Numerical and Analytical Determination of Rockburst Characteristics: Case Study from Polish Deep Copper Mine

Abstract

:1. Introduction

2. Recent Advances in the Evaluation of Rockburst Characteristics

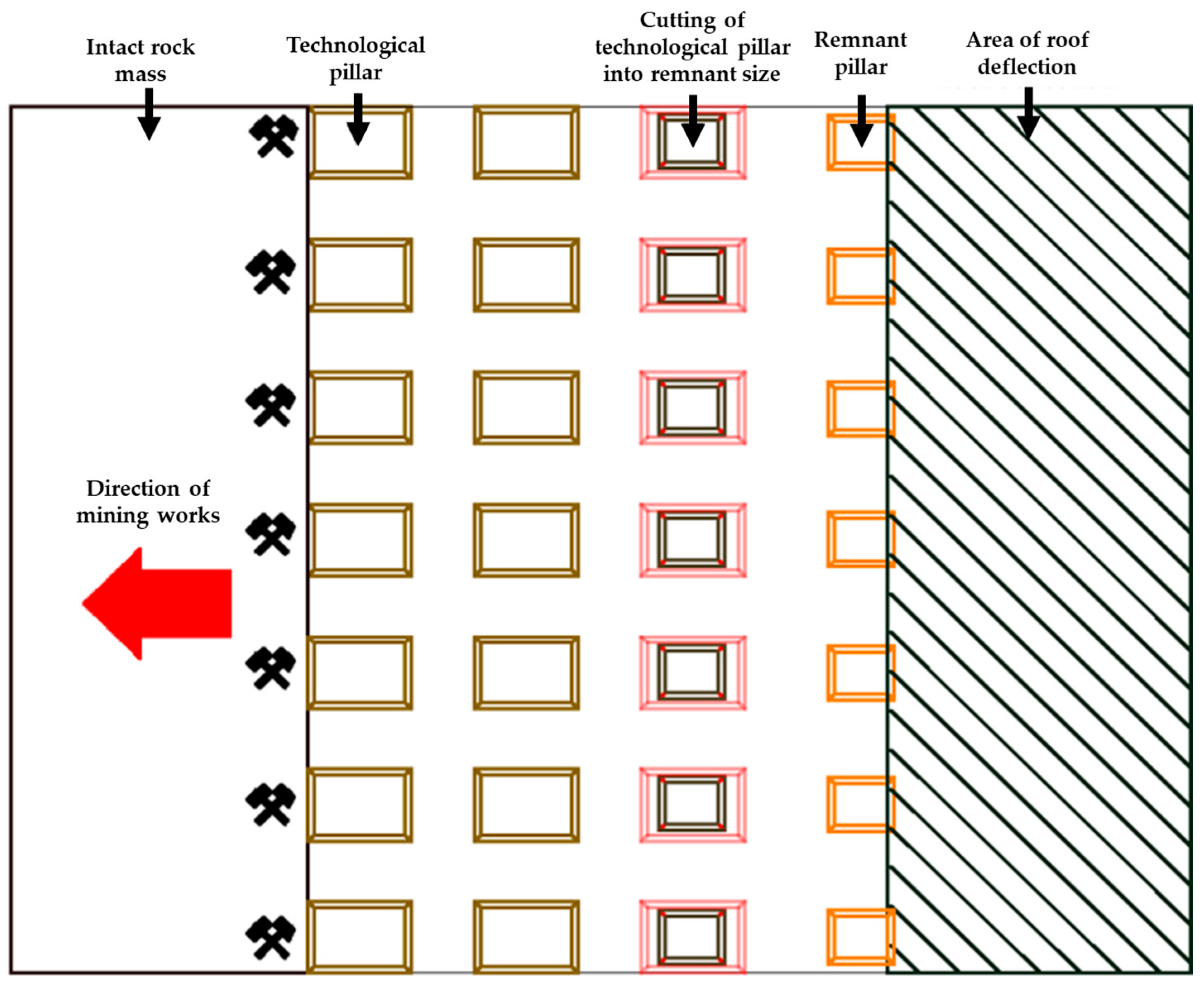

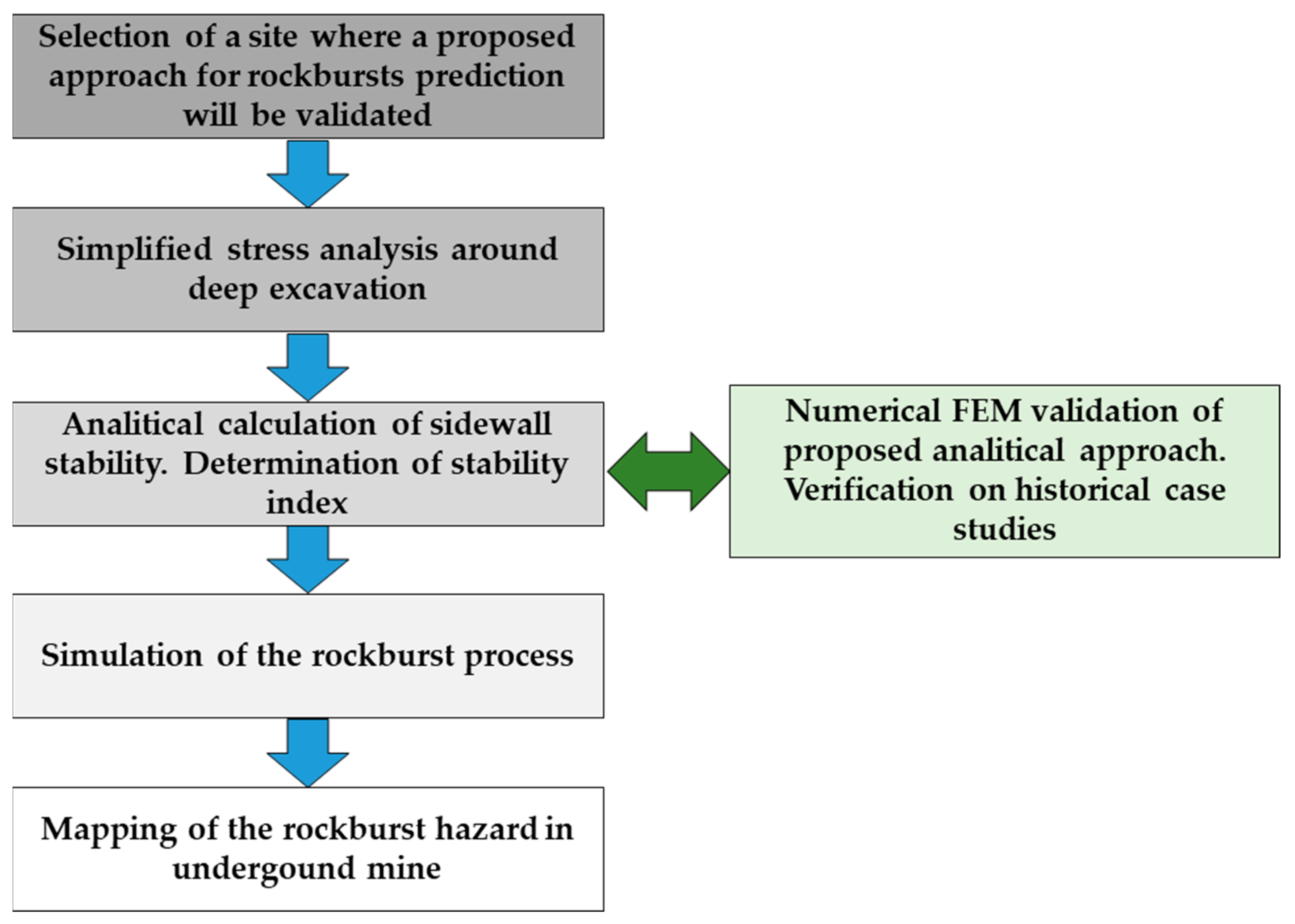

3. Material and Methods

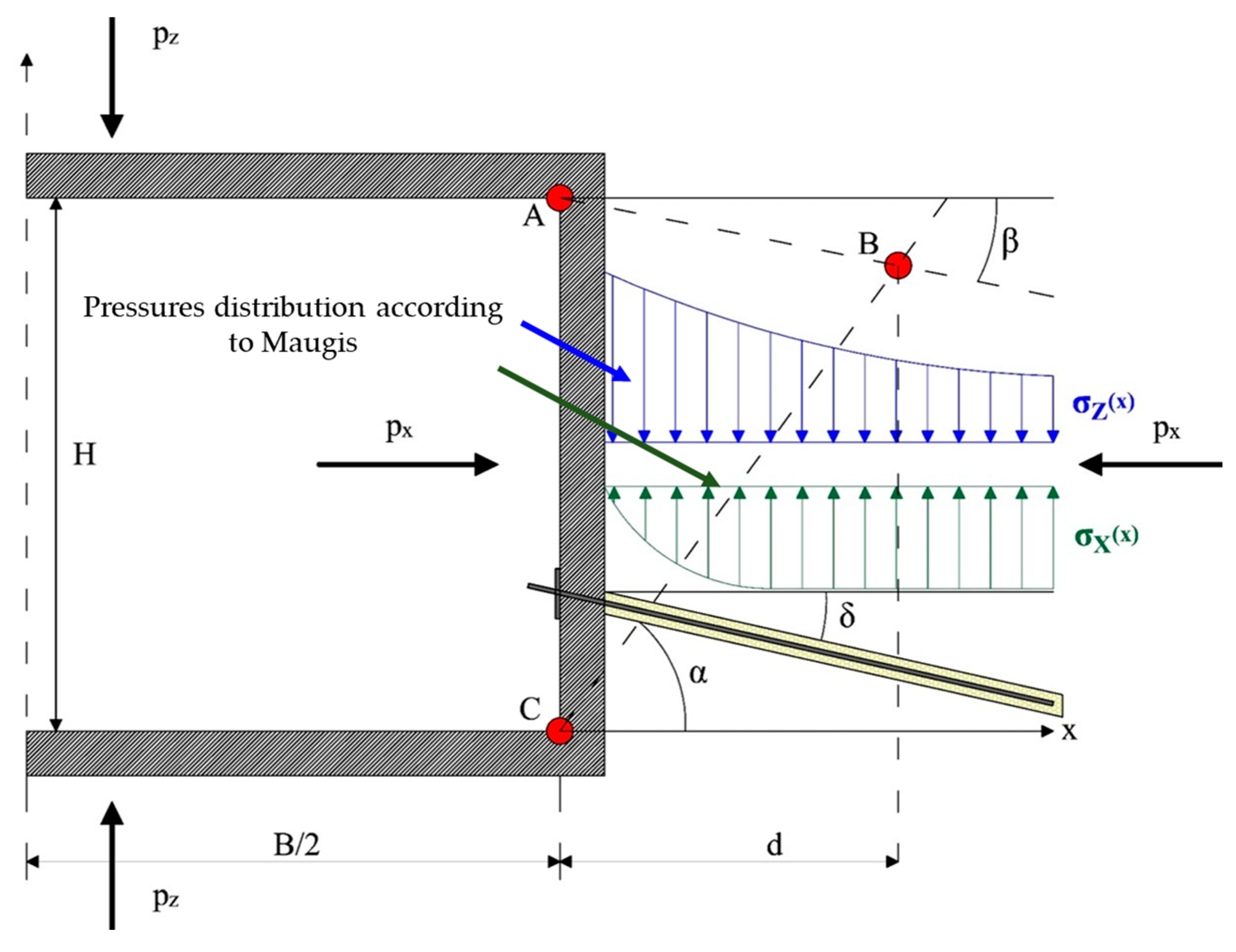

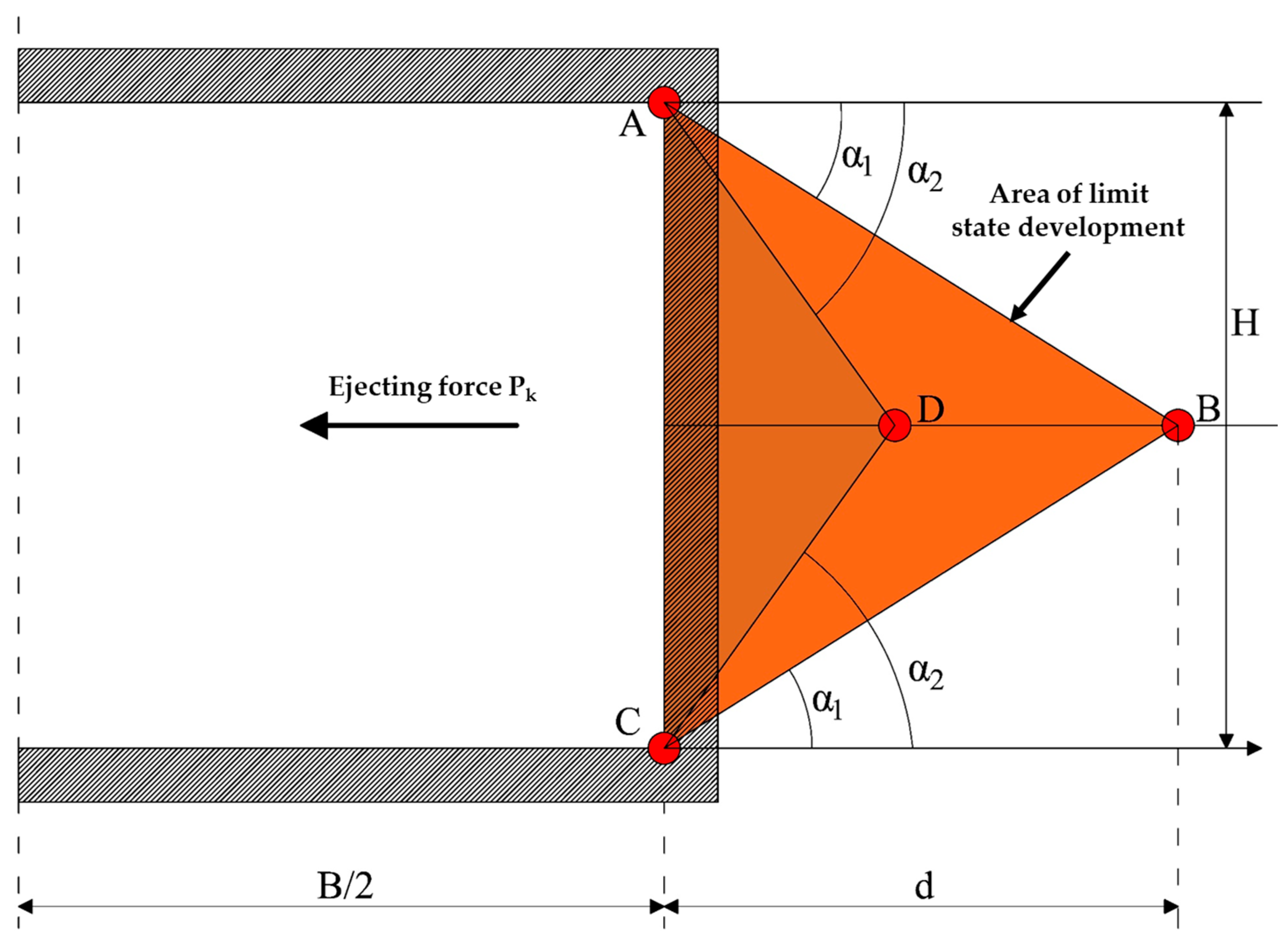

3.1. Analytical Solution

3.2. Numerical Calculations

- the galleries’ rectangular cross-section size: B × H = 6 m × 3 m;

- overburden vertical pressure pz = 20 MPa;

- strength parameters of the rock mass: cohesion c = 8 MPa, angle of internal friction ϕ = 35°;

- deformation parameters of the rock mass: modulus of deformation: E = 40 GPa, Poisson’s ratio ν = 0.2 (px = 5 MPa).

4. Results

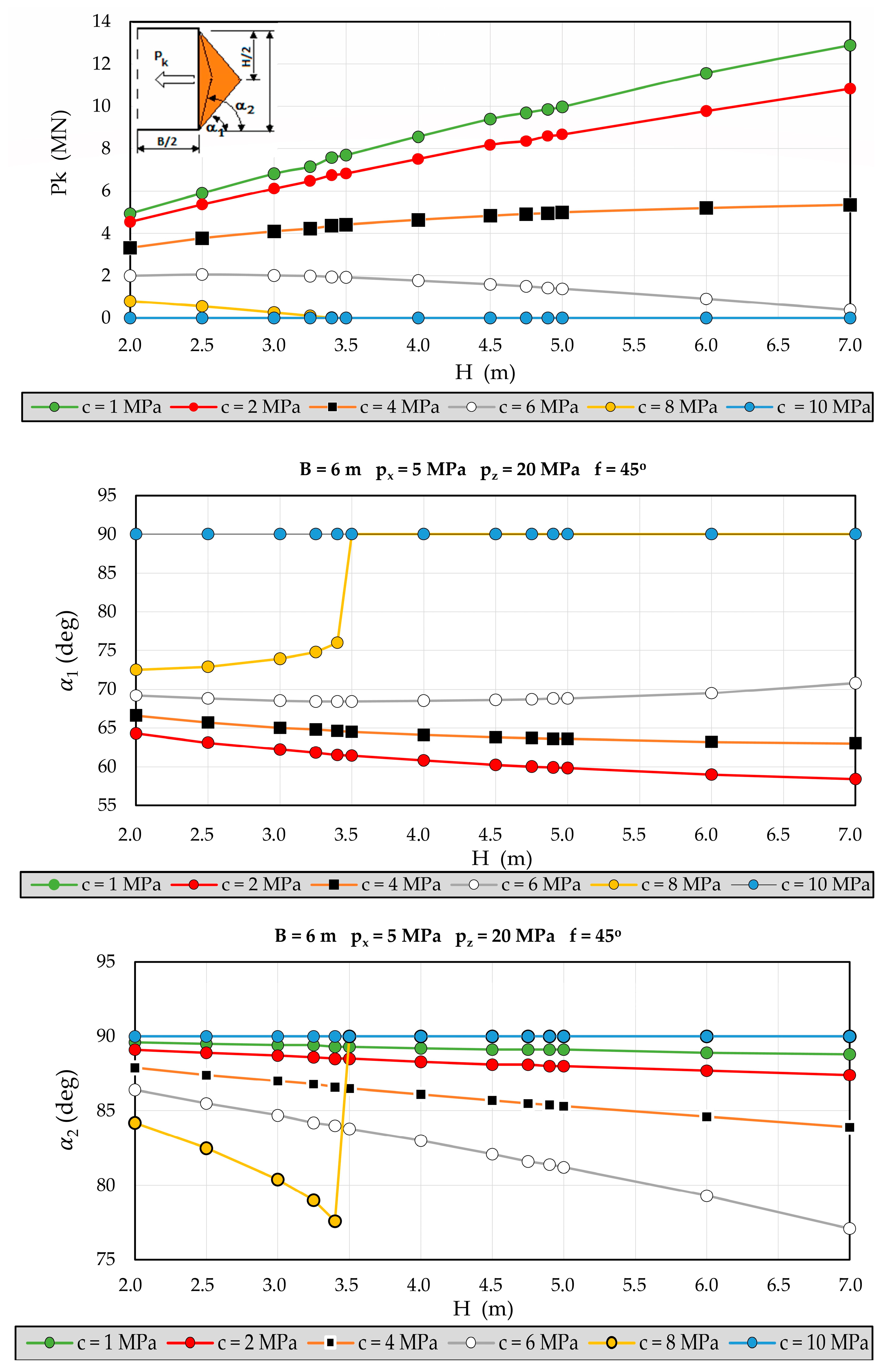

4.1. Calculation of Ejecting Force Pk and Angles

4.2. FEM Validation Resuts and Identification of Rockburst-Prone Areas

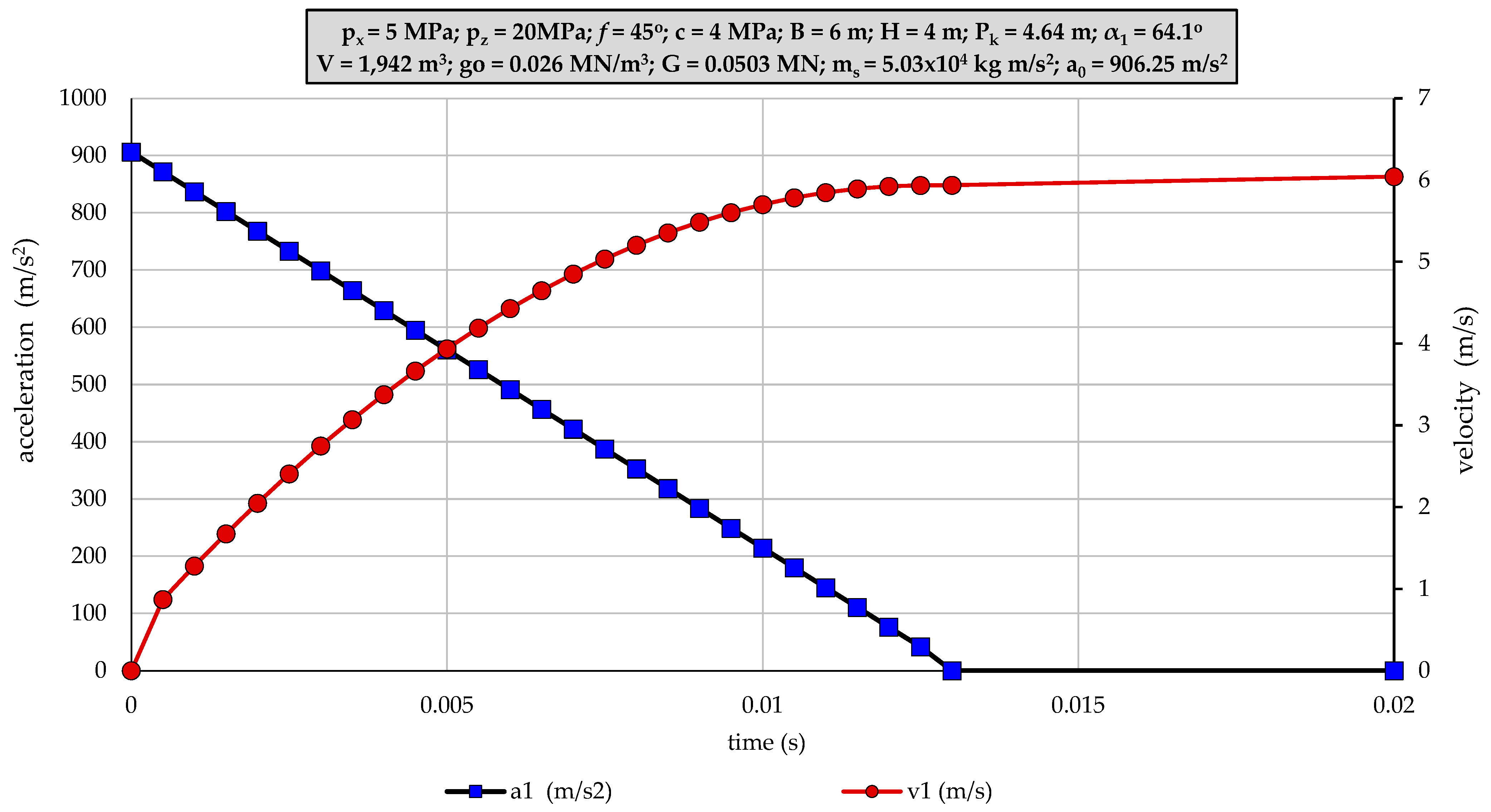

4.3. Simulation of the Rockburst Process

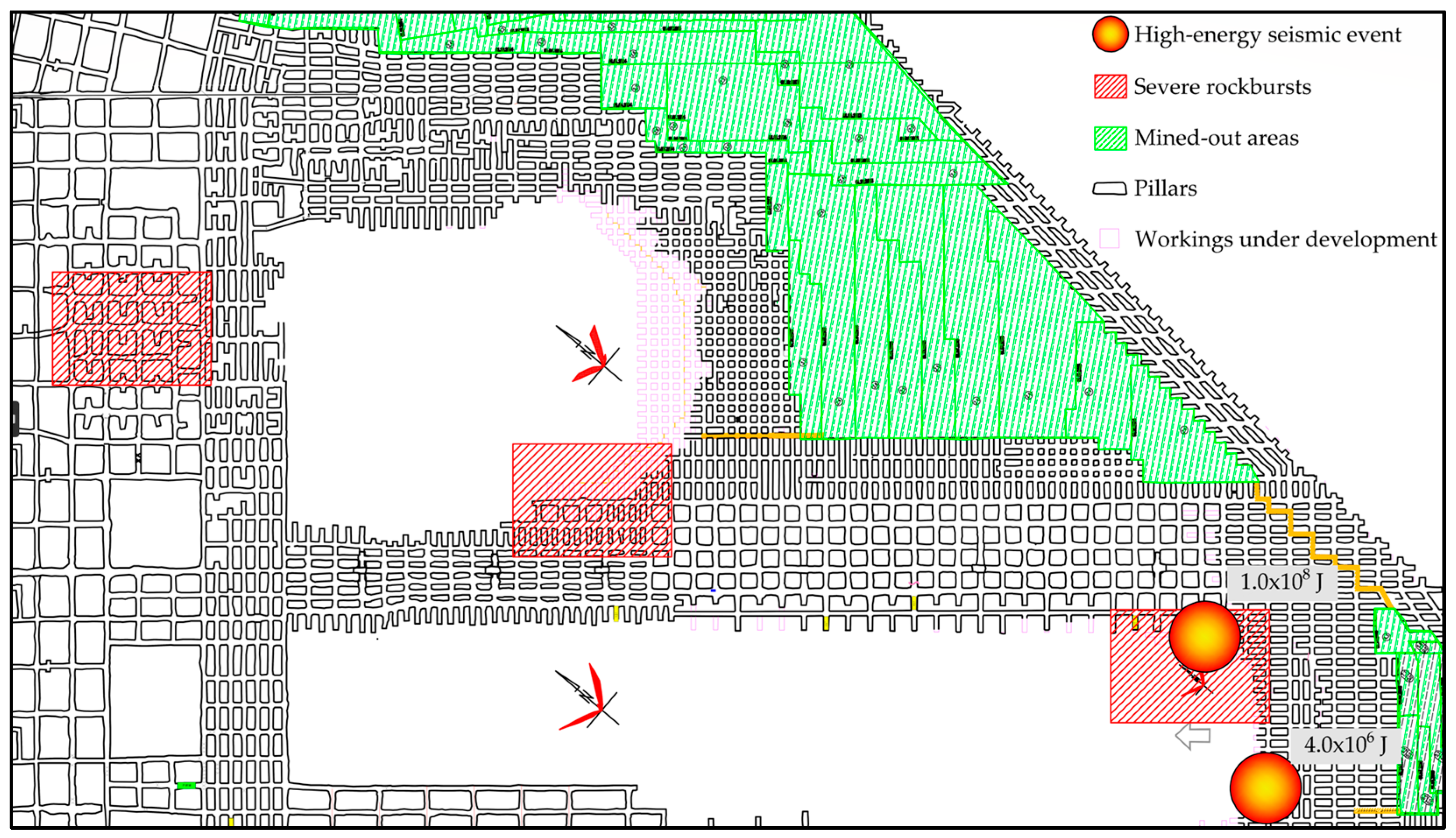

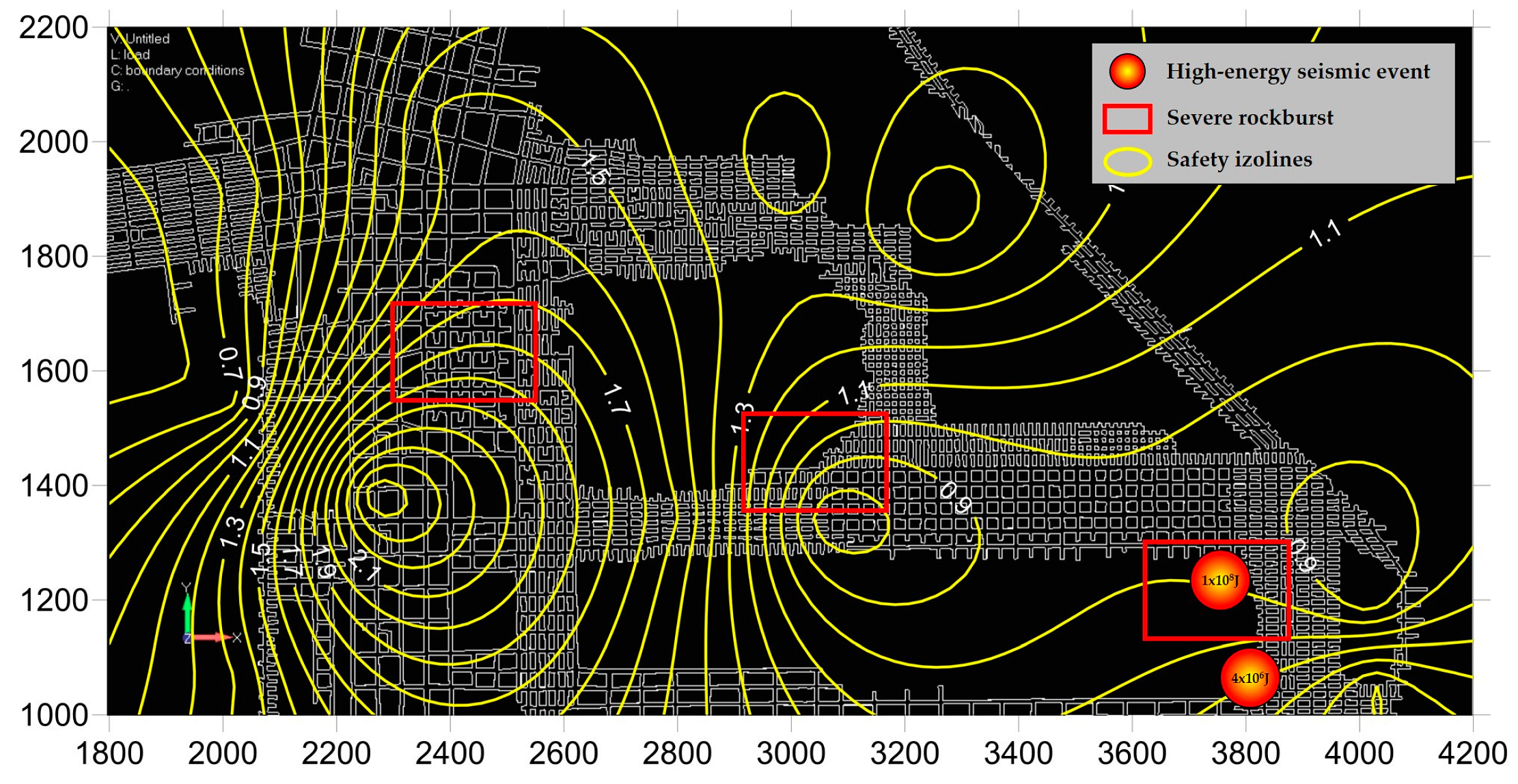

4.4. Identification of Rockburst-Prone Mine Areas

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ghorbani, M.; Shahriar, K.; Sharifzadeh, M.; Masoudi, R. A Critical Review on the Developments of Rock Support Systems in High Stress Ground Conditions. Int. J. Min. Sci. Technol. 2020, 30, 555–572. [Google Scholar] [CrossRef]

- Fuławka, K.; Pytel, W.; Mertuszka, P. The Effect of Selected Rockburst Prevention Measures on Seismic Activity—Case Study from the Rudna Copper Mine. J. Sustain. Min. 2021, 17, 1–10. [Google Scholar] [CrossRef]

- Ptak, M.; Podolska, P.; Podolski, R. Challenges for Science: The Exploitation of Deep Deposits. E3S Web Conf. 2018, 71, 00008. [Google Scholar] [CrossRef]

- Cichy, T.; Prusek, S.; Świątek, J.; Apel, D.B.; Pu, Y. Use of Neural Networks to Forecast Seismic Hazard Expressed by Number of Tremors per Unit of Surface. Pure Appl. Geophys. 2020, 177, 5713–5722. [Google Scholar] [CrossRef]

- Pu, Y.; Apel, D.B.; Prusek, S.; Walentek, A.; Cichy, T. Back-Analysis for Initial Ground Stress Field at a Diamond Mine Using Machine Learning Approaches. Nat. Hazards 2021, 105, 191–203. [Google Scholar] [CrossRef]

- Blake, W.; Hedley, D.G.F. Rockbursts: Case Studies from North American Hard-Rock Mines; Society for Mining, Metallurgy, and Exploration: Littleton, CO, USA, 2003; ISBN 9780873352321. [Google Scholar]

- Mark, C. Coal Bursts in the Deep Longwall Mines of the United States. Int. J. Coal Sci. Technol. 2016, 3, 1–9. [Google Scholar] [CrossRef]

- Zhang, W.; Feng, X.-T.; Xiao, Y.-X.; Feng, G.-L.; Yao, Z.-B.; Hu, L.; Niu, W.-J. A Rockburst Intensity Criterion Based on the Geological Strength Index, Experiences Learned from a Deep Tunnel. Bull. Eng. Geol. Environ. 2020, 79, 3585–3603. [Google Scholar] [CrossRef]

- Pan, J.; Ren, F.; Cai, M. Effect of Joint Density on Rockburst Proneness of the Elastic-Brittle-Plastic Rock Mass. Shock Vib. 2021, 2021, 5574325. [Google Scholar] [CrossRef]

- Wang, J.; Apel, D.B.; Pu, Y.; Hall, R.; Wei, C.; Sepehri, M. Numerical Modeling for Rockbursts: A State-of-the-Art Review. J. Rock Mech. Geotech. Eng. 2021, 13, 457–478. [Google Scholar] [CrossRef]

- Małkowski, P.; Niedbalski, Z. A Comprehensive Geomechanical Method for the Assessment of Rockburst Hazards in Underground Mining. Int. J. Min. Sci. Technol. 2020, 30, 345–355. [Google Scholar] [CrossRef]

- Zhou, J.; Li, X.; Mitri, H.S. Evaluation Method of Rockburst: State-of-the-Art Literature Review. Tunn. Undergr. Space Technol. 2018, 81, 632–659. [Google Scholar] [CrossRef]

- Farhadian, H. A New Empirical Chart for Rockburst Analysis in Tunnelling: Tunnel Rockburst Classification (TRC). Int. J. Min. Sci. Technol. 2021, 31, 603–610. [Google Scholar] [CrossRef]

- Wojtecki, Ł.; Mendecki, M.J.; Gołda, I.; Zuberek, W.M. The Seismic Source Parameters of Tremors Provoked by Long-Hole Destress Blasting Executed During the Longwall Mining of a Coal Seam Under Variable Stress Conditions. Pure Appl. Geophys. 2020, 177, 5723–5739. [Google Scholar] [CrossRef]

- Wojtecki, Ł.; Konicek, P. Estimation of Active Rockburst Prevention Effectiveness during Longwall Mining under Disadvantageous Geological and Mining Conditions. J. Sustain. Min. 2016, 15, 1–7. [Google Scholar] [CrossRef]

- Tannant, D.D.; McDowell, G.M.; Brummer, R.K.; Kaiser, P.K. Ejection velocities measured during a rock burst simulation experiment. In Rockbursts and Seismicity in Mines 93, Proceedings of the 3rd International Symposium, Kingston, ON, Canada, 16–18 August 1993; Balkema: Rotterdam, The Netherlands, 1993; pp. 129–133. [Google Scholar]

- He, M.; Cheng, T.; Qiao, Y.; Li, H. A Review of Rockburst: Experiments, Theories, and Simulations. J. Rock Mech. Geotech. Eng. 2023, 15, 1312–1353. [Google Scholar] [CrossRef]

- Qiu, S.; Feng, X.; Zhang, C.; Xiang, T. Estimation of Rockburst Wall-Rock Velocity Invoked by Slab Flexure Sources in Deep Tunnels. Can. Geotech. J. 2014, 51, 520–539. [Google Scholar] [CrossRef]

- Barton, N. The Shear Strength of Rock and Rock Joints. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1976, 13, 255–279. [Google Scholar] [CrossRef]

- Esterhuizen, G.S. Extending Empirical Evidence through Numerical Modelling in Rock Engineering Design. J. South. Afr. Inst. Min. Metall. 2014, 114, 755–764. [Google Scholar]

- Terzaghi, K. Theoretical Soil Mechanics; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1943; ISBN 9780470172766/9780471853053. [Google Scholar]

- Malan, D.; Napier, J. A Limit Equilibrium Fracture Zone Model to Investigate Seismicity in Coal Mines. Int. J. Min. Sci. Technol. 2018, 28, 745–753. [Google Scholar] [CrossRef]

- Sengani, F.; Mulenga, F. Application of Limit Equilibrium Analysis and Numerical Modeling in a Case of Slope Instability. Sustainability 2020, 12, 8870. [Google Scholar] [CrossRef]

- Ohnishi, Y.; Nishiyama, S.; Sasaki, T. Development and application of discontinuous deformation analysis. In Rock Mechanics in Underground Construction; World Scientific: Singapore, 2006; pp. 59–70. [Google Scholar]

- Zhao, J.; Xiao, M.; Chen, J.; Li, D. Explicit Dynamic DDA Method Considering Dynamic Contact Force. Shock Vib. 2016, 2016, 7431245. [Google Scholar] [CrossRef]

- Fan, H.; Huang, D.; Wang, G.; Wang, J. Discontinuous Deformation Analysis for SH-Body. Comput. Geotech. 2020, 117, 103234. [Google Scholar] [CrossRef]

- Wu, W.; Zhu, H.; Lin, J.-S.; Zhuang, X.; Ma, G. Tunnel Stability Assessment by 3D DDA-Key Block Analysis. Tunn. Undergr. Space Technol. 2018, 71, 210–214. [Google Scholar] [CrossRef]

- Lin, J.; Zuo, Y.; Wang, J.; Zheng, L.; Chen, B.; Sun, W.; Liu, H. Stability Analysis of Underground Surrounding Rock Mass Based on Block Theory. J. Cent. South Univ. 2020, 27, 3040–3052. [Google Scholar] [CrossRef]

- Hoek, E. Practical Rock Engineering. RocScience. 2007. Available online: http://www.rocscience.com/hoek/PracticalRockEngineering.asp (accessed on 21 July 2023).

- Billaux, D.; Detournay, C.; Hart, R.; Rachez, X. (Eds.) FLAC and Numerical Modeling in Geomechanics 2001; CRC Press: Boca Raton, FL, USA, 2020; ISBN 9781000099607. [Google Scholar]

- Khabbaz, H.; Fatahi, B.; Nucifora, C. Finite Element Methods against Limit Equilibrium Approaches for Slope Stability Analysis. In Proceedings of the 11th Australia—New Zealand Conference on Geomechanics—Ground Engineering in a Changing World (ANZ 2012), Melbourne, Australia, 14–18 July 2012; Geomechanical Society: Sydney, Australia; New Zealand Geotechnical Society: Wellington, New Zealand, 2012; ISBN 9780646543017. [Google Scholar]

- Blake, W. Rockburst mechanics. Q. Colo. Sch. Mines 1972, 67, 1–64. [Google Scholar]

- Tajduś, A.; Cieślik, J.; Tajduś, K. Rockburst Hazard Assessment in Bedded Rock Mass: Laboratory Tests of Rock Samples and Numerical Calculations. Arch. Min. Sci. 2014, 59, 591–608. [Google Scholar] [CrossRef]

- Fulawka, K.; Szumny, M.; Pytel, W.; Mertuszka, P. Conceptual Design of Underground Laboratory under Dynamic Load Condition in Deep Copper Mine. In Proceedings of the 22nd EGU General Assembly, Online, 4–8 May 2020. [Google Scholar]

- Fulawka, K.; Pytel, W.; Mertuszka, P.; Szumny, M. Finite Element Method-Based Geomechanical Risk Assessment of Underground Laboratory Located in the Deep Copper Mine. In Proceedings of the 23rd EGU General Assembly, Online, 19–30 April 2021. [Google Scholar]

- Maugis, D. Stresses and Displacements around Cracks and Elliptical Cavities: Exact Solutions. Eng. Fract. Mech. 1992, 43, 217–255. [Google Scholar] [CrossRef]

- Exadaktylos, G.E.; Stavropoulou, M.C. A closed-form elastic solution for stresses and displacements around tunnels. Int. J. Rock Mech. Min. Sci. 2002, 39, 905–916. [Google Scholar] [CrossRef]

- Kargar, A.R.; Rahmannejad, R.; Hajabasi, M.A. A semi-analytical elastic solution for stress field of lined non-circular tunnels at great depth using complex variable mrthod. Int. J. Solids Struct. 2014, 51, 1475–1482. [Google Scholar] [CrossRef]

- Ye, Z.K.; Ai, Z.Y. A novel complex variable solution for the stress and displacement fields around a shallow non-circular tunnel. Comput. Geotech. 2023, 164, 105797. [Google Scholar] [CrossRef]

- RocSciecnce. RS2 Finite Element Analysis for Excavations—Rocscience. 2016. Available online: https://www.rocscience.com/rocscience/products/rs2 (accessed on 21 September 2023).

- Hoek, E.; Diederichs, M.S. Empirical Estimation of Rock Mass Modulus. Int. J. Rock Mech. Min. Sci. 2006, 43, 203–215. [Google Scholar] [CrossRef]

- NEi Software. NEi Nastran Reference Manual, Version 9.2; Trafford Publishing: Bloomington, IN, USA, 2009.

- Ortlepp, W.D. The Design of Support for the Containment of Rockburst Damage in Tunnels—An Engineering Approach. In Proceedings of the International Symposium on Rock Support in Mining and Underground Construction, Sudbury, ON, Canada, 16–19 June 1992. [Google Scholar]

- Nussbaumer, M.M. A Comprehensive Review on Rock Burst. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2000. [Google Scholar]

- Pytel, W. Geomechanical Problems of Ground Support Selection for Mine Excavations; KGHM Cuprum: Wrocław, Poland, 2012; 423p. (In Polish) [Google Scholar]

- Lasocki, S.; Orlecka-Sikora, B.; Mutke, G.; Pytel, W.; Rudzinski, L.; Markowski, P.; Piasecki, P. A catastrophic event in Rudna copper-ore mine in Poland on 29 November, 2016: What, how and why. In Proceedings of the Ninth International Symposium on Rockbursts and Seismicity in Mines, RaSiM9, Santiago, Chile, 15–17 November 2017. [Google Scholar]

| Reference Result Values | Increment of the Basic Parameters | |||

|---|---|---|---|---|

| ΔB = 1 m | Δpx = 1 MPa | Δpz = 1 MPA | Δφ = 1 deg. | |

| Pk = 4.64 MN | 0.375 MN/m | −0.167 MN/MPa | 1.13 MN/MPa | −0.42 MN/deg. |

| α1 = 64.1 deg. | 0.45 deg./m | 0.260 deg./MPa | −0.52 deg./MPa | 0.82 deg./deg. |

| α2 = 86.1 deg. | 0.35 deg./m | −0.12/deg./MPa | 0.32 deg./MPa | −0.02 deg./deg. |

| Model | Cohesion c (MPa) | Angle of Internal Friction ϕ (deg) |

|---|---|---|

| 1 | 8 | 35 |

| 2 | 4 | 35 |

| 3 | 8 | 25 |

| 4 | 4 | 25 |

| No. | Proposed LEM Approach | FEM Solution | Correlation | |||||

|---|---|---|---|---|---|---|---|---|

| 1LEM (deg.) | 2LEM (deg.) | 1FEM (deg.) | 2FEM (deg.) | 1FEM | 2FEM | |||

| 1 | 0.84 | 0.89 | 56.9 | 78.8 | 51 | 79 | 0.86 | 0.97 |

| 2 | 0.55 | 0.69 | 49.3 | 85.4 | 47 | 84 | ||

| 3 | 0.73 | 0.81 | 47.8 | 79.8 | 50 | 79 | ||

| 4 | 0.47 | 0.62 | 40.9 | 85.5 | 38 | 86 | ||

| Type of Rock | Sandstones | Anhydrites | Grainy Dolomites and Limestones | |

|---|---|---|---|---|

| UCS (MPa) | 71–142 | 100–141 | 151–224 | |

| GSI | 45–70 | 60–75 | 75–90 | |

| Angle of internal friction (°) | Triaxial tests | 64–67 | 61–65 | 64–69 |

| Reduced using GSI | 31.5–44.0 | 36.4–44.2 | 46.2–62.7 | |

| Cohesion c (MPa) | Triaxial tests | 17.5–20.5 | 15.8–18.8 | 18.0–22.5 |

| Reduced using GSI | 2.8–11.6 | 5.5–11.4 | 13.2–30.1 | |

| Stress ratio | 0.14–0.60 | 0.27–0.80 | 0.33–1.39 | |

| Horizontal stress px (MPa) | 4–12 | 6–30 | 8–40 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pytel, W.; Fuławka, K.; Pałac-Walko, B.; Mertuszka, P. Numerical and Analytical Determination of Rockburst Characteristics: Case Study from Polish Deep Copper Mine. Appl. Sci. 2023, 13, 11881. https://doi.org/10.3390/app132111881

Pytel W, Fuławka K, Pałac-Walko B, Mertuszka P. Numerical and Analytical Determination of Rockburst Characteristics: Case Study from Polish Deep Copper Mine. Applied Sciences. 2023; 13(21):11881. https://doi.org/10.3390/app132111881

Chicago/Turabian StylePytel, Witold, Krzysztof Fuławka, Bogumiła Pałac-Walko, and Piotr Mertuszka. 2023. "Numerical and Analytical Determination of Rockburst Characteristics: Case Study from Polish Deep Copper Mine" Applied Sciences 13, no. 21: 11881. https://doi.org/10.3390/app132111881

APA StylePytel, W., Fuławka, K., Pałac-Walko, B., & Mertuszka, P. (2023). Numerical and Analytical Determination of Rockburst Characteristics: Case Study from Polish Deep Copper Mine. Applied Sciences, 13(21), 11881. https://doi.org/10.3390/app132111881