Design and Dynamic Simulation Verification of an On-Orbit Operation-Based Modular Space Robot

Abstract

:1. Introduction

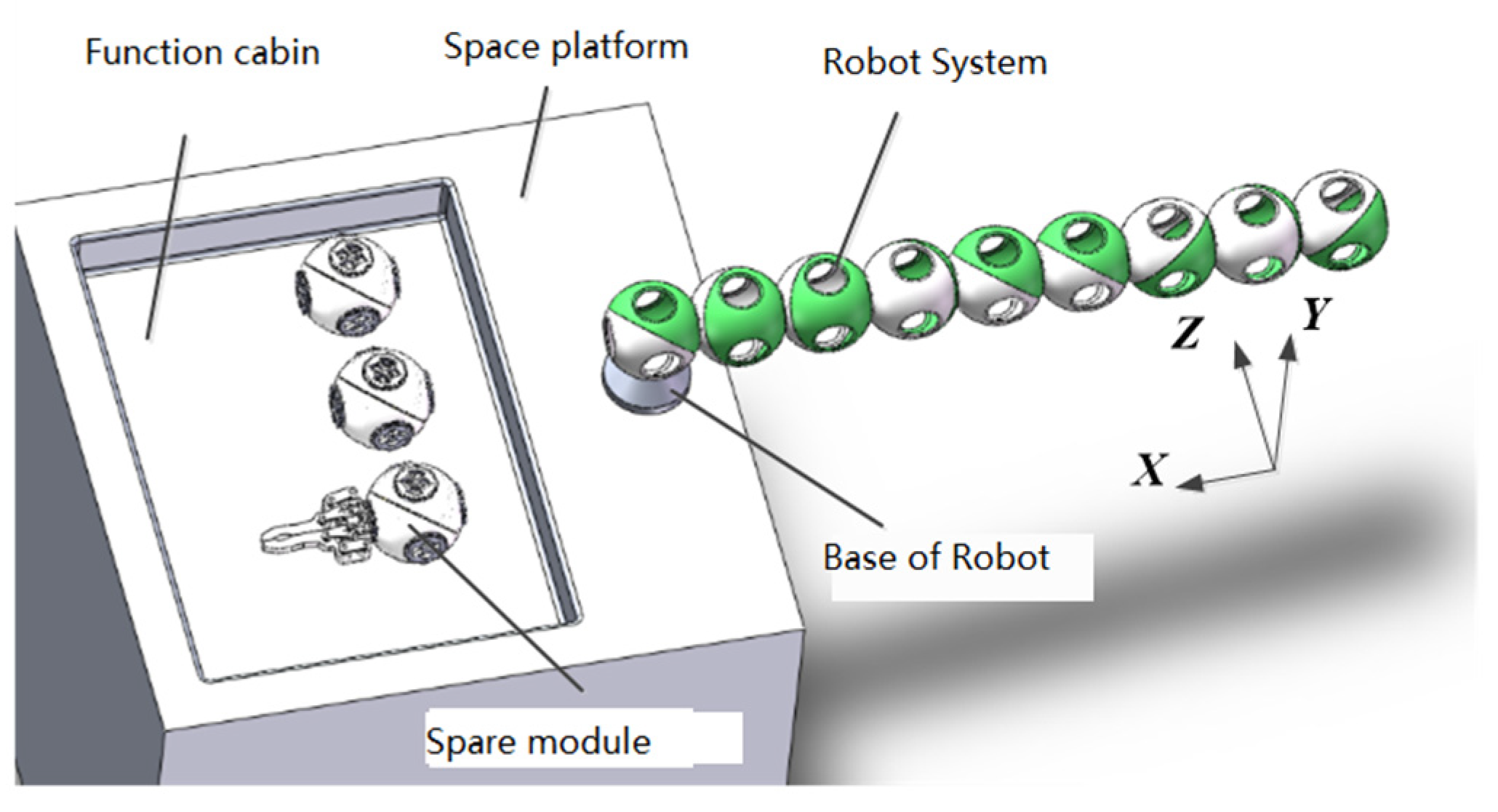

2. Configuration Design of Reconfigurable Modular Space Robot

2.1. Space Mission Description

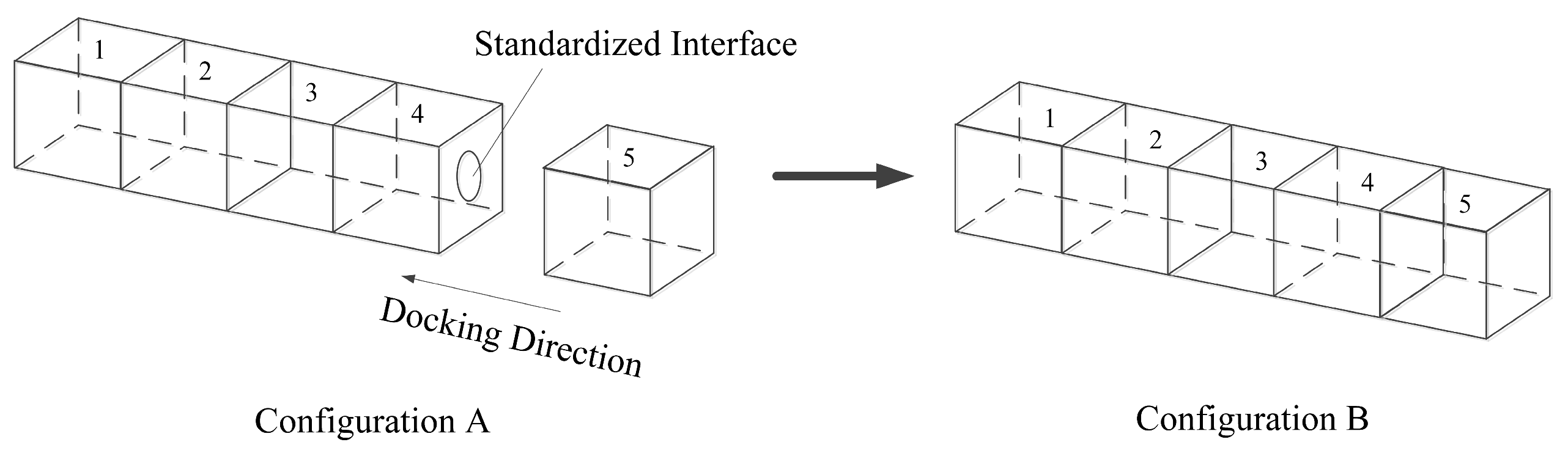

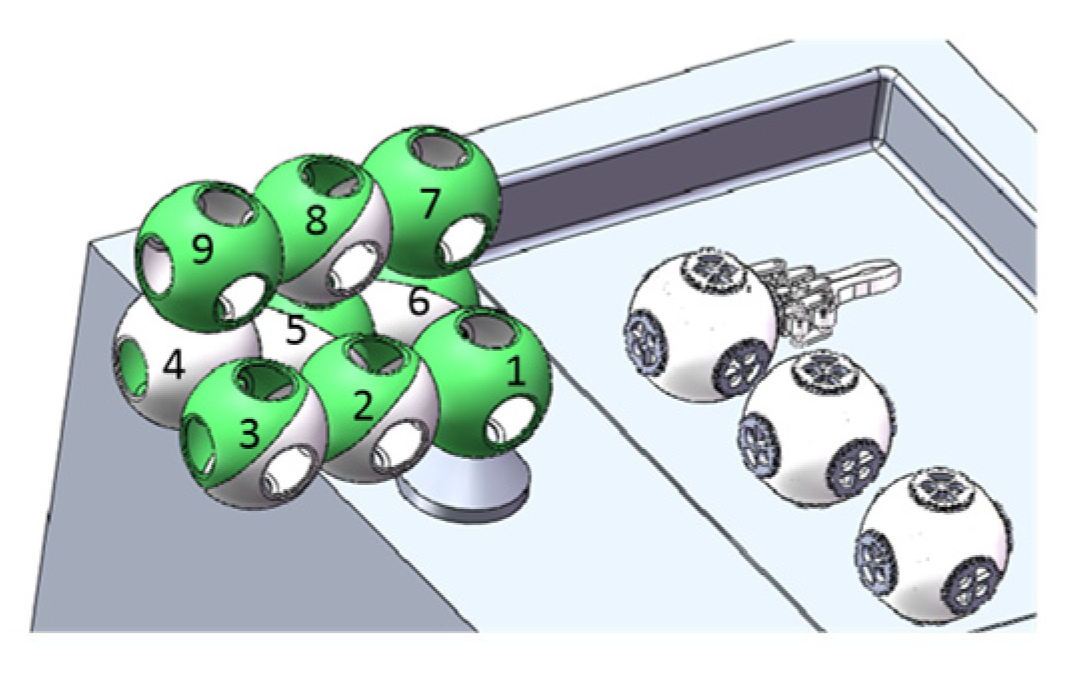

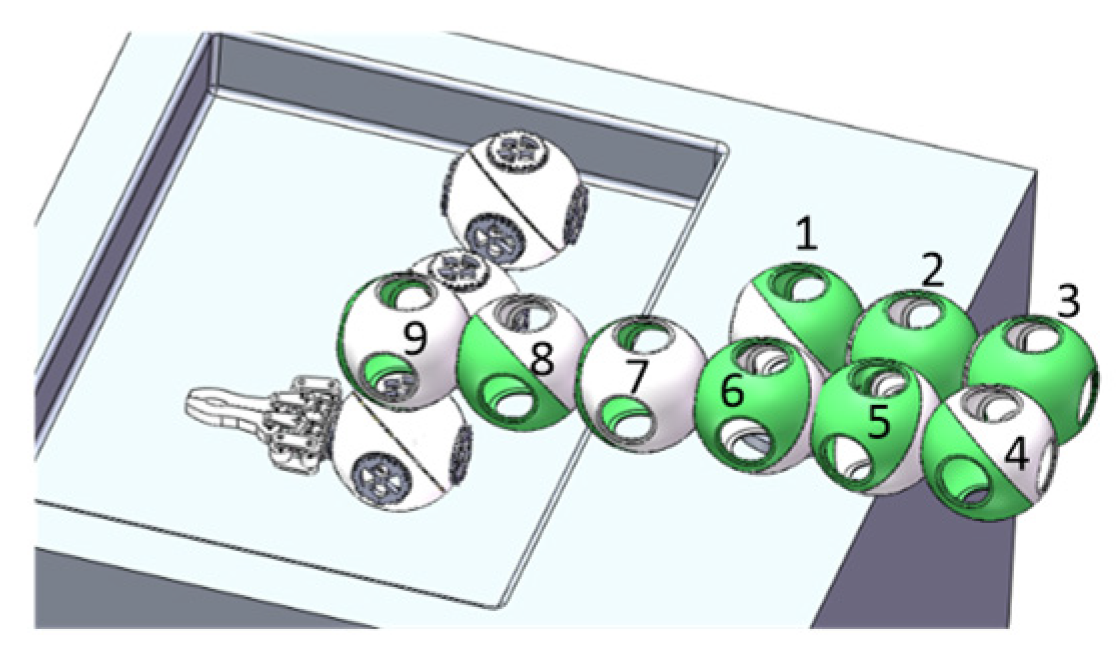

2.1.1. System Module Addition and Removal

2.1.2. Position Changes between System Modules

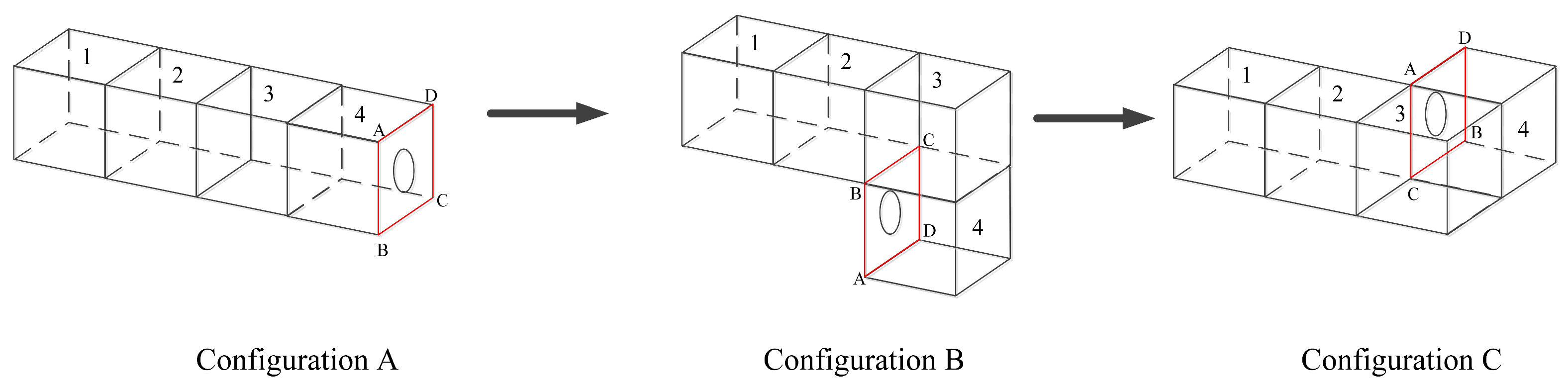

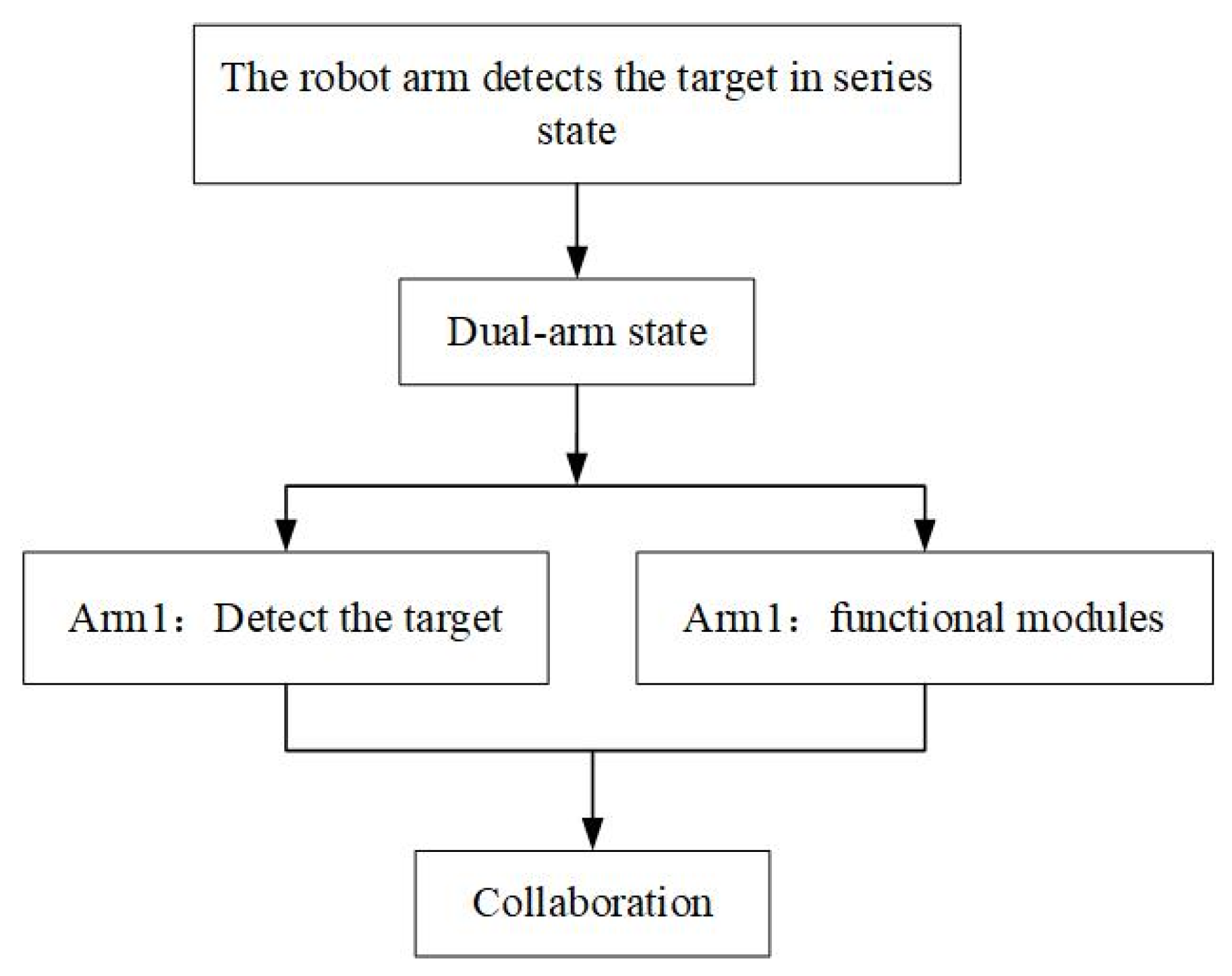

2.1.3. Reconstruction Changes from Single-Arm to Multi-Arm Robot System

2.1.4. Module Design Principles

- (1)

- Versatility: the system is composed of unit modules and assembled into systems with different configurations and functions to meet different mission requirements.

- (2)

- Interface standardization: to meet the connection and disconnection between any two modules, the interface must adopt an isomorphic design and have a simple structure.

- (3)

- Self-driving capability: each module is the joint of a robot system, and the module contains a motor and a mechanical transmission system.

- (4)

- Independence: in order to achieve rapid reconstruction of the entire system, each module must have independent data processing capabilities, data transmission capabilities, and independent power supplies.

- (5)

- Platform: the robot module must have the ability to carry payloads, reserve a payload cabin inside the module, and set up a connecting mechanism outside the module.

- (6)

- Miniaturization: modular reconfigurable robots can use a certain number of modules to complete space missions in a limited space area and have the advantages of flexibility and adaptability.

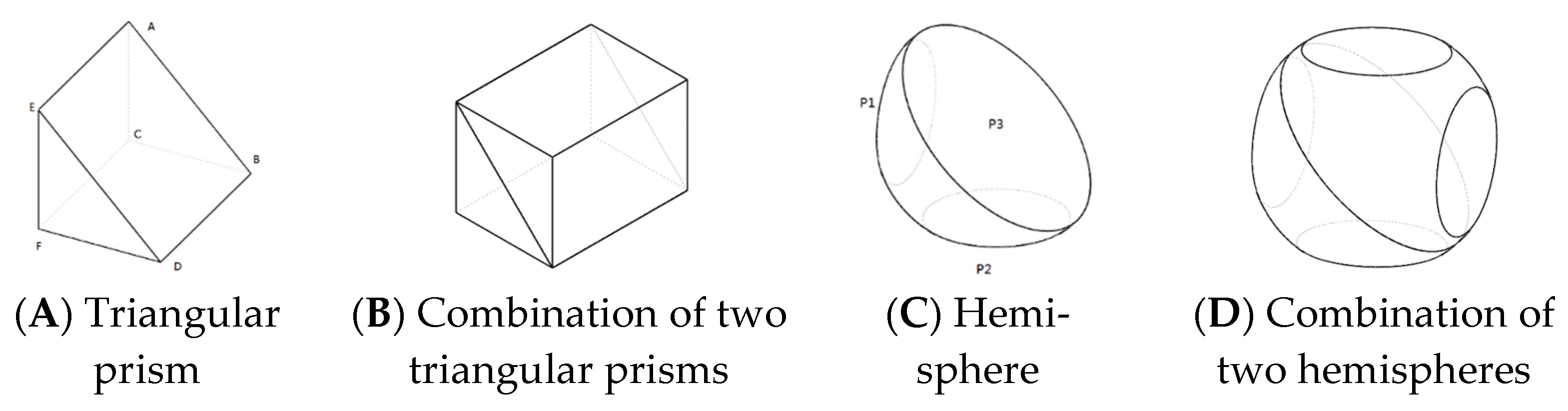

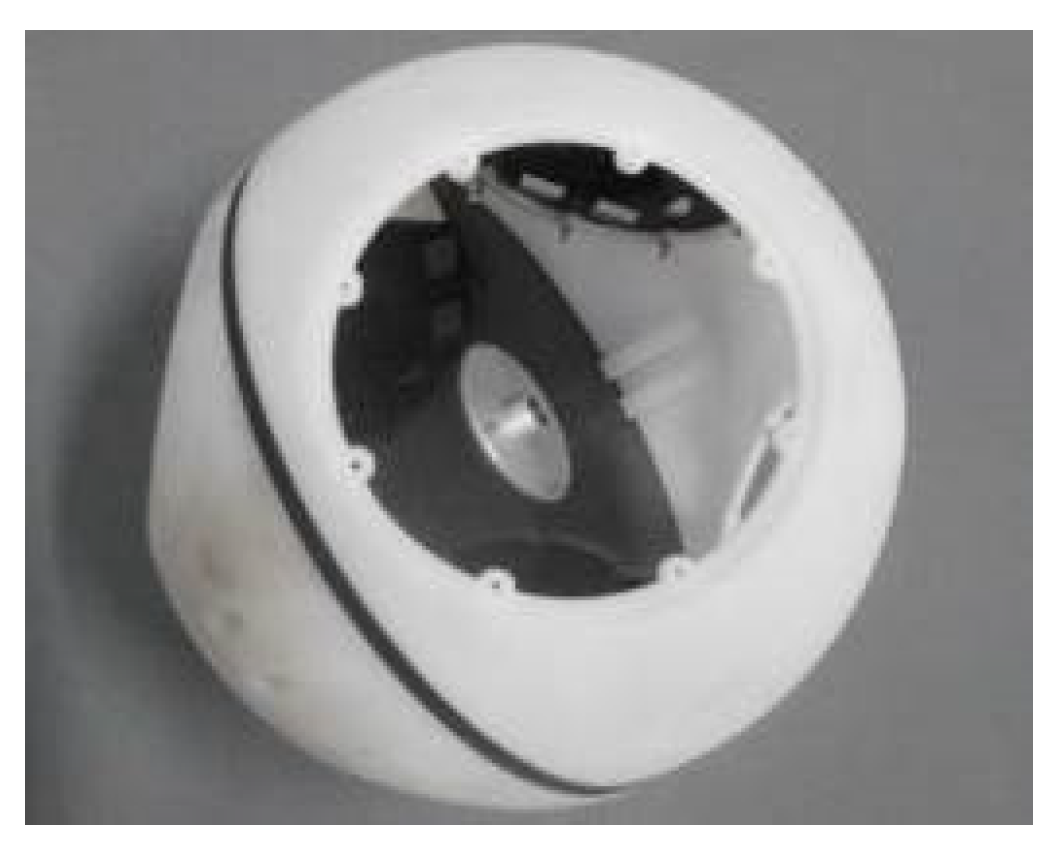

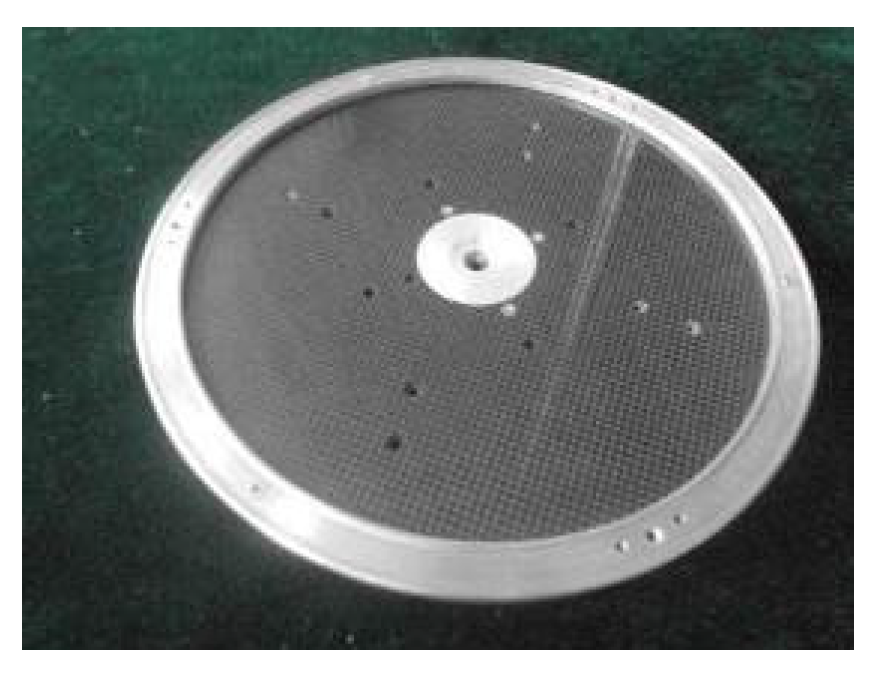

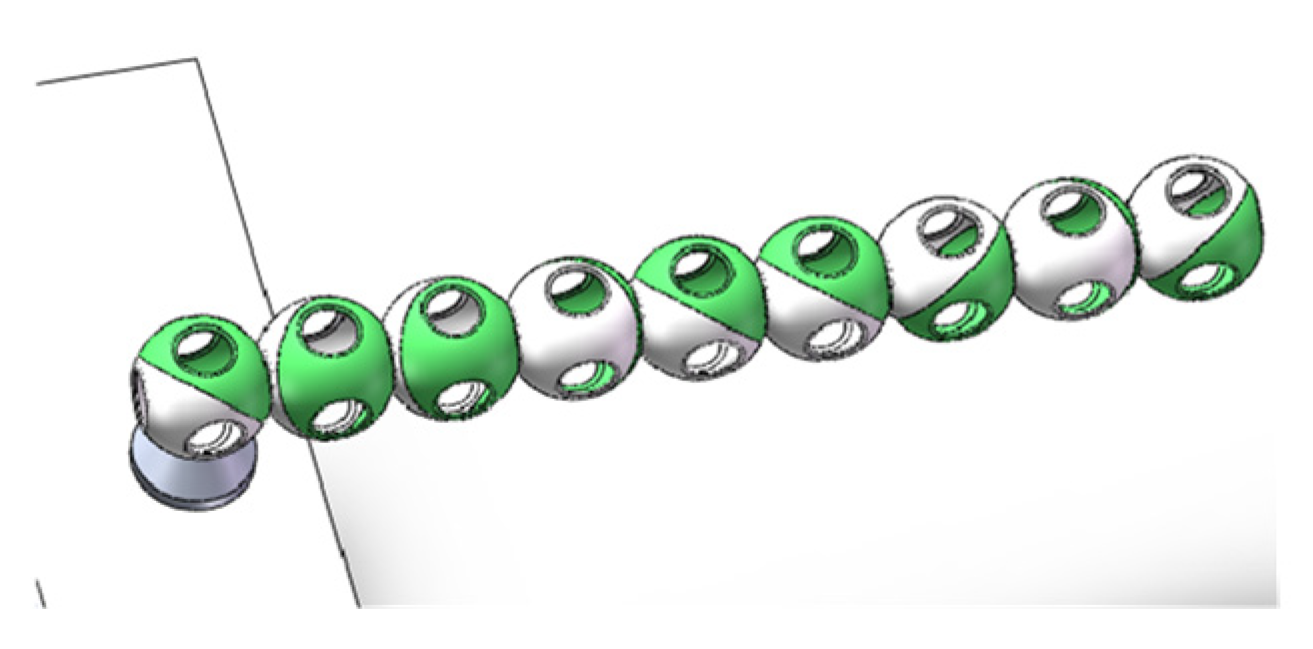

2.2. Unit Module Design

- (1)

- The two sub-modules have a common rotation surface that is connected and perpendicular to the rotation axis.

- (2)

- Modules can be connected through the connection surfaces opened on the sub-modules.

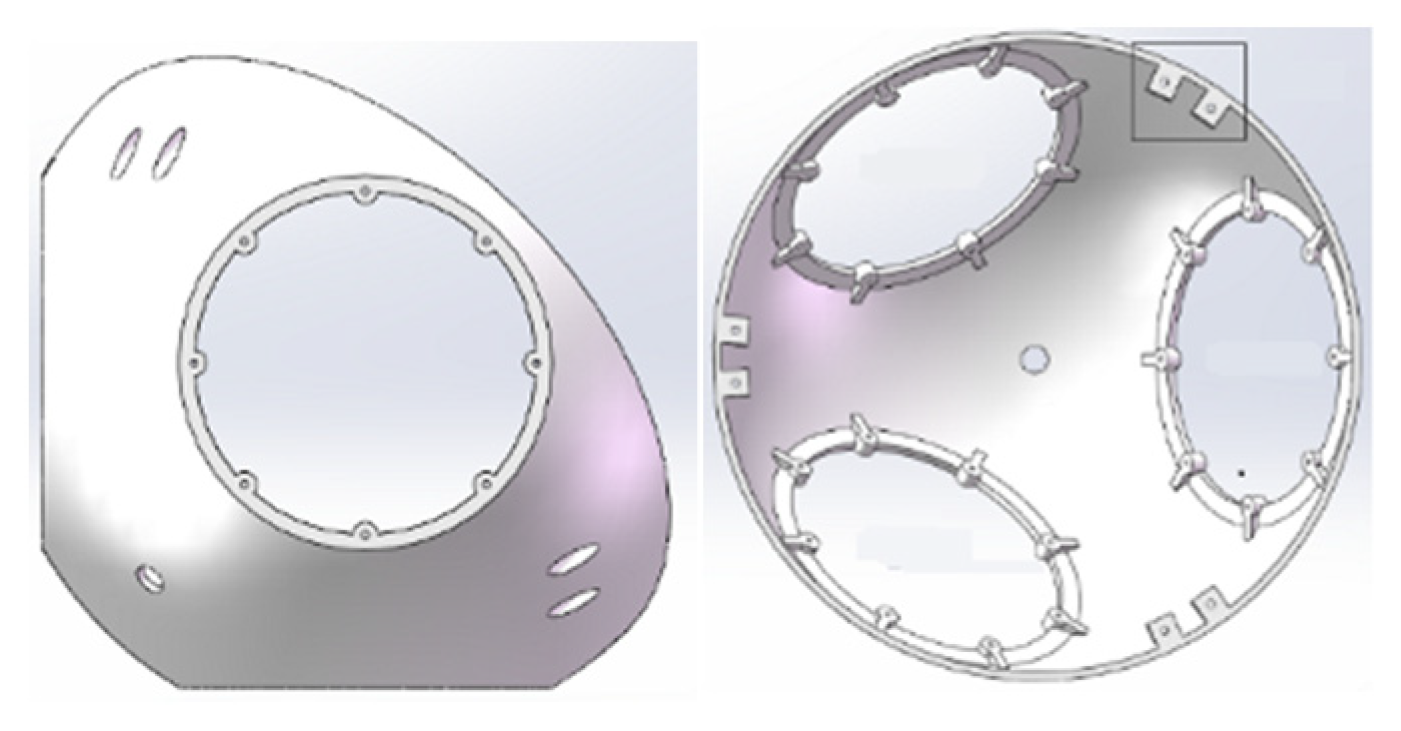

2.3. Unit Module Mechanism Design

2.3.1. Drive Selection and Transmission System Design

2.3.2. Power System

2.3.3. System Assembly

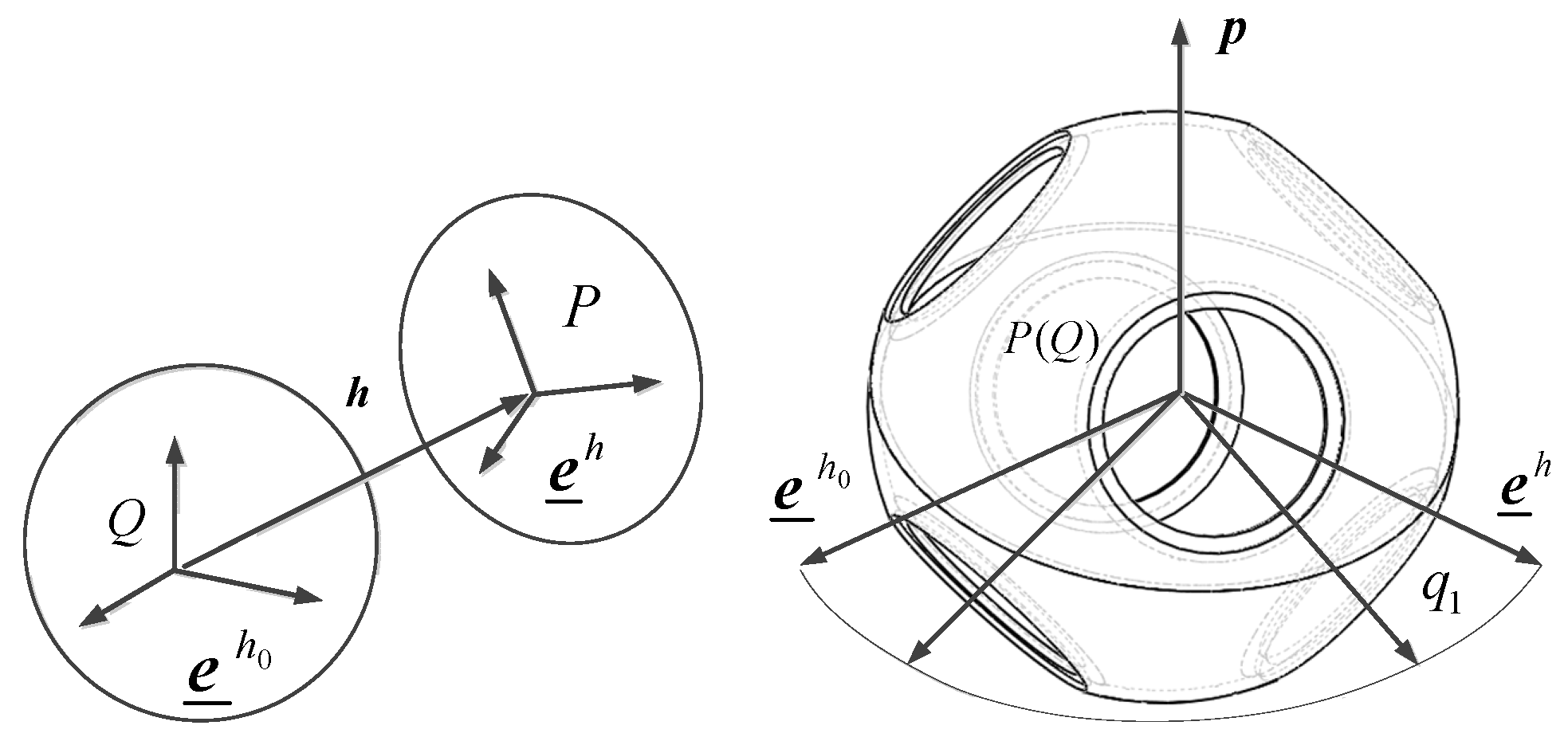

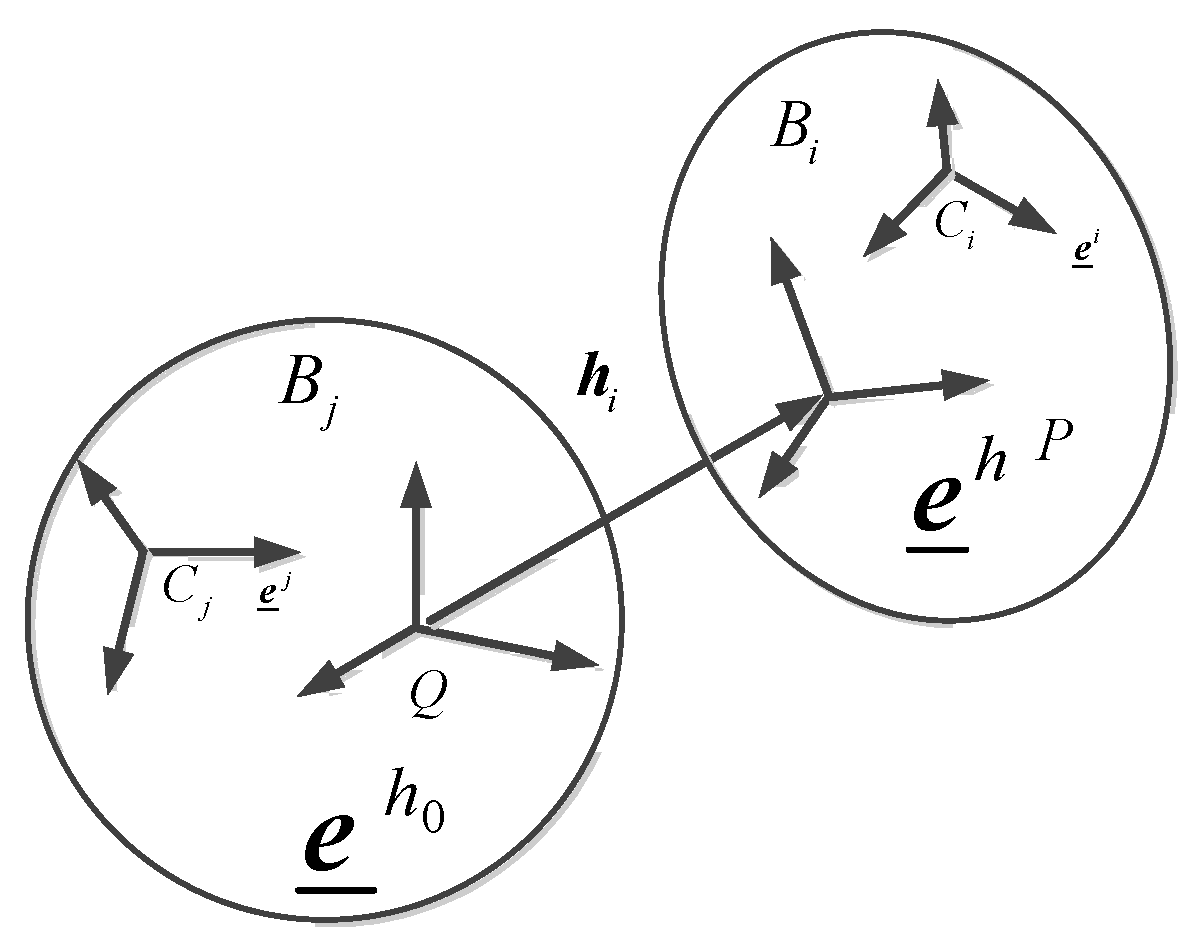

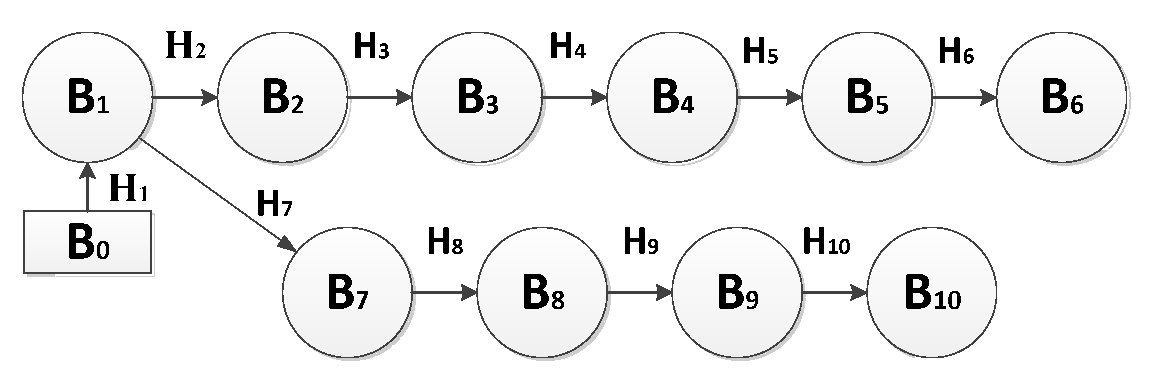

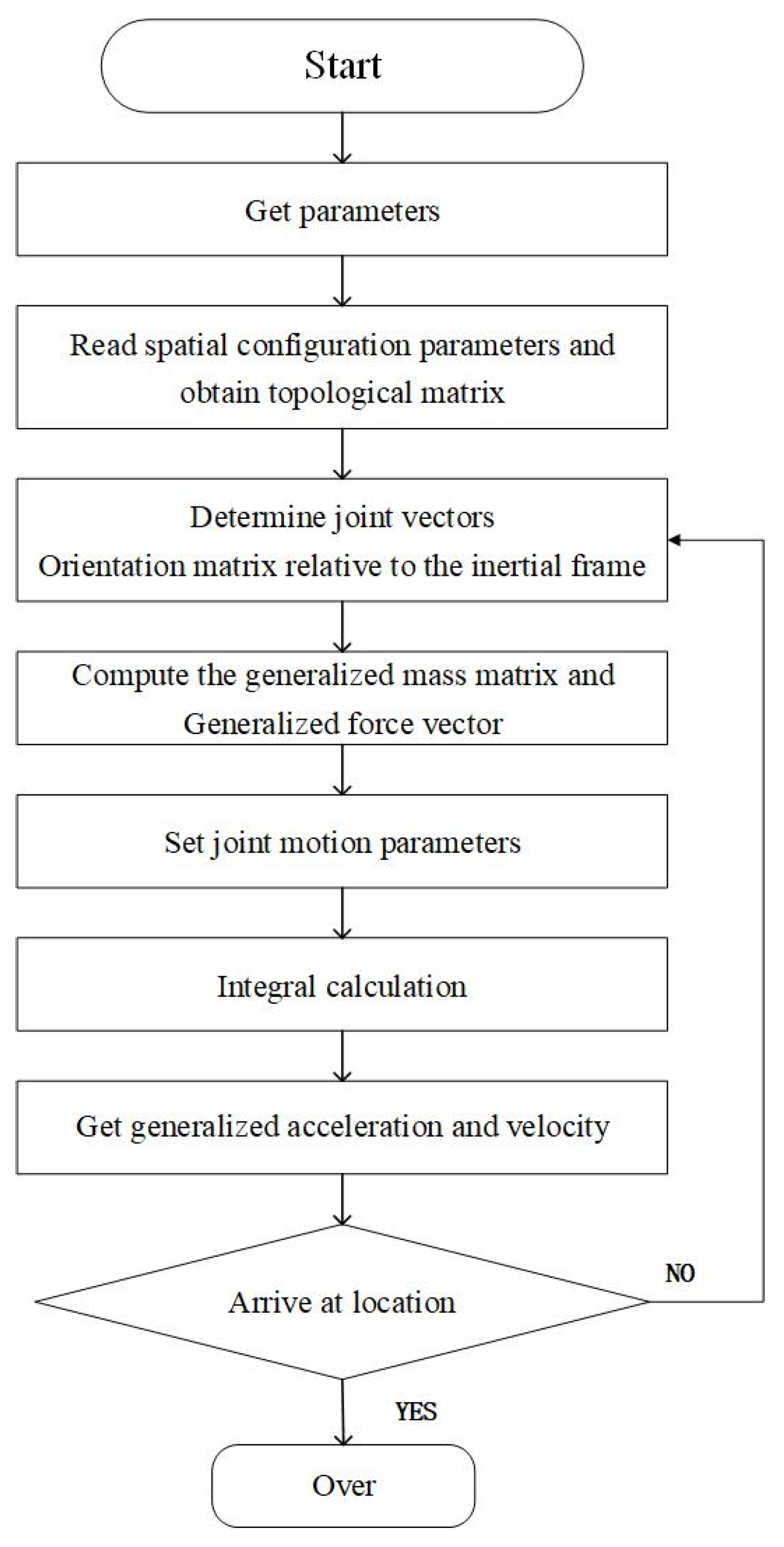

3. Dynamic Modeling of Spatial Modular Robot Based on R-W Method

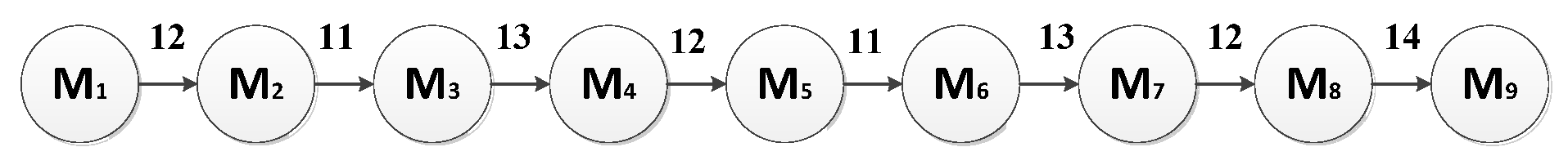

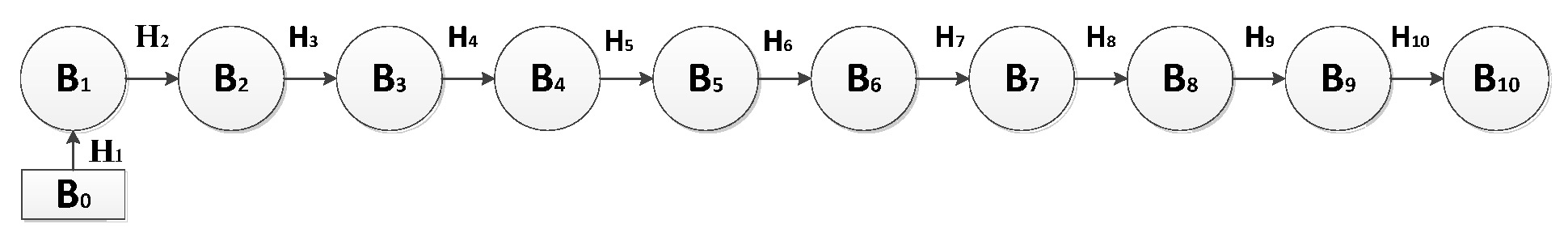

3.1. Joint Motion Model

3.2. Attitude Motion of Each Rigid Body in the System

3.3. Position Motion of Each Rigid Body in the System

3.4. Establishment of Kinetic Equations

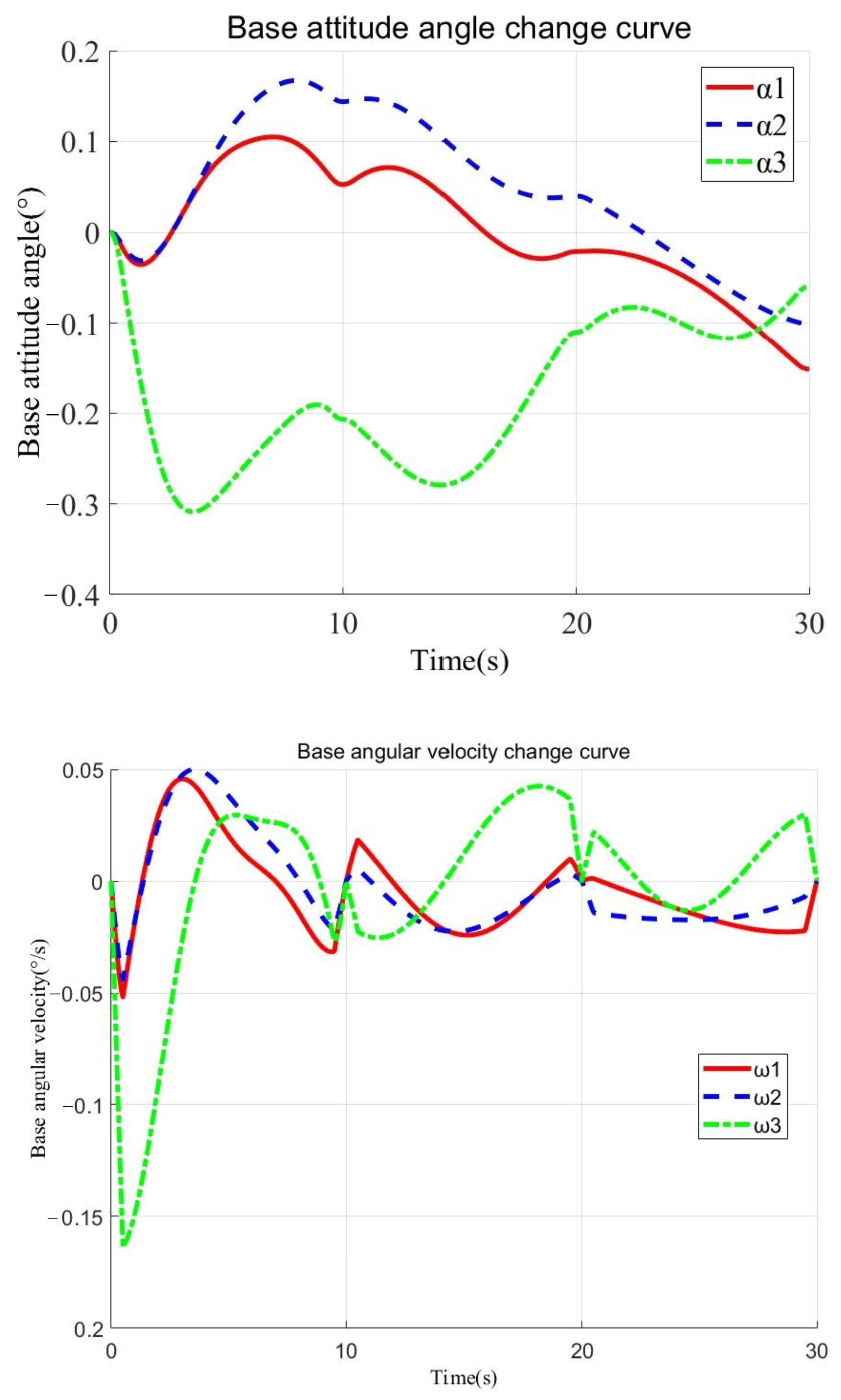

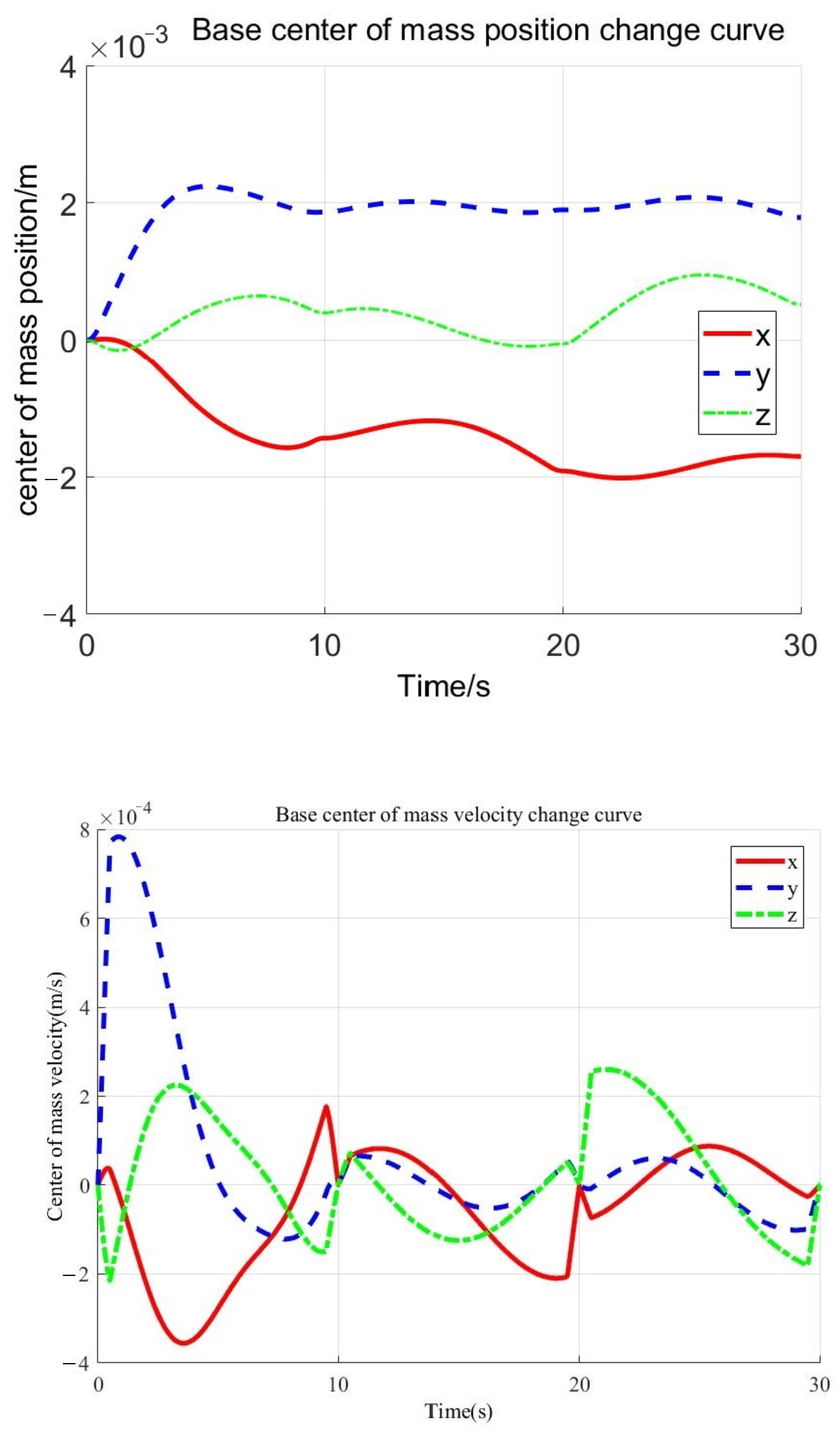

4. Dynamic Model Simulation Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Schmitz, D.; Khosla, P.; Kanade, T. The CMU reconfigurable modular manipulator system. In Proceedings of the International Symposium and Exposition on Robots, Sydney, Australia, 6–10 November 1988; pp. 473–488. [Google Scholar]

- Zhang, Y.; Oğuz, S.; Wang, S.; Garone, E.; Wang, X.; Dorigo, M.; Heinrich, M.K. Self-reconfigurable hierarchical frameworks for formation control of robot swarms. IEEE Trans. Cybern. 2023, 1–14. [Google Scholar] [CrossRef] [PubMed]

- Yim, M.; Shen, W.-M.; Salemi, B.; Rus, D.; Moll, M.; Lipson, H.; Klavins, E.; Chirikjian, G.S. Modular Self-Reconfigurable Robot Systems: Grand Challenges of Robotics. IEEE Robot. Autom. Mag. 2007, 14, 43–52. [Google Scholar] [CrossRef]

- Yim, M.; Duff, D.G.; Roufas, K.D. Polybot: A modular reconfigurable robot. In Proceedings of the 2000 ICRA. Millennium Conference. IEEE International Conference on Robotics and Automation Symposia Proceedings (Cat. No.00CH37065), San Francisco, CA, USA, 24–28 April 2000; pp. 514–520. [Google Scholar]

- Castano, A.; Shen, W.M.; Will, P. CONRO: Towards deployable robots with inter-robots metamorphic capabilities. Auton. Robot. 2000, 8, 309–324. [Google Scholar] [CrossRef]

- Moeckel, R.; Jaquier, C.; Drapel, K.; Dittrich, E.; Upegui, A.; Ijspeert, A. YaMoR and bluemove—An autonomous modular robot with bluetooth interface for exploring adaptive locomotion. In Proceedings of the 8th International Conference on Climbing and Walking Robot, London, UK, 30 June 2005; pp. 685–692. [Google Scholar]

- Mondada, F.; Guignard, A.; Bonani, M.; Bar, D.; Lauria, M.; Floreano, D. SWARM-BOT: From concept to implementation. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS 2003) (Cat. No.03CH37453), Las Vegas, NV, USA, 27–31 October 2003; pp. 1626–1631. [Google Scholar]

- Wei, H.; Liu, M.; Li, D.; Wang, T. A novel self-assembly modular swarm robot-docking mechanism design and self-assembly control. Jiqiren (Robot) 2010, 32, 614–621. [Google Scholar]

- Zykov, V.; Mytilinaios, E.; Desnoyer, M.; Lipson, H. Evolved and Designed Self-Reproducing Modular Robotics. IEEE Trans. Robot. 2007, 23, 308–319. [Google Scholar] [CrossRef]

- Zykov, V.; Chan, A.; Lipson, H. Molecubes: An Open-Source Modular Robotics Kit. In Proceedings of the IROS, San Diego, CA, USA, 29 October–2 November 2007. [Google Scholar]

- Bonardi, S.; Blatter, J.; Fink, J.; Moeckel, R.; Jermann, P.; Dillenbourg, P.; Jan Ijspeert, A. Design and Evaluation of a Graphical iPad Application for Arranging Adaptive Furniture; Institute of Electrical and Electronics Engineers Inc.: Paris, France, 2012. [Google Scholar]

- Sprowitz, A.; Pouya, S.; Bonardi, S.; Van Den Kieboom, J.; Möckel, R.; Billard, A.; Dillenbourg, P.; Jan Ijspeert, A. Roombots: Reconfigurable Robots for Adaptive Furniture. IEEE Comput. Intell. Mag. 2010, 5, 20–32. [Google Scholar] [CrossRef]

- Murata, S.; Yoshida, E.; Kamimura, A.; Kurokawa, H.; Tomita, K.; Kokaji, S. M-TRAN: Self-Reconfigurable Modular Robotics System. IEEE/ASME Trans. Mechatron. 2002, 7, 431–441. [Google Scholar] [CrossRef]

- Shen, W.M.; Krivokon, M.; Chiu, H.; Everist, J.; Rubenstein, M.; Venkatesh, J. Multimode locomotion via SuperBot reconfigurable robots. Auton. Robot. 2006, 20, 165–177. [Google Scholar] [CrossRef]

- Zhao, J.; Wei, Y.; Fan, J.; Shen, J.; Cai, H. New type reconfigurable modular robot design and intelligent control method research. In Proceedings of the Word Congress on Intelligent Control and Automation, Dalian, China, 21–23 June 2006; pp. 8907–8911. [Google Scholar]

- Yang, G. Kinematics, Dynamics, Calibration, and Configuration Optimization of Modular Reconfigurable Robots; Nanyang Technological University: Singapore, 1999. [Google Scholar]

- Albu-Schaffer, A.; Eiberger, O.; Grebenstein, M.; Haddadin, S.; Ott, C.; Wimbock, T.; Wolf, S.; Hirzinger, G. Soft robotics. IEEE Robot. Autom. Mag. 2008, 15, 20–30. [Google Scholar] [CrossRef]

- Paredis, C.J.J.; Brown, H.B.; Khosla, P.K. A rapidly deployable manipulator system. Robot. Auton. Syst. 1997, 21, 289–304. [Google Scholar] [CrossRef]

- Pan, X.; Wang, H.; Jiang, Y.; Zheng, L.; Gao, W. Development of a modular reconfigurable robot system. J. Intell. Syst. 2013, 8, 1–6. [Google Scholar]

- Liu, C.; Yue, X.; Shi, K.; Sun, Z. Spacecraft Attitude Control: A Linear Matrix Inequality Approach; Elsevier/Science Press: Amsterdam, The Netherlands, 2022. [Google Scholar]

- Zhou, X. DARPA launches the ”Phoenix” project to use space waste to build new satellites. J. Equip. Command. Technol. Inst. 2012, 23, 113. [Google Scholar]

- Neubert, J.; Lipson, H. Soldercubes: A self-soldering self-reconfiguring modular robot system. Auton. Robot. 2016, 40, 139–158. [Google Scholar] [CrossRef]

- Odem, S.; Hacohen, S.; Medina, O. An RRT That Uses MSR-Equivalence for Solving the Self-Reconfiguration Task in Lattice Modular Robots. IEEE Robot. Autom. Lett. 2023, 8, 2922–2929. [Google Scholar] [CrossRef]

- Le, A.V.; Parween, R.; Kyaw, P.T.; Mohan, R.E.; Minh, T.H.Q.; Borusu, C.S.C.S. Reinforcement Learning-Based Energy-Aware Area Coverage for Reconfigurable hRombo Tiling Robot. IEEE Access 2020, 8, 209750–209761. [Google Scholar] [CrossRef]

- Niu, S.; Ye, L.; Liu, H.; Liang, B.; Jin, Z. Ant3DBot: A Modular Self-reconfigurable Robot with Multiple Configurations. In Proceedings of the ICIRA 2022: Intelligent Robotics and Applications, Harbin, China, 1–3 August 2022; pp. 552–563. [Google Scholar]

- Kaneishi, D.; Takijo, K. Module-W: Reconfigurable Modular Robots Forming Compliant Structures. In Proceedings of the 2022 IEEE 5th International Conference on Soft Robotics (RoboSoft), Edinburgh, UK, 4–8 April 2022. [Google Scholar]

| FAULHABER2642CR | Unit | |

|---|---|---|

| Voltage | 24 | V |

| armature resistance | 5.78 | Ω |

| Maximum output power | 23.2 | W |

| Maximum efficacy | 79 | % |

| No-load speed | 6400 | rpm |

| No-load electric current | 0.058 | A |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, D.; Yue, X.; Guo, M. Design and Dynamic Simulation Verification of an On-Orbit Operation-Based Modular Space Robot. Appl. Sci. 2023, 13, 12949. https://doi.org/10.3390/app132312949

Yang D, Yue X, Guo M. Design and Dynamic Simulation Verification of an On-Orbit Operation-Based Modular Space Robot. Applied Sciences. 2023; 13(23):12949. https://doi.org/10.3390/app132312949

Chicago/Turabian StyleYang, Dong, Xiaokui Yue, and Ming Guo. 2023. "Design and Dynamic Simulation Verification of an On-Orbit Operation-Based Modular Space Robot" Applied Sciences 13, no. 23: 12949. https://doi.org/10.3390/app132312949

APA StyleYang, D., Yue, X., & Guo, M. (2023). Design and Dynamic Simulation Verification of an On-Orbit Operation-Based Modular Space Robot. Applied Sciences, 13(23), 12949. https://doi.org/10.3390/app132312949