Abstract

Floor heave is a typical tunnel issue in tunnelling engineering. To gain deep insights into the deformation mechanism and failure processes of floor heave at the bottom of a tunnel in layered rock, biaxial step-loading tests were conducted on rock samples (including schist and sandstone) with and without prefabricated invert arches. The failure processes of the samples were observed by the three-dimensional digital image correlation technique (3D-DIC) during the test. The test results showed that the deformation evolution processes of the floor heave of the sample included the following steps: (1) crack initiation at the interlayer weak planes; (2) separation of the rock matrix into platy structures along the bedding planes and flexures; and (3) fracture and uplift of the platy structures in the middle part. As the stress redistributes on the bottom plate of the sample, and stress concentration zones shift toward locations far away from the arching surface, the deformation evolution shows a similar variation trend with the stress. Continuous buckling fracturing takes place progressively from the vicinity of the arch surface to certain distant regions. Based on the test results, the key location of internal surrounding rock deformation was determined, and the mechanism of floor heave was clarified. The schist sample SC-BI-10 began to experience floor heave at 1064.4 s, and the deformation curve (the relationship between Y and U) showed a convex shape in the range of 0–20 mm in the Y-coordinate. The displacement reached its maximum value at y = 11.7 mm, corresponding to the position where the rock slab was broken. In addition, the influence of the interlayer properties and cover depth of rocks on bottom uplift was also studied. The design of tunnel supports and the monitoring and prevention of floor heave can benefit from this study.

1. Introduction

Gently dipping layered rocks are widely distributed in Southwest and Northwest China, and it is inevitable that highways, tunnels, and mining engineering within these areas will cross layered rock masses. Due to the development of interlayer bedding and schistosity structural planes, layered rock masses have significant anisotropy in the mechanical properties, including strength and deformation characteristics. The failure mode of layered rock tunnels depends on the interlayer weak planes or bedding planes, which are more prone to layer cracking, buckling, and sliding than ordinary rock masses.

The excessive floor deformation of roadways is known as floor heave in the mining and tunnelling engineering [1,2]. Floor heave is also described as either “breaking or lifting up of immediate floor strata” or “extrusion of floor strata” [2,3]. Under the influence of ground stress conditions, the phenomena of floor heave and the crushing behavior of surrounding rock in tunnels exhibit similarities in their extrusion behavior [2]. This engineering issue requires higher costs for tunnel construction and subsequent maintenance and repair work. Additionally, the increased risk of collapse, which can result in significant human and financial losses, highlights the urgency of taking proactive measures. Consequently, it is crucial to concentrate on the failure mechanism of the layered surrounding rock at the bottom of the inverted arch.

The methodologies of the studies involve laboratory studies [4,5,6,7], numerical modeling [5,8,9,10], theoretical studies [2,8,10,11,12,13], and site investigations [14]. Shigekazu et al. [4] conducted model experiments and numerical analysis to evaluate the uplift phenomena of expressway tunnels and created three load levels for the model. The materials of experiments consisted of a mixture of gypsum, lime, standard sand, and water. Shigekazu analyzed the primary causes of inverted uplift and used the ratio of loading stress, including horizontal and vertical stress, to overburden pressure as a predictor of floor heave. With the increase in the lateral stress coefficient or horizontal stress, the floor heave of the roadway was more obvious, and it presented serious asymmetric structural damage [5]. Zhou et al. [10] proposed a safety factor K for roadway floor heave based on the Mohr–Coulomb yield criterion and the sliding surface of the Prandall–Riesner solution. Moreover, Mo et al. [2] found that it is unlikely that floor failures were associated with the bearing capacity failure mechanism. Tsimbarevich [15] used the limit equilibrium theory to calculate the stress exerted by the floor heave rock layer on the roadway. Wen et al. [12] proposed a mechanical model for the occurrence of extrusion flow floor heave in a tunnel. The vertical stress and horizontal stress transmitted from both sides to the surrounding rock at the bottom of the tunnel are the main inducing factors for the occurrence of floor heave. In the mechanical model of the surrounding rock of the tunnel base, the inverted arch and the surrounding rock base are mainly subjected to two parts of force: one is the external force of the train, rail, and other facilities, and the other is the stress transmitted along both sides of the tunnel to the surrounding rock and inverted arch in the lower part of the tunnel. Due to the difficulty in establishing and simulating indoor models, there are limited indoor experimental studies on the floor heave of tunnel.

Among these studies, the failure mechanism and inducing factors of floor heave are the most concerning questions. There are many factors influencing the deformation of the tunnel bottom structure, including internal factors such as crustal stress conditions [2,16], surrounding rock lithology [16,17,18], and ground water [9] and external factors such as inverted arch size [6], support design [10], and train load [19]. The study of surrounding rock stress conditions helps to predict the critical burial depth of tunnel floor heave. Zhai et al. [20] proposed a mechanical model of asymmetric floor heave and demonstrated that the stability of the roadway floor is influenced by the stress concentration coefficient of the roadway sidewalls and the burial depth of the roadway. As the burial depth increases, the displacement of the surrounding rock in the tunnel also increases to varying degrees. Horizontal stress plays an important role in the stress conditions of the surrounding rock. Under high horizontal stress conditions, the laminated rock at the bottom of a tunnel is prone to interlayer delamination, deflection, and deformation damage [21]. Luo et al. investigated the floor heave at the bottom of the tunnel under biaxial loading by pouring soft and hard interlayer cement. The analysis of the stress distribution within the tunnel structure indicated that the predominant factor contributing to floor heave was the presence of significant horizontal stress [18]. The rise in horizontal ground stress led to notable extensions of the feeble stratum and the transfer of the primary bearing strata [5]. Mo et al. [16] concluded that mainly high horizontal stresses with greater depths of cover and certain types of floor lithology configuration are likely to contribute to the failures of floor strata. They investigated the relatively hard tuff layers with higher strength and ruled out the possibility of bearing capacity failure. The primary internal factors leading to roadway floor heave in weakly cemented soft rock are high stress and strong disturbances [22]. Currently, research on floor heave mainly focuses on indoor model experiments or numerical simulations of soft rock or soft interbedded pouring samples. However, there are limited indoor experimental studies on the mechanism of floor heave in natural layered hard rocks.

The extensive engineering practices have demonstrated that the layered structure of rocks is one of the significant factors contributing to floor heave [23,24,25,26]. Common layered rocks include schist, gneiss, slate, and shale. Many studies have been performed on the physical and mechanical characteristics of layered rocks. To investigate the transverse anisotropy on strength and deformational responses of schist, Nasseri et al. [27] conducted uniaxial compressive strength tests on rock specimens with schistosity ranging from 0° to 90° with respect to the axial stress and performed triaxial tests under five different confining stresses. The predicted values of strength and modulus were found to closely match the experimental stress–strain curves using a nonlinear strength criterion. The rock sample mainly exhibited tensile splitting and buckling of compression when the load was applied parallel to the schistosity plane. In addition, the surrounding rock of tunnels was susceptible to shear sliding along the schistosity plane when passing through horizontal schistosity planes [28]. Han et al. [29] illustrated that the interlayer strength of the structural plane of the rock affects the rupture process, and the tensile cracks at the interlayer level were characterized in their study by the digital image correlation (DIC) technique. The tensile cracks propagated mainly along the loading direction, and the weak face played a buffering role against deformation. The thinly bedded configuration may be the cause of the buckling, as it continued even after the immediate floor was fractured [16]. To demonstrate the impact of microcracks or fabric anisotropy on the mechanical and physical properties of rocks, Richard et al. [30] investigated the effect of fracture orientations on the longitudinal wave velocity in dry and saturated rocks. Velocity anisotropy arises mainly from the preferred orientation of microcracks and is used to predict the anisotropic behavior in other mechanical or physical properties. Meanwhile, he found that when the intermediate principal stress was parallel to the schistosity, the stress-induced effect and the schistosity structural effect combined to promote the emergence of microcracks, resulting in a reduction in rock strength. Previous studies on floor heave and anisotropy of layered rocks have provided in-depth and significant contributions to rock mechanics. However, there has been limited research analyzing the influence of the layered rock at the microscale on floor heave of tunnel. Therefore, the comparison of the floor heave between homogeneous and layered rock masses is important for understanding the failure mechanism. For example, what is the difference between the failure modes of homogeneous rock and layered rock under the same stress conditions? What is the reason for this difference?

To better understand the deformation mechanism of tunnel floor heave in layered rock, a loading device was designed to perform step-loading tests on rock samples with a prefabricated inverted arch. The DIC technique was used to observe the surface displacement and strain evolution of the sample. Schist and sandstone were used for the experiments, and the floor heave deformation and failure mechanism of rock samples with different lithologies were compared and analyzed. In addition, different lateral stresses were set to determine the influence of stress conditions on the deformation mechanism of rock samples.

2. Test Methodology

2.1. Material Characterization

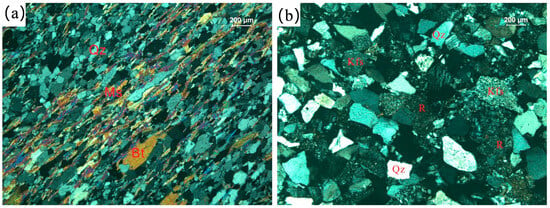

In this study, layered schists from the Wudang Mountain Group in Hubei Province and sandstones from Neijiang City, Sichuan Province, China, were selected for testing. Figure 1 shows the mineral composition and distribution of the schist and sandstone specimens by using a polarizing microscope. Table 1 lists the detailed mineral compositions and grain sizes. The majority of the quartz, feldspar, and biotite in schist were lengthy with directional layouts. Muscovite and biotite were in sheet form, and parts of quartz and potassium feldspar were in granular form, showing a similar interlayer structure for the two minerals. The anisotropy of schist was mostly caused by this special mineral arrangement. In contrast, the rock texture was relatively uniform and homogeneous.

Figure 1.

Polarized light micrographs: (a) schist; (b) sandstone. (Qz, Ms, Bt, Kfs, and R stand for quartz, muscovite, biotite, potassium feldspar, and rock debris, respectively).

Table 1.

Mineral composition and grain size distribution of the tested schist and sandstone.

The basic mechanical properties of the sandstone and layered schist with loading directions parallel to the schistosity direction were obtained and are summarized in Table 2.

Table 2.

Basic mechanical properties of rock specimens.

2.2. Sample Preparation

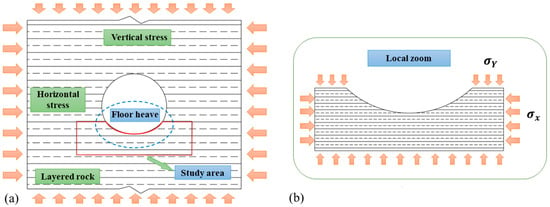

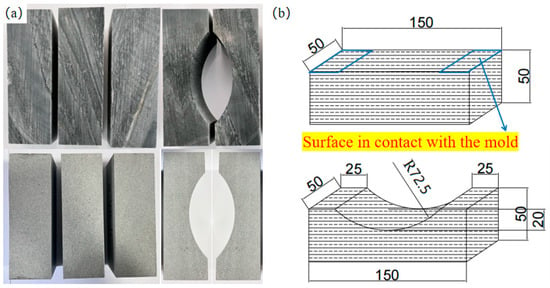

The physical model of the layered surrounding rock at the bottom of the tunnel is shown in Figure 2. The surrounding rock at the bottom of the tunnel is mainly subjected to the horizontal stress and vertical stress transmitted from both sides of the tunnel. To observe the process of the floor heave phenomenon in the laboratory, intact prismatic samples and samples with prefabricated inverted arches (α = 0°) were prepared to test, with an average height, width, and thickness of 150 mm, 50 mm, and 50 mm, respectively. To analyze the influence of weak surfaces between layers of schist and the effect of prefabricated inverts, four types of rock samples were prepared for comparison, namely intact schist, schist with a prefabricated inverted arch, intact sandstone, and sandstone with a prefabricated inverted arch. The geometric shape and dimensions of the invert are shown in Figure 3.

Figure 2.

Physical model of the layered surrounding rock at the bottom of the tunnel: (a) the stress state of a tunnel engineering project; (b) the stress state of a novel designed rock sample.

Figure 3.

Prepared rock samples: (a) sample photos; (b) diagram of sample size.

The geometric shape of the prefabricated inverted arch is considered to reflect the loading situation in underground circular openings [31]. It has a major effect on the failure pattern and crack propagation type in rock materials [32]. The inverted rise-to-span ratio of the sample was set to 1:20. To ensure uniform force throughout the loading process, the prefabricated inverted arch was cut using a precision steel wire saw, and each surface was polished to be smooth and flat. Increasing the aspect ratio of the sample not only helps to weaken the end effect but also stabilizes the strength index value. In this study, the height-to-width ratio of the rock samples was designed as 3:1 for the tests.

2.3. Testing Setup and Method

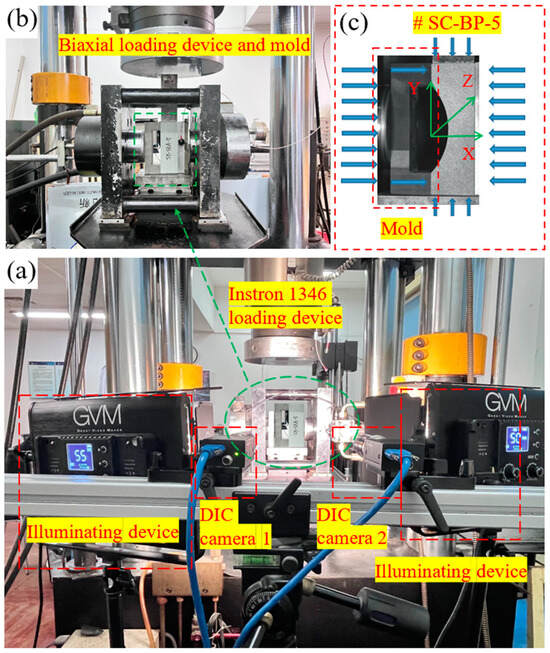

The tests were carried out by the INSTRON 1346 electrohydraulic servo universal testing machine at the Central South University, monitored by a 3D-DIC system. The overview and details of the test equipment are shown in Figure 4. The usage, basic principles, and calculation methods of 3D-DIC have been fully discussed in our previous studies and thus are not repeated here [21,33,34,35].

Figure 4.

Photos of test devices: (a) overview of the test system; (b) detail of biaxial loading mold; (c) schematic diagram of loading direction.

After tunnel excavation in practical engineering, the stress in the upper part of the tunnel structure is transmitted to the surrounding rock below the inverted arch of the tunnel along the surrounding rock on both sides of the tunnel. To simulate the stress condition, the mold was designed to transfer the force from the testing machine to the local position of the sample. The loading concave mold and test method are shown in Figure 4. Different from the general biaxial test, the biaxial step-loading test has different stresses in the lateral direction. Although the forces in both directions of X are equal, the force applied area is different for the specimen. Therefore, the surface in contact with the mold is subjected to greater stress compared to the other side. The lateral stresses (5 MPa, 10 MPa, and 15 MPa) refer to the stress on the surface in contact with the mold, while the other side only provides a restraining effect. This can help simulate the stress concentration state of the tunnel arch foot. In addition, the concave mold provides a free surface and deformation space for the specimen. It is possible to clearly observe the heave phenomenon and record the corresponding displacement by using the DIC system.

Underground excavation activities change the stress state surrounding the excavation from a three-dimensional stress state to a two-dimensional or one-dimensional stress state. In this study, a step-stress-loading scheme was developed. To simulate different stress states of rock samples, three lateral stress values were set. In addition, to reasonably formulate the step-loading gradient value of rock samples, the maximum uniaxial compression load of rock samples was tested. The loading schemes for the rock samples are listed in Table 3. The test methods were introduced as follows:

Table 3.

Loading schemes for rock samples.

Uniaxial compression test: The displacement control method was used to apply the load until the overall failure of the sample, and the maximum uniaxial compressive load was obtained. The samples were loaded at a displacement rate of 0.006 mm/s. The load–time curves were recorded by the data acquisition system of the testing machine, and the displacement, strain, and deformation information were recorded by the 3D-DIC system. In this study, the “strain ε” denotes the axial strain of the overall sample and was measured by using an extensometer.

Biaxial step-loading test: First, the sample was loaded to the predetermined values at a loading rate of 0.42 kN/s in the X-direction. The first stage of the lateral load was then applied and maintained for 90 s. Subsequently, the axial load was increased to the next level and held constant for 90 s. The above steps were repeated until the rock sample was completely destroyed.

3. Test Results and Analysis

3.1. Mechanical and Deformation Properties

Table 4 lists the testing results of the maximum compressive loads for intact schist, schist with a prefabricated inverted arch, intact sandstone, and sandstone with a prefabricated inverted arch, denoted as . Since the cross-section area of the rock sample with an arch was uneven, the actual stress varied in the specimen. Therefore, the maximum load instead of the stress was used to evaluate the bearing capacity of the sample. Compared with the intact sample, the maximum loads of the schist and sandstone samples with a prefabricated inverted arch were reduced by 26.43% and 43.24%, respectively.

Table 4.

The maximum compressive load of the prismatic samples.

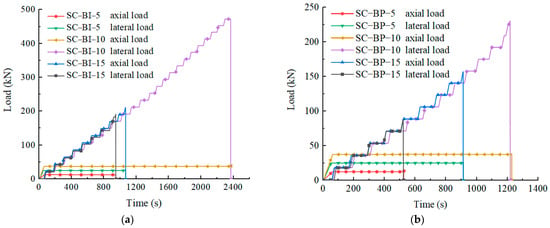

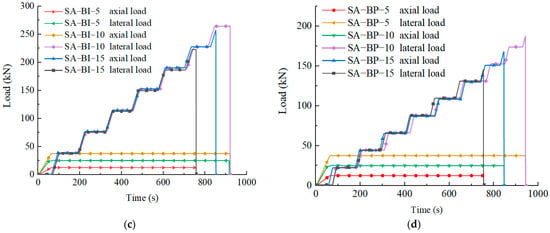

The testing results of the biaxial step-loading test are listed in Table 5, and the maximum loads under biaxial tests are denoted by . The step-loading path of the biaxial step-loading test is shown in Figure 5. It can be seen in Figure 6 that during the stage when the load remains constant, the strain continues to increase with time, and the strain of the sample with a prefabricated inverted arch shows a stepwise relationship with time.

Table 5.

Testing results of the biaxial step-loading test.

Figure 5.

Load path of biaxial step-loading test: (a) intact schist; (b) schist with a prefabricated inverted arch; (c) intact sandstone; (d) sandstone with a prefabricated inverted arch. (Notes: denotes the maximum uniaxial compressive load of prism).

Figure 6.

Strain–time curves for the step-loading process.

During the initial stage of stepwise load application, there was a significant and immediate deformation that accounted for a relatively large proportion of the total strain at approximately 46.56% (SC-BP-5), 35.74% (SC-BP-10), and 29.33% (SC-BP-15). At this point, the mechanical properties of the samples near the bottom deteriorated rapidly. As the load was continuously applied, the instantaneous strain increments gradually decreased. The open structural surface and internal pore structures were compacted during the early compression process, resulting in relatively large deformation. When the load continued to increase, the energy absorbed by the rock was utilized to create new cracks with relatively little deformation. The cracks gradually extended and coalesced with each other, and finally, the overall failure of the sample occurred with sudden changes in the axial strain at this time. From the enlarged local details, upon applying load to the sample, there was a rapid increase in axial strain. As the stress was maintained, the axial strain continued to increase slightly. Finally, just before the sample failed instantaneously, there was a sharp increase in axial strain.

3.2. Failure Mode Analysis

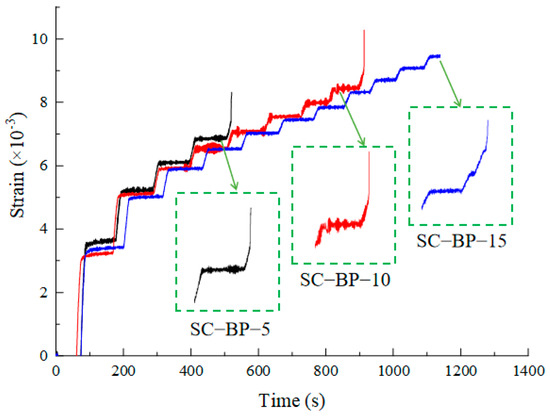

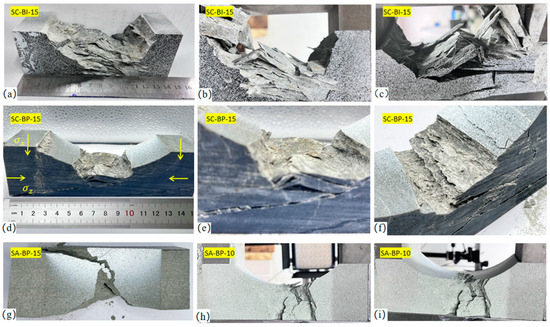

The evolution of the crack propagation and strain field can be visually observed by the 3D-DIC system. Identifying the final failure mode of the sample under biaxial test was critical for understanding the crack propagation characteristics and general failure mechanism inside the rock mass. The failure modes of schist and sandstone under various lateral stresses and sample types are displayed in Figure 7. The failure modes of different types of rocks were classified as follows:

Figure 7.

Strain contours and failure photos of rock samples under biaxial step loading: (a) schist; (b) sandstone.

- (1)

- Intact schist sample: The failure mode of sample SC-BI-5 is single-slope shear failure. The macroscopic cracks consist of coalescence cracks with a single slope and arc-like cracks close to the inverted arch. The major crack was indicated by the greatest strain value in the strain concentration zone, which was seen from the strain contour to be in the main diagonal direction (second and fourth quadrants). The failure mode of sample SC-BI-10 is tensile failure along the weak bedding plane and shear failure across the weak bedding plane. The failure mode of sample SC-BI-15 is tensile–shear composite failure along the weak bedding plane. The failure process was similar to that of sample SC-BI-10, but the crack propagation range was wider, and the sample was separated by the crack into slab-shaped rock blocks with a wider width;

- (2)

- Schist sample with a prefabricated inverted arch: The failure mode of sample SC-BP-5 involved splitting tensile failure along the weak bedding plane and shear failure across the weak bedding plane. First, several early cracks that formed near the free surface expanded out and coincided with the weak bedding plane. Then, parallel platy structures formed in the central layers at the bottom of the inverted arch of the samples, followed by the outward bulging of the crushed fractures. Subsequently, the tensile cracks interconnected with each other at the distal ends to form new cracks, showing an inverted trapezoidal failure surface, and eventually an overall destabilization fracture. The failure modes of samples SC-BP-10 and SC-BP-15 are similar to that of sample SC-BP-5;

- (3)

- Intact sandstone sample: The failure modes of samples SA-BI-5, SA-BI-10 and SA-BI-15 are composite failures of tension and shear. The sandstone failure process was relatively simple. There were arc-shaped rock blocks peeling off near the free surface in the same direction as the concave mold, and an oblique dislocated shear plane was formed on the plane perpendicular to the Y0Z plane, accompanied by massive fragments peeling off;

- (4)

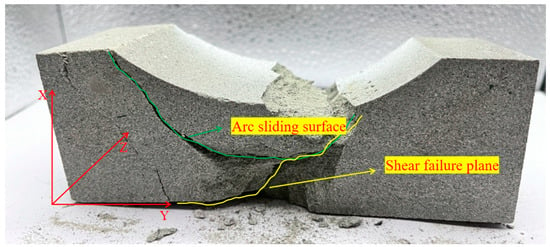

- Sandstone sample with a prefabricated inverted arch: The failure mode of samples SA-BP-5, SA-BP-10, and SA-BP-15 involved compressive shear failure, which formed an oblique shear plane perpendicular to the X0Y plane, resulting in overall failure of the sample. The sample remained relatively intact after failure, as shown in Figure 8.

Figure 8. Image of sandstone after failure.

Figure 8. Image of sandstone after failure.

3.3. Deformation Process of Schist Sample under Biaxial Step Loading

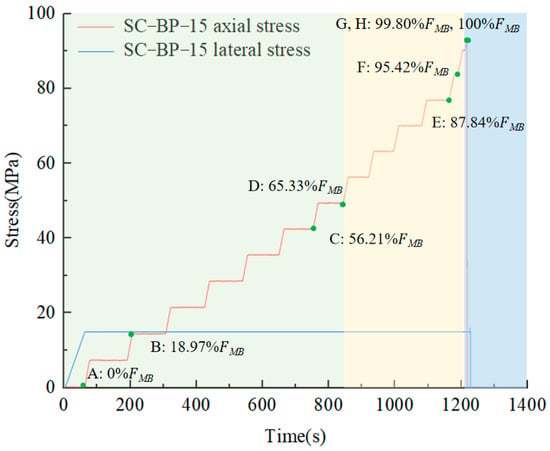

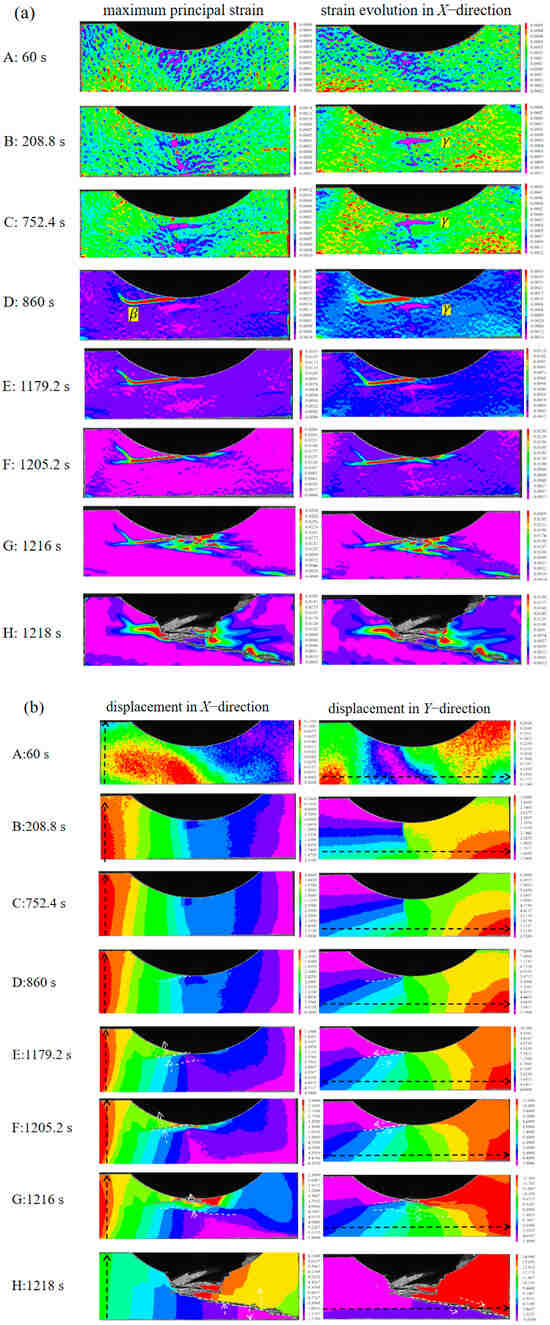

To explore the evolution process and displacement variation of cracks in schist samples, sample SC-BP-15 was taken as an example for analysis. Figure 9 and Figure 10 highlight eight crucial nodes during the biaxial step loading of sample SA-BP-15. The maximum principal strain e1, the strain exx in the X-direction, the displacement U in the X-direction, and the displacement V in the Y-direction were among the data acquired by the 3D-DIC system. To better comprehend, the contour was obtained by rotating the photo taken after the test counterclockwise by 90°. Overall, the process can be divided into three stages: the quiet stage (A–D), crack initiation stage (D–G), and floor heave deformation stage (G–H).

Figure 9.

Step loading path of schist sample with a prefabricated inverted arch (SC-BP-15).

Figure 10.

Contours of strain and displacement evolution of schist sample with a prefabricated inverted arch (SC-BP-15): (a) strain variation; (b) displacement variation.

The axial load started at point A after the lateral stress was applied. The strain field was currently quite symmetrical and uniform. As shown in Figure 9 and Figure 10, when the second level of load was applied (point B), a local compressive stress concentration point emerged in the rock near the bottom of the invert center, which may also be considered as stress concentration. Due to the axial asymmetry of the structure, the application of axial force resulted in two effects: compression and bending torque. When the axial force was small, the neutral axis of the sample was located at the lower middle position, and there was compressive strain concentration on the weak plane between layers. Before the application of the seventh level of loading (point C), the local compressive concentration zones propagated and interconnected to form a complete strain concentration zone coinciding with the location of the layered weak surface.

In the quiet stage, obvious macroscopic cracks were not observed on the rock surface. The displacement in the X and Y directions was symmetrically distributed along the middle position of the inverted arch, but the directions of the left and right parts of the displacement in the Y-direction were different. Under the influence of vertical stress and bending moment, the middle part of the sample tended to bulge outward. Then, the left half of the sample showed a shear strain concentration zone subparallel to the bedding weak plane at point D, indicating that a macroscopic shear crack β was formed, beginning the crack initiation stage. At this time, the difference in displacement between the two sides of crack β was also significant. The peeling process was similar to that of spalling.

Next, when the load rose at point E, crack β continued to extend and develop. The displacement field was altered at this point, causing the rocks on both sides of the crack to deform each other and move toward the free surface. When the load was increased to the 12th level (point F), the strain began to concentrate on the right side of the center of the invert bottom, forming a small area of strain concentration. When the load reached 92.33 MPa (near the maximum load at point G), several tensile strain concentration zones emerged, leading to crack propagation in the X-direction. The strain concentration area increased and extended away from the facing surface, and the displacement field near the strain concentration area also formed a clear layered area. The displacement in the X-direction gradually increased along its negative coordinate, and the displacement contour plot exhibited a layered arch shape, indicating that the rock was about to undergo stratification and arching outward. During the process from point G to point H, high strain concentration zones aggregated and nucleated into extensional cracks that traversed the rock, causing it to fracture into a platy structure. The fractured layers were subsequently continuously broken and bulged outward, and near parallel tensile cracks overlapped at their distal ends, forming a trapezoidal failure surface composed of multiple cracks. The H-point meant that the maximum load was reached, and macroscopic shear cracks were formed in the diagonal direction, leading to a loss of carrying capacity and overall failure of the sample. The failure mode was splitting tensile failure along the weak bedding plane and shear failure across the weak bedding plane. The failure process at the bottom of the inverted arch was the quiet period, crack initiation period, and floor heave deformation period, lasting for 860, 356, and 2 s, accounting for 70.61%, 29.23%, and 0.16% of the total time, respectively.

3.4. Displacement Analysis of the Key Position

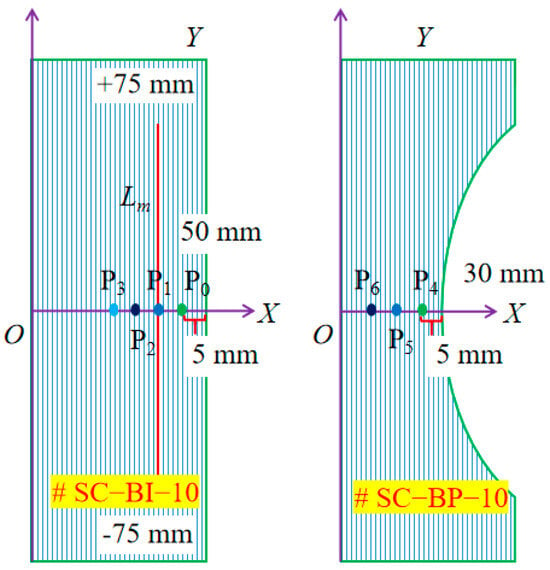

The displacement of the surrounding rock at the bottom of a tunnel is an important indicator of the failure mechanism of the tunnel bottom. Comprehending the displacement changes in vital sections of prefabricated inverted arch rock samples is essential for tunnel construction. It should be emphasized that the experimental displacement results cannot be directly compared with the actual deformation of the project. Therefore, it is also crucial to analyze key locations and failure times in lab tests. As shown in Figure 11, taking the typical samples SC-BI-10 and SC-BP-10 as an example, the measurement line Lm (X = 10 mm) and measurement points P1–P6 are set on the observation surface of the sample.

Figure 11.

Schematic diagram of monitoring points and lines.

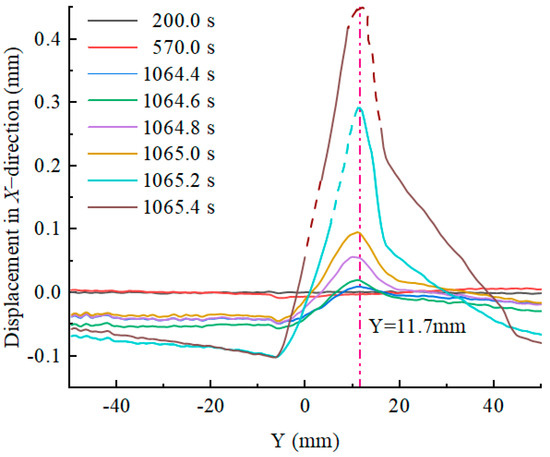

Figure 12 shows that there is a significant increase in the displacement of the bottom surrounding rock within the range of 0–20 mm compared to the adjacent area. In addition, the displacement in the X-direction of the sample at measurement line Lm gradually enhanced with increasing load. Even if the loading method and the shape of the force were symmetrical, asymmetric deformation could occur. Similar experimental models and numerical simulations have previously shown this phenomenon [15,36]. During the time period of 0–1064.4 s, the displacement of the measurement line Lm was very small, and the deflection of the sample was not significant. When t = 1064.4 s, the displacement measurement line Lm jumped. One second later, the maximum displacement increased from 0.01 mm to 0.42 mm at Y = 11.7 mm. It reached a maximum load at t = 1074 s, but the fragment size was small, and the displacement was too large, making it difficult to capture by the DIC technique. The change in displacement was abrupt, and uplift occurred within a very short period. Therefore, during the engineering support process, special attention should be given to the bulge at the center of the floor.

Figure 12.

Displacement curve of the measurement line Lm under different loading levels.

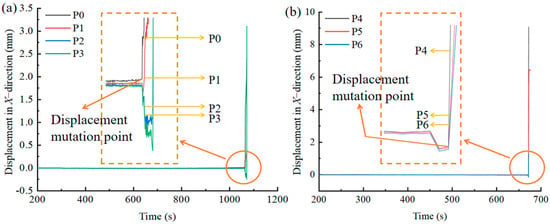

As shown in Figure 13, for sample SC-BI-10, the displacement in the X-direction at the measurement point remained relatively stable from 0 to 1064.4 s. However, at t = 1064.4 s, there was a displacement mutation. Sample SC-BI-10 experienced tensile failure at points P0 and P1, resulting in an outward uplift and positive displacement in the X-direction. In contrast, it was under compression at points P2 and P3 and did not begin to heave. The displacement at point P0 started to change abruptly first, followed by points P1, P2, and P3, indicating bulging deformation. At t = 1065.2 s, the order of displacement magnitudes in the X-direction for the strain monitoring points was P0 > P1 > P2 > P3. For sample SC-BP-10, the displacement in the X-direction at the monitoring point remained relatively stable from 0 to 671.2 s. Subsequently, the displacement of the monitoring point moved toward the positive Y-coordinate, and a sudden change in displacement occurred at t = 671.6 s. This was considered to be a manifestation of arching, which slowed the occurrence of floor heave. This could also be seen as a precursor signal for the occurrence of floor heave. At t = 672.2 s, the order of displacement magnitudes in the X-direction for the strain monitoring points was P4 > P5 > P6. In general, floor heave first occurred in the outermost layer near the surface of the inverted arch and then transferred to the inner rocks. After the outermost layer of rock was destroyed, the bearing area of the middle part decreased, leading to a decrease in bearing capacity. The stress was transferred to the interior, and the deep surrounding rock of the floor continued to rise upward. Repeating this process, floor heave gradually occurred and could not be prevented. At the same time, it also increased the difficulty of supporting this part of the area. The maximum uplift displacement near the surface of the inverted arch was observed in the outermost region, gradually decreasing along the negative X-coordinate.

Figure 13.

Displacement–time curve of the measurement points: (a) sample SC-BI-10; (b) sample SC-BP-10.

4. Discussion

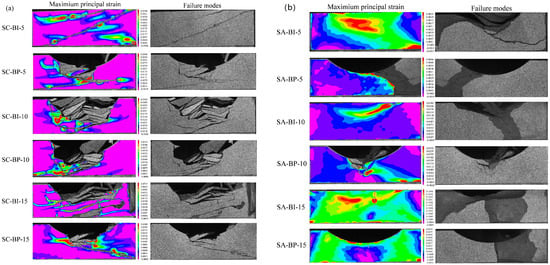

4.1. Influence of Rock Type, Lateral Stress, and Invert

Two types of rocks are discussed here: layered schist and homogenous sandstone. The elastic modulus of schist was higher than that of sandstone, and the rock particles were relatively dense, with weak deformation ability. The failure modes of schist and sandstone were quite different. Due to the weak bond strength between muscovite and bedrock, the main failure modes of schist are splitting and tensile failure. The sample was separated along the bedding plane to form a rock slab resembling a platy and beam structure. The comparison of failure modes of schist and sandstone under uniaxial compression showed that rock bedding weak planes had a substantial influence on the distribution and propagation of cracks. When the Y-direction load was parallel to the joint plane, the cracks preferentially propagated along the joint plane with the weakest strength. In contrast, sandstone typically suffered from compressive shear failure and still had good integrity after failure.

The inverted arch was used to improve the stress conditions at the bottom of the tunnel; thus, the intact sample under the same stress condition was tested for comparison. As shown in Figure 14a–f, distinct delamination fractures and ejection features were observed in the two shapes of schist samples, and the inverted notch changed from a circular arc to an inverted trapezoid after failure. The shape and location of the fracture surface indicated the areas of weakness in the surrounding rock, which must be reinforced and carefully considered when designing tunnel support. As shown in Figure 14g–i, the sandstone exhibited no apparent signs of interlayer splitting or surface bulging, and the main failure mode was characterized by shear along the diagonal of the sample. Compared with samples containing prefabricated inverted arches, the cracked slabs of intact schist samples were longer, with more layers of slabs, more severe damage, greater uplift displacement, and a wider range of damage. The inverted arch played a positive role in preventing the occurrence of floor heave. Presumably, a new free surface first formed once the upper layer of the rock sample from the inverted arch had been peeled off. Due to the weakened optimization effect of the new free surface compared to the older one, internal failures persisted, and some fragments peeled off from the surface. The floor heave of the intact rock sample without the inverted arch was more obvious. The layered rock plate and rock sheet were successively broken and uplifted from the near free surface outside to the deeper inside.

Figure 14.

Typical photos of schist and sandstone samples after failure: (a) overall failure mode; (b) localized details of failure; (c) localized details of failure; (d) overall failure mode; (e) localized details of failure; (f) localized details of failure; (g) vertical view; (h) side view; (i) side view.

One of the key elements affecting tunnel floor heave is high ground stress. As the lateral stress increased, the maximum value of gradually increased. In contrast to the traditional biaxial test, the order of the axial strain values was as follows after the same level of load was applied: ε5 > ε10 > ε15. Given that the lateral stress restricted the deformation of the rock sample under low-stress conditions, the restriction effect became more evident as the lateral stress increased. The ultimate axial strain value of failure followed the general law: ε15 > ε10 > ε5. At the same time, the larger the lateral stress was, the longer it took to reach the limitations of the bearing capacity of the samples. This demonstrated that deeper-buried tunnels would suffer more severe damage and generate greater displacement in actual tunnel engineering due to the greater surrounding stress accumulating more energy inside the rock.

In general, the interlayer weak surface in the rock mass is the main reason for the uplift of the tunnel bottom. This experiment also proves that the inverted arch can improve the stress state of the tunnel bottom. When the inverted arch was damaged and deformed, the optimization effect decreased, and the layered rock at the bottom began to deform, demonstrating floor heave.

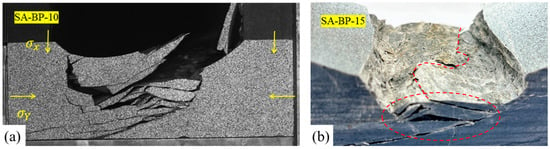

4.2. Similarity between of the Laboratory Test and Tunnel Floor Heave Phenomenon

There is a certain similarity between the macroscopic phenomena found in indoor experiments and actual engineering. Figure 15a shows that the layered surrounding rock at the bottom of the inverted arch is separated into a platy structure under the action of two-direction loads and breaks off from the middle, resulting in displacement towards the free surface in the model experiment. This was consistent with the fracture and floor heave at the bottom of the underground hole found by [14]. This study also showed that at the notch tip, the dilation mechanisms in the process zone were visible [14]. If this failed material was removed, a slab would form on the flank of the notch. The surrounding rock of the tunnel underwent deformation toward the free surface under high stress. Similarly, under the influence of a stable lateral stress and increasing axial load, cracks generated and propagated along the weak planes between layers in the schist, resulting in the formation of multilayer platy structures. The platy rock experienced buckling failure due to the axial load, and the local stress in the central region exceeded its strength and fractured. The macroscopic phenomenon was an upward uplift at the bottom of the inverted arch. Furthermore, the maximum depth of failure occurred in the middle of the bottom of the inverted arch, forming an inverted trapezoidal failure surface. The main reason was that the stress concentration coefficient at this location was the highest. In contrast, the results of the DIC system indicated that the initial failure occurred in the region near the surface of the inverted arch and gradually propagated toward the interior, away from that region.

Figure 15.

Destructive morphology of floor heave: (a) fracture of sample platy rock; (b) surface cracks in the sample.

The uplift and cracking of the inverted surface in the indoor experiment are shown in Figure 15b. Generally, only surface deformation can be seen from actual engineering phenomena without special treatment, usually manifested as the uplift and cracking of the tunnel surface. This phenomenon was also found in the indoor test. From the cross-sectional view of the tested samples, the displacement caused by the surface uplift was due to the bottom surrounding rock being separated into a plate shape and broken from the middle, forced out toward the outermost surrounding rock. However, due to local deformation, heterogeneity of the rock, and the limiting effect of lateral stress, the deformation of the sample did not lead to the overall uplift of the entire sample. Instead, the “S”-shaped crack and local protrusion could be observed. The formation of surface cracks was mainly caused by tensile failure.

5. Conclusions

In this study, a novel rock sample with a prefabricated inverted arch was designed and subjected to biaxial step loads. Based on 3D-DIC, the deformation mechanism of rock samples with prefabricated inverted arches was analyzed. The main conclusions are listed as follows:

- (1)

- Under the combined compression effect of vertical stress and horizontal stress in the biaxial step-loading test, the tensile stress of the interlayer weak plane exceeded the tensile strength. Then, the sample was cut into a layered platy structure. Due to stress concentration and the influence of the weak planes between layers, the outermost rock blocks near the surface of the inverted arch peeled off under continuous loads parallel to the bedding planes. After that, the stress was transferred to the deep part of the rock toward the negative direction of the X-coordinate. Subsequently, the separated plate-shaped sample buckled under the effect of force and fractured in the middle position. Eventually, the bottom of the inverted arch uplifted, and an “S”-shaped crack on the surface was formed near the center of the inverted arch;

- (2)

- The layered structure is an important factor causing uplift deformation at the bottom of the rock sample. The failure of schist is mainly due to weak cementation between layers. The orientation and propagation of cracks depend on the position of weak joint surfaces. The main failure mode of schist is splitting tensile failure, while that of homogeneous sandstone is compression shear failure. As the lateral stress increases, the time required to reach the maximum axial load increases;

- (3)

- Floor heave initially occurs near the bottom of the inverted arch, rapidly and continuously moving away from the arch surface. The displacement of the uplift gradually decreases from the position near the bottom of the inverted arch to the direction away from the arch surface. The displacement of the bottom surrounding rock increases significantly within the Y-coordinate range of 0–20 mm compared to the adjacent area. The curve of displacement in the X–direction along the Y–coordinate exhibited a protruding shape, with the maximum displacement at Y = 11.7 mm;

- (4)

- During the experiment, the phenomena of rock plate separation, fracture, and surface uplift displacement were observed, which is consistent with floor heave damage in actual engineering tunnels.

The careful investigation and analysis of the deformation mechanism and pattern of layered rock masses for tunnel floor heave is a key issue for tunnel-support design and subsequent remediation. The main objectives of upcoming research will be to investigate the rheological deformation mechanism of the weak surrounding rock as well as suitable support approaches.

Author Contributions

Conceptualization, D.L. and Z.P.; methodology, D.L. and Z.P.; software, H.G.; validation, Q.Z. and J.M.; formal analysis, Q.Z.; investigation, D.L. and Z.P.; writing—original draft preparation, Z.P.; writing—review and editing, Q.Z. and J.M.; supervision, D.L.; funding acquisition, D.L. All authors have read and agreed to the published version of the manuscript.

Funding

The work presented in this paper was financially supported by the National Natural Science Foundation of China (No. U1934211).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available in the article.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Małkowski, P.; Ostrowski, Ł.; Stasica, J. Modeling of Floor Heave in Underground Roadways in Dry and Waterlogged Conditions. Energies 2022, 15, 4340. [Google Scholar] [CrossRef]

- Mo, S.; Ramandi, H.L.; Oh, J.; Masoumi, H.; Canbulat, I.; Hebblewhite, B.; Saydam, S. A new coal mine floor rating system and its application to assess the potential of floor heave. Int. J. Rock Mech. Min. Sci. 2020, 128, 104241. [Google Scholar] [CrossRef]

- Peng, S.S. Coal Mine Ground Control; Department of Mining Engineering/College of Engineering and Mineral Resources: Morgantown, WV, USA, 2008; ISBN 978-0-9789383-4-5. [Google Scholar]

- Seki, S.; Kaise, S.; Morisaki, Y.; Azetaka, S.; Jiang, Y. Model experiments for examining heaving phenomenon in tunnels. Tunn. Undergr. Space Technol. 2008, 23, 128–138. [Google Scholar] [CrossRef]

- Peng, R.; Meng, X.; Zhao, G.; Ouyang, Z.; Li, Y. Multi-echelon support method to limit asymmetry instability in different lithology roadways under high ground stress. Tunn. Undergr. Space Technol. 2021, 108, 103681. [Google Scholar] [CrossRef]

- Yao, W.; Pang, J.; Zhang, J.; Liu, G. Key Technique Study of Stability Control of Surrounding Rock in Deep Chamber with Large Cross-Section: A Case Study of the Zhangji Coal Mine in China. Geotech. Geol. Eng. 2021, 39, 299–316. [Google Scholar] [CrossRef]

- Zhu, Q.; Li, T.; Zhang, H.; Ran, J.; Li, H.; Du, Y.; Li, W. True 3D geomechanical model test for research on rheological deformation and failure characteristics of deep soft rock roadways. Tunn. Undergr. Space Technol. 2022, 128, 104653. [Google Scholar] [CrossRef]

- He, F.; Zhai, W.; Xu, X.; Song, J.; Li, L.; Lv, K. Study on Mechanism and Control Technology of Asymmetric Floor Heave in a Deep Soft Rock Main Roadway. Geofluids 2022, 2022, e1149000. [Google Scholar] [CrossRef]

- Sakhno, I.; Sakhno, S.; Skyrda, A.; Popova, O. Numerical Modeling of Controlling a Floor Heave of Coal Mine Roadways with a Method of Reinforcing in Wet Soft Rock. Geofluids 2022, 2022, e3855799. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, S.; Li, X.; Meng, J.; Li, Z.; Zhang, L.; Pu, D.; Wang, L. Research on Theory and Technology of Floor Heave Control in Semicoal Rock Roadway: Taking Longhu Coal Mine in Qitaihe Mining Area as an Example. Lithosphere 2022, 2022, 3810988. [Google Scholar] [CrossRef]

- Liu, H.; Liu, C.; Zhai, M.; Zhang, P.; Wang, L.; Wang, F.; Liu, J. Collaborative Control Technology of Crosscut Floor Heave in Soft Rocks under Deep High Horizontal Stress. Math. Probl. Eng. 2022, 2022, e8260169. [Google Scholar] [CrossRef]

- Wen, Z.; Jing, S.; Meng, F.; Jiang, Y. Control technology for floor heave of Jurassic soft rock in the Erdos Basin of China: A case study. J. Cent. South Univ. 2022, 29, 4051–4065. [Google Scholar] [CrossRef]

- Xiao, Z.; Liu, J.; Gu, S.; Liu, M.; Zhao, F.; Wang, Y.; Ou, C.; Zhen, M. A Control Method of Rock Burst for Dynamic Roadway Floor in Deep Mining Mine. Shock Vib. 2019, 2019, e7938491. [Google Scholar] [CrossRef]

- Martini, C.D.; Read, R.S.; Martino, J.B. Observations of brittle failure around a circular test tunnel. Int. J. Rock Mech. Min. Sci. 1997, 34, 1065–1073. [Google Scholar] [CrossRef]

- Tsimbarevich, P.M. Mine Support; Coal Industry Publishing House: Beijing, China, 1957. [Google Scholar]

- Mo, S.; Tutuk, K.; Saydam, S. Management of floor heave at Bulga Underground Operations—A case study. Int. J. Min. Sci. Technol. 2019, 29, 73–78. [Google Scholar] [CrossRef]

- Chen, Z.; He, C.; Xu, G.; Ma, G.; Wu, D. A Case Study on the Asymmetric Deformation Characteristics and Mechanical Behavior of Deep-Buried Tunnel in Phyllite. Rock Mech. Rock Eng. 2019, 52, 4527–4545. [Google Scholar] [CrossRef]

- Ou, X.; Ouyang, L.; Xu, X.; Wang, L. Case study on floor heave failure of highway tunnels in gently inclined coal seam. Eng. Fail. Anal. 2022, 136, 106224. [Google Scholar] [CrossRef]

- Liu, Y.; Song, H.L.; Sun, X.D.; Xing, H.P.; Feng, C.Y.; Liu, J.F.; Zhao, G.T. Characteristics of rail deformation caused by tunnel floor heave and corresponding running risk of high-speed train. Constr. Build. Mater. 2022, 346, 128385. [Google Scholar] [CrossRef]

- Zhai, W.; He, F.; Xu, X.; Lv, K.; Li, L.; Song, J. Floor heave mechanism in water-rich soft rock roadways and a DS-IBA control approach. Geomat. Nat. Hazards Risk 2022, 13, 2107–2123. [Google Scholar] [CrossRef]

- Luo, P.; Wang, L.; Li, D.; Yang, J.; Lv, X. Deformation and failure mechanism of horizontal soft and hard interlayered rock under uniaxial compression based on digital image correlation method. Eng. Fail. Anal. 2022, 142, 106823. [Google Scholar] [CrossRef]

- Yang, X.; Yu, F.; Ma, C.; Zhang, T.; Wang, B.; Zhao, X. Study on Floor Heave Characteristics and the Control Method of Gob-Side Entry Driving in Weakly Cemented Soft Rock. Sustainability 2023, 15, 3969. [Google Scholar] [CrossRef]

- Sun, X.; Jiang, M.; Miao, C.; Wang, J.; Zhang, J. Study on large deformation and failure mechanism of deep buried stratified slate tunnel and control strategy of high constant resistance anchor cable. Eng. Fail. Anal. 2023, 144, 106953. [Google Scholar] [CrossRef]

- Tao, Z.; Zhu, C.; Zheng, X.; Wang, D.; Liu, Y.; He, M.; Wang, Y. Failure mechanisms of soft rock roadways in steeply inclined layered rock formations. Geomat. Nat. Hazards Risk 2018, 9, 1186–1206. [Google Scholar] [CrossRef]

- Wang, F.N.; Guo, Z.B.; Qiao, X.B.; Fan, J.Y.; Li, W.; Mi, M.; Tao, Z.G.; He, M.C. Large deformation mechanism of thin-layered carbonaceous slate and energy coupling support technology of NPR anchor cable in Minxian Tunnel: A case study. Tunn. Undergr. Space Technol. 2021, 117, 104151. [Google Scholar] [CrossRef]

- Zhu, Y.; Hua, X.; Li, Y.; Li, W.; Yang, K. Study on the effect of rock stratum structure on the stability of weakly cemented layered floor and the floor control measures: A case study of Meihuajing Mine. Energy Sci. Eng. 2023, 11, 2238–2252. [Google Scholar] [CrossRef]

- Nasseri, M.H.B.; Rao, K.S.; Ramamurthy, T. Anisotropic strength and deformational behavior of Himalayan schists. Int. J. Rock Mech. Min. Sci. 2003, 40, 3–23. [Google Scholar] [CrossRef]

- Liu, S.; Chen, S.; Yu, F.; Zhao, W. Anisotropic properties study of chlorite schist. Rock Soil Mech. 2012, 33, 3616–3623. (In Chinese) [Google Scholar] [CrossRef]

- Han, Z.; Li, D.; Li, X. Dynamic mechanical properties and wave propagation of composite rock-mortar specimens based on SHPB tests. Int. J. Min. Sci. Technol. 2022, 32, 793–806. [Google Scholar] [CrossRef]

- Thill, R.E.; Bur, T.R.; Steckley, R.C. Velocity anisotropy in dry and saturated rock spheres and its relation to rock fabric. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1973, 10, 535–557. [Google Scholar] [CrossRef]

- Jacobsson, L.; Christiansson, R.; Martin, C.D. Experimental determination of spalling initiation in hard rock. In Rock Mechanics in Civil and Environmental Engineering; CRC Press: London, UK, 2010. [Google Scholar]

- Lei, R.; Zhang, Z.; Berto, F.; Ranjith, P.G.; Liu, L. Cracking process and acoustic emission characteristics of sandstone with two parallel filled-flaws under biaxial compression. Eng. Fract. Mech. 2020, 237, 107253. [Google Scholar] [CrossRef]

- Li, D.; Zhu, Q.; Zhou, Z.; Li, X.; Ranjith, P.G. Fracture analysis of marble specimens with a hole under uniaxial compression by digital image correlation. Eng. Fract. Mech. 2017, 183, 109–124. [Google Scholar] [CrossRef]

- Han, Z.; Li, D.; Zhou, T.; Chen, J.; Xie, S. Dynamic progressive fracture behavior of axially confined sandstone specimens containing a single flaw. Theor. Appl. Fract. Mech. 2022, 122, 103597. [Google Scholar] [CrossRef]

- Ma, J.; Li, D.; Zhu, Q.; Liu, M.; Wan, Q. The mode I fatigue fracture of fine-grained quartz-diorite under coupled static loading and dynamic disturbance. Theor. Appl. Fract. Mech. 2022, 117, 103140. [Google Scholar] [CrossRef]

- Liu, H.; Li, P.; Liu, J. Numerical investigation of underlying tunnel heave during a new tunnel construction. Tunn. Undergr. Space Technol. 2011, 26, 276–283. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).