Abstract

Natural antimicrobials are effective against both food-borne pathogens and spoilage bacteria. The current study aimed to evaluate the in vitro antimicrobial activity of eight natural bioactive compounds (BACs) and one synthetic compound, butylated hydroxytoluene (BHT), and to evaluate the effect of one selected BAC (AITC) on the safety and quality of minced chicken meat. Additionally, physicochemical (pH, color, water-holding capacity (WHC), chemical forms of myoglobin (deoxymyoglobin-DeoMb, oxymyoglobin-OxyMb, and metmyoglobin-MetMb), thiobarbituric-acid-reactive substances (TBARs)), and microbiological properties (in vitro antimicrobial activity and determination of minimum inhibitory concentration (MIC)) were also evaluated through electronic-nose odor detection. Allyl-isothiocyanate (AITC), thymol, eugenol, and geraniol showed the broadest spectrum of in vitro antibacterial activity against one major meat spoilage bacterium and five pathogenic bacteria that were tested. Subsequently, AITC was selected to be applied to fresh minced chicken meat at different concentrations (at concentrations of the MIC (MIC-1), two times the MIC (MIC-2), and four times the MIC (MIC-4)). The chicken meat was then vacuum-packaged and kept for up to 14 days at 4 °C, and its quality properties were checked during storage. In this study, the addition of low concentrations of AITC (MIC-1) maintained the lightness (L*) and increased the WHC of the meat. High concentrations (MIC-2 and MIC-4) caused a significant increase in lightness (L*) and folded yellowness (b*) value, and they significantly reduced the redness (a*) and TBARS values compared to the control meat. The amounts of MetMb and DeoMb were reduced and the quantity of OxyMb was increased as a result of the addition of AITC to the chicken breast. Throughout storage, particularly at MIC-4, AITC showed the lowest numbers of aerobic mesophilic cells, as well as a reduction in Listeria monocytogenes cell numbers and a decrease in Salmonella Typhimurium counts. In addition, the meat containing MIC-4 did not exhibit growth of Pseudomonas lundensis after 10 days. During the storage period, an electronic-nose assay demonstrated a distinction in the odor buildup of AITC across the various meat groups, and meat treated with MIC-4 showed a trend that was clearly opposite to that of untreated meat. These encouraging results demonstrate the potential of AITC to improve the safety and shelf life of meat and meat products.

1. Introduction

Chicken meat is preferred by consumers worldwide due to its versatility, low price, and desirable nutritional qualities. Poultry meat is marketed as a healthier alternative to ground beef or red meats. It has a low fat content and a relatively high concentration of polyunsaturated fatty acids [1]. Fresh chicken meat products are usually marketed under chilled conditions (2–5 °C). However, this type of meat belongs to the category of perishable food commodities, which are prone to quality deterioration, and it has a shelf life of less than 5 days post-slaughter. Several causes are responsible for the deterioration in meat and meat products, particularly during processing, storage, distribution, and marketing [2,3], such as microbial contamination, oxidation reactions, and changes in the organoleptic properties (flavor, odor, color, and texture) [4,5,6]. Changes in quality attributes associated with the freshness and safety of meat influence product acceptance by consumers and can result in the rejection of a product, eventually resulting in economic loss. Therefore, it is essential to properly preserve and handle meat and meat products to protect their nutritional quality [7,8]. It has been estimated that, due to inadequate preservation methods and facilities, almost 50% of the total meat produced worldwide is spoiled and wasted during its consumption at the level of the household [9]. Lipid oxidation—the most prevalent chemical, nonmicrobial cause of quality degradation in meat during processing—is a significant contributor to the deterioration and shorter shelf life of meat products. In addition, the main factor limiting meat’s shelf life, increasing its toxicity, and lowering its market value is lipid oxidation [10]. Oxidative damage can easily disrupt lipids and proteins in meat due to the prompt loss of endogenous antioxidants after slaughter [11]. The oxidation of lipids is a complicated process that depends on the chemical constituents that exist in meat, access to light and oxygen, and the temperature of storage facilities [12].

Microbial growth and contamination in meat are other major concerns that cause quality defects and possess the potential to cause foodborne illness. Meat and poultry products have often been reported to be contaminated with microbes throughout the butchering and manufacturing process. These microorganisms produce undesirable quality changes in meats and can cause potential public health issues. A range of intrinsic and extrinsic factors can co-operate in accelerating the spoilage process in meat products and the growth of spoilage and pathogenic microorganisms. These pathogenic bacteria can be Pseudomonas strains, Listeria monocytogenes, enterohemorrhagic Escherichiacoli O157:H7, Salmonella Typhimurium, Staphylococcus aureus, Bacillus cereus, Campylobacter spp., Clostridium botulinum and perfringens, and so on [13,14]. It is essential to control growth of pathogens in poultry products and in the meat industry. The best strategy for improving the safety of meat products throughout the stages of preharvest, postharvest, processing, storage, distribution, and consumption is providing adequate hygiene and applying antimicrobial intervention technologies [15]. Concurrently with lipid oxidation, microbial spoilage leads to significant sensory defects in meat. Especially in poultry meat products, changes in sensory properties, such as color changes, are important quality attributes among the purchase criteria that directly affect product acceptance by consumers; therefore, an exceptional protection strategy that offers extended shelf life and effectively diminishes food waste is required.

Considering these facts, the meat industry is always concerned with finding various ways to increase shelf life and improve product quality. One method includes using antioxidants/antimicrobials of either synthetic or natural origin. The demand for synthetic antioxidants/antimicrobials, such as butylated hydroxytoluene (BHT), sodium ascorbate, and propyl gallate (PG), has decreased in recent years due to their safety and potential toxicological and carcinogenic effects [4,5,16,17]. On the other hand, the demand for clean-label foods has increased, and the use of natural and bioactive compounds (BACs), especially those of plant origin, as preservatives has gained wide interest and has attracted the attention of researchers. Furthermore, several essential oils (EOs) and their BACs have been documented and considered to be ‘Generally Recognized as Safe’ (GRAS) to be applied in different food systems and have been approved by the Food and Drug Administration (FDA), the European Union in the Council Directive No. 95/2/EC of 20 February 1995 on the regulation on food additives, and the European Commission (2002/113/EC, 2002) [18,19].

Numerous natural-occurring derivatives such as carvacrol, thymol, cinnamaldehyde, allyl-isothiocyanate, eugenol, linalool, piperine, and others are utilized as BACs in meat and food products. Several of these BACs are receiving significant attention due to their multiple antimicrobial, flavoring, antioxidant, and organoleptic properties in preserving and enhancing the nutritional quality of meat and other food products [20]. More specifically, it is advantageous for improving the production of healthier meat and meat products [5,18], as an antimicrobial to eliminate undesirable food-borne pathogens, and to control spoilage microorganisms [21,22,23], to prevent food discoloration, to decrease the dependency on antibiotics, as an antioxidant to reduce lipid/protein oxidation and to prevent the production of secondary products that cause oxidative rancidity issues [24], and to extend shelf life [25,26,27]. Furthermore, to improve the effectiveness of BACs’ different food matrices, they may be applied in combination with other hurdles such as active or modified atmosphere packaging [3], high-pressure processing [1], and coating agents containing BACs such as carrageenan/chitosan [28,29]. However, only low concentrations of BACs can be used to preserve meat, due to their strong flavor properties. Moreover, certain properties of BACs such as low aqueous solubility, pungent odor, and reactions with meat constituents may lead to a reduction in their antimicrobial activity, thus limiting their application in meat and other foods [30,31]. Although the use of some BACs and EOs as meat preservatives has been investigated, they have not been commercially utilized. This requires in-depth knowledge of the minimum acceptable concentration and the mechanism of action related to the mentioned properties in the preservation of meat and other food products [32,33].

Allyl-isothiocyanate (AITC) is a naturally occurring BAC present in cruciferous plants, predominantly in their seeds, stems, leaves, and roots. AITC is an aliphatic sulfur-containing and colorless volatile compound [34]. Plants containing AITC include horseradish, cabbage, wasabi, Brussels sprouts, watercress, broccoli, and cauliflower [35,36,37]. It comprises almost 90% of the composition of horseradish root [38]. The use of AITC in food preservation has already been approved in Japan [26] and is considered as GRAS by the US FDA [39]. The use of BACs such as AITC in food as a food additive, flavoring, and anti-spoilage agent is currently being revised in Europe [40].

The aim of the current study was to assess the in vitro antimicrobial properties of eight natural BACs and determine the BAC with the widest range of in vitro antibacterial activity at various concentrations in refrigerated fresh minced chicken meat. To the best of our knowledge, this is the first paper to analyze the effects of AITC on common spoilage-causing Pseudomonas in poultry meat in addition to food-borne pathogenic bacteria and conduct a comprehensive analysis on the quality characteristics, including meat pigment profile, WHC, and E-nose aroma analyses in chilled stored chicken meat treated with the AITC.

2. Materials and Methods

2.1. Preparation of Raw Meat Samples and Experimental Design

Fresh chicken breast meat was obtained from a local abattoir 24 h after slaughtering and transported to the laboratory at a temperature of 4 ± 0.5 °C. Before dividing the meat into treatment groups (including BACs) and the control group, it was minced, with the skin removed and homogenized using a meat grinder (BOSCH-Slovenia). Following this, the samples were vacuum-sealed in polyethylene bags using a packaging machine (Multivac C200, Multivac Sepp Haggenmüller GmbH and Co., Wolfertschwerden, Germany) and subsequently stored at 4 ± 0.5 °C for a maximum of 14 days. The ambient temperature during experimentation ranged from 22 to 25 °C (Appendix A Figure A1).

To investigate the antimicrobial effect of BACs in vitro, two assays, disc diffusion and minimum inhibitory concentration (MIC), were applied. The experiment incorporated various BACs, including β-citronellol (≥95%), geraniol (>96%), (−)-α-Bisabolol, allyl isothiocyanate (95%), thymol (5-Methyl-2-isopropylphenol) ≥ 98.5%, eugenol (99%), cuminaldehyde (98%), limonene (97%), and butylated hydroxytoluene (BHT) (≥99%) (SIGMA, Darmstadt, Germany). All the natural bioactive compounds assessed have been designated as generally recognized as safe (GRAS) by the Food and Drug Administration (FDA) of the United States. The selected BAC (AITC) was applied to minced chicken breast meat at different concentrations designated as MIC-1, MIC-2, and MIC-4, based on its in vitro antimicrobial activity. The ratio of 5% of a mixture containing 0.00088 g of AITC, 4.99384 g of distillated water (DW), and 0.0044 g ethanol, respectively, in 100 g of meat was used in MIC-1 (Appendix A Table A1). The proportion of AITC was doubled in samples labelled as MIC-2 and quadrupled in meat samples designated as MIC-4. Various measurements were taken on days 0, 3, 7, 10, and 14. Additionally, the quality properties of chicken meat that were assessed include physicochemical characteristics (pH, color, and WHC), meat pigments, lipid oxidation (thiobarbituric acid reactive substances—TBARS), odor detection (using an electronic nose), and microbiological characteristics (aerobic mesophilic counts (AMCs), L. monocytogenes, S. Typhimurium, and P. lundensis).

2.2. Physicochemical Properties of Chicken Meat

2.2.1. Measurement of pH

The pH level of ground chicken meat was measured in triplicate using a pH electrode (Testo 206; Testo-AG, Titisee-Neustadt, Germany). The electrode was inserted into the meat and readings were taken 24 h after slaughter and immediately after grinding the meat.

2.2.2. Color Measurement

The color values of minced meat were determined using the CIELAB scoring system [41] and Konica Minolta CR-400 colorimeter (Konica Minolta Sensing Inc., Tokyo, Japan). The resulting parameters were as follows: L* (lightness), a* redness (+a for red; −a for green), and b* yellowness (+b for yellow; −b for blue). Calibration was performed prior to taking readings from each treatment [39]. To calculate the relative colorfulness or chroma scale (C*) and hue angle (h*), the values obtained from measuring L*, a*, and b* were averaged and the following equations were used:

- -

- Chroma: C* = [(a*)2 + (b*)2]1/2.

- -

- Hue angle: h* = tan−1 (arctangent) (b*/a*).

2.2.3. Measurement of Water Holding Capacity (WHC)

The water holding capacity in meat was measured using the filter paper press technique. A meat sample weighing 0.25–0.32 g was positioned on a filter paper (Whatman no. 10) placed between two Plexiglas plates and pressed for five minutes with a 500 g weight. Following pressing, the filter paper was placed in an oven for 10 min and then in a desiccator for 5 min. The WHC was computed by determining the proportion of meat film area to total liquid defined area [42]. The measurements were performed three times for each sample.

2.2.4. Determination of Metmyoglobin, Deoxymyoglobin, and Oxymyoglobin Pigments

The method of Utama et al. [43] with some minor modifications was used to quantify the levels of oxymyoglobin (OxyMb), metmyoglobin (MetMb), and deoxymyoglobin (DeoMb) pigments in meat. The myoglobin content was determined by measuring the absorbance of the sarcoplasmic extract, dissolved in millimolar phosphate buffer (pH 6.8) at 503, 525, 557, 572, 582, and 700 nm, by reflex attenuation. Briefly, 20 mL of phosphate buffer was added to 2 g of ground meat samples, which were then homogenized at 10,000 rpm for 20 s using a Digital Ultra-Turrax homogenizer (Staufen, Germany), followed by centrifugation of the homogenate at 5500× g for 30 min. The absorbance was measured once the supernatant had been filtered through filter paper. Measurements were taken in triplicate for each sample. The method modified by Tang et al. [44] was used to determine the proportional amounts of the three myoglobin forms (OxyMb, DeoM, and MetMb) as shown below:

- % MetMb = (−0.159R1 − 0.085R2 + 1.262R3 − 0.520) ∗ 100

- % DeoMb = (−0.543R1 + 1.594R2 + 0.552R3 − 1.329) ∗ 100

- % OxyMb = (0.722R1 − 1.432R2 − 1.659R3 + 2.599) ∗ 100

- *R1 = A582/A557, R2 = A557/A525, and R3 = A503/A525

2.3. Determinations of Thiobarbituric Acid Reactive Substances (TBARS)

The lipid oxidation was determined using the method described by Dias et al. [39], which involves measuring the index of thiobarbituric acid reactive substances (TBARs). Briefly, 5 g of meat samples were blended with 20 mL of 5% trichloroacetic-acid (TCA) (SIGMA, Darmstadt, Germany). Then 0.5 mL of antioxidant (0.15% BHT), specifically 2,6-ditert-butyl-4-methylphenol, was added to the mixture to prevent oxidation during the preparation and homogenized for two minutes. After centrifugation (5000× g for 10 min) of the homogenates, the supernatant was filtered through filter paper into 25 mL volumetric flasks, and 5% TCA was added to adjust to the desired final volume of 25 mL. After adding 2 mL of 0.08% (w/v) TBA reagent (0.02 M) (SIGMA, Steinheim, Germany) to 2 mL of filtrate, the tubes were sealed and immersed in a water bath at 95 °C for 30 min. The samples were mixed using a vortex after being cooled, and their absorbance was quantified at 532 nm using a spectrophotometer (U-2900 Hitachi Ltd., Tokyo, Japan). The blank solution incorporated all of the reagents except the sample. The TBAR values were determined in mg of malondialdehyde (MDA equivalent) per kg of meat [45].

2.4. Microbiological Properties

2.4.1. In Vitro Antimicrobial Activity of BACs

The in vitro antibacterial activity of the 8 natural antimicrobials was tested against three Gram-positive (G+veB) bacteria (Listeria monocytogenes CCM 4699, Staphylococcus aureus ATCC 6538, and Bacillus cereus T1) as well as three Gram-negative (G-veB) bacteria (Escherichia coli O157:H7 BO1909, Salmonella Typhimurium B1310, and Pseudomonas lundensis CCP5). The strains were obtained from the Department of Food Microbiology, Hygiene and Safety, Institute of Food Science and Technology. The bacterial strains were cultured on Tryptic-Soy agar (TSA) (Biokar Diagnostics BK046HA) and incubated overnight at either 30 °C (P. lundensis) or at 37 °C (the other five strains).

2.4.2. Disc Diffusion Assay

Disc diffusion assays were carried out using 9 cm diameter sterile plastic Petri dishes, which contained 20 mL of TSA providing a constant layer thickness plate. The surface of the agar plates was inoculated with 1 mL of the test bacterium (approximately 106 CFU/mL, adjusted by OD measurement). The 1 mL inoculum was evenly distributed on the surface of the Petri dishes by gently moving the plates before carefully sloping them sideways. Excess liquid was removed using a pipette. The plates were then allowed to dry and 5 mm diameter sterile filter paper discs (Whatman no. 1, ≥10.5 cm in diameter) were placed in their middle using sterile forceps. Then, 4 μL of undiluted BACs (AITC, thymol, eugenol, limonene, cuminaldehyde, β-citronellol, geraniol, and (−)-α-Bisabolol) and nonliquid synthetic compound (BHT), which was diluted in 96% ethanol (50 mg/500 μL), were pipetted on the filter paper discs. As a control, 4 μL of sterile 96% ethanol was used. To prevent the evaporation of the samples and the loss of volatile BAC components, each Petri dish was covered with a layer of parafilm [46]. The plates were subsequently incubated at either 30 °C (P. lundesis) or 37 °C (the other 5 strains) for 24, 48, and 72 h, depending on the required temperature for the growth of the test bacteria. The thickness of the zone of inhibition (where no bacterial growth occurred, measured from the edge of the disc) was recorded in mm using a Digital Vernier Caliper (Workzone-Caliper, Tokyo, Japan). The experiments were conducted in triplicate for all bacterial strains.

2.4.3. Minimum Inhibitory Concentration (MIC)—Micro-Dilution Method

The determination of the MIC values was carried out with the microdilution method using a resazurin microtiter-plate-based antibacterial assay published by Semeniuc et al. [47] with slight modifications. Ethanol was used to prepare stock solutions of the BACs (to enhance their solubility) and they were diluted in absolute ethanol (200 μL/mL). Ethanol (50 mg/500 μL) was also used to dilute nonliquid BHT.

For each well of a 96-well microtiter plate, 100 µL of tryptic soy broth (TSB) and 100 µL of sterile DW were pipetted. Then, 100 µL of properly diluted BAC stock solution was pipetted into the first column. The suspensions were homogenized 2–3 times by pipetting. Next, a serial half-dilution was performed in 11 steps. Finally, each well was inoculated to achieve an initial cell count of approximately 106 CFU/mL. Pure ethanol was used as a control to test its antimicrobial effect. Microtiter plates were incubated at temperatures of 30 °C (for P. lundensis) and 37 °C (for the other 5 test strains) for 24 h. Subsequently, 10 μL of aqueous resazurin solution (as explained in further detail later) was added to each well, resulting in a final volume of 290 µL (excluding the first row). Any color changes were indicative of microbial growth. In case of no growth, there was no change in blue color, whereas growth was indicated by pink color. The MIC value was determined as the minimum concentration that inhibited bacterial growth. Three replicates were performed for each BAC.

Resazurin–menadione solution was prepared by mixing resazurin solution (0.025 g resazurin sodium salt dissolved in 1 mL sterile DW and then added to 8 mL double TSB) with menadione solution (0.014 g menadione/1 mL DMSO) and distributed in Eppendorf tubes. The resazurin–menadione stock solution was stored in a freezer at −20 °C until needed. Following incubation, 10 μL of this mixture stock solution was added to each well of the microtiter plate.

2.5. Determination of Aerobic Mesophilic Counts (AMCs), Pseudomonas lundensis, Listeria monocytogenes, and Salmonella Typhimurium in Meat

2.5.1. Preparation of Bacterial Strains and Inocula

A challenge test was performed to assess the safety and potential shelf life of refrigerated meat. Fresh overnight cultures of the G+veB (L. monocytogenes CCM 4699) and G-veB (S. Typhimurium B1310 and P. lundensis CCP5) bacteria were tested. Bacterial cultures were prepared on TSA agar plates and suspended in Maximum Recovery Diluent (MRD), followed by incubation at 37 °C (except for P. lundensis, which was incubated at 30 °C). The suspension for each strain was adjusted to reach an initial cell count of approximately 107–108 CFU/mL (measured by OD) and was then mixed in a 1:1:1 ratio. This mixture was used for the inoculation of the chicken breast to assess the antimicrobial efficacy of AITC. No-BAC marked the control samples, which were not inoculated.

2.5.2. Bacterial Inoculation on Chicken Meat

Approximately 10 grams of chicken breast samples per bag were inoculated with a 10 µL mixture of L. monocytogenes, S. Typhimurium, and P. lundensis, resulting in an initial cell count of the meat samples of approximately 106–107 CFU/g (marked as Inoc.Cont.). A portion of the inoculated samples were mixed with the AITC, creating treated samples. The bags were then vacuum-sealed and stored under refrigeration (4 °C) until the day of sampling.

2.5.3. Microbial Enumeration

Each sample (10 g/bag) was diluted aseptically with 40 mL of sterile MRD solution. The mixture was homogenized for 2 min in a Stomacher bag (Inter-science, Saint-Nom-la-Bretèche, France) containing a sterile filter. Decimal serial dilutions were performed in MRD and appropriate dilutions were pour plated with TGE agar (0.5% peptone, 0.1% glucose, 0.25% yeast extract, and 1.5% bacteriological agar) to determine the aerobic mesophilic counts (AMCs) [48]. The test bacteria were quantified by spread plating on XLD agar (SIGMA, Darmstadt, Germany) for Salmonella, on PALCAM agar (SIGMA, Darmstadt, Germany) for L. monocytogenes, and on Cetrimide agar (SIGMA, Darmstadt, Germany) for Pseudomonas.

2.6. Electronic Nose Analysis

The electronic nose analyses were performed following the methodology applied by Friedrich et al. [49], using the NST-3320 apparatus (Applied Sensor-Technologies, Linköping, Sweden). For each meat sample (three replicates in total), eight grams were placed in a septum-sealed glass vial. The samples were held at 20 °C until the incubation phase started and then acclimatized at 60 °C for 30 min before analysis (incubation phase). The entire cycle duration of each sample was 430 s. The change in sensor signals occurring after the sampling time elapsed between the baseline and the value signals was utilized as the response of the sensor for multivariate statistical analysis.

2.7. Statistical Analysis

In order to assess the experimental data, SPSS (Version 23.0, SPSS Inc., Chicago, IL, USA) was used. A general linear model (GLM) and analysis of variance (ANOVA) were applied to the data. The Tukey test was implemented to determine the level of significance at (p < 0.05). The average values and standard deviation have been provided in the analysis of physiochemical and lipid oxidation. Canonical discrimination analysis (CDA) was used in the E-nose measurements to distinguish between meat samples.

3. Results and Discussion

3.1. Evaluation of the In Vitro Antimicrobial Activity of BACs

3.1.1. Disc Diffusion Assay

The results presented in Table 1 demonstrate the antimicrobial activity of each of the BACs from applying the filter paper disc method. The antibacterial activity of several BACs, namely AITC, thymol, eugenol, limonene, (−)-α-Bisabolol, β-citronellol, cuminaldehyde, geraniol, and synthetic compound (BHT), was evaluated. The result indicated that AITC had the broadest spectrum of antibacterial activity against the investigated bacteria, followed by thymol, eugenol, cuminaldehyde, geraniol, β-citronellol, and limonene. After 24 h of incubation, AITC, thymol, cuminaldehyde, eugenol, β-citronellol, and geraniol all showed an inhibition zone against the investigated strains. Additionally, AITC completely inhibited the growth of P. lundensis, St. aureus, and S. Typhimurium. In contrast, limonene, (−)-α-Bisabolol, and BHT had a minimal effect on the growth of studied bacteria, showing no inhibition against L. monocytogenes. Furthermore, BHT exhibited a zone of inhibition of less than 1.09 ± 0.51 mm against P. lundensis, St. aureus, and S. Typhimurium.

Table 1.

The antimicrobial activity (inhibition zone) of various BACs against P. lundensis, E. coli O157:H7, St. aureus, L. monocytogenes, S. Typhimurium, and B. cereus determined by filter paper disc diffusion.

In a study by Kim et al. [50] the antimicrobial efficacy of specific BACs was evaluated against four G-veB bacteria (E. coli, E. coli 0157:H7, S. Typhimurium, and Vibrio vulnificus) and one G+veB bacterium (L. monocytogenes). Using the disc diffusion method, they ranked the effectiveness of BACs against E. coli as follows: citronellal > perillaldehyde > citral > geraniol > linalool > eugenol > terpineol > carvacrol and against S. Typhimurium as citronellal > citral > geraniol > perillaldehyde > linalool > eugenol > terpineol > carvacrol. Their finding was not in agreement with ours. They also found that geraniol, perillaldehyde, and citral (500 μg/mL) effectively eliminated E. coli, E. coli 0157:H7, and S. Typhimurium, while citronellal (250 μg/mL) showed only minimal effect against Vibrio vulnificus and limonene exhibited negligible activity. Lin et al. [34] conducted an in vitro test of liquid AITC against G+veB bacterium (L. monocytogenes) and G-veB bacteria (Salmonella Montevideo and E. coli O157:H7). Their results indicate that Salmonella Montevideo and E. coli O157:H7 were more sensitive to AITC than L. monocytogenes. In their study, they found that concentration of 500 μg/mL (approximately 0.5 μL/mL) was needed to achieve a 3 to 4 log reduction in E. coli O157:H7 and Salmonella Montevideo; however, a higher concentration of 2500 μg/mL of AITC was required for L. monocytogenes. AITC can cause damage to the cell membrane of E. coli and Salmonella Montevideo. Although it did not result in cell lysis, it causes the leakage of cellular metabolites. These bacteria are more susceptible to AITC during the early and late exponential growth stages as compared to the lag and stationary phases. Additionally, a strong antimicrobial activity of thymol and eugenol against B. cereus, S. Typhimurium, E. coli, and St. aureus was reported by Guimarães et al. [51]. Meanwhile, m-Cymene, trans-Geraniol, terpineol, (±)-citronellal, and (+)-borneol were among the least effective compounds against the strains. R-(+)-limonene, (−)-α-Bisabolol, and eucalyptol did not have any effect on the studied strains. In this study, the BACs AITC, thymol, and eugenol were identified as potent antimicrobials in inhibiting the growth of both G+veB and G-veB. Inhibition zones were observed against all strains studied.

3.1.2. Minimum Inhibitory Concentration

The results presented in Table 2 show the antibacterial properties of the studied BACs against six food-borne and spoilage bacteria in a liquid phase using the micro-dilution method. The BAC that demonstrated the highest level of activity out of all the studied BACs was AITC. Following AITC were geraniol, β-citronellol, thymol, eugenol, and cuminaldehyde, respectively. It was observed that, using a concentration of AITC of 0.004 μL/mL, AITC exhibited the lowest MIC against both St. aureus and S. Typhimurium. In contrast, α limonene, (−)-α-Bisabolol, and BHT showed smaller antimicrobial activity as assessed by the MIC assay. Amongst the BACs, the AITC was selected as the most effective antimicrobial agent to control the growth of P. lundensis, E. coli, St. aureus, L. monocytogenes, S. Typhimurium, and B. cereus. This was primarily due to its consistently lower MIC values. On the other hand, the BACs geraniol, thymol, and -citronellol were less active against P. lundensis when compared to AITC. Similar to the disc diffusion assay, BHT was found to be less effective in demonstrating MIC.

Table 2.

The antimicrobial activity (minimum inhibitory concentration) of various BACs against P. lundensis, E. coli O157:H7, St. aureus, L. monocytogenes, S. Typhimurium, and B. cereus determined by micro-dilution method.

Guarda et al. [52] conducted a study which demonstrated that thymol and carvacrol exhibited significant antimicrobial activity against E. coli O157:H7, St. aureus, Listeria innocua, Saccharomyces cerevisiae, and Aspergillus niger, with MIC values of 125–250 ppm and 75–375 ppm for thymol and carvacrol, respectively. Their study also found that a synergistic effect of thymol and carvacrol was observed at a concentration of 50% and 50%. López et al. [53] found that thymol and carvacrol showed similar results against a yeast (Candida albicans), a mold (Aspergillus flavus), and G+veB (L. monocytogenes). Nevertheless, thymol demonstrated significantly (p < 0.05) greater effect than carvacrol against G-veB (Salmonella choleraesuis). In addition, linalool exhibited activity against Salmonella choleraesuis and Candida albicans. However, no inhibitory activity was found against these microorganisms with other BACs, including camphor, estragol, 1.8-cineole, p-Cymene, and limonene. In accordance with this study, Lopez-Romero et al. [54] found that citronellol exhibited effectiveness against both E. coli and St. aureus, followed by citronellal, carveol, and carvone. The authors reported that the hydrophobicity, surface charge, and disruption of membrane integrity of E. coli and St. aureus were affected by citronellol, leading to subsequent K+ leakage. Boskovic et al. [55] treated minced pork with thyme EO (Thymus vulgaris) at concentrations of 0.3%, 0.6%, and 0.9%. The treated minced pork was then packaged using either vacuum or modified atmosphere packaging. Their results showed that the MIC was highest for thymol and carvacrol, followed by thyme EO, against four Salmonella serovars (S. Enteritidis, S. Typhimurium, S. Montevideo, and S. Infantis). In accordance with our results, they also observed that thymol exhibits greater antimicrobial activity than thyme EO and BACs such as p-Cymene, cinnamaldehyde, and eugenol. Furthermore, Churklam et al. [56] conducted a checkerboard assay and revealed the synergistic effect of BACs, including carvacrol and nisin, against L. monocytogenes. The current study concluded that natural BACs exhibited better antimicrobial activity against food-borne pathogens and spoilage microorganisms compared to synthetic BHT.

3.2. Physicochemical Properties of Chicken Meat

3.2.1. pH of the Meat

The results presented in Table 3 demonstrate the effect of AITC on the physicochemical properties of chicken meat. After the chicken meat was treated with AITC, the pH values decreased significantly (p < 0.05). The different concentrations of AITC exhibited a significant difference in pH reduction compared to the control group at day 14 and day 1 of storage. As the AITC concentration increased, the pH decline intensified, with a slight decrease observed in the control group. The pH values of the control and MIC-4 were 6.02 and 6.04, respectively, at the beginning of the storage. Both declined to 5.82 and 5.72 on the last day of storage. Similarly to this study, Olaimat Holley [28] also recorded a decrease in pH of chicken meat after coating it with AITC-rich mustard extract solution. However, Chacon et al. [31] found no effect of AITC on reducing the pH value of meat, thus rendering the current study’s results inconsistent with their findings. It has been reported that a decrease in pH by one unit increases protein denaturation rate by twelvefold; therefore, the enzyme activity can determine the rate of pH decline during postmortem glycolysis [57].

Table 3.

The effect of various AITC concentrations on the physicochemical properties of fresh chicken meat kept for up to 14 days at 4 °C.

3.2.2. Color Values

Throughout the 14-day storage period, the color of the chicken meat changed considerably (Table 3). Although the lightness of the meat increased significantly in all samples, it was particularly pronounced in the L* values of the sample that contained a high amount of AITC (MIC-2 and MIC-4) when compared to the control. The addition of a smaller amount of AITC (MIC-1) successfully maintained the L* value in comparison to the control. Meanwhile, MIC-2 and MIC-4 showed significant differences at the end of storage, with final values of 58.09 ± 0.72 and 62.82 ± 0.33, respectively, compared to the control, which had a final L* value of 52.34 ± 0.56 on day 14. On the final day of storage, meat treated with AITC showed significantly lower a* values in comparison to the control meat, which exhibited an increasing trend. During storage, the a* values increased significantly until day 10 before experiencing a sharp decline on day 14. Furthermore, a* values of meat treated with MIC-1 showed lower decreases, remaining close to their initial values at the beginning of storage, and showed no significant difference when compared to the untreated meat. In contrast, when comparing the MIC-4 to other samples, including control meat, the redness decreased significantly. Regarding the yellowness of meat, b* values were significantly higher for all meat samples, except for MIC-4, which demonstrated a steady increase until the last day of storage, despite the fact that the yellowness of the meat samples had decreased by day 10 of storage. Additionally, the findings of the present study have also been confirmed by Chai and Sheen [1], who found that a low dose of AITC did not have any effect on L*, a*, and b* color values of ground chicken meat compared to the control.

The b* value of meat treated with AITC MIC-2 and MIC-4 significantly increased. When compared to the meat’s initial values on the first day of storage, the meat containing MIC-4 exhibited a twofold increase in b* value. Both treated and untreated meat exhibited increasing trends in color intensity (C*) similar to yellowness. The C* values for the control, MIC-1, MIC-2, and MIC-4 on day 0 were 4.84 ± 0.58, 5.16 ± 0.56, 5.03 ± 0.94, and 4.87 ± 0.40, respectively; on day 14, the values increased to 6.62 ± 0.87, 6.73 ± 0.59, 7.54 ± 0.45, and 8.97 ± 0.53, respectively. A decreased tendency was discernible for MIC-1 and MIC-2 on day 10, before beginning to decline again on day 14, while the increasing trend of control and MIC-4 was maintained throughout the storage. At the end of the storage period, an increase in h* was found in all meat samples. By elevating the BAC level in meat, the impact of AITC on h* values could be observed effectively; as AITC concentration rose, h* values increased likewise. One of the primary quality attributes that consumers look for in poultry meat products is their physical properties, such as shelf life or appearance [8]. Shin et al. [3] found that a release rate of 0.6 μg/h of AITC did not affect the color of the chicken meat. However, our findings showed that a release rate of 1.2 μg/h of AITC results in discoloration of the chicken’s meat surface. The authors concluded that low concentrations of AITC have the potential to maintain color values L*, a*, and b* of ground chicken meat without deteriorating the appearance or attractiveness to consumers.

3.2.3. Water Holding Capacity

Table 3 presents the effect of different AITC concentrations on the WHC characteristics of chicken breast meat. On day 14 of storage, MIC-2 and MIC-4 concentrations slightly increased the extent of water released, as opposed to the increased rate of WHC in the treatment of MIC-1 and control group. During the storage days, various meat groups kept separate did not show any significant influence of AITC (p = 0.074). Only MIC-2 and MIC-4 showed a statistically significant difference in comparison with MIC-1 and the control on days 10 and 14 with regards to AITC concentration (p = 0.040). The stability of muscular proteins in WHC might be related to the decrease in meat pH observed in this study by adding AITC to the meat [58]. This highlights a close correlation between meat color and its final pH and WHC [59].

3.2.4. Meat Pigments (Metmyoglobin, Deoxymyoglobin, and Oxymyoglobin)

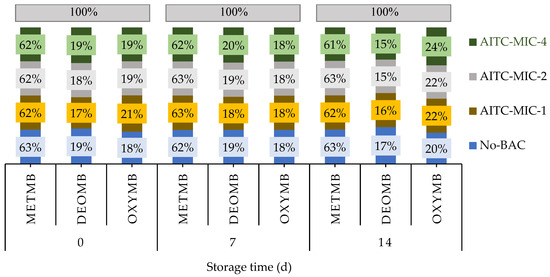

Figure 1 presents the outcomes of AITC on MetMb, DeoMb, and OxyMb fresh chicken meat pigments. At the beginning of storage, the initial DeoMb percentages in control, AITC MIC-1, MIC-2, and MIC-4 were 19%, 17%, 18%, and 19%, respectively. These percentages were subsequently reduced to 17%, 16%, 15%, and 15%, correspondingly, at the end of the storage period. Based on the present findings, the levels of MetMb and DeoMb in chicken meat treated with AITC were reduced, particularly in meat that contained MIC-4. MetMb levels were reduced from 62% to 61% and DeoMb levels decreased from 19% to 15% after 14 days of storage. At the same time, OxyMb levels increased from 19% to 24%. There were no significant changes in MetMB levels in the control samples; however, there was a concurrent decrease in DeoMb levels and increase in OxyMb levels. The findings from this study confirm previous research suggesting that the heightened L* in fresh meat results from increased OxyMb auto-oxidation and the generation of reactive oxygen species [60,61]. Discoloration of fresh meat during processing may be caused by conformational changes in Mb, such as globin denaturation or oxidation of ferrous ions [62]. It has been reported that the color change in chicken meat mainly arises due to denaturation of myoglobin, release or displacement of heme and oxidation of ferrous myoglobin to ferric MetMB [1].

Figure 1.

The influence of AITC on meat pigments (metmyoglobin (MetMb), deoxymyoglobin (DeoMb), and oxymyoglobin (OxyMb)) in fresh chicken stored up to 14 days at 4 °C.

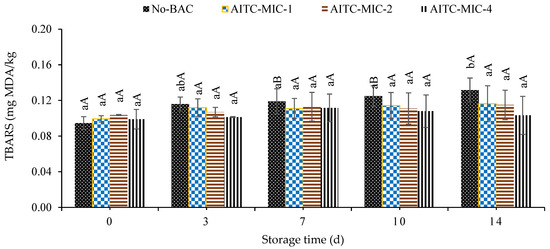

3.3. Effect of AITC on the TBARS Values of Chicken Meat.

Lipid oxidation investigation results are shown in Figure 2. The TBARS values increased in all meat groups as storage progressed, with a higher increase observed in the control group. TBARS scores decreased in AITC containing meat (p < 0.05), but reductions were more pronounced in the meat treated with MIC-2 and MIC-4. No significant difference was detected. In the meat samples treated with MIC-1, MIC-2, and MIC-4, the TBARS values were 0.099, 0.104, and 0.099, respectively, on day 0. There was an observed increasing trend, with values reaching 0.103, 0.115, and 0.116 mg MDA/kg at day 14 of storage. In contrast, the control samples exhibited TBARS scores of around 0.095 that significantly increased to 0.132 mg MDA/kg. These findings demonstrate the antioxidant activities of AITC, as evidenced by TBARS scores being less than 2 mg MDA/kg in the chicken meat samples. This could be attributed to the strong antioxidant activity of BACs, which has the potential to prevent the production of secondary lipid oxidation products that might be responsible for the off flavor in stored meat products. Several studies have indicated, that vacuum-packaged chicken results in much lower TBARS scores as compared to meat that has been stored aerobically [63]. In a study conducted by Karwowska and Dolatowski [64], they used a cooked model meat product with mustard seed for 12 days (mustard contains a high level of AITC in its composition) and observed decreased TBARS readings in comparison to the control. Lipid oxidation is a complex chemical process that significantly reduces the stability of meat products during storage. Several factors, such as the meat fat composition, meat grinding degree, and the use or nonuse of thermal processing method, affect this process.

Figure 2.

Effect of different concentrations of AITC on TBARS values of chicken meat stored up to 14 days at 4 °C. * a,b Means with different superscripts are significantly different regarding the storage days; A,B means with different superscripts are significantly different regarding the concentrations of AITCs (p < 0.05).

In the present study, AITC was found to have kept the TBARS scores below 2 mg MDA/kg in vacuum-packed ground chicken meat, with the decrease in secondary product formation from lipid oxidation potentially due to the antioxidant activity of AITC. These findings suggests that the treated meat did not encounter significant changes in lipid oxidation. On the other hand, it is important to note that MDA is a significant determinant of lipid oxidation levels in lipids. Its bifunctional aldehydic property allows for cross-linking of proteins, which, in turn, reduces their functional capacity. MDA also reacts with nucleophilic amine groups such as lysine and arginine. Thus, from a nutritional perspective, it is crucial to reduce lipid oxidation [64]. Depending on the BAC, the natural antioxidants found in meat products act differently. The ability of antioxidants to reduce reactive species, their ability to inhibit autoxidation by donating a hydrogen atom to stabilize the first oxidation products, their potential to chelate metal ions (pro-oxidants), and their function as a hydroperoxide degradation inhibitor are all factors that contribute to their protective effects [65]. In our previous study, the antioxidant protective effect of BACs (AITC) on chicken meat was also analyzed, and AITC exhibited great activity in reducing TBARS values [66].

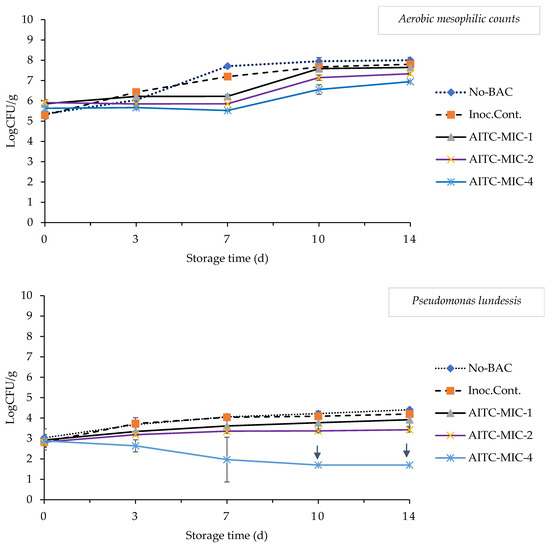

3.4. Effect of AITC on the Microbiological Properties of Chicken Meat

The results of the antimicrobial efficacy of AITC against aerobic mesophilic counts (AMC) of L. monocytogenes, S. Typhimurium, and P. lundensis in chicken breast meat are presented in Figure 3. The initial count of aerobic mesophilic bacteria (day 0) in control meat samples was less than 5 log CFU/g, which is satisfactory for acceptable quality chicken meat. The non-inoculated control samples followed by the inoculated control samples showed the highest microbial load at the end of storage, which was 8 and 7.8 log CFU/g, respectively. AITC resulted in some inhibition of AMCs; as the concentration of AITC increased, the number of AMCs decreased. The lowest number of AMCs was recorded in chicken breast samples treated with MIC-4 concentration of AITC; samples treated with AITC concentrations of MIC-1, MIC-2, and MIC-4 were 7.6, 7.3, and 6.9 log CFU/g, respectively, on day 14 of storage.

Figure 3.

Effect of various AITC concentrations on aerobic mesophilic counts of Pseudomonas lundessis, Listeria monocytogenes, and Salmonella Typhimurium of chicken meat kept for up to 14 days at 4 °C. The arrow line (↓) represents the numbers below the detection limit.

The antimicrobial effect of AITC on L. monocytogenes, S. Typhimurium, and P. lundensis counts was also investigated in chicken breast. During storage, Pseudomonas counts increased in all treatment groups, except the MIC-4 AITC-treated sample, which showed no increase from day 10 onwards. Since Pseudomonas species are present in significant numbers in the microbiota of meat, the control and inoculated control samples showed the highest Pseudomonas counts, with 6.4 and 4.2 log CFU/g at the end of storage. While the samples treated with AITC at MIC-1 and MIC-2 concentrations showed P. lundensis counts of 2.9 and 2.8 log CFU/g on day 0, which gradually increased to reach 3.9 and 3.4 log CFU/g on day 14, respectively, the initial cell count of 2.8 in the MIC-4 group decreased to below 1.7 log CFU/g by the end of storage. Furthermore, L. monocytogenes counts increased in all chicken breast samples, except those treated with MIC-4 AITC concentration, which reduced the count of Listeria from 5.2 to 4.0 log CFU/g for the end of the storage period. In addition, MIC-4 caused a reduction of 2.3 log L. monocytogenes compared to the inoculated control. In non-inoculated control samples, the number of L. monocytogenes began to increase from day 10. Since AITC is a volatile compound and easily degrades to new products in aqueous media, this may facilitate the action of AITC against L. monocytogenes, which possesses a cell wall that contains only a thick peptidoglycan layer covering the cytoplasmic membrane [28]. In this study, among the inoculated samples, the control showed the highest Listeria counts, increasing from 5.3 log CFU/g to 6.5 log CFU/g, while chicken breast samples treated with the AITC concentrations of MIC-1 and MIC-2 had Listeria counts of 6.1 and 5.4 log CFU/g, respectively, at the end of storage. In the case of S. Typhimurium, the highest counts were observed in the inoculated control, reaching 6.4 log CFU/g on day 14, while the control samples had S. Typhimurium counts below the detection limit of the inoculation method. AITC treatment reduced the growth of S. Typhimurium in chicken breast samples and the highest concentration of AITC not only prevented Salmonella growth but also caused a reduction in its numbers (Figure 3). The initial Salmonella counts in samples treated with MIC-1, MIC-2, and MIC-4 AITC concentrations were 6.2, 6.2, and 5.7 log CFU/g at the beginning of storage, respectively, and decreased to 5.9, 5.7, and 5.4 log CFU/g by day 14, respectively. Moreover, L. monocytogenes is able to proliferate in chilled, stored poultry meat and poses a serious threat to the food industry as a postprocessing contaminant, increasing food safety risks. As shown in this study, four-times MIC concentration of AITC prominently reduced L. monocytogenes counts on day 14 compared to the inoculated control. The inhibitory effect of AITC was also evaluated by Ahn et al. [67], who used transmission electron microscopy (TEM) to study L. monocytogenes cells treated with AITC and found that this component reduced intracellular ATP levels and altered internal cell structures in the cells without causing cell wall damage. Furthermore, Shin et al. [3] applied 0.6 and 1.2 μg/h AITC to fresh chicken breasts stored in modified atmosphere packaging at 4 °C for 21 days. In their study, they observed a maximum reduction of 0.77 log10 CFU/g Listeria count and 1.3 log10 CFU/g S. Typhimurium count. In a study by Olaimat Holley [28], they applied acidified κ-carrageenan/chitosan coatings containing 25–50 μL/g AITC or 100–250 mg/g mustard and they confirmed the antibacterial effect of AITC and noticed a reduction in the viability of L. monocytogenes and aerobic bacteria on cooked, cured roast chicken slices by 4.1 to >7.0 log10 CFU/g. In our previous experiments, we investigated the effect of AITC in chicken meat, and AITC, especially at 1000 ppm, which reduced the growth of P. lundensis, St. aureus, and Bacillus cereus and resulted in a reduction of 3 log10 CFU/g in AMCs [66].

In this regard, Chacon et al. [31] microencapsulated AITC in a concentration of 500, 750, or 1000 ppm mixed in sausage batters (17.59% beef, 60.67% pork, and 17.59% lard) that were stored at 13 °C for 25 days. They found that AITC at 750 and 1000 ppm was able to reduce the number of E. coli O157:H7 by 6.5 log10 CFU/g after processing for approximately 21 and 16 days. Meira et al. [68] investigated the combined effect of AITC and carvacrol applied together with phenolic acids (PA), ferulic acid (FA), o-coumaric acid (CA), and p-hydroxybenzoic acid (AHB) in vitro and in dry fermented sausages. They observed an MIC value of 0.25; 1.3; 5.12; 18.27; and 37 mM for AITC, carvacrol, FA, CA, and AHB, respectively, when they were tested against a five-strain mixture of E. coli O157:H7. AITC showed synergism with all phenolic acids (FA, CA, and AHB) in contrast to carvacrol, which only showed synergism with o-coumaric acid. The strongest synergistic effect was observed with the combination of AITC and CA at 10–20-times the MIC in dry fermented sausages. It was also noted that the number of E. coli O157 was reduced by ≥5 log cycle after 21 days. Ward et al. [38] investigated the antimicrobial potential of AITC-rich horseradish distillates added to a filter paper disc and packaged with ground beef patties. It was observed that, after 7 days of storage at 12 °C, at aerobic conditions (4000 nL distillate/L), the growth of St. aureus, E. coli O157:H7, S. Typhimurium, and L. monocytogenes was completely inhibited by the applied antimicrobial agent. AITC inhibits G-veBs more than G+veBs [34,37]. In a study by Chai and Sheen [1], using AITC with high-pressure processing in raw ground chicken meat, they observed 5 log reduction in Salmonella survivals at 350 MPa (4 min) combined with 0.05% AITC (w/w). Lin et al. [34] investigated the antimicrobial effect of liquid AITC in vitro against G+veB (L. monocytogenes) and G-veB bacteria (Salmonella Montevideo and E. coli O157:H7), and they found that G-veB were more sensitive to AITC than G+veB. Their studies have shown that AITC caused cell membrane damage in the G-veB studied. Under the influence of AITC, their cells did not exhibit cell lysis but their metabolites leaked [34]. In addition, AITC showed antimicrobial activity against yeasts and molds in cottage cheese [69], against Listeria innocua in frozen ready-to-eat shrimps [70], and against Salmonella enterica in liquid egg albumen [71]. In accordance with the current study, Dias et al. [39] found that the diffusion of the AITC from the packaging film into shredded, cooked chicken meat reduced the microbial contamination, controlled oxidation, and reduced the color changes. Additionally, the mechanism of action of the antibacterial activity of AITC has been found to occur through several pathways, including alteration in cell membrane permeability, disruption of energy production, breakage of disulfide bonds, and inactivation of oxidative induction [29]. Eventually, it causes cell membrane damage and leakage of cellular metabolites at all growth stages, and this action is thought to be due to its chemical group [30,72]. In this study, due to the effect of AITC on AMCs, a cell count below 7 log CFU/g was only observed in samples treated with four times the MIC concentration of AITC, indicating that the shelf life of meat in this group was extended to 2 weeks of storage time. Regarding the safety of AITC-treated chicken breasts, further presence/absence detection studies are needed to determine the survival of L. monocytogenes and S. Typhimurium.

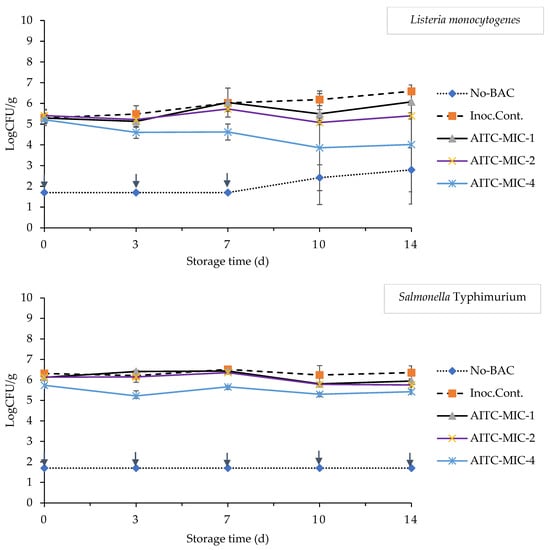

3.5. Effect of AITC on the Smell Detection by Electronic Nose in Chicken Meat

The results presented in Figure 4 a–c show the effect of AITC on meat and the use of E-nose to identify different meat groups. In contrast to untreated meat, the treated meat groups showed different directions for the second discriminant function when comparing the various concentrations of AITC. In addition, the E-nose appropriately differentiated between groups of meat, particularly at storage days 10 and 14. The E-nose had demonstrated overlap between the control and meat treated with AITC MIC-1, MIC-2, and MIC-4 by comparing the BAC levels and different days of storage. However, MIC-4 showed a clear tendency toward the first discriminant function on various days. In the present experiment, when the bags were opened, the meat containing MIC-1 produced a slight odor, and the odor intensity increased in the bags containing higher levels of AITC. In a study by Chacon et al. [31], the results were in agreement with those of the present study. They observed that meat samples treated with AITC at concentrations below 1480 ppm showed only a weak residual odor. The strong aroma of AITC is the main challenge for its application in food, and it is concentration-dependent, which has the potential to negatively affect taste perception of food [31,35,73]. In the present study, MIC-2 and MIC-4 also showed higher L*, b*, C*, and h* values, lower pH and a* values, a decrease in TBARSs scores, and a decrease in numbers of L. monocytogenes, S. Typhimurium, and P. lundessis, demonstrating that the application of E-nose apparatus can be useful in classifying the chicken meat as either fresh or spoiled with a rancid flavor. In addition, it is not yet known how AITC as a natural BAC affects the organoleptic qualities (flavor and texture) of meat (whether it is raw or ready-to-eat meat) and its minimum acceptable levels in relation to oxidation of lipids and microbiological properties of meat and meat products. However, there are some limitations to the use of AITC, including its poor solubility in water, the pungent flavor and smell that is associated with isothiocyanate, its instability at high temperatures, and its susceptibility to nucleophilic molecular destruction [73]. A higher concentration of AITC may, therefore, not be suitable for food preservation due to changes in flavor and odor.

Figure 4.

Effect of various AITC concentrations on odor detection by E-nose in chicken meat kept for up to 14 days at 4 °C. Canonical discriminant analysis score plot of (a): the separation based on the AITC concentration, (b): the separation based on storage days, and (c): the separation based on storage days and AITC concentration.

4. Conclusions

It has been reported that synthetic compounds used as food preservatives are of increasing concern to consumers due to their toxicological and carcinogenic effects. The present study was carried out to obtain a clear illustration of the use of AITC as a natural preservative in chicken meat. In this study, throughout the 14-day storage period, high concentrations of AITC showed a significant reduction in pH and a* values and an increase in L* values compared to untreated meat. On the other hand, the addition of a low concentration of AITC (MIC-1) was beneficial in maintaining the meat lightness, and increasing WHC at the end of storage. The strength of this study is that it demonstrated that the meat containing AITC showed a visible reduction in TBARS values in meat treated with MIC-2 and MIC-4 compared to a significant increase in the control. In addition, AITC caused a reduction in cell counts of AMCs, L. monocytogenes, S. Typhimurium, and P. lundensis in treated meat samples. The E-nose showed that AITC at concentration MIC-4 exhibited a clear tendency to the opposite direction of untreated meat on different days; however, strong changes in flavor and odor may limit the use of a high concentration of AITC in food. The result of the present research suggests that low levels of AITC have great potential to enhance the quality attributes of chicken meat without having a drastic effect on the appearance of the meat. However, further studies on the use of AITC in combination with other technologies and the assessment of organoleptic quality and nutritional losses are required to clarify the feasibility of applying AITC to improve the safety and extend the shelf life of fresh chicken meat.

Author Contributions

Conceptualization, K.N.H. and I.D.; investigation, visualization, K.N.H.; formal analysis, I.D.; methodology and resources, K.N.H. and G.K.; writing—original draft, K.N.H.; writing—review and editing, I.D. and G.K.; supervision, I.D. and L.F.; funding acquisition, I.D. All authors have read and agreed to the published version of the manuscript.

Funding

The current research was supported by the European Union and co-financed by the European Social Fund (grant agreement no. EFOP-3.6.3.-VEKOP-16-2017-00005).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors acknowledge the technician members of laboratories and the Doctoral School of Food Sciences (Institute of Food Science and Technology-HUALS) for their support during this research.

Conflicts of Interest

The authors declare no conflict of interest.

Appendix A

Table A1.

Calculation of AITC concentrations applied in 100 g chicken breast meat.

Table A1.

Calculation of AITC concentrations applied in 100 g chicken breast meat.

| MIC-1: | 0.0088 g AITC | in 1000 | g final mixture | ||

| if | 0.0088 g AITC | In 1000 | g final mixture | let 1 mL AITC is 1 g AITC | |

| then | 0.00088 g AITC | In 100 | g final mixture | ||

| AITC | 0.00088 g | ||||

| + | ethanol | 0.0044 g | |||

| AITC with ethanol | 0.00528 g | ||||

| + | Distillate water | 4.99384 g | |||

| AITC + Distillate water + ethanol | 5 g | 5% of total weight | |||

| + | meat | 95 g | 95% of total weight | ||

| 100 g | Total weight | ||||

| The concentration of AITC was two times higher in MIC-2 and four times higher in MIC-4. | |||||

Figure A1.

Schematic diagram of an experimental work.

References

- Chai, H.-E.; Sheen, S. Effect of High Pressure Processing, Allyl Isothiocyanate, and Acetic Acid Stresses on Salmonella Survivals, Storage, and Appearance Color in Raw Ground Chicken Meat. Food Control 2021, 123, 107784. [Google Scholar] [CrossRef]

- Zhang, H.; Wu, J.; Guo, X. Effects of Antimicrobial and Antioxidant Activities of Spice Extracts on Raw Chicken Meat Quality. Food Sci. Hum. Wellness 2016, 5, 39–48. [Google Scholar] [CrossRef]

- Shin, J.; Harte, B.; Ryser, E.; Selke, S. Active Packaging of Fresh Chicken Breast, with Allyl Isothiocyanate (AITC) in Combination with Modified Atmosphere Packaging (MAP) to Control the Growth of Pathogens. J. Food Sci. 2010, 75, M65–M71. [Google Scholar] [CrossRef] [PubMed]

- Karabagias, I.; Badeka, A.; Kontominas, M.G. Shelf Life Extension of Lamb Meat Using Thyme or Oregano Essential Oils and Modified Atmosphere Packaging. Meat Sci. 2011, 88, 109–116. [Google Scholar] [CrossRef] [PubMed]

- Šojić, B.; Tomović, V.; Jokanović, M.; Ikonić, P.; Džinić, N.; Kocić-Tanackov, S.; Popović, L.; Tasić, T.; Savanović, J.; Šojić, N.Ž. Antioxidant Activity of Juniperus communis L. Essential Oil in Cooked Pork Sausages. Czech J. Food Sci. 2017, 35, 189–193. [Google Scholar] [CrossRef]

- Lucera, A.; Costa, C.; Conte, A.; Nobile, M.A.D. Food Applications of Natural Antimicrobial Compounds. Front. Microbiol. 2012, 3. [Google Scholar] [CrossRef]

- Sant’Ana, A.S.; Igarashi, M.C.; Landgraf, M.; Destro, M.T.; Franco, B.D.G.M. Prevalence, Populations and Pheno- and Genotypic Characteristics of Listeria Monocytogenes Isolated from Ready-to-Eat Vegetables Marketed in São Paulo, Brazil. Int. J. Food Microbiol. 2012, 155, 1–9. [Google Scholar] [CrossRef]

- Cegiełka, A.; Chmiel, M.; Hać-Szymańczuk, E.; Pietrzak, D. Evaluation of the Effect of Sage (Salvia officinalis L.) Preparations on Selected Quality Characteristics of Vacuum-Packed Chicken Meatballs Containing Mechanically Separated Meat. Appl. Sci. 2022, 12, 12890. [Google Scholar] [CrossRef]

- FAO. Fao-World Livestock 2011—Livestock in Food Security. Available online: http://www.fao.org/3/i2373e/i2373e00.htm (accessed on 8 May 2020).

- Sampels, S. Oxidation and Antioxidants in Fish and Meat from Farm to Fork. Food Ind. 2013. Chapter 6. [Google Scholar] [CrossRef]

- Xiao, S.; Zhang, W.G.; Lee, E.J.; Ma, C.W.; Ahn, D.U. Effects of Diet, Packaging, and Irradiation on Protein Oxidation, Lipid Oxidation, and Color of Raw Broiler Thigh Meat during Refrigerated Storage. Poult. Sci. 2011, 90, 1348–1357. [Google Scholar] [CrossRef]

- Kanner, J. Oxidative Processes in Meat and Meat Products: Quality Implications. Meat Sci. 1994, 36, 169–189. [Google Scholar] [CrossRef] [PubMed]

- Dave, D.; Ghaly, A.E. Meat Spoilage Mechanisms and Preservation Techniques: A Critical Review. Am. J. Agric. Biol. Sci. 2011, 6, 486–510. [Google Scholar]

- Karanth, S.; Feng, S.; Patra, D.; Pradhan, A.K. Linking Microbial Contamination to Food Spoilage and Food Waste: The Role of Smart Packaging, Spoilage Risk Assessments, and Date Labeling. Front. Microbiol. 2023, 14, 1198124. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez, D.; Delgado, S.; Vázquez-Sánchez, D.; Martínez, B.; Cabo, M.L.; Rodríguez, A.; Herrera, J.J.; García, P. Incidence of Staphylococcus Aureus and Analysis of Associated Bacterial Communities on Food Industry Surfaces. Appl. Environ. Microbiol. 2012, 78, 8547–8554. [Google Scholar] [CrossRef] [PubMed]

- Fasseas, M.K.; Mountzouris, K.C.; Tarantilis, P.A.; Polissiou, M.; Zervas, G. Antioxidant Activity in Meat Treated with Oregano and Sage Essential Oils. Food Chem. 2008, 106, 1188–1194. [Google Scholar] [CrossRef]

- Jayathilakan, K.; Sharma, G.K.; Radhakrishna, K.; Bawa, A.S. Antioxidant Potential of Synthetic and Natural Antioxidants and Its Effect on Warmed-over-Flavour in Different Species of Meat. Food Chem. 2007, 105, 908–916. [Google Scholar] [CrossRef]

- FDA. CFR—Code of Federal Regulations Title 21. Available online: https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?CFRPart=101 (accessed on 9 May 2020).

- Karre, L.; Lopez, K.; Getty, K.J.K. Natural Antioxidants in Meat and Poultry Products. Meat Sci. 2013, 94, 220–227. [Google Scholar] [CrossRef]

- Pinto, L.; Tapia-Rodríguez, M.R.; Baruzzi, F.; Ayala-Zavala, J.F. Plant Antimicrobials for Food Quality and Safety: Recent Views and Future Challenges. Foods 2023, 12, 2315. [Google Scholar] [CrossRef]

- Burt, S. Essential Oils: Their Antibacterial Properties and Potential Applications in Foods--a Review. Int. J. Food Microbiol. 2004, 94, 223–253. [Google Scholar] [CrossRef]

- Chuang, S.; Sheen, S.; Sommers, C.H.; Zhou, S.; Sheen, L.-Y. Survival Evaluation of Salmonella and Listeria Monocytogenes on Selective and Nonselective Media in Ground Chicken Meat Subjected to High Hydrostatic Pressure and Carvacrol. J. Food Prot. 2020, 83, 37–44. [Google Scholar] [CrossRef]

- Piñon, M.I.; Alarcon-Rojo, A.D.; Renteria, A.L.; Mendez, G.; Janacua-Vidales, H. Reduction of Microorganisms in Marinated Poultry Breast Using Oregano Essential Oil and Power Ultrasound. Acta Aliment. 2015, 44, 527–533. [Google Scholar] [CrossRef]

- Hernández-Ochoa, L.; Aguirre-Prieto, Y.B.; Nevárez-Moorillón, G.V.; Gutierrez-Mendez, N.; Salas-Muñoz, E. Use of Essential Oils and Extracts from Spices in Meat Protection. J. Food Sci. Technol. 2014, 51, 957–963. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Camo, J.; Beltrán, J.A.; Roncalés, P. Extension of the Display Life of Lamb with an Antioxidant Active Packaging. Meat Sci. 2008, 80, 1086–1091. [Google Scholar] [CrossRef] [PubMed]

- Dufour, V.; Stahl, M.; Baysse, C. The Antibacterial Properties of Isothiocyanates. Microbiology 2015, 161, 229–243. [Google Scholar] [CrossRef] [PubMed]

- Gutierrez, J.; Barry-Ryan, C.; Bourke, P. Antimicrobial Activity of Plant Essential Oils Using Food Model Media: Efficacy, Synergistic Potential and Interactions with Food Components. Food Microbiol. 2009, 26, 142–150. [Google Scholar] [CrossRef]

- Olaimat, A.N.; Holley, R.A. Inhibition of Listeria Monocytogenes on Cooked Cured Chicken Breasts by Acidified Coating Containing Allyl Isothiocyanate or Deodorized Oriental Mustard Extract. Food Microbiol. 2016, 57, 90–95. [Google Scholar] [CrossRef]

- Moller, A.; Leone, C.; Kataria, J.; Sidhu, G.; Rama, E.N.; Kroft, B.; Thippareddi, H.; Singh, M. Effect of a Carrageenan/Chitosan Coating with Allyl Isothiocyanate on Microbial Load in Chicken Breast. LWT 2022, 161, 113397. [Google Scholar] [CrossRef]

- Nadarajah, D.; Han, J.H.; Holley, R.A. Inactivation of Escherichia Coli O157:H7 in Packaged Ground Beef by Allyl Isothiocyanate. Int. J. Food Microbiol. 2005, 99, 269–279. [Google Scholar] [CrossRef]

- Chacon, P.A.; Muthukumarasamy, P.; Holley, R.A. Elimination of Escherichia Coli O157:H7 from Fermented Dry Sausages at an Organoleptically Acceptable Level of Microencapsulated Allyl Isothiocyanate. Appl. Environ. Microbiol. 2006, 72, 3096–3102. [Google Scholar] [CrossRef]

- Hintz, T.; Matthews, K.K.; Di, R. The Use of Plant Antimicrobial Compounds for Food Preservation. BioMed Res. Int. 2015, 2015, e246264. [Google Scholar] [CrossRef]

- Tajkarimi, M.M.; Ibrahim, S.A.; Cliver, D.O. Antimicrobial Herb and Spice Compounds in Food. Food Control 2010, 21, 1199–1218. [Google Scholar] [CrossRef]

- Lin, C.M.; Preston, J.F.; Wei, C.I. Antibacterial Mechanism of Allyl Isothiocyanate. J. Food Prot. 2000, 63, 727–734. [Google Scholar] [CrossRef] [PubMed]

- Delaquis, P.J.; Mazza, G. Antimicrobial Properties of Isothiocyanates in Food Preservation. Food Technol. 1995, 49, 73–84. [Google Scholar]

- Kyung, K.H.; Fleming, H.P. Antimicrobial Activity of Sulfur Compounds Derived from Cabbage. J. Food Prot. 1997, 60, 67–71. [Google Scholar] [CrossRef]

- Isshiki, K.; Tokuoka, K.; Mori, R.; Chiba, S. Preliminary Examination of Allyl Isothiocyanate Vapor for Food Preservation. Biosci. Biotechnol. Biochem. 1992, 56, 1476–1477. [Google Scholar] [CrossRef]

- Ward, S.M.; Delaquis, P.J.; Holley, R.A.; Mazza, G. Inhibition of Spoilage and Pathogenic Bacteria on Agar and Pre-Cooked Roast Beef by Volatile Horseradish Distillates. Food Res. Int. 1998, 31, 19–26. [Google Scholar] [CrossRef]

- Dias, M.; Soares, N.; Borges, S.; Sousa, M.; Nunes, C.; Oliveira, I.; Medeiros, E. Use of Allyl Isothiocyanate and Carbon Nanotubes in an Antimicrobial Film to Package Shredded, Cooked Chicken Meat. Food Chem. 2013, 141, 3160–3166. [Google Scholar] [CrossRef]

- EFSA Scientific Opinion on the Safety of Allyl Isothiocyanate for the Proposed Uses as a Food Additive. EFSA J. 2010, 8, 1943. [CrossRef]

- CIE (Commission Internationale de L’Eclairage). Colorimetry, Publication CIE 15.2-1986, 2nd ed.; Commission Internationale de L’Eclairage: Viena, Austria, 1986; ISBN 3-900-734-00-3. [Google Scholar]

- Grau, R.; Hamm, R. A Simple Method for the Determination of Water Binding in Muscles. Naturswissenschaften 1953, 40, 29–30. [Google Scholar] [CrossRef]

- Utama, D.T.; Lee, S.G.; Baek, K.H.; Chung, W.S.; Chung, I.A.; Jeon, J.T.; Lee, S.K. High Pressure Processing for Dark-Firm-Dry Beef: Effect on Physical Properties and Oxidative Deterioration during Refrigerated Storage. Asian-Australas. J. Anim. Sci. 2017, 30, 424–431. [Google Scholar] [CrossRef]

- Tang, J.; Faustman, C.; Hoagland, T.A. Krzywicki Revisited: Equations for Spectrophotometric Determination of Myoglobin Redox Forms in Aqueous Meat Extracts. J. Food Sci. 2004, 69, C717–C720. [Google Scholar] [CrossRef]

- Ganhão, R.; Estévez, M.; Morcuende, D. Suitability of the TBA Method for Assessing Lipid Oxidation in a Meat System with Added Phenolic-Rich Materials. Food Chem. 2011, 126, 772–778. [Google Scholar] [CrossRef]

- Dussault, D.; Vu, K.D.; Lacroix, M. In Vitro Evaluation of Antimicrobial Activities of Various Commercial Essential Oils, Oleoresin and Pure Compounds against Food Pathogens and Application in Ham. Meat Sci. 2014, 96, 514–520. [Google Scholar] [CrossRef] [PubMed]

- Semeniuc, C.A.; Pop, C.R.; Rotar, A.M. Antibacterial Activity and Interactions of Plant Essential Oil Combinations against Gram-Positive and Gram-Negative Bacteria. J. Food Drug Anal. 2017, 25, 403–408. [Google Scholar] [CrossRef] [PubMed]

- Jridi, M.; Siala, R.; Fakhfakh, N.; Ayadi, M.A.; Elhatmi, M.; Taktak, M.A.; Nasri, M.; Zouari, N. Effect of Rosemary Leaves and Essential Oil on Turkey Sausage Quality. Acta Aliment. 2015, 44, 534–541. [Google Scholar] [CrossRef]

- Friedrich, L.; Siró, I.; Dalmadi, I.; Horváth, K.; Ágoston, R.; Balla, C. Influence of Various Preservatives on the Quality of Minced Beef under Modified Atmosphere at Chilled Storage. Meat Sci. 2008, 79, 332–343. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Marshall, M.R.; Wei, C. Antibacterial Activity of Some Essential Oil Components against Five Foodborne Pathogens. J. Agric. Food Chem. 1995, 43, 2839–2845. [Google Scholar] [CrossRef]

- Guimarães, A.C.; Meireles, L.M.; Lemos, M.F.; Guimarães, M.C.C.; Endringer, D.C.; Fronza, M.; Scherer, R. Antibacterial Activity of Terpenes and Terpenoids Present in Essential Oils. Molecules 2019, 24, 2471. [Google Scholar] [CrossRef]

- Guarda, A.; Rubilar, J.F.; Miltz, J.; Galotto, M.J. The Antimicrobial Activity of Microencapsulated Thymol and Carvacrol. Int. J. Food Microbiol. 2011, 146, 144–150. [Google Scholar] [CrossRef]

- López, P.; Sanchez, C.; Batlle, R.; Nerín, C. Vapor-Phase Activities of Cinnamon, Thyme, and Oregano Essential Oils and Key Constituents against Foodborne Microorganisms. J. Agric. Food Chem. 2007, 55, 4348–4356. [Google Scholar] [CrossRef]

- Lopez-Romero, J.C.; González-Ríos, H.; Borges, A.; Simões, M. Antibacterial Effects and Mode of Action of Selected Essential Oils Components against Escherichia Coli and Staphylococcus aureus. Available online: https://www.hindawi.com/journals/ecam/2015/795435/ (accessed on 6 August 2020).

- Boskovic, M.; Djordjevic, J.; Ivanovic, J.; Janjic, J.; Zdravkovic, N.; Glisic, M.; Glamoclija, N.; Baltic, B.; Djordjevic, V.; Baltic, M. Inhibition of Salmonella by Thyme Essential Oil and Its Effect on Microbiological and Sensory Properties of Minced Pork Meat Packaged under Vacuum and Modified Atmosphere. Int. J. Food Microbiol. 2017, 258, 58–67. [Google Scholar] [CrossRef] [PubMed]

- Churklam, W.; Chaturongakul, S.; Ngamwongsatit, B.; Aunpad, R. The Mechanisms of Action of Carvacrol and Its Synergism with Nisin against Listeria Monocytogenes on Sliced Bologna Sausage. Food Control 2020, 108, 106864. [Google Scholar] [CrossRef]

- Mir, N.A.; Rafiq, A.; Kumar, F.; Singh, V.; Shukla, V. Determinants of Broiler Chicken Meat Quality and Factors Affecting Them: A Review. J. Food Sci. Technol. 2017, 54, 2997–3009. [Google Scholar] [CrossRef] [PubMed]

- Shirzadegan, K.; Falahpour, P. The Physicochemical Properties and Antioxidative Potential of Raw Thigh Meat from Broilers Fed a Dietary Medicinal Herb Extract Mixture. Open Vet. J. 2014, 4, 69–77. [Google Scholar] [CrossRef]

- Jauhar, S.; Ismail-Fitry, M.R.; Chong, G.H.; Nor-Khaizura, M.A.R.; Ibadullah, W.Z.W. Different Pressures, Low Temperature, and Short-Duration Supercritical Carbon Dioxide Treatments: Microbiological, Physicochemical, Microstructural, and Sensorial Attributes of Chill-Stored Chicken Meat. Appl. Sci. 2020, 10, 6629. [Google Scholar] [CrossRef]

- Bekhit, A.E.D.; Cassidy, L.; Hurst, R.D.; Farouk, M.M. Post-Mortem Metmyoglobin Reduction in Fresh Venison. Meat Sci. 2007, 75, 53–60. [Google Scholar] [CrossRef]

- Csehi, B.; Szerdahelyi, E.; Pásztor-Huszár, K.; Salamon, B.; Tóth, A.; Zeke, I.; Jónás, G.; Friedrich, L. Changes of Protein Profiles in Pork and Beef Meat Caused by High Hydrostatic Pressure Treatment. Acta Aliment. 2016, 45, 565–571. [Google Scholar] [CrossRef]

- Toldrà, M.; Dàvila, E.; Saguer, E.; Fort, N.; Salvador, P.; Parés, D.; Carretero, C. Functional and Quality Characteristics of the Red Blood Cell Fraction from Biopreserved Porcine Blood as Influenced by High Pressure Processing. Meat Sci. 2008, 80, 380–388. [Google Scholar] [CrossRef]

- Arshad, M.S.; Amjad, Z.; Yasin, M.; Saeed, F.; Imran, A.; Sohaib, M.; Anjum, F.M.; Hussain, S. Quality and Stability Evaluation of Chicken Meat Treated with Gamma Irradiation and Turmeric Powder. Int. J. Food Prop. 2019, 22, 154–172. [Google Scholar] [CrossRef]

- Karwowska, M.; Dolatowski, Z.J. Effect of Mustard on Lipid Oxidation in Model Pork Meat Product. Eur. J. Lipid Sci. Technol. 2014, 116, 311–318. [Google Scholar] [CrossRef]

- Bellucci, E.R.B.; Bis-Souza, C.V.; Domínguez, R.; Bermúdez, R.; Barretto, A.C.D.S. Addition of Natural Extracts with Antioxidant Function to Preserve the Quality of Meat Products. Biomolecules 2022, 12, 1506. [Google Scholar] [CrossRef] [PubMed]

- Hussein, K.; Friedrich, L.; Kisko, G.; Ayari, E.; Nemeth, C.; Dalmadi, I. Use of Allyl-Isothiocyanate and Carvacrol to Preserve Fresh Chicken Meat during Chilling Storage. Czech J. Food Sci. 2019, 37, 417–424. [Google Scholar] [CrossRef]

- Ahn, E.S.; Kim, Y.S.; Shin, D.H. Observation of Bactericidal Effect of Allyl Isothiocyanate on Listeria Monocytogenes. Food Sci. Biotechnol. 2001, 10, 31–35. [Google Scholar]

- Meira, N.V.B.; Holley, R.A.; Bordin, K.; de Macedo, R.E.F.; Luciano, F.B. Combination of Essential Oil Compounds and Phenolic Acids against Escherichia Coli O157:H7 in Vitro and in Dry-Fermented Sausage Production. Int. J. Food Microbiol. 2017, 260, 59–64. [Google Scholar] [CrossRef] [PubMed]

- Gonçalves, M.P.J.C.; Pires, A.C.D.S.; Soares, N.d.F.F.; Araújo, E.A. Use of Allyl Isothiocyanate Sachet to Preserve Cottage Cheese. J. Foodserv. 2009, 20, 275–279. [Google Scholar] [CrossRef]

- Guo, M.; Jin, T.Z.; Scullen, O.J.; Sommers, C.H. Effects of Antimicrobial Coatings and Cryogenic Freezing on Survival and Growth of Listeria Innocua on Frozen Ready-to-Eat Shrimp during Thawing. J. Food Sci. 2013, 78, M1195–M1200. [Google Scholar] [CrossRef]

- Jin, T.; Gurtler, J.B. Inactivation of Salmonella on Tomato Stem Scars by Edible Chitosan and Organic Acid Coatings. J. Food Prot. 2012, 75, 1368–1372. [Google Scholar] [CrossRef]

- Luciano, F.B.; Holley, R.A. Enzymatic Inhibition by Allyl Isothiocyanate and Factors Affecting Its Antimicrobial Action against Escherichia Coli O157:H7. Int. J. Food Microbiol. 2009, 131, 240–245. [Google Scholar] [CrossRef]

- Kim, Y.S.; Ahn, E.S.; Shin, D.H. Extension of Shelf Life by Treatment with Allyl Isothiocyanate in Combination with Acetic Acid on Cooked Rice. J. Food Sci. 2002, 67, 274–279. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).