A Three-Dimensional Mesoscale Computational Simulation Method for Soil–Rock Mixtures Considering Grain Crushing

Abstract

:1. Introduction

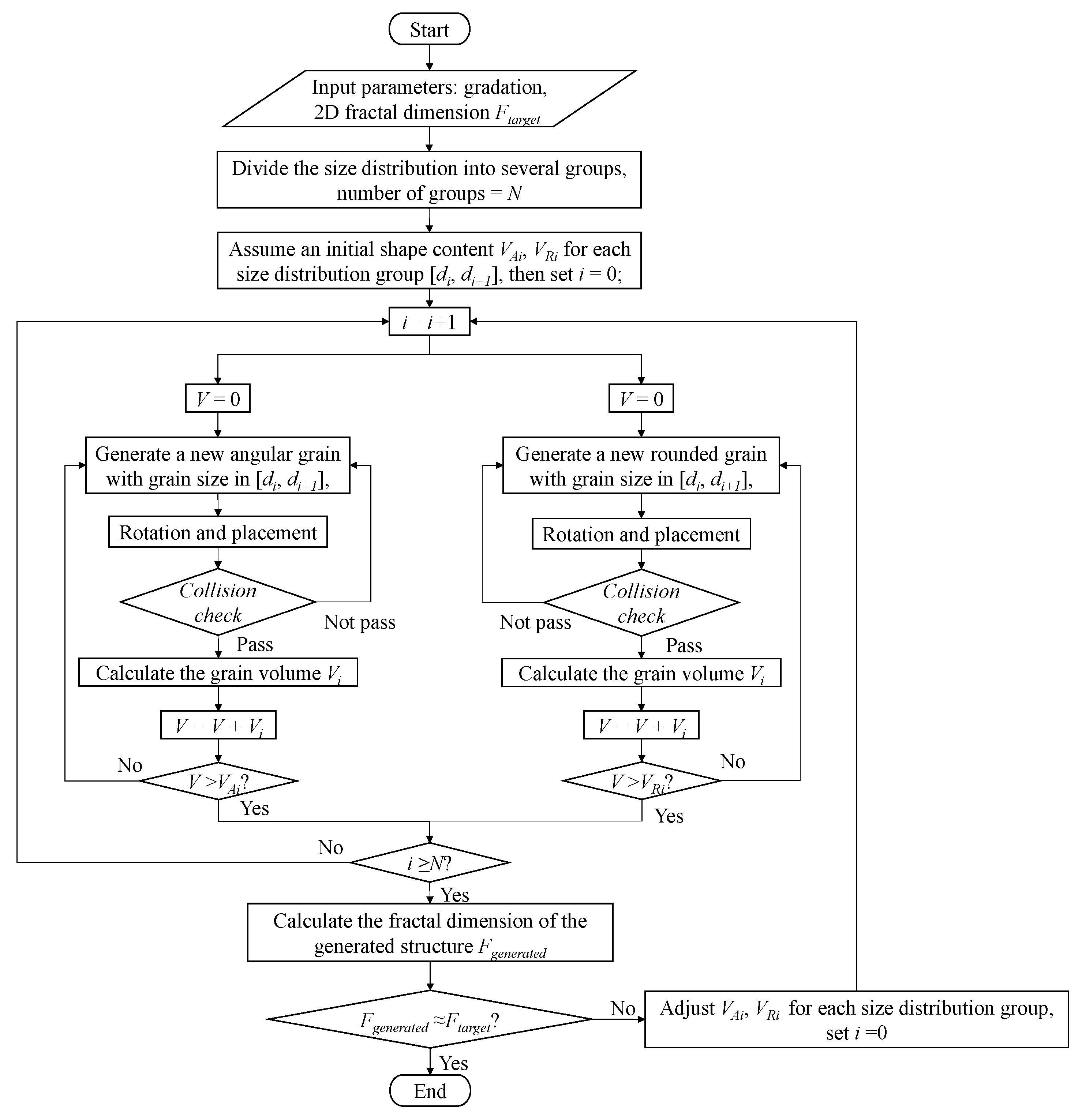

2. Generation Algorithm of Random Soil–Rock Mixtures

2.1. General Generation Algorithm

2.2. Generation of Single Rock Particle

2.3. Grain Placement and Collection Detection

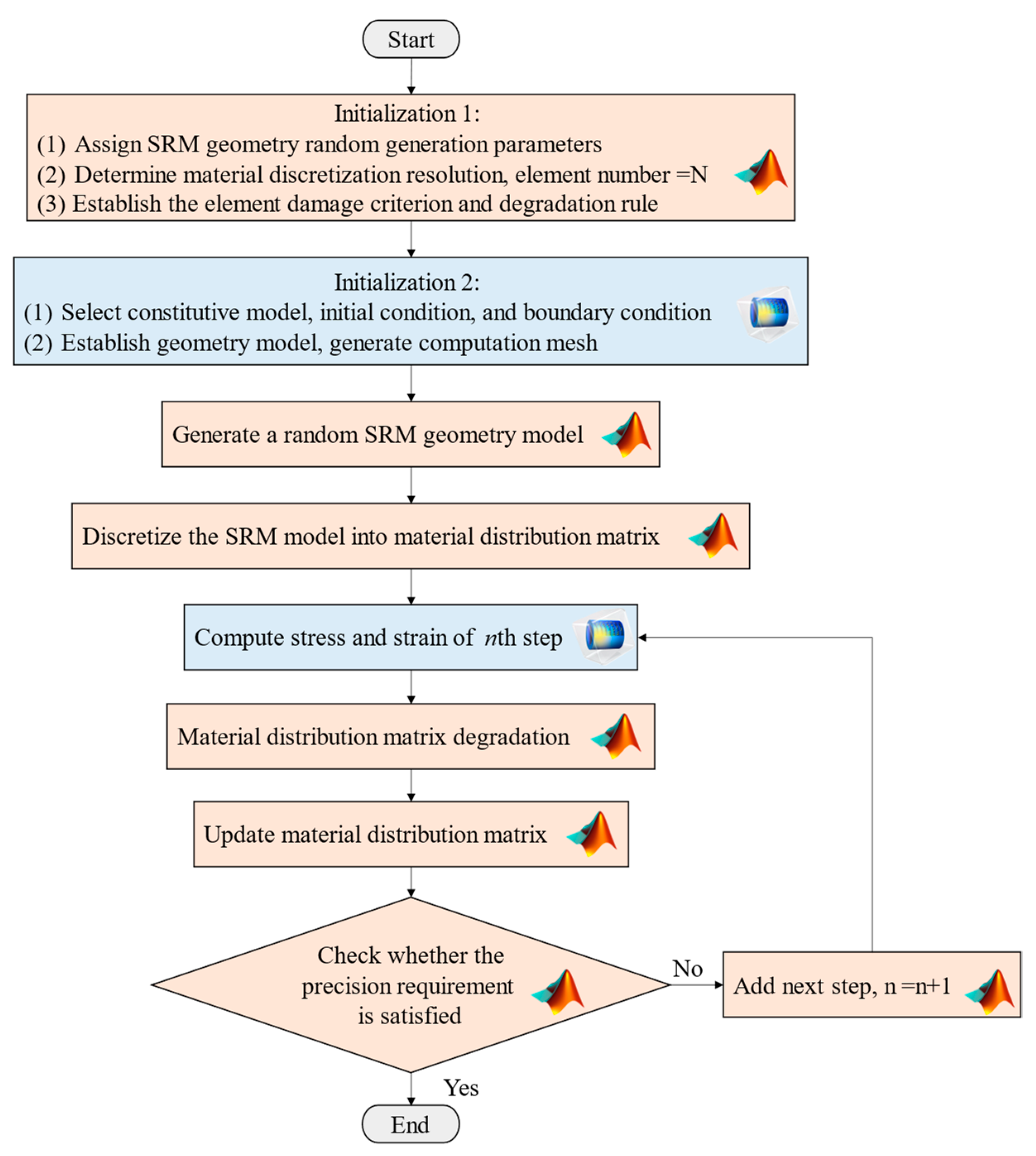

3. Mesoscale Simulation of Soil Rock Mixtures

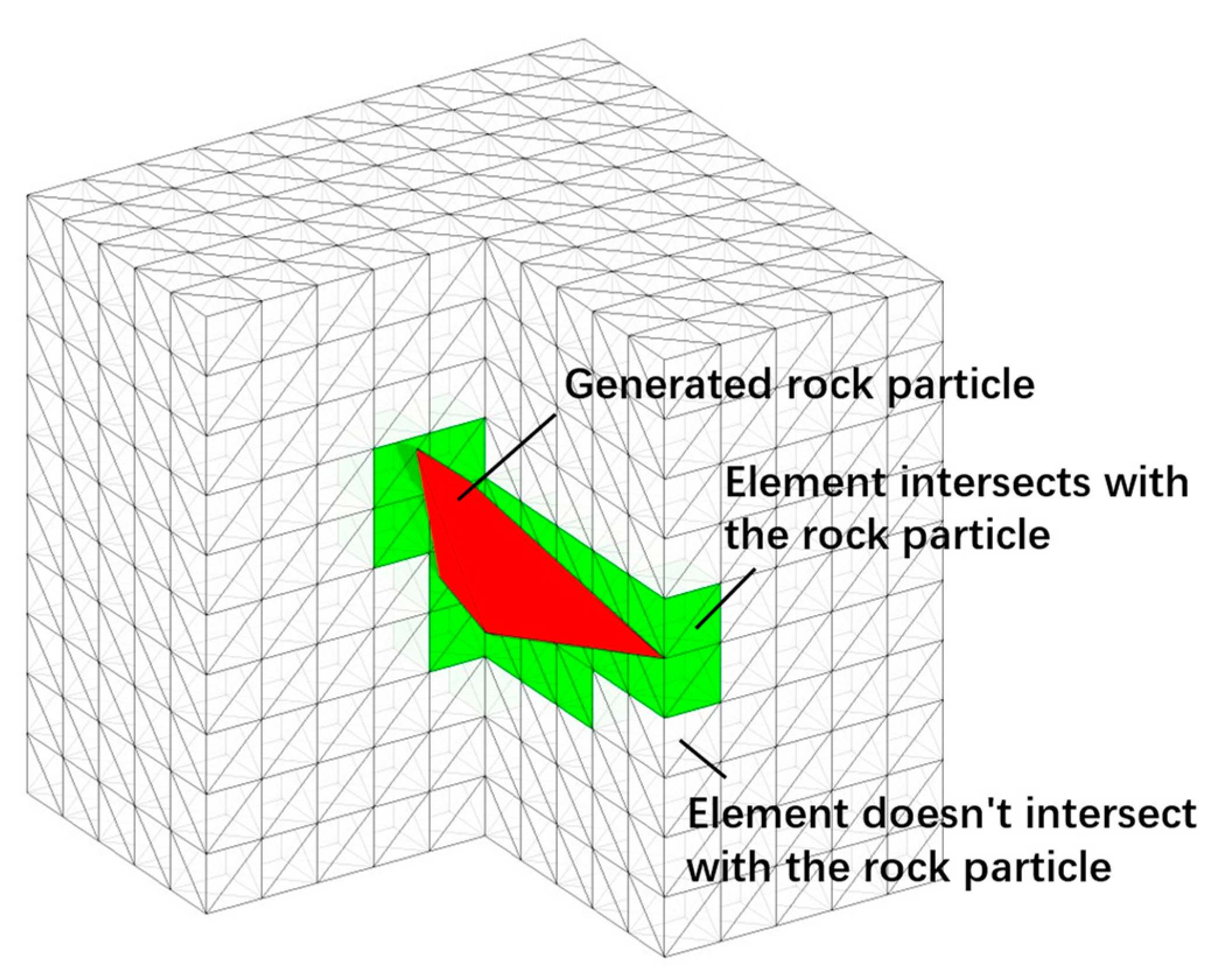

3.1. Area Discretization and Material Distribution Matrix Calculation

3.2. Implementation of the Mesoscale Computational Approach

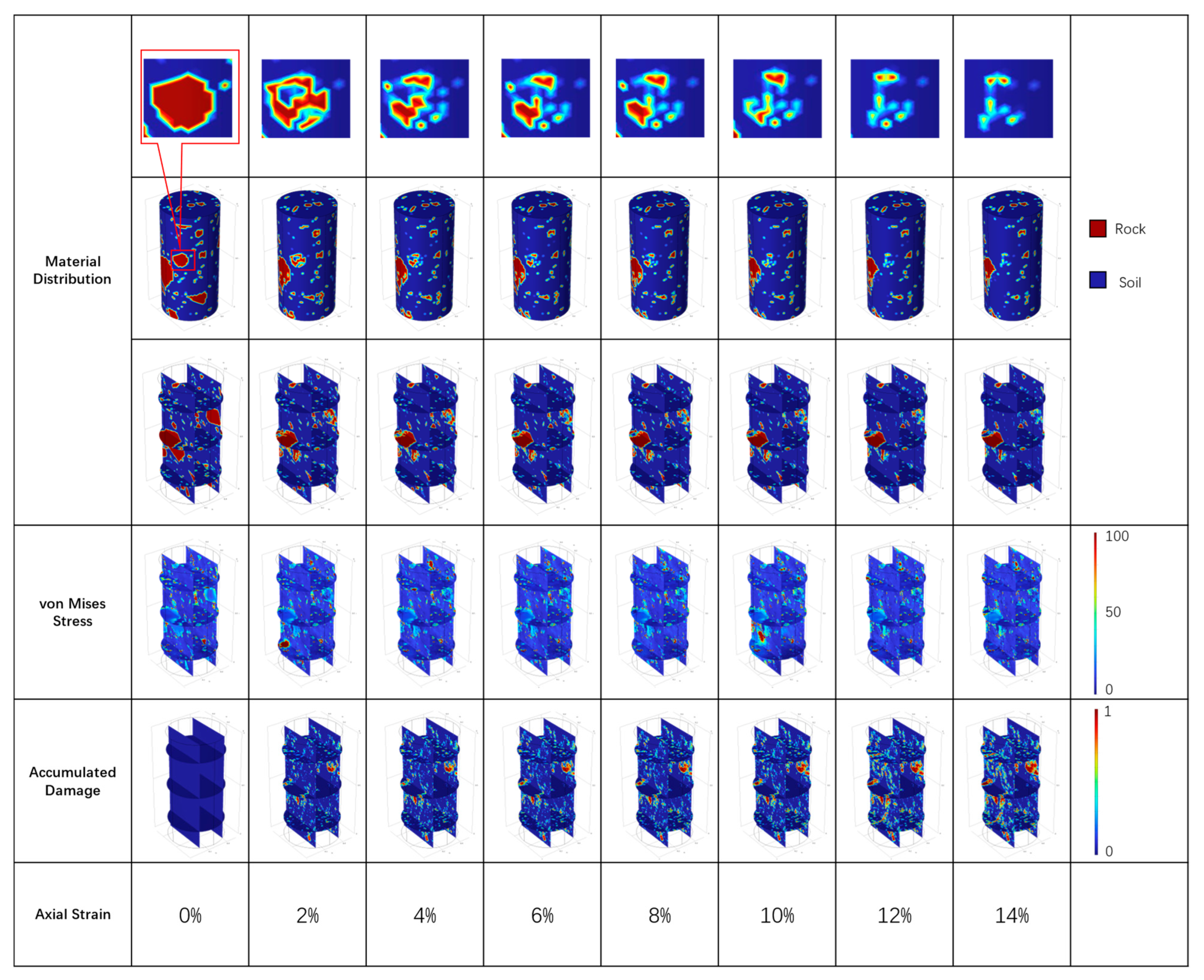

4. Model Validation and Parametric Study

5. Conclusions

- In contrast to other related studies, the proposed computational approach in this study not only employs randomly generated geometric models but also takes into account the breakage of rock particles under loadings;

- The numerical simulation results of the uniaxial compressive test show that, in the SRM structure, the rock particles bear the majority of the load, and the stress concentration phenomenon is observed at the edges of the rock particles. Due to the stress concentration, large rock particles break down into several smaller rock particles and the stress is redistributed;

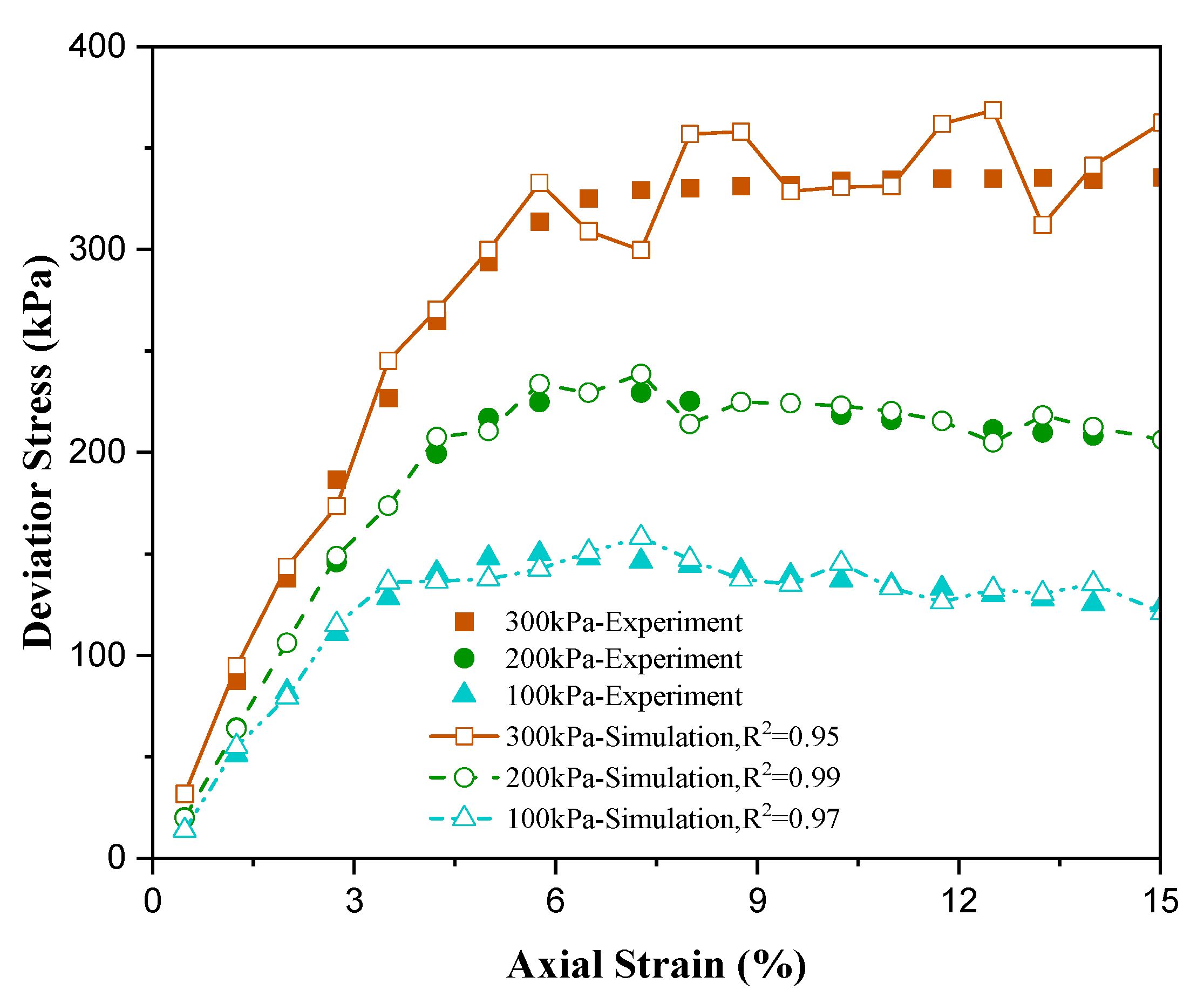

- The stress–strain curve of the numerical simulation is in good agreement with the results from the experiment. This result indicates that the proposed computational approach can accurately characterize the mechanical behavior of SRM material.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, C. Numerical Simulation of Rock-Soil Aggregate Mixture-Throughout Digital Image Processing. Soil Eng. Found. 2019, 33, 49. [Google Scholar]

- Medley, E.W. The Engineering Characterization of Melanges and Similar Block-in-Matrix Rocks (Bimrocks); University of California: Berkeley, CA, USA, 1994. [Google Scholar]

- Xu, W.-J.; Yue, Z.-Q.; Hu, R.-L. Study on the mesostructure and mesomechanical characteristics of the soil–rock mixture using digital image processing based finite element method. Int. J. Rock Mech. Min. Sci. 2008, 45, 749–762. [Google Scholar] [CrossRef]

- Meng, Q.; Wang, H.; Xu, W.; Zhang, Q. A coupling method incorporating digital image processing and discrete element method for modeling of geomaterials. Eng. Comput. 2018, 35, 411–431. [Google Scholar] [CrossRef]

- Xu, W.-J.; Hu, L.-M.; Gao, W. Random generation of the meso-structure of a soil-rock mixture and its application in the study of the mechanical behavior in a landslide dam. Int. J. Rock Mech. Min. Sci. 2016, 86, 166–178. [Google Scholar] [CrossRef]

- Xu, W.-J.; Zhang, H.-Y.; Jie, Y.-X.; Yu, Y.-Z. Generation of 3D random meso-structure of soil-rock mixture and its meso-structural mechanics based on numerical tests. J. Central South Univ. 2015, 22, 619–630. [Google Scholar] [CrossRef]

- Meng, Q.; Wang, H.; Xu, W.; Cai, M. A numerical homogenization study of the elastic property of a soil-rock mixture using random mesostructure generation. Comput. Geotech. 2018, 98, 48–57. [Google Scholar] [CrossRef]

- Li, Z.; Yi, H.; Zhu, C.; Zhuo, Z.; Liu, G. Randomly Generating the 3D Mesostructure of Soil Rock Mixtures Based on the Full In Situ Digital Image Processed Information. Fractal Fract. 2022, 6, 570. [Google Scholar] [CrossRef]

- Cecconi, M.; DeSimone, A.; Tamagnini, C.; Viggiani, G.M. A constitutive model for granular materials with grain crushing and its application to a pyroclastic soil. Int. J. Numer. Anal. Methods Géoméch. 2002, 26, 1531–1560. [Google Scholar] [CrossRef]

- Daouadji, A.; Hicher, P.-Y.; Rahma, A. An elastoplastic model for granular materials taking into account grain breakage. Eur. J. Mech. A/Solids 2001, 20, 113–137. [Google Scholar] [CrossRef]

- Li, X.; Liao, Q.; He, J. In-situ tests and a stochastic structural model of rock and soil aggregate in the three gorges reservoir area, china. Int. J. Rock Mech. Min. Sci. 2004, 41, 702–707. [Google Scholar] [CrossRef]

- Zhang, H.-Y.; Xu, W.-J.; Yu, Y.-Z. Triaxial tests of soil–rock mixtures with different rock block distributions. Soils Found. 2016, 56, 44–56. [Google Scholar] [CrossRef]

- Zhang, Z.-L.; Xu, W.-J.; Xia, W.; Zhang, H.-Y. Large-scale in-situ test for mechanical characterization of soil–rock mixture used in an embankment dam. Int. J. Rock Mech. Min. Sci. 2016, 86, 317–322. [Google Scholar] [CrossRef]

- Cen, D.; Huang, D.; Ren, F. Shear deformation and strength of the interphase between the soil–rock mixture and the benched bedrock slope surface. Acta Geotech. 2016, 12, 391–413. [Google Scholar] [CrossRef]

- Jin, L.; Zeng, Y.; Xia, L.; Ye, Y. Experimental and Numerical Investigation of Mechanical Behaviors of Cemented Soil–Rock Mixture. Geotech. Geol. Eng. 2016, 35, 337–354. [Google Scholar] [CrossRef]

- Zhang, J.; Rao, Q.; Yi, W. Viscoelastic Parameter Prediction of Multi-Layered Coarse-Grained Soil with Consideration of Interface-Layer Effect. Appl. Sci. 2020, 10, 8879. [Google Scholar] [CrossRef]

- Meng, Q.; Wang, H.; Cai, M.; Xu, W.; Zhuang, X.; Rabczuk, T. Three-dimensional mesoscale computational modeling of soil-rock mixtures with concave particles. Eng. Geol. 2020, 277, 105802. [Google Scholar] [CrossRef]

- Xu, W.-J.; Wang, S.; Zhang, H.-Y.; Zhang, Z.-L. Discrete element modelling of a soil-rock mixture used in an embankment dam. Int. J. Rock Mech. Min. Sci. 2016, 86, 141–156. [Google Scholar] [CrossRef]

- Shan, P.; Lai, X. Mesoscopic structure PFC∼2D model of soil rock mixture based on digital image. J. Vis. Commun. Image Represent. 2018, 58, 407–415. [Google Scholar] [CrossRef]

- Latham, J.-P.; Munjiza, A.; Garcia, X.; Xiang, J.; Guises, R. Three-dimensional particle shape acquisition and use of shape library for DEM and FEM/DEM simulation. Miner. Eng. 2008, 21, 797–805. [Google Scholar] [CrossRef]

- Gu, F.; Sahin, H.; Luo, X.; Luo, R.; Lytton, R.L. Estimation of Resilient Modulus of Unbound Aggregates Using Performance-Related Base Course Properties. J. Mater. Civ. Eng. 2015, 27, 04014188. [Google Scholar] [CrossRef]

- Sun, S.; Zhu, F.; Wei, J.; Wang, W.; Le, H. Experimental Study on Shear Failure Mechanism and the Identification of Strength Characteristics of the Soil-Rock Mixture. Shock. Vib. 2019, 2019, 1–25. [Google Scholar] [CrossRef]

- Kockara, S.; Halic, T.; Iqbal, K.; Bayrak, C.; Rowe, R. Collision detection: A survey. In Proceedings of the 2007 IEEE International Conference on Systems, Man and Cybernetics, Montreal, QC, Canada, 7–10 October 2007. [Google Scholar]

- Yao, Y.; Li, J.; Ni, J.; Liang, C.; Zhang, A. Effects of gravel content and shape on shear behaviour of soil-rock mixture: Experiment and DEM modelling. Comput. Geotech. 2022, 141, 104476. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Yi, H.; Xu, Y.; Li, G.; Zhuo, Z. A Three-Dimensional Mesoscale Computational Simulation Method for Soil–Rock Mixtures Considering Grain Crushing. Appl. Sci. 2023, 13, 10552. https://doi.org/10.3390/app131810552

Li Z, Yi H, Xu Y, Li G, Zhuo Z. A Three-Dimensional Mesoscale Computational Simulation Method for Soil–Rock Mixtures Considering Grain Crushing. Applied Sciences. 2023; 13(18):10552. https://doi.org/10.3390/app131810552

Chicago/Turabian StyleLi, Zhengsheng, Haiyang Yi, Yiming Xu, Gangqiang Li, and Zhuang Zhuo. 2023. "A Three-Dimensional Mesoscale Computational Simulation Method for Soil–Rock Mixtures Considering Grain Crushing" Applied Sciences 13, no. 18: 10552. https://doi.org/10.3390/app131810552

APA StyleLi, Z., Yi, H., Xu, Y., Li, G., & Zhuo, Z. (2023). A Three-Dimensional Mesoscale Computational Simulation Method for Soil–Rock Mixtures Considering Grain Crushing. Applied Sciences, 13(18), 10552. https://doi.org/10.3390/app131810552