A Simple Method to Convert Cellular Polymers into Auxetic Metamaterials

Abstract

1. Introduction

2. Experimental

2.1. Materials

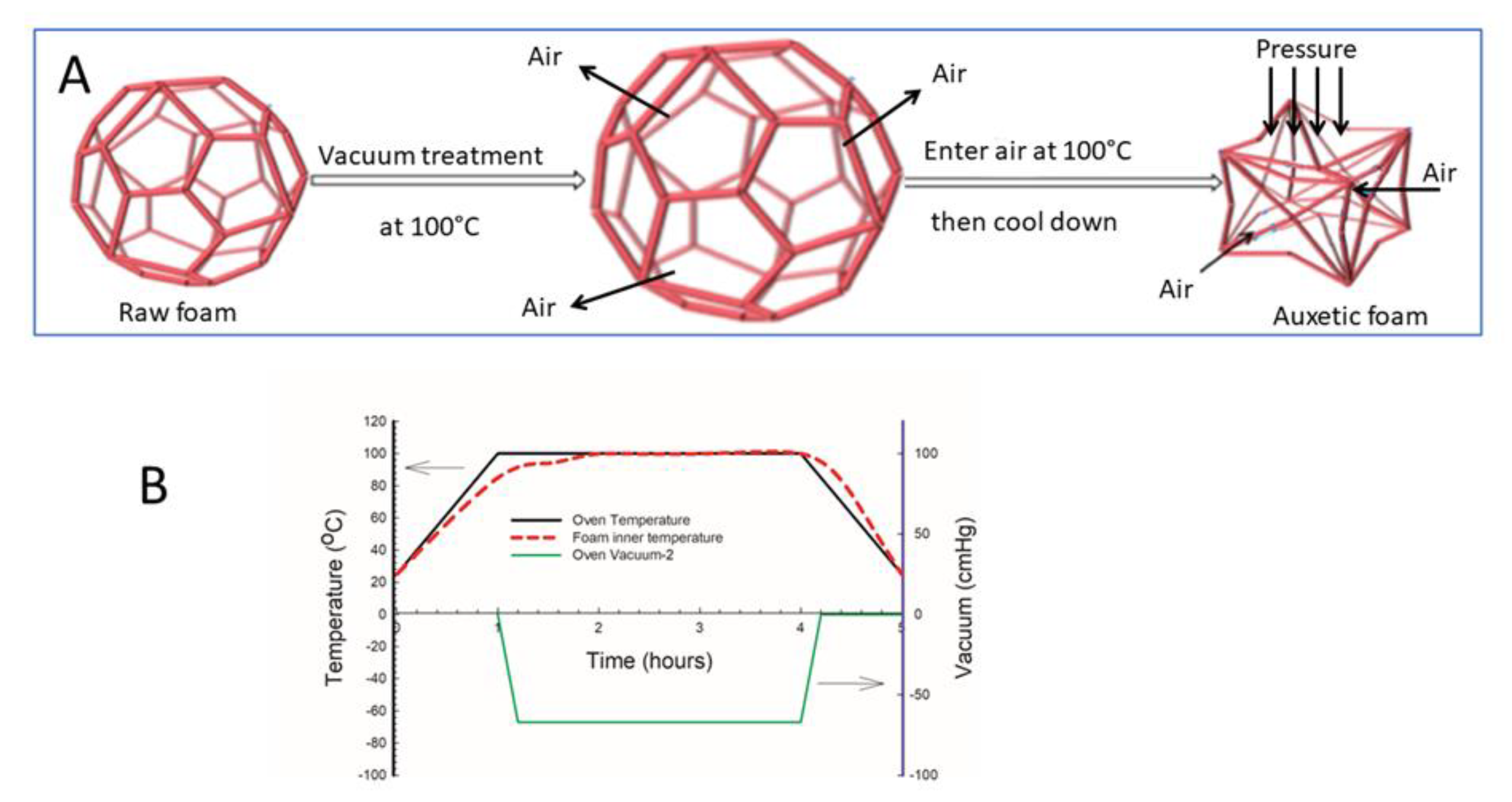

2.2. Methods

2.3. Characterization

2.3.1. Initial LDPE Foams

2.3.2. Foam Structure

2.3.3. Differential Scanning Calorimetry

2.3.4. Poisson’s Ratio

2.3.5. Mechanical Properties

3. Results and Discussion

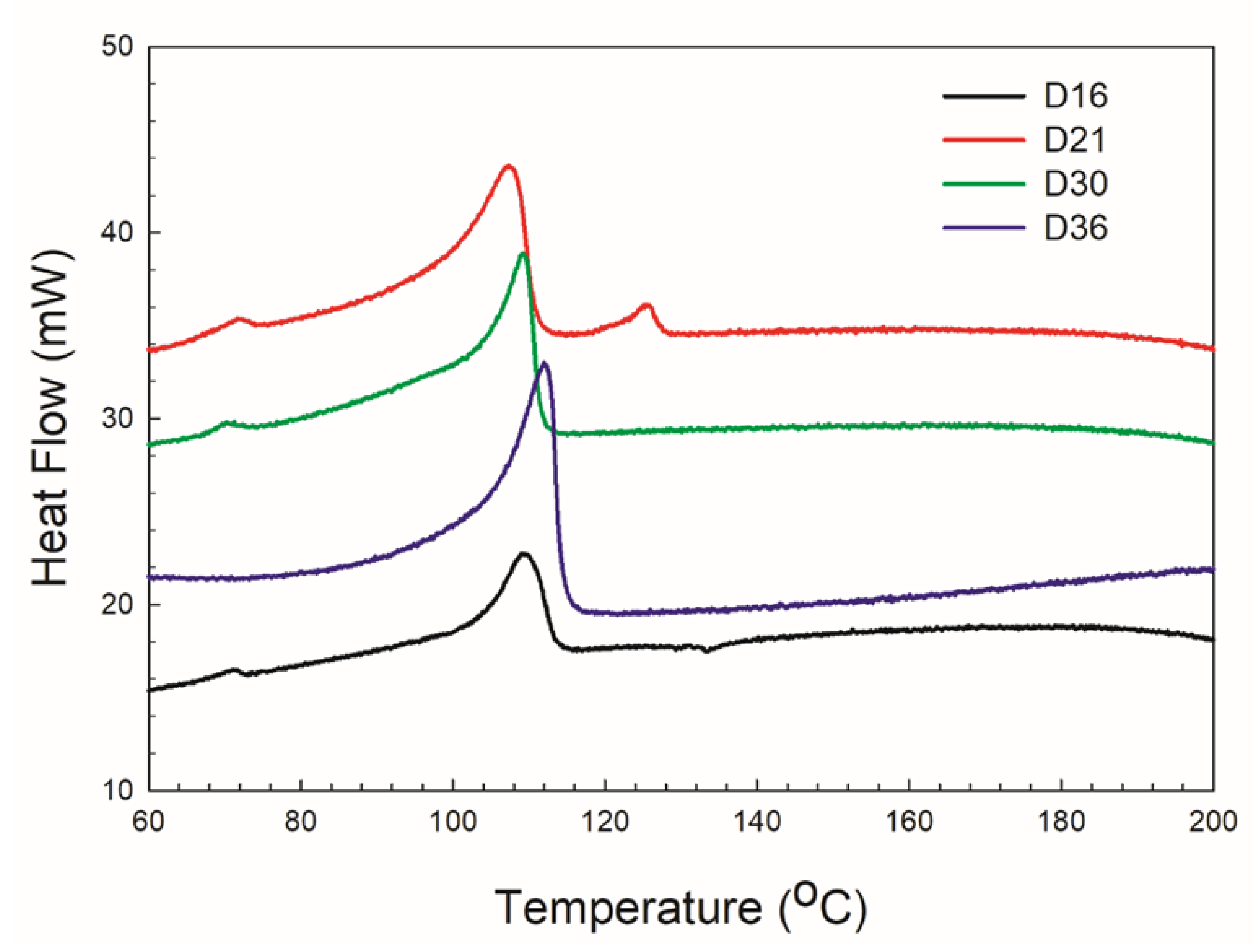

3.1. Properties of the LDPE

3.2. Auxetic Foams

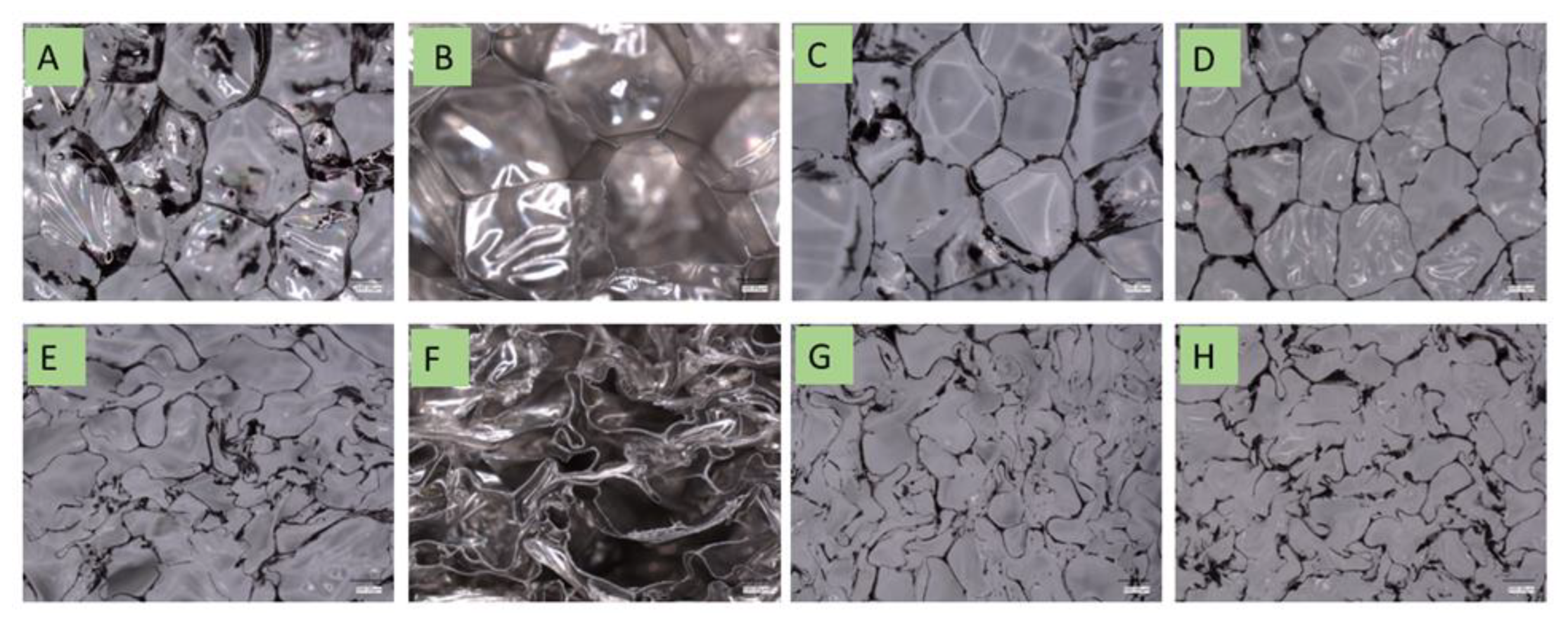

3.2.1. Morphological Properties

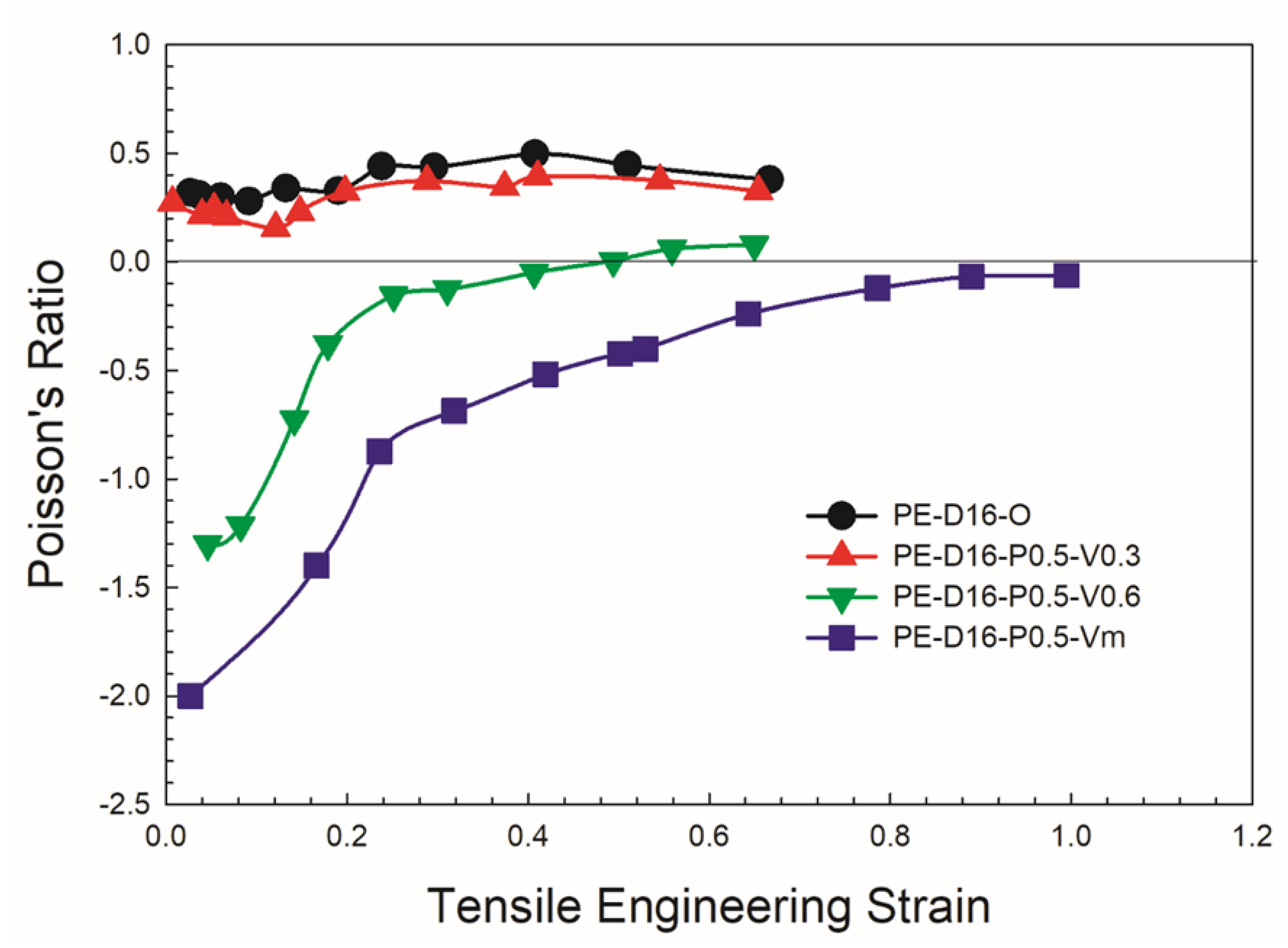

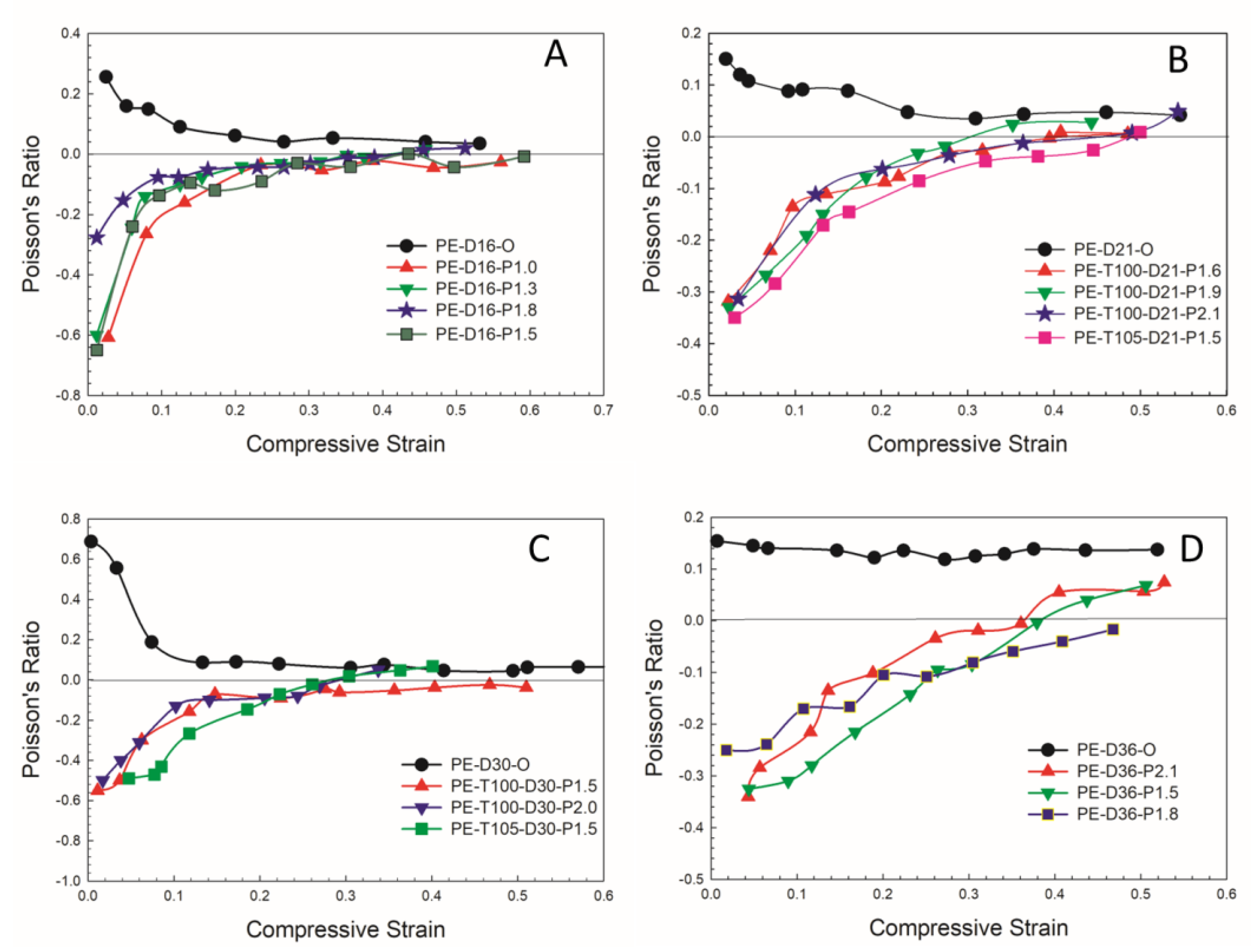

3.2.2. Poisson’s Ratio

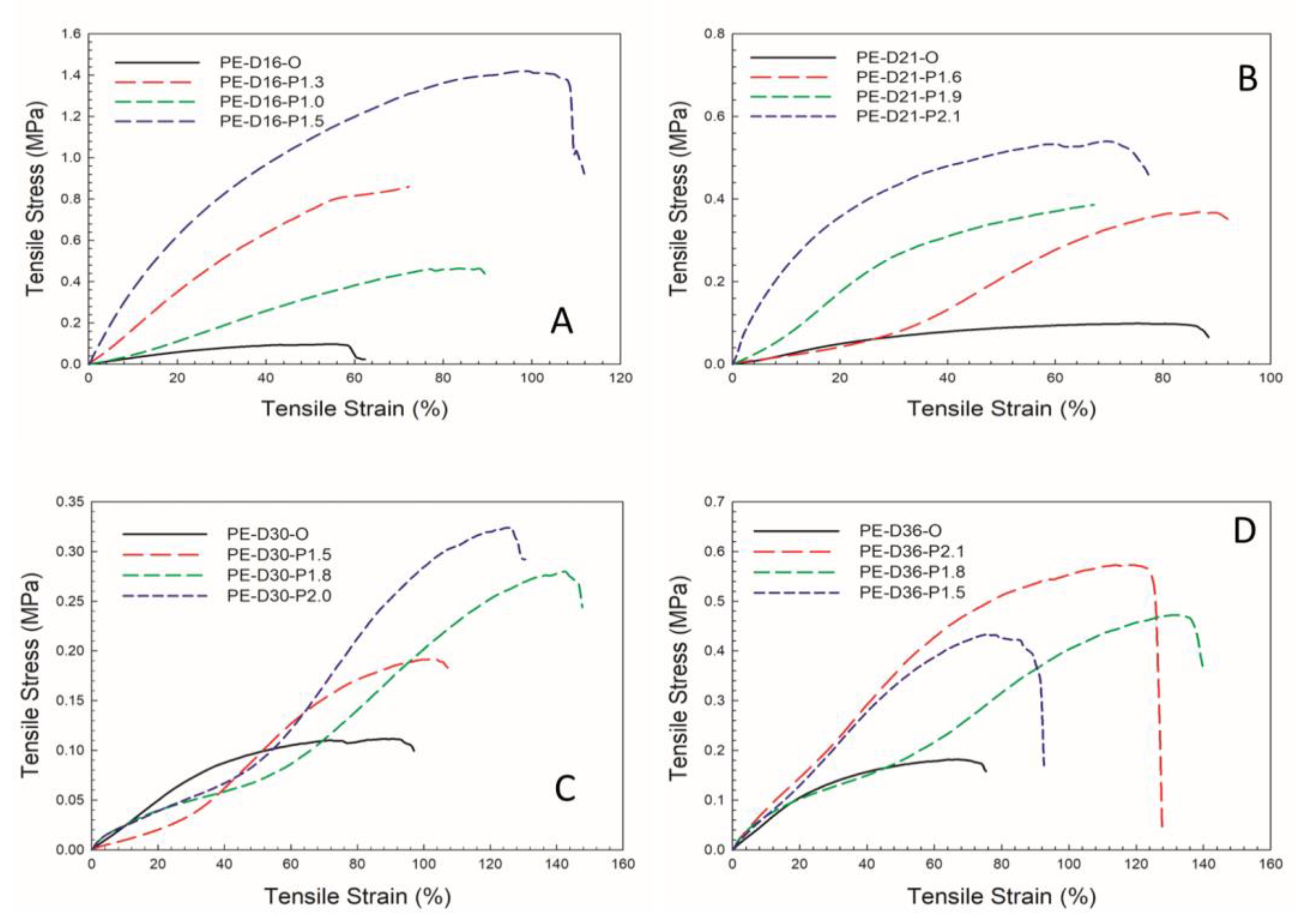

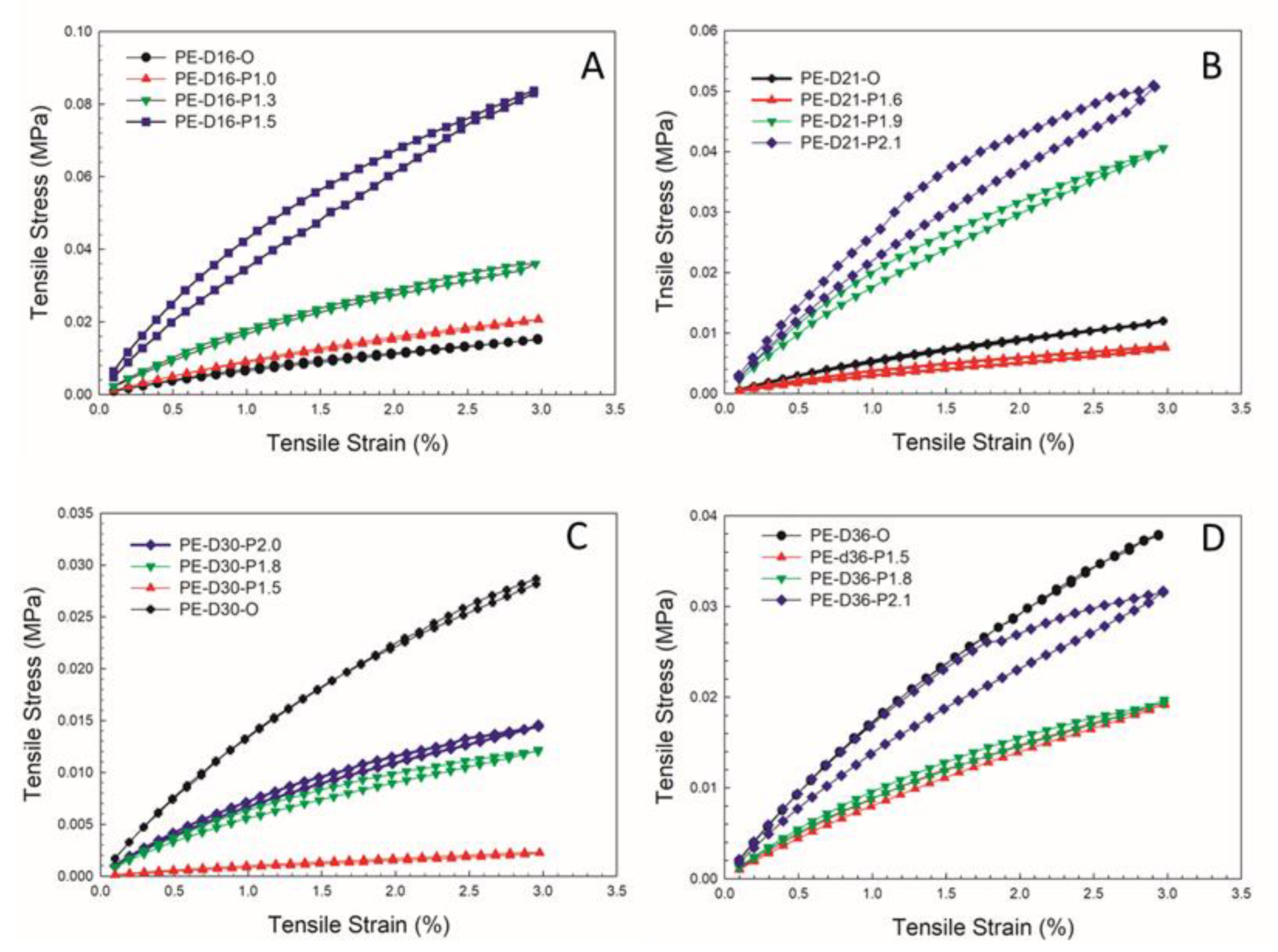

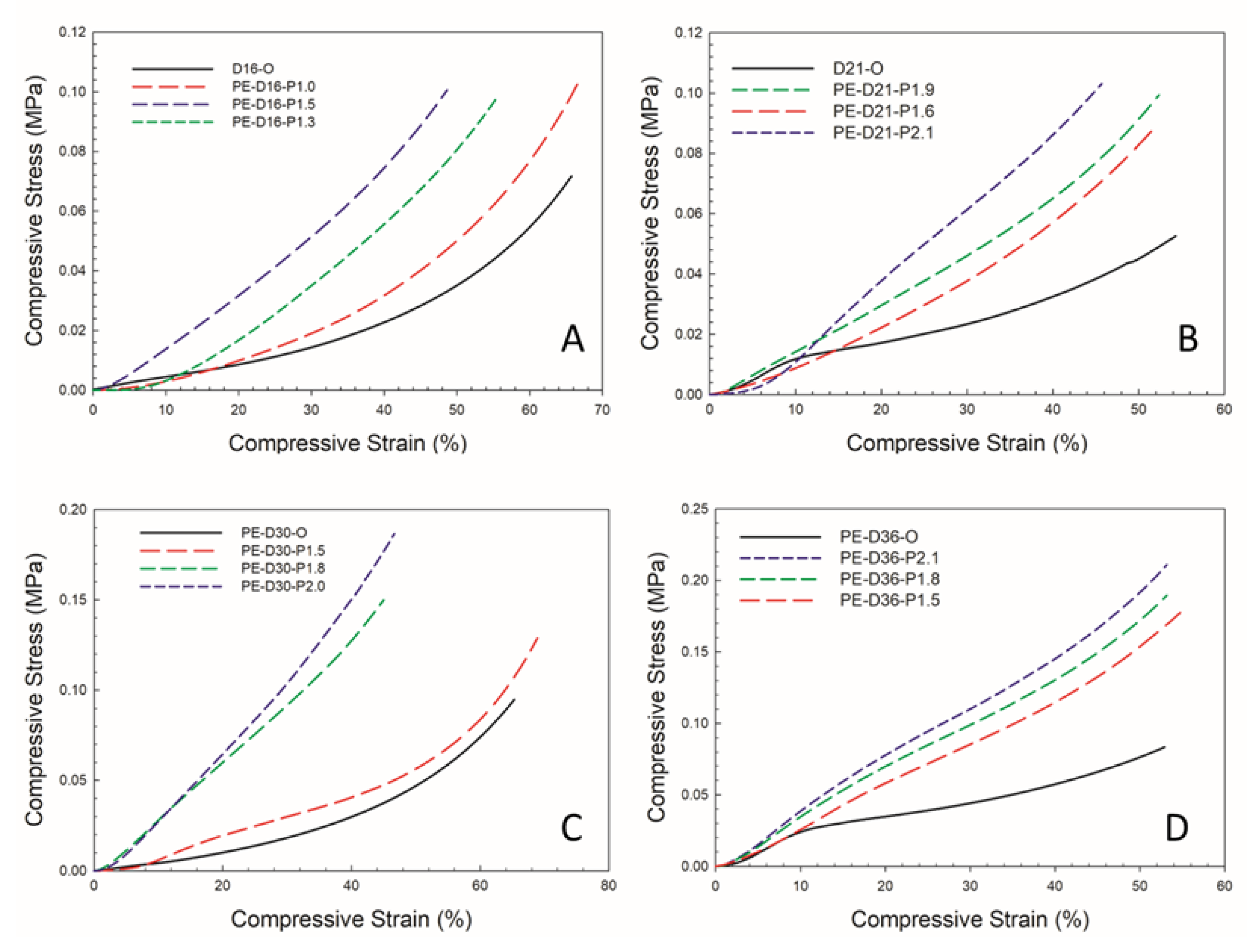

3.2.3. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| DSC | differential scanning calorimetry |

| Ed | dissipated energy |

| Ep | maximum potential energy |

| LDPE | low-density polyethylene |

| NE | nylon elastomer |

| NPR | negative Poisson’s ratio |

| OCP | open-cell percentage |

| p | porosity |

| PE | polyethylene |

| PMI | polymethacrylimide |

| PP | polypropylene |

| PU | polyether urethane foam |

| SECC | solvent evaporation–condensation and mechanical compression |

| Va | air volume |

| Vl | solid volume |

| VMC | vacuum combined with mechanical compression |

| Xc | crystallinity |

| εx | axial deformation |

| εy or εz | transverse deformations |

| ∆H100 | enthalpy of 100% crystalline LDPE |

| ∆Hm | sample enthalpy |

| ρa | density of air |

| ρf | foam density |

| ρl | solid matrix density |

| ʋ | Poisson’s ratio |

| Ψ | damping capacity |

References

- Raps, D.; Hossieny, N.; Park, C.B.; Altstädt, V. Past and present developments in polymer bead foams and bead foaming technology. Polymer 2015, 56, 5–19. [Google Scholar] [CrossRef]

- Kuhnigk, J.; Standau, T.; Dörr, D.; Brütting, C.; Altstädt, V.; Ruckdäschel, H. Progress in the development of bead foams—A review. Cell. Plast. 2022, 58, 707–735. [Google Scholar] [CrossRef]

- Available online: https://www.flexipack.com/blog/epe-foam (accessed on 10 October 2022).

- Hamdi, O.; Rodrigue, D. Production, Modeling and Applications. Curr. Appl. Polym. Sci. 2021, 4, 159. [Google Scholar] [CrossRef]

- Jiang, W.; Ren, X.; Wang, S.L.; Zhang, X.G.; Zhang, X.Y.; Luo, C.; Xie, Y.M.; Scarpa, F.; Alderson, A.; Evans, K.E. Manufacturing, characteristics and applications of auxetic foams: A state-of-the-art review. Compos. Part B 2022, 235, 109733. [Google Scholar] [CrossRef]

- Chen, X.; Hamdi, O.; Rodrigue, D. Conversion of low-density polyethylene foams into auxetic metamaterials. Polym. Adv. Technol. 2023, 34, 228–237. [Google Scholar] [CrossRef]

- Alderson, K.; Alderson, A.; Ravirala, N.; Simkins, V.; Davies, P. Manufacture and characterization of thin flat and curved auxetic foam sheets. Phys. Status. Solidi B 2012, 249, 1315–1321. [Google Scholar] [CrossRef]

- Alderson, K.A.; Alderson, P.; Davies, G.; Smart, G. Process for the Preparation of Auxetic Foams. Patent 8277719, 10 May 2012. [Google Scholar]

- Lakes, R. Foam structures with a negative Poisson’s ratio. Science 1987, 235, 1038–1040. [Google Scholar] [CrossRef]

- Chan, N.; Evans, K. Fabrication methods for auxetic foams. J. Mater. Sci. 1997, 32, 5945–5953. [Google Scholar] [CrossRef]

- Bianchi, M.; Scarpa, F.; Banse, M.; Smith, C. Novel generation of auxetic open cell foams for curved and arbitrary shapes. Acta Mater. 2011, 59, 686. [Google Scholar] [CrossRef]

- Bianchi, F.M.; Scarpa, C.W. Smith Stiffness and energy dissipation in polyurethane auxetic foams. J. Mater. Sci. 2008, 43, 5851. [Google Scholar] [CrossRef]

- Bianchi, F.M.; Scarpa, C.W. Smith, Shape memory behaviour in auxetic foams: Mechanical properties. Acta Mater. 2010, 58, 858–865. [Google Scholar] [CrossRef]

- Bianchi, F.M.; Frontoni, F.; Scarpa, C.W. Smith, Density changes during the manufacturing process of PU–PE open cell auxetic foams. Phys. Status Solidi B 2011, 248, 30–38. [Google Scholar] [CrossRef]

- Zhang, Q.; Lu, W.; Scarpa, F.; Barton, D.; Lakes, R.; Zhu, Y.; Lang, Z.; Peng, H. Large stiffness thermoformed open cell foams with auxeticity. Appl. Mater. Today 2020, 20, 100775. [Google Scholar] [CrossRef]

- Zhang, Q.; Lu, W.; Scarpa, F.; Barton, D.; Rankin, K.; Zhu, Y.; Lang, Z.-Q.; Peng, H.-X. Topological characteristics and mechanical properties of uniaxially thermoformed auxetic foam. Mater. Des. 2021, 211, 110139. [Google Scholar] [CrossRef]

- Zhang, Q.; Yu, X.; Scarpa, F.; Barton, D.; Rankin, K.; Lang, Z.; Zhang, D. Anisotropy in conventional and uniaxially thermoformed auxetic polymer foams. Compos. B Eng. 2011, 237, 109849. [Google Scholar] [CrossRef]

- Martz, E.; Lee, T.; Lakes, R.; Goel, V.; Park, J. Re-entrant transformation of methods in closed cell foams, adapted from cellular polymers. Polymers 1996, 15, 229. [Google Scholar]

- Fan, D.; Li, M.; Qiu, J.; Xing, H.; Jiang, Z.; Tang, T. Preparing Auxetic Foam from Closed-Cell Polymer Foam Based on the Steam Penetration and Condensation Process. ACS Appl. Mater. Interfaces 2018, 10, 22669. [Google Scholar] [CrossRef]

- Duncan, O.; Allen, T.; Birch, A.; Foster, L.; Hart, J.; Alderson, A. Effect of steam conversion on the cellular structure, Young’s modulus and negative Poisson’s ratio of closed-cell foam. Smart Mater. Struct. 2020, 30, 015031. [Google Scholar] [CrossRef]

- Duncan, O.; Leslie, G.; Moyle, S.; Sawtell, D.A.G.; Allen, T. Developments on auxetic closed cell foam pressure vessel fabrications. Smart Mater. Struct. 2022, 31, 074002. [Google Scholar] [CrossRef]

- Li, N.; Liu, Z.; Shi, X.; Fan, D.; Xing, H.; Qiu, J.; Li, M.; Tang, T. Preparing Polypropylene Auxetic Foam by a One-Pot CO2 Foaming Process. Adv. Eng. Mater. 2021, 24, 2100859. [Google Scholar] [CrossRef]

- Fan, D.; Shi, Z.; Li, N.; Qiu, J.; Xing, H.; Jiang, Z.; Li, M.; Tang, T. Novel Method for Preparing a High-Performance Auxetic Foam Directly from Polymer Resin by a One-Pot CO2 Foaming Process. ACS Appl. Mater. Interfaces 2020, 12, 48040–48048. [Google Scholar] [CrossRef]

- Duncan, O.; Bailly, N.; Allen, T.; Petit, Y.; Wagnac, E.; Alderson, A. Effect of Compressive Strain Rate on Auxetic Foam. Appl. Sci. 2021, 11, 1207. [Google Scholar] [CrossRef]

- Critchley, R.; Corni, I.; Wharton, J.; Walsh, F.; Wood, R.; Stokes, K. A review of the manufacture, mechanical properties and potential applications of auxetic foams. Phys. Status. Solid 2013, 250, 1963–1982. [Google Scholar] [CrossRef]

- Evans, K.; Alderson, A. Auxetic Materials: Functional Materials and Structures from Lateral Thinking. Adv. Mater. 2000, 12, 617–628. [Google Scholar] [CrossRef]

- Frioui, N.; Bezazi, A.; Remillat, C.; Scarpa, F.; Gomez, J. Viscoelastic and compression fatigue properties of closed cell PVDF foam. Mech. Mater. 2010, 42, 189. [Google Scholar] [CrossRef]

- Belaadi, A.; Bezazi, A.; Bourchak, M.; Scarpa, F. Tensile static and fatigue behaviour of sisal fibres. Mater. Des. 2012, 46, 76–83. [Google Scholar] [CrossRef]

- Panin, S.; Bogdanov, A.; Eremin, A.; Buslovich, D.; Alexenko, V. Estimating Low- and High-Cyclic Fatigue of Polyimide-CF-PTFE Composite through Variation of Mechanical Hysteresis Loops. Materials 2022, 15, 4656. [Google Scholar] [CrossRef]

- Li, D.; Zhou, L.; Wang, X.; He, L.; Yang, X. Effect of Crystallinity of Polyethylene with Different Densities on Breakdown Strength and Conductance Property. Materials 2019, 12, 1746. [Google Scholar] [CrossRef]

- Bouchahdane, K.; Ouelaa, N.; Belaadi, A. Static and fatigue compression behaviour of conventional and auxetic open-cell foam. Adv. Mater. Struct. 2021, 29, 6154–6167. [Google Scholar] [CrossRef]

- Yuan, S.; Chua, C.K.; Zhou, K. 3D-Printed Mechanical Metamaterials with High Energy Absorption. Adv. Mater. Technol. 2019, 4, 1800419. [Google Scholar] [CrossRef]

- Williams, J.; Bartos, J.; Wilkerson, M. Elastic modulus dependence on density for polymeric foams with systematically changing microstructures. J. Mater. Sci. 1990, 25, 5134. [Google Scholar] [CrossRef]

- Bezazi, A.; Scarpa, F. Tensile fatigue of conventional and negative Poisson’s ratio open cell PU foams. Int. J. Fatigue 2009, 31, 488–494. [Google Scholar] [CrossRef]

- Zhang, Y.; Rodrigue, D. High Density Polyethylene Foams. II. Elastic Modulus. J. Appl. Polym. Sci. 2003, 90, 2130. [Google Scholar] [CrossRef]

- Scarpa, F.; Giacomin, J.; Bezazi, A.; Bullough, W. Dynamic behavior and damping capacity of auxetic foam pads. In Smart Structures and Materials 2006: Damping and Isolation; SPIE: Bellingham, WA, USA, 2006; Volume 6169. [Google Scholar] [CrossRef]

- Duncan, O.; Shepherd, T.; Moroney, C.; Foster, L.; Venkatraman, P.D.; Winwood, K.; Allen, T.; Alderson, A. Review of Auxetic Materials for Sports Applications: Expanding Options in Comfort and Protection. Appl. Sci. 2018, 8, 941. [Google Scholar] [CrossRef]

| Foam Code | Initial Foam Density | Cell Diameter | Porosity | OCP | Auxetic Foam Code | Density | Porosity | OCP |

|---|---|---|---|---|---|---|---|---|

| - | kg/m3 | µm | % | % | - | kg/m3 | % | % |

| D16 | 15.5 ± 0.4 | 752 ± 204 | 98.4 | 7.3 | PE-D16-P1.5 | 120.0 | 86.9 | 43.8 |

| D21 | 20.9 ± 0.3 | 1107 ± 238 | 97.8 | 12.3 | PE-D21-P1.6 | 98.9 | 89.2 | 19.8 |

| D30 | 29.7 ± 0.3 | 1209 ± 279 | 96.8 | 8.3 | PE-D30-P1.5 | 116.0 | 87.3 | 22.2 |

| D36 | 35.6 ± 0.4 | 694 ± 203 | 96.2 | 6.3 | PE-D36-P1.5 | 89.6 | 90.3 | 10.1 |

| Sample | Tm (°C) | ΔHm (J/g) | Xc (%) | Auxetic Foams | Tm (°C) | ΔHm (J/g) | Xc (%) |

|---|---|---|---|---|---|---|---|

| D16 | 110.3 | 45.7 | 15.6 | PE-D16-P1.5 | 110.1 | 15.0 | 5.1 |

| D21 | 107.3 | 64.8 | 21.8 | PE-D21-P1.6 | 107.9 | 12.6 | 4.3 |

| D30 | 108.8 | 45.5 | 15.5 | PE-D30-P1.5 | 108.9 | 18.5 | 6.3 |

| D36 | 112.0 | 94.8 | 32.4 | PE-D36-P1.5 | 112.2 | 15.4 | 5.2 |

| Sample | Initial Density (kg/m3) | Final Density (kg/m3) | Compression Ratio (Df/Do) | Minimum PR (Tension) | Minimum PR (Compression) | |

|---|---|---|---|---|---|---|

| D16 | PE-D16-O | 15.5 | 15.5 | 1 | 0.38 (mean) | 0.10 (mean) |

| PE-D16-P1.0 | 15.5 | 76.0 | 4.90 | −2.55 | −0.61 | |

| PE-D16-P1.3 | 15.5 | 109 | 7.03 | −2.83 | −0.60 | |

| PE-D16-P1.5 | 15.5 | 118 | 7.61 | −2.89 | −0.65 | |

| PE-D16-P1.8 | 15.5 | 120 | 7.74 | −0.89 | −0.28 | |

| D21 | PE-D21-O | 20.9 | 20.9 | 1 | 0.34 (mean) | 0.08 (mean) |

| PE-T105-D21-P1.5 | 20.9 | 88.0 | 4.21 | −1.52 | −0.35 | |

| PE-D21-P1.6 | 20.9 | 88.8 | 4.25 | −1.60 | −0.32 | |

| PE-D21-P1.9 | 20.9 | 98.4 | 4.71 | −2.55 | −0.33 | |

| PE-D21-P2.1 | 20.9 | 99.5 | 4.76 | −1.07 | −0.31 | |

| D30 | PE-D30-O | 29.7 | 29.7 | 1 | 0.37 (mean) | 0.16 (mean) |

| PE-D30-P1.5 | 29.7 | 116 | 3.91 | −1.60 | −0.55 | |

| PE-D30-P1.8 | 29.7 | 120 | 4.04 | −0.97 | −0.51 | |

| PE-D30-P2.0 | 29.7 | 126 | 4.24 | −1.52 | −0.50 | |

| PE-T105-D30-P1.5 | 29.7 | 125.2 | 4.22 | −1.00 | −0.49 | |

| D36 | D36-O | 35.6 | 35.6 | 1 | 0.40 (mean) | 0.13 (mean) |

| PE-D36-P2.1 | 35.6 | 108.7 | 3.05 | −0.49 | −0.34 | |

| PE-D36-P1.8 | 35.6 | 89.0 | 2.50 | −0.72 | −0.32 | |

| PE-D36-P1.5 | 35.6 | 81.5 | 2.29 | −1.50 | −0.25 | |

| Sample | Tensile Modulus (kPa) | Strain Energy (Ep) (kPa) | Energy Dissipated (Ed) (mJ/cm3) | Damping Capacity (%) | Tensile NPR (-) |

|---|---|---|---|---|---|

| PE-D16-O | 3.26 | 25.0 | 0.95 | 3.80 | 0.38 |

| PE-D16-P1.0 | 3.97 | 31.2 | 1.22 | 3.91 | −2.55 |

| PE-D16-P1.3 | 15.6 | 64.6 | 3.47 | 5.68 | −2.83 |

| PE-D16-P1.5 | 40.4 | 136 | 15.5 | 11.4 | −2.89 |

| PE-D21-O | 1.73 | 20.3 | 0.47 | 2.38 | 0.34 |

| PE-D21-P1.6 | 2.06 | 13.7 | 1.97 | 16.7 | −1.60 |

| PE-D21-P1.9 | 6.07 | 67.4 | 4.91 | 7.28 | −2.55 |

| PE-D21-P2.1 | 30.1 | 81.3 | 11.2 | 13.8 | −1.07 |

| PE-D30-O | 2.39 | 49.5 | 0.43 | 0.871 | 0.37 |

| PE-D30-P1.5 | 1.13 | 3.41 | 0.46 | 13.4 | −1.60 |

| PE-D30-P1.8 | 3.49 | 24.9 | 1.30 | 5.20 | −0.97 |

| PE-D30-P2.0 | 3.54 | 20.6 | 1.83 | 8.88 | −1.52 |

| PE-D36-O | 2.18 | 64.5 | 0.078 | 0.12 | 0.40 |

| PE-D36-P1.5 | 6.39 | 31.6 | 1.69 | 5.30 | −1.50 |

| PE-D36-P1.8 | 5.11 | 33.3 | 1.77 | 5.33 | −0.72 |

| PE-D36-P2.1 | 9.44 | 52.5 | 8.13 | 15.5 | −0.49 |

| Sample | Compressive Modulus (kPa) | Strain Energy(Ep)(kPa) | Energy Dissipated (Ed)(mJ/cm3) | Damping Capacity (%) | |

| PE-D16-O | 0.209 | 2.41 | 0.086 | 3.56 | |

| PE-D16-P1.0 | 0.159 | 1.64 | 0.24 | 14.3 | |

| PE-D16-P1.3 | 0.268 | 3.89 | 0.51 | 13.0 | |

| PE-D16-P1.5 | 1.04 | 2.55 | 0.26 | 10.2 | |

| PE-D21-O | 0.678 | 3.09 | 0.34 | 10.9 | |

| PE-D21-P1.6 | 0.760 | 2.26 | 0.46 | 20.2 | |

| PE-D21-P1.9 | 0.439 | 3.42 | 0.37 | 12.3 | |

| PE-D21-P2.1 | 0.942 | 4.54 | 0.45 | 10.0 | |

| PE-D30-O | 0.788 | 5.63 | 0.34 | 6.11 | |

| PE-D30-P1.5 | 0.471 | 3.41 | 0.46 | 13.4 | |

| PE-D30-P1.8 | 2.42 | 5.65 | 0.61 | 12.0 | |

| PE-D30-P2.0 | 1.71 | 8.60 | 1.96 | 29.7 | |

| PE-D36-O | 1.68 | 4.28 | 0.68 | 15.8 | |

| PE-D36-P1.5 | 2.56 | 7.19 | 1.90 | 26.4 | |

| PE-D36-P1.8 | 3.10 | 8.92 | 2.50 | 28.1 | |

| PE-D36-P2.1 | 2.54 | 17.6 | 3.43 | 19.5 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.Y.; Underhill, R.S.; Rodrigue, D. A Simple Method to Convert Cellular Polymers into Auxetic Metamaterials. Appl. Sci. 2023, 13, 1148. https://doi.org/10.3390/app13021148

Chen XY, Underhill RS, Rodrigue D. A Simple Method to Convert Cellular Polymers into Auxetic Metamaterials. Applied Sciences. 2023; 13(2):1148. https://doi.org/10.3390/app13021148

Chicago/Turabian StyleChen, Xiao Yuan, Royale S. Underhill, and Denis Rodrigue. 2023. "A Simple Method to Convert Cellular Polymers into Auxetic Metamaterials" Applied Sciences 13, no. 2: 1148. https://doi.org/10.3390/app13021148

APA StyleChen, X. Y., Underhill, R. S., & Rodrigue, D. (2023). A Simple Method to Convert Cellular Polymers into Auxetic Metamaterials. Applied Sciences, 13(2), 1148. https://doi.org/10.3390/app13021148