3D Printing Progress in Gluten-Free Food—Clustering Analysis of Advantages and Obstacles

Abstract

:1. Introduction

2. Methods

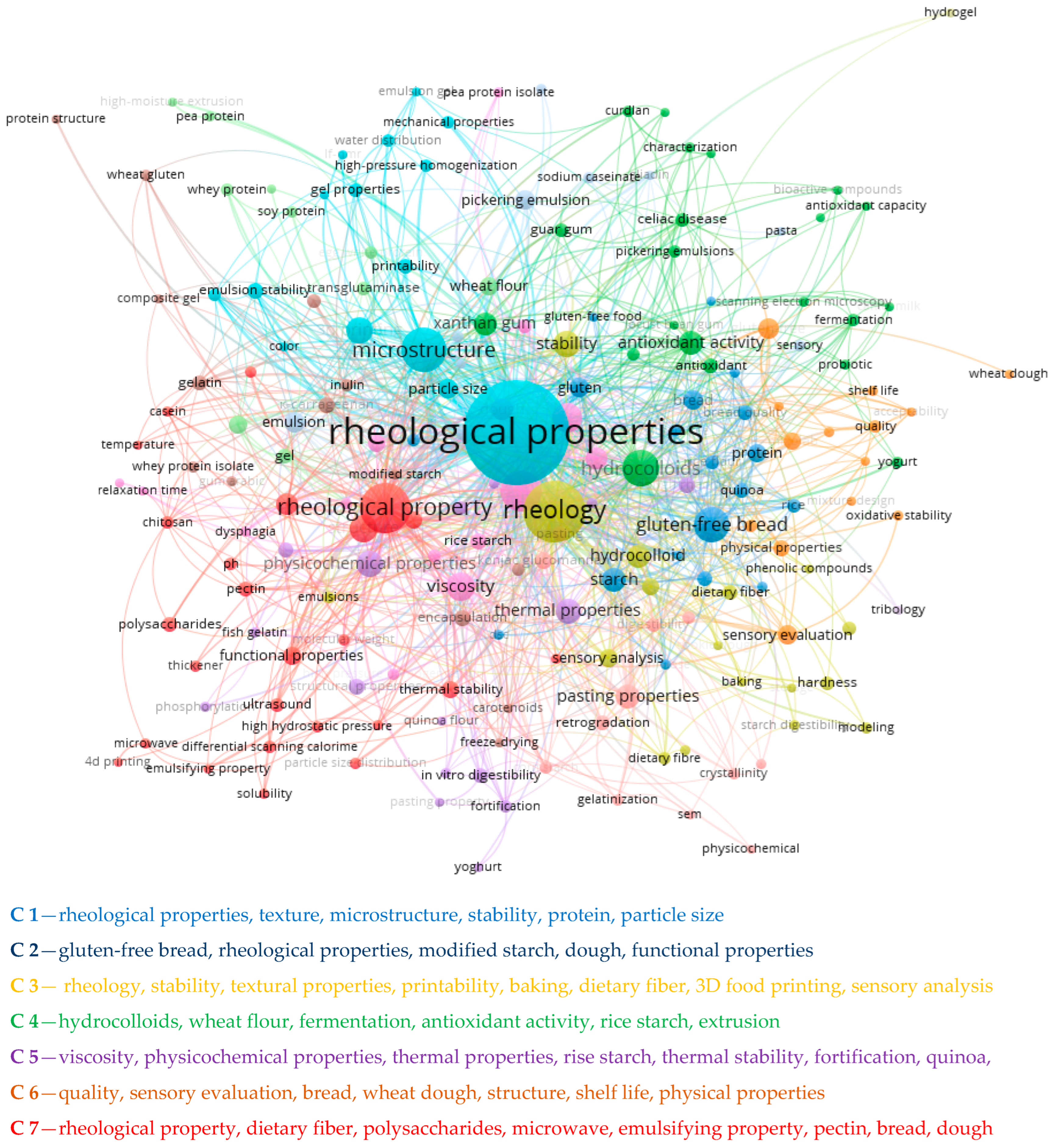

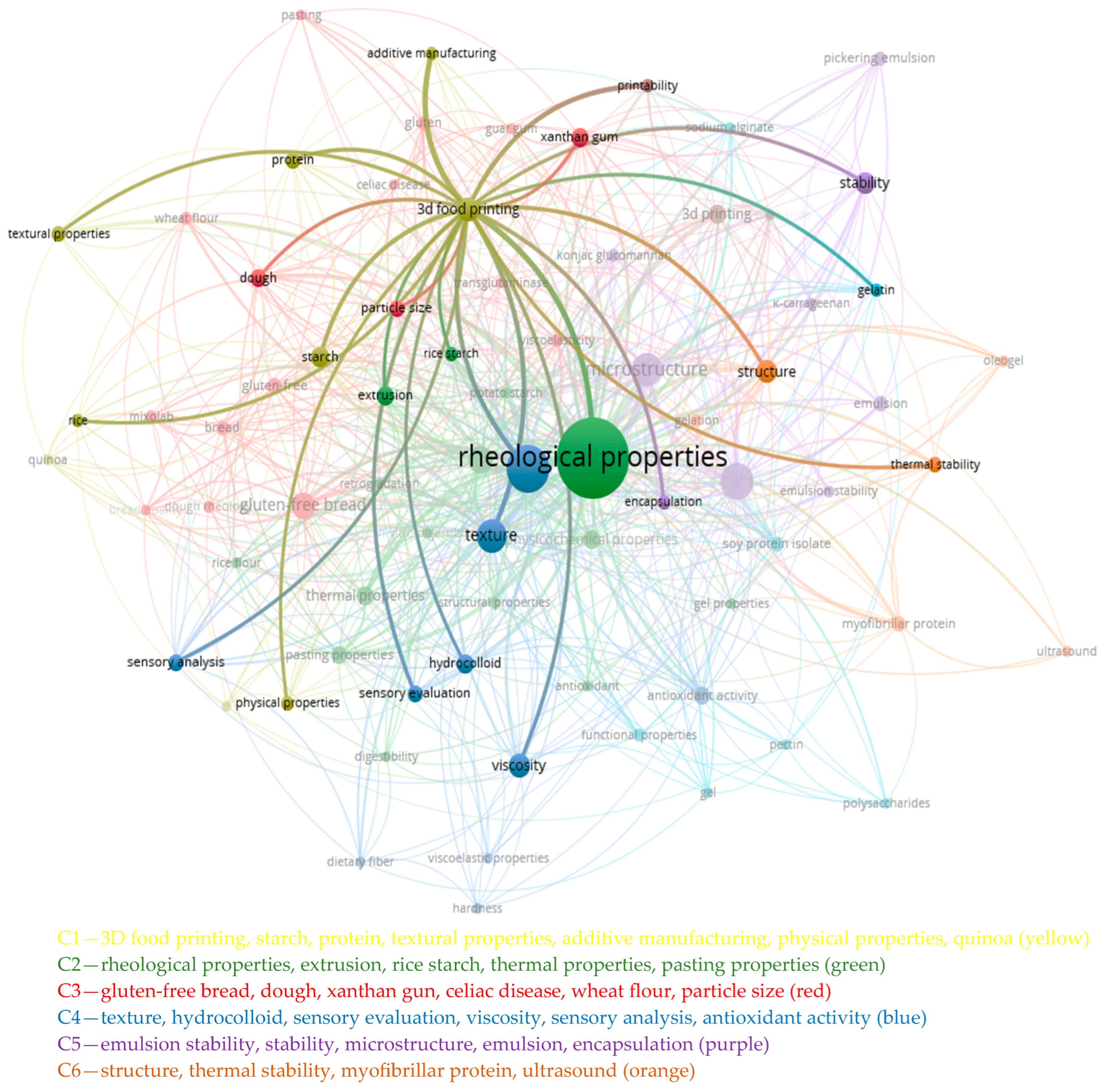

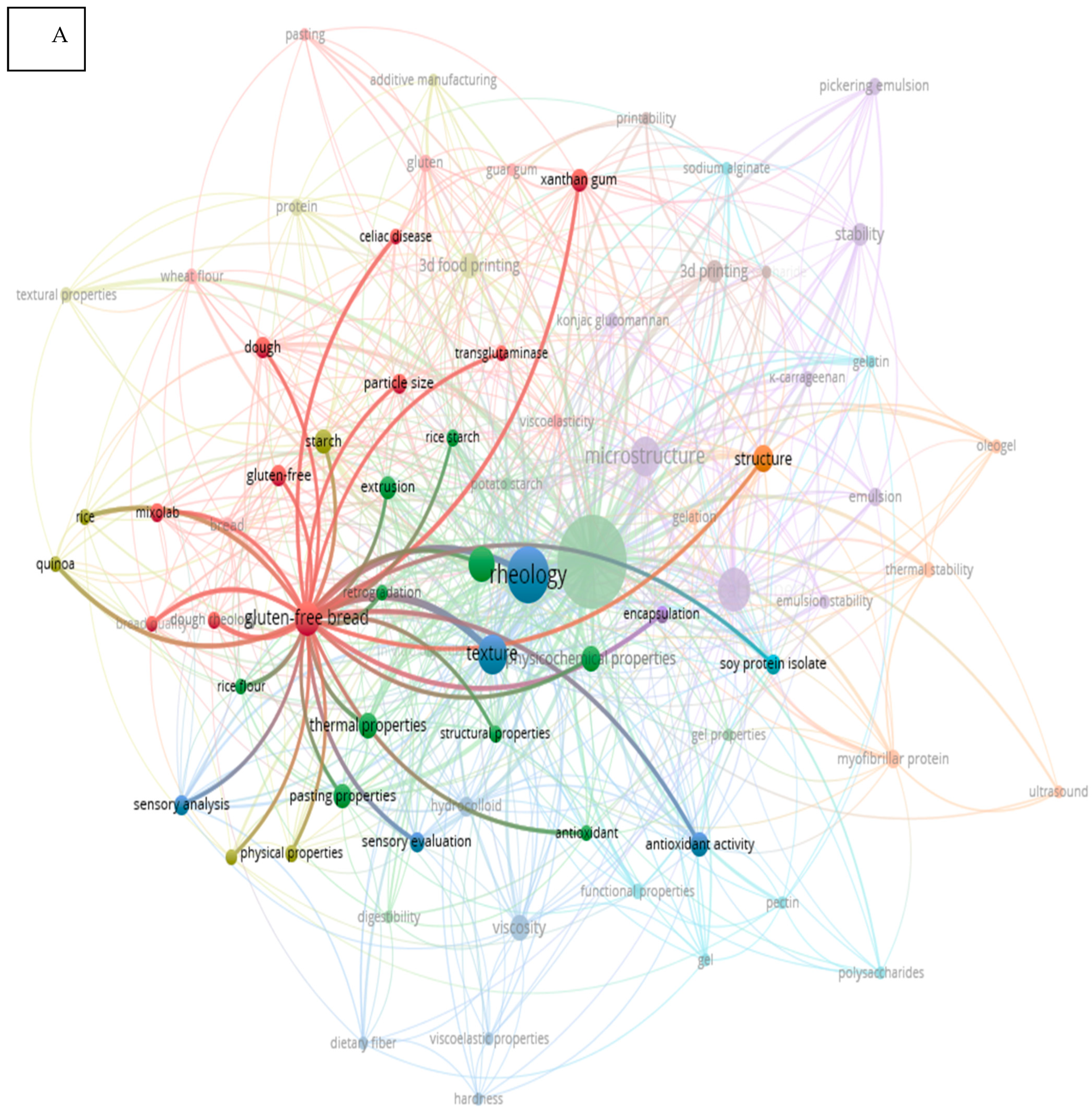

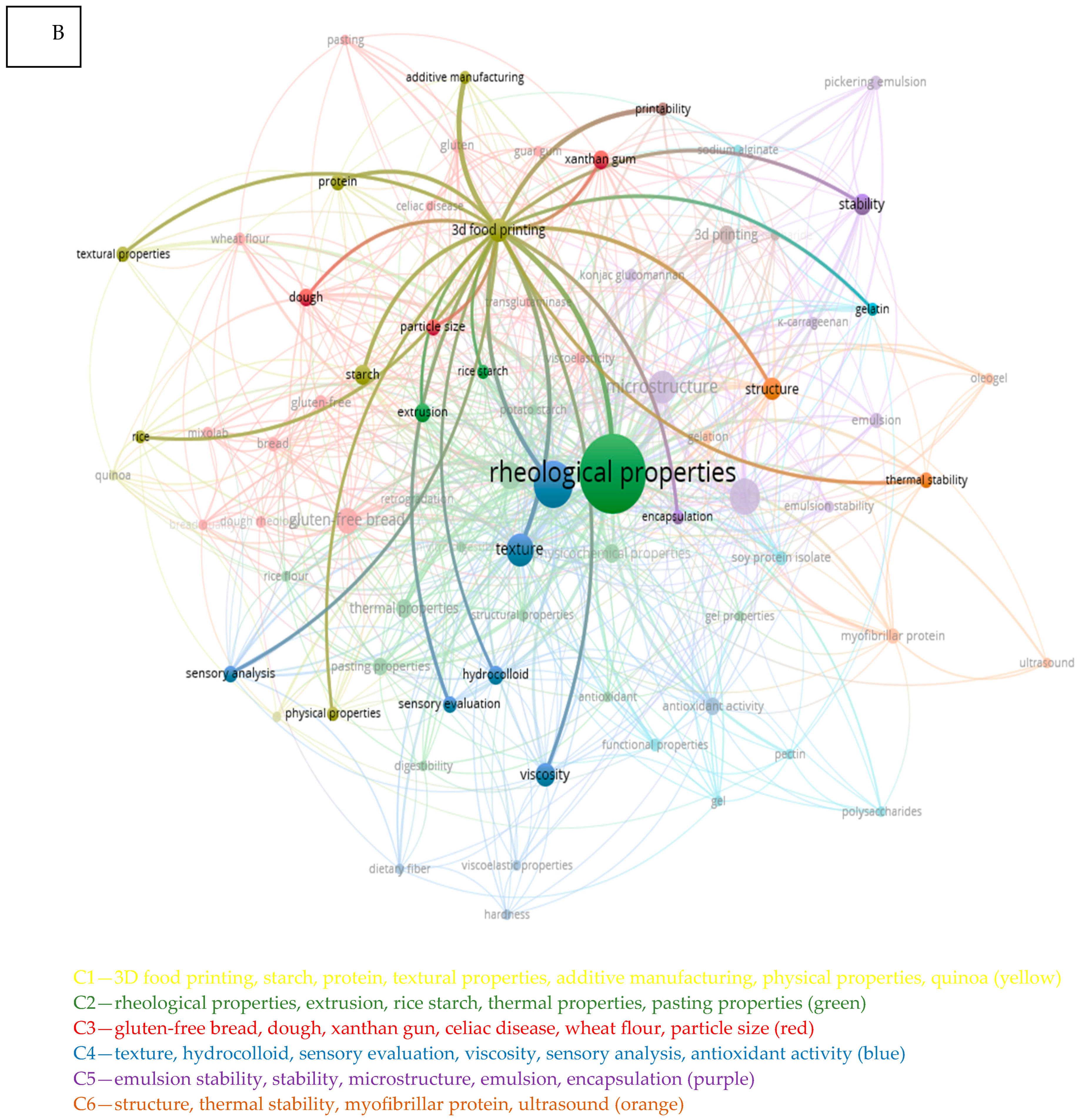

3. Results and Discussion

3.1. Using 3D Printing of Gluten-Free Products

3.2. Advantages and Obstacles of Gluten-Free Food Production Using 3D printing

4. Conclusions and Future Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Thangalakshmi, S.; Arora, V.K.; Prithviraj, V. A Comprehensive Assessment of 3D Food Printing: Technological and Processing Aspects. J. Biosyst. Eng. 2021, 46, 286–304. [Google Scholar] [CrossRef]

- Azam, S.M.R.; Zhang, M.; Mujumdar, A.S.; Yang, C. Study on 3D printing of orange concentrate and material characteristics. J. Food Process Eng. 2018, 41, e12689. [Google Scholar] [CrossRef]

- Ghazal, A.F.; Zhang, M.; Liu, Z. Spontaneous Color Change of 3D Printed Healthy Food Product over Time after Printing as a Novel Application for 4D Food Printing. Food Bioprocess Technol. 2019, 12, 1627–1645. [Google Scholar] [CrossRef]

- Cheng, Y.; Fu, Y.; Ma, L.; Yap, P.L.; Losic, D.; Wang, H.; Zhang, Y. Rheology of edible food inks from 2D/3D/4D printing, and its role in future 5D/6D printing. Food Hydrocoll. 2022, 132, 107855. [Google Scholar] [CrossRef]

- Derossi, A.; Caporizzi, R.; Paolillo, M.; Severini, C. Programmable texture properties of cereal-based snack mediated by 3D printing technology. J. Food Eng. 2020, 289, 110160. [Google Scholar] [CrossRef]

- Pulatsu, E.; Lin, M. A review on customizing edible food materials into 3D printable inks: Approaches and strategies. Trends Food Sci. Technol. 2021, 107, 68–77. [Google Scholar] [CrossRef]

- Maniglia, B.C.; Lima, D.C.; da Matta Júnior, M.; Oge, A.; Le-Bail, P.; Augusto, P.E.; Le-Bail, A. Dry heating treatment: A potential tool to improve the wheat starch properties for 3D food printing application. Food Res. Int. 2020, 137, 109731. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, M.; Chitrakar, B.; Adhikari, B. Recent advances in functional 3D printing of foods: A review of functions of ingredients and internal structures. Crit. Rev. Food Sci. Nutr. 2020, 61, 3489–3503. [Google Scholar] [CrossRef]

- Szabo, K.; Dulf, F.V.; Teleky, B.-E.; Eleni, P.; Boukouvalas, C.; Krokida, M.; Kapsalis, N.; Rusu, A.V.; Socol, C.T.; Vodnar, D.C. Evaluation of the Bioactive Compounds Found in Tomato Seed Oil and Tomato Peels Influenced by Industrial Heat Treatments. Foods 2021, 10, 110. [Google Scholar] [CrossRef]

- Varvara, R.-A.; Szabo, K.; Vodnar, D.C. 3D Food Printing: Principles of Obtaining Digitally-Designed Nourishment. Nutrients 2021, 13, 3617. [Google Scholar] [CrossRef]

- Liu, L.; Meng, Y.; Dai, X.; Chen, K.; Zhu, Y. 3D Printing Complex Egg White Protein Objects: Properties and Optimization. Food Bioprocess Technol. 2019, 12, 267–279. [Google Scholar] [CrossRef]

- Huang, M.-S.; Zhang, M.; Bhandari, B. Assessing the 3D Printing Precision and Texture Properties of Brown Rice Induced by Infill Levels and Printing Variables. Food Bioprocess Technol. 2019, 12, 1185–1196. [Google Scholar] [CrossRef]

- Lorenz, T.; Iskandar, M.M.; Baeghbali, V.; Ngadi, M.O.; Kubow, S. 3D Food Printing Applications Related to Dysphagia: A Narrative Review. Foods 2022, 11, 1789. [Google Scholar] [CrossRef]

- Derossi, A.; Caporizzi, R.; Paolillo, M.; Oral, M.O.; Severini, C. Drawing the scientific landscape of 3D Food Printing. Maps and interpretation of the global information in the first 13 years of detailed experiments, from 2007 to 2020. Innovat. Food Sci. Emerg. Technol. 2021, 70, 102689. [Google Scholar] [CrossRef]

- Liu, Y.; Tang, T.; Duan, S.; Qin, Z.; Li, C.; Zhang, Z.; Liu, A.; Wu, D.; Chen, H.; Han, G.; et al. Effects of sodium alginate and rice variety on the physicochemical characteristics and 3D printing feasibility of rice paste. LWT 2020, 127, 109360. [Google Scholar] [CrossRef]

- Thangalakshmi, S.; Arora, V.K.; Kaur, B.P.; Singh, R.; Malakar, S.; Rathi, S.; Tarafdar, A. Effect of Steaming as Postprocessing Method on Rice Flour and Jaggery 3D Printed Construct. J. Food Qual. 2022, 2022, 3531711. [Google Scholar] [CrossRef]

- Noya, L.I.; Vasilaki, V.; Stojceska, V.; González-García, S.; Kleynhans, C.; Tassou, S.; Moreira, M.T.; Katsou, E. An Environmental Evaluation of Food Supply Chain Using Life Cycle Assessment: A Case Study on Gluten Free Biscuit Products. J. Clean. Prod. 2018, 170, 451–461. [Google Scholar] [CrossRef]

- Kim, H.W.; Lee, I.J.; Park, S.M.; Lee, J.H.; Nguyen, M.-H.; Park, H.J. Effect of hydrocolloid addition on dimensional stability in post-processing of 3D printable cookie dough. LWT 2019, 101, 69–75. [Google Scholar] [CrossRef]

- Kewuyemi, Y.O.; Kesa, H.; Adebo, O.A. Trends in functional food development with three-dimensional (3D) food printing technology: Prospects for value-added traditionally processed food products. Crit. Rev. Food Sci. Nutr. 2022, 62, 7866–7904. [Google Scholar] [CrossRef]

- Pulatsu, E.; Su, J.-W.; Lin, J.; Lin, M. Factors affecting 3D printing and post-processing capacity of cookie dough. Innov. Food Sci. Emerg. Technol. 2020, 61, 102316. [Google Scholar] [CrossRef]

- Dankar, I.; Haddarah, A.; Sepulcre, F.; Pujolà, M. Assessing Mechanical and Rheological Properties of Potato Puree: Effect of Different Ingredient Combinations and Cooking Methods on the Feasibility of 3D Printing. Foods 2019, 9, 21. [Google Scholar] [CrossRef]

- García-Segovia, P.; García-Alcaraz, V.; Balasch-Parisi, S.; Martínez-Monzó, J. 3D printing of gels based on xanthan/konjac gums. Innov. Food Sci. Emerg. Technol. 2020, 64, 102343. [Google Scholar] [CrossRef]

- Derossi, A.; Paolillo, M.; Caporizzi, R.; Severini, C. Extending the 3D food printing tests at high speed. Material deposition and effect of non-printing movements on the final quality of printed structures. J. Food Eng. 2019, 275, 109865. [Google Scholar] [CrossRef]

- Liu, Y.; Tang, T.; Duan, S.; Qin, Z.; Zhao, H.; Wang, M.; Li, C.; Zhang, Z.; Liu, A.; Han, G.; et al. Applicability of Rice Doughs as Promising Food Materials in Extrusion-Based 3D Printing. Food Bioprocess Technol. 2020, 13, 548–563. [Google Scholar] [CrossRef]

- Pavičić, T.V.; Grgić, T.; Ivanov, M.; Novotni, D.; Herceg, Z. Influence of Flour and Fat Type on Dough Rheology and Technological Characteristics of 3D-Printed Cookies. Foods 2021, 10, 193. [Google Scholar] [CrossRef]

- Lille, M.; Kortekangas, A.; Heiniö, R.-L.; Sozer, N. Structural and Textural Characteristics of 3D-Printed Protein- and Dietary Fibre-Rich Snacks Made of Milk Powder and Wholegrain Rye Flour. Foods 2020, 9, 1527. [Google Scholar] [CrossRef]

- Carrillo-Navas, H.; Guadarrama-Lezama, A.Y.; Vernon-Carter, E.J.; García-Díaz, S.; Reyes, I.; Alvarez-Ramírez, J. Effect of gelatinized flour fraction on thermal and rheological properties of wheat-based dough and bread. J. Food Sci. Technol. 2016, 53, 3996–4006. [Google Scholar] [CrossRef]

- Sae-Eaw, A.; Wongsaichia, S.; Giacalone, D.; Naruetharadhol, P.; Ketkaew, C. Conceptualizing a Gluten-Free Instant Noodle Prototype Using Environmental Sustainability Aspects: A Cross-National Qualitative Study on Thai and Danish Consumers. Foods 2022, 11, 2437. [Google Scholar] [CrossRef]

- Waltman, L.; van Eck, N.J.; Noyons, E.C.M. A unified approach to mapping and clustering of bibliometric networks. J. Informetr. 2010, 4, 629–635. [Google Scholar] [CrossRef]

- Mingers, J.; Leydesdorff, L. A review of theory and practice in scientometrics. Eur. J. Oper. Res. 2015, 246, 1–19. [Google Scholar] [CrossRef]

- van Eck, N.J.; Waltman, L.; van Raan, A.F.J.; Klautz, R.J.M.; Peul, W.C. Citation Analysis May Severely Underestimate the Impact of Clinical Research as Compared to Basic Research. PLoS ONE 2013, 8, e62395. [Google Scholar] [CrossRef] [PubMed]

- Suclupe-Navarro, P.; Limaymanta, C.H.; Ramírez, N.H.; Guillén, H. Producción científica sobre ansiedad bibliotecaria: Un análisis bibliométrico y cienciométrico desde Scopus. Rev. Española Doc. Científica 2021, 44, e291. [Google Scholar] [CrossRef]

- Różańska, A.; Gruszka, A. Current research trends in multitasking: A bibliometric mapping approach. J. Cogn. Psychol. 2020, 32, 278–286. [Google Scholar] [CrossRef]

- VOSviewer—Visualizing Scientific Landscapes. Available online: https://www.vosviewer.com/ (accessed on 10 November 2023).

- Janzen, J.; Zulauf, C. The Russia-Ukraine War and Changes in Ukraine Corn and Wheat Supply: Impacts on Global Agricultural Markets. Farmdoc Daily: 34, Department of Agricultural and Consumer Economics, University of Illinois at Urbana-Champaign. 2023. Available online: https://farmdocdaily.illinois.edu/2023/02/the-russia-ukraine-war-and-changes-in-ukraine-corn-and-wheat-supply-impacts-on-global-agricultural-markets.html (accessed on 10 November 2023).

- Paolillo, M.; Derossi, A.; van Bommel, K.; Noort, M.; Severini, C. Rheological properties, dispensing force and printing fidelity of starchy-gels modulated by concentration, temperature and resting time. Food Hydrocoll. 2021, 117, 106703. [Google Scholar] [CrossRef]

- Zhang, L.; Lou, Y.; Schutyser, M.A. 3D printing of cereal-based food structures containing probiotics. Food Struct. 2018, 18, 14–22. [Google Scholar] [CrossRef]

- Matas, A.; Igual, M.; García-Segovia, P.; Martínez-Monzó, J. Application of 3D Printing in the Design of Functional Gluten-Free Dough. Foods 2022, 11, 1555. [Google Scholar] [CrossRef]

- Mirazimi, F.; Saldo, J.; Sepulcre, F.; Pujolà, M. Study the correlation between the instrumental and sensory evaluation of 3D-printed protein-fortified potato puree. Eur. Food Res. Technol. 2023, 249, 1669–1675. [Google Scholar] [CrossRef]

- Horiuchi, M.; Akachi, T.; Kawakami, M.; Furukawa, H. Texture Design and Its Effect of Soft Foods Suitable for Nursing Foods Using Macroscopic 3D Structures Printed by 3D Food Printer. Jpn. J. Food Eng. 2021, 22, 119–134. [Google Scholar] [CrossRef]

- Pan, H.; Pei, F.; Ma, G.; Ma, N.; Zhong, L.; Zhao, L.; Hu, Q. 3D printing properties of Flammulina velutipes polysaccharide-soy protein complex hydrogels. J. Food Eng. 2022, 334, 111170. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Y.; Cai, Y.; Ahmad, I.; Zhang, A.; Ding, Y.; Qiu, Y.; Zhang, G.; Tang, W.; Lyu, F. Hot extrusion 3D printing technologies based on starchy food: A review. Carbohydr. Polym. 2022, 294, 119763. [Google Scholar] [CrossRef]

- Radoš, K.; Benković, M.; Mustač, N.Č.; Habuš, M.; Voučko, B.; Pavičić, T.V.; Ćurić, D.; Ježek, D.; Novotni, D. Powder properties, rheology and 3D printing quality of gluten-free blends. J. Food Eng. 2023, 338, 111251. [Google Scholar] [CrossRef]

- Chen, H.; Xie, F.; Chen, L.; Zheng, B. Effect of rheological properties of potato, rice and corn starches on their hot-extrusion 3D printing behaviors. J. Food Eng. 2019, 244, 150–158. [Google Scholar] [CrossRef]

- Krishnaraj, P.; Anukiruthika, T.; Choudhary, P.; Moses, J.A.; Anandharamakrishnan, C. 3D Extrusion Printing and Post-Processing of Fibre-Rich Snack from Indigenous Composite Flour. Food Bioprocess Technol. 2019, 12, 1776–1786. [Google Scholar] [CrossRef]

- Verma, V.K.; Kamble, S.S.; Ganapathy, L.; Belhadi, A.; Gupta, S. 3D Printing for sustainable food supply chains: Modelling the implementation barriers. Int. J. Logist. Res. Appl. 2023, 26, 1190–1216. [Google Scholar] [CrossRef]

- Harasym, J. 3D Printers for Food Printing—Advantages and Drawbacks of Market Ready Technical Solutions. Nauk. Inżynierskie I Technol. 2022, 1, 41–59. [Google Scholar] [CrossRef]

| SDGs UN | Specific SDG Indicator | Brief Explanation of the Correlation with the Production of Gluten-Free Food Products Using 3D Printing |

|---|---|---|

SDG 1 | SDG 1.5 is designed to help build the resilience of the poor and vulnerable against extreme events and disasters. | The first SDG is related to humanity’s efforts to end poverty in all its possible forms, which also includes food security and sustainable access to food. Experience has shown that the most vulnerable segments of the population (the poorest, least developed countries in Africa) suffered from food shortages, primarily due to the lack of cereals (wheat, corn) caused by the military conflict in Ukraine [35]. Therefore, the production of food products with the planned nutritional content through 3D printing using non-traditional gluten-free raw materials is a promising method of ensuring the sustainability of food chains, which will increase the resilience of the poor and those in vulnerable environments and reduce their vulnerability to extreme events. |

SDG 2 | SDG 2.1–2.5 is directly related to the achievement of food security, designed to help improve nutrition, which is possible through the development of gluten-free food products with the prescribed nutritional content through 3D printing. | Achieving this goal implies equal access to safe, sufficient, and nutritious food for all people, including those in vulnerable situations, the poor, infants, and people with special needs. The production of food with the intended nutritional content through 3D printing using non-traditional gluten-free raw materials will contribute to sustainable food production systems. Such production can use food waste from other food production as non-traditional gluten-free raw materials, which will also contribute to increasing the added value of food, gradually improving land and soil quality, and helping maintain ecosystems. |

SDG 3 | SDG 3 is directly related to the topic under study because ensuring a healthy lifestyle and promoting the well-being of people at any age cannot be achieved without ensuring sustainable food chains. | Reducing the global maternal mortality ratio, mortality of newborns and children under 5 years of age, as well as reducing premature mortality from non-communicable diseases and diseases associated with air, water, and soil pollution—the achievement of these goals and positive changes in the relevant indicators will be facilitated by the production of enriched functional gluten-free products with adjustable composition, manufactured by 3D printing, which does not create additional food waste and is designed to meet the shortage of specific foods. |

SDG 9 | SDG 9.4–9.5 are indirectly related to the 3D printing of gluten-free products—improving technological capabilities, supporting local technologies, research, and innovation. | This SDG 9 aims to promote the modernization of various industries for sustainability in order to increase resource efficiency in the development of gluten-free products through 3D printing—this can be achieved through the introduction of local clean and environmentally friendly raw materials. It also includes encouraging innovation and increasing research; in developing countries, this could include researching and incorporating locally available ingredients, including gluten-free raw materials, into the technology. |

SDG 12 | SDG 12.3, 12.5, 12.7, and 12 a are about developing models of sustainable consumption and production, replacing wheat flour with other plant-based ingredients, and creating food products with adjustable composition by 3D printing, which directly contributes to this goal. | To ensure the efficient use of natural resources, this area of research on the use of local, environmentally friendly, available resources as raw materials for the production of gluten-free products by 3D printing requires further development. In addition, the use of food waste from one food production facility for use in the technology of gluten-free products with a controlled composition will reduce food losses along the production chain. The proposed method of 3D printing gluten-free food products with a predetermined composition contributes to the prevention, reduction, and reuse of food waste. |

| Promising Materials Proposed for 3D Printing | The Scientific Manuscript Short-Cuts | Ref. |

|---|---|---|

| Programmable texture properties of cereal-based snacks mediated by 3D printing technology | ||

| . | The paper shows the possibility of producing cereal snacks with different texture properties using 3D printing technology. 3D printing of food products can be used to create controlled pores in cereal-based snacks in order to create new foods with different structural properties | [5] |

| Applicability of Rice Doughs as Promising Food Materials in Extrusion-Based 3D Printing | ||

| Flour from waxy rice, indica rice, and japonica rice. | This study has shown that the use of high-amylose rice for 3D printing of food products has a high potential and can be used as a basis for the production of fortified food products by 3D printing. | [15] |

| 3D printing of cereal-based food structures containing probiotics | ||

| Wheat dough, calcium caseinate, the probiotic strain of Lactobacillus plantarum. | The possibility of 3D printing of wheat dough enriched with probiotic cultures that were well preserved during baking was shown. | [36] |

| Application of 3D Printing in the Design of Functional Gluten-Free Dough | ||

| Gluten-free flour preparation was supplied from Sinblat (Sinblat Alimentación Saludable S.L., Foios, Spain), Rosehip (Rosa canina). | The possibility of 3D printing of gluten-free products enriched with rose hips is shown. This study has shown the prospect of 3D printing of bread dough as a method of personalizing food products, which opens up wide opportunities for enrichment. | [37] |

| Study the correlation between the instrumental and sensory evaluation of 3D-printed protein-fortified potato puree | ||

| Dehydrated potato puree, Protein acid hydrolysate soy, Cricket protein powder 70% protein (Acheta domesticus), Egg albumin 75% protein. | This study aims to develop 3D printed products for people with swallowing problems, i.e., to show the possibility of developing individualized nutrition with simultaneous enrichment with protein components. In general, the usefulness of using the instrumental method to characterize food products with modified texture was demonstrated with statistical correlation. | [38] |

| Texture Design and Its Effect on Soft Foods Suitable for Nursing Foods Using Macroscopic 3D Structures Printed by 3D Food Printer | ||

| Protein, Egg white, Milk, Gelling agent, Gelling agent mixture, Auxiliary Ingredient, Powdered oils, Wheat fiber, sucrose. | The research is concerned with studying the effect of macroscopic 3D structures of soft food products printed on a 3D printer on the texture of soft food products for baby food. The possibility of reproducing the texture of printed objects, even for soft foods, is shown. It is established that the texture of soft foods can be controlled by a macroscopic three-dimensional structure created using a 3D food printer. | [39] |

| Rheological properties, dispensing force, and printing fidelity of starchy gels modulated by concentration, temperature, and resting time | ||

| A starchy-gel system. | This study demonstrates the flexibility of 3D-printed food structures, the properties of which can be adjusted by changing the composition of the starch gel food ink. This research on 3D printing starch gels can serve as a basis for the development of food matrices for 3D printing gluten-free food products. | [40] |

| 3D printing properties of Flammulina velutipes polysaccharide-soy protein complex hydrogels | ||

| Soy protein isolate hydrogels, Flammulina velutipes polysaccharide | The research is aimed at improving the 3D printing technology based on soy protein isolate for special consumer groups. The study of food matrices for 3D printing based on polysaccharide-soy protein hydrogels has the potential to be used in the creation of gluten-free food products by 3D printing. | [34] |

| Hot extrusion 3D printing technologies based on starchy food: A review, Carbohydrate Polymers | ||

| Native Starch, Acetylated Starch, Cationic Starch, OSA Starch, Distarch Phosphate, Oxidised Starch | The review aims to show the potential and capabilities of 3D printing starch-based food products and the impact of various additives, design features, and 3D printing process parameters. The study of the rheology, microstructure, and interaction of components and processing methods and 3D printing process parameters helps in the further development and adjustment of the composition and process parameters of gluten-free food products. | [41] |

| Powder properties, rheology, and 3D printing quality of gluten-free blends | ||

| Corn, millet, buckwheat, chia, flaxseed, sweet potato flour, rice protein | The proposed method of cryo-milling, which has not been used before for the preparation of powders for 3D printing, has achieved the best results in 3D printing gluten-free products. The prospects for the development of gluten-free food products by 3D printing and the dependence of the quality of the finished product on the properties and size of raw material powders and the amount of water are shown. | [42] |

| Effect of rheological properties of potato, rice, and corn starches on their hot-extrusion 3D printing behaviors | ||

| Rice starch (RS), potato starch (PS) and corn starch (CS) | This study focuses on the HE-3D printing of starch, and the relationship between rheological properties and printability was established. The results showed that concentrated starches exhibit shear liquefaction and strain sensitivity, which could be printed as HE-3D printing materials. In addition, the parameters τ y and G′ of all the studied samples, which are crucial for maintaining the deposited layers and preserving the printed forms, increased with increasing starch concentration. The correlation between rheological properties and printability of several types of starch was established, which can serve as a basis for the development of gluten-free food products by 3D printing. | [43] |

| 3D extrusion printing and post-processing of fibre-rich snack from indigenous composite flour | ||

| A fiber- and protein-rich composite flour made from local ingredients (millet, roasted gram, green gram, and ajwain seeds) | The mixtures were developed and 3D printed as snacks with the best resolution and stability under optimized printing parameters. Appropriate pretreatment methods were used to optimize the food matrix component without adding additives as structure improvers. The development of gluten-free snacks by 3D printing using a composite flour rich in fiber and protein and without the use of structure enhancers serves as a basis for further research. | [44] |

| Trends in functional food development with three-dimensional (3D) food printing technology: prospects for value-added traditionally processed food products | ||

| This review of the 3D printing process discusses key factors, including the suitability of edible inks for 3D printing purposes, printing parameters, and additional post-printing treatments, that influence the process of developing successful edible 3D structures with the potential to develop structures for dietary/functional foods. | [45] | |

| Countries and Territories | Scholarly Output | Views Count | Field-Weighted Citation Impact (Excl. Self-Citation) | Citation Count (Excl. Self-Citation) |

|---|---|---|---|---|

China China | 208 | 9770 | 2.84 | 5433 |

India India | 71 | 3311 | 2.20 | 923 |

Australia Australia | 70 | 4748 | 3.70 | 3455 |

United States United States | 48 | 2478 | 2.66 | 796 |

Republic of Korea Republic of Korea | 37 | 1272 | 1.54 | 370 |

Canada Canada | 32 | 1275 | 2.22 | 382 |

The Netherlands The Netherlands | 23 | 1455 | 2.16 | 376 |

Singapore Singapore | 21 | 1455 | 2.87 | 633 |

Italy Italy | 20 | 1937 | 2.68 | 482 |

Spain Spain | 19 | 1158 | 1.74 | 473 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lisovska, T.; Harasym, J. 3D Printing Progress in Gluten-Free Food—Clustering Analysis of Advantages and Obstacles. Appl. Sci. 2023, 13, 12362. https://doi.org/10.3390/app132212362

Lisovska T, Harasym J. 3D Printing Progress in Gluten-Free Food—Clustering Analysis of Advantages and Obstacles. Applied Sciences. 2023; 13(22):12362. https://doi.org/10.3390/app132212362

Chicago/Turabian StyleLisovska, Tetiana, and Joanna Harasym. 2023. "3D Printing Progress in Gluten-Free Food—Clustering Analysis of Advantages and Obstacles" Applied Sciences 13, no. 22: 12362. https://doi.org/10.3390/app132212362

APA StyleLisovska, T., & Harasym, J. (2023). 3D Printing Progress in Gluten-Free Food—Clustering Analysis of Advantages and Obstacles. Applied Sciences, 13(22), 12362. https://doi.org/10.3390/app132212362