Quantification of Microplastics in Plastic-Bottled Chinese Baijiu Using Micro-FTIR in Imaging Mode

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sampling and Sample Preparation

2.2. Microplastic Extraction

2.3. Micro-FTIR Analysis

2.4. Microplastic Identification and Quantification

2.5. Quality Control Measures

2.6. Statistical Analysis

2.7. Estimation of Human Uptake of Microplastics

3. Results

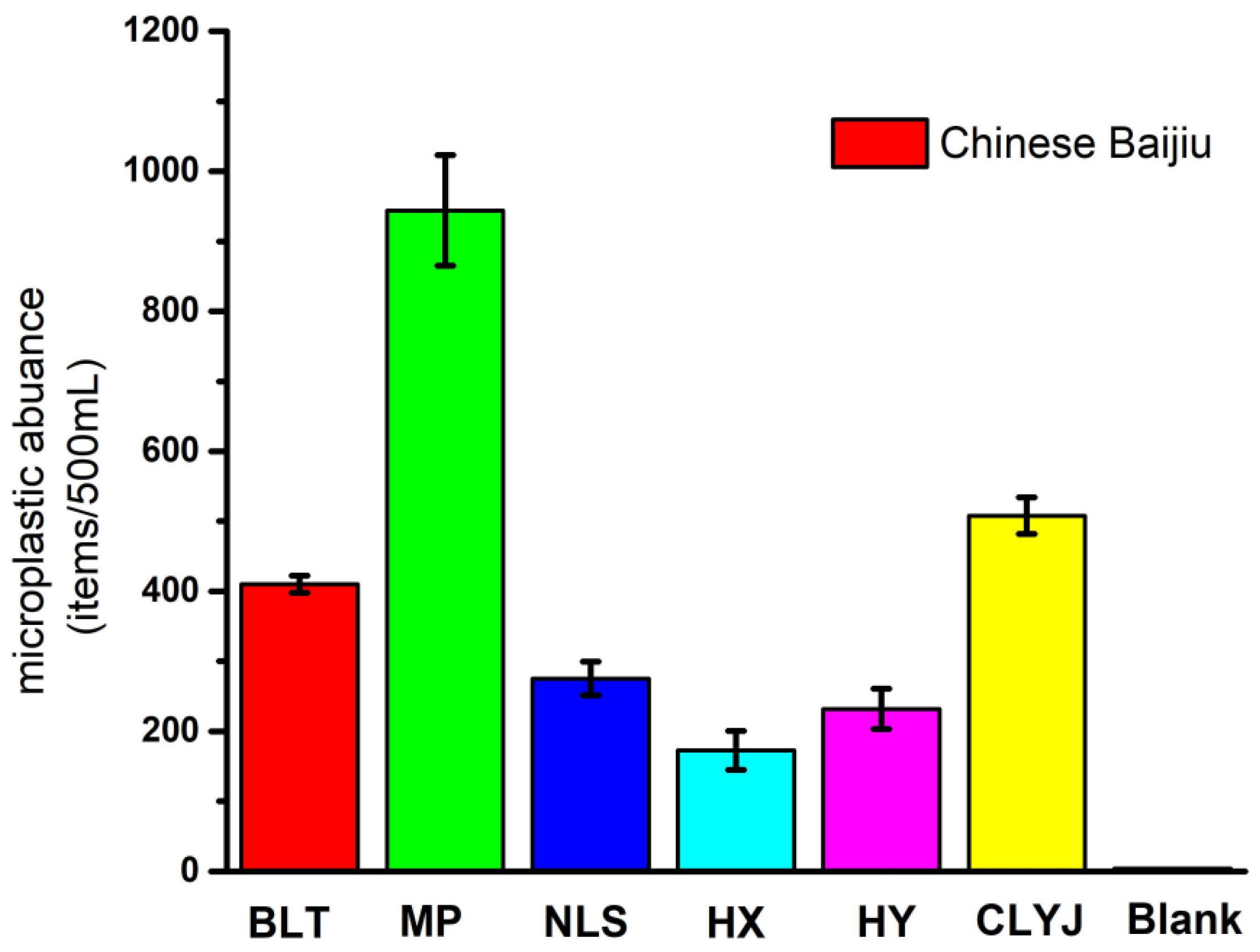

3.1. Microplastic Abundance

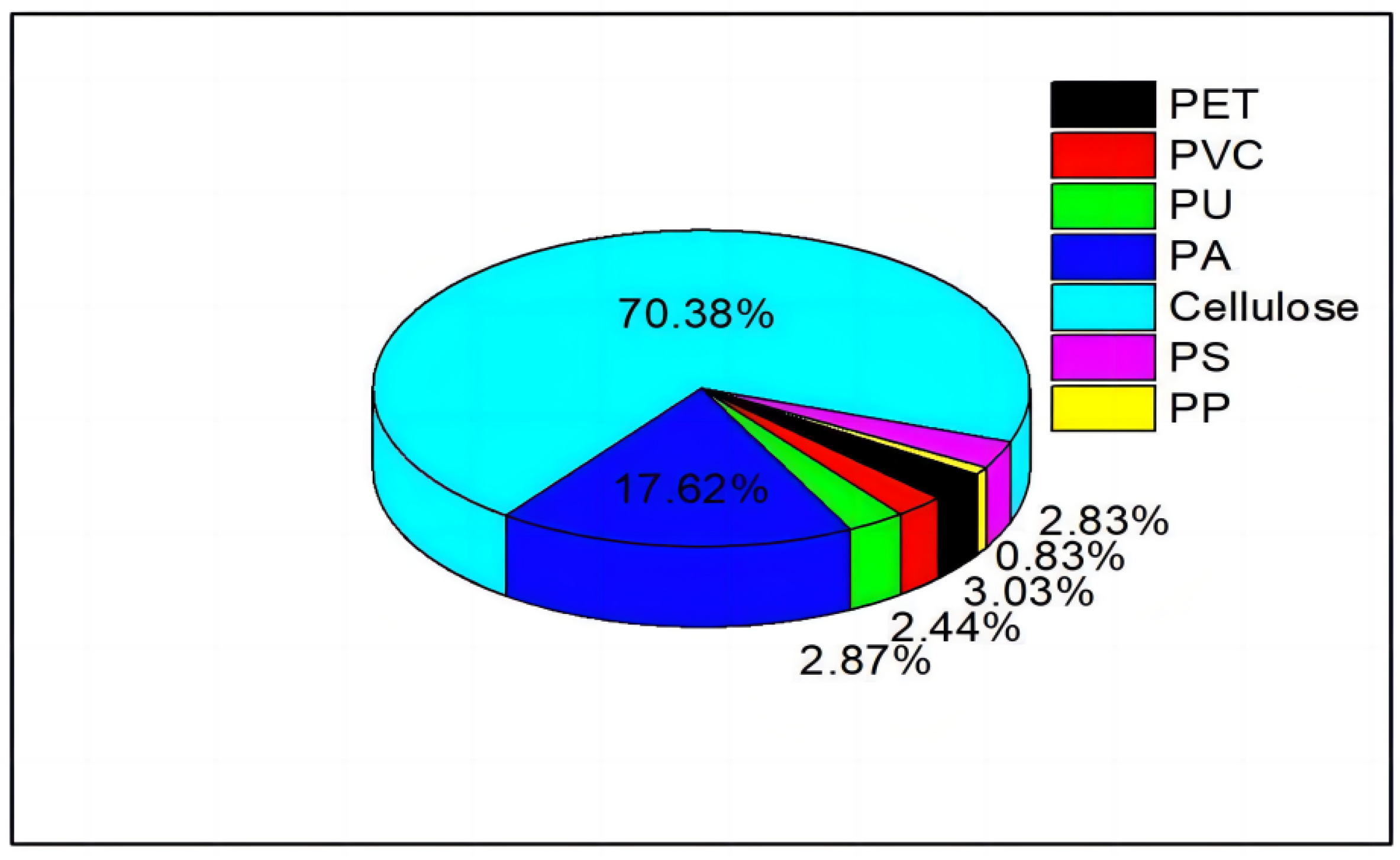

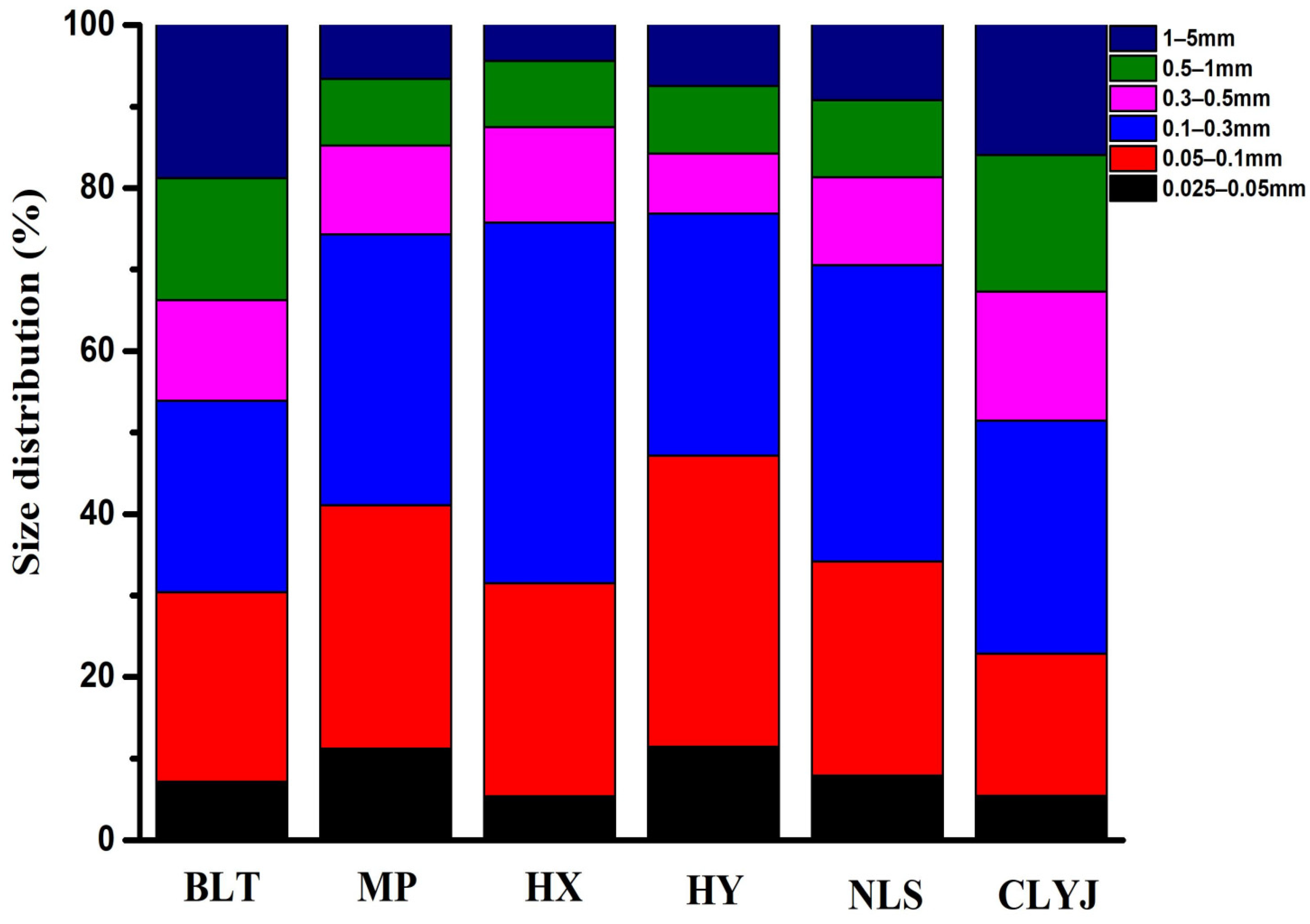

3.2. Distribution of the Size and Shape of Microplastics

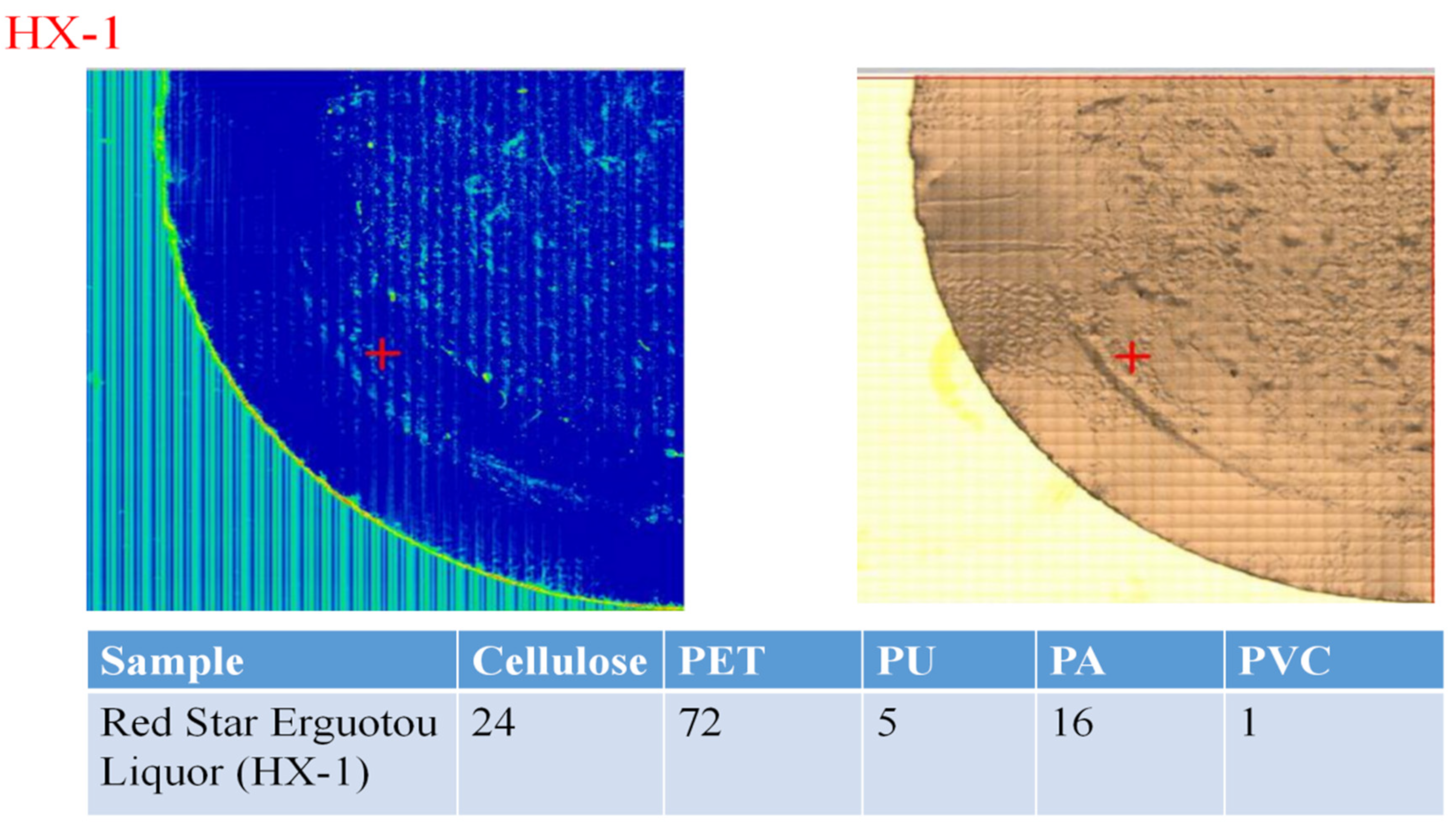

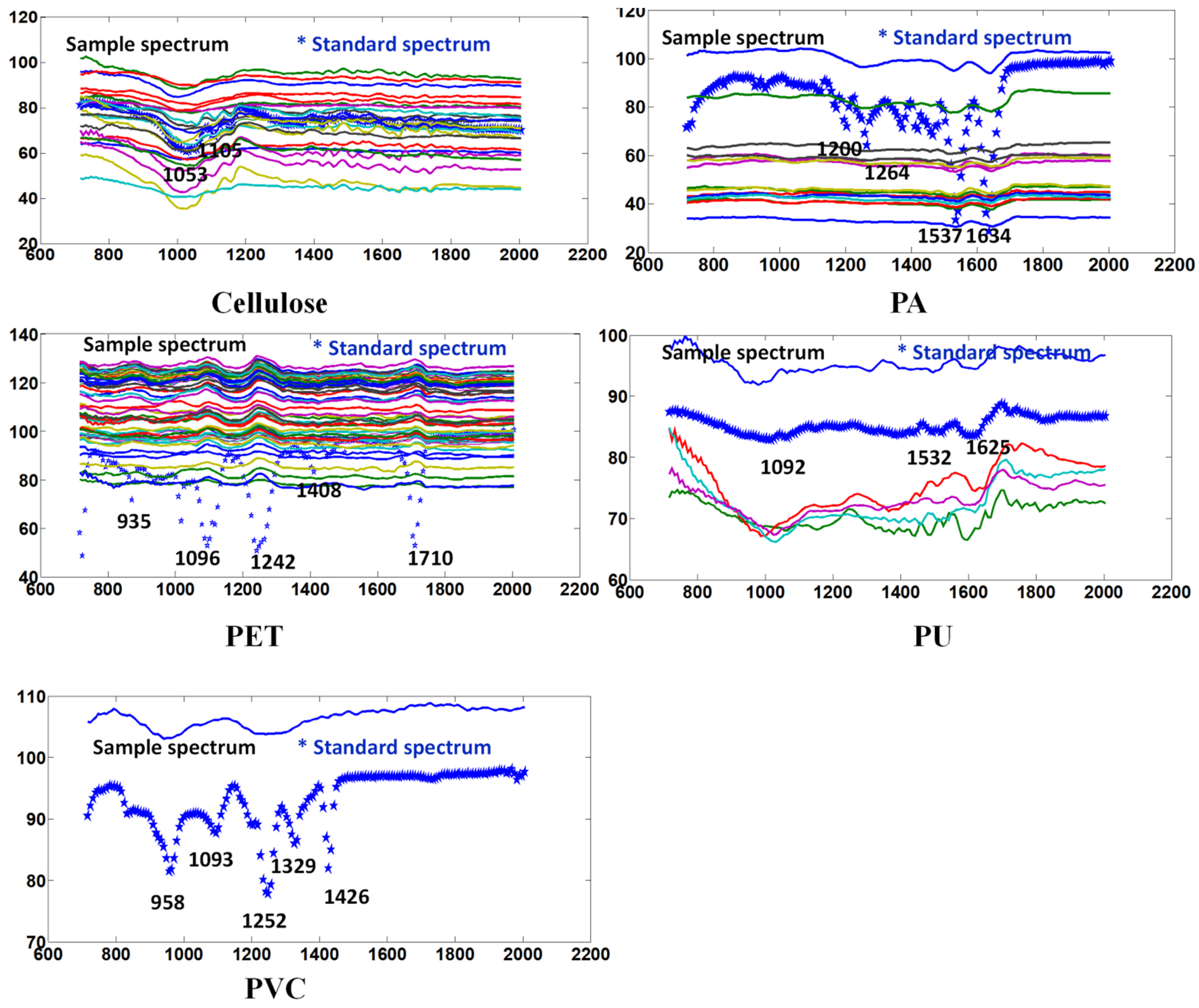

3.3. Validation and Data Analysis of Plastic-Bottled Chinese Baijiu Using Micro-FTIR

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

References

- Hajiouni, S.; Mohammadi, A.; Ramavandi, B.; Arfaeinia, H.; De-la-Torre, G.E.; Tekle-Röttering, A.; Dobaradaran, S. Occurrence of microplastics and phthalate esters in urban runoff: A focus on the Persian Gulf coastline. Sci. Total Environ. 2022, 806 Pt 1, 150559. [Google Scholar] [CrossRef]

- Kadac-Czapska, K.; Knez, E.; Grembecka, M. Food and human safety: The impact of microplastics. Crit. Rev. Food Sci. 2022. [Google Scholar] [CrossRef] [PubMed]

- Sewwandi, M.; Wijesekara, H.; Rajapaksha, A.U.; Soysa, S.; Vithanage, M. Microplastics and plastics-associated contaminants in food and beverages; Global trends, concentrations, and human exposure. Environ. Pollut. 2023, 317, 120747. [Google Scholar] [CrossRef] [PubMed]

- Çıtar Dazıroğlu, M.E.; Bilici, S. The hidden threat to food safety and human health: Microplastics. Environ. Dev. Sustain. 2023. [Google Scholar] [CrossRef]

- Zuri, G.; Karanasiou, A.; Lacorte, S. Microplastics: Human exposure assessment through air, water, and food. Environ. Int. 2023, 179, 108150. [Google Scholar] [CrossRef] [PubMed]

- Bostan, N.; Ilyas, N.; Akhtar, N.; Mehmood, S.; Saman, R.U.; Sayyed, R.Z.; Shatid, A.A.; Alfaifi, M.Y.; Eldin EI, E.; Pandiaraj, S.S. Toxicity assessment of microplastic (MPs): A threat to the ecosystem. Environ. Res. 2023, 234, 116523. [Google Scholar] [CrossRef] [PubMed]

- Pham, D.T.; Kim, J.; Lee, S.H.; Kim, J.; Kim, D.; Hong, S.; Jung, J.; Kwon, J.H. Analysis of microplastics in various foods and assessment of aggregate human exposure via food consumption in korea. Environ. Pollut. 2023, 322, 121153. [Google Scholar] [CrossRef] [PubMed]

- Crosta, A.; Parolini, M.; Felice, B.D. Microplastics Contamination in Nonalcoholic Beverages from the Italian Market. Int. J. Environ. Res. Public Health 2023, 20, 4122. [Google Scholar] [CrossRef] [PubMed]

- Lin, Q.H.; Zhao, S.S.; Pang, L.H.; Sun, C.Z.; Chen, L.Y.; Li, F.M. Potential risk of microplastics in processed foods: Preliminary risk assessment concerning polymer types, abundance, and human exposure of microplastics. Ecotoxicol. Environ. Saf. 2022, 24, 114260. [Google Scholar] [CrossRef]

- Li, Y.N.; Peng, L.; Fu, J.X.; Dai, X.L.; Wang, G.Q. A microscopic survey on microplastics in beverages: The case of beer, mineral water and tea. Analyst 2022, 147, 109. [Google Scholar] [CrossRef]

- Manthey, J.; Shield, K.D.; Rylett, M.; Hasan, O.S.M.; Probst, C.; Rehm, J. Global alcohol exposure between 1990 and 2017 and forecasts until 2030: A modelling study. Lancet 2019, 393, 2493–2502. [Google Scholar] [CrossRef] [PubMed]

- Liebezeit, G.; Liebezeit, E. Synthetic particles as contaminations in German beers. Food Addit. Contam. Part A 2014, 31, 1574–1578. [Google Scholar] [CrossRef]

- Shruti, V.C.; Perez-Guevara, F.; Elizalde-Martinez, I.; Kutralam-Muniasamy, G. Toward a unified framework for invessti gating micro (nano) plastics in packaged beverages intended for human consumption. Environ. Pollut. 2021, 268, 115811. [Google Scholar] [CrossRef] [PubMed]

- Wiesheu, A.C.; Anger, P.M.; Baumann, T.; Niessner, R.; Ivleva, N.P. Raman microspectroscopic analysis of fibers in beverages. Anal. Methods 2016, 8, 5722–5725. [Google Scholar] [CrossRef]

- Cox, K.D.; Covernton, G.A.; Davies, H.L.; Dower, J.F.; Juanes, F.; Dudas, S.E. Human consumption of microplastics. Environ. Sci. Technol. 2019, 53, 7068–7074. [Google Scholar] [CrossRef] [PubMed]

- Prata, J.C.; Paço, A.; Reis, V.; da Costa, J.P.; Fernandes, A.J.S.; da Costa, F.M.; Duarte, A.C.; Rocha-Santos, T. Identification of microplastics in white wines capped with polyethylene stoppers using micro-Raman spectroscopy. Food Chem. 2020, 331, 127323. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.J.; Wang, J.; Ren, J.F. Analysis of Microplastics in Takeaway Food Containers in China Using FPA-FTIR Whole Filter Analysis. Molecules 2022, 27, 2646. [Google Scholar] [CrossRef]

- Schymanski, D.; Oßmann, B.E.; Benismail, N.; Boukerma, K.; Dallmann, G.; von der Esch, E.; Fischer, D.; Fischer, F.; Gilliland, D.; Glas, K.; et al. Analysis of microplastics in drinking water and other clean water samples with micro-Raman and micro-infrared spectroscopy: Minimum requirements and best practice guidelines. Anal. Bioanal. Chem. 2021, 413, 5969. [Google Scholar] [CrossRef]

- Gupta, S.; Kumar, R.; Rajput, A.; Gorka, R.; Gupta, A.; Bhasin, N.; Yadav, S.; Verma, A.; Ram, K.; Bhagat, M. Atmospheric Microplastics: Perspectives on Origin, Abundances, Ecological and Health Risks. Environ. Sci. Pollut. Res. 2023. [Google Scholar] [CrossRef]

- Dris, R.; Gasperi, J.; Saad, M.; Mirande, C.; Tassin, B. Synthetic fibers in atmospheric fallout: A source of microplastics in the environment? Mar. Pollut. Bulletin. 2016, 104, 290–293. [Google Scholar] [CrossRef]

- Xu, J.L.; Martin, H.; Yu, K.P.; Gowen, A.A. Microplastic Characterization by Infrared Spectroscopy. In Handbook of Microplastics in the Environment; Springer: Berlin/Heidelberg, Germany, 2020; pp. 1–33. [Google Scholar]

- Morgado, V.; Palma, C.; da Bettencourt Silva, J.N.R. Microplastics identification by Infrared spectroscopy—Evaluation of identification criteria and uncertainty by the Bootstrap method. Talanta 2021, 224, 121814. [Google Scholar] [CrossRef] [PubMed]

- Mecozzi, M.; Pietroletti, M.; Monakhova, Y.B. FTIR spectroscopy supported by statistical techniques for the structural characterization of plastic debris in the marine environment:application to monitoring studies. Mar. Pollut. Bull. 2016, 106, 155–161. [Google Scholar] [CrossRef] [PubMed]

- Renner, G.; Schmidt, T.C.; Schram, J. A new chemometric approach for automatic identification of microplastics from environmental compartments based on FT-IR spectroscopy. Anal. Chem. 2017, 89, 12045–12053. [Google Scholar] [CrossRef] [PubMed]

- Renner, G.; Sauerbier, P.; Schmidt, T.C.; Schram, J. Robust automatic identification of microplastics in environmental samples using FTIR microscopy. Anal. Chem. 2019, 91, 9656–9664. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.Y.; Wen, D.S.; Pei, J.C.; Fei, Y.F.; Ouyang, D.; Zhang, H.B.; Luo, Y.M. Identification and quantification of microplastics using Fouriertransform infrared spectroscopy: Current status and future prospects. Curr. Environ. Health Rep. 2020, 18, 14–19. [Google Scholar]

- Kankanige, D.; Babel, S. Smaller-sized micro-plastics (MPs) contamination in single-use PET-bottled water in Thailand. Sci. Total Environ. 2020, 717, 137232. [Google Scholar] [CrossRef]

- Dessì, C.; Okoffo, E.D.; O’Brien, J.W.; Gallen, M.; Samanipour, S.; Kaserzon, S.; Rauert, C.; Wang, X.Y.; Thomas, K.V. Plastics contamination of store-bought rice. J. Hazard. Mater. 2021, 416, 125778. [Google Scholar] [CrossRef]

- Huang, Y.; Liu, Q.; Jia, W.Q.; Yan, C.G.; Wang, J. Agricultural plastic mulching as a source of microplastics in the terrestrial environment. Environ. Pollut. 2020, 260, 114096. [Google Scholar] [CrossRef]

- Kumar, M.V.; Sheela, A.M. Effect of plastic film mulching on the distribution of plastic residues in agricultural fields. Chemosphere 2020, 273, 128590. [Google Scholar] [CrossRef]

- Zhang, Q.; Ma, Z.; Cai, Y.; Li, H.; Ying, G. Agricultural Plastic Pollution in China: Generation of Plastic Debris and Emission of Phthalic Acid Esters from Agricultural Films. Environ. Sci. Technol. 2021, 55, 12459–12470. [Google Scholar] [CrossRef]

- Liu, Y.Y.; Guo, R.; Zhang, S.W.; Sun, Y.H.; Wang, F.Y. Uptake and translocation of nano/microplastics by rice seedlings: Evidence from a hydroponic experiment. J. Hazard. Mater. 2022, 421, 126700. [Google Scholar] [CrossRef]

- Winkler, A.; Santo, N.; Ortenzi, M.A.; Bolzoni, E.; Bacchetta, R.; Tremolada, P. Does mechanical stress cause microplastic release from plastic water bottles. Water Res. 2019, 166, 115082. [Google Scholar] [CrossRef] [PubMed]

- Jin, Y.X.; Lu, L.; Tu, W.Q.; Luo, T.; Fu, Z.W. Impacts of polystyrene microplastic on the gut barrier, microbiota and metabolism of mice. Sci. Total Environ. 2019, 649, 308–317. [Google Scholar] [CrossRef] [PubMed]

- Lu, L.; Wan, Z.Q.; Luo, T.; Fu, Z.W. Polystyrene microplastics induce gut microbiota dysbiosis and hepatic lipid metabolism disorder in mice. Sci. Total Environ. 2018, 631–632, 449–458. [Google Scholar] [CrossRef] [PubMed]

- Jin, H.B.; Ma, T.; Sha, X.X.; Liu, Z.Y.; Zhou, Y.; Meng, X.N.; Chen, Y.B.; Han, X.D.; Ding, J. Polystyrene microplastics induced male reproductive toxicity in mice. J. Hazard. Mater. 2021, 401, 123430. [Google Scholar] [CrossRef] [PubMed]

- Deng, Y.Y.; Zhang, Y.; Lemos, B.; Ren, H.Q. Tissue accumulation of microplastics in mice and biomarker responses suggest widespread health risks of exposure. Sci. Rep. 2017, 7, 46687. [Google Scholar] [CrossRef] [PubMed]

- Schirinzi, G.F.; Pérez-Pomeda, I.; Sanchís, J.; Rossini, C.; Farré, M.; Barceló, D. Cytotoxic effects of commonly used nanomaterials and microplastics on cerebral and epithelial human cells. Environ. Res. 2017, 159, 579–587. [Google Scholar] [CrossRef] [PubMed]

- Fu, L.N.; Li, J.; Wang, G.Y.; Luan, Y.N.; Dai, W. Adsorption behavior of organic pollutants on microplastics. Ecotoxicol. Environ. Saf. 2021, 217, 112207. [Google Scholar] [CrossRef]

- Godoy, V.; Blázquez, G.; Calero, M.; Quesada, L.; Martín-Lara, M.A. The potential of microplastics as carriers of metals. Environ. Pollut. 2019, 255, 113363. [Google Scholar] [CrossRef]

- Khalid, N.; Aqeel, M.; Noman, A.; Khan, S.M.; Akhter, N. Interactions and effects of microplastics with heavy metals in aquatic and terrestrial environments. Environ. Pollut. 2021, 290, 118104. [Google Scholar] [CrossRef]

- Gkoutselis, G.; Rohrbach, S.; Harjes, J.; Obst, M.; Brachmann, A.; Horn, M.A.; Rambold, G. Microplastics accumulate fungal pathogens in terrestrial ecosystems. Sci. Rep. 2021, 11, 13214. [Google Scholar] [CrossRef]

- Rochman, C.M.; Hoh, E.; Hentschel, B.T.; Kaye, S. Long-term field measurement of sorption of organic contaminants to five types of plastic pellets: Implications for plastic marine debris. Environ. Sci. Technol. 2013, 47, 1646–1654. [Google Scholar] [CrossRef]

| Brand | Alcohol by Volume | Volume | Packaging Tape | Manufacturer |

|---|---|---|---|---|

| RedStar Erguotou Liquor (HX) | 62% | 5 L | PET | Beijing Red Star Company Limited (Beijing, China) |

| Mao Pu Pure grain wine (MP) | 50% | 5 L | PET | JinPower Company Limited. (Huangshi, Hubei Province, China) |

| Niu Lan Shan Erguotou Liquor (NLS) | 52% | 5 L | PET | Beijing Shunxin Agriculture Company Limited Niulanshan Distillery (Beijing, China) |

| Hui Yi Erguotou Liquor (HY) | 52% | 5 L | PET | Beijing Jianguo Brewery (Beijing, China) |

| Chun liang Liquor (CLYJ) | 52% | 2.5 L | PET | Luzhou Luqi Wine Industry Company Limited(Luzhou, Sichuan Province, China) |

| Bu Lao Tan grain wine (BLT) | 52% | 2.5 L | PET | Sichuan Bu Lao Tan Wine Company Limited(Luzhou, Sichuan Province, China) |

| Sample | Average Microplastic Abundance (Items/500 mL) | Total Microplastic Abundance (Items/500 mL) | RSD (%) | ||

|---|---|---|---|---|---|

| Bu Lao Tan grain wine (BLT) | Cellulose 147, PET 41, PS 68, PU18, PA 125, PVC 11 | 410 | 422 | 398 | 0.029 |

| Mao Pu Pure grain wine (MP) | Cellulose 833, PET 9, PU3, PA 56, PVC 43 | 942 | 1024 | 866 | 0.084 |

| Niu Lan Shan Erguotou Liquor (NLS) | Cellulose 214, PET 16, PU14, PA 31, PVC 1 | 274 | 252 | 300 | 0.087 |

| RedStar Erguotou Liquor (HX) | Cellulose 89, PU17, PA 61, PVC 5, PP 1 | 178 | 143 | 198 | 0.161 |

| Hui Yi Erguotou Liquor (HY) | Cellulose 172, PET 8, PU10, PA40, PVC 1, PP 1 | 240 | 256 | 200 | 0.124 |

| Chun liang Liquor (CLYJ) | Cellulose 334, PET 3, PS 4, PU11, PA135, PVC 1, PP 20 | 496 | 538 | 490 | 0.051 |

| Blank (Milli-Q water) | Cellulose 4 | 4 | 4 | 4 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, X.; Wang, Q.; Wang, J.; Li, H.; Ren, J.; Tang, S. Quantification of Microplastics in Plastic-Bottled Chinese Baijiu Using Micro-FTIR in Imaging Mode. Appl. Sci. 2023, 13, 11142. https://doi.org/10.3390/app132011142

Zhou X, Wang Q, Wang J, Li H, Ren J, Tang S. Quantification of Microplastics in Plastic-Bottled Chinese Baijiu Using Micro-FTIR in Imaging Mode. Applied Sciences. 2023; 13(20):11142. https://doi.org/10.3390/app132011142

Chicago/Turabian StyleZhou, Xuejun, Qian Wang, Jin Wang, Hongyan Li, Jiefang Ren, and Shali Tang. 2023. "Quantification of Microplastics in Plastic-Bottled Chinese Baijiu Using Micro-FTIR in Imaging Mode" Applied Sciences 13, no. 20: 11142. https://doi.org/10.3390/app132011142

APA StyleZhou, X., Wang, Q., Wang, J., Li, H., Ren, J., & Tang, S. (2023). Quantification of Microplastics in Plastic-Bottled Chinese Baijiu Using Micro-FTIR in Imaging Mode. Applied Sciences, 13(20), 11142. https://doi.org/10.3390/app132011142