Eco-Design and Additive Manufacturing of an Innovative Double-Casing Pedometer for Oestrus Detection in Dairy Cow †

Abstract

:1. Introduction

2. Materials and Methods

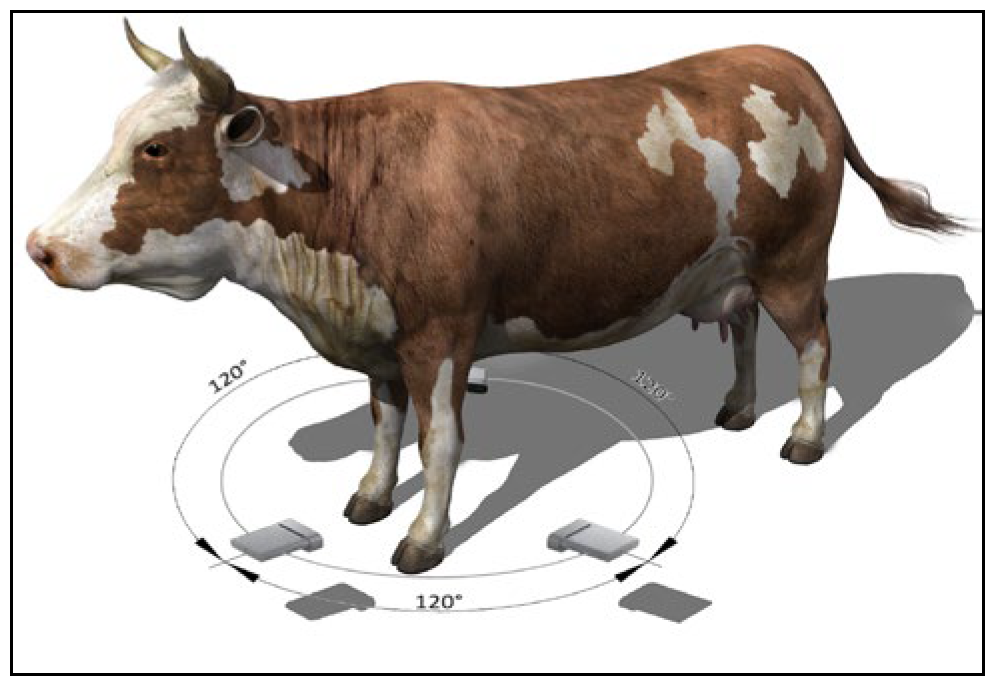

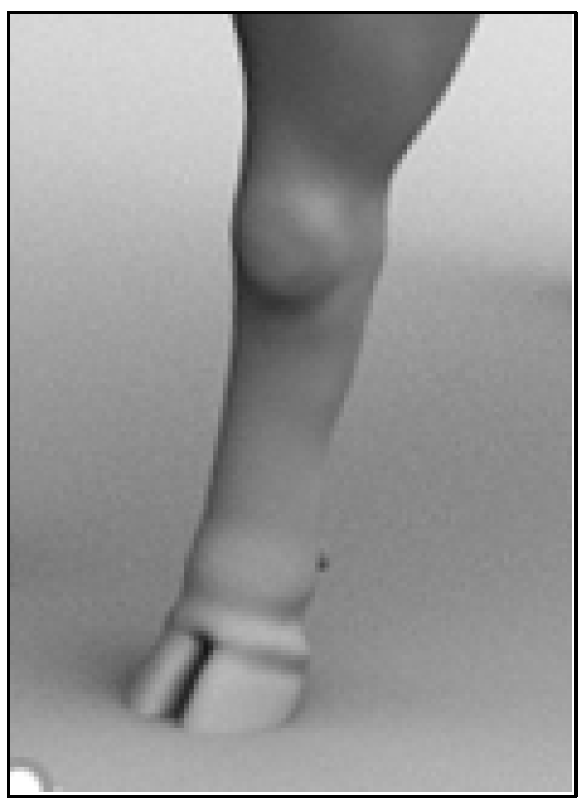

2.1. Cow Foreleg Anatomy Acquisition

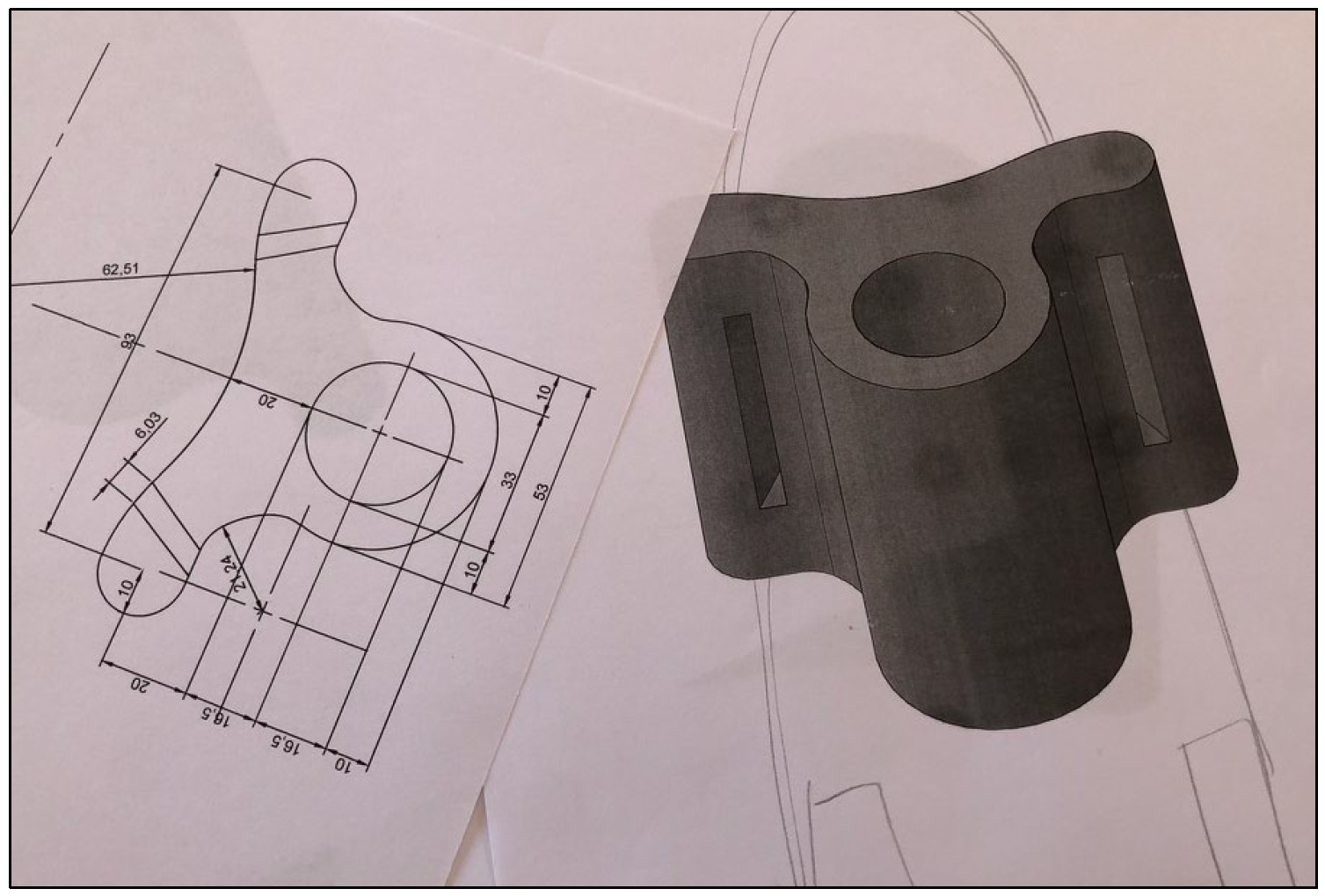

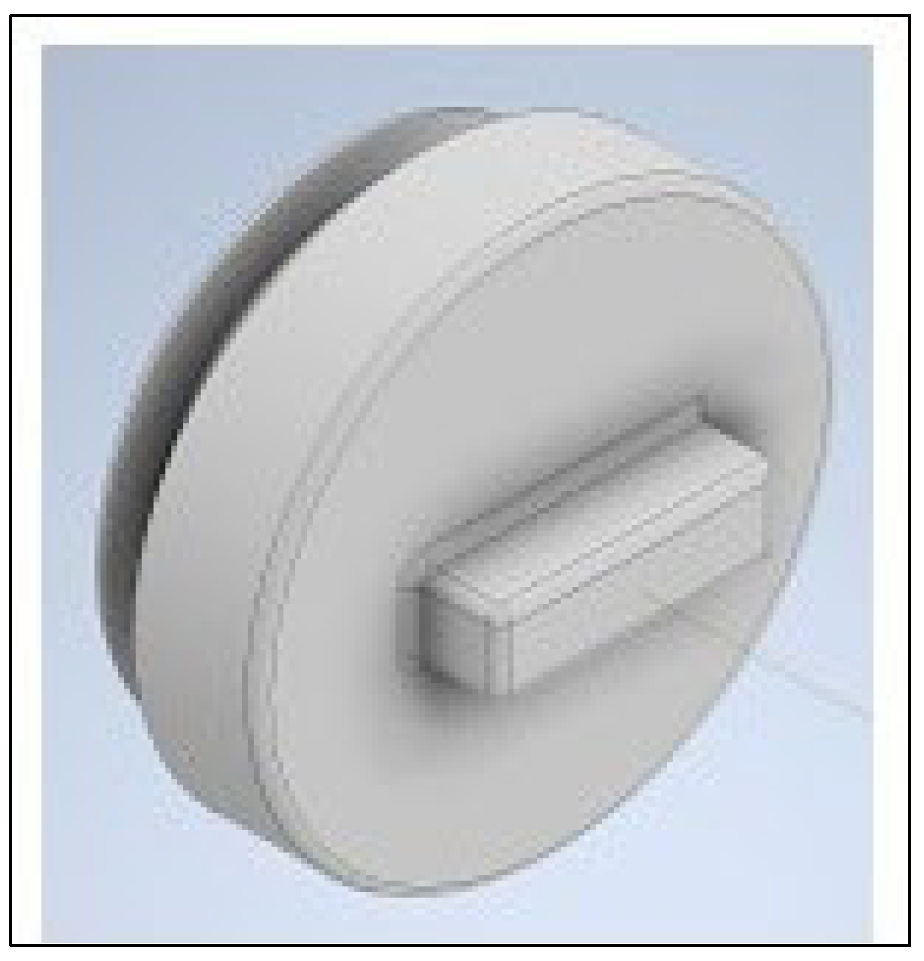

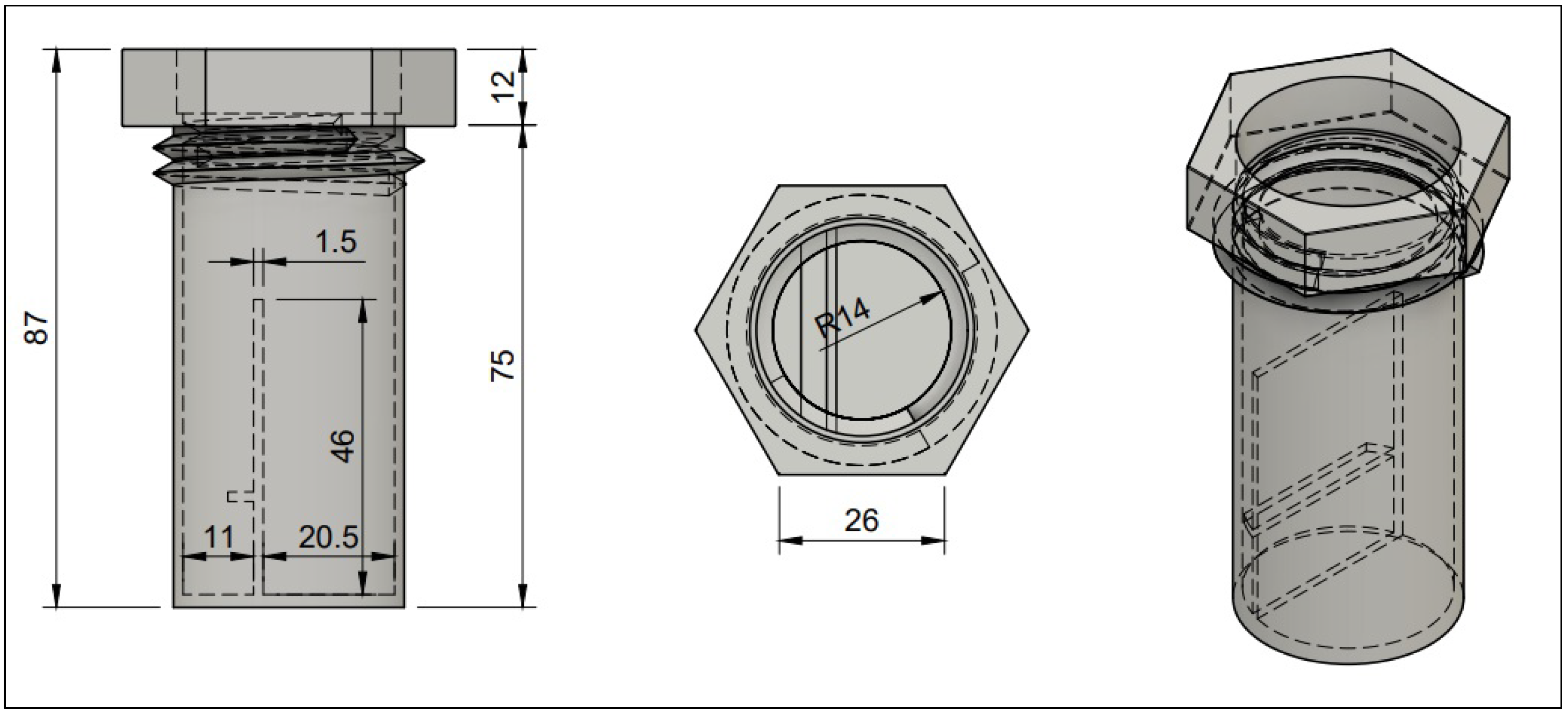

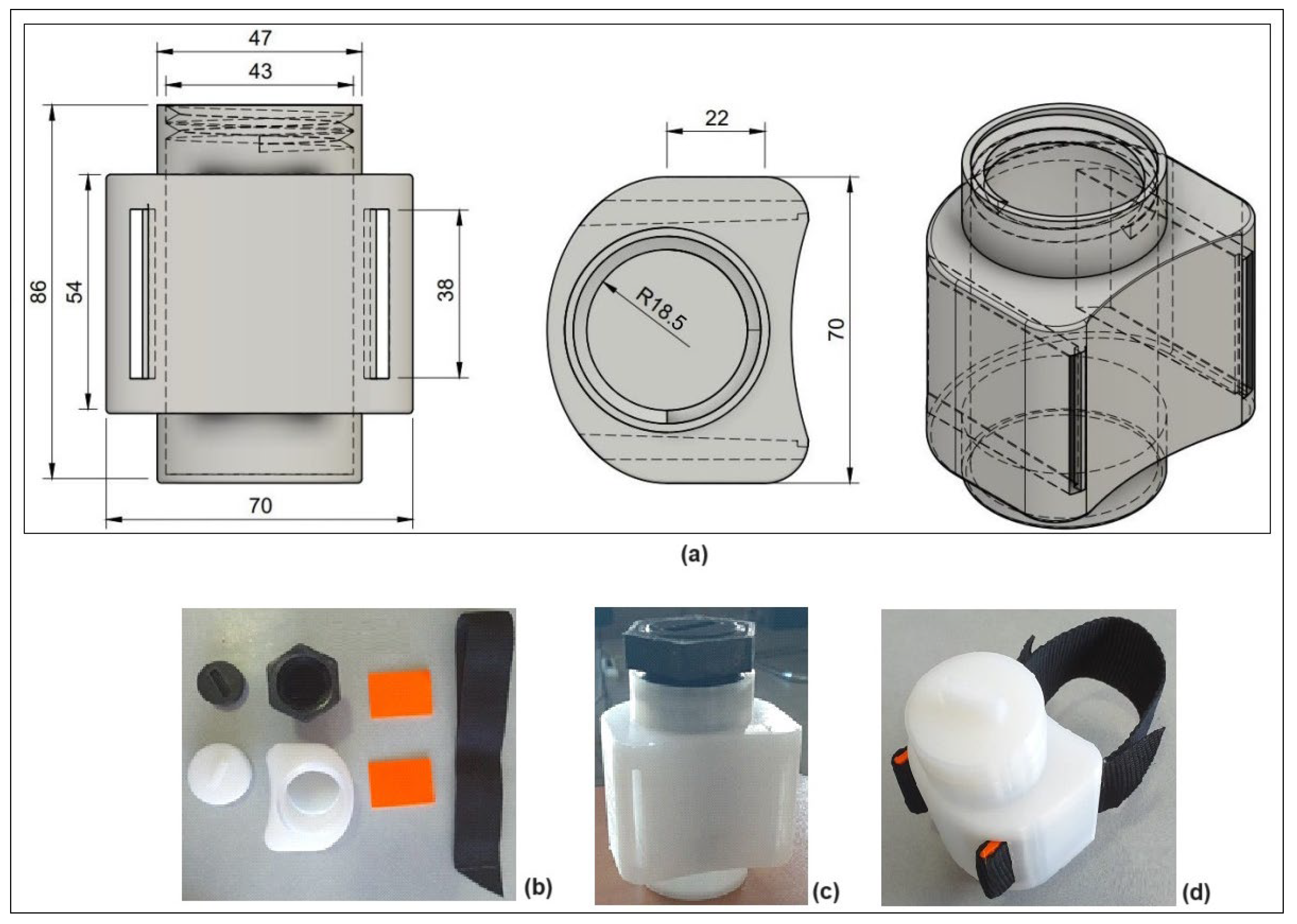

2.2. Pedometer Shape Design

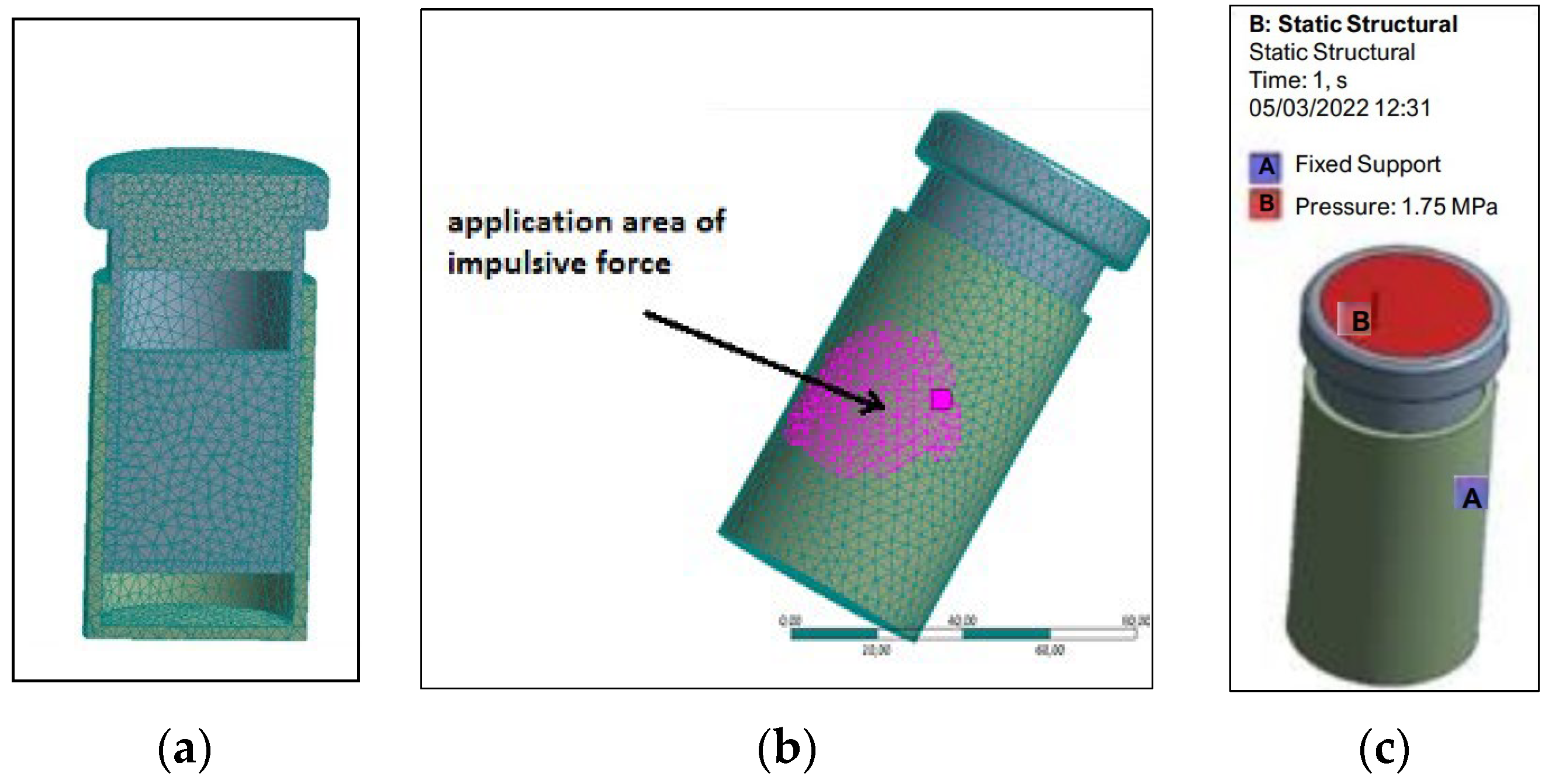

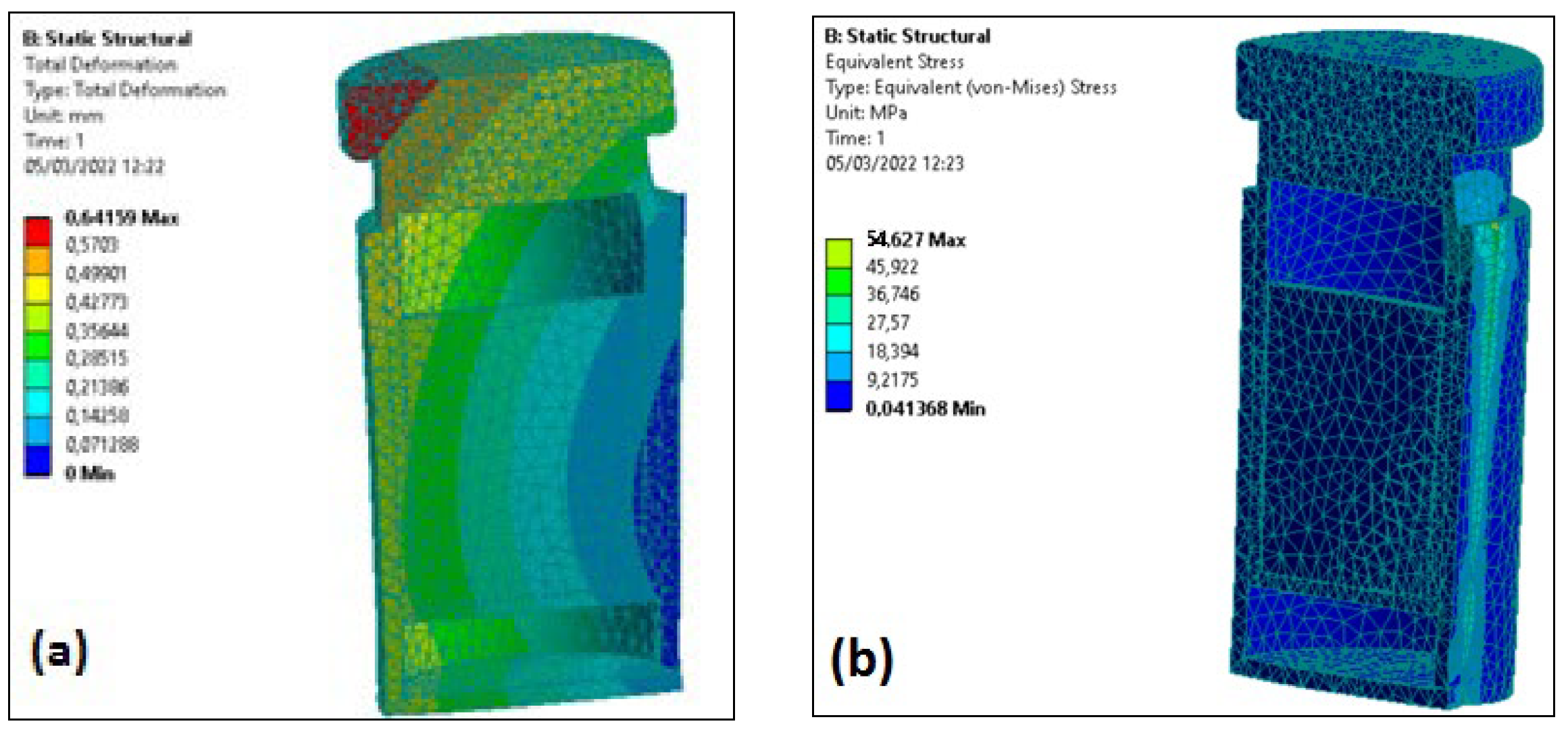

2.3. Finite Element Analyses

- Double extrusion ready for composites;

- Filtering capacity of ultrafine particles equal to 95%;

- Storage of the reels of material with controlled humidity;

- Compatibility with over 90 materials.

2.4. Pedometer Material Choice

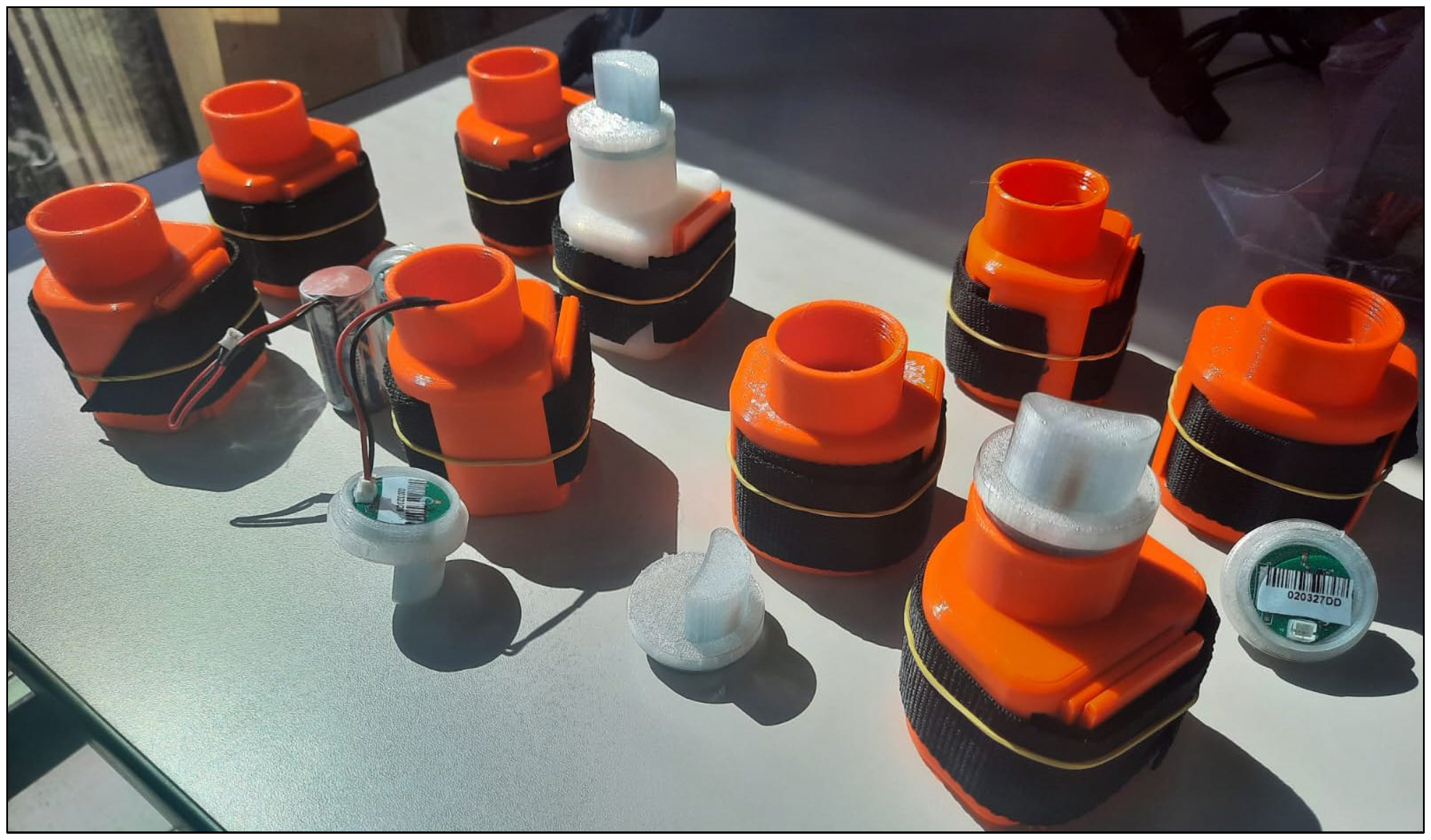

2.5. The Hardware of the Stand-Alone Smart Pedometer (SASP)

3. Functional Evaluation and Coupling Tolerances Assignment

4. Main Outcomes from Manufacturing Adoptions

5. Discussion and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mottram, T. Animal board invited review: Precision livestock farming for dairy cows with a focus on oestrus detection. Anim. 2015, 10, 1575–1584. [Google Scholar] [CrossRef]

- Hurnik, J.F.; Webster, A.B.; DeBoer, S. An investigation of skin temperature differentials in relation to estrus in dairy cattle us-ing a thermal infrared scanning technique. J. Anim. Sci 1985, 61, 1095–1102. [Google Scholar] [CrossRef] [PubMed]

- Perez Marquez, H.J.; Ambrose, D.J.; Schaefer, A.L.; Cook, N.J.; Bench, C.J. Infrared thermography and behavioral biometrics associated with estrus indicators and ovulation in estrus-synchronized dairy cows housed in tiestalls. Int. J. Dairy Sci 2019, 102, 4427–4440. [Google Scholar] [CrossRef]

- Blanchard, T.; Kenney, D.; Garcia, M.; Kristula, M.; Wolfer, J.; Haenlein, G. Relationship of declines in grain consumption and milk-yield to estrus in dairy-cattle. Theriogenology 1987, 28, 407–415. [Google Scholar] [CrossRef] [PubMed]

- Schofield, S.A.; Phillips, C.J.C.; Owens, A.R. Variation in the milk-production, activity rate and electrical-impedance of cervical-mucus over the estrus period of dairy cows. Anim. Reprod. Sci 1991, 24, 231–248. [Google Scholar] [CrossRef]

- Muxlov, J. Importance of estrus detection on dairy farms. Afimilk, 7 April 2005. [Google Scholar]

- Firk, R.; Stamer, E.; Junge, W.; Krieter, J. Automation of oestrus detection in dairy cows: A review. Livest. Prod. Sci. 2002, 75, 219–232. [Google Scholar] [CrossRef]

- Wendl, G.; Klindtworth, K.; Wagner, M. Einsatz von Aktivitatssensoren und injizierbaren Transpondern mit integ-riertem Tem-peratursensor in der Milchviehhaltung. In Proceedings of the 46th Annual Meeting of the European Association of Animal Production, Prague, Czech Republic, 5–8 September 1995. [Google Scholar]

- Kiddy, C.A. Variation in physical activity as an indicator of oestrus in dairy cows. Int. J. Dairy Sci. 1977, 60, 235–243. [Google Scholar] [CrossRef]

- Williams, W.F.; Yver, D.R.; Gross, T.S. Comparison of oestrus detection techniques in dairy heifers. Int. J. Dairy Sci. 1981, 64, 1738–1741. [Google Scholar] [CrossRef]

- Yang, Y. Rechnergestutzte Ostrusuberwachung bei Milch-kuhen unter Anwendung der Fuzzy-Logic-Methode; Institut für Landtechnik der Technischen Universität: München, Germany, 1998. [Google Scholar]

- De Mol, R.M.; Kroeze, G.H.; Achten, J.M.F.H.; Maatje, K.; Rossing, W. Results of a multivariate approach to automated oestrus and mastitis detection. Livest. Prod. Sci. 1997, 48, 219–227. [Google Scholar] [CrossRef]

- De Mol, R.M.; Keen, A.; Kroeze, G.H.; Achten, J.M.F.H. Description of a detection model for oestrus and diseases in dairy cattle based on time series analysis combined with a Kalman filter. Comput. Electron. Agric. 1999, 22, 171–185. [Google Scholar] [CrossRef]

- Eradus, W.J.; Rossing, W.; Hogewerf, P.H.; Benders, E. Signal processing of activity data for oestrus detection in dairy cattle. In Proceedings of the International Symposium on Prospects for Automatic Milking, Wageningen, The Netherlands, 23–25 November 1992. [Google Scholar]

- Deluyker, H.A.; Shumway, R.H.; Wecker, W.E.; Azari, A.S.; Weaver, L.D. Modeling milk yield in Holstein cows using time series analysis. Int. J. Dairy Sci 1990, 73, 539–548. [Google Scholar] [CrossRef]

- Mottram, T. Automatic monitoring of the health and metabolic status of dairy cows. Livest. Prod. Sci. 1997, 48, 209–217. [Google Scholar] [CrossRef]

- Makridakis, S.; Wheelwright, S.C.; McGee, V.E. Forecasting: Methods and Applications. J. Oper. Res. Soc. 1984, 35, 79. [Google Scholar]

- Peter, A.T.; Bosu, W.T.K. Postpartum ovarian activity in dairy cows: Correlation between behavioural oestrus, pedometer measurements and ovulations. Theriogenology 1986, 26, 111–115. [Google Scholar] [CrossRef] [PubMed]

- Koelsch, R.K.; Aneshansley, D.J.; Butler, W.R. Analysis of activity measurement for accurate estrus detection in dairy-cattle. J. Agric. Eng. Res. 1994, 58, 107–114. [Google Scholar] [CrossRef]

- Van Vliet, J.H.; Van Eerdenburg, F.J.C.M. Sexual activities and oestrus detection in lactating Holstein cows. Appl. Anim. Behav. Sci. 1996, 50, 57–69. [Google Scholar] [CrossRef]

- Brehme, U.; Stollberg, U.; Holz, R.; Schleusener, T. ALT pedometer—New sensor-aided measurement system for improvement in oestrus detection. Comput. Electron. Agric. 2008, 62, 73–80. [Google Scholar] [CrossRef]

- Arcidiacono, C.; Mancino, M.; Porto, S.M.C. Moving mean-based algorithm for dairy cow’s oestrus detection from uniaxial-accelerometer data acquired in a free-stall barn. Comput. Electron. Agric. 2020, 175, 105498. [Google Scholar] [CrossRef]

- Porto, S.M.C.; Bonfanti, M.; Midolo, G.; Castagnolo, G.; Valenti, F.; Arcidiacono, C.; Cascone, G. Preliminary outcomes of a low-power cow oestrus detection system in dairy farms. In Proceedings of the 10th European Conference on Precision Livestock Farming ECPLF 2022, Vienna, Austria, 29 August–2 September 2022. [Google Scholar]

- Bonfanti, M.; Cascone, G.; Porto, S.M.C. Proposal for a double-casing prototype of a pedometer for dairy cows, made to be in-terchangeable, through numerical investigation and 3D modeling of geometry. In Proceedings of the 31st International Conference on Flexible Automation and Intelligent Manufacturing FAIM 2022, Detroit, MI, USA, 19–23 June 2022. [Google Scholar]

- Haines, L. Boffins Debunk Cow-Tipping Myth. The Register, 9 November 2005. [Google Scholar]

- Heinrichs, A.J.; Hargrove, G.L. Standards of Weight and Height for Holstein Heifers. Int. J. Dairy Sci 1987, 70, 653–660. [Google Scholar] [CrossRef]

- Henriksen, C.J.; Munksgaard, L. Validation of AfiTagII, a device for automatic measuring of lying behaviour in Holstein and Jersey cows on two different bedding materials. Animal 2017, 13, 617–621. [Google Scholar] [CrossRef]

- Calì, M.; Pascoletti, G.; Gaeta, M.; Milazzo, G.; Ambu, R. A new generation of bio-composite thermoplastic filaments for a more sustainable de-sign of parts manufactured by FDM. Appl. Sci. 2020, 10, 5852. [Google Scholar] [CrossRef]

- Calì, M.; Pascoletti, G.; Gaeta, M.; Milazzo, G.; Ambu, R. New filaments with natural fillers for FDM 3D printing and their applications in bio-medical field. Procedia Manuf. 2020, 51, 698–703. [Google Scholar] [CrossRef]

- Aida, H.J.; Nadlene, R.; Mastura, M.T.; Yusriah, L.; Sivakumar, D.; Ilyas, R.A. Natural fibre filament for Fused Deposition Modelling (FDM): A review. Int. J. Sustain. Eng. 2021, 14, 1988–2008. [Google Scholar] [CrossRef]

- Garg, A.; Tai, K.; Savalani, M.M. State-of-the-art in empirical modelling of rapid prototyping processes. Rapid Prototyp. J. 2014, 20, 164–178. [Google Scholar] [CrossRef]

- Baturynska, I.; Semeniuta, O.; Martinsen, K. Optimization of Process Parameters for Powder Bed Fusion Additive Manufacturing by Combination of Machine Learning and Finite Element Method: A Conceptual Frame-work. Procedia CIRP 2018, 67, 227–232. [Google Scholar] [CrossRef]

| External Casing | Inner Casing (Central Body) | Top Cap | Assembly | |

|---|---|---|---|---|

| External diameter [mm] | 1 | 45 | 45 | 55 (Upper part) 51 (Central body) |

| Thickness [mm] | 3 | 3 | 10 | - |

| Length [mm] | 95 | 80 | - | 110 |

| Thread [mm] | M45 × 4.5 * | M39 × 4 ** | ||

| Separator | ||||

| Thickness [mm] | 1.5 | |||

| Length [mm] | 50 | |||

| Mechanical Properties | |

| Poisson ratio | 0.4 |

| Elastic Modulus [MPa] | 2230 |

| Yield Tensile Strenght [MPa] | 62.5 |

| Elongation at Yield [%] | 50–75 |

| Physical-Chemical Properties | |

| Density [g/cm3] | 1.14 |

| Solubility in water | Insoluble |

| Solubility in other solvents | 96% in sulfuric acid |

| Melting point [°C] | 185–195 |

| Thermal decomposition [°C] | >300 |

| Flash point [°C] | >400 |

| REACH/EU | Components compliant with REACH |

| Parameter | Working Value | Variation Range | Parameter | Working Value | Variation Range |

|---|---|---|---|---|---|

| Layer thickness [mm] | 0.2 | 0.1–0.5 | Print velocity [mm/s] | 20 | 5–210 |

| Initial thickness [mm] | 0.3 | 0.1–0.6 | Filling velocity [mm/s] | 50 | 5–210 |

| Perimeter threads | 2 | 1–∞ | Outer wall print velocity [mm/s] | 20 | 5–210 |

| Horizontal expansion % | 0 | 0–100 | Lower surface print vel. [mm/s] | 30 | 5–210 |

| N° upper layers | 3 | 1–∞ | Movement velocity [mm/s] | 100 | 5–210 |

| N° lower layers | 3 | 1–∞ | Lower layers print vel. [mm/s] | 25 | 5–210 |

| Fill density | 20 | 10–30 | Print acceleration [mm/s2] | 1000 | 0–1000 |

| Fill configuration | Zig Zag | − | Feedback distance [mm] | 6 | 0–300 |

| Print temperature [°C] | 230 | 180–240 | Feedback velocity [mm/s] | 40 | 30–60 |

| Print bed temperature [°C] | 70 | 20–100 | Fan speed % | 100 | 0–100 |

| Flow % | 100 | 0–100 | Print bed adhesion type | Brim | − |

| Initial layer flow % | 105 | 0–100 | Brim line number | 3 | 1–∞ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Porto, S.M.C.; Calì, M.; Bonfanti, M. Eco-Design and Additive Manufacturing of an Innovative Double-Casing Pedometer for Oestrus Detection in Dairy Cow. Appl. Sci. 2023, 13, 11725. https://doi.org/10.3390/app132111725

Porto SMC, Calì M, Bonfanti M. Eco-Design and Additive Manufacturing of an Innovative Double-Casing Pedometer for Oestrus Detection in Dairy Cow. Applied Sciences. 2023; 13(21):11725. https://doi.org/10.3390/app132111725

Chicago/Turabian StylePorto, Simona Maria Carmela, Michele Calì, and Marco Bonfanti. 2023. "Eco-Design and Additive Manufacturing of an Innovative Double-Casing Pedometer for Oestrus Detection in Dairy Cow" Applied Sciences 13, no. 21: 11725. https://doi.org/10.3390/app132111725

APA StylePorto, S. M. C., Calì, M., & Bonfanti, M. (2023). Eco-Design and Additive Manufacturing of an Innovative Double-Casing Pedometer for Oestrus Detection in Dairy Cow. Applied Sciences, 13(21), 11725. https://doi.org/10.3390/app132111725