Abstract

The use of adhesive joints has become increasingly popular in various industries due to their many benefits, such as low weight and good mechanical performance. However, adhesive joints can suffer from defects, one of them being weak adhesion. This defect poses a significant risk to structural integrity and can lead to premature failure, but is hard to detect using existing nondestructive testing methods. Therefore, there is a need for an effective technique that can detect weak adhesion in single-lap joints (SLJ) to prevent failure and assist in maintenance, namely in the framework of structural health monitoring. This paper presents a novel approach utilizing machine learning and Lamb Waves (LW) to determine the level of weak adhesion. Firstly, a numerical model of SLJs with different levels of weak adhesion is created and an original approach is proposed for its validation with data from real samples so that reliable LW data can further be easily generated to train and test any other data-driven algorithm for tackling damage. Secondly, a damage detection method is proposed, based on artificial neural networks and fed with simulated data, to determine the level of damage in SLJs, independent of their location. The results show that the simulation model can be validated with a small set of experimental data, being capable of replicating real damage in SLJs. Additionally, the use of simulated data in the training algorithm can increase the accuracy of the simulation model up to 26% when compared to only considering experimental data. The adopted artificial neural network for detecting weak adhesion emerges as a promising approach, yielding a precision of over 95%. Thus, machine learning and LW data can be used to improve the reliability and accuracy of adhesive bonding quality control, as well function as a technique for structural health monitoring, which can enhance the safety and durability of bonded structures.

1. Introduction

In the last few years, the utilization of adhesive joints has seen an increase in various industries. This is attributed to their ability to connect different materials while providing uniform stress distributions around the joining areas, as well as to create structures that are lighter than those obtained with traditional joining methods [1,2,3]. Examples of industries that have benefited from the use of adhesives are the automotive manufacturing industry, with adhesive bonds in body panels, interior components, and even in joining chassis parts, allowing for cars to be built in fewer parts and thus making them lighter and cheaper [1], and the healthcare industry, with delicate applications for securing catheters to human skin, or even for attaching orthopedics to bones [4]. Other industries that can be mentioned are the renewable energy sector, with the fabrication of efficient and easier-to-install solar panels, the marine industry, with the fabrication of lightweight hulls and deck components, and the packaging industry, where adhesive tapes have been heavily relied upon to secure and protect packages [5,6,7].

The single lap joint (SLJ) is one of the most used types of adhesive assembles, with applications in different industries, ranging from the automotive to the aeronautical sectors [8]. However, the use of adhesive structural joints in cutting-edge industries has been restricted due to the high certification and inspection requirements posed by industry standards, as is the case for the Federal Aviation Regulations (FAR) Section 23.573(5)-(iii) [9]. Indeed, these standards demand reliable and robust non-destructive testing methods (NDT) to detect damage in joined parts, but existing testing methods for adhesive joints have great limitations and are inadequate in detecting some types of damage [9,10].

One of the primary types of damage that affects adhesive joints, for which there is a lack of suitable NDT methods, is weak adhesion. This defect is present when the maximum adhesive strength of the joint decreases more than 20% without showing any noticeable voids, cracks, or other visible changes. Usually, this happens when, during the manufacturing process, there is contamination between the adhesive and the substrates, which is often caused by oils, dust, or a poorly prepared surface that does not allow the adhesive to adhere properly [11].

To detect weak adhesion, several methods have been proposed, one of the most promising being based on the use of Lamb wave (LWs) data. LWs are a kind of guided wave that have the ability to travel over long distances and to sensitively interact with structural defects, meaning that their characteristic parameters change in the presence of defects, even in parts with complex geometries, making them a powerful tool in the realm of NDT [8]. The major drawback to their application is the complexity of the signals produced, which poses challenges to correlating LW with damage. To counter this problem, the implementation of robust methods, such as those based on machine learning, is needed.

While traditional signal-processing approaches may struggle when dealing with low signal-to-noise ratios or sparse data acquisition points, machine learning algorithms can effectively process complex information and still yield valuable insights. As more data are collected from different structures and inspection scenarios, the algorithms can continually refine their understanding of complex LW data, enabling them to better discriminate between normal wave patterns and those associated with defects.

When using machine learning, large datasets are often needed to train and test the algorithms. Creating large datasets experimentally is costly or even impracticable. Therefore, developing reliable numerical models of the SLJs, validated with experimental data from real parts, can reduce the overall burden [12]. An added benefit is that any large volumes of data can be obtained to develop machine learning algorithms.

In recent years there have been a few attempts to develop weak adhesion detection in SLJ. Initial studies were conducted with simulated data to determine features and find the best visualization methods to detect this form of damage in Loreiro et al. [13]. Further studies were conducted with simulated data and limited experimental validation such as in Ramalho et al. [14], where machine learning was used together with LWs to detect damage using a limited number of classes, but no direct correlation to experimental data was used to increase accuracy nor was the damage limited to a small area of the SLJ and intensity found independent of its position.

This paper proposes a new framework for the detection and classification of weak adhesion within SLJs through a fusion of LW data and machine learning techniques. The main contributions are as follows:

- A finite element method (FEM)-based model of SLJs for properly modeling weak adhesion is developed.

- An approach to validate the numerical model of SLJs subjected to weak adhesion using a small set of experimental data and machine learning algorithms is derived.

- A machine learning algorithm for classifying weak adhesion based on simulated LWs data and neural networks is proposed, exhibiting remarkable potential in precisely predicting the extent of weak adhesion, and being robust even when the defect’s location within the joint is altered.

This paper is divided into sections. In Section 2, a numerical method is developed, able to generate LW data characterizing SLJs with different levels of weak adhesion. The numerical model is tuned and validated by comparing, via machine learning, the LW signals with those obtained from a real experimental setup. The validated model, being reliable, constitutes the basis upon which further algorithms are trained and tested for weak adhesion classification. In Section 3, large volumes of model-simulated data for multiple cases of weak adhesion are generated, and a suitable machine learning algorithm is developed, which is robust enough to detect the level of weak adhesion independent of where it is located within the SLJs. The results are reviewed and discussed. Finally, in Section 4, the main conclusions are drawn.

2. Numerical Model Development and Experimental Validation

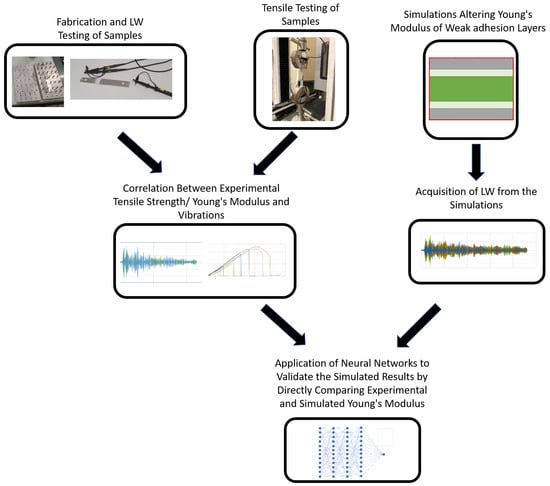

In this section, a numerical model for generating LW data from SLJs subjected to weak adhesion is developed. The model is validated, using machine learning techniques, by comparing the simulation results with those from experimental tests with real SLJs. A diagram of the approach can be seen in Figure 1. The experimental part is shown on the left-hand side, comprising SLJ fabrication, with distinct levels of weak adhesion, and LWs and strain–stress data acquisition. These data are correlated to correctly match LWs to levels of weak adhesion. The FEM simulation model of the SLJs is represented on the right-hand side of the diagram. At the bottom of the chart, a machine learning algorithm is used, which takes numerical and experimental data and validates the FEM model.

Figure 1.

Diagram of the proposed approach for FEM model development and validation.

2.1. Experimental Setup

The experimental setup is divided into two stages. For SLJs manufactured with distinct levels of weak adhesion, the first stage consists of exciting the samples and capturing the relevant LWs. The second stage involves subjecting the SLJs to tensile tests in order to determine their corresponding stress–strain curves.

2.1.1. Creating Weak Adhesion

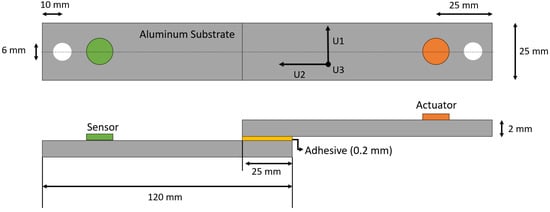

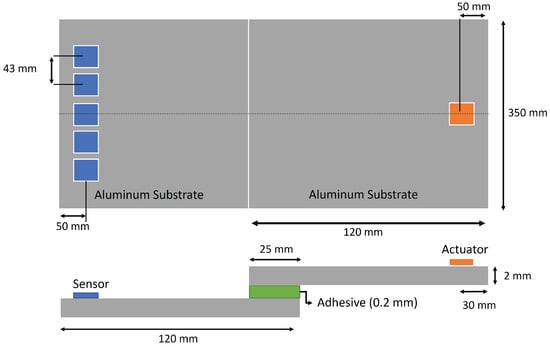

Before any experimental tests, samples were produced with multiple levels of weak adhesion. This was done by initially cutting aluminum 6061 bars into mm parts to have the upper and lower substrates of the SLJs. Each part was then drilled with a 6 mm hole at 10 mm from one of its ends to allow it to be held at the tension testing machine, as will be described in the follow-up. The other end of each substrate, where the adhesive would go, was sand blasted to maximize adhesive interaction. Next, the parts were geometrically finalized and thoroughly cleaned with acetone to remove any particles that could alter the adhesive bonding results. After adhesive curing, piezoelectric elements were bonded on the substrates to allow LW excitation and measurement. In Figure 2, a diagram of a final part can be seen, along with the overall measurements and the Cartesian coordinates that are used during simulation. The piezoelectric elements’ dimensions and their placement are also represented.

Figure 2.

Representation and dimensions of a SLJ along with the Cartesian axis description that is used during simulations.

To create multiple levels of weak adhesion, various quantities of release agent Loctite 770-NC Frekote were used. For the study at hand, four overall levels were created, comprising a total of 11 SLJs. The first level corresponded to full adhesion, with no release agent applied, and two samples were manufactured. The second and third levels, with three SLJs each, corresponded to intermediary levels of weak adhesion, where the parts were subjected to one layer of release agent and one layer of a mixture of 50% release agent plus 50% acetone, respectively. Finally, the fourth level, with three samples, was a severe weak adhesion case, where the SLJs were subjected to two layers of release agent. After the parts had the necessary quantity of release agent applied, they were placed in a dimensional jig and received the adhesive Plexus MA 560-1 [15] in order to create the SLJs.

It is worth emphasizing that, although the SLJs were manufactured based on controlling the quantity of release agent applied, fabrication issues may affect the production and the obtention of the desired four levels of weak adhesion. Therefore, further testing is necessary to determine the real level of weak adhesion, as will be described in the follow-up.

2.1.2. Experimental Testing

As previously described, there were two stages in the experimental setup, with the first being used to determine the effect of weak adhesion on LW parameters, and the second one to determine the real level of weak adhesion affecting the manufactured SLJs, so that a direct relationship between values is possible.

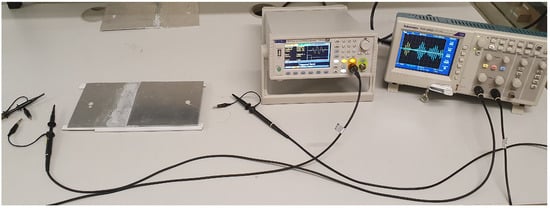

Regarding the first stage, each individual part was instrumented with two piezoelectric elements PIC 255 piezoceramic (PRYY + 1119 model), with one serving as sensor and the other working as an actuator, as illustrated in Figure 2. These piezoelectric elements were chosen due to their light weight, low cost, and versatility to serve as either actuators or sensor. This versatility will also allow for further tests to be conducted and will allow for having an array of sensors to analyze large areas. A five-cycle Hanning-windowed sinusoidal burst centered at a frequency of 100 kHz [16,17,18,19] was applied to the actuator by a signal generator AIM & Thurbly Thander Instruments, model TGF4042. This type of excitation signal keeps LW dispersion and attenuation at a minimum, while still maximizing sensitivity. The sensor was connected to a digital oscilloscope Tektronix, model TBS1000C, which samples and memorizes the signals. To facilitate input and output synchronization, the Hanning window signal applied to the actuator was also collected by the oscilloscope. In Figure 3 the data acquisition setup can be seen.

Figure 3.

Data acquisition setup of one SLJ, with actuator and sensor connected to a signal generator and an oscilloscope, respectively.

After all LW data were acquired from the SLJs, in a second stage, the sensors and actuators were removed and the samples were subjected to tensile tests. Each part was carefully placed on an Instron 3367 machine and stressed until rupture.

It is important to analyze the stress–strain curves obtained, as adhesives are inherently complex, and even when fully cured in the correct manner, variations in Young modulus over 275 Mpa can be verified [15]. This uncertainty may be higher when dealing with artificially created SLJs with weak adhesion and might cause difficulties when trying to simulate vibration data.

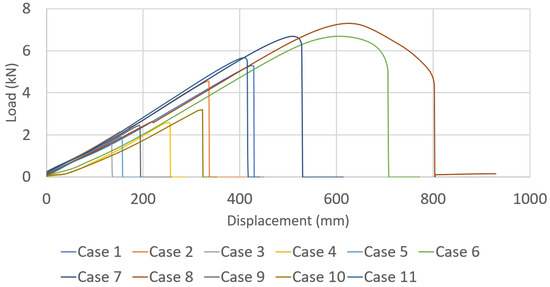

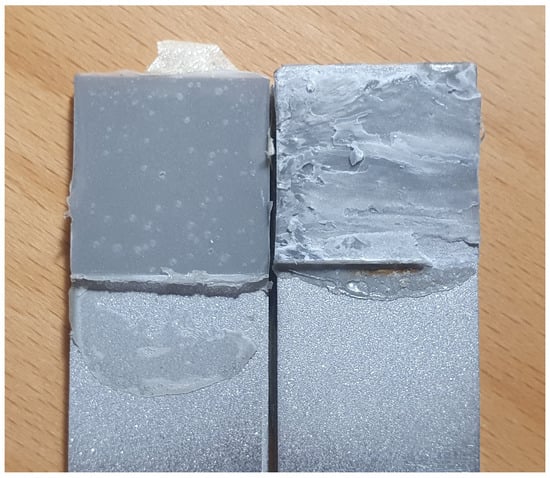

In Figure 4, the load-displacement curves of all SLJs are depicted. As expected, four groups with distinct levels of maximum load can be identified. The group produced with two layers of release agent reveals the smallest ultimate stress, while the cases without release agent correspond to the largest loads. Therefore, the method adopted for the fabrication of SLJs based on the application of a release agent to create distinct levels of weak adhesion is quite reliable. It is also interesting to observe that the two cases without the release agent presented a larger plastic deformation, which may be caused by the adhesive material deforming under loads, instead of a clean break of the adhesive on the contact surface of the substrate, as seen for the other cases. When analyzing the samples, there is a stark contrast between the adhesive of the samples that reinforces this theory. In Figure 5, it is possible to observe the difference between the sample that had plastic deformation and the sample where the limit layer of the adhesive failed.

Figure 4.

Load-displacement curves for all 11 experimental SLJs. Each case represents a sample fabricated with a different level of weak adhesion, adding up to four different fabrication groups.

Figure 5.

Comparison between a sample that had no plastic deformation (left) and one that had intense plastic deformation (right).

With the maximum loads determined, all samples can now be referenced to these values, and a linear percentile analysis of Young’s modulus is used to compare simulated and experimental data. It is important to note that Young’s modulus is being used as it is a variable that can be calculated by the tensile test and is the main variable that is altered to determine the desired level of weak adhesion present in the simulation.

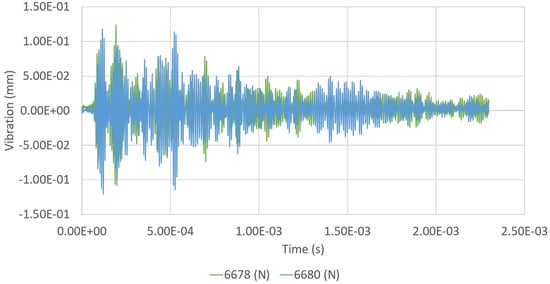

When LW data from all 11 SLJs are analyzed and compared, it is possible to verify that no clear patterns emerge. This is more evident when analyzing two tests that have almost exactly the same maximum tensile strength but possess completely different vibrational patterns, as can be seen in Figure 6. This means that directly correlating LWs with specific levels of weak adhesion is unfeasible. Thus, it is preferable to have the machine learning algorithm compare the acquired data directly than to forcefully try to distill any type of results from these signals.

Figure 6.

The LW of two samples 6678 N and 6680 N, obtained during the tensile test, shows that even very similar tensile strengths generate completely different signals.

As can be seen, the process of obtaining experimental data from SLJ is very labor-intensive and complex, which results in a very high overall cost to create a large number of cases. In any real-world cases, this could not be reliably used. Therefore, these collected data will be used in conjunction with simulated data to validate the simulated methodology.

2.2. Numerical Model

A FEM model of SLJ was developed and simulated using the software Abaqus (Dassault Systemes, Vélizy-Villacoublay, France). To create the simulation model, the values of most parameters were chosen based on the existing literature. The mesh size of 1.5 mm was selected, as this is the largest allowable value still below half the LW wavelength, as suggested by the works of Jeenjitkaew et al. [11]. Along the thickness of the substrates, another approach was taken, with the mesh size being governed by the number of layers rather than by the overall size of each element. The value chosen was four layers in each part thickness in order to have enough elements on the thickness to allow the wave to transverse it while still maintaining a reasonable simulation time, which on average corresponded to 1 h per case. A dynamic explicit simulation was chosen due to the temporal flow intrinsic to the problem at hand, while the element type chosen was C3D8R.

2.2.1. Lamb Waves Simulation

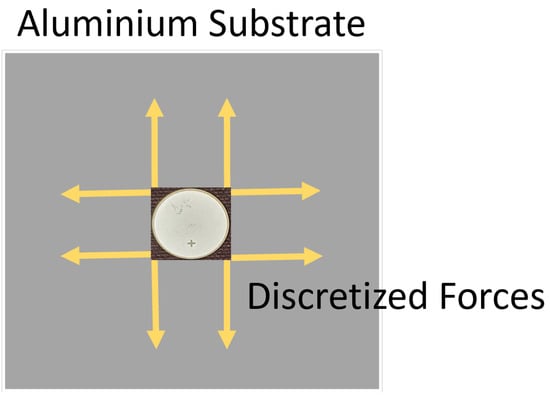

To simulate LWs, it was first necessary to observe how the vibrations are induced on the real SLJs. In this work, piezoelectric actuators were used. Thus, the overall excitation occurs on the surface of the substrate, radially from the actuator. To approximate this behavior, the forces were discretized and placed on the edges of the actuator, represented in yellow in Figure 7. Through empirical testing, it was seen that this discretization was enough to mimic experimental tests and, thus, was deemed accepted.

Figure 7.

Illustration of a piezoelectric sensor with the forces being discretized at the tips of the square that encompasses the sensor.

The LWs were generated with Hanning window pulse forces with the same characteristics as in the experiment setup. There are multiple ways of creating and representing these waves in Abaqus, the one chosen in this work was to create a Python script that would apply a variable deformation on the surface of the part simulating the sinusoidal pattern of the Hanning window. Furthermore, the simulation program Abaqus discretizes the vibrations received into the three primary Cartesian components, U1, U2, and U3, as shown in Figure 2. This will be further analyzed in Section 2.3.2 to determine what component or combination of components is most suited and similar to the real signal.

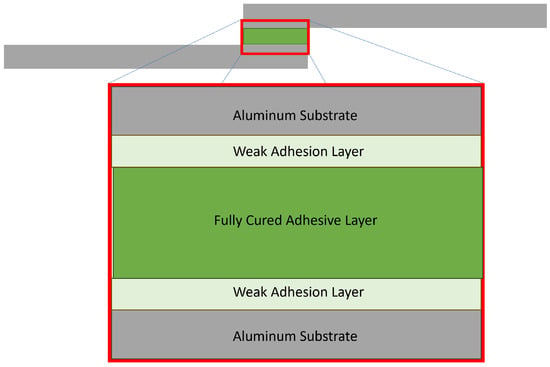

2.2.2. Weak Adhesion Simulation

To simulate weak adhesion, it was first necessary to divide the simulated adhesive into three parts, as represented in Figure 8. The outside edges were considered a layer of weak adhesion with an overall thickness of 0.001 mm, while the center of the adhesive, with the remaining height, was considered not to have been subjected to any physical alterations and thus had the total mechanical properties of the material.

Figure 8.

Representation of the three-layer approach to simulating weak adhesion.

In regards to the materials’ properties, the overall value of stiffness of the weak adhesion layer was lowered by reducing its Young’s modulus, as suggested in [20,21] and reinforced in [22], where it is possible to see the initial validation of the weak adhesion simulation.

Utilizing the previously described techniques, a total of 72 unique cases were generated, each one with a different level of weak adhesion varying from 100 to 700 MPa. These simulations presented time-series that had an overall close visual aspect to the experimental ones, but no conclusions or validation could be made based only on this due to the discrepancies of data previously commented on and seen in Figure 6.

2.3. Numerical Model Validation

2.3.1. Data Processing

Before any analysis of the experimental and simulated data, the collected LW time-series were subjected to interpolation with a step size of , so that their overall size and start and finishing points were the same. Then, all data were normalized in amplitude to the interval . Furthermore, due to the small size of the experimental dataset, it was necessary to do a cross-validation where each of the 11 experimental time-series was used as a validation set. To do this, the 11 experimental time-series were divided into three categories, with one case being used as a validation set, two used for testing, and the other eight used for training. Once the validation dataset was classified, a new validation dataset was chosen, and this was repeated until all 11 were chosen. This was done so that the results were not subjected to any bias that could arise from the low number of experimental cases and possible inconsistencies of the experimental setup.

As stated previously, during the simulations, a total of 72 were created, thus there was a large discrepancy between the 11 experimental datasets we had and the 72 that came from the simulation. Therefore it was necessary to implement a data augmentation method to increase the number of experimental points. The chosen method was the application of a Gaussian white noise filter that was 5% of the average size of the overall signal. This allows for multiple cases that directly correlate to an experimental setup where multiple data acquisitions are taken of the same sample and the only difference is the noise caused by small environmental variations. After all data were treated and augmented, it was combined and normalized in order to have the same dimensionality.

2.3.2. Machine Learning

The objective of this machine learning algorithm is to analyze the correlation between the experimental and simulated data and determine if the simulations can be used as stand-ins for experimental tests and what are their limitations.

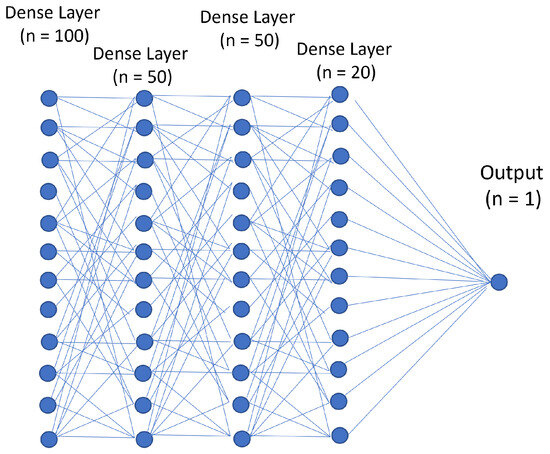

With all the data correctly organized and divided, the machine learning method of choice was a Feed Forward Neural Network (FFNN) due to its simplicity and ease of use. It was also chosen due to its suitability as a regression model, thus the damage can be detected more precisely without the need for classes. The chosen batch size was 16 and the number of data points/input data used was 500 from the total 1700 obtained during the interpolation process of the time-series previously acquired. On the other hand, the output data used were, for the simulated data, Young’s modulus of the damaged area, and for the experimental, an approximation of Young’s modulus obtained from the tensile test was used. This small number of 500 points out of 1700 from the time-series was used as they possessed a portion of the initial vibration without a large influence of the reflections. This shows that the simulation is lacking in the reflections when compared to the experimental cases and thus there is a fine-tuning between too few data points and where the reflections start to heavily influence the data. The mean absolute error (MAE) was chosen both as a loss function and as an evaluation metric, while for the optimization the ADAM method was used. Finally, a total of 100 epochs was selected as previous analysis showed that there was no need for more iterations and the overall training times were in the accepted range.

The overall structure of the FFNN can be seen in Figure 9, with a total of five layers, one input, three hidden, and one output layer. The input consisted of the 500 data points of one signal and the subsequent layers had several nodes that were tested empirically until the best results were achieved.

Figure 9.

Overall structure of the chosen FFNN with five layers, each one with a different kernel size.

The first test conducted was to determine what signal direction from the simulation should be used. To do this, five tests for each direction were conducted, whose results are listed in Table 1.

Table 1.

Average error for each validation case for the three Cartesian Axes plus two others that represent an average of the results in order to represent other intermediate directions. All data are represented in MPa.

The average of the five combinations of directions was taken for each case. Finally, the average of these results was obtained. It is possible to see that the direction U2 has the lowest average value, with a total of 240 MPa of average error. Finally, when analyzing the complete dataset obtained from the five cases, U2 was the only case where there was no complete error case and where the algorithm obtained the wrong result by at least the maximum analysis range. The use of U2 also makes sense when analyzing the simulated specimen, as U2 is the direction in which the sensor is from the actuator, thus it is the shortest path and has fewer cases of reflections when compared with the other Cartesian directions.

With the chosen vibrational direction, it is possible to determine the influence of the simulated data when combined with the experimental. This was done following the previous test but instead of the vibrational direction, the number of experimental cases was altered in comparison to the simulated. For each case, a total of five tests were conducted and the average can be seen in Table 2.

Table 2.

Multiple tests conducted with different levels of simulated data and noise with the chosen Cartesian direction. All values are represented in MPa.

In Table 2, the previously mentioned results can be seen and it is possible to conclude two things:

- A few experimental cases constantly have bad results. This is probably because the tests had some form of inconsistency during the experimental setup and thus can be considered faulty.

- The average values are always lower when simulated values are used, showing their reliability as a form of simple data augmentation.

- The validation cases cannot be correctly determined when testing and training are done only with simulated values, showing that there is still a need for a few experimental cases to create a correlation between the experimental and simulated data.

It is also important to note that the experimental cases shown in this validation had a very narrow shape and thus were subjected to many reflections, this shows the robustness of the method as it was capable of detecting damage and even detecting a few of the samples to extremely close values. This test demonstrates that the use of experimental and simulated data in conjunction allows for the correct identification of damage and thus validates the use of the simulated parameters.

3. Weak Adhesion Detection and Classification

With the simulation model validated, the necessary volumes of data for training and testing machine learning algorithms can be reliably generated, and weak adhesion detection can be performed without the need for experimental data.

In this section, the basic parameters for the simulations are maintained as previously performed, as well as the methods to simulate LWs and to create weak adhesion, while only the size of the samples and the positioning of the sensors/actuators were changed. Larger parts have fewer LW reflections captured by the sensors, which had already been seen as detrimental. Furthermore, weak adhesion detection is conducted in SLJs considering a wide enough damaged areas to have damage detection independent of position.

3.1. Simulation Data

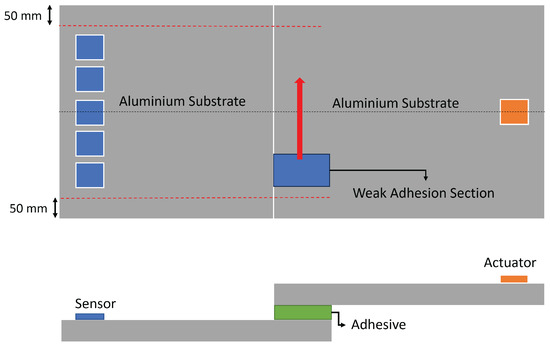

The experimental setup is composed of two substrates with dimensions mm and the same adhesive structure previously described in Section 2.2. There is also one actuator located on the top substrate at a distance of 50 mm from the edge. On the lower substrate, there are five sensors equally positioned, as can be seen in Figure 10.

Figure 10.

Simulated parts dimensions and positioning of the actuator and sensor components.

As the objective is to detect damage without any dependence on its location, the damaged section with a width of 25 mm was moved in increments of 1 mm in the adhesive area, always keeping a minimum distance of 50 mm from the edges to reduce the effect of the reflections on the acquired data. In Figure 11, it is possible to see the overall size, limits, and positioning of the weak adhesion region.

Figure 11.

Simulated parts showing the region of weak adhesion.

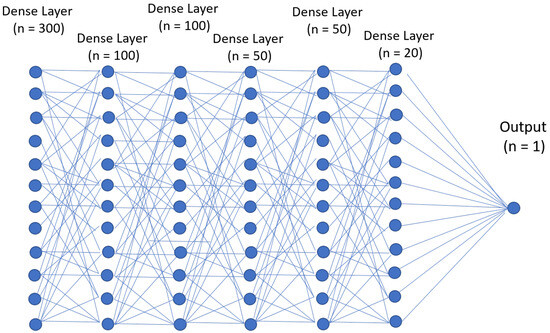

3.2. Machine Learning Application

As a simple FFNN has been shown to detect damage without any significant problems, it will also be used to detect the damage in this case. The overall structure of the FNNN has only been slightly altered to six layers after a few empirical tests were conducted to maximize the results obtained and the final configuration can be seen in Figure 12.

Figure 12.

Graphic representation of a FFNN used in the final study with six dense layers.

To iterate on the used parameters and data, a total of 1255 cases were used, divided into 225 different positions for five different levels of damage ranging from 100 to 500 MPa. Each case had five sensors receiving the signal from one actuator and all these data were combined into one continuous time-series. Therefore, the input used was a time-series composed of a total of 2500 data points, concatenated from 500 points from each of the five sensors. For the machine learning algorithm, 500 epochs were chosen to better guarantee conversion, with a batch size of 64, and the maximum absolute error (MAE) was used for both loss function and metrics.

4. Results and Discussion

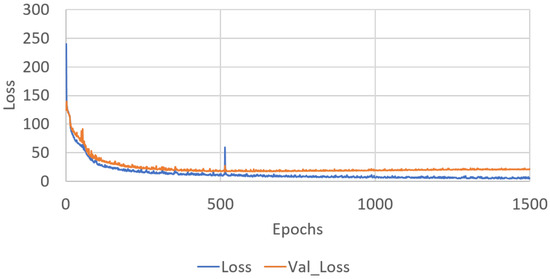

From the machine learning setup, it was possible to accomplish the required simulations and in Figure 13 it is possible to see the loss function for both the training and validation cycles. In this figure, there is a gradual decrease in loss from both cases, with the training loss always lower than the validation. It is possible to see that, after around 500 epochs, there is a stabilization of the value of the validation loss, followed by an increase at around 800 epochs. For the training loss, there is a slow decrease after 500 epochs, thus showing signs of overfitting. The option for 1500 epochs was for allowing to visualize the behavior of the loss curve and have the guarantee of its convergence.

Figure 13.

Plot of the loss function for both the training and the validation sets per epoch.

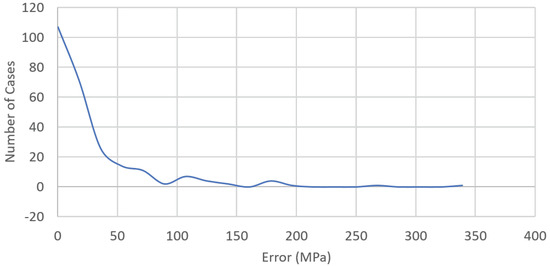

In Figure 14, the predicted values obtained from the validation dataset were compared to the original values and the error was plotted from smallest to largest. In the figure, the difference between them is plotted, showing that there are more cases with less than 50 MPa of error, with a few cases above 150 MPa of error. These values by themselves do not hold a large significance but, when compared with the values of Young’s modules from weak adhesion, it is possible to see that most of the error represents, on average, less than 5% of the damage. This means that this method can detect the level of damage with a 95% accuracy without needing to know where the damage is located. Furthermore, the figure shows that only a few occurrences have an error over 25%, which may be acceptable. However, due to the possible future practical applications of this method, it is important to better understand when these errors occur, to allow for further investigation and increase robustness.

Figure 14.

Plot of the number of cases in each error class showing that most errors are below 50 MPa.

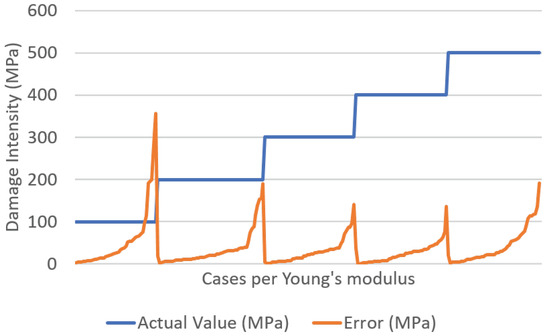

To analyze the data even further, the cases were separated between their real value, and in Figure 15 it is possible to see how the error is spread out for each case. It can be seen that the case with the most and largest errors is when the weak adhesion has a Young’s modulus of 100 MPa, while all other cases present few errors with a value over 100 MPa. This shows that there is a more pronounced difference between the simulations in the lower range tested and thus, to create a more robust method, a minimum threshold should be adopted, where any values lower than 200 MPa are indicative of damage and no further evaluation should be taken.

Figure 15.

Comparison between the error for each real value of damage.

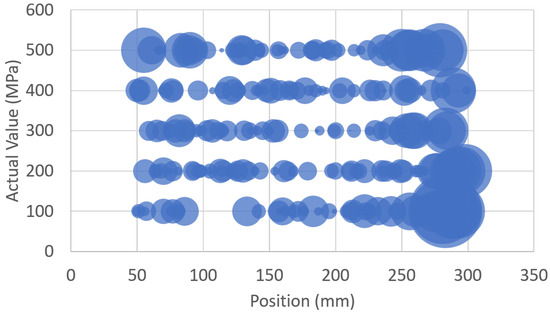

Following the previous analysis, the data were divided into not only the error but also the overall position of the error for each different case of real value. This division can be seen in Figure 16, where each of the circles corresponds to a different level of real value and the overall dimension of the circles represents the size of the error. In this Figure, it is possible to see that the larger errors occur on the edges of the panels where there is less information being captured by the sensors and the information that does get captured can be subjected to reflections on the walls. This shows not only where the errors are occurring but also reinforces that the previous study of comparing the simulated and experimental data was done in sub-optimal conditions and still generated significant positive results.

Figure 16.

Comparison between the error for each real value of damage in their x coordinate location. The size of the circles represents the dimension of the error.

5. Conclusions

This paper delves into a comprehensive investigation of weak adhesion detection within SLJ through a fusion of LW simulations and advanced machine learning techniques.

Adhesive joints have gained considerable popularity in diverse industries, yet weak adhesion remains a formidable challenge due to its difficult detection before triggering premature structural failure. The utilization of Law, acknowledged for its sensitivity to these types of defects, coupled with machine learning algorithms, presents a novel and promising avenue for addressing this critical issue.

The study methodology encompasses the generation of validated simulated weak adhesion scenarios, closely aligned with experimental ones. Leveraging the intrinsic capabilities of LWs, combined with the sophisticated capabilities of machine learning, enables accurate determination of weak adhesion damage levels. The simulations are compared with realistic cases, leading to LW signals that are subsequently harnessed by machine learning models for robust damage quantification with an over 26% increase in capacity. The validation process serves to underscore the efficacy of amalgamating simulated data with a more limited experimental dataset to train the machine learning models, as these augmentations of the experimental dataset result in tangible improvements in terms of detection accuracy. It also allows for further studies to be conducted only with simulated data. The proposed machine learning framework, manifested as a FFNN, exhibits remarkable potential in precisely predicting the extent of weak adhesion damage, holding true even when the defect’s location within the joint is altered, with an overall damage quantification of 95%.

In essence, this study advances the notion that the integration of LW simulations and machine learning techniques offers a pioneering solution that enhances both the precision and dependability of weak adhesion defect detection in adhesive joints. The resultant synergy between these two methodologies holds the key to elevating the quality control of adhesive bonding processes, providing an unparalleled degree of accuracy in damage assessment. This promising approach not only bolsters quality control but also offers the prospect of serving as a potent structural health monitoring tool, thereby fortifying the integrity and longevity of adhesive joint applications across an array of industries.

Using the methods outlined in this paper along with more simulations will allow to determine not only the intensity of the damage but also its location, shape, and dimension. It can also be used to determine whether the damage is a void, weak adhesion, adhesive cracks, or any other type of damage. Furthermore, there is a large area of practical research where the effects of temperature, humidity, and noise need to be studied and determined. Finally, in order to widen the scope and practicality of this study, it should include highly flexible adhesives, as is the case of silicone, and those with a broad band of characteristics, such as epoxies.

Author Contributions

Conceptualization, G.M.F.R., L.F.M.d.S. and A.M.L.; methodology, G.M.F.R. and A.M.L.; software, G.M.F.R.; validation, G.M.F.R., L.F.M.d.S. and A.M.L.; formal analysis, G.M.F.R., L.F.M.d.S. and A.M.L.; investigation, G.M.F.R. and A.M.L.; writing—original draft preparation, G.M.F.R.; writing—review and editing, G.M.F.R., L.F.M.d.S. and A.M.L.; supervision, L.F.M.d.S. and A.M.L.; project administration, L.F.M.d.S. and A.M.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data available on request to the authors.

Conflicts of Interest

The authors declare no conflict of interest.

References

- da Silva, L.F.M.; Öchsner, A.; Adams, R.D. Handbook of Adhesion Technology, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Higgins, A. Adhesive bonding of aircraft structures. Int. J. Adhes. Adhes. 2000, 20, 367–376. [Google Scholar] [CrossRef]

- Binhasan, M.; Al-Habeeb, K.M.; Almuqbil, A.S.; Alhaidary, T.A.; Alfawaz, Y.F.; Farooq, I.; Vohra, F.; Abduljabbar, T. Assessment of the physical properties of an experimental adhesive dentin bonding agent with carbon nanoparticles. Crystals 2022, 12, 1441. [Google Scholar] [CrossRef]

- Shah, N.V.; Meislin, R. Current state and use of biological adhesives in orthopedic surgery. Orthopedics 2013, 36, 945–956. [Google Scholar] [CrossRef] [PubMed]

- Mehdi, G.; Ali, N.; Hussain, S.; Zaidi, A.A.; Shah, A.H.; Azeem, M.M. Design and fabrication of automatic single axis solar tracker for solar panel. In Proceedings of the 2019 2nd International Conference on Computing, Mathematics and Engineering Technologies (iCoMET), Sukkur, Pakistan, 30–31 January 2019; IEEE: Piscataway Township, NJ, USA, 2019; pp. 1–4. [Google Scholar]

- Mahmud, K.; Morsalin, S.; Khan, M.I. Design and fabrication of an automated solar boat. Int. J. Adv. Sci. Technol. 2014, 64, 31–42. [Google Scholar] [CrossRef]

- Ciccotti, M.; Giorgini, B.; Vallet, D.; Barquins, M. Complex dynamics in the peeling of an adhesive tape. Int. J. Adhes. Adhes. 2004, 24, 143–151. [Google Scholar] [CrossRef]

- Ramalho, G.M.; Lopes, A.M.; da Silva, L.F. Structural health monitoring of adhesive joints using Lamb waves: A review. Struct. Control Health Monit. 2021, 29, e2849. [Google Scholar] [CrossRef]

- Archives, U.N.; Administration, R. Federal Aviation Regulations-Section 23.573; U.S. Government Printing Office: Washington, DC, USA, 2014.

- Guyott, C.C.H.; Cawley, P.; Adams, R. The non-destructive testing of adhesively bonded structure: A review. J. Adhes. 1986, 20, 129–159. [Google Scholar] [CrossRef]

- Jeenjitkaew, C.; Guild, F.J. The analysis of kissing bonds in adhesive joints. Int. J. Adhes. Adhes. 2017, 75, 101–107. [Google Scholar] [CrossRef]

- Teixeira de Freitas, S.; Zarouchas, D.; Poulis, J. The use of acoustic emission and composite peel tests to detect weak adhesion in composite structures. J. Adhes. 2018, 94, 743–766. [Google Scholar] [CrossRef]

- Loreiro, V.; Ramalho, G.; Tenreiro, A.; Lopes, A.M.; da Silva, L. Feature extraction and visualization for damage detection on adhesive joints, utilizing Lamb waves and supervised machine learning algorithms. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 09544062221086410. [Google Scholar] [CrossRef]

- Ramalho, G.M.; Lopes, A.M.; Carbas, R.J.; Da Silva, L.F. Identifying Weak Adhesion in Single-Lap Joints Using Lamb Wave Data and Artificial Intelligence Algorithms. Appl. Sci. 2023, 13, 2642. [Google Scholar] [CrossRef]

- Plexus Technical Data Sheet MA560-1. ITW Performance Polymers. Available online: https://itwperformancepolymers.com/ (accessed on 29 April 2023).

- Lee, B.; Staszewski, W. Modelling of Lamb waves for damage detection in metallic structures: Part I. Wave propagation. Smart Mater. Struct. 2003, 12, 804. [Google Scholar] [CrossRef]

- Packo, P.; Bielak, T.; Spencer, A.; Staszewski, W.; Uhl, T.; Worden, K. Lamb wave propagation modelling and simulation using parallel processing architecture and graphical cards. Smart Mater. Struct. 2012, 21, 075001. [Google Scholar] [CrossRef]

- Ahmad, Z.; Gabbert, U. Simulation of Lamb wave reflections at plate edges using the semi-analytical finite element method. Ultrasonics 2012, 52, 815–820. [Google Scholar] [CrossRef] [PubMed]

- Adin, H.; Yıldız, B.; Adin, M.S. Numerical investigation of fatigue behaviours of non-patched and patched aluminium pipes. Eur. J. Tech. (EJT) 2021, 11, 60–65. [Google Scholar] [CrossRef]

- Xu, Y.; Tao, C.; Qiu, J. Debonding detection of scarf-repaired composite laminates with laser ultrasonic Lamb waves. Proc. J. Phy. Conf. Ser. 2022, 2184, 012041. [Google Scholar] [CrossRef]

- Zhuang, Y.; Kopsaftopoulos, F.; Dugnani, R.; Chang, F.K. Integrity monitoring of adhesively bonded joints via an electromechanical impedance-based approach. Struct. Health Monit. 2018, 17, 1031–1045. [Google Scholar] [CrossRef]

- Mehrabi, M.; Soorgee, M.H.; Habibi, H.; Kappatos, V. A novel application of ultrasonic Lamb waves: Studying adhesive effects on the inspection of coating debonding in a three-layer waveguide. Nondestruct. Test. Eval. 2021, 36, 616–636. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).