MASH’s design solutions and constitute an approximate method but a reliable environmental assessment of the halls. The EET indicator assessment enables the elimination of incorrect technical solutions in the ecological and economic aspects already at the design stage. In the analyzed case, halls A and B, with a span of 21.0–36.0 m, have the most unfavorable WEIIo indicators, higher on average by 14.3–28% than the others.

As previously mentioned, Tingley and Allwood [13] and Cullen and Drewniok [12] showed that the reuse of building structure elements is uneconomical. However, the integrated approach presented in the EET analysis proved the profitability of the secondary use of steel hall structures by as much as 67% compared to new construction.

Using the EET method, the technological, economic and ecological aspects included in the dimensioned execution processes were combined. Simple indicators for assessing the return on environmental outlays were derived, i.e., the Wa depreciation indicator and the subsequent assembly Wkm index specifying the minimum reuse number of the hall structure to balance the environmental capital incurred for the original production of the facility. The presented approach, based on simple ecological indicators WEI and WEII, enables a quick analysis of the use of existing structures, which, in the era of limited raw material resources, are a good source of materials.

Reusing MASH elements is one aspect of the implementation of the construction sector sustainability paradigm [17]. It should be emphasized that the implementation of the reuse of MASH elements will require changes in the market from all participants in the investment process [19]. Starting from designers, through investors, traders, contractors, users and dismantling workers. This is important information for policymakers who should use a set of legal and financial instruments to lower the cost of reusing MASH structures.

The changes should also concern the creation of the MASH construction elements and the system of certification and trade in these elements [46], e.g., CER marking as an extension of the CE marking procedure has already been used for other products in the European Union.

However, due to widespread e-commerce, checking the availability of recycled MASH elements should not pose any major problems.

It is also important to change the perception of reusing MASH structural elements by the actors of the investment process. The common belief that only a “new” structural element will meet expectations regarding the safety of the structure should change.

The EET method can be dedicated to any steel structure, e.g., multi-span systems with any girders made of cylindrical profiles, openwork, plate girders or trusses; the same applies to columns.

The disadvantages of this method are the indirect assessment of ecological effects and the focus on material and economic gains in the life cycle of particular types of structures. However, the method is open to parallel parameterization of effects and ecological impacts, with an indication of environmental hazards resulting from the adoption of a specific design solution.

Author Contributions

Conceptualization, P.S.; Methodology, P.S., R.D. and J.A.; Software, P.S.; Validation, P.S., R.D. and J.A.; Resources, P.S.; Data Curation, P.S.; Writing—Original Draft Preparation, P.S., J.A. and R.D.; Writing—Review & Editing, P.S., J.A. and R.D.; Visualization, P.S.; Supervision, P.S.; Project Administration, P.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data available on request due to restrictions privacy.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| C2C— | Cradle to Cradle® is a trademark of McDonough Braungart Design, Chemistry, |

| C2G— | cradle to grave |

| CE— | circular economy |

| CEAP— | Circular Economy Action Plan |

| CEMO— | Cost Estimated Material Outlays |

| CP— | Cleaner Production |

| DFE— | design for the environment |

| EAB— | ecological amortization of buildings |

| EAU— | Ecological Accounting Units |

| EET— | assessment of cumulative ecological, economic and technical parameters |

| EPDs— | environmental product declarations |

| LCA— | life cycle assessment |

| LCI— | life cycle inventory |

| LCIA— | life cycle impact assessment |

| LE— | linear economy |

| LLC— | life cycle cost |

| LSF— | Light steel frame in building systems |

| MAO— | Multiple Assembly Objects |

| MASH— | multi-assembly steel halls |

| OSC— | Off-site construction, system for Off-Site Construction Projects |

| QI,II— | determines the total cumulative cost of the hall after life cycle I and II |

| PLA— | Product Line Analysis |

| TQEM— | Total Quality Environmental Management |

| UE— | share of ecological costs of environmental regeneration in the process of execution and operation of MASH |

| UK— | share of economic costs for the execution and assembly of the MASH facility structure (original hall structure cost) |

| WE— | generalized ecological indicator |

References

- Tam, V.W.Y.; Tam, C.M. Evaluations of existing waste recycling methods: A Hong Kong study. Build. Environ. 2006, 41, 1649–1660. [Google Scholar] [CrossRef]

- Stahel, W.R. The Circular Economy: A User’s Guide; Routledge: Oxfordshire, UK, 2019; ISBN 9780367200176. [Google Scholar]

- Jelčić Rukavina, M.; Skejić, D.; Kralj, A.; Ščapec, T.; Milovanović, B. Development of Lightweight Steel Framed Construction Systems for Nearly-Zero Energy Buildings. Buildings 2022, 12, 929. [Google Scholar] [CrossRef]

- Sun, J.; Han, B.; Ekwaro-Osire, S.; Zhang, H.-C. Design for Environment: Methodologies, Tools, and Implementation. J. Integr. Des. Process Sci. 2003, 7, 59–75. [Google Scholar]

- Yilmaz, M.; Bakış, A. Sustainability in Construction Sector. Procedia Soc. Behav. Sci. 2015, 195, 2253–2262. [Google Scholar] [CrossRef]

- Weerasuriya, A.U.; Zhang, X.; Wang, J.; Lu, B.; Tse, K.T.; Liu, C.-H. Performance evaluation of population-based metaheuristic algorithms and decision-making for multi-objective optimization of building design. Build. Environ. 2021, 198, 107855. [Google Scholar] [CrossRef]

- Brachet, A.; Schiopu, N.; Clergeau, P. Biodiversity impact assessment of building’s roofs based on Life Cycle Assessment methods. Build. Environ. 2019, 158, 133–144. [Google Scholar] [CrossRef]

- McCollough, J. Determinants of a throwaway society—A sustainable consumption issue. J. Socio-Econ. 2012, 41, 110–117. [Google Scholar] [CrossRef]

- Tesfamariam, S.; Goda, K. (Eds.) Handbook of Seismic Risk Analysis and Management of Civil Infrastructure Systems; Woodhead Publishing Limited: Sawston, UK, 2013. [Google Scholar] [CrossRef]

- Girão Coelho, A.M.; Pimentel, R.; Ungureanu, V.; Hradil, P.; Kesti, J. European Recommendations for Reuse of Steel Products in Single-Storey Buildings, 1st ed.; ECCS—European Convention for Constructional Steelwork: Brussels, Belgium, 2020; Available online: https://www.steelconstruct.com/wp-content/uploads/PROGRESS_Design_guide_final-version.pdf (accessed on 3 May 2022).

- Fiedor, B.; Czaja, S.; Graczyk, A.; Jakubczyk, Z. Podstawy Ekonomii Środowiska i Zasobów Naturalnych (Fundamentals of Economics of the Environment and Natural Resources); Wyd. C.H. Beck: Warszawa, Poland, 2002. (In Polish) [Google Scholar]

- Cullen, J.; Drewniok, M. Structural Steel Reuse. Steel and the Circular Economy; The Building Centre: London, UK, 2016; Available online: https://steel-sci.com/assets/downloads/structural-steel-reuse/161130-bcsa-cullen%20002.pdf (accessed on 3 May 2022).

- Tingley, D.D.; Allwood, J. Reuse of structural steel: The opportunities and challenges. In Proceedings of the European Steel Environment & Energy Congress, Teeside University, Middlesbrough, UK, 15–17 September 2014. [Google Scholar]

- Górka, K.; Poskropko, B.; Radecki, W. Ochrona Środowiska; PWE: Warszawa, Poland, 2001. (In Polish) [Google Scholar]

- Bokhari, S.; Geltner, D. Characteristics of Depreciation in Commercial and Multi-Family Property: An Investment Perspective. Real Estate Econ. 2016, 46, 745–782. [Google Scholar] [CrossRef]

- Allwood, J.; Cullen, J. Sustainable Materials: With Both Eyes Open; UIT Cambridge Ltd.: Cambridge, UK, 2012. [Google Scholar]

- Tingley, D.D.; Davison, B. Design for deconstruction and material reuse. Proc. Inst. Civ. Eng. Energy 2011, 164, 195–204. [Google Scholar] [CrossRef]

- Brown, D.G.; Pimentel, R.J.; Sansom, M.R. Structural Steel Reuse Assessment, Testing and Design Principles. 2019. Available online: https://steel-sci.com/assets/downloads/steel-reuse-event-8th-october-2019/SCI_P427.pdf (accessed on 5 May 2022).

- Stephan, A.; Athanassiadis, A. Towards a more circular constructionsector: Estimating and spatialising current and future non-structural materialreplacement flows to maintain urban building stocks. Resour. Conserv. Recycl. 2018, 129, 248–262. [Google Scholar] [CrossRef]

- Foster, G. Circular economy strategies for adaptive reuse of cultural heritage buildings to reduce environmental impacts. Resour. Conserv. Recycl. 2020, 152, 104507. [Google Scholar] [CrossRef]

- Upadhayay, S.; Alqassimi, O. A Study on Assessing a Business Viability for Transition to a Circular Economy. Westcliff Int. J. Appl. Res. 2020, 4, 78–94. [Google Scholar] [CrossRef]

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circulareconomy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Wu, H.; Zuo, J.; Zillante, G.; Wang, J.; Yuan, H. Status quo and future directions of construction and demolition waste research: A critical review. J. Clean. Prod. 2019, 240, 118163. [Google Scholar] [CrossRef]

- Reisinger, J.; Kugler, S.; Kovacic, I.; Knoll, M. Parametric Optimization and Decision Support Model Framework for Life Cycle Cost Analysis and Life Cycle Assessment of Flexible Industrial Building Structures Integrating Production Planning. Buildings 2022, 12, 162. [Google Scholar] [CrossRef]

- Sammut-Bonnici, T. Wiley Encyclopedia of Management—Volume 12 Strategic Management; John Wiley & Sons, Ltd.: New York, NY, USA, 2015. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions the European Green Deal, COM/2019/640; European Commission: Brussels, Belgium, 2019.

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions a New Circular Economy Action Plan for a Cleaner and More Competitive Europe COM/2020/98 Final; European Commission: Brussels, Belgium, 2020.

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.; Hultink, E.J. The circular economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Burman, M.; Braimah, N. Pathways to circular construction: An integrated management of construction and demolition waste for resource recovery. J. Clean. Prod. 2020, 244, 118710. [Google Scholar] [CrossRef]

- Vieira, L.C.; Amaral, F.G. Barriers and strategies applying Cleaner Production: A systematic review. J. Clean. Prod. 2016, 113, 5–16. [Google Scholar] [CrossRef]

- Klöpffer, W.; Grahl, B. Life Cycle Assessment (LCA): A Guide to Best Practice; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2014; 440p. [Google Scholar] [CrossRef]

- Adamczyk, J.; Dylewski, R. Ecological and Economic Benefits of the “Medium” Level of the Building Thermo-Modernization: A Case Study in Poland. Energies 2020, 13, 4509. [Google Scholar] [CrossRef]

- Sobierajewicz, P. Kształtowanie Zabudowy Miejskiej o Zwiększonej Efektywności Ekologicznej i Energetycznej: Architektura, Rozwój, Społeczeństwo, Ekologia; Oficyna Wydaw. Uniwersytetu Zielonogórskiego: Zielona Góra, Poland, 2013; p. 274. [Google Scholar]

- Arvidsson, R.; Svanström, M. A framework for energy use indicators and their reporting in life cycle assessment. Integr. Environ. Assess. Manag. 2016, 12, 429–436. [Google Scholar] [CrossRef]

- Hertwich, E.G.; Gibon, T.; Bouman, E.A.; Arvesen, A.; Suh, S.; Heath, G.A.; Bergesen, J.D.; Ramirez, A.; Vega, M.I.; Shi, L. Integrated life-cycle assessment of electricity-supply scenarios confirms global environmental benefit of low-carbon technologies. Proc. Natl. Acad. Sci. USA 2014, 112, 6277–6282. [Google Scholar] [CrossRef] [PubMed]

- PAEC. Final Report on Environmental Accounting and Reporting; Parliament of Victoria: Melbourne, VIC, Australia, 2002. Available online: http://www.parliament.vic.gov.au/papers/govpub/VPARL1999-2002No141.pdf (accessed on 9 May 2022).

- Sagarduy, G.; Bandinelli, S.; Lerchundi, R. Product-line Analysis: Do we go ahead? In Proceedings of the Software Product Lines: Economics, Architectures, and Implications, Workshop #15 at 22nd International Conference on Software Engineering (ICSE), Limerick, Ireland, 10 June 2000. [Google Scholar]

- Sherif, Y.S.; Kolarik, W.J. Life Cycle Costing: Concept and Practice. Omega 1981, 9, 287–296. [Google Scholar] [CrossRef]

- Braungart, M.; McDonough, W. Cradle to Cradle: Remaking the Way We Make Things; North Point Press: New York, NY, USA, 2002. [Google Scholar]

- Kacprzak, M. Chapter: Cradle to Cradle Marketplace, Biodegradable Waste Management in the Circular Economy; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2022; pp. 13–18. ISBN1 9781119679844. ISBN2 9781119679523. [Google Scholar] [CrossRef]

- Diaz-Granados, J. Encyclopedia of Sustainable Management; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Jurkait, K.; Stiglmair, J. Cradle-to-Cradle in Building Services. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012013. [Google Scholar] [CrossRef]

- Lowe, E.A.; Evans, L.K. Industrial ecology and industrial ecosystems. J. Clean. Prod. 1995, 3, 47–53. [Google Scholar] [CrossRef]

- Sertyesilisik, B.; Sertyesilisik, E. Eco industrial Development: As a Way of Enhancing Sustainable Development. J. Econ. Dev. Environ. People 2016, 5, 6–27. [Google Scholar] [CrossRef]

- Srinivasan, R.; Ingwersen, W.; Trucco, C.; Ries, R.; Campbell, D. Comparison of energy-based indicators used in life cycle assessment tools for buildings. Build. Environ. 2014, 79, 138–151. [Google Scholar] [CrossRef]

- EU Ecolabel Home. Available online: https://ec.europa.eu/environment/topics/circular-economy/eu-ecolabel-home_en (accessed on 4 May 2022).

- Pinto, J.L.Q.; Matias, J.C.O.; Pimentel, C.; Azevedo, S.G.; Govindan, K. Just in Time Factory; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Public Procurement for a Circular Economy 2017. Available online: https://ec.europa.eu/environment/gpp/pdf/CP_European_Commission_Brochure_webversion_small.pdf (accessed on 12 November 2022).

- Bilal, M.; Oyedele, L.O.; Akinade, O.O.; Ajayi, S.O.; Alaka, H.A.; Owolabi, H.A.; Qadir, J.; Pasha, M.; Bello, S.A. Big data architecture for construction waste analytics (CWA): A conceptual framework. J. Build. Eng. 2016, 6, 144–156. [Google Scholar] [CrossRef]

- Konstrukcje Stalowe hal Wielkopowierzchniowych—Inżynier Budownictwa. Available online: https://inzynierbudownictwa.pl/konstrukcje-stalowe-hal-wielkopowierzchniowych/ (accessed on 12 November 2022).

- Kim, H.-W.; Dong, L.; Jung, S.; Park, H.-S. The Role of the Eco-Industrial Park (EIP) at the National Economy: An Input-Output Analysis on Korea. Sustainability 2018, 10, 4545. [Google Scholar] [CrossRef]

- Life and the Circular Economy, European Commission, Environment Directorate General. 2017. Available online: https://ec.europa.eu/environment/archives/life/publications/lifepublications/flippingbook/circulareconomy/HTML/files/assets/common/downloads/publication.pdf (accessed on 15 May 2022).

- Pozacenowe Kryteria Oceny Ofert. Poradnik z Katalogiem Dobrych Praktyk; Urząd Zamówień Publicznych: Warszawa, Poland, 2020. (In Polish) [Google Scholar]

- Gawęcki, A.; Garstecki, A.; Gawęcki, M. Optymalizacja Systemu Lekkich hal Stalowych, Opracowanie, 6; Instytut Podstawowych Problemów Techniki PAN: Warszawa, Poland, 1978. (In Polish) [Google Scholar]

- Biegus, A. Projektowanie konstrukcji budowlanych według Eurokodów. Builder 2010, 4, 1–48. (In Polish) [Google Scholar]

- Heinisuo, M.; Laine, V.; Lehtimäki, E. Enlargement of the component method into 3D. In Proceedings of the Nordic Steel Construction Conference (NSCC 2009), Malmö, Sweden, 2–4 September 2009; pp. 430–437. [Google Scholar]

- PN-EN 1993-1-1: 2006; Eurokod 3: Projektowanie Konstrukcji Stalowych Część 1–1: Reguły Ogólne i Reguły dla Budynków. Polish Committee for Standardization: Warszawa, Poland, 2006.

- PN-EN 1993-1-8: 2006; Eurokod 3: Projektowanie Konstrukcji Stalowych. Część 1–8: Projektowanie Węzłów. Polish Committee for Standardization: Warszawa, Poland, 2006.

- Bogucki, W.; Żyburtowicz, M. Tablice do Projektowania Konstrukcji Metalowych; Arkady: Warszawa, Poland, 2008. (In Polish) [Google Scholar]

- Heller, H. Bautechnische Tabellen Interaktiv—WINTAB RA 2.0 Rahmenformeln; Ernst & Sohn: Berlin, Germany, 2001. [Google Scholar]

- Kindmann, R.; Stracke, M. Verbindungen im Stahl- und Verbundbau, 2. Auflage; Ernst und Sohn: Berlin, Germany, 2009. [Google Scholar]

- PN-EN 1090-2+A1:2012; Wykonanie Konstrukcji Stalowych i Aluminiowych—Część 2: Wymagania Techniczne Dotyczące Konstrukcji Stalowych. Polish Committee for Standardization: Warszawa, Poland, 2012.

- PN-EN 1997-1:2008; Eurokod 7—Projektowanie Geotechniczne—Część 1: Zasady Ogólne. Polish Committee for Standardization: Warszawa, Poland, 2008.

- PN-EN 1992-1-1:2008; Eurokod 2, Projektowanie Konstrukcji z Betonu, Część 1-1: Reguły Ogólne i Reguły dla Budynków. Polish Committee for Standardization: Warszawa, Poland, 2008.

- SECOCENBUD. Available online: www.sekocenbud.pl/produkty/wydawnictwa-sekocenbud/ (accessed on 20 April 2022).

- Biegus, A. Projektowanie Konstrukcji Stalowych Według Eurokodu 3, Materiały Dydaktyczne; Politechnika Wrocławska WBLiW: Wrocław, Poland, 2010; Available online: http://www.metale.pwr.wroc.pl/files/A.Biegus-Polaczenia_Srubowe.pdf (accessed on 25 April 2022).

- Shah, R.A.; Pitroda, D.J. Recycling of Construction Materials for Sustainability. In Proceedings of the Conference: National Conference on Recent Trends in Engineering & Technology (NCRTET), BVM Engineering College, Vallabh Vidyanagar, India, 13–14 May 2011. [Google Scholar]

- Shinde, D.S.; Kadam, A.; Wadke, A.; Wani, A. A Study on Sustainable Construction Practices and Management. In Proceedings of the Conference: IOP Conference, Coimbatore, India, 12–13 February 2022. [Google Scholar]

- Patel, V.; Solanki, J. Just in Time Concept Used in Construction Project. Int. Res. J. Eng. Technol. 2020, 7, 3298–3303. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).