Abstract

Biomass syngas can be considered as a supplementary fuel to partially substitute coal, which is beneficial to CO2 emission reduction. For the case study, the influences of co-firing typical biomass syngas (gasification from palm, straw, and wood) with coal on the thermodynamic parameters of a 300 MW tangentially fired boiler are evaluated through a thermal calculation based on the principles of mass conservation, heat conservation, and heat transfer. The effects of boiler loads, biomass syngas species, and consumption rates are discussed. The results show that the introduction of biomass syngas weakens the radiative characteristics of the flame and reduces the furnace exit flue-gas temperature. As 3 × 104 m3 h−1 of wood syngas is introduced, the decrement of thermal efficiency reaches 0.4%, while that of the coal consumption rate is 5.1%. The retrofitting of the boiler was not necessary and the corrosion of the low-temperature heating surface did not appear. The CO2 annual emission reduction could achieve 0.001 to 0.095 million tons for palm syngas, 0.005 to 0.069 million tons for straw syngas, and 0.013 to 0.107 million tons for wood syngas with increasing biomass syngas consumption rates under the full load. Moreover, the main thermodynamic parameters changed more significantly under the low loads.

1. Introduction

CO2 emissions, which contribute to 76% of entire greenhouse gas emissions, can lead to a number of problems driven by global warming [1]. Moreover, power generation industries in China are facing tremendous pressure to mitigate CO2 emissions, which should be lower than 550 g kW−1 h−1 [2]. Therefore, reducing CO2 emissions has become a primary issue, especially emissions from the combustion of fossil fuels. Biomass can be adopted as an alternative energy resource to partially substitute coal in a boiler, which is a promising solution to reduce the emissions of CO2 and NOx, as well as improve the combustion characteristics of fuel owing to its renewability, CO2 neutrality, and relatively high volatile-matter content [3,4,5].

Co-firing technologies include direct, indirect, and separate co-firing [6]. For direct co-firing, fuels are milled before entering the furnace. Although this method is a straightforward and economical option, it can create some challenges, such as the pre-treatment and feeding of biomass, fouling, and corrosion, which prevents it from being widely applied [7]. Separate co-firing can be adopted to increase the steam capacity of an existing boiler as a separate biomass-fired boiler is added to the entire system, which is costly and redundant [6]. For indirect co-firing, the biomass must be converted into syngas by a gasifier at first, and then the biomass syngas enters the furnace and is co-fired with the coal [8]. The interaction between alkali species from the biomass and the sulfur from the coal during co-firing might alleviate the ash deposition created by biomass combustion [9]. A high number of problems related to corrosion and deactivation can also be mitigated by indirect co-firing [7,10]. The distinct benefit of the indirect co-firing method is the preservation of some substances (containing K, Na, S, and Cl) that ordinarily contribute to the high-temperature corrosion of the water-cooled wall in the furnace. In addition, serious fouling of the heat exchangers produced by the inorganic components that contain K, Na, S, and Cl can be prevented [7]. Therefore, the indirect co-firing of coal with biomass syngas is an attractive scheme.

A great number of experimental [9,11,12,13,14,15,16,17] and numerical studies [8,18,19,20,21,22] have been performed on co-firing in a boiler. The researchers mainly focus on the impacts on NOx emissions [12,19], slagging/ash deposition [9,13,14], combustion characteristics [15,16], and temperature distribution [8,18,19]. The variations in the main thermodynamic parameters, such as the radiant attenuation factor, furnace exit flue-gas temperature, thermal efficiency, and coal combustion rate, are not fully evaluated. Additionally, the thermal calculations of the principles of mass conservation, heat conservation, and heat transfer are precise and helpful in understanding the design, operation, and retrofit of boilers through the variations in the thermodynamic parameters [2]. However, only a few studies [23,24] (our previous studies) have been conducted to investigate the influence of co-firing on the thermodynamic parameters through thermal calculations, to our knowledge, but not for co-firing with the biomass syngas, which is beneficial to the reduction in CO2 emissions. Moreover, it is significant to study the indirect co-firing method under different loads, especially a low load, in conjunction with the current deep-peaking issue. Biomass syngas, especially syngas from the gasification of woody biomass, contain low levels of nitrogen, virtually no sulfur, and have a relatively high heating value, which can lead to an apparent reduction in NOx emissions [12]. Thus, it is beneficial to study the effect of co-firing as the boiler load alters.

In this study, three typical types of biomass syngases (from the gasifications of palm, straw, and wood) are chosen to investigate the impact of co-firing on the thermodynamic parameter variations in a 300 MW tangentially coal-fired boiler through thermal calculations. The influences of boiler loads, biomass syngas species, and consumption rates are discussed in detail. The solely coal-fired condition is employed as a reference to be compared with the other conditions. It is expected to provide a reference for the design, operation, and retrofit of boilers under co-firing conditions.

2. Thermal Calculation

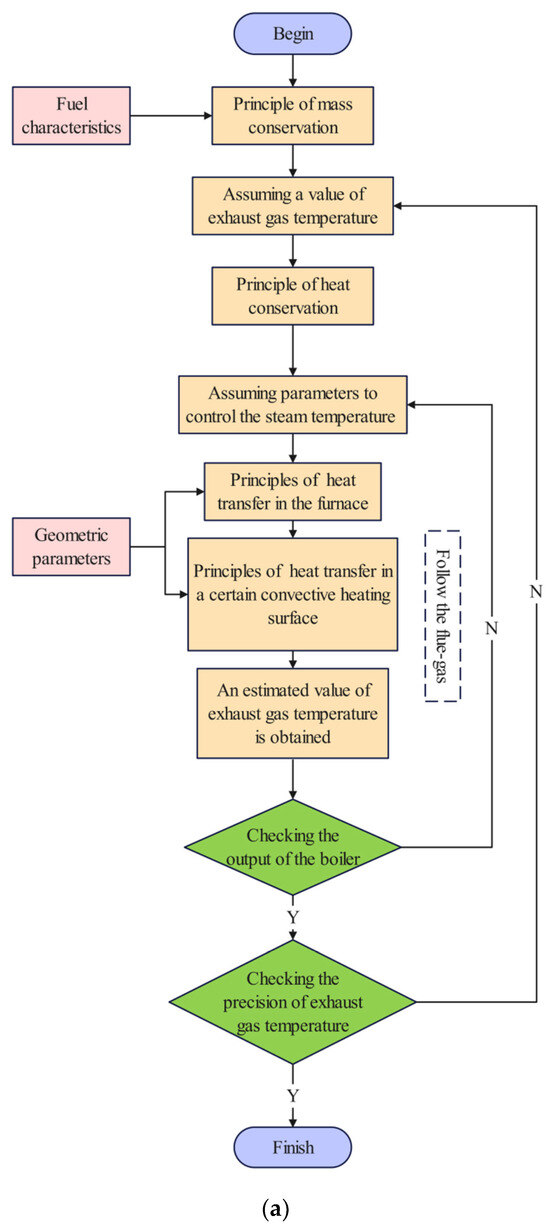

The primary thermodynamic parameters, including the radiant attenuation factor, thermal efficiency, exhaust gas temperature (, °C), and acidic dew point, were obtained through thermal calculations. Then, the heat distribution and effectiveness (including efficiency and reliability) of the boiler were evaluated. Since the 0-dimensional model has been employed in many previous studies [25,26,27], a semiempirical method based on it, proposed by the former Soviet Union and Russia, was adopted in this study [28,29]. It was widely applied for heat transfer calculations in the furnace, the basic equations of which were created according to the principles of heat conservation and heat transfer, as the heat transfer and combustion of the fuels occurred simultaneously in the furnace. By the principle of heat conservation, the heat absorption from the flue gas was considered to be equal to the enthalpy decreasing from the theoretical combustion temperature to the furnace exit flue-gas temperature. By the principle of heat transfer, the heat transfer calculation is equal to radiant heat transfer since the level of radiant heat transfer accounts for more than 95% of the total heat transfer in the furnace, which can be conducted through the Stephan–Boltzmann law. Since the heat obtained from heat conservation is equal to that from radiant heat transfer, some main thermodynamic parameters can be evaluated [28]. The similitude and differential theorems are adopted to build the model. The flowcharts of the thermal calculation procedures applied in this study are presented in Figure 1 [23]. First, the values of exhaust gas temperature (for the boiler), furnace exit flue-gas temperature (for the furnace), and outlet gas temperature (for the convective heating surfaces) should be assumed. Then, an estimated value of these thermodynamic parameters can be obtained according to the principles of mass conservation, heat conservation, and heat transfer. Finally, it is of vital importance to note that iterative calculations are required until the discrepancy between the estimated and fictitious exhaust gas temperatures of the boiler falls within a suitable range (±1 °C in this study). Based on the above procedures, a calculation program was proposed by our group [24]. The accuracy of the program can be verified since it has been applied in lots of manufacturers and research institutes [23,24]. The calculation methods of thermodynamic parameters described below are based on 1 kg of coal and the corresponding volume of biomass syngas, represented by (m3 kg−1), which is correlated to the volume fraction of biomass syngas and the fuel compositions under the standard condition.

Figure 1.

Flowcharts of the thermal calculation procedures [23]. (a) The boiler. (b) The furnace. (c) The convective heating surfaces.

2.1. Mass Conservation

To evaluate whether the retrofitting of boilers is necessary after the introduction of biomass syngas, the total air and flue-gas flow rates (m3 s−1) under the standard condition should be evaluated. The calculation methods are listed in Equations (1) and (2) [23,28].

where (kg s−1) represents the calculation coal consumption rate, the definition of which would be displayed in Section 2.2. The excess air coefficients at the inlet and outlet of the air heater are represented by and , respectively, is equal to 1.49 in this study, the air density represented by in Equation (2) is equal to 1.29 kg m−3 under the standard condition, and the ratio of water vapor mass to air mass () is around 0.01.

The theoretical air volume represented by (m3 kg−1) can be obtained by Equation (3), while that of flue gas (, m3 kg−1) is determined by Equation (4) [28].

where , , , , and (%) are the contents of carbon, sulfur, hydrogen, oxygen, and nitrogen on the as-received basis, respectively.

(m3 kg−1) represents the theoretical water vapor volume, which is mainly determined by the components of fuels. It is confirmed from Equations (3) and (4) that and can be calculated as the fuel components are known.

The water vapor volume fraction () is the ratio of the total water vapor volume (, m3 kg−1) to the total flue-gas volume (, m3 kg−1), which can be defined as [28].

where represents the excess air coefficient of the furnace exit (about 1.10–1.35 in this study). can be obtained by [28].

2.2. Heat Conservation

Heat conservation, which is the balance between the heat entering and leaving the boiler envelope, is calculated to obtain the coal consumption rate and thermal efficiency of boilers [23,24,28]. The coal consumption rate (kg s−1) is defined as

The total available heat of working fluid represented by

(kW) is decided by the mass flow rate of heated steam and enthalpies of heated steam and feed water, which is closely related to boiler loads. (%) is the thermal efficiency, which can be calculated by Equation (8) as the heat losses are given.

where and (%) are the heat losses owing to incomplete combustion of biomass syngas and coal, respectively, and are the heat losses that are related to the radiation and convection, and ash residue, respectively. , , , and are primarily determined by the fuel characteristics, boiler structure, and boiler capacity. is the heat loss owing to the exhaust gas, the value of which can be obtained by

where and (kJ kg−1) represent the enthalpies of cold air and exhaust gas, respectively. The heat entering the boiler envelope represented by (kJ kg−1) is a combination of the sensible heat and lower heating value (LHV) of the mixed fuels (kJ kg−1), which can be calculated by

where and are the sensible heats of coal and biomass syngas, while the LHV of coal and biomass syngas are represented by (kJ kg−1) and (kJ m−3), respectively. It should be noted that is correlated to the environment temperature.

Thus, the calculation coal consumption rate mentioned in Equations (1) and (2) can be obtained by

2.3. Heat Transfer Calculations in the Furnace

The furnace exit flue-gas temperature (, K) is defined as [26].

where , , and are dimensionless coefficients. is related to the fuel characteristics, combustion mode, and temperature distribution. The theoretical combustion temperature (, K) depends on the available heat of fuels (, kJ kg−1) that can be obtained by Equation (13) [23].

where (kJ kg−1) represents the sensible heat of combustion air.

The radiant heat transfer, which is affected by the suspensions of triatomic gases and solid substances in the furnace, makes the primary contribution to the heat transfer of boilers. The radiative characteristics can be described with radiant attenuation factor (, m−1 MPa−1), including that of triatomic gases (), soot (), fly ash (), and char (), which is calculated by [28].

where is a dimensionless coefficient which is correlated to the proportion of the luminous area.

The heat absorption of flue gas (, kW) is calculated by [28].

where is the heat retention factor (about 0.9–1.0), and the enthalpy of flue gas at the furnace exit is represented by (kJ kg−1).

2.4. Heat Transfer Calculations of the Convective Heating Surfaces

The heat transfer of the convective heating surfaces, consisting of convective heat transfer and radiant heat transfer from the fluegas and flame, can be evaluated through Equations (16)–(18) [28].

(W m−2 K−1) represents the heat transfer coefficient, which can be determined by

where is the utilization factor considering imperfect sweeping by flue gas, (m2 K W−1) is the fouling factor. The heat transfer coefficients in the flue-gas side include that of radiation and convection, which are represented by and (W m−2 K−1), respectively. In the working fluid side, only convective heat transfer happens, while is the corresponding coefficient.

The temperature difference of heat transfer (, K) is obtained by

where is the temperature correction factor which is correlated to the terms of specific arrangement, and (K) are the larger one, and the smaller one of initial and final temperature differences between hot fluid and cold fluid, respectively.

The heat transfer quantity (, W) can be determined by

where is the area of convective heating surfaces (m2).

2.5. Acidic Dew Point

To evaluate whether the corrosion would happen in the furnace, the acidic dew point (, °C) should be calculated after coupling coal with biomass syngas, which can be obtained by [23,29].

the water dew point is represented by (°C), is correlated to the excess air coefficient at the furnace exit, and is related to fly ash (around 0.75–0.95). When the components and LHV of fuels are given, the converted contents of sulfur and ash represented by and (%), respectively, can be calculated.

2.6. CO2 Annual Emission Reduction

The CO2 annual emission reduction (, t) can be determined by [24].

where (t) is the CO2 annual emission under the boiler maximum continuous rating (BMCR), and (t) is the CO2 annual emission, which is calculated by [24].

The CO2 annual emission is the product of CO2 emission intensity (, g kW−1 h−1) and generation capacity (, kW h). can be calculated by [24].

where (MW) represents the power generation, and (%) is the combustion efficiency determined by the structure, capacity, and operation of boilers, which is equal to 0.99 in this study.

3. Case Study

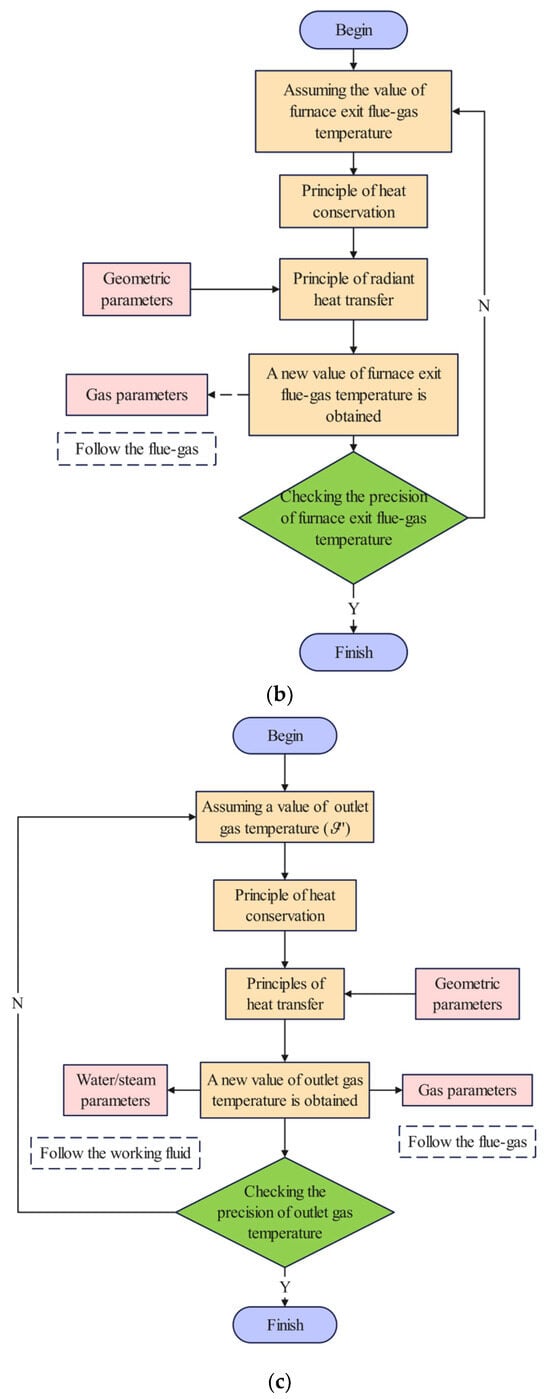

A subcritical 300 MW tangentially fired boiler, the type of which is SG-1025/17.50-M749, is applied for the case study. The intricate boiler structure can be seen from Figure 2. The main design parameters of the boiler under BMCR, 75% THA (turbine heat acceptance), 50% THA, and 30% THA are shown in Table 1. The design parameters are adopted under (BMCR), with the main steam output of 1025 t h−1, and the outlet temperatures of both superheated steam and reheated steam of 540 °C. The height, width, and depth of the furnace are 50,868, 14,020, and 12,350 mm, respectively. The wall reheater, platen superheaters, and high-temperature superheaters are sequentially arranged in the upper part of the boiler, while the horizontal convective superheater and economizer are installed in the tail flue vibration from top to bottom. The chosen biomass syngases in this study are palm syngas, straw syngas, and wood syngas from previous studies [30,31,32]. The biomass syngas can be obtained through the gasification of the biomass by a gasifier. The processes consist of desiccation, volatile release, oxidation, and reduction. Then, the tar and dust removal are required at high temperatures. Finally, the biomass syngas should be cooled at 450 °C before entering the furnace since the temperature of biomass syngas should be controlled below 500 °C [2]. The biomass syngas are injected into the furnace at the bottom level of the reburn zone in this study since NO emissions were at their lowest value in this condition according to the results in our previous study [8]. The details about the coal and biomass syngases are listed in Table 2.

Figure 2.

Boiler structure.

Table 1.

Main design parameters of the boiler.

Table 2.

Fuel characteristics of coal (as-received basis) and biomass syngases.

Since the fuel burnt in the boiler changes from coal to biomass syngas and coal, the thermal calculations are performed with the verification method. The comparisons of thermodynamic parameters for various biomass syngas consumption rates are conducted under a full load. The biomass syngas consumption rates coupled with coal vary from 0 to 5 × 104 m3 h−1. Moreover, the comparisons of thermodynamic parameters between burning coal alone and co-firing coal with 3 × 104 m3 h−1 of wood syngas (taking the safety and economy into consideration) are performed with different boiler loads. The results of thermal calculations are similar to that the boiler manufacturer provided, which means the thermodynamic parameters calculated by our developed program are reliable and valid. The following assumptions are made after the introduction of biomass syngas:

- (1)

- The excess air coefficient remains unchanged at the exits of the furnace and convective heating surfaces;

- (2)

- The temperatures of the cold air and hot air, and the proportions of primary and secondary air remain unchanged;

- (3)

- No variations happen in the fuel characteristics, boiler structure, and boiler capacity.

4. Results and Discussion

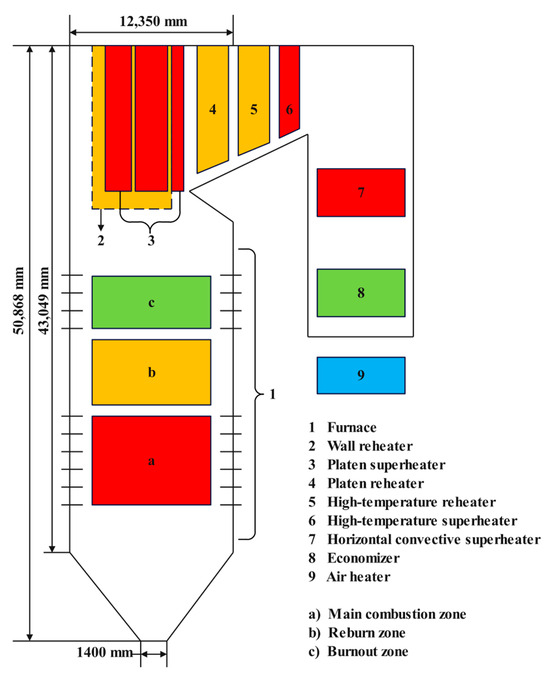

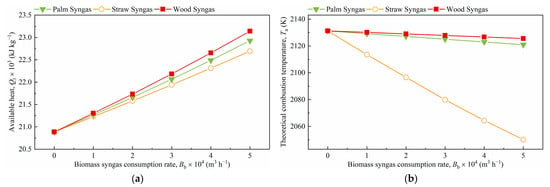

4.1. Effect of Co-Firing on Radiant Heat Transfer

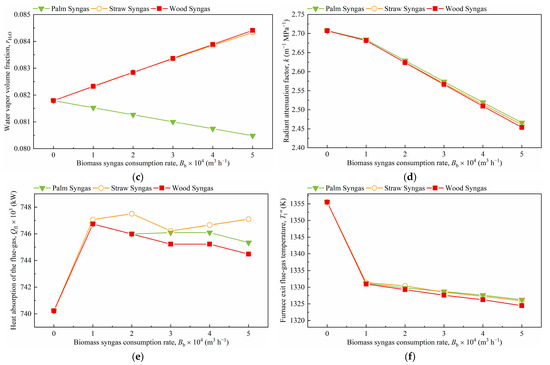

The primary thermodynamic parameters of the boiler under BMCR are shown in Figure 3. The heating value of the fuel, the quantity, and the specific heat of the combustion products determine the theoretical combustion temperature, which represents the highest temperature that the combustion products can achieve [28]. The available heat of fuels is correlated to the volume, specific heat, and theoretical combustion temperature if the fuel is burnt completely and adiabatically. It can be seen from Figure 3a that the available heat would rise monotonically, as the consumption rates and heating value of biomass syngas increase. The result is the same as that in our previous study [23]. Compared with the other two types of biomass syngases, the increment of available heat can reach 10.8% after introducing wood syngas with 5 × 104 m3 h−1. It can be noted from Figure 3b that the theoretical combustion temperature increases with ascending heating values, while the trend reverses with increasing consumption rates. The result is similar to that in the study of Wang et al. [2]. The reason for the variations in volume and specific heat might be different compositions and quantities of combustion products. The variation in the straw syngas consumption rate has the most pronounced influence on the theoretical combustion temperature, the highest decrement of which is 3.8%.

Figure 3.

Furnace thermodynamic parameters for various biomass syngas consumption rates (BMCR). (a) Available heat of fuel; (b) theoretical combustion temperature; (c) water vapor volume fraction in flue gas; (d) radiant attenuation factor of flue gas; (e) heat absorption of flue gas; (f) furnace exit flue-gas temperature.

It is believed that the radiant attenuation factor of flue gas (, m−1 MPa−1) can be applied to represent the radiative characteristics of flame [28]. The water vapor volume fraction rises with increasing biomass syngas consumption rates after the introductions of straw and wood syngases, while that decreases after the introduction of palm syngas (see Figure 3c). The radiant attenuation factor is related to that of triatomic gases (), soot (), fly ash (), and char () according to Equation (14). The for a coal-fired boiler can be disregarded, while would not change owing to the unchanged coal characteristics [28]. The rises as a result of the rising volume fraction of CO2, while decreases due to the decreasing fly ash concentration after the introduction of biomass syngas. Consequently, the descends as the biomass syngas consumption rate rises according to Figure 3d.

The heat absorption of flue gas (, kW) is determined by the average temperature and radiative characteristics of the flame, and the size and shape of the furnace [24]. The average temperature of the flame decreases due to the falling theoretical combustion temperature. Compared with the solely coal-fired condition, the heat absorption ascends after introducing the biomass syngas. For the introduction of wood syngas, the heat absorption descends with rising biomass syngas consumption rates. However, the heat absorption for introducing palm and straw syngases does not present a monotonous trend (see Figure 3e), since the complex combustion products produced by burning mixed fuels can contribute to radiant heat transfer in numerous ways [28]. Since the difference between the available heat and heat absorption of flue gas ascends, the enthalpy of flue gas, which reflects the variations of the volume, specific heat, and temperature in flue gas, rises as the biomass syngas consumption rate increases. It can be seen that declines with ascending biomass syngas consumption rates in Figure 3f. decreases by 2.1% for palm syngas and straw syngas, while that for wood syngas can reach 2.3%, as 5 × 104 m3 h−1 of biomass syngas is entrained.

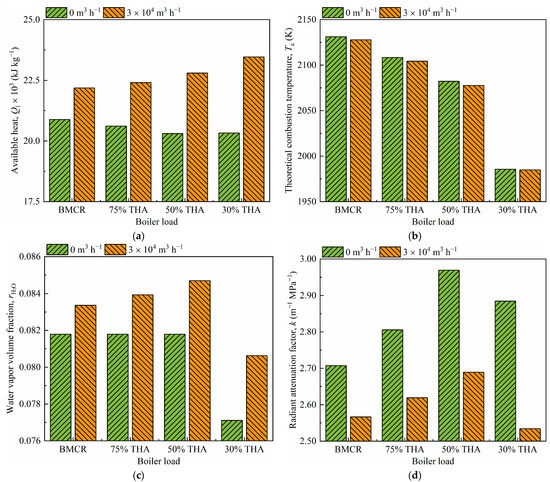

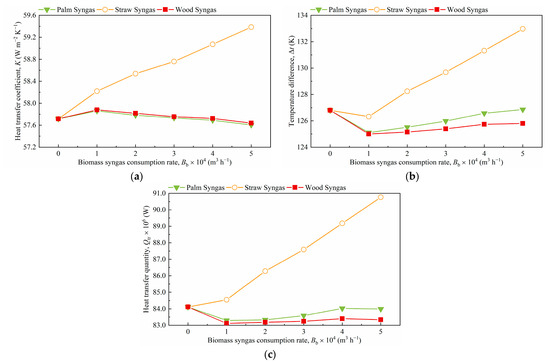

To evaluate the influence of boiler load variation on the thermodynamic parameters after the introduction of biomass syngas, the consumption rate of the biomass syngas would not change (3 × 104 m3 h−1 in this study) because of the difficulty of adjusting the load of the gasifier. The comparisons of the primary thermodynamic parameters between burning coal alone and co-firing coal with biomass syngas (3 × 104 m3 h−1 of wood syngas) under different boiler loads are revealed in Figure 4. The results demonstrate that the available heat and water vapor volume fraction ascend after coupling the wood syngas, while the radiant attenuation factor and furnace exit flue-gas temperature descend after the introduction of syngas. Meanwhile, the influence of wood syngas introduction on the theoretical combustion temperature and heat absorption is weakened. For the solely coal-fired condition, the available heat declines with falling boiler loads, while that for the wood syngas introduction shows a reverse trend. It could be confirmed that the introduction of wood syngas affects the available heat more significantly under a low load (see Figure 4a). The syngas from the gasification of the woody biomass contains low levels of nitrogen, a high volume fraction of combustible materials, and a relatively high heating value, which would result in a higher water vapor volume fraction after the introduction of wood syngas (see Figure 4c). As the consumption rate of biomass syngas remains unchanged, operating the boiler under lower loads means a higher consumption rate percentage of biomass syngas than that of coal. Thus, the water vapor volume fraction increases more dramatically under low boiler loads. The variation in the water vapor volume fraction would affect that of the radiant attenuation factor, which can be seen in Figure 4d. The difference ratios are 4.6% for the water vapor volume fraction and 12.1% for the radiant attenuation factor under 30% THA. The other three thermodynamic parameters decrease when the boiler load descends (see Figure 4b,e,f).

Figure 4.

Furnace thermodynamic parameters comparison under various boiler loads (wood syngas, 450 °C). (a) Available heat of fuel; (b) theoretical combustion temperature; (c) water vapor volume fraction in flue gas; (d) radiant attenuation factor of flue gas; (e) heat absorption of flue gas; (f) furnace exit flue-gas temperature.

4.2. Effect of Co-Firing on Heat Transfer of the Convective Heating Surfaces

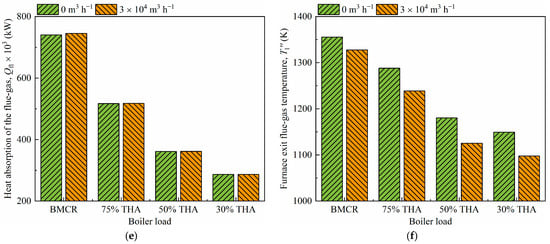

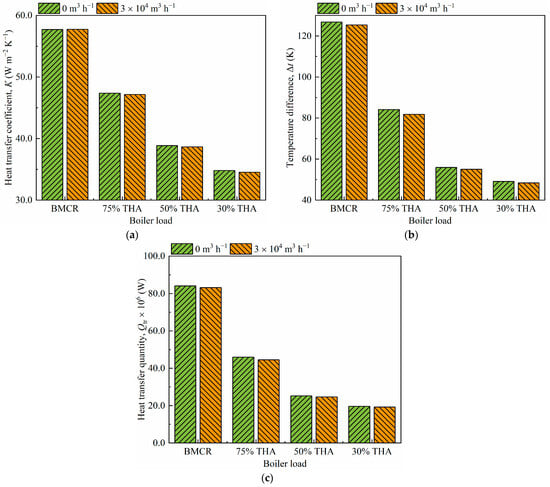

The heat transfer coefficient (), temperature difference (), and heat transfer quantity () of a certain convective heating surface with various biomass syngas consumption rates under BMCR are displayed in Figure 5. is affected by many factors, such as the radiative characteristics of the flue gas, and the physical characteristics and velocity of the flue gas and working fluid. Since the convective heat transfer on the working fluid side is scarcely affected, is primarily impacted by the heat transfer (including convective and radiant heat transfer) on the flue-gas side. The inflection point occurs when only the coal is burned, the result is similar to that in our previous study [24]. The heat transfer coefficient decreases (for the palm and wood syngases) or increases (for the straw syngas) with ascending biomass syngas consumption rates (see Figure 5a). A possible explanation might be the alterations of the temperature, component, and quantity. The temperature difference is influenced by the inlet and outlet temperatures of the working fluid and flue gas of a certain heating surface. The temperature of the working fluid could be barely impacted. Although declines with rising biomass syngas consumption rates, the flue-gas temperature of the low-temperature superheater rises slightly. Thus, climbs moderately in Figure 5b. is related to , , and geometric parameters according to Equation (18), while the geometric parameters remain unchanged. The variations in the heat transfer quantity are displayed in Figure 5c. It can be seen from Figure 6 that all of these three thermodynamic parameters decrease when the boiler load declines, while the introduction of the wood syngas could not lead to a dramatic variation.

Figure 5.

Some parameters related to heat transfer of a low-temperature superheater under various biomass syngas consumption rates (BMCR). (a) Heat transfer coefficient; (b) temperature difference; (c) heat transfer quantity.

Figure 6.

Some parameters comparison related to heat transfer of a low-temperature superheater under various boiler loads (wood syngas, 450 °C). (a) Heat transfer coefficient; (b) temperature difference; (c) heat transfer quantity.

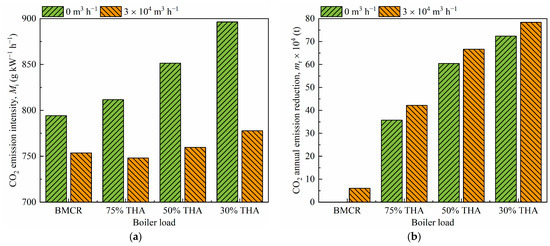

4.3. Effect of Co-Firing on Thermal Efficiency

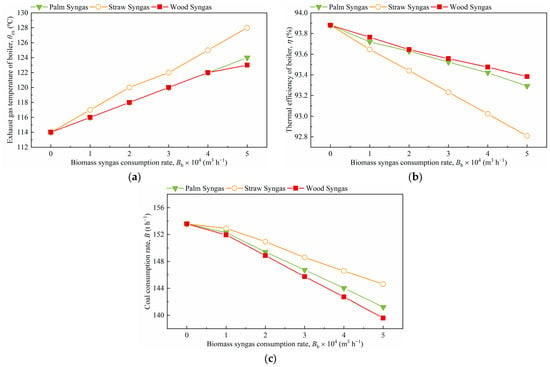

Figure 7 reveals the results of the exhaust gas temperature, thermal efficiency, and coal consumption rate through heat balance calculations. As the biomass syngas is entrained, the alterations of the component, velocity, volume, and physical characteristics of the flue gas, which happen in the processes of convective and radiant heat transfer in the boiler, would result in the exhaust gas temperature variation according to Figure 7a. The exhaust gas temperature increases with increasing biomass syngas consumption rates. The highest variations of the exhaust gas temperature for various consumption rates under a full load are 9 °C for the wood syngas, 10 °C for the palm syngas, and 14 °C for the straw syngas. It can be inferred from Equations (8) and (9) and the assumption made in Section 3 that the thermal efficiency (, %) is mainly determined by the heat losses owing to the exhaust gas (, %), while the other heat losses remain unchanged. The growth of the exhaust gas temperature would lead to the growth of , and then the thermal efficiency would descend with increasing biomass syngas consumption rates (see Figure 7b). A combination of the available heat of the working fluid and the thermal efficiency would reduce the coal consumption rate, as the biomass syngas consumption rate increases (see Figure 7c). As 3 × 104 m3 h−1 of wood syngas is entrained, the thermal efficiency is reduced by 0.4%, while the coal consumption rate is declined by 5.1%. The variations of the exhaust gas temperature and thermal efficiency under various coupling percentages of the fuels between this current study and the previous studies [23,24] are quite different due to the different fuels co-firing with the coal, while it could be confirmed from these three studies [23,24] that the coal consumption rate would significantly descend with increasing coupling percentages of the fuels.

Figure 7.

Exhaust gas temperature, thermal efficiency and coal consumption rate under various biomass syngas consumption rates (BMCR). (a) Exhaust gas temperature of boiler; (b) thermal efficiency of boiler; (c) coal consumption rate.

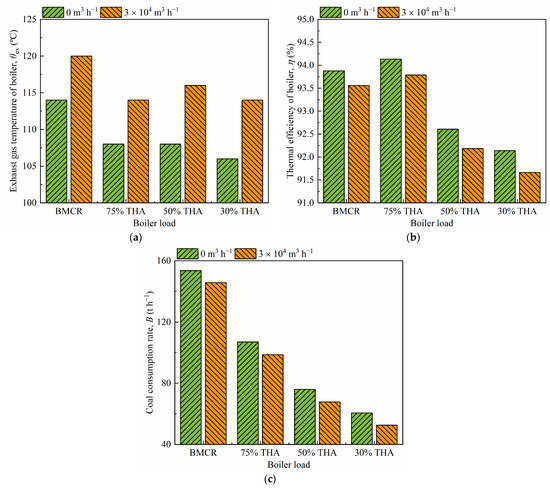

The alterations of the exhaust gas temperature, thermal efficiency of the boiler, and coal consumption rate under various boiler loads after introducing 3 × 104 m3 h−1 of the wood syngas are shown in Figure 8. Coupling wood syngas with the coal would lead to the growth of the exhaust gas temperature (see Figure 8a), but reduce the thermal efficiency of the boiler and the coal consumption rate (see Figure 8b,c). The alterations of the exhaust gas temperature and the thermal efficiency are not monotonous as the boiler load is changed. However, the increment (for the exhaust gas temperature) or the decrement (for the thermal efficiency and the coal consumption rate) rises monotonously with declining boiler loads. When the boiler operates under 30% THA, the exhaust gas temperature is increased by 7.5%, while and are decreased by 0.5% and 13.2%, respectively.

Figure 8.

Exhaust gas temperature, thermal efficiency, and coal consumption rate comparison under various boiler loads (wood syngas, 450 °C). (a) Exhaust gas temperature of boiler; (b) thermal efficiency of boiler; (c) coal consumption rate.

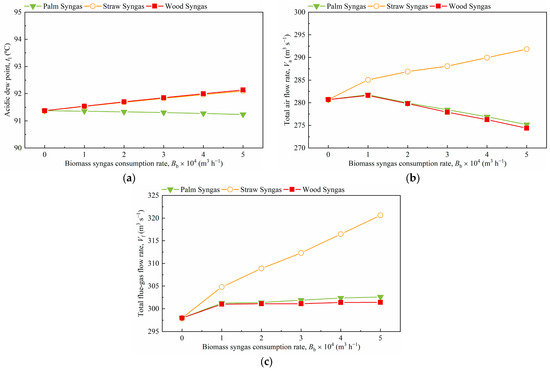

4.4. Effect of Co-Firing on Operational Safety

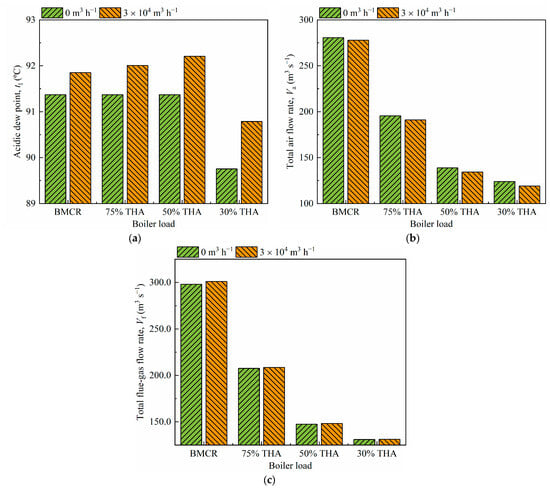

It can be determined from Equation (19) that the acidic dew point depends on the water dew point, excess air coefficient, and converted contents of sulfur and fly ash [23]. The introduction of biomass syngas brings a large increment of the volume fraction of hydrogen, and thus the content of the water vapor rises. Therefore, the water dew point ascends with the growth of the biomass syngas consumption rate. The contents of both sulfur and fly ash decrease as the biomass syngas is entrained. A combination of these factors mentioned above causes the acidic dew point to climb (for the straw and wood syngases) or decline (for the palm syngas), the variation in which is within ±1 °C (see Figure 9a). It can be clearly seen from Figure 7a and Figure 9a that the exhaust gas temperature has a greater value than the acidic dew point. Therefore, the low-temperature heating surface would not be corroded after the introduction of biomass syngas.

Figure 9.

Acidic dew point, total air flow rate, and total flue-gas flow rate with various biomass syngas consumption rates (BMCR, standard condition). (a) Acidic dew point; (b) total air flow rate of air heater inlet; (c) total flue-gas flow rate of air heater outlet.

Figure 9b,c show the total air and flue-gas flow rates evaluated under the standard condition for various biomass syngas consumption rates. These two parameters are influenced by the coal consumption rate and theoretical volumes of the air and flue gas [23,28]. After coupling biomass syngas with coal, the theoretical volumes of the air and flue gas ascend with increasing biomass syngas consumption rates, while the coal consumption rate descends. Therefore, the variations in the total air and flue-gas flow rates are within ±4.0% and ±7.6%, respectively. Consequently, the retrofitting of the boiler is not required.

It could be implied from Figure 8a and Figure 10a that although the acidic dew point would rise slightly after the introduction of wood syngas under various boiler loads, the acidic dew point is still lower than the exhaust gas temperature. Consequently, no corrosion occurs on the low-temperature heating surface even under a low load. Compared with the standard condition, the total air and flue-gas flow rates do not alter dramatically as 3 × 104 m3 h−1 of wood syngas is entrained. However, the total air and flue-gas flow rates decline significantly with decreasing boiler loads (see Figure 10b,c).

Figure 10.

Acidic dew point, total air flow rate, and total flue-gas flow rate comparison with various boiler loads (wood syngas, 450 °C, standard condition). (a) Acidic dew point; (b) total air flow rate of air heater inlet; (c) total flue-gas flow rate of air heater outlet.

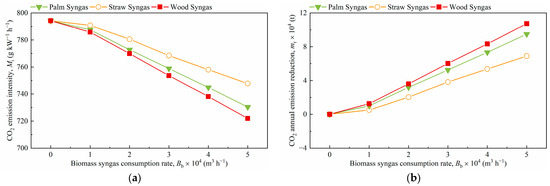

4.5. Effect of Co-Firing on CO2 Emissions

The CO2 emissions are related to the content of carbon and the calculation coal consumption rate [24]. Therefore, the CO2 emissions descend gradually due to the drop of the calculation coal consumption rate with ascending biomass syngas consumption rates. Then, the CO2 emission intensity of power generation and the CO2 annual emission (, t) decline according to Equations (21) and (22), the result is displayed in Figure 11a. Consequently, an obvious growth of the CO2 annual emission reduction (, t) for different biomass syngas consumption rates under BMCR can be seen in Figure 11b. The results in Figure 11a,b are the same as those in our previous study [24], which could confirm that co-firing the fuels, such as biomass syngas and hydrogen-derived fuel, with the coal is significantly beneficial to CO2 emission reduction. The CO2 annual emission reduction equals 0.001 to 0.095 million tons for the palm syngas, 0.005 to 0.069 million tons for the straw syngas, and 0.013 to 0.107 million tons for the wood syngas.

Figure 11.

CO2 emission intensity and CO2 annual emission reduction for various biomass syngas consumption rates (BMCR). (a) CO2 emission intensity; (b) CO2 annual emission reduction.

As 3 × 104 m3 h−1 of wood syngas is entrained, the CO2 emission intensity decreases and the CO2 annual emission reduction rises compared with the standard condition. It can be seen from Figure 12a that the decrement of the CO2 emission intensity increases with descending boiler loads, which could achieve 13.2% under 30% THA. It is apparent from Figure 12b that the CO2 annual emission reduces more under a low load, while the introduction of wood syngas would exacerbate the reduction.

Figure 12.

CO2 emission intensity and CO2 annual emission reduction comparison under various boiler loads (wood syngas, 450 °C). (a) CO2 emission intensity; (b) CO2 annual emission reduction.

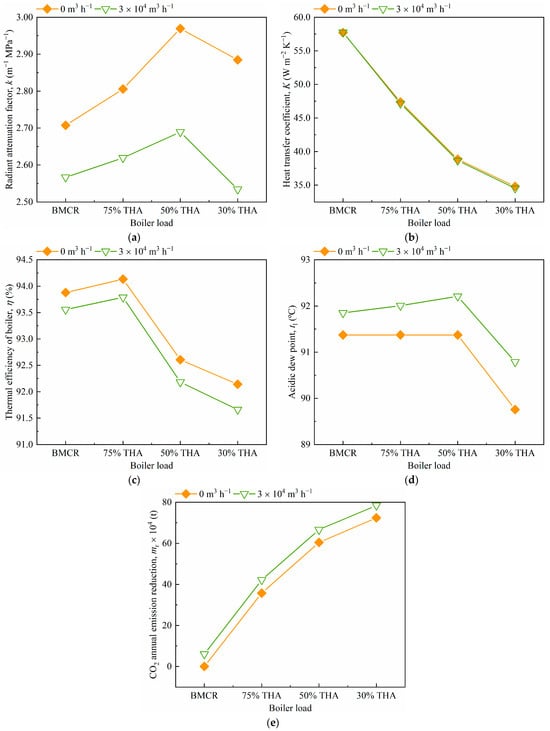

4.6. Effect of Co-Firing on the Boiler during Peak Regulation

Figure 13 displays the variations of some thermodynamic parameters under different boiler loads. The result in Figure 13a suggests that the radiant attenuation factor decreases more significantly after coupling wood syngas with coal under a low load. The radiant attenuation factor increases gradually and then decreases when the boiler load descends, while the inflection point occurs under 50% THA. As the boiler load is reduced, the heat transfer coefficient declines dramatically in Figure 13b. It could be easily concluded from the result in Figure 13c that the thermal efficiency of the boiler does not alter monotonously with decreasing boiler loads. The thermal efficiency rises (from 100% BMCR to 75% THA) and then decreases (from 75% THA to 30% THA) when the boiler load declines. Co-firing coal with wood syngas would reduce the thermal efficiency slightly. Although the introduction of wood syngas would increase the acidic dew point, the difference between the acidic dew point and the exhaust gas temperature can be enlarged, which means the boiler would operate more safely. The differences between these two parameters are higher than 20 K under various boiler loads after coupling wood syngas with the coal. It could be revealed from Figure 13d and Figure 8a. What could be significantly concluded from Figure 13e is that co-firing coal with the wood syngas under a low load would increase the CO2 annual emission reduction apparently, which is beneficial for the environment.

Figure 13.

Some thermodynamic parameters variations under different boiler loads (wood syngas, 450 °C). (a) Radiant attenuation factor; (b) heat transfer coefficient; (c) thermal efficiency of boiler; (d) acidic dew point; (e) CO2 annual emission reduction.

5. Conclusions

The thermal calculations are conducted to investigate the effect of co-firing coal with biomass syngas on the thermodynamic parameters in a 300 MW tangentially fired boiler in this study. The biomass syngas is applied as a supplementary fuel entering the furnace with various consumption rates under BMCR. In addition, the comparisons of thermodynamic parameters between two typical conditions are performed under different boiler loads. The conclusions are listed as follows:

- (1)

- The introduction of biomass syngas weakens the average temperature in the furnace and the radiative characteristics of flame, which leads to a reduction of furnace exit flue-gas temperature. The alterations of these thermodynamic parameters are monotonically related to the biomass syngas consumption rate;

- (2)

- The heat absorption of flue gas would be enhanced after the introduction of biomass syngas. Coupling palm syngas and wood syngas with coal would increase the heat transfer on the convective heating surfaces, while that for the straw syngas would be weakened. Thus, a combination of these two parameters leads to an increment in the exhaust gas temperature of the boiler and a decrement in the thermal efficiency of the boiler;

- (3)

- The variations of acidic dew point, total air, and flue-gas flow rates are not monotonous with increasing biomass syngas consumption rates. The variations are within ±1 °C, ±4.0%, and ±7.6%, respectively. The difference between the acidic dew point and exhaust gas temperature ascends after the introduction of biomass syngas. Therefore, the retrofitting of the boiler is not necessary and the corrosion of a low-temperature heating surface would not appear. The coal consumption rate descends dramatically after coupling;

- (4)

- The CO2 annual emission reduction increases dramatically with increasing biomass syngas consumption rates under BMCR, which equals 0.001 to 0.095 million tons for palm syngas, 0.005 to 0.069 million tons for straw syngas, and 0.013 to 0.107 million tons for wood syngas. Although the variations are not monotonous, the introduction of wood syngas enlarges the difference of these thermodynamic parameters between two different consumption rates of wood syngas as the boiler load decreases.

Author Contributions

Conceptualization, J.W., Q.Y., X.J. and L.D.; Data Curation, J.W., Q.Y. and L.D.; Investigation, J.W., Q.Y., X.J. and L.D.; Resources, L.D.; Supervision, L.D.; Writing—Original Draft, J.W., Q.Y. and X.J.; Writing—Review and Editing, L.D. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China, grant number [51406147].

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| content of ash on the as-received basis (%) | |

| converted content of ash (%) | |

| coal consumption rate (kg s−1) | |

| calculation coal consumption rate (kg s−1) | |

| Boltzmann number | |

| effective value of Bouguer number | |

| content of carbon on the as-received basis (%) | |

| the ratio of water vapor mass to air mass | |

| content of fixed carbon on the as-received basis (%) | |

| area of convective heating surfaces (m2) | |

| content of hydrogen on the as-received basis (%) | |

| sensible heat of mixed fuels (kJ kg−1) | |

| sensible heat of coal (kJ kg−1) | |

| sensible heat of biomass syngas (kJ kg−1) | |

| enthalpy of cold air (kJ kg−1) | |

| enthalpy of exhaust gas (kJ kg−1) | |

| enthalpy of flue gas at the furnace exit (kJ kg−1) | |

| radiant attenuation factor of flue gas (m−1 MPa−1) | |

| radiant attenuation factor of soot (m−1 MPa−1) | |

| radiant attenuation factor of fly ash (m−1 MPa−1) | |

| radiant attenuation factor of char (m−1 MPa−1) | |

| radiant attenuation factor of triatomic gases (m−1 MPa−1) | |

| heat transfer coefficient of convective heating surfaces (W m−2 K−1) | |

| a dimensionless coefficient correlated to the proportion of luminous area in the flame | |

| CO2 annual emission reduction (t) | |

| CO2 annual emission (t) | |

| CO2 annual emission under BMCR (t) | |

| a dimensionless coefficient related to fuel characteristics, combustion mode, and temperature distribution | |

| content of moisture on the as-received basis (%) | |

| CO2 emission intensity of power generation (g kW−1 h−1) | |

| content of nitrogen on the as-received basis (%) | |

| content of oxygen on the as-received basis (%) | |

| power generation (MW) | |

| heat loss owing to the exhaust gas (%) | |

| heat loss owing to incomplete combustion of gaseous fuels (%) | |

| heat loss owing to incomplete combustion of solid fuels (%) | |

| heat loss owing to radiation and convection (%) | |

| heat loss owing to ash residue (%) | |

| available heat of fuel (kJ kg−1) | |

| heat transfer quantity of convective heating surfaces (W) | |

| heat absorption of flue gas (kJ kg−1) | |

| sensible heat of combustion air (kJ kg−1) | |

| lower heating value of mixed fuels (kJ kg−1) | |

| lower heating value of coal (kJ kg−1) | |

| lower heating value of biomass syngas (kJ m−3) | |

| heat entrained into the boiler envelope (kJ kg−1) | |

| total available heat of working fluid (kW) | |

| water vapor volume fraction | |

| content of sulfur on the as-received basis (%) | |

| converted content of sulfur (%) | |

| acidic dew point (°C) | |

| water dew point (°C) | |

| furnace exit flue-gas temperature (K) | |

| theoretical combustion temperature (K) | |

| theoretical air volume (m3 kg−1) | |

| total air flow rate of air heater inlet (m3 s−1) | |

| total flue-gas flow rate of air heater outlet (m3 s−1) | |

| theoretical water vapor volume (m3 kg−1) | |

| total water vapor volume (m3 kg−1) | |

| total flue-gas volume (m3 kg−1) | |

| theoretical flue-gas volume (m3 kg−1) | |

| content of volatile matter on a dry ash-free basis (%) | |

| generation capacity of the boiler (kW h) | |

| volume of biomass syngas to 1 kg of coal under standard conditions (m3 kg−1) | |

| temperature difference of heat transfer (K) | |

| the larger one of initial and final temperature differences between hot and cold fluid (K) | |

| the smaller one of initial and final temperature differences between hot and cold fluid (K) | |

| excess air coefficient of furnace exit | |

| a dimensionless coefficient related to fly ash | |

| excess air coefficient of the air heater outlet | |

| convective heat transfer coefficient of flue gas (W m−2 K−1) | |

| convective heat transfer coefficient of working fluid (W m−2 K−1) | |

| radiant heat transfer coefficient of flue gas (W m−2 K−1) | |

| utilization factor considering imperfect sweeping by flue gas | |

| fouling factor (m2 K W−1) | |

| a dimensionless coefficient that depends on the excess air coefficient at the furnace exit | |

| excess air coefficient of the air heater inlet | |

| thermal efficiency of the boiler (%) | |

| combustion efficiency | |

| heat retention factor | |

| exhaust gas temperature (°C) | |

| air density (kg m−3) | |

| outlet gas temperature (°C) | |

| temperature correction factor | |

| BMCR | boiler maximum continuous rating |

| THA | turbine heat acceptance |

| LHV | lower heating value |

References

- Ziegler, C.; Morelli, V.; Fawibe, O. Climate Change and Underserved Communities. Physician Assist. Clin. 2019, 4, 203–216. [Google Scholar] [CrossRef]

- Wang, Y.; Deng, L.; Chang, G.; Liu, H.; Lyu, K.; Nie, X.; Zhang, G. Influence of biomass gas parameters on coupled coal-fired biomass generation. Therm. Power Gener. 2021, 50, 34–40. (In Chinese) [Google Scholar] [CrossRef]

- Long, J.; Deng, L.; Che, D. Analysis on organic compounds in water leachate from biomass. Renew. Energy 2020, 155, 1070–1078. [Google Scholar] [CrossRef]

- Olivieri, A.; Ravelli, S. Cogasification of Coal and Biomass in an Integrated Gasification Combined Cycle Power Plant: Effects on Thermodynamic Performance and Gas Composition. J. Energy Eng. 2020, 146, 04020071. [Google Scholar] [CrossRef]

- Roni, M.S.; Chowdhury, S.; Marufuzzaman, M.; Mamun, S.; Lein, W.; Johnson, S. Biomass co-firing technology with policies, challenges, and opportunities: A global review. Renew. Sustain. Energy Rev. 2017, 78, 1089–1101. [Google Scholar] [CrossRef]

- Neville, A. Biomass Cofiring: A Promising New Generation Option. Power 2011, 155, 52–56. [Google Scholar]

- Kalisz, S.; Pronobis, M.; Baxter, D. Co-firing of biomass waste-derived syngas in coal power boiler. Energy 2008, 33, 1770–1778. [Google Scholar] [CrossRef]

- Deng, L.; Ma, S.; Jiang, J.; Tie, Y.; Zhang, Y.; Zhu, Z.; Belošević, S.; Tomanović, I.; Che, D. Numerical Investigation on Cofiring Characteristics of Biomass Syngas and Coal in a 660-MW Tower Boiler. J. Energy Eng. 2022, 148, 04022014. [Google Scholar] [CrossRef]

- Robinson, A.L.; Junker, H.; Baxter, L.L. Pilot-Scale Investigation of the Influence of Coal−Biomass Cofiring on Ash Deposition. Energy Fuels 2002, 16, 343–355. [Google Scholar] [CrossRef]

- Badour, C.; Gilbert, A.; Xu, C. Combustion and air emissions from co-firing a wood biomass, a Canadian peat and a Canadian lignite coal in a bubbling fluidised bed combustor. Can. J. Chem. Eng. 2012, 90, 1170–1177. [Google Scholar] [CrossRef]

- Yao, X.; Zhou, H.; Xu, K.; Chen, S.; Ge, J.; Xu, Q. Systematic study on ash transformation behaviour and thermal kinetic characteristics during co-firing of biomass with high ratios of bituminous coal. Renew. Energy 2020, 147, 1453–1468. [Google Scholar] [CrossRef]

- Harding, N.S.; Adams, B.R. Biomass as a reburning fuel: A specialized cofiring application. Biomass Bioenergy 2000, 19, 429–445. [Google Scholar] [CrossRef]

- Sefidari, H.; Ma, C.; Fredriksson, C.; Lindblom, B.; Wiinikka, H.; Nordin, L.O.; Wu, G.; Yazhenskikh, E.; Müller, M.; Öhman, M. The effect of co-firing coal and woody biomass upon the slagging/deposition tendency in iron-ore pelletizing grate-kiln plants. Fuel Process. Technol. 2020, 199, 106254. [Google Scholar] [CrossRef]

- Ma, W.; Zhou, H.; Zhang, J.; Zhang, K.; Liu, D.; Zhou, C.; Cen, K. Behavior of Slagging Deposits during Coal and Biomass Co-combustion in a 300 kW Down-Fired Furnace. Energy Fuels 2018, 32, 4399–4409. [Google Scholar] [CrossRef]

- Luo, Z.; Xu, D.; Ma, Y.; Cheng, Q. Experimental Study on Co-Firing of Coal and Brewery Wastewater Sludge. Appl. Sci. 2020, 10, 7589. [Google Scholar] [CrossRef]

- Unchaisri, T.; Fukuda, S.; Phongphiphat, A.; Saetia, S.; Sajjakulnukit, B. Experimental Study on Combustion Characteristics in a CFB during Co-firing of Coal with Biomass Pellets in Thailand. Int. Energy J. 2019, 19, 101–114. [Google Scholar]

- Hou, S.; Huang, W.; Lin, T. Co-combustion of Fast Pyrolysis Bio-oil Derived from Coffee Bean Residue and Diesel in an Oil-fired Furnace. Appl. Sci. 2017, 7, 1085. [Google Scholar] [CrossRef]

- Chen, C.; Wu, X.; Zhao, L. Simulation of Coal and Biomass Cofiring with Different Particle Density and Diameter in Bubbling Fluidized Bed under O2/CO2 Atmospheres. J. Combust. 2018, 2018, 6931483. [Google Scholar] [CrossRef]

- Szufa, S.; Piersa, P.; Junga, R.; Błaszczuk, A.; Modliński, N.; Sobek, S.; Marczak-Grzesik, M.; Adrian, Ł.; Dzikuć, M. Numerical modeling of the co-firing process of an in situ steam-torrefied biomass with coal in a 230 MW industrial-scale boiler. Energy 2023, 263, 125918. [Google Scholar] [CrossRef]

- Liu, Q.; Zhong, W.; Yu, A.; Wang, C.-H. Modelling the co-firing of coal and biomass in a 10 kWth oxy-fuel fluidized bed. Powder Technol. 2022, 395, 43–59. [Google Scholar] [CrossRef]

- Zhou, M.; Wang, S.; Luo, K.; Fan, J. Three-dimensional modeling study of the oxy-fuel co-firing of coal and biomass in a bubbling fluidized bed. Energy 2022, 247, 123496. [Google Scholar] [CrossRef]

- Dong, L.; Alexiadis, A. Simulation of char burnout characteristics of biomass/coal blend with a simplified single particle reaction model. Energy 2023, 264, 126075. [Google Scholar] [CrossRef]

- Deng, L.; Wang, Y.; Wu, S.; Che, D. Utilization of combustible waste gas as a supplementary fuel in coal-fired boilers. Int. J. Energy Res. 2018, 42, 1677–1692. [Google Scholar] [CrossRef]

- Yao, Q.; Li, R.; Wang, Y.; Li, Y.; Zhang, L.; Deng, L.; Che, D. Feasibility Analysis of Coupling Hydrogen-Derived Fuel on a Coal-Fired Boiler for Power Generation. Energy Fuels 2023, 37, 477–491. [Google Scholar] [CrossRef]

- Blokh, A.G.; Zhuravlev, Y.A.; Gorb, E.I.; Talibdzhanov, Z.S. Heat transfer in furnaces of high-power boilers. Heat Transf. Res. 1993, 25, 418–424. [Google Scholar]

- Antonovskii, V.I. Heat Transfer in Steam Boiler Furnaces. A Retrospective View on the Development of a Standard Calculation Method. Therm. Eng. 2004, 51, 738–749. [Google Scholar]

- Alekhnovich, A.N. Thermal efficiency coefficient of furnace shields as applied to standard method for thermal calculation of boilers. Teploenergetika 2009, 9, 23–29. [Google Scholar]

- Che, D. Boilers: Theory, Design and Operation; Xi’an Jiaotong University Press: Xi’an, China, 2008. [Google Scholar]

- Kuznetsov, N.; Mitor, V.; Karasina, E. Thermal Calculation of Boiler Units (Standard Method); Energiya Press: Moscow, Russia, 1973. [Google Scholar]

- Hsi, C.-L.; Kuo, J.-T. Estimation of fuel burning rate and heating value with highly variable properties for optimum combustion control. Biomass Bioenergy 2008, 32, 1255–1262. [Google Scholar] [CrossRef]

- Song, Q. Numerical Simulation and Combustion Analysis of Biomass Gas and Coal Co-firing Process. J. Henan Sci. Technol. 2016, 15, 25–28. (In Chinese) [Google Scholar]

- Atnaw, S.M.; Sulaiman, S.A.; Yusup, S. Syngas production from downdraft gasification of oil palm fronds. Energy 2013, 61, 491–501. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).